A clamping device for preparing thermal barrier coatings by electron beam physical vapor deposition

A physical vapor deposition, thermal barrier coating technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problem of uncontrollable blade rotation speed, limited inclination angle, and inability to achieve blade body coating Thickness uniformity control and other issues, to achieve the effect of improving uniformity and strain tolerance, extending service life, improving preheating temperature and coating thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Using this device, six high-pressure turbine blades are respectively installed on six workpiece holders 14, and sprayed by EB-PVD.

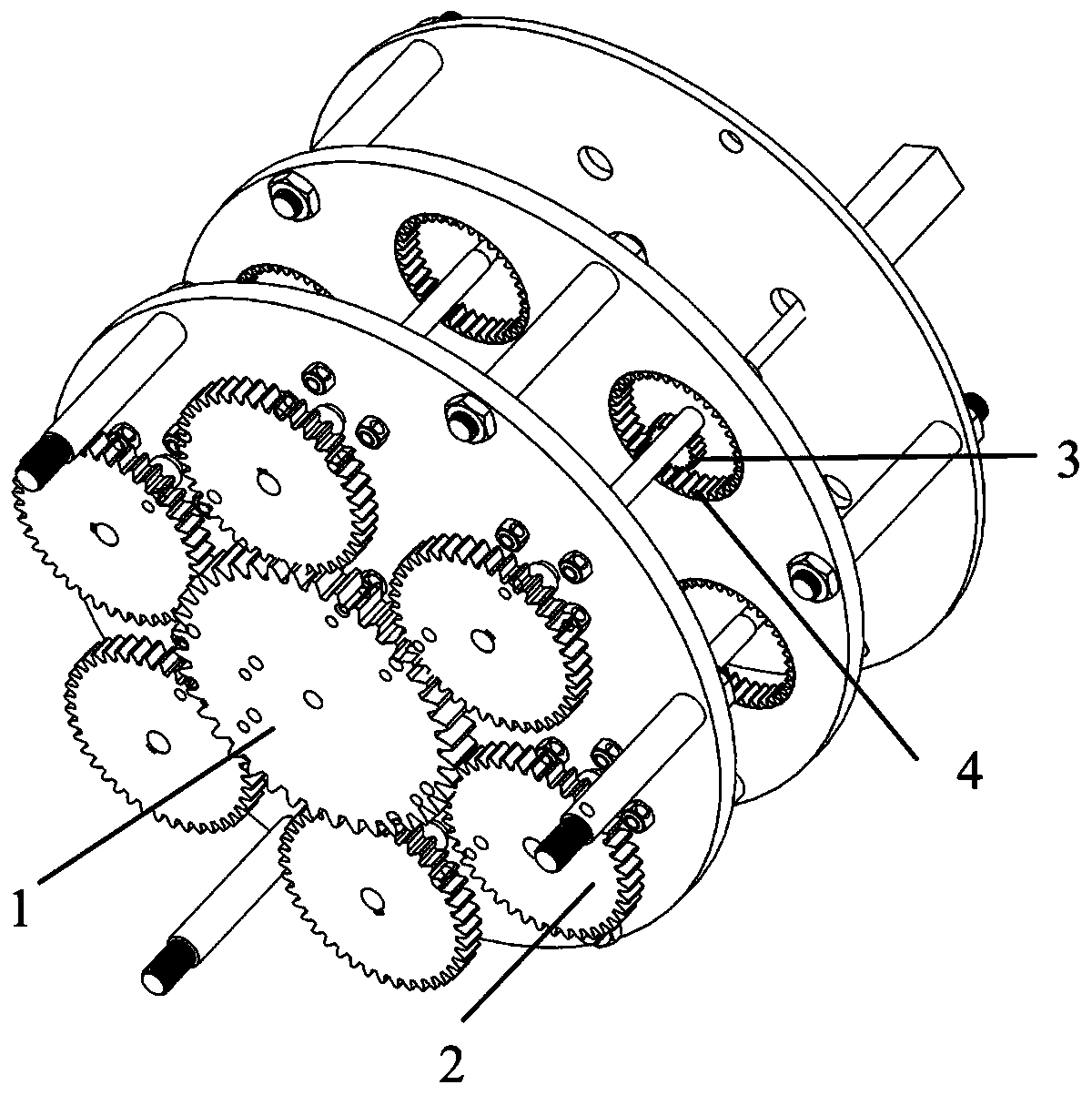

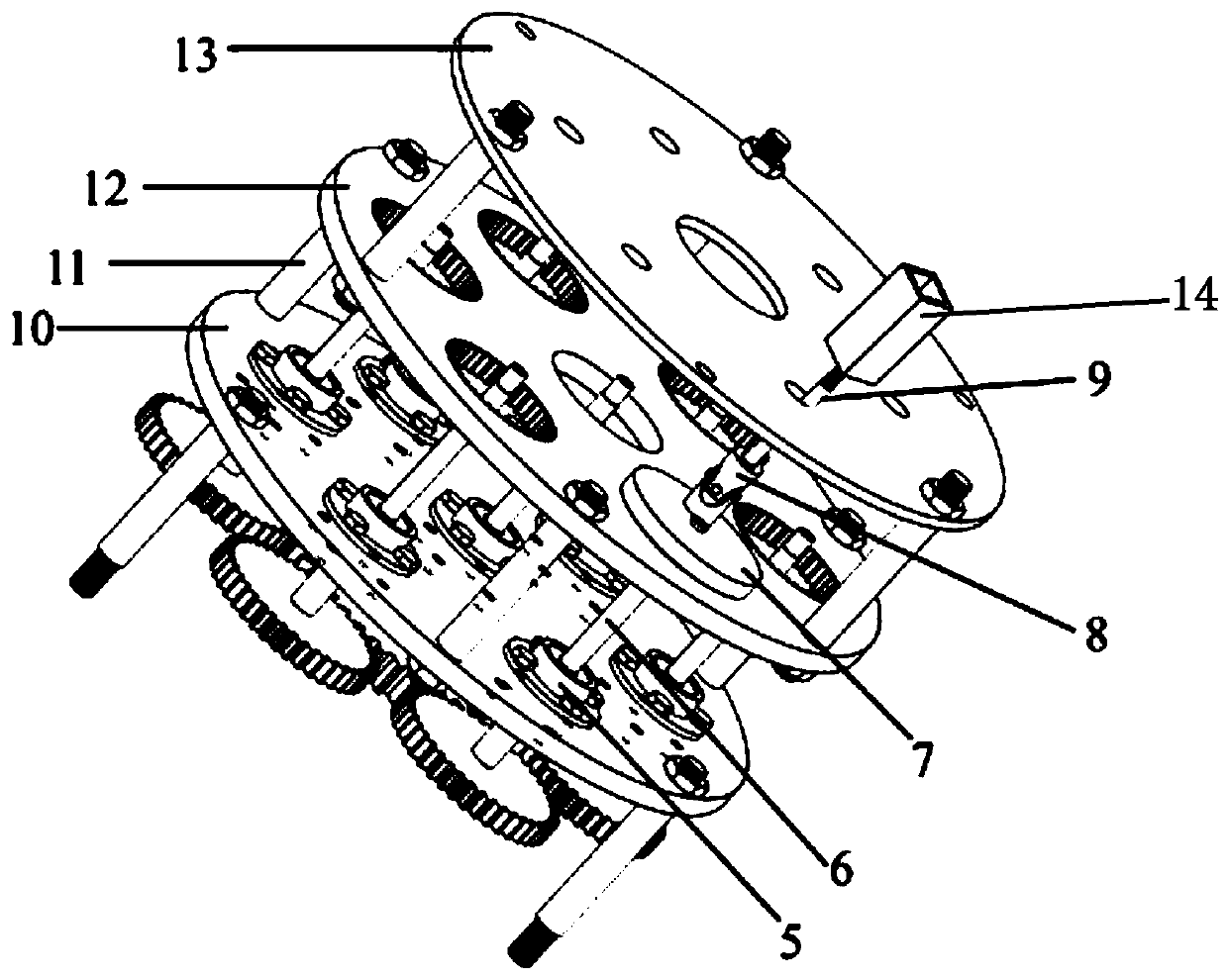

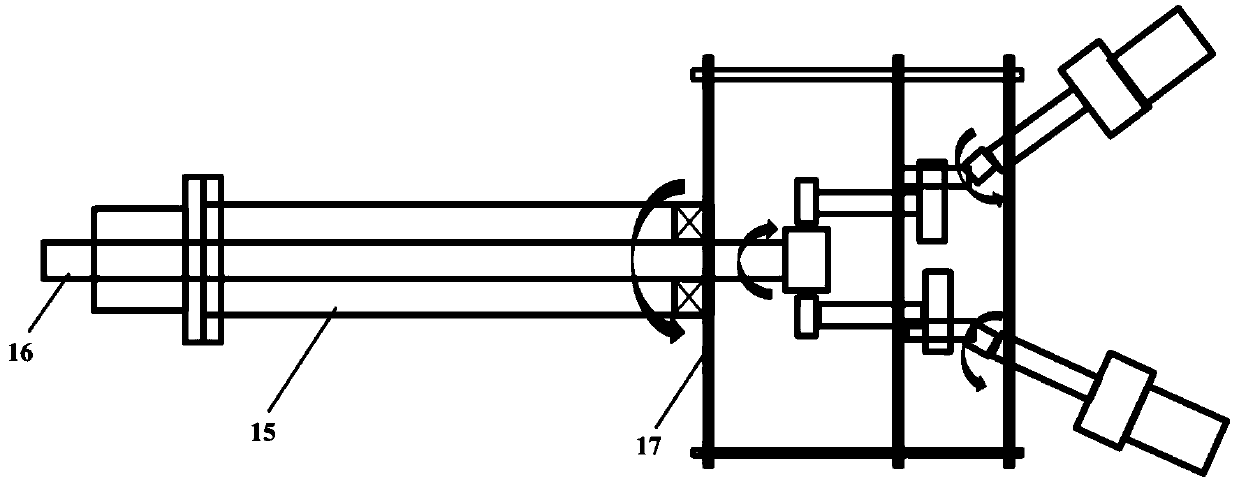

[0050] The rotation of the first main transmission shaft 15 drives the entire device to rotate, realizing the overall revolution; the rotation of the second main transmission shaft 16 drives the rotation of the main gear 1. After the rotation of the main gear 1, the rotation gear 2 and the driven shaft 6 rotate simultaneously, and the driven shaft 6 Drive the swing disc 7 to rotate, the swing rod 9 also tilts and rotates accordingly, so that the blades rotate and swing by themselves. Therefore, this device realizes the simultaneous preparation of 6 high-pressure turbine blades by EB-PVD, and realizes the 3-degree-of-freedom rotation of revolution, rotation, and free swing of the blades.

[0051] attached Figure 4 In order to observe the positions of the cross-sectional morphology of the turbine blade airfoil and edge plate coating, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com