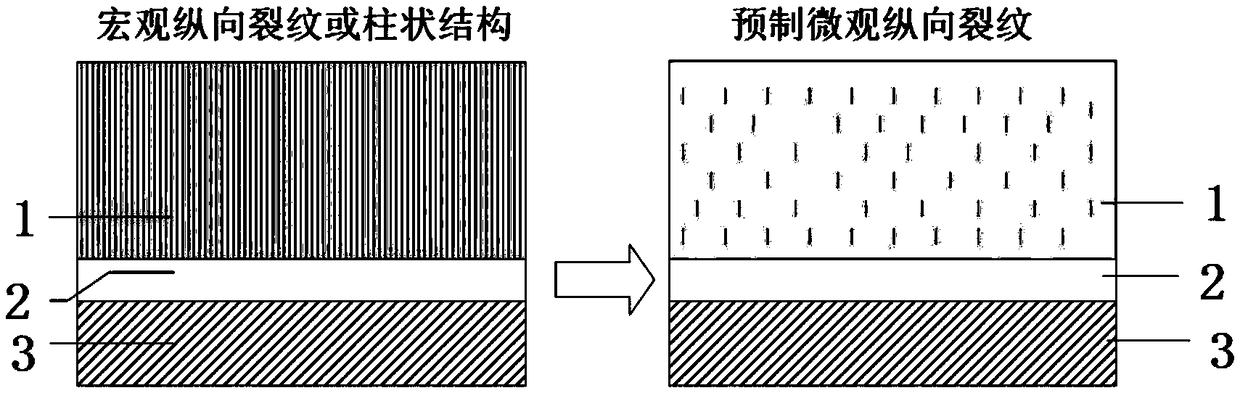

Thermal barrier coating provided with prefabricated microcosmic longitudinal crack structure and preparing method of thermal barrier coating

A longitudinal crack and thermal barrier coating technology, applied in the field of materials, can solve the problems of uncontrollable coating thickness, CMAS corrosion failure, spalling and other problems, and achieve the effect of increased microscopic longitudinal crack density, simple and convenient operation, and safe and reliable application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

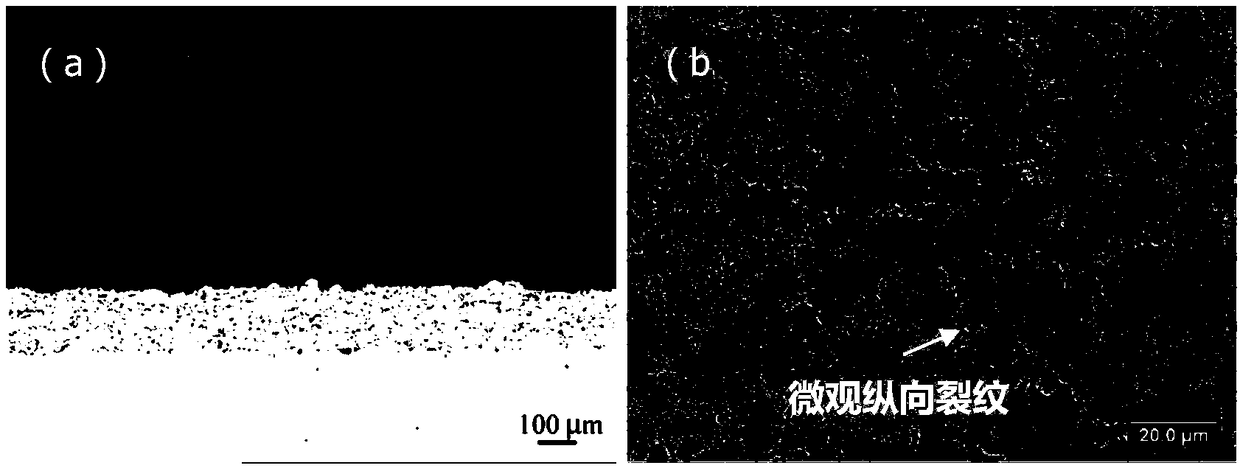

Embodiment 1

[0024] (1) Preheat the samples with CoNiCrAlY metal bonding layer through atmospheric plasma spraying flame flow coupled with dry ice particle blasting process. Plasma spraying flame preheating; according to the requirements of atmospheric plasma spraying equipment, the plasma spraying voltage is 65.0V, the current is 630A, and the plasma spraying distance is 115mm; according to the requirements of dry ice particle spraying equipment, the diameter is 3mm and the length is 3-10mm Cylindrical dry ice particles, the dry ice flow rate is 42kg / h, the distance between the dry ice particle spray gun and the coating is 25mm; the angle between the dry ice spray gun and the plasma spray gun is 30°; the preheating temperature is 100°C;

[0025] (2) Through atmospheric plasma spraying coupled with dry ice particle blasting process, the particle size is 15-58 μm and the mass fraction is 8% Y 2 o 3 Partially stabilized ZrO 2 (8YSZ) powder is deposited on the above preheated sample to obta...

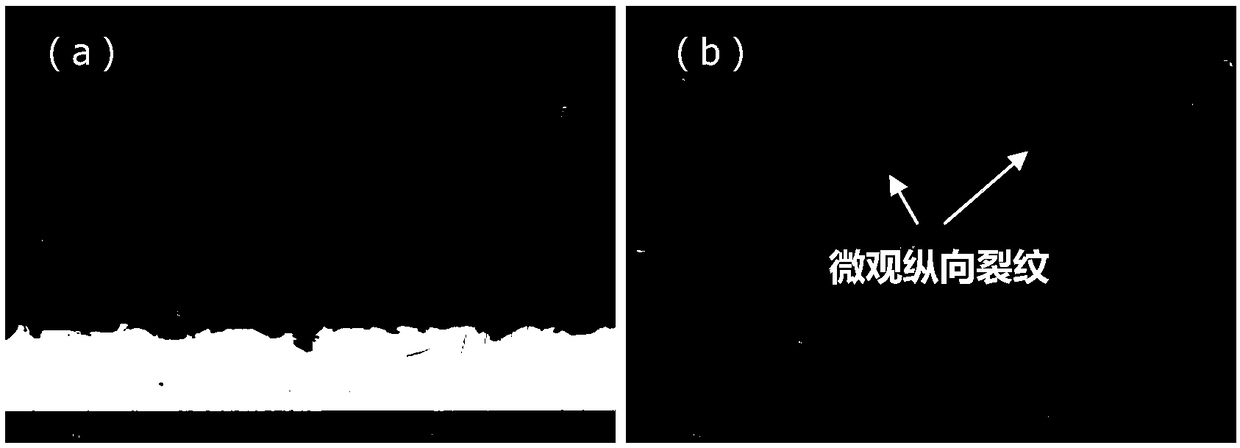

Embodiment 2

[0031](1) Preheat the samples with NiCrAlY metal bonding layer by atmospheric plasma spraying flame flow coupled with dry ice particle blasting process. The specific coupling method is preheating by atmospheric plasma spraying flame flow and then dry ice particle spraying pretreatment ;According to the requirements of atmospheric plasma spraying equipment, the spraying voltage is 67.2V, the current is 617A, and the plasma spraying distance is 100mm; The spraying distance is 25mm, the angle between the dry ice spray gun and the plasma spray gun is 30°; the preheating temperature is 60°C.

[0032] (2) LaMgAl with a particle size of 32-125 μm was sprayed by atmospheric plasma spraying coupled with dry ice particle blasting 11 o 19 (LMA) powder is deposited on the above preheated sample to obtain an LMA thermal barrier coating with a proportion of 46.84% of microscopic longitudinal cracks; according to the requirements of atmospheric plasma spraying equipment, the spraying volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com