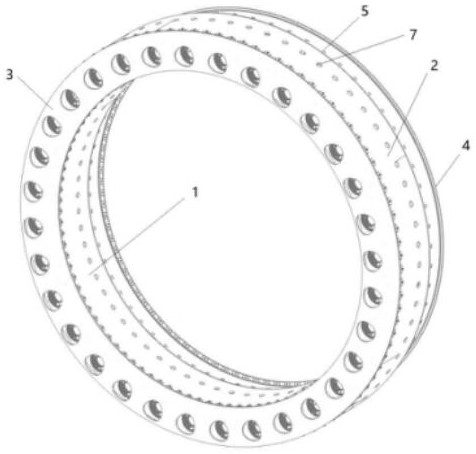

Ceramic-based annular flame tube

A ceramic-based, flame tube technology, applied in the direction of combustion methods, combustion chambers, combustion equipment, etc., to achieve the effects of reducing exhaust emissions, improving thermal efficiency, and increasing working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

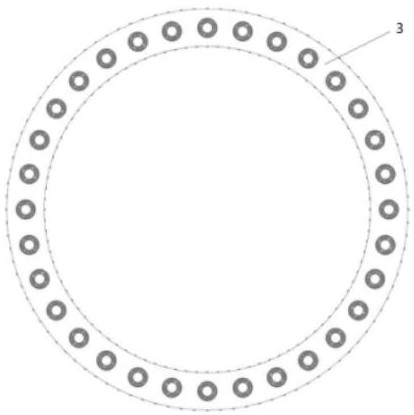

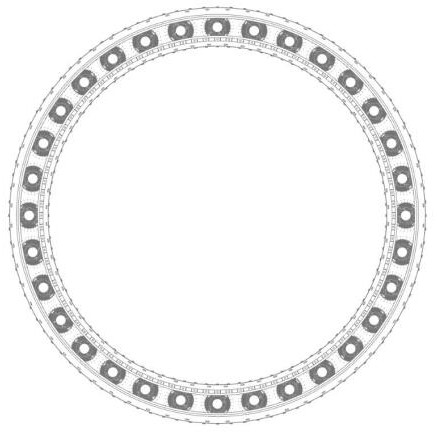

Image

Examples

example

[0053] The maximum thrust state on the ground is selected as the working condition for simulation. Working condition parameters are shown in Table 1.

[0054] Table 1 Combustion chamber working condition parameters

[0055]

[0056] In order to simplify the calculation and design quickly, without affecting the reliability of the design, the following assumptions are made:

[0057] 1) Look at the air as an ideal gas, and use the ideal gas state equation to calculate the density and pressure in the calculation;

[0058] 2) In the calculation, the expansion process is regarded as adiabatic, so the total temperature remains unchanged;

[0059] The simulation results are as follows:

[0060] Such as Figure 12 As shown, due to the existence of the recirculation zone, there will be a region in the flow field where the gas velocity is exactly equal to the flame propagation velocity, so that the ignition source exists stably. The combustion in the flame tube is mainly concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com