Foam concrete light compound wall board and preparation method thereof

A foamed concrete and composite wallboard technology, applied in building materials and other directions, can solve the problems of fragility, environmental pollution, high energy consumption, etc., and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

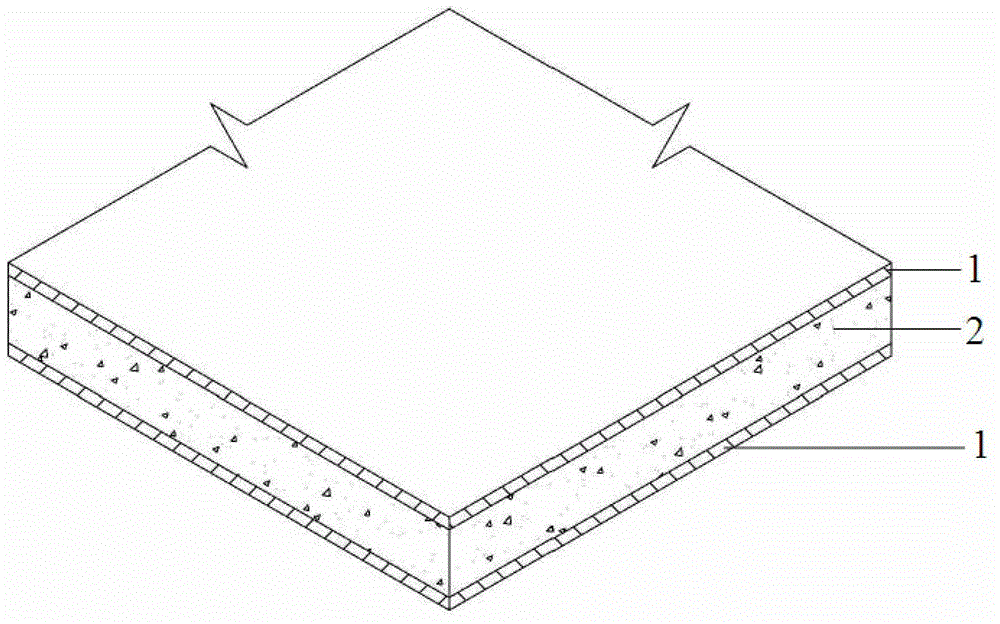

[0025] A foam concrete lightweight composite wallboard, the structure is as figure 1 As shown, the wallboard includes upper and lower surface layers 1 and an intermediate layer 2 filled between the upper and lower surface layers 1, the upper and lower surface layers 1 are silicon-calcium boards, and the intermediate layer 2 is a foam concrete layer.

[0026] The thickness of the composite wallboard is 60mm, the thickness of the silicon-calcium board is 15mm, and the thickness of the foamed concrete layer is 30mm. The foam concrete layer and the silicon-calcium board are bonded and connected. Calcium silicon board is rectangular.

[0027] Foam concrete includes solid components and foaming agent foam. The solid components are composed of 40 parts of mud, 20 parts of cement, 5 parts of slaked lime, 2 parts of gypsum, 0.1 part of fiber, and 1 part of early strength agent. The density of mud produced during the construction of cast-in-place piles is 1.2-1.3g / mm 3 The waste mud;...

Embodiment 2

[0035] A foam concrete lightweight composite wallboard, the structure is as figure 1 As shown, the wallboard includes upper and lower surface layers 1 and an intermediate layer 2 filled between the upper and lower surface layers 1, the upper and lower surface layers 1 are silicon-calcium boards, and the intermediate layer 2 is a foam concrete layer. The thickness of the composite wallboard is 90mm, the thickness of the silicon-calcium board is 16mm, and the thickness of the foamed concrete layer is 58mm. The foam concrete layer and the silicon-calcium board are bonded and connected. Calcium silicon board is rectangular.

[0036] Foam concrete includes solid components and foaming agent foam. The solid components are composed of 50 parts of mud, 30 parts of cement, 7 parts of slaked lime, 2.5 parts of gypsum, 0.2 parts of fiber, and 2 parts of early strength agent. The density of mud produced during the construction of cast-in-place piles is 1.2-1.3g / mm 3 waste mud; cement i...

Embodiment 3

[0044] A foam concrete lightweight composite wallboard, the structure of which is as follows figure 1As shown, the wallboard includes upper and lower surface layers 1 and an intermediate layer 2 filled between the upper and lower surface layers 1, the upper and lower surface layers 1 are silicon-calcium boards, and the intermediate layer 2 is a foam concrete layer. The thickness of the composite wallboard is 110mm, the thickness of the silicon-calcium board is 15mm, and the thickness of the foamed concrete layer is 80mm. The foam concrete layer and the silicon-calcium board are bonded and connected. Calcium silicon board is rectangular.

[0045] Foam concrete includes solid components and foaming agent foam. The solid components are composed of 60 parts of mud, 50 parts of cement, 8 parts of hydrated lime, 3 parts of gypsum, 0.3 parts of fiber, and 3 parts of early strength agent. The density of mud produced during the construction of cast-in-place piles is 1.2-1.3g / mm 3 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com