Thickness-adjustable heat insulation/infrared stealth composite coating, titanium alloy material with surface coated with coating and preparation method of titanium alloy material

A composite coating and surface coating technology, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problem that it is difficult to meet the application requirements of long-term high-temperature thermal shock resistance, non-wear resistance, and lower emissivity, etc. problems, to achieve the effects of improving anti-sintering properties and thermal shock resistance, excellent high-temperature structure and chemical stability, and improving fracture toughness and strain tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

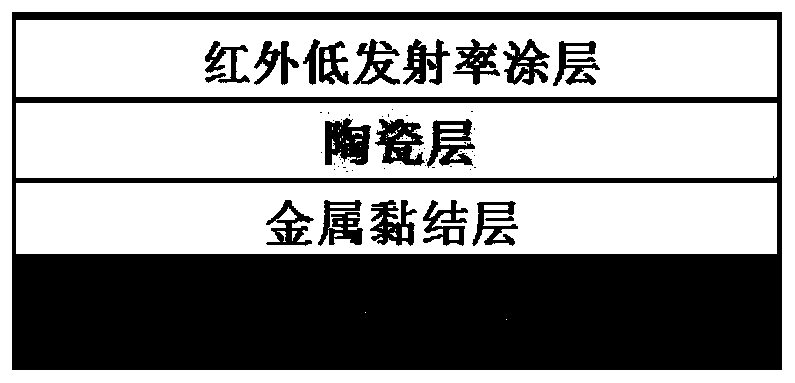

[0043] Such as figure 1 As shown, a thermal insulation / infrared stealth composite coating with adjustable thickness is a multi-layer superimposed structure, starting from the titanium alloy substrate, including a metal bonding layer, a lanthanum phosphate-hexaaluminate composite ceramic layer and Infrared low emissivity layer. The metal bonding layer is a NiCrAlY metal bonding layer, and the lanthanum phosphate-hexaaluminate composite ceramic layer is 5wt% LaPO 4 -LaAl 11 o 18 The composite ceramic layer, the infrared low emissivity layer is made of Ag conductive phase and Bi 2 o 3 -Al 2 o 3 -TiO 2 -Li 2 O-SiO 2 It is composed of a low-melting point glass bonding phase, and the Ag conductive phase accounts for 85% of the total mass of the conductive phase and the bonding phase.

[0044] The thickness of the metal bonding layer is 0.05mm, the thickness of the ceramic layer is 0.08mm, the thickness of the infrared low emissivity layer is 0.02mm, and the total thickness...

Embodiment 2

[0071] A thermal insulation / infrared stealth composite coating with adjustable thickness is a multi-layer superimposed structure, starting from the titanium alloy substrate, including NiCrAlY metal bonding layer, lanthanum phosphate-hexaaluminate composite ceramic layer and infrared low Emissivity layer. Lanthanum phosphate-hexaaluminate composite ceramic layer is 5wt% LaPO 4 -LaAl 11 o 18 Composite ceramic layer, infrared low emissivity layer is made of Ag conductive phase and Bi 2 o 3 -Al 2 o 3 -TiO 2 -Li 2 O-SiO 2 It is composed of a low-melting point glass bonding phase, and the Ag conductive phase accounts for 85% of the total mass of the conductive phase and the bonding phase.

[0072] The thickness of the metal bonding layer is 0.10mm, the thickness of the ceramic layer is 0.9mm, the thickness of the infrared low emissivity layer is 0.02mm, and the total thickness of the coating is 1.02mm.

[0073] A titanium alloy material coated with a coating on the surface...

Embodiment 3

[0087] A thermal insulation / infrared stealth composite coating with adjustable thickness is a multi-layer superimposed structure, starting from the titanium alloy substrate, including a CoNiCrAlY metal bonding layer, a lanthanum phosphate-hexaaluminate composite ceramic layer and an infrared low Emissivity layer. Lanthanum phosphate-hexaaluminate composite ceramic layer is 25wt% LaPO 4 -SrAl 12 o 19 Composite ceramic layer, infrared low emissivity layer is made of Ag conductive phase and Bi 2 o 3 -Al 2 o 3 -TiO 2 -Li 2 O-SiO 2 It is composed of a low-melting point glass bonding phase, and the Ag conductive phase accounts for 90% of the total mass of the conductive phase and the bonding phase.

[0088] The thickness of CoNiCrAlY metal bonding layer is 0.08mm, 25wt% LaPO 4 -SrAl 12 o 19 The thickness of the composite ceramic layer is 0.25mm, the thickness of the infrared low emissivity layer is 0.02mm, and the total thickness of the coating is 0.35mm.

[0089] A tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com