Patents

Literature

69results about How to "Highly curved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

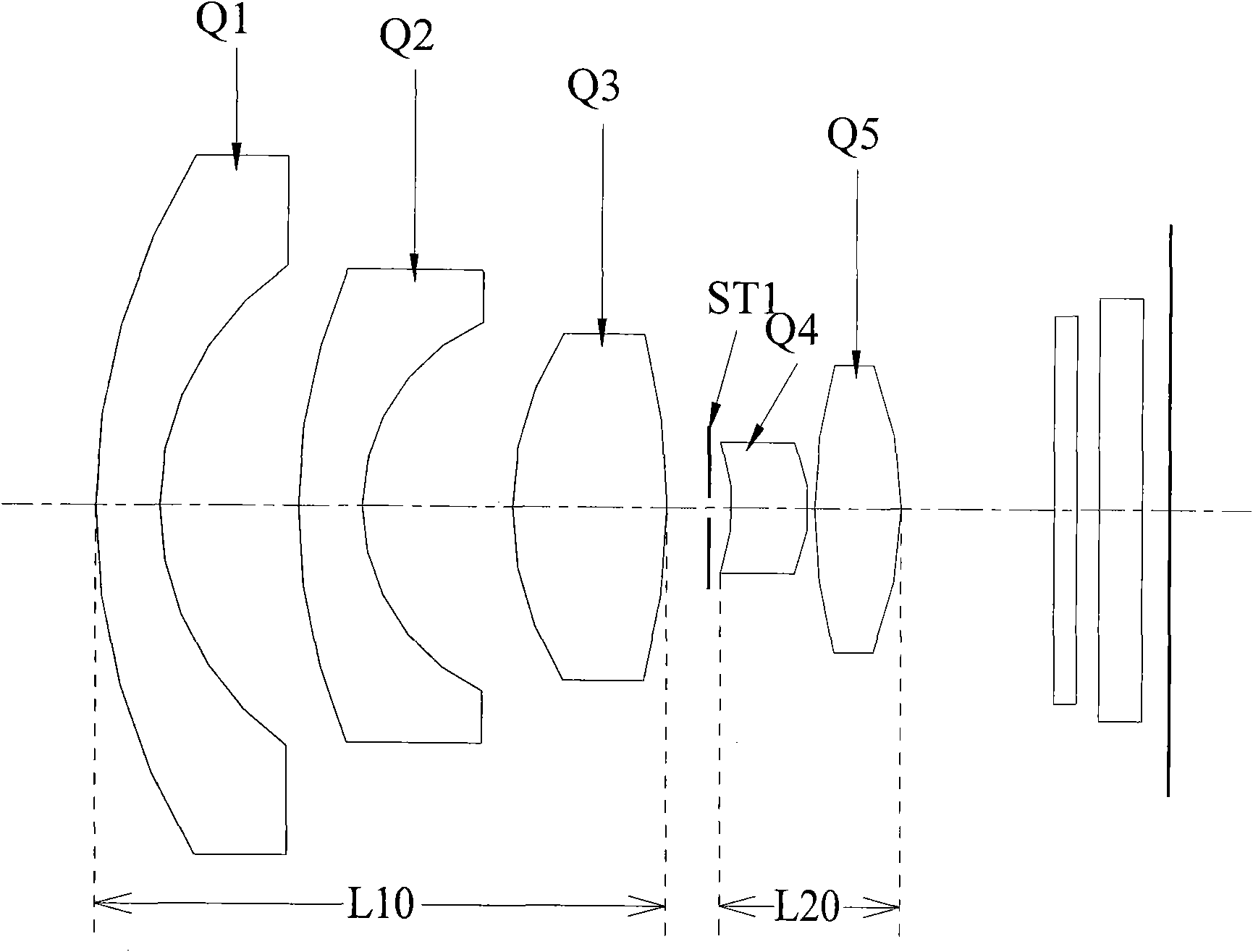

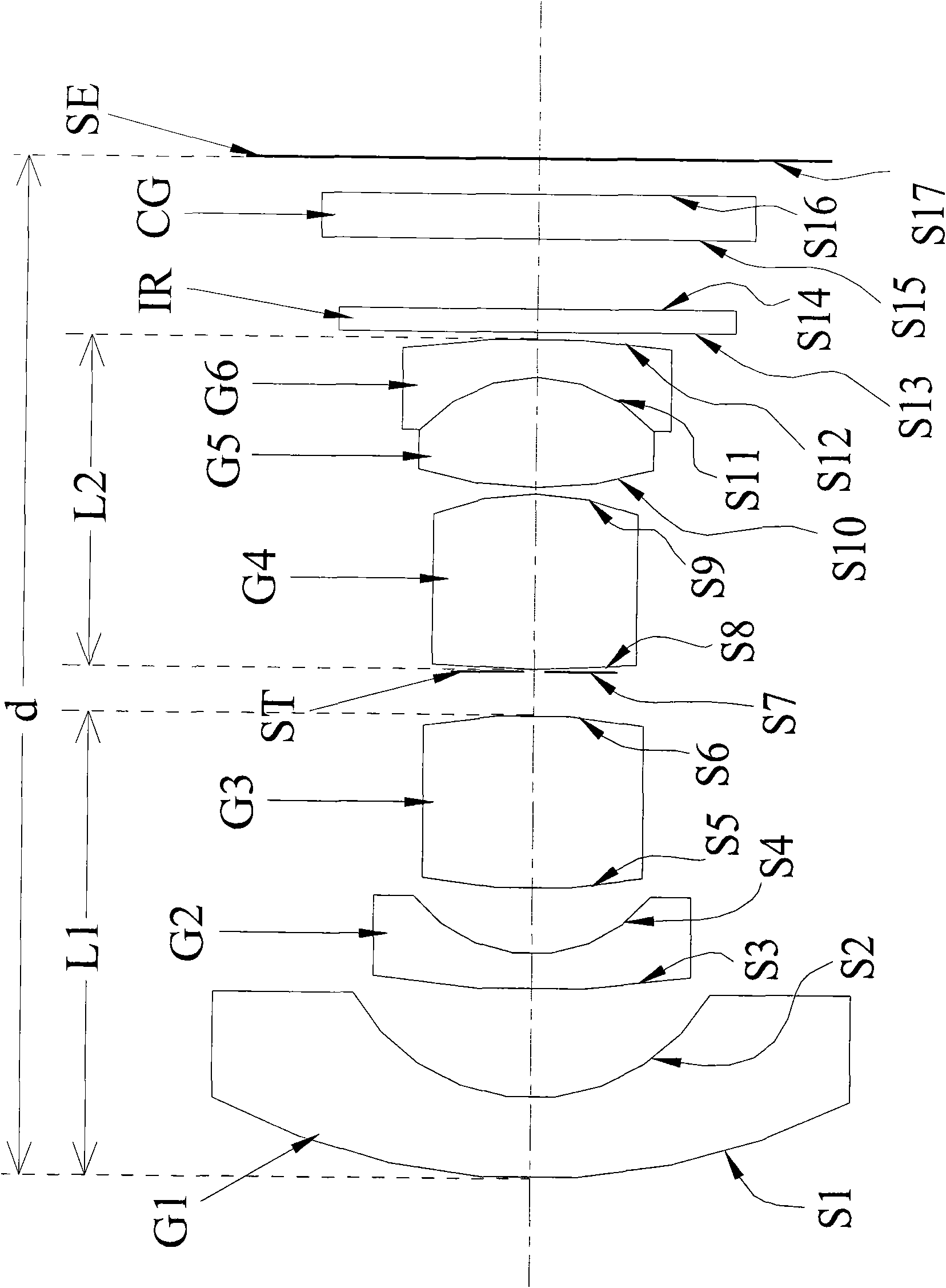

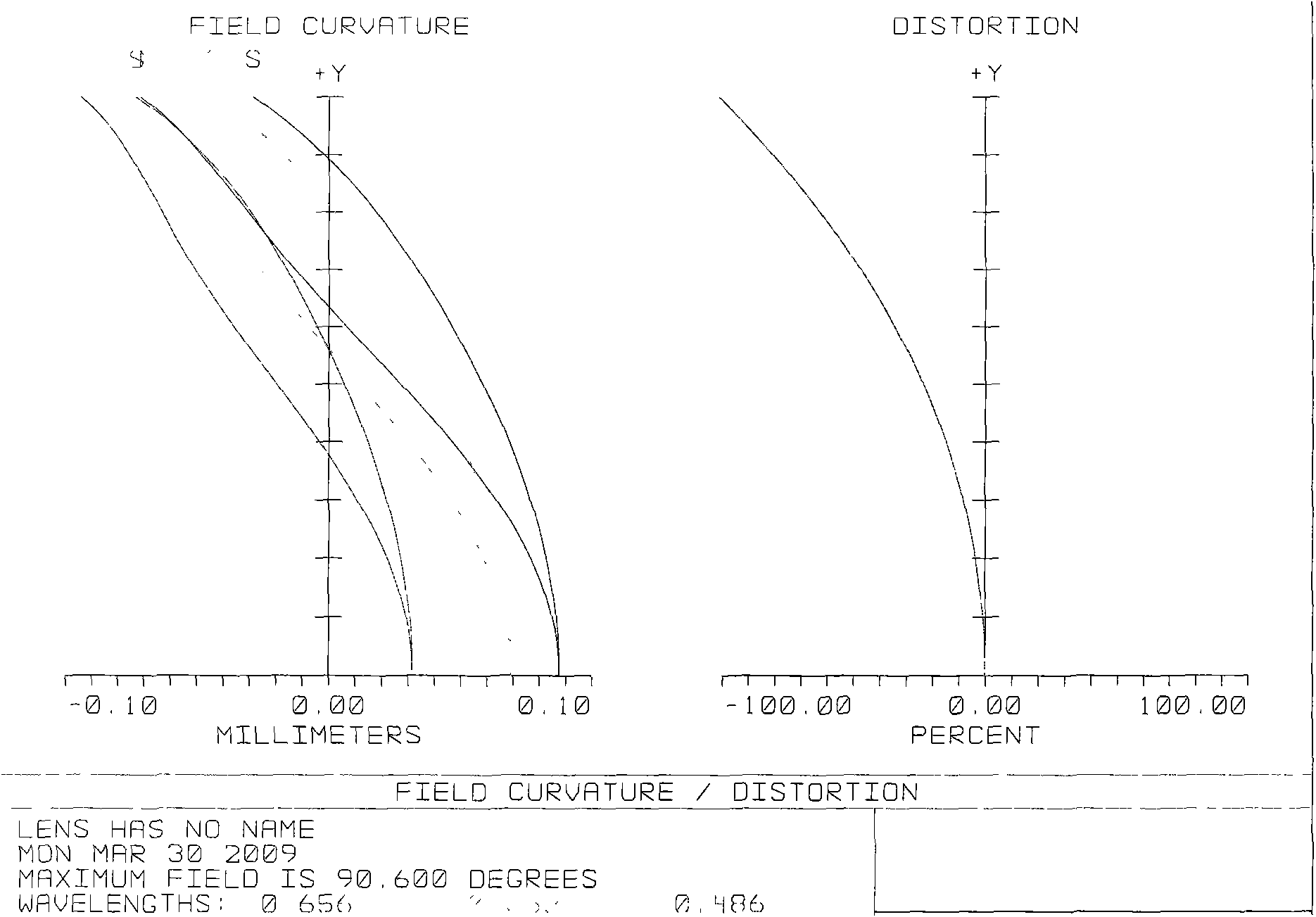

Wide-angle lens

InactiveCN101930111AIncrease the total lengthCompact structureOptical viewingOptical elementsImaging qualityLens plate

The invention discloses a wide-angle lens which comprises a first lens group with negative focus length, a diaphragm and a second lens group with positive focus length from an object, wherein the first lens group comprises a first lens with negative focus length, a second lens with negative focus length and a third lens with positive focus length; the second lens group comprises a fourth lens, a fifth lens and a sixth lens, the fourth lens is provided with positive focus length, and the fifth lens and the sixth lens have positive focus length after being glued; and the first lens group and the second lens group meet the following condition of -3<fL1 / fL2<-0.5, wherein fL1 expresses the combined focus length of the first lens group, and fL2 expresses the combined focus length of the second lens group. By adopting six full-glass lens structures, the invention has the advantages of compact structure, better machining manufacturability and low production cost. The wide-angle lens has better imaging quality under the condition of ensuring wide angle, and improves the imaging quality because the whole optical system enlarges the tolerance.

Owner:凤凰光学(广东)有限公司

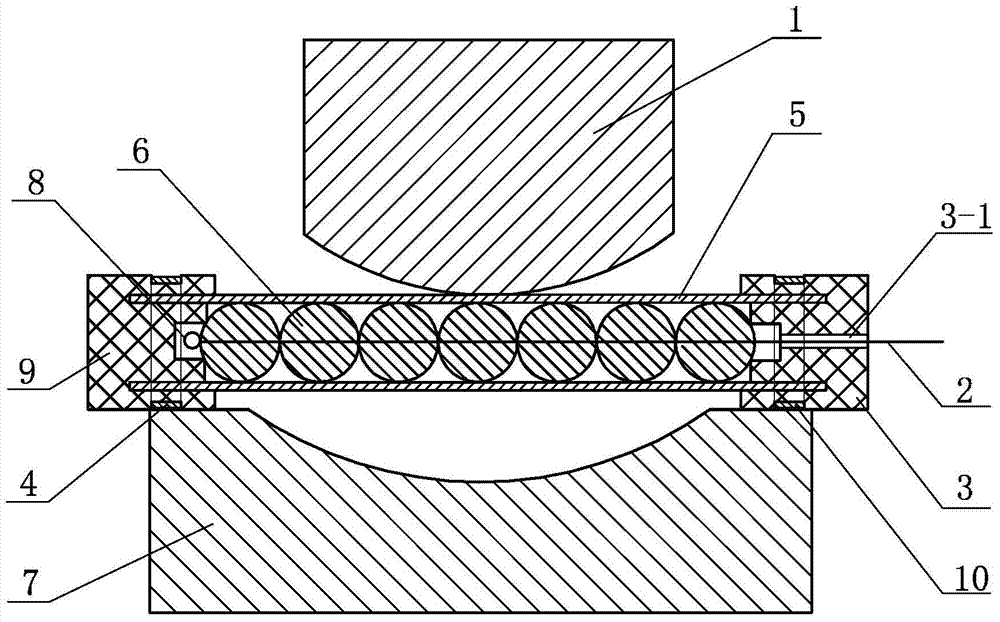

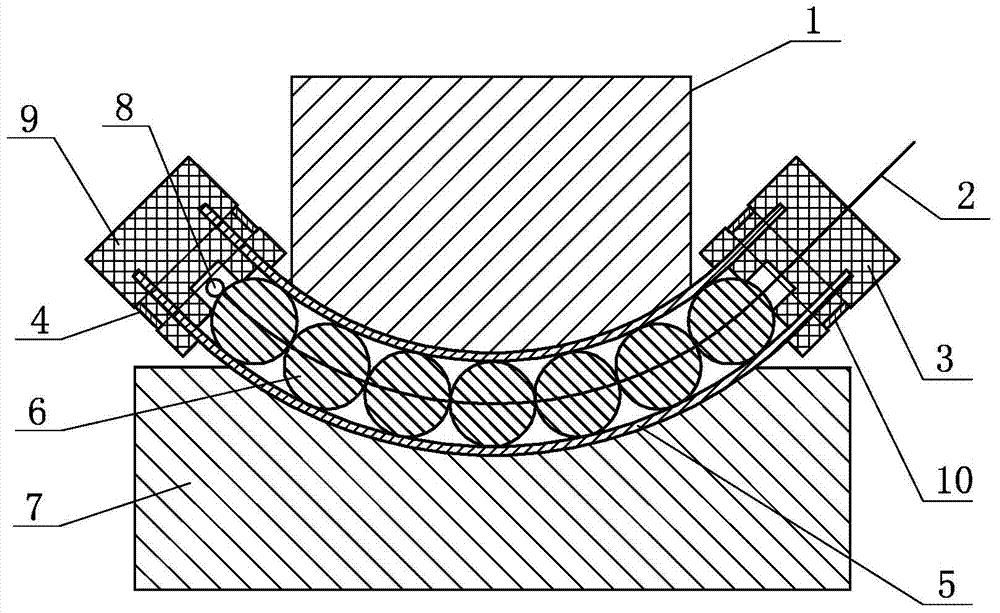

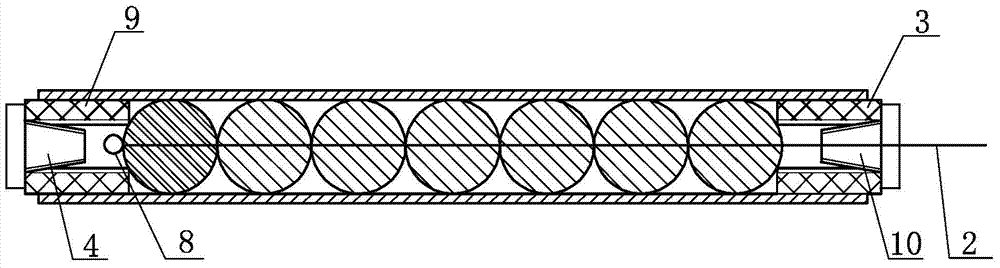

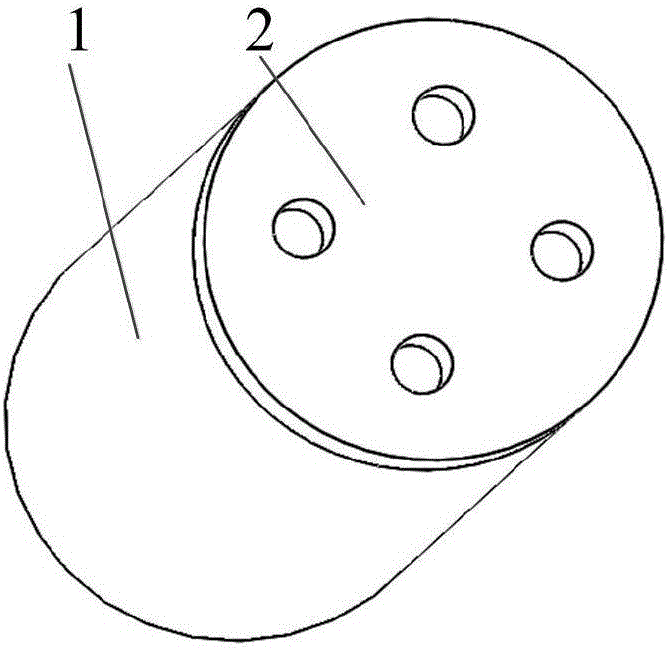

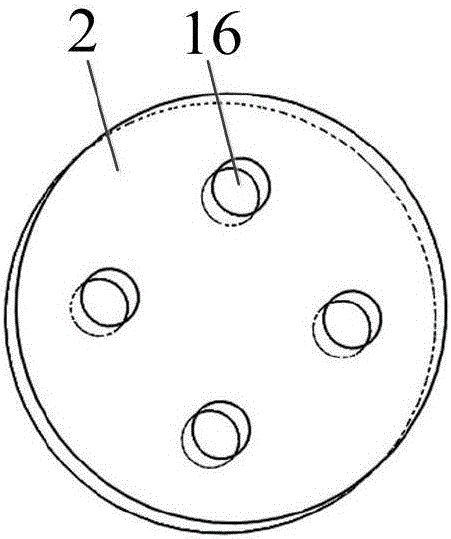

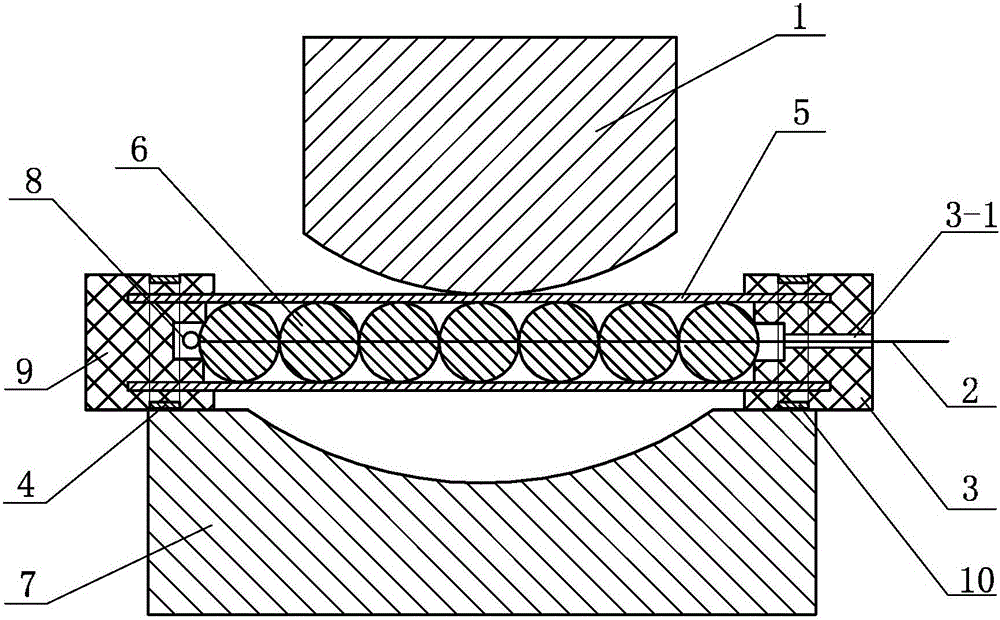

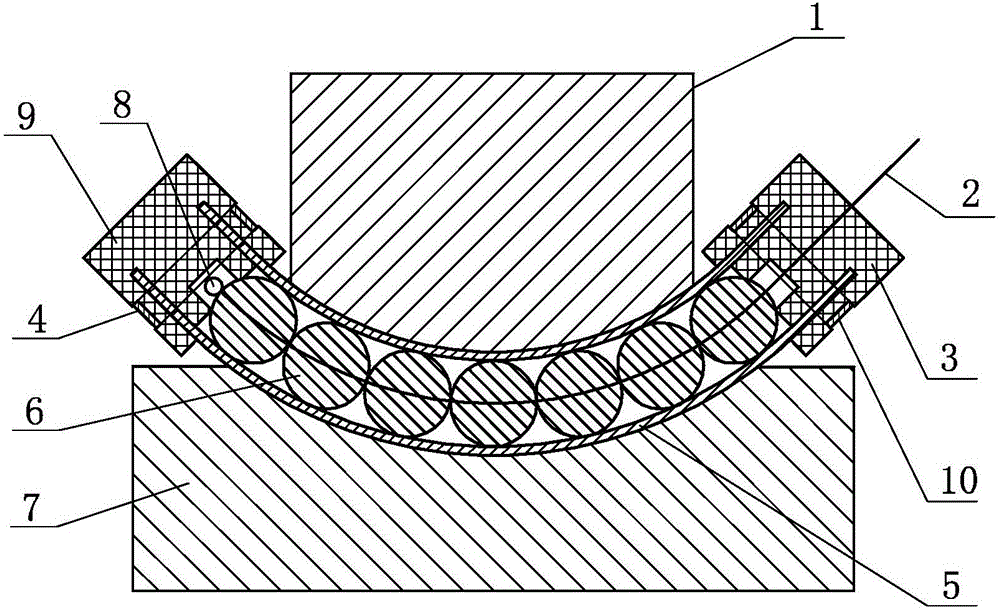

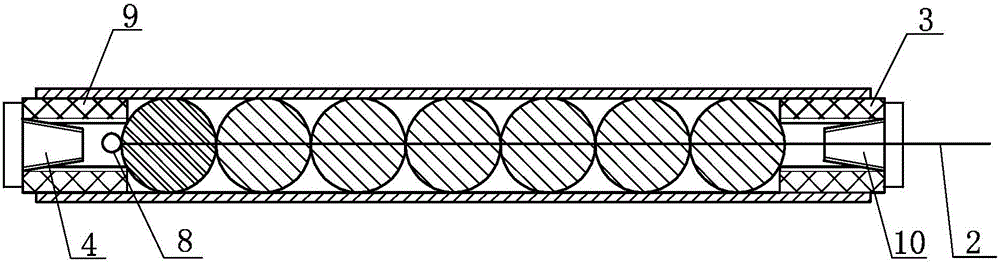

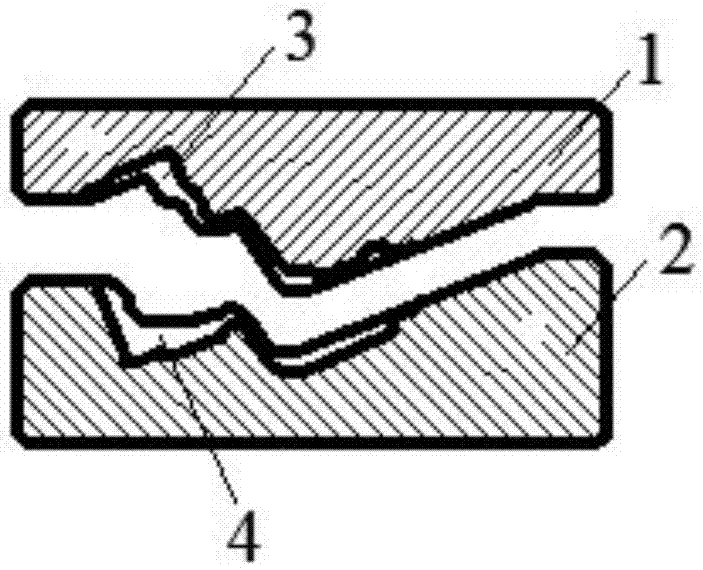

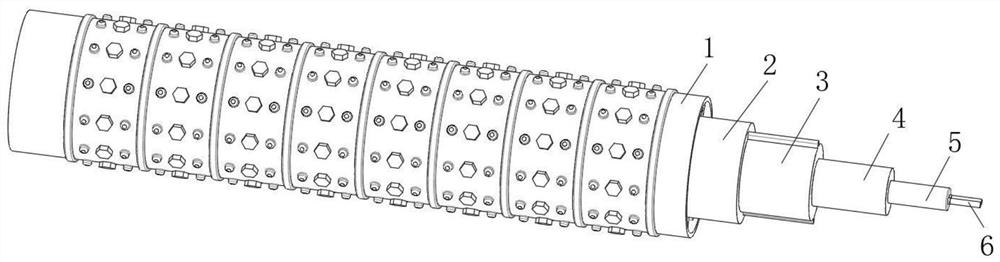

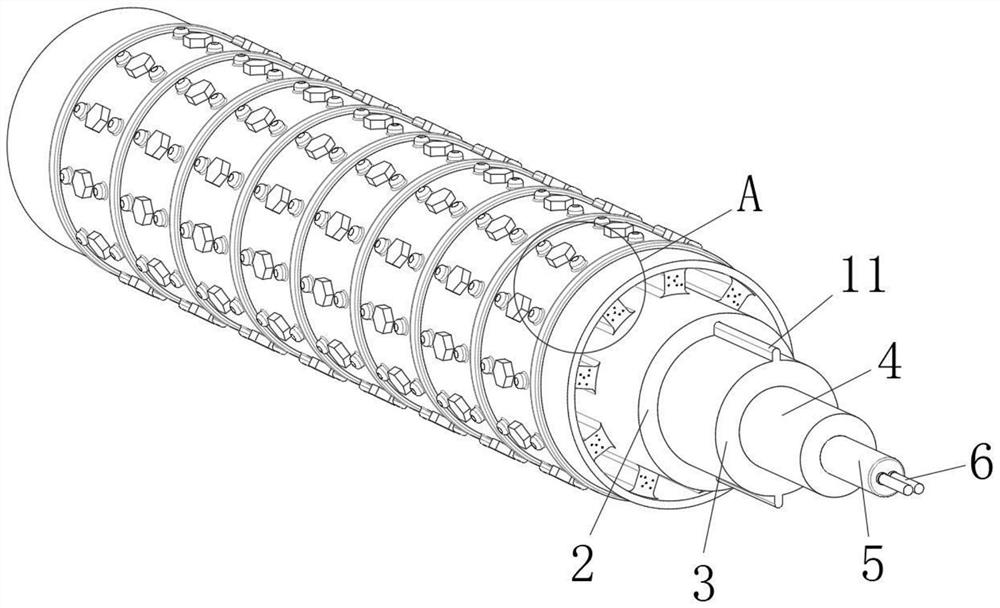

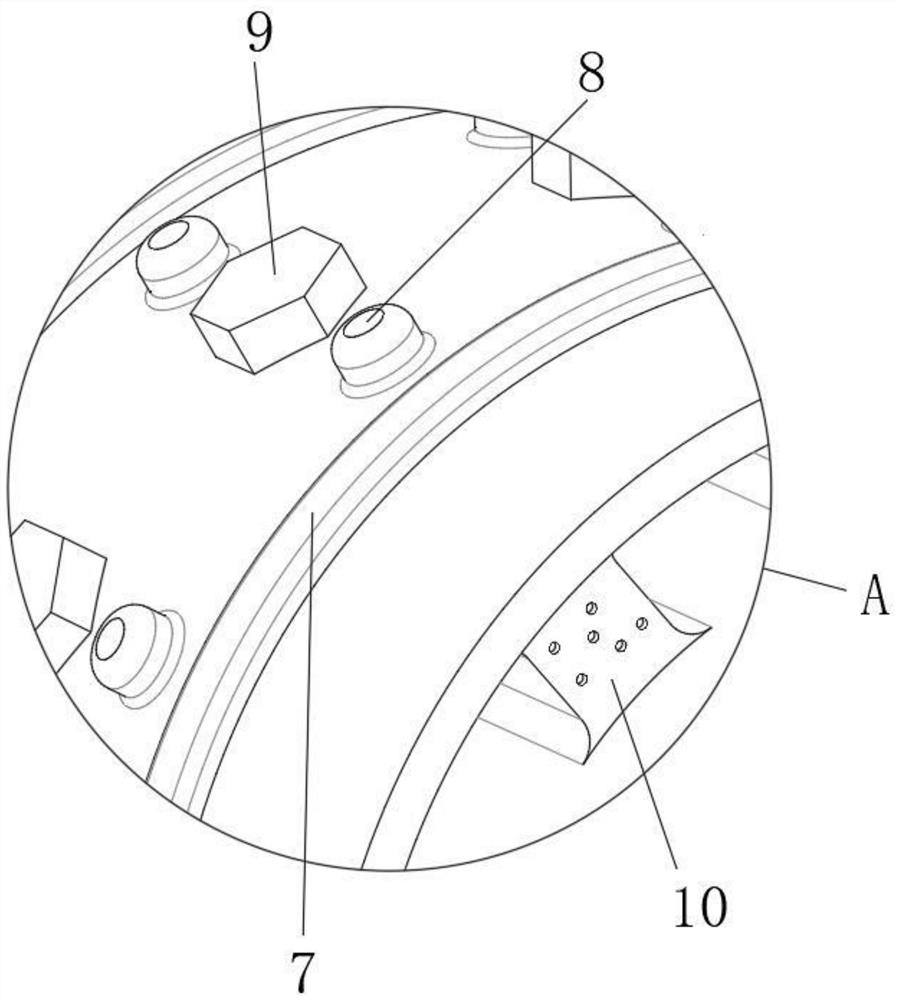

Bending method of pipes with flexible chained-ball mandrel

InactiveCN103752666AThere is no problem of mutual interferenceUniform deformationEngineeringMachine press

The invention relates to a pipe bending method, in particular to a bending method of pipes with a flexible chained-ball mandrel and solves the problem that high bending degree in the existing process of bending pipes having a mandrel causes mutual interference. The method includes: 1, threading a plurality of balls with a rope having a restraint ring at one end; 2, inserting a combined flexible chained-ball mandrel into a pipe to be bent; 3, placing a first rubber plug into one end of the pipe to be bent, fastening the first rubber plug through a first fastener, placing a second rubber plug into the other end of the pipe to be bent, and fastening the second rubber plug through a second fastener; 4, placing the pipe to be bent, onto a female die, and driving a male die to move down by a press until the pipe to be bent is bent; 5, after bending, loosening the first fastener, the second fastener, the first rubber plug and the second rubber plug to obtain a bent pipe. The bending method of pipes with one flexible chained-ball mandrel is applicable to pipe bending.

Owner:HARBIN UNIV OF SCI & TECH

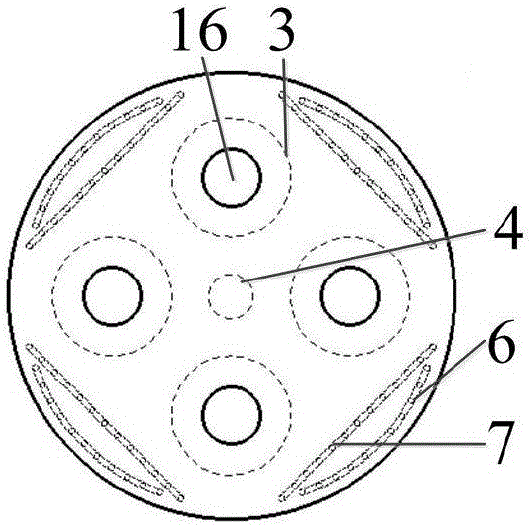

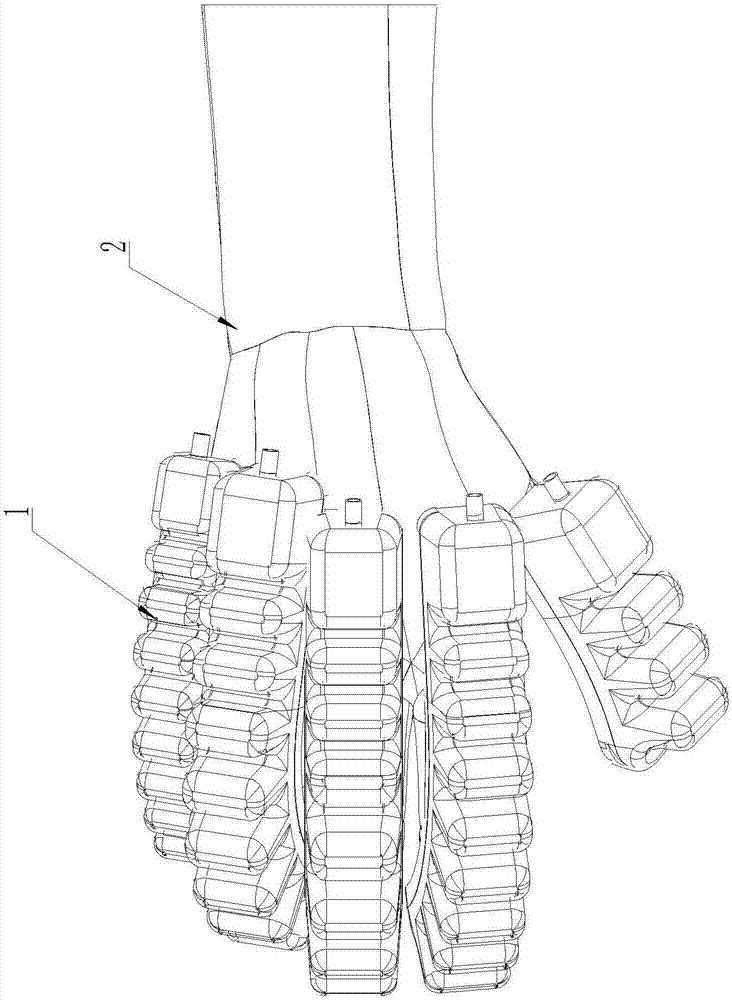

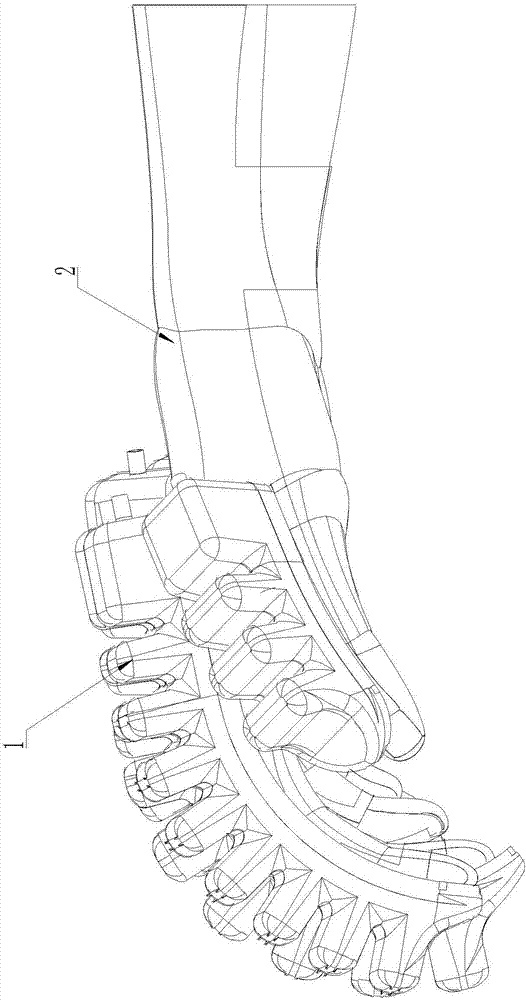

Pneumatic redundancy self-sensing multi-degree-of-freedom flexible nimble finger

PendingCN106695854AUniform forceAvoid breakingProgramme-controlled manipulatorGripping headsEngineeringMulti degree of freedom

A pneumatic redundancy self-sensing multi-degree-of-freedom flexible nimble finger comprises a cylindrical flexible finger base body and a circular-truncated-cone-shaped flexible connecting base body. The flexible finger base body is provided with four pneumatic cavities distributed circumferentially and evenly in the axial direction. A bent inner core is arranged at the axis of the flexible finger base body, and tube connectors are arranged at the end of the flexible finger base body. Four micro sensitive channels distributed circumferentially and evenly are formed in the peripheries of the pneumatic cavities. Each micro sensitive channel comprises an arc sensitive channel body and a linear sensitive channel body and is filled with gallium-indium-tin liquid alloy or a liquid sensitive piezoresistive element. Four rubber tube connectors are arranged at the finger root of the flexible nimble finger and correspond to the pneumatic cavities. The pneumatic redundancy self-sensing multi-degree-of-freedom flexible nimble finger has the advantages of being simple in structure, low in weight, clean, safe, large in working space, high in control precision and the like, the effect that the multi-degree-of-freedom flexible mechanical finger has high precision during operation can be ensured, and the finger can be widely applied to the multiple fields such as industrial and agricultural production, national defense security and medical rehabilitation.

Owner:YANSHAN UNIV

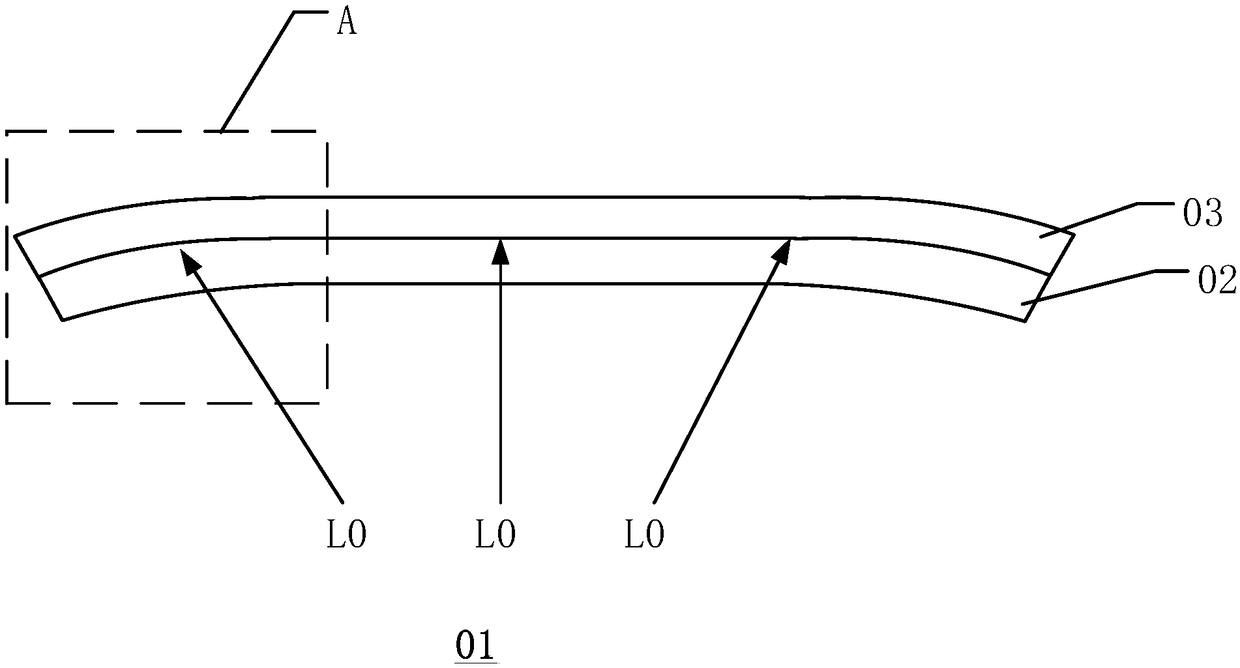

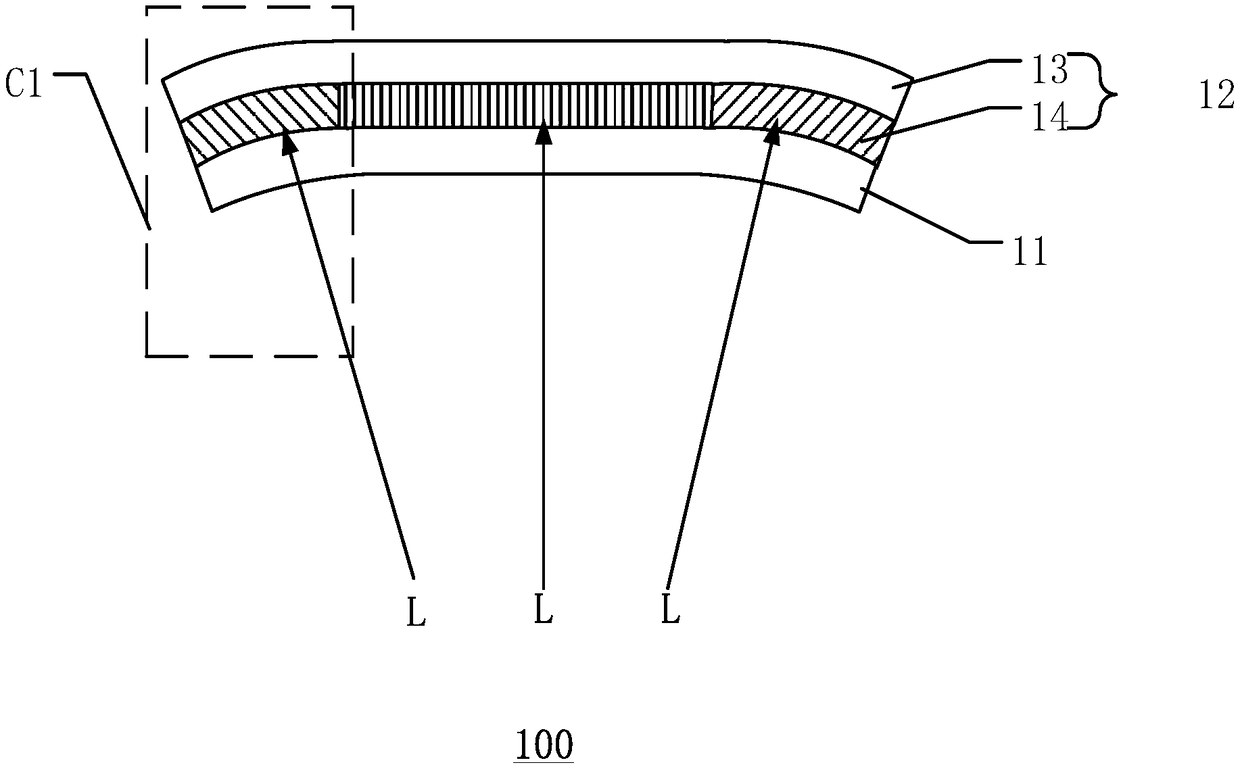

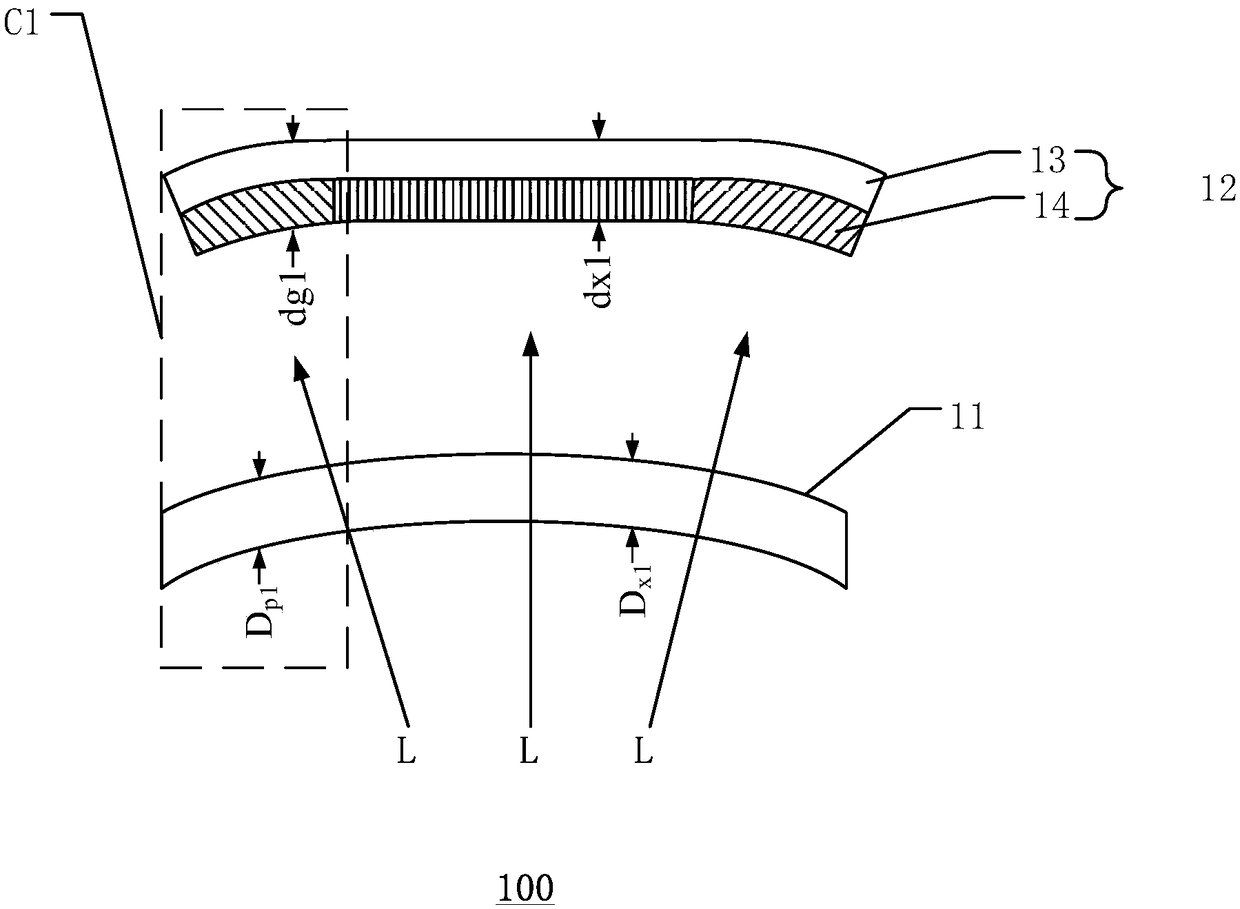

Display device and manufacturing method thereof

ActiveCN108663840AHigh refractive indexReduce brightness differenceNon-linear opticsSurface displayGlass cover

The invention discloses a display device and a manufacturing method thereof, and belongs to the technical field of displaying. The display device comprises a hook-surface display panel and a glass cover plate fitting the hook-surface display panel; the glass cover plate comprises a glass substrate and a refraction layer, and the refraction layer is located at one side, close to the hook-surface display panel, of the glass cover plate; the display device is provided with a first curve area. The curvature R1 of the glass substrate in the first curve area is minimum, R1 is less than Rx, and the refractive index of the glass substrate in the first curve area is Nj1. In order to avoid illumination differences between the first curve area and other areas in the display device, the refractive index of the glass cover plate in the first curve area is Ng1, the refractive index of the glass cover plate in other areas is Ngx, the relationship is set that Ng1 is less than Nj1, and Ng1 is less thanNgx. Therefore, the illumination differences between the first curve area and other areas are reduced, the illumination uniformity of the display device is improved, and the display quality is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

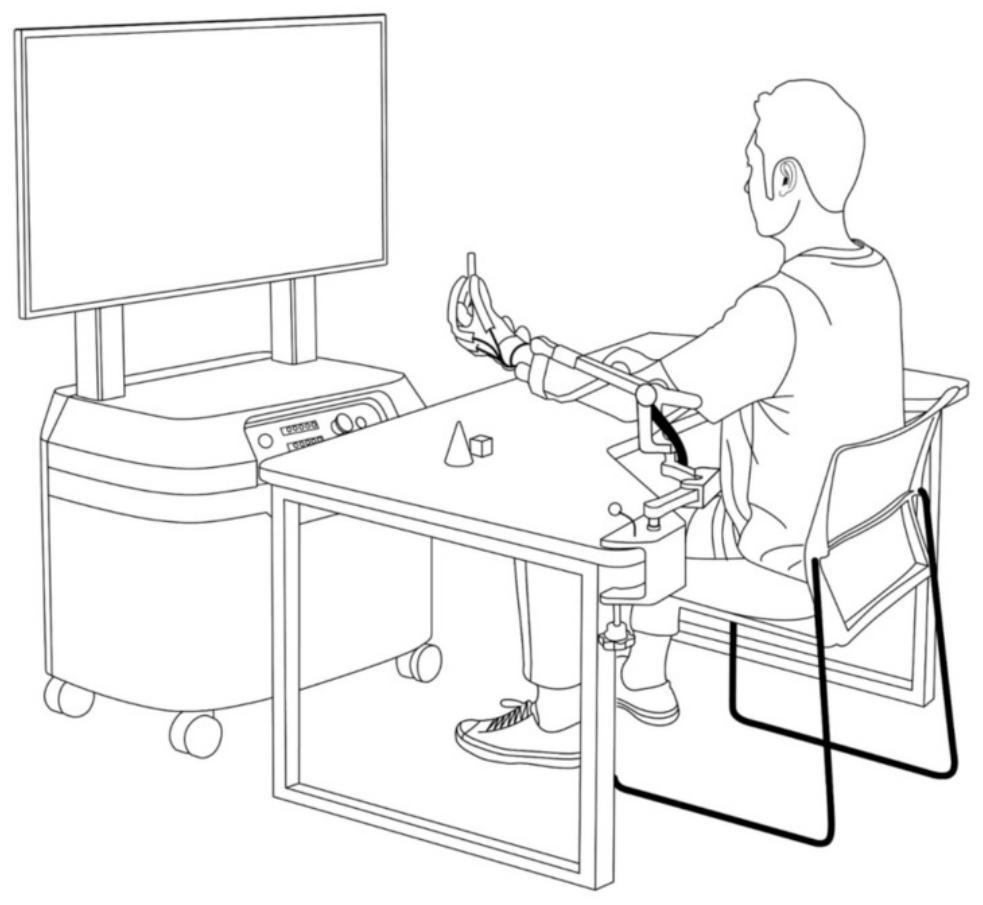

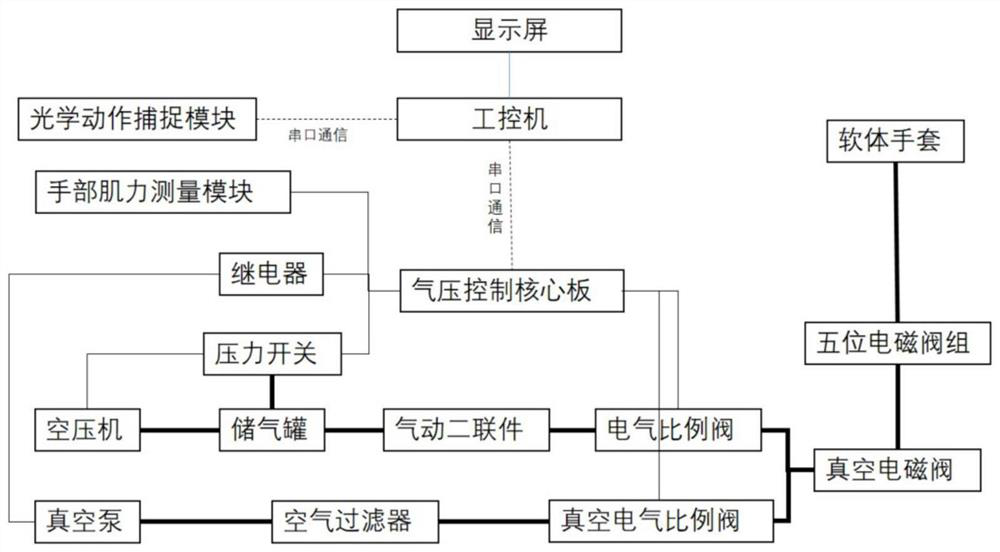

Finger joint rehabilitation training evaluation method and system

ActiveCN112089427ARealize evaluationEasy to controlChiropractic devicesMuscle exercising devicesPhysical medicine and rehabilitationHand movements

The invention relates to a finger joint rehabilitation training evaluation method. On the basis of a soft glove with pneumatic structures on finger joint positions respectively, various rehabilitationtraining methods are designed through high-precision tracking of hand movement postures, and the active and passive combined rehabilitation training is realized for an affected side hand of a hemiplegic patient from multiple aspects. Meanwhile, a system of the finger joint rehabilitation training evaluation method is designed, an optical motion capture module based on binocular vision is provided, the movement range measurement and calculation can be performed on palm fingers, far-end finger joints and wrist joint of a hand of the patient to obtain a hand movement state, and the calculation date serve as data support of the hand movement state, and can serve as the real-time input of movement signals of the affected side soft glove. Meanwhile, a grip strength sensor and a finger pinchingforce sensor are added at the same time, so that the evaluation of hand muscle strength and movement of the patient is realized, and the closed-loop rehabilitation treatment of performing evaluation,performing training and then performing evaluation in the rehabilitation training is completed.

Owner:NANJING MEDLANDER MEDICAL TECH CO LTD +1

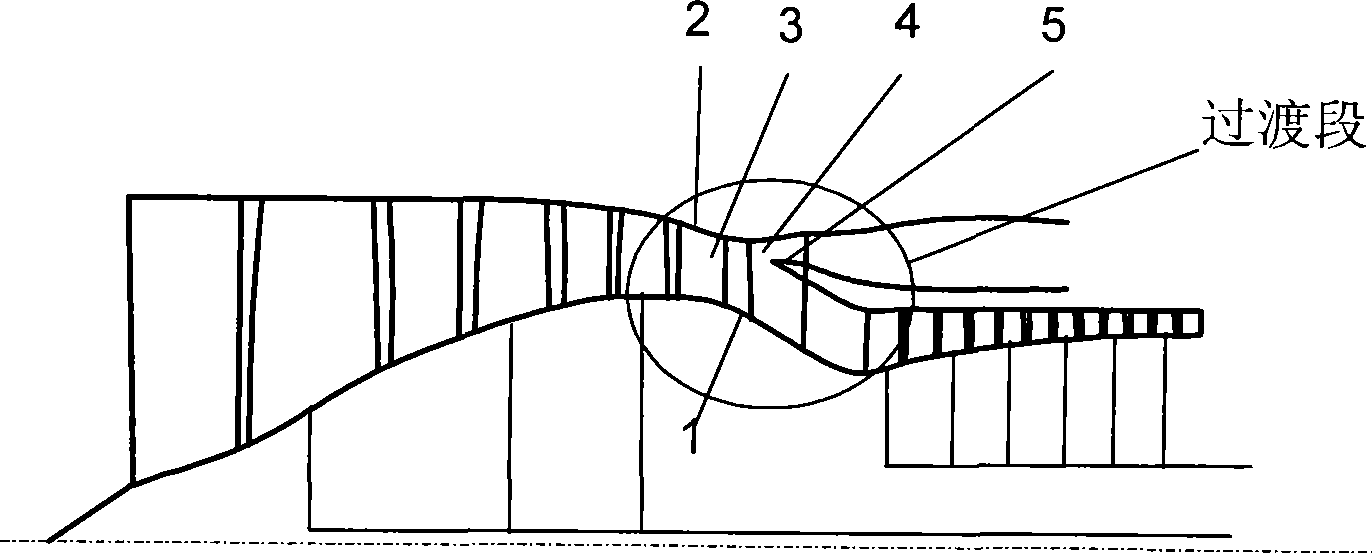

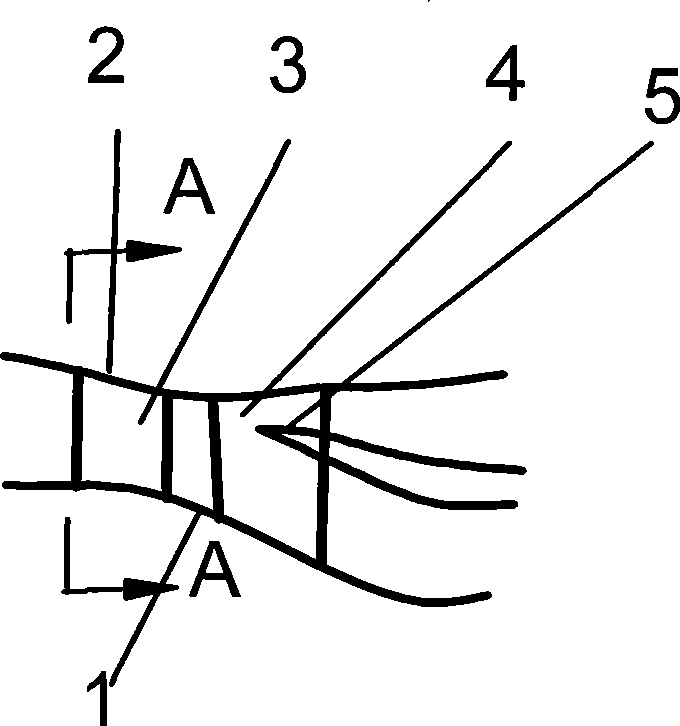

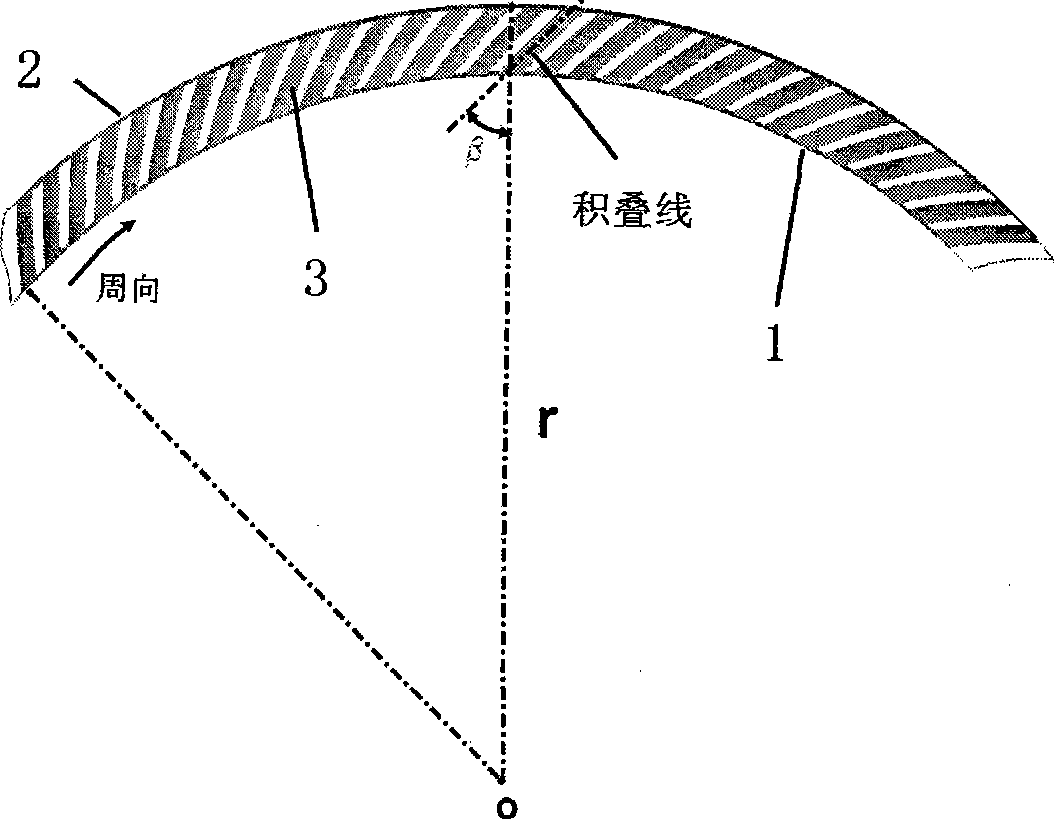

Method for restraining flow separation in transition section by utilizing guide vane

The invention relates to a method for inhibiting flow separation in a transition section of a compression system of an engine of a low-bypass aerial turbofan by using a guide vane. The method comprises the following steps: placing the guide vane at a first curved conduit on the inner wall of a transition section of an air compressor, and forming a vane force with gradient opposite to that of the prior pressure at the curved conduit of the transition section through changing a peripheral included angle of a laminated line and a radial line of the guide vane, so as to reduce pressure gradient of the flow direction at the curved conduit, and inhibit the flow separation in the transition section. Because the method can inhibit the flow separation in the transition section, the method can increase bending degree of the transition section, so as to reduce the length of the transition section. At the same time, because the guide vane is placed in the transition section, the method saves space occupied by the prior guide vane, and is favorable for reducing the length of the whole air compressor. The length of the transition section is estimated to be shortened by about 20 percent by adopting the method and the method contributes to the thrust mass ratio of the engine by about 1 percent.

Owner:廊坊智驰动力科技有限公司

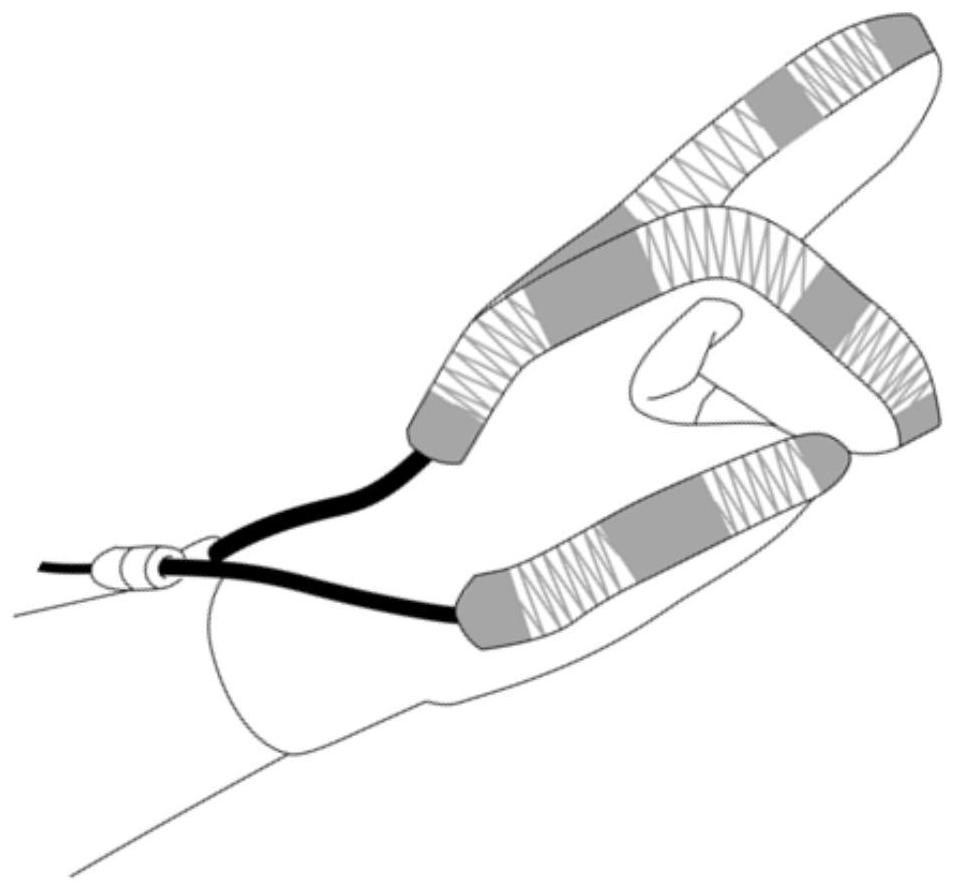

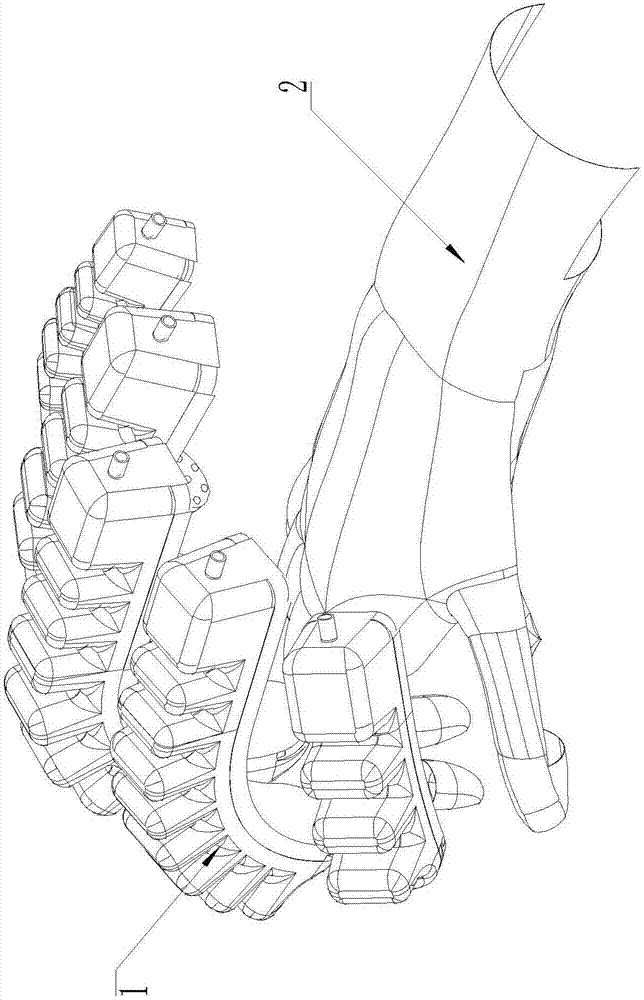

Joint rehabilitation device

PendingCN107374908ALow costAchieve bending deformationGripping headsChiropractic devicesFinger surfaceEngineering

The invention discloses a joint rehabilitation device which comprises at least one flexible finger. Each flexible finger comprises a finger baseplate and a finger surface which is connected on one side plate face of the finger baseplate, elastic modulus of each finger baseplate is greater than that of the corresponding finger surface, each finger surface and the corresponding finger baseplate jointly surround to form a driving cavity, a ventilation port is arranged on each finger surface or the corresponding finger baseplate and communicated with an airway system through a pipeline, a fixing structure for fixing the corresponding flexible finger on a first bone section and a second bone section which form a joint is arranged on each finger baseplate, and each flexible finger covers the whole corresponding joint from the corresponding first bone section and extends to the corresponding second bone section. The joint rehabilitation device utilizes own deformation of the flexible fingers to drive the joints to act, in this way, rehabilitation action of bending or unfolding of the joints is comparatively gentle, and damage to the joints is avoided.

Owner:SUZHOU ROROBOT TECH CO LTD

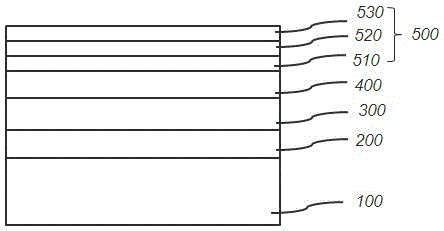

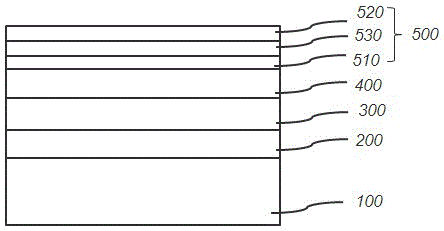

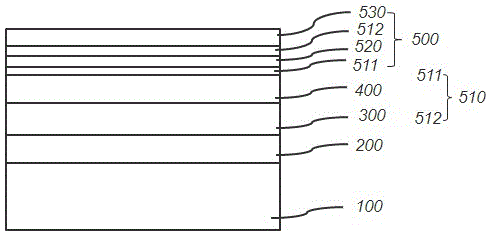

Gallium nitride-based light emitting diode structure and preparation method therefor

ActiveCN106784204AEnhanced two-dimensional hole gas concentrationLower resistanceMaterial nanotechnologySemiconductor devicesBand bendingHole injection layer

Disclosed is a gallium nitride-based light emitting diode structure. The gallium nitride-based light emitting diode structure comprises a substrate, a bottom layer, an N type layer, a light emitting layer and a P type layer in sequence; the gallium nitride-based light emitting diode structure is characterized in that the P type layer consists of an electron barrier layer, at least one energy band deformation layer and a hole injection layer; the energy band deformation layer is inserted in the electron barrier layer or positioned between the electron barrier layer and the hole injection layer, or inserted in the hole injection layer or positioned on the hole injection layer; and the energy band deformation layer is a non-P type layer with carbon impurity content of not greater than 5*10<16>cm<-3>. By virtue of the low carbon impurity content, the energy band of the energy band deformation layer can be bent, and the two-dimensional hole gas concentration on a contact interface between the energy band deformation layer and the adjacent layer can be increased.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

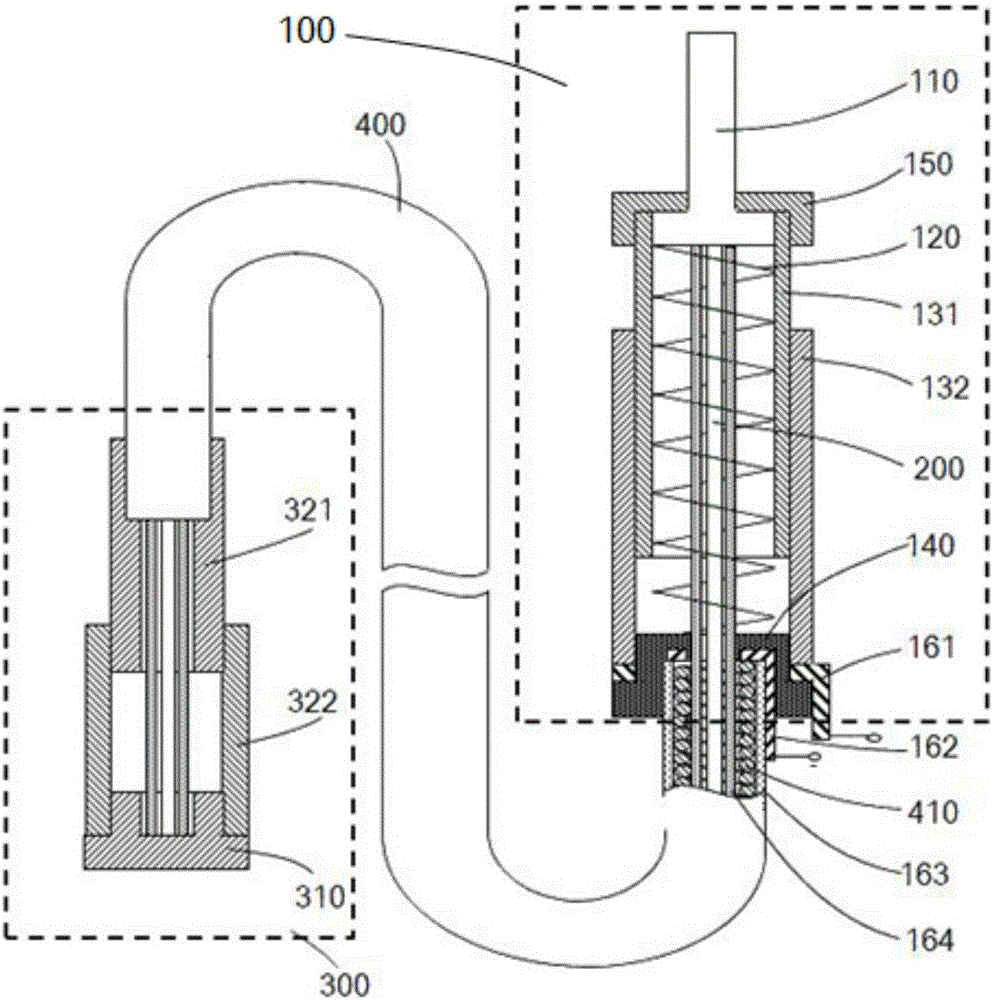

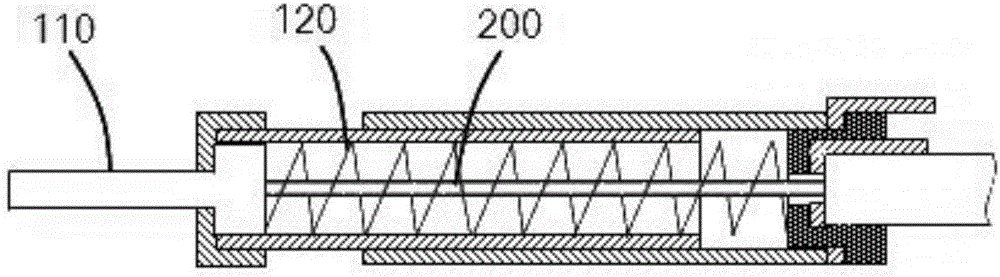

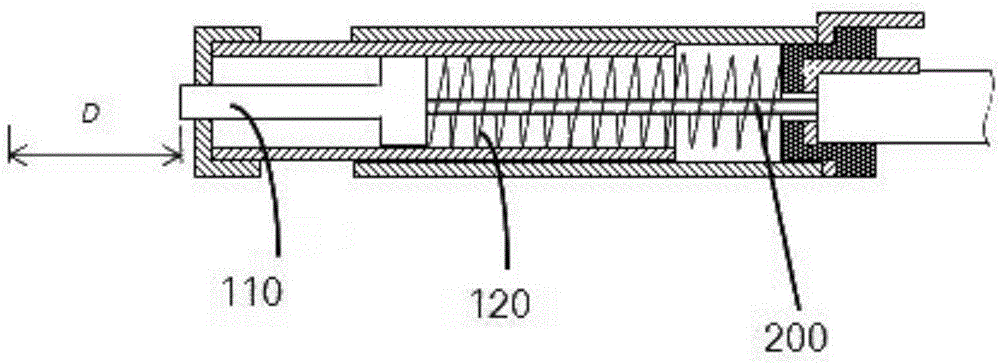

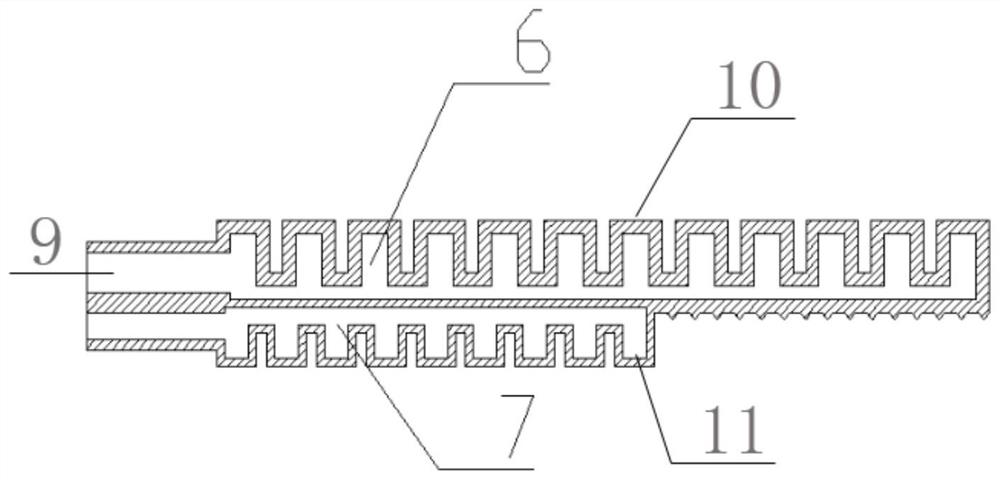

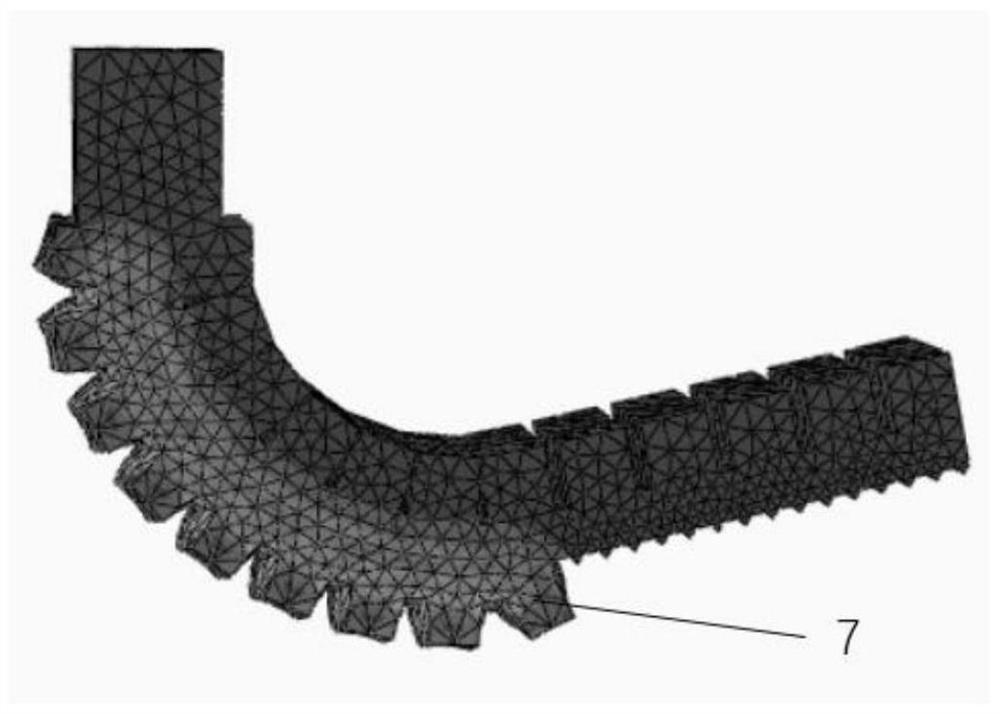

Flexible and bendable shape-memory alloy actuator

InactiveCN105114270AReduce volumeReduce shockMachines/enginesMechanical power devicesAlloyMaterials science

The invention relates to a flexible and bendable shape-memory alloy actuator. A shape-memory alloy wire is taken as an actuation element, is retracted when electrified and heated and is elongated when cooled, so that displacement of the actuator and output of force are realized. The actuator comprises a drive end, a flexible solenoid and a fixed end, wherein the shape-memory alloy wire is arranged in the bendable solenoid, one end of the shape-memory alloy wire is in rigid connection with an output shaft, and the other end of the shape-memory alloy wire is connected with a fixed end cap; a bias spring is arranged in the drive end and can assist the shape-memory alloy wire in elongation in the cooling process. The actuator is small in size, light in weight and simple and reliable in structure, can bend according to certain curvature and can be easily mounted and integrated with an external mechanism, and the output force and the displacement are adjustable.

Owner:JILIN UNIV

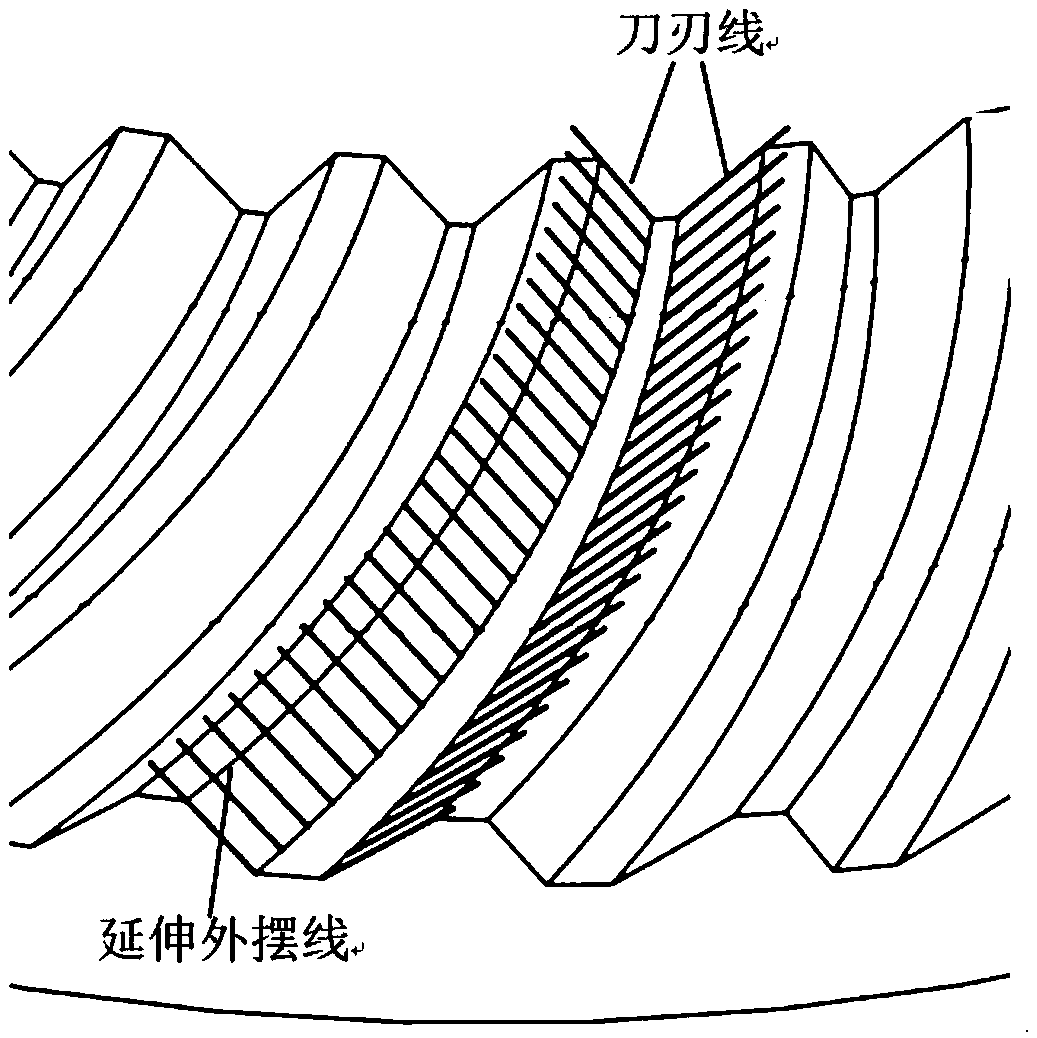

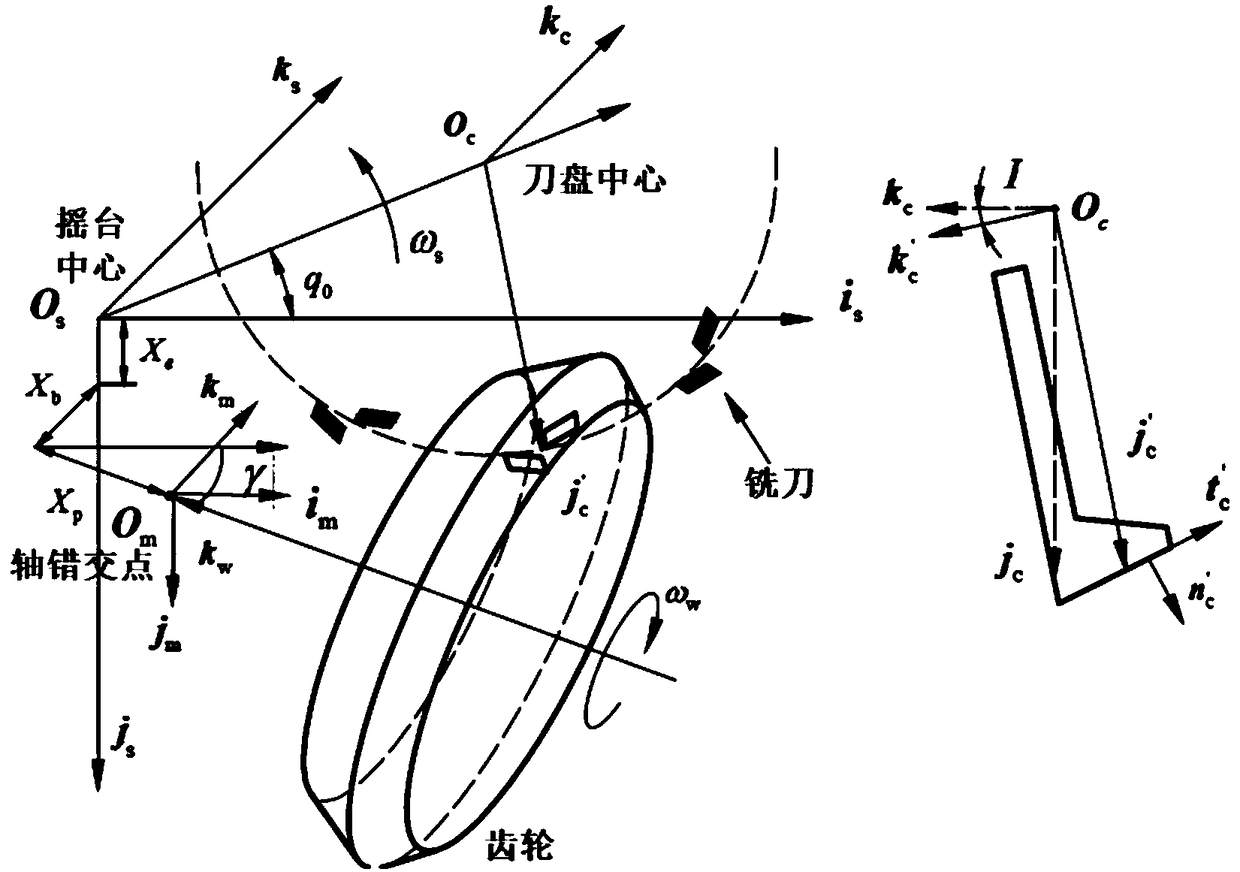

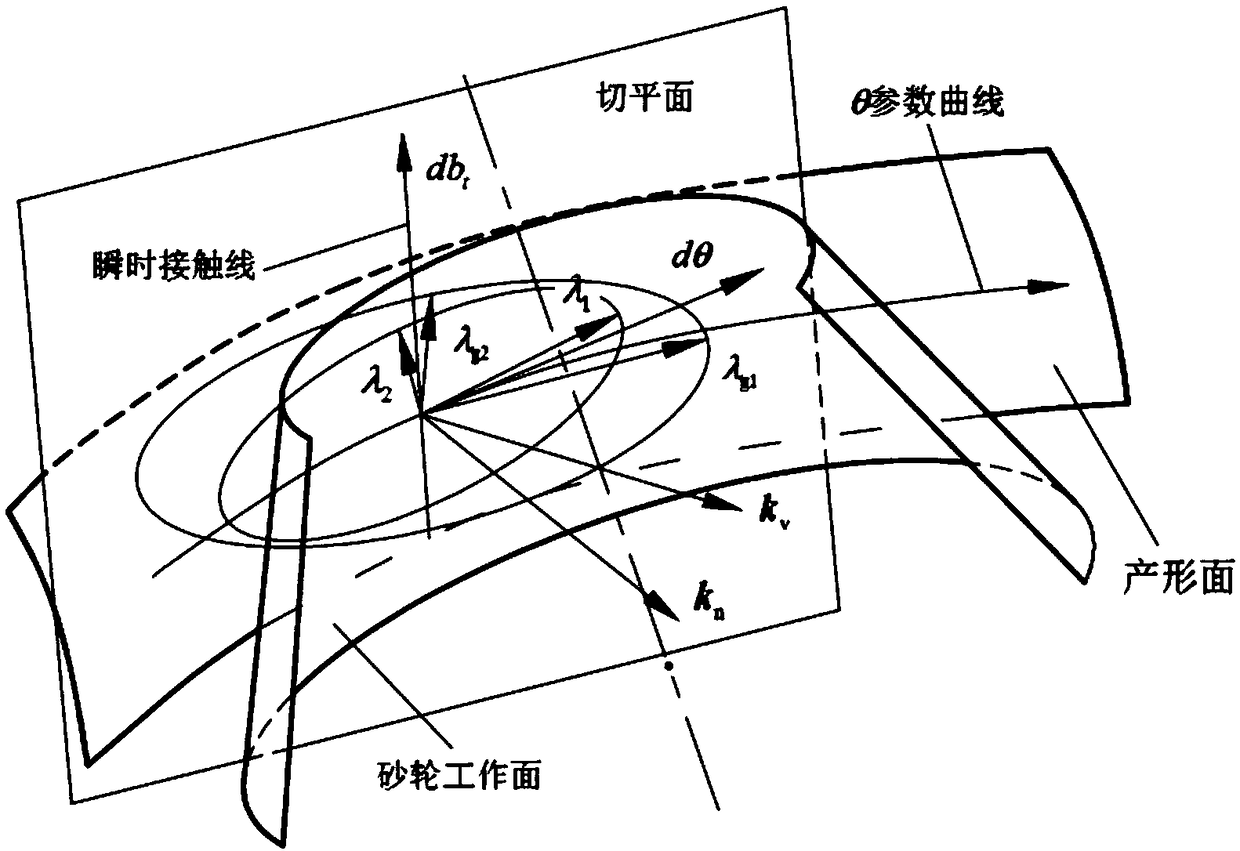

Generating method cycloid tooth bevel gear grinding method

ActiveCN109482984AHighly curvedInterference judgment conditions simplifiedGear teethGear grindingGear wheel

The invention discloses a generating method cycloid tooth bevel gear grinding method. The generating method cycloid tooth bevel gear grinding method comprises the following steps: first, a machining coordinate system set of a generating method cycloid tooth bevel gear is established; second, the tooth surface equation of a generating wheel is determined, and the generating wheel tooth surface of the generating method cycloid tooth bevel gear is the gear tooth surface; third; grinding wheel parameters for gear grinding are determined; fourth, interference analysis and correction calculation areconducted; and fifth, the gear grinding tool position is calculated. According to the generating method cycloid tooth bevel gear grinding method, a grinding wheel structure of gear grinding and geargrinding moving parameters are determined according to a tooth surface machining mathematical model and parameter calculation, one tooth surface is ground in one-time gear grinding movement by adopting a large-diameter conical surface grinding wheel, and thus the precision and the efficiency are high.

Owner:CHONGQING UNIV OF TECH

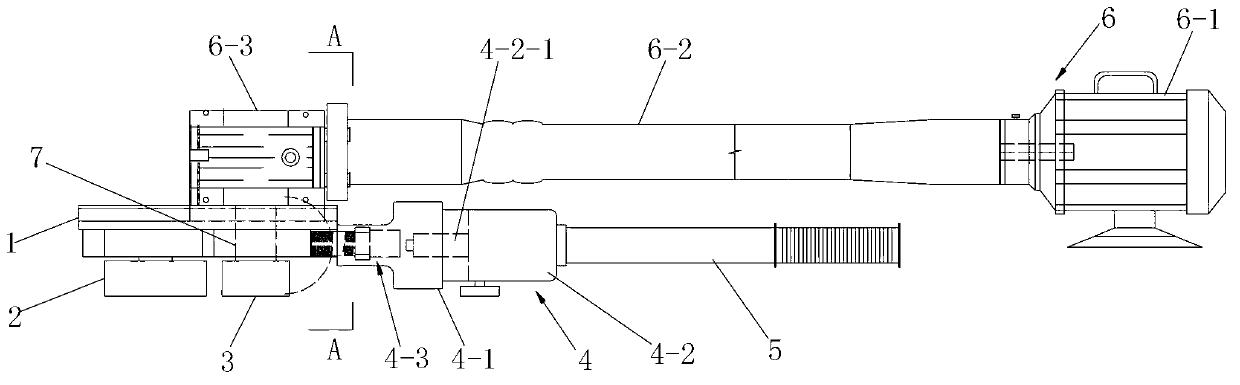

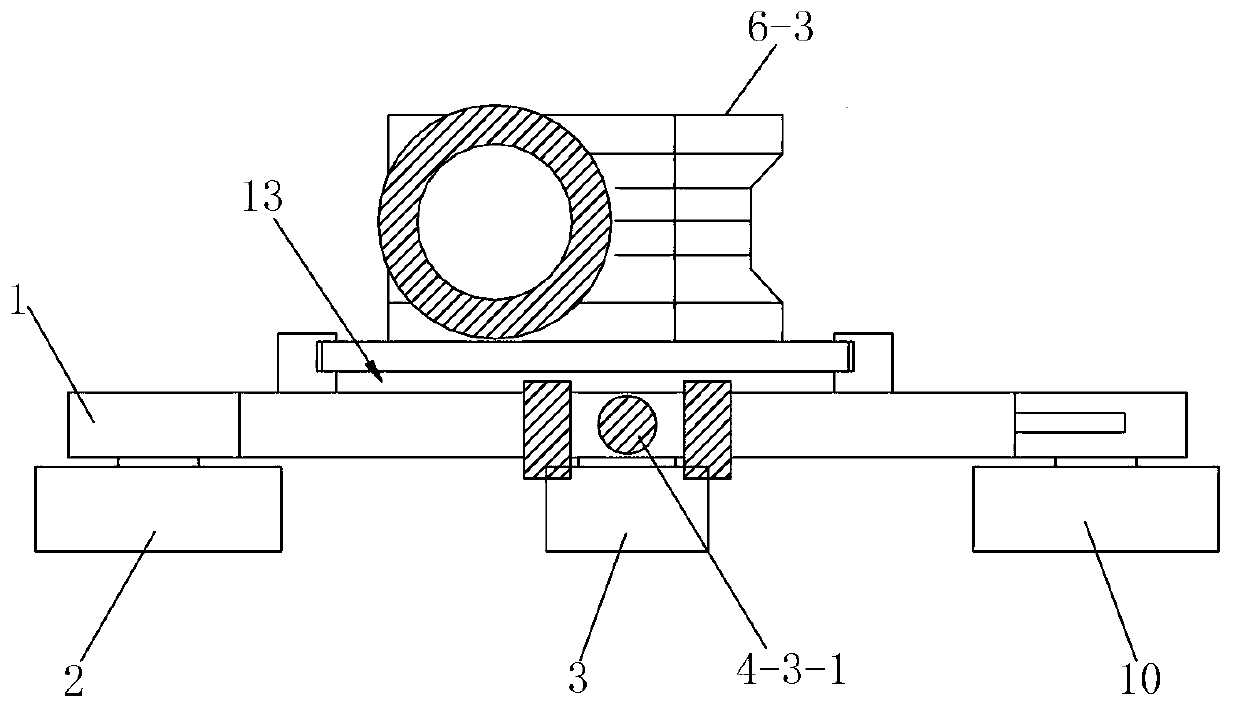

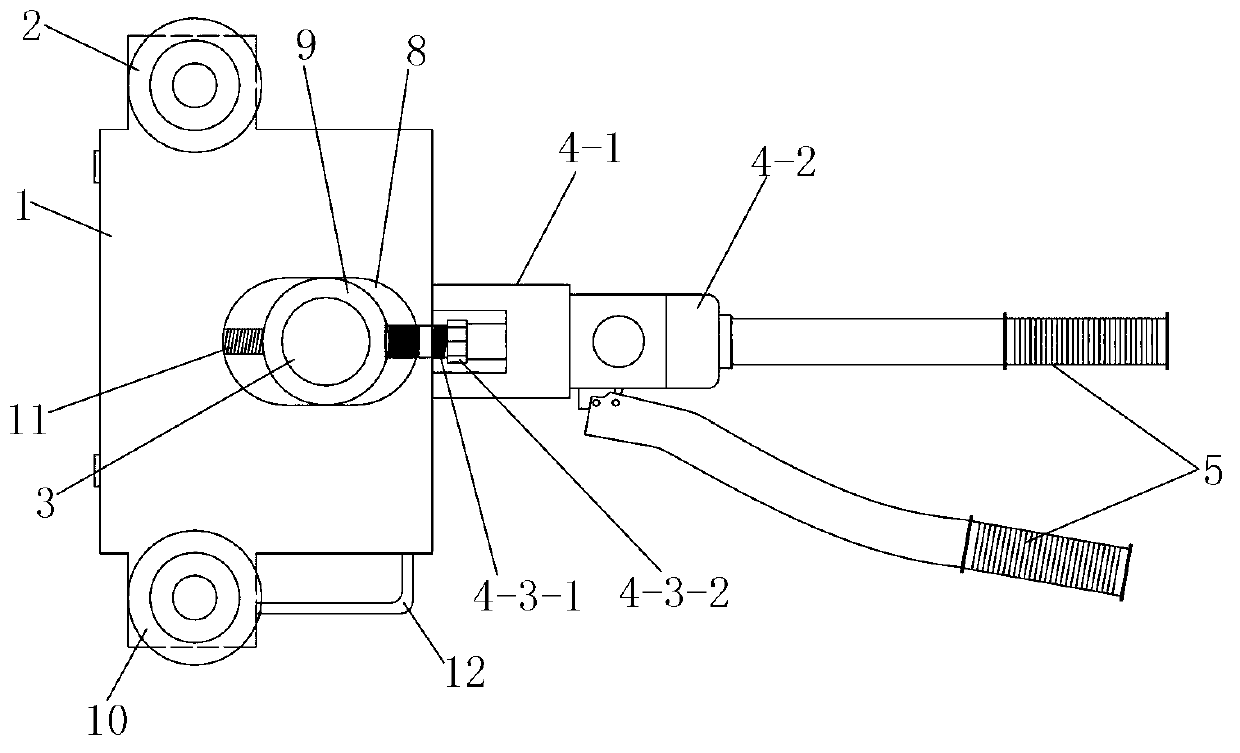

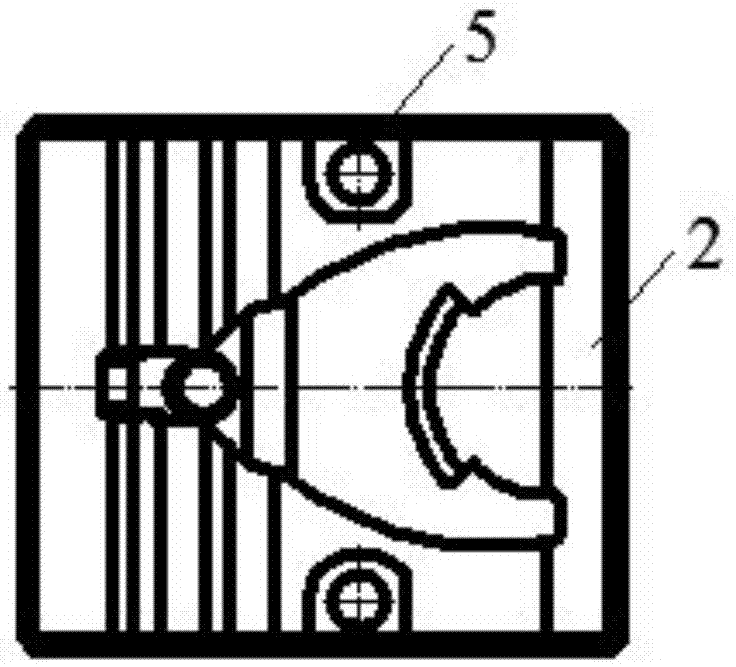

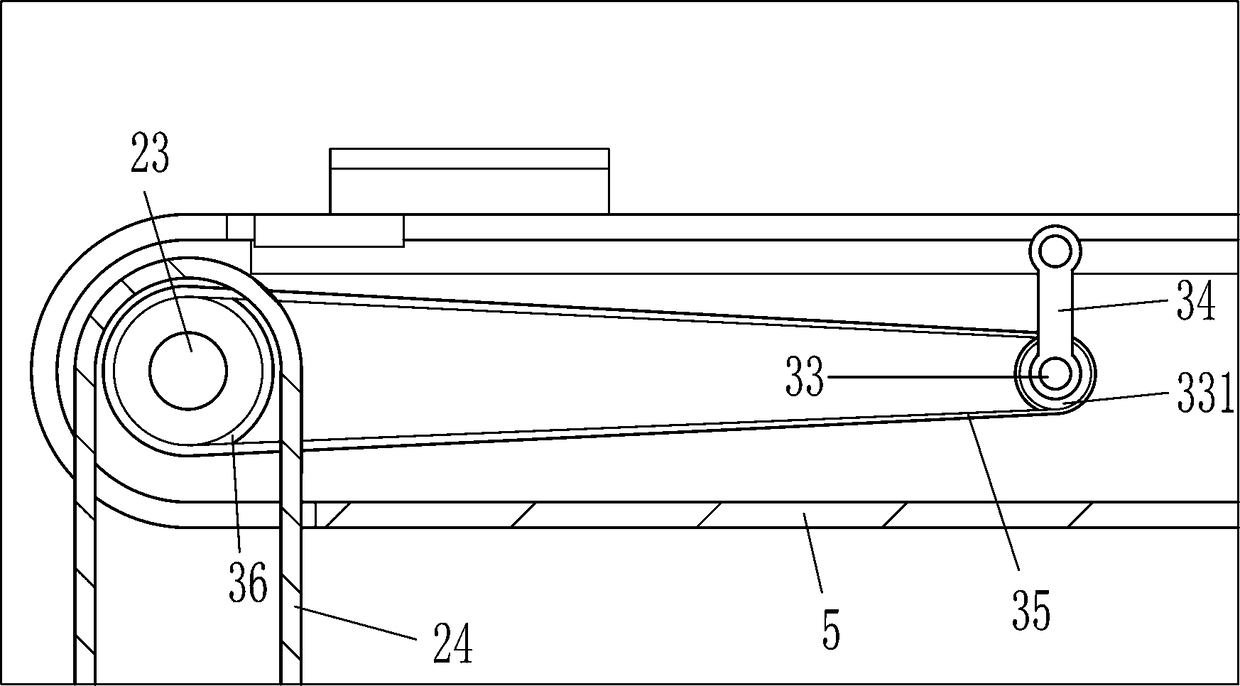

Tunnel inverted arch rebar connecting rib bending machine

ActiveCN103341570ABending work is simple and easyMinus the case of repeated handling of steel barsEngineeringRebar

The invention discloses a tunnel inverted arch rebar connecting rib bending machine which comprises a supporting face plate, a rolling shaft, a driving mechanism and an ejector. A first guide wheel is arranged at one end of the supporting face plate, a second guide wheel is arranged at the other end of the supporting face plate, an adjusting hole is formed in the supporting face plate, the adjusting hole is formed between the first guide wheel and the second guide wheel and is formed in one side of the connecting line of the first guide wheel and the second guide wheel, a bearing is arranged on the rolling shaft and arranged in the adjusting hole, a rolling wheel is arranged at one end of the rolling shaft, the other end of the rolling shaft is connected with the driving mechanism, the first guide wheel, the second guide wheel and the rolling wheel are all arranged on the front side face of the supporting face plate, and a sliding groove allowing the driving mechanism to slide along with the rolling shaft is formed in the rear side face of the supporting face plate. The tunnel inverted arch rebar connecting rib bending machine can pre-bend one portion of an inverted arch rebar connecting rib, and can further carry out continuous rolling on the inverted arch rebar connecting rib, and the bending of the inverted arch rebar connecting rib is achieved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

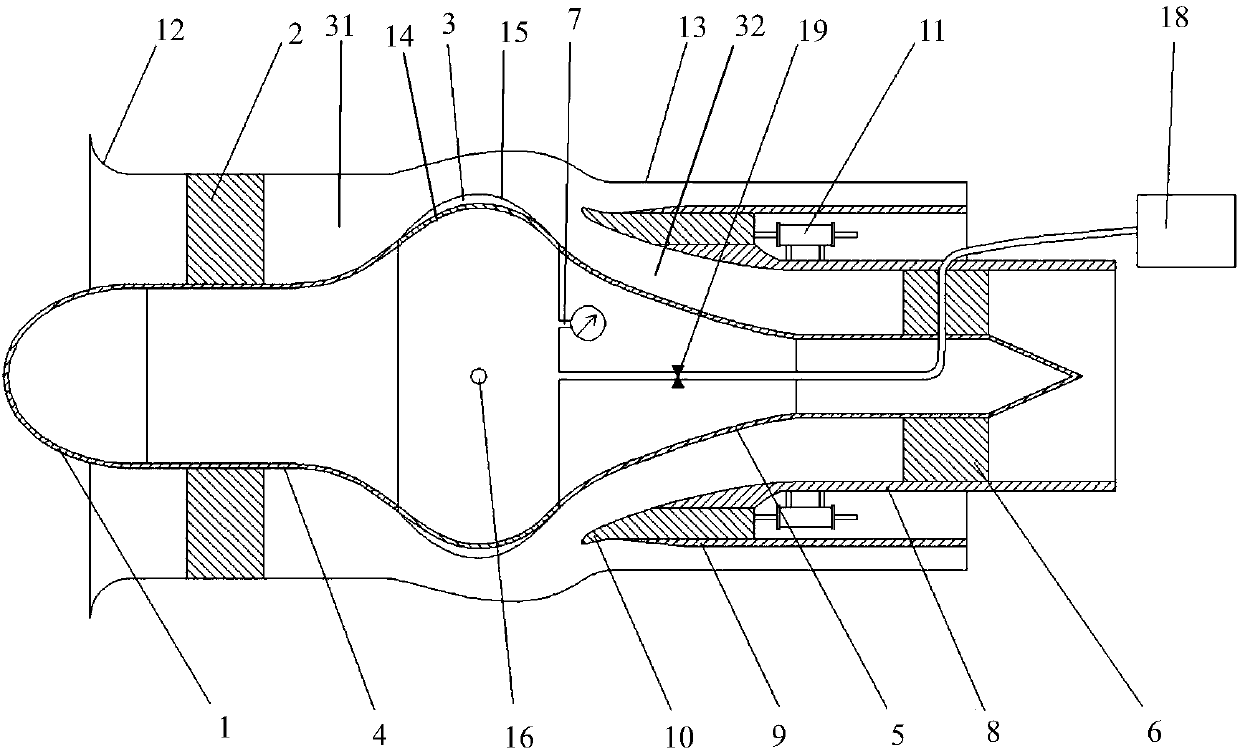

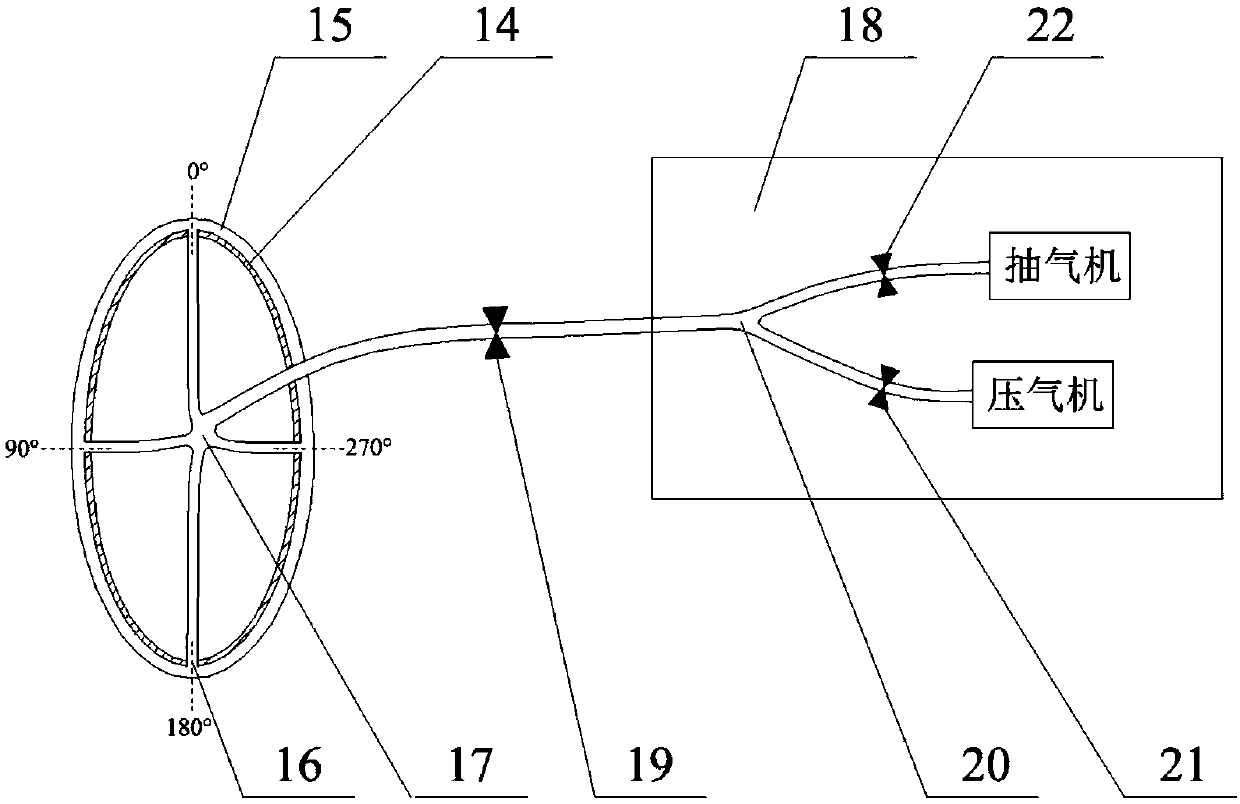

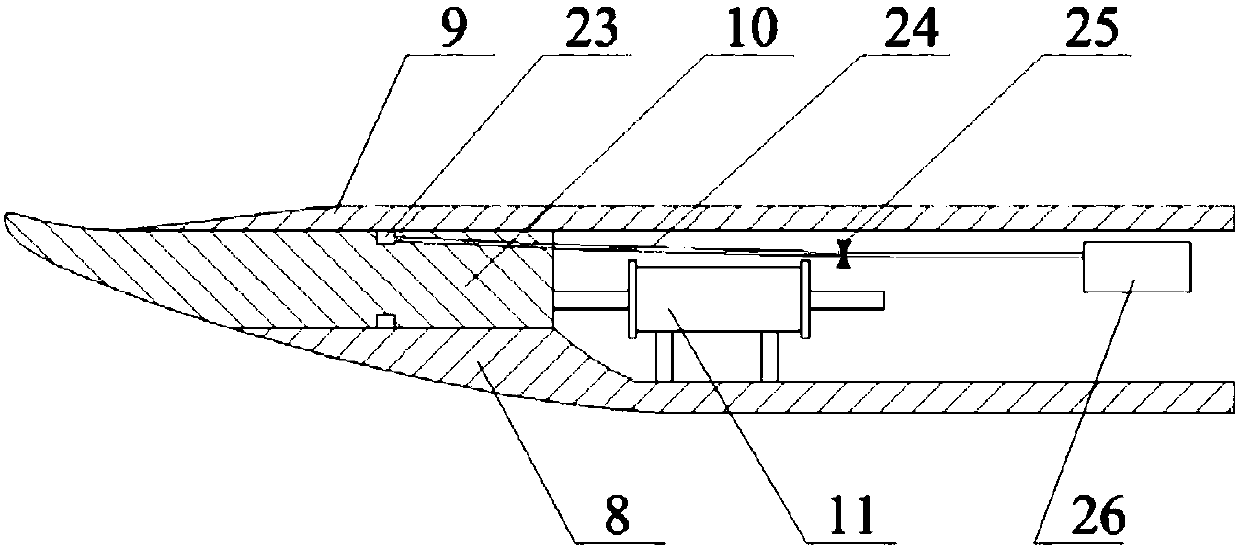

Variable structure turboshaft engine gas intake system

ActiveCN107605602AImprove aerodynamic efficiencyReduce the overall heightGas turbine plantsTurbine/propulsion air intakesWorking environmentEngineering

The invention discloses a turboshaft engine gas intake system. The gas intake system comprises a center body assembly, a wedge assembly and a casing assembly. A flexible and deformable annular gas chamber is embedded in the center body assembly; a wedge capable of moving in the axial direction is designed at the same time; and according to the work environment and the work state of an engine, themolded surface of a gas chamber and the axial position of the wedge are adjusted. When a helicopter works in an unclean air environment of dust sand and the like, the height of the gas chamber is increased, the position of the wedge moves forwards, and the gas intake system is made to be in a high dust sand separation efficiency mode; and when the helicopter is in a cruising condition, the heightof the gas chamber is reduced, the position of the wedge moves backwards, and the gas intake system is made to work in a high pneumatic efficiency mode. By means of the turboshaft engine gas intake system, the problem that a traditional fixed geometric gas intake system can not consider both efficient sand discharging and high pneumatic performance of cruising is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Hydraulic part servo valve body material formula and preparation process thereof

PendingCN103966499AReduce the amount of C and SiPrevent pitting and small holesFoundry mouldsFoundry coresLiquid stateGraphite

The invention discloses a hydraulic part servo valve body material formula and a preparation process thereof. The method comprises the following steps of: (1) smelting by adopting an electric furnace, adding 15-25 parts (in parts by weight) of raw iron, 40-60 parts of waste steel and 20-40 parts of foundry returns into the electric furnace for melting; (2) adding Sn in the electric furnace after melting; (3) continuously adding ferrochrome into the electric furnace; (4) then, continuously adding copper; (5) then carrying out inoculation treatment in three steps; (6) pouring liquid-state cast iron into a casting mould cavity of a sand mould to form hydraulic part servo valve body blank. According to the invention, formation of thick sheet-shaped graphite can be prevented, hard spot shaped small holes can be prevented, and mechanical performances of cast iron can be improved.

Owner:SHANDONG CHANGLIN MACHINERY GRP

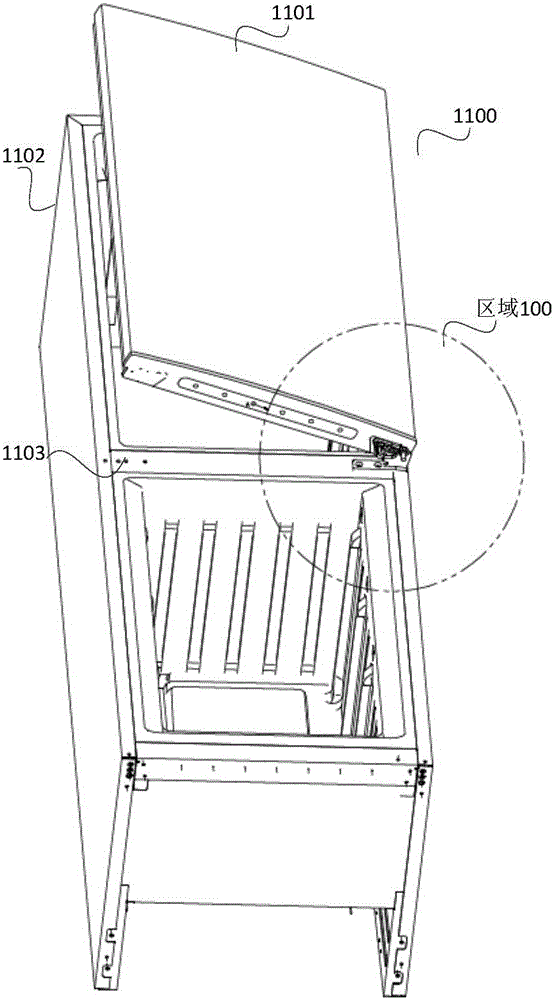

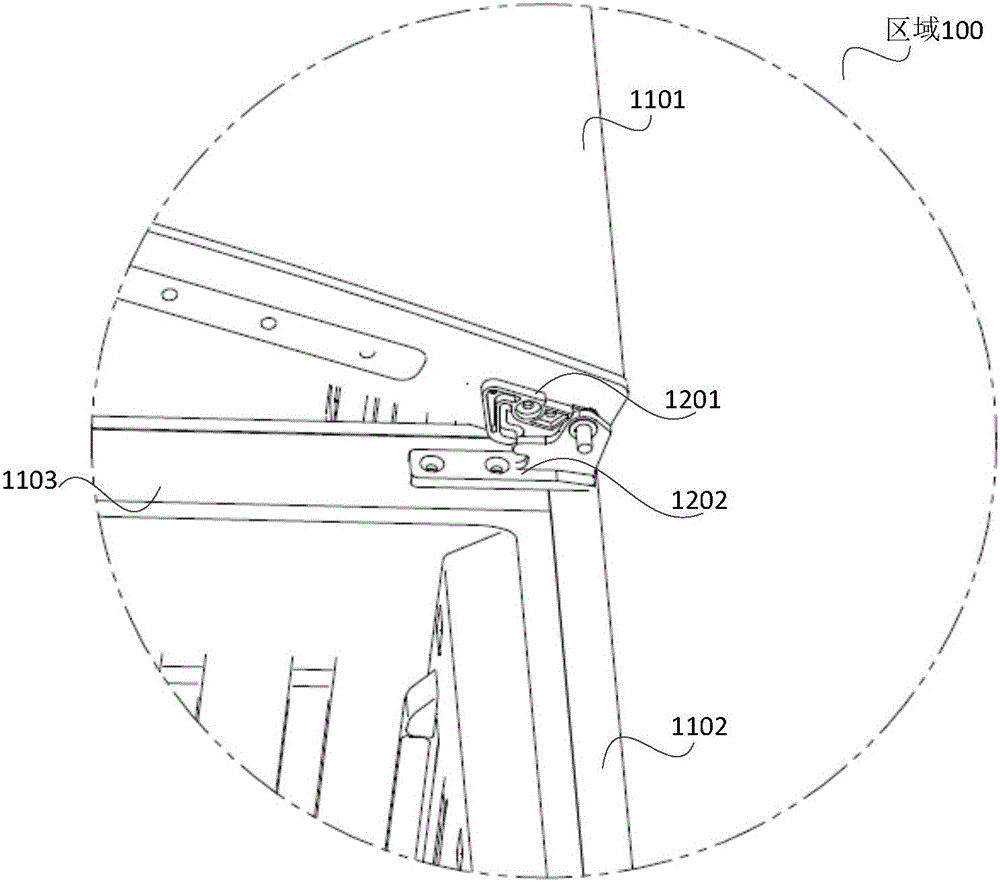

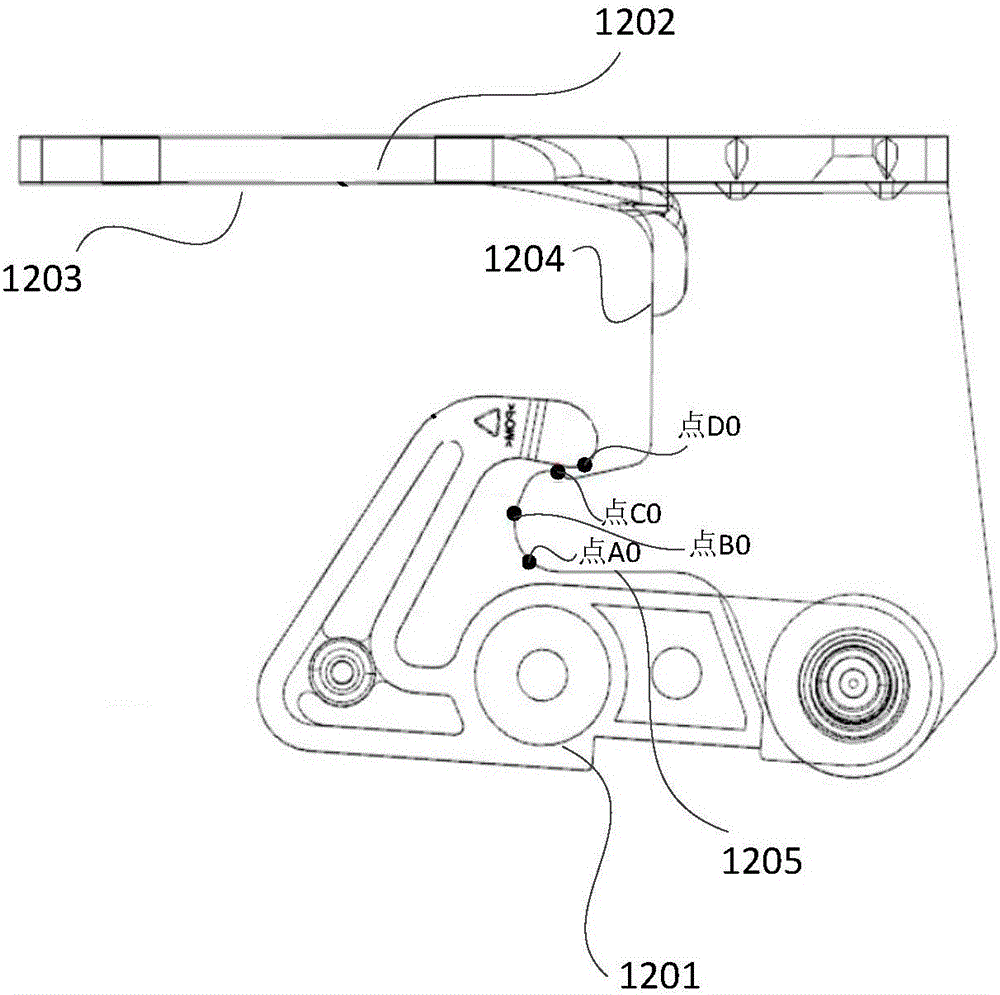

Door body suction assisting device and refrigerator

InactiveCN106123458AIncrease suction powerEnhance suction effectLighting and heating apparatusHingesEngineeringRefrigerated temperature

Owner:HISENSE RONGSHENG YANGZHOU REFRIGERATOR CO LTD

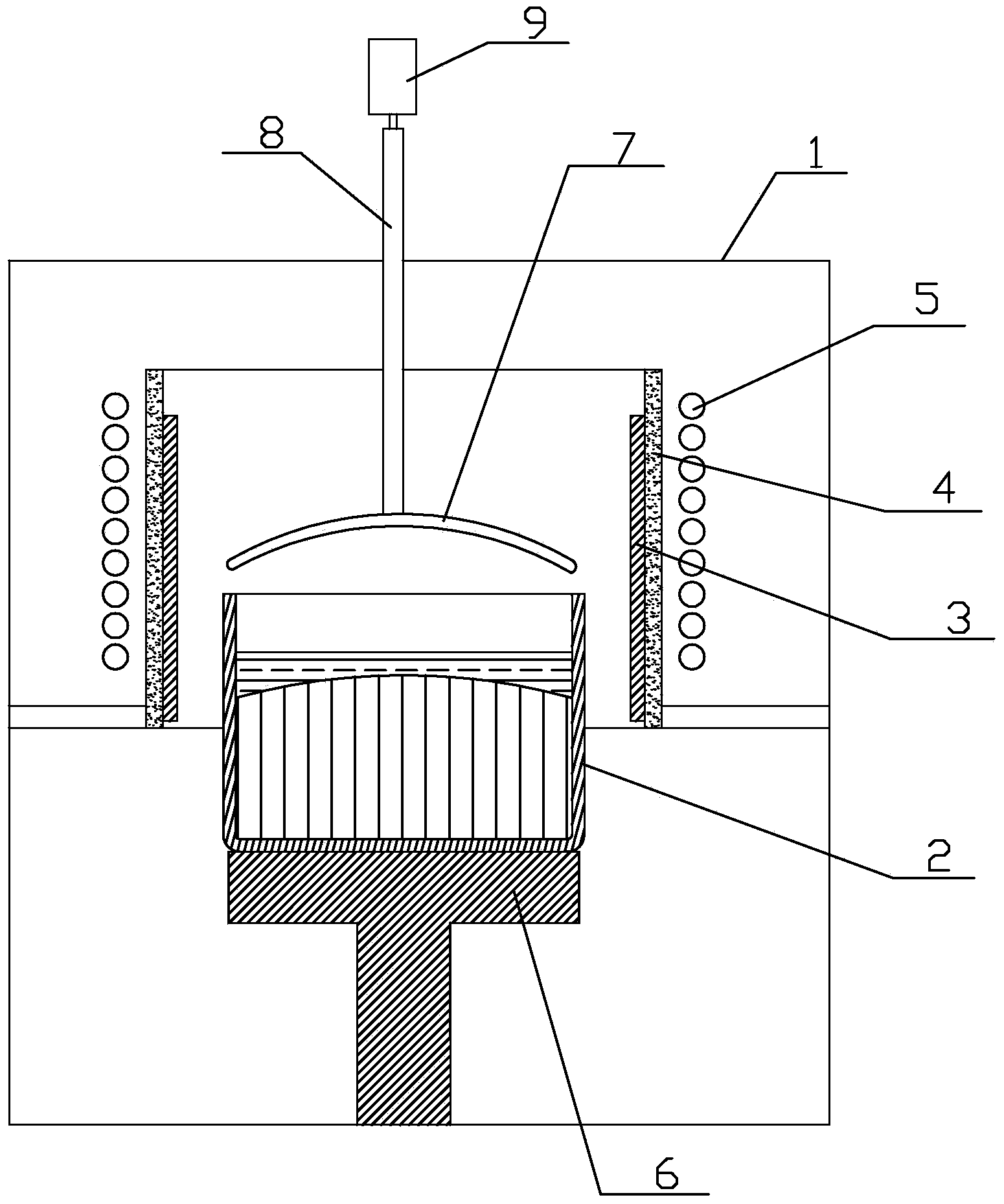

Polycrystalline silicon directional solidifying method and device capable of improving impurity removal effect

The invention belongs to the field of polycrystalline silicon purification, and particularly relates to a polycrystalline silicon directional solidifying method and device capable of improving the impurity removal effect. A curved graphite heater is additionally arranged in an existing device, when silicon liquid is directionally solidified by 75% to 85%, the silicon liquid on the upper portion is influenced by the curved graphite heater above a quartz crucible in a heat radiating mode, and therefore the curved degree of a solid liquid interface inside the quartz crucible is enlarged. The polycrystalline silicon directional solidifying method and device have the advantages that distribution of metal impurities has the directionality in a directionally solidified silicon ingot and can be conveniently cut off, and the cutting rate of waste on the tail portion is reduced; the device is easily transformed, on the basis of the existing device, only the curved graphite heater is additionally arranged above the quartz crucible, and the cost is well controlled; waste of raw materials is reduced, and the cost of polycrystalline silicon raw materials is greatly reduced.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

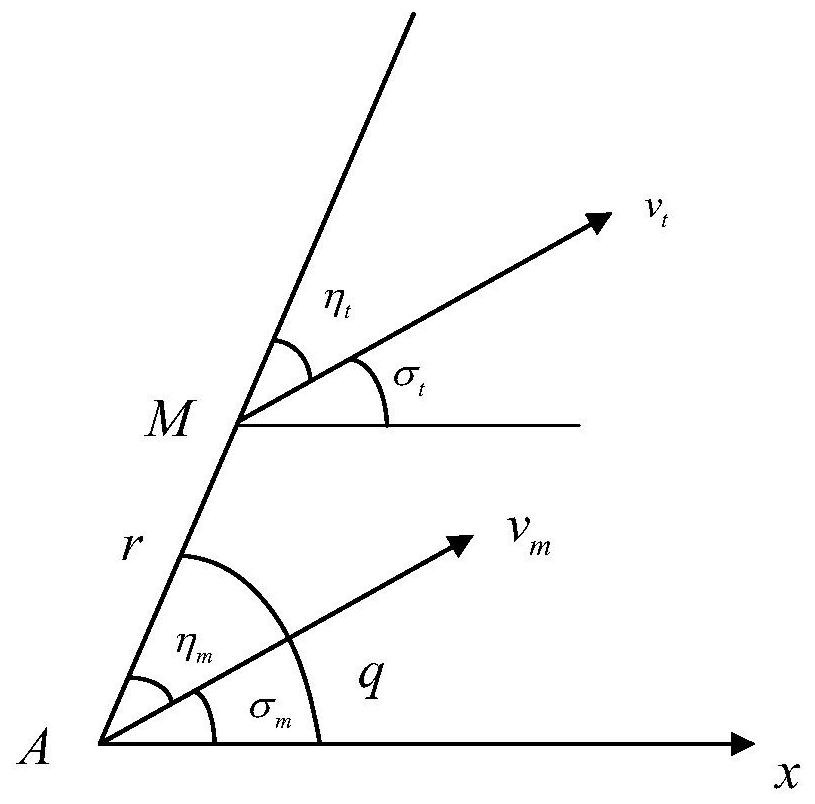

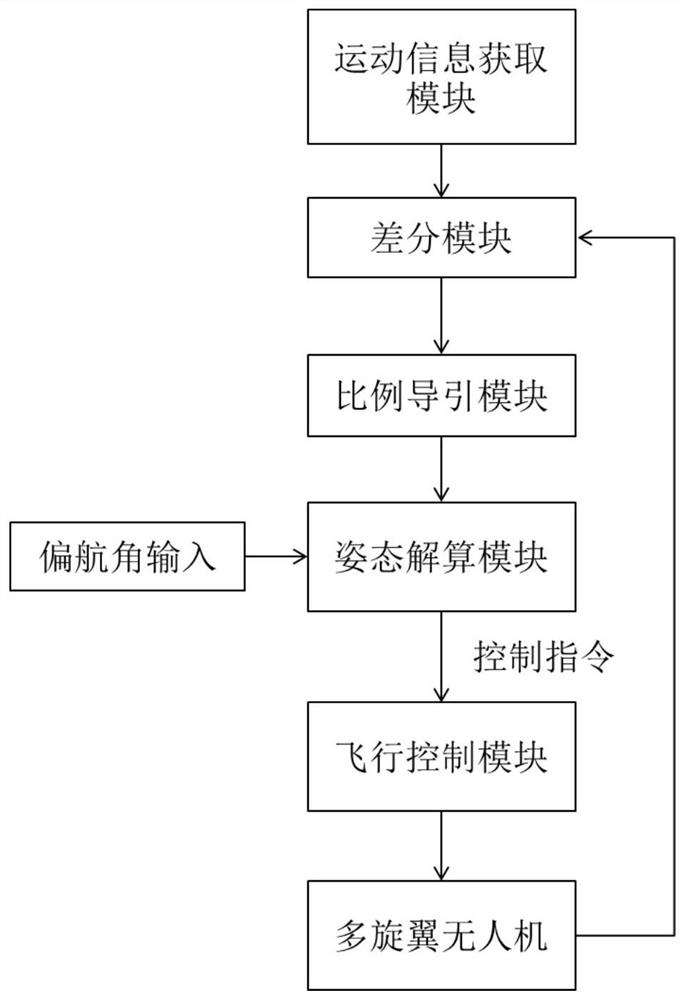

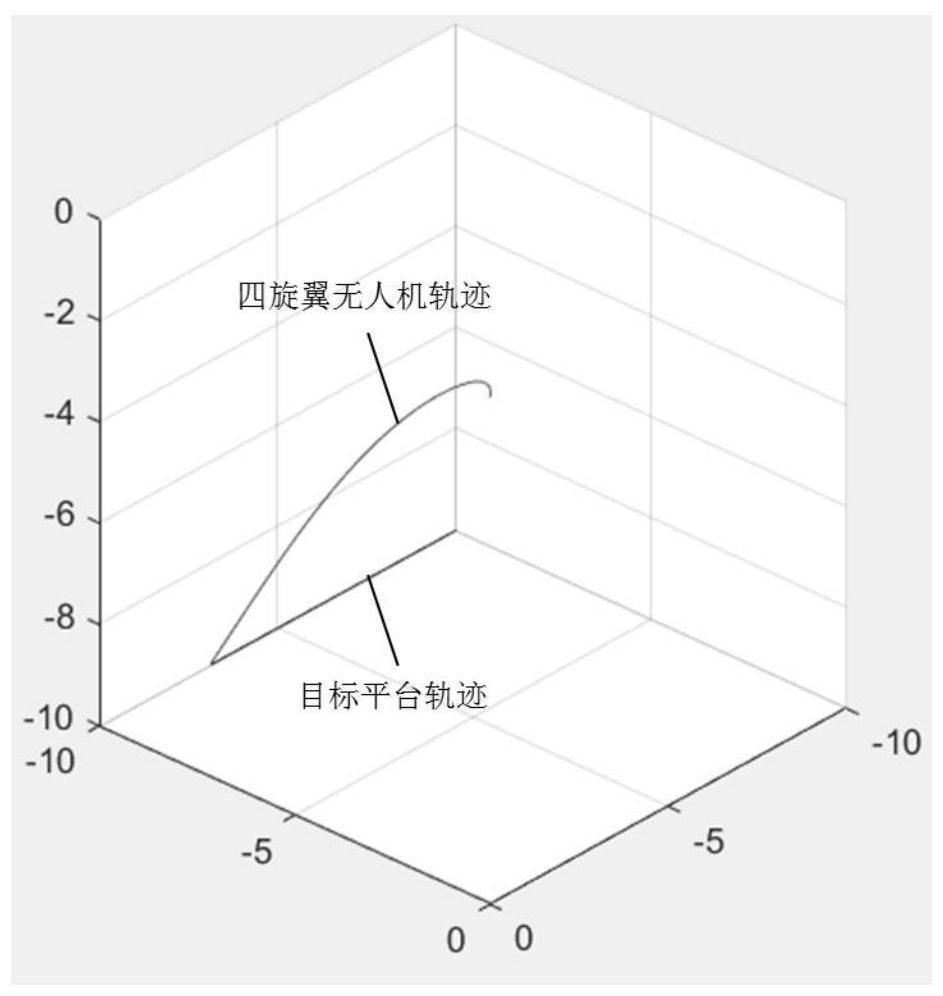

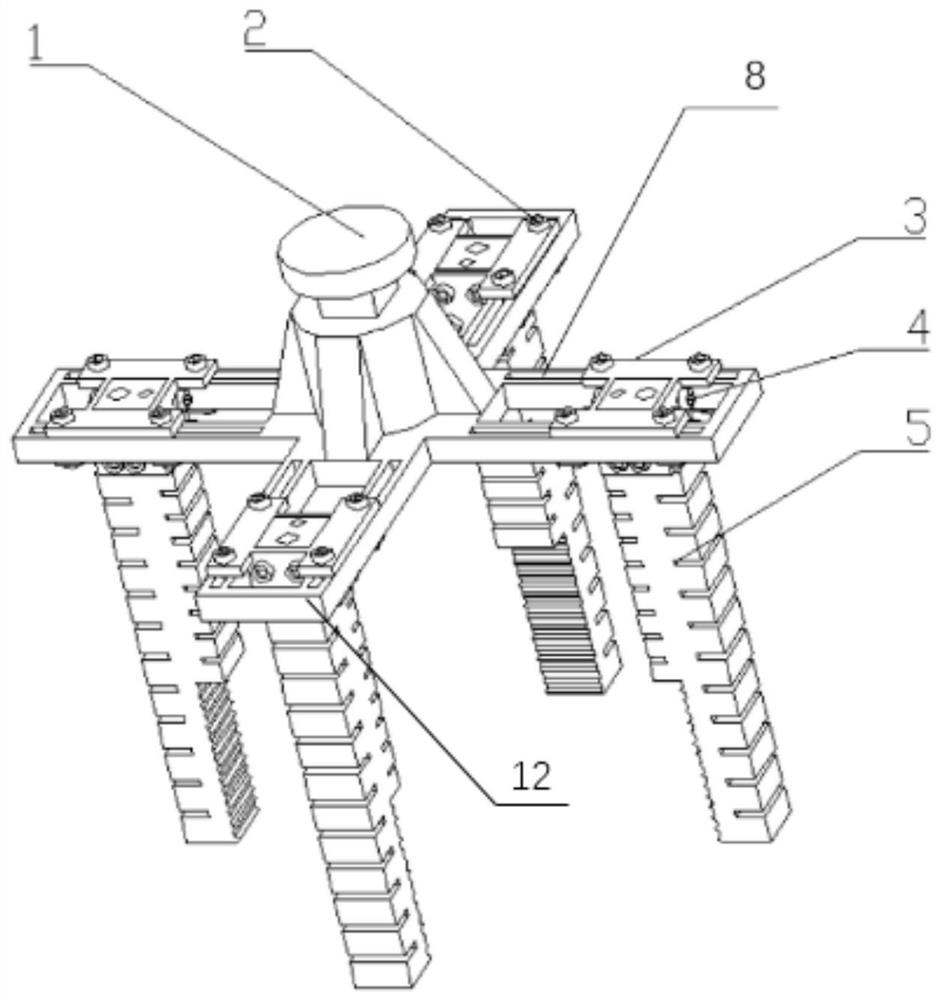

Unmanned aerial vehicle control method capable of meeting autonomous landing requirements of maneuvering platform

ActiveCN112198885ASimple calculationSmooth landing trajectoryTarget-seeking controlAttitude controlAerospace engineeringControl system

The invention discloses an unmanned aerial vehicle control system and control method for meeting the autonomous landing requirement of a maneuvering platform; and the system comprises a motion information obtaining module which is used for obtaining motion information of a target platform and an unmanned aerial vehicle, a difference module used for calculating relative motion information of the target platform and the unmanned aerial vehicle, a proportional guidance module used for obtaining the three-axis overload amount of the unmanned aerial vehicle according to the relative position information, an attitude calculation module used for obtaining the expected attitude quantity of the unmanned aerial vehicle according to the three-axis overload quantity, and a flight control module used for controlling the flight attitude of the unmanned aerial vehicle according to the expected attitude quantity so as to realize autonomous landing of the unmanned aerial vehicle on the maneuvering platform. According to the control system and method provided by the invention, a proportional guidance algorithm is adopted, so that three-axis overload change and speed change in the autonomous landingprocess of the unmanned aerial vehicle are stable, the landing trajectory is smooth, a target platform can be tracked quickly and accurately, and accurate autonomous landing is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

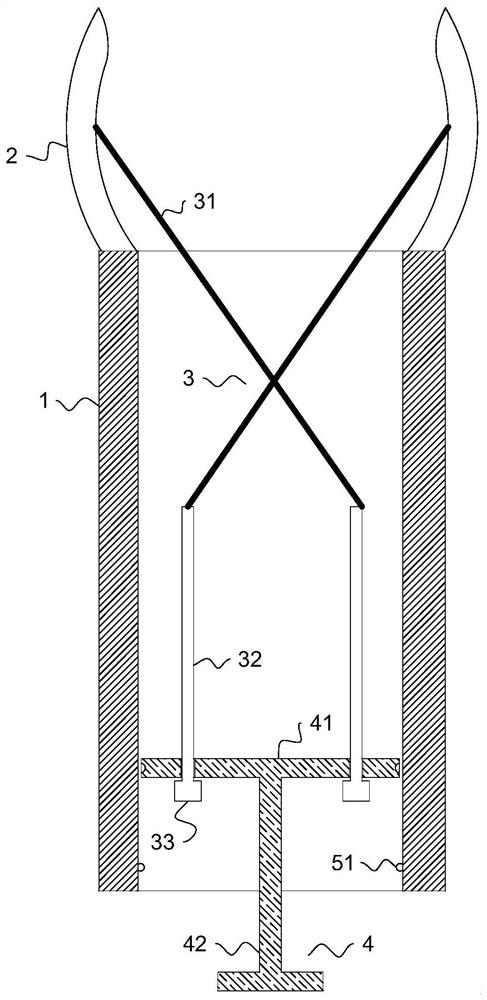

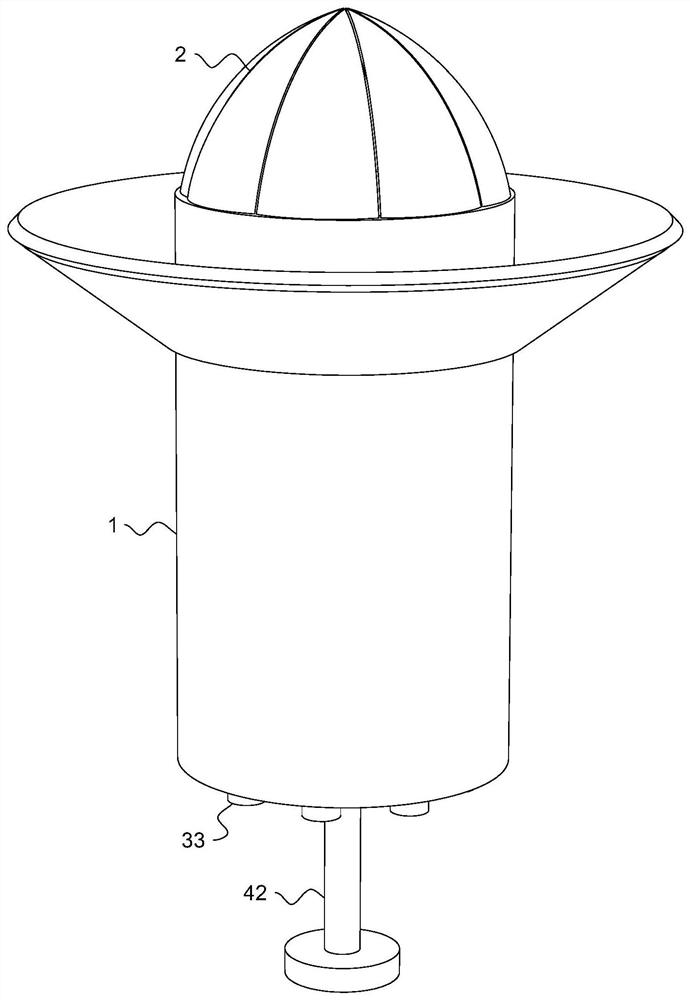

Pneumatic soft clamping hand with variable grabbing range and using method of pneumatic soft clamping hand

The invention belongs to the field of soft mechanical arms, and provides a pneumatic soft clamping hand with a variable grabbing range and a using method of the pneumatic soft clamping hand. The pneumatic soft clamping hand comprises a finger supporting frame and soft fingers, wherein the positions of the soft fingers at the supporting frame extending end are adjusted by forming guide grooves in the supporting frame extending end of the finger supporting frame, and further the opening degree of the soft fingers is adjusted, so that the grabbing force is increased to adapt to different grabbing objects; large cavities and small cavities are provided with air inlets and are independently controlled by an air source, so that the bending degree of the soft fingers is increased, the clamping hand has higher stability in the object grabbing process, and grabbing is firmer; each soft finger is provided with a corrugated large cavity and the corrugated small cavity, and different air pressures are input into large air bags and small air bags of the cavities, so that objects are grabbed and released by the soft fingers; and the soft fingers are made of flexible materials, so that the degree of damage to an object can be reduced when the object is grabbed.

Owner:SHAANXI UNIV OF SCI & TECH

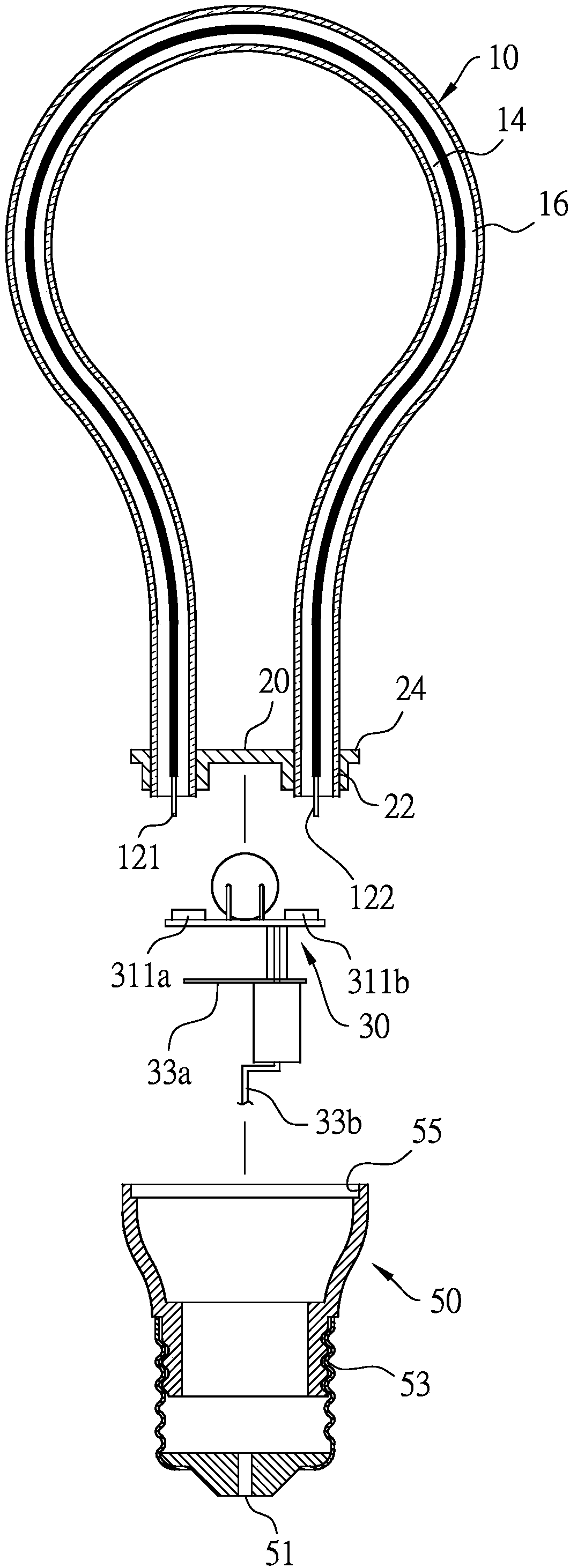

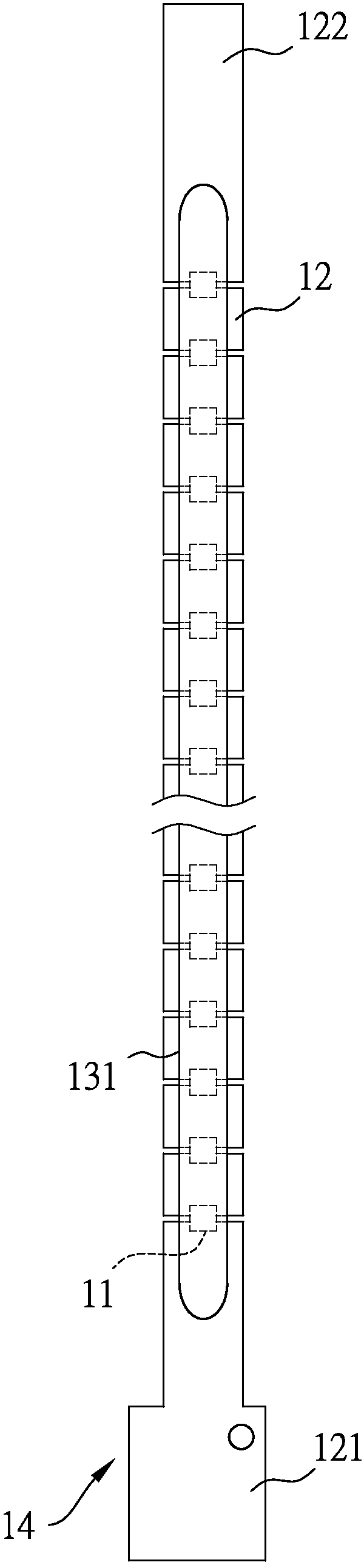

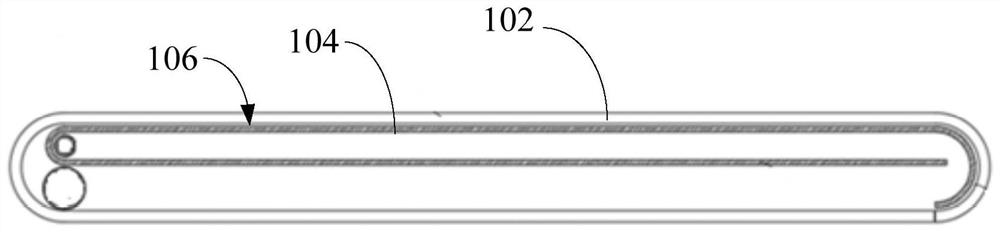

LED lamps and lanterns

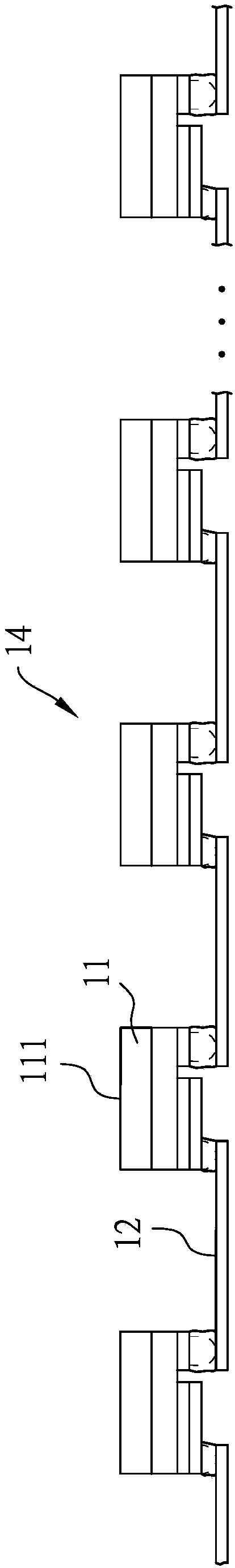

ActiveCN108662446AFlexibleHighly curvedElongate light sourcesElectric circuit arrangementsDouble phaseEngineering

The invention relates to a light emitting diode (LED) lamps and lanterns, the LED lamps and lanterns include a LED device and a lamp holder, and the LED device contains a plurality of LED crystallinegrains, a plurality of electrically-conductive backing plates, an encapsulated layer, a protective sheath, and the a plurality of electrically-conductive backing plates are the interval and set up, and each LED crystalline grain bears and form electric connection by two double-phase adjacent electrically-conductive backing plate jointly, the plurality of LED crystalline grains of the encapsulatedlayer cladding and cover are on the subregion of each electrically-conductive backing plate, and the plurality of LED crystalline grains of the protective sheath cladding and the plurality of electrically-conductive backing plates form a flexible LED device. Because the LED crystalline grains are close to the protective sheath, heat energy produced by the LED crystalline grains can be emitted rapidly to air, so as to improve heat dissipation. Arrangement of each LED crystalline grain makes the LED device reach light succession and uniform light effects..

Owner:LIQUIDLEDS LIGHTING

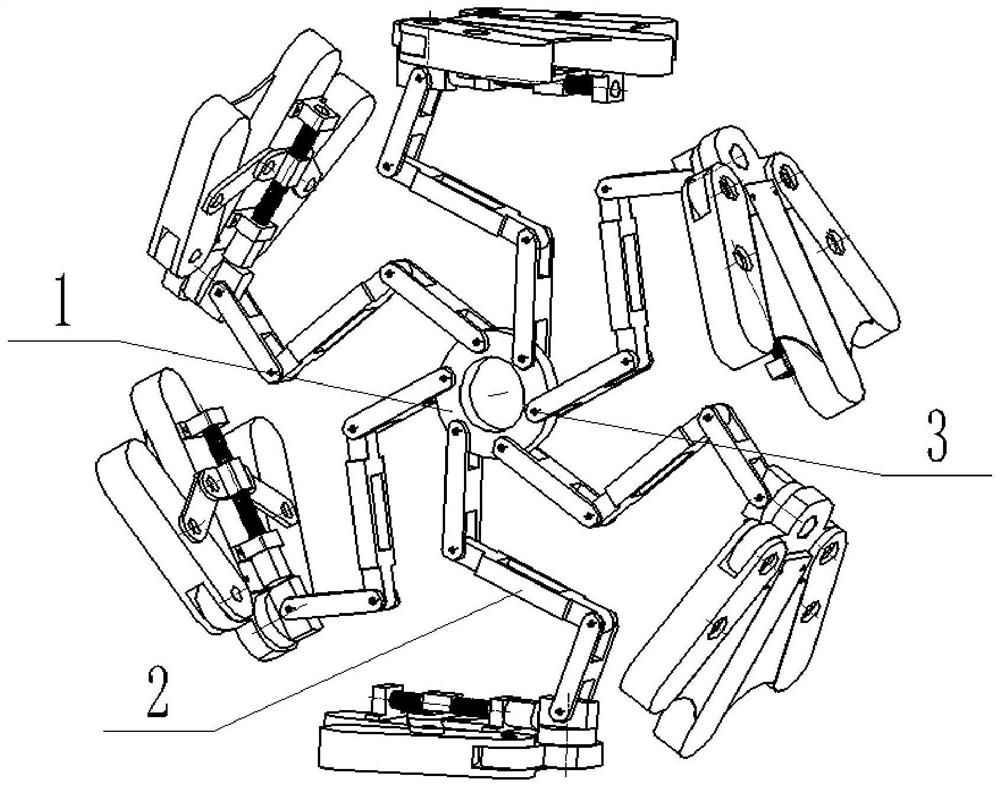

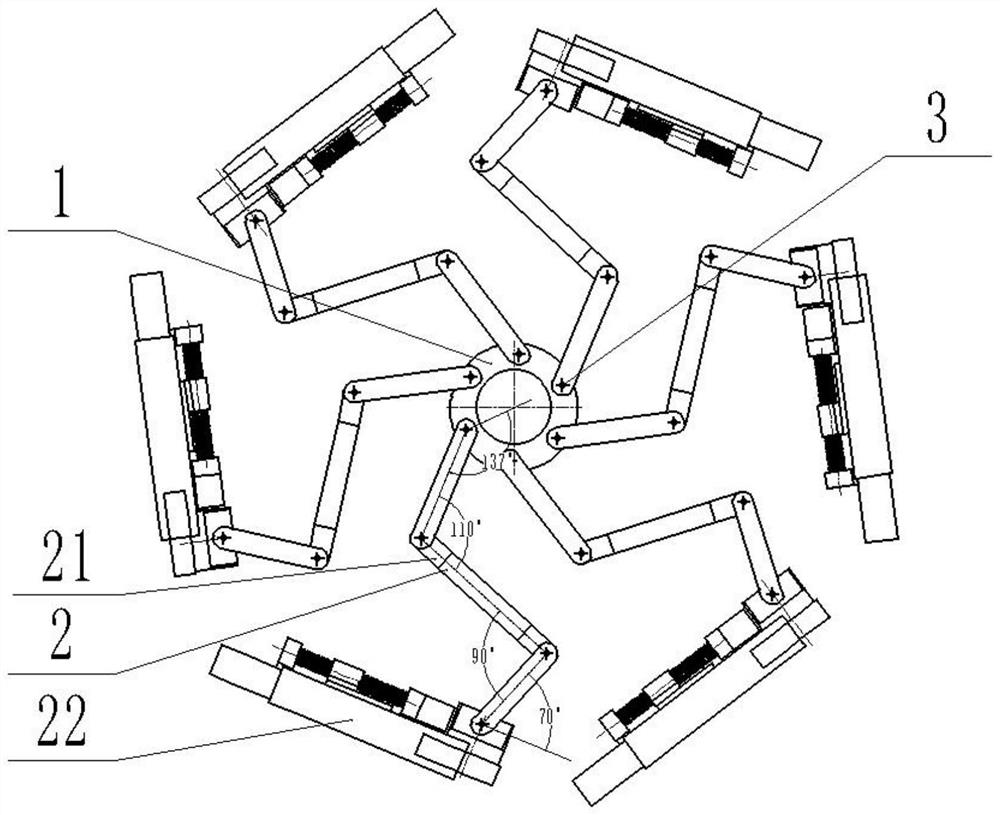

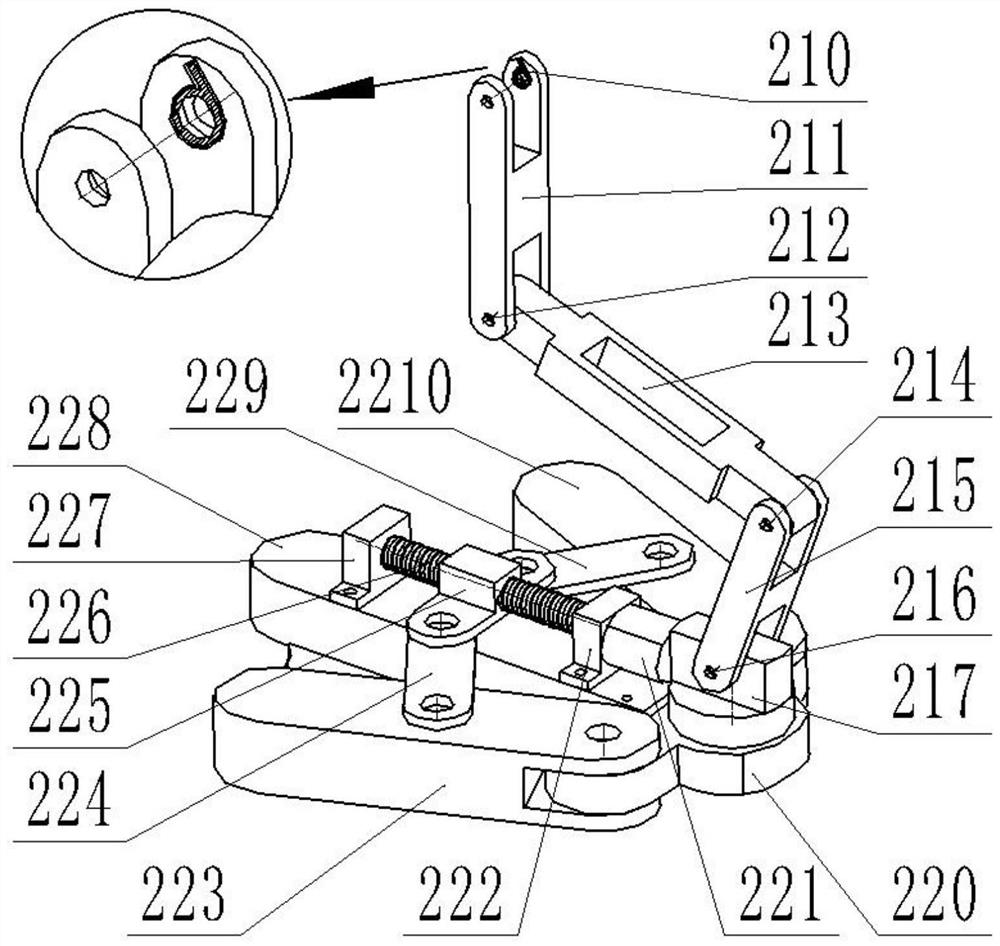

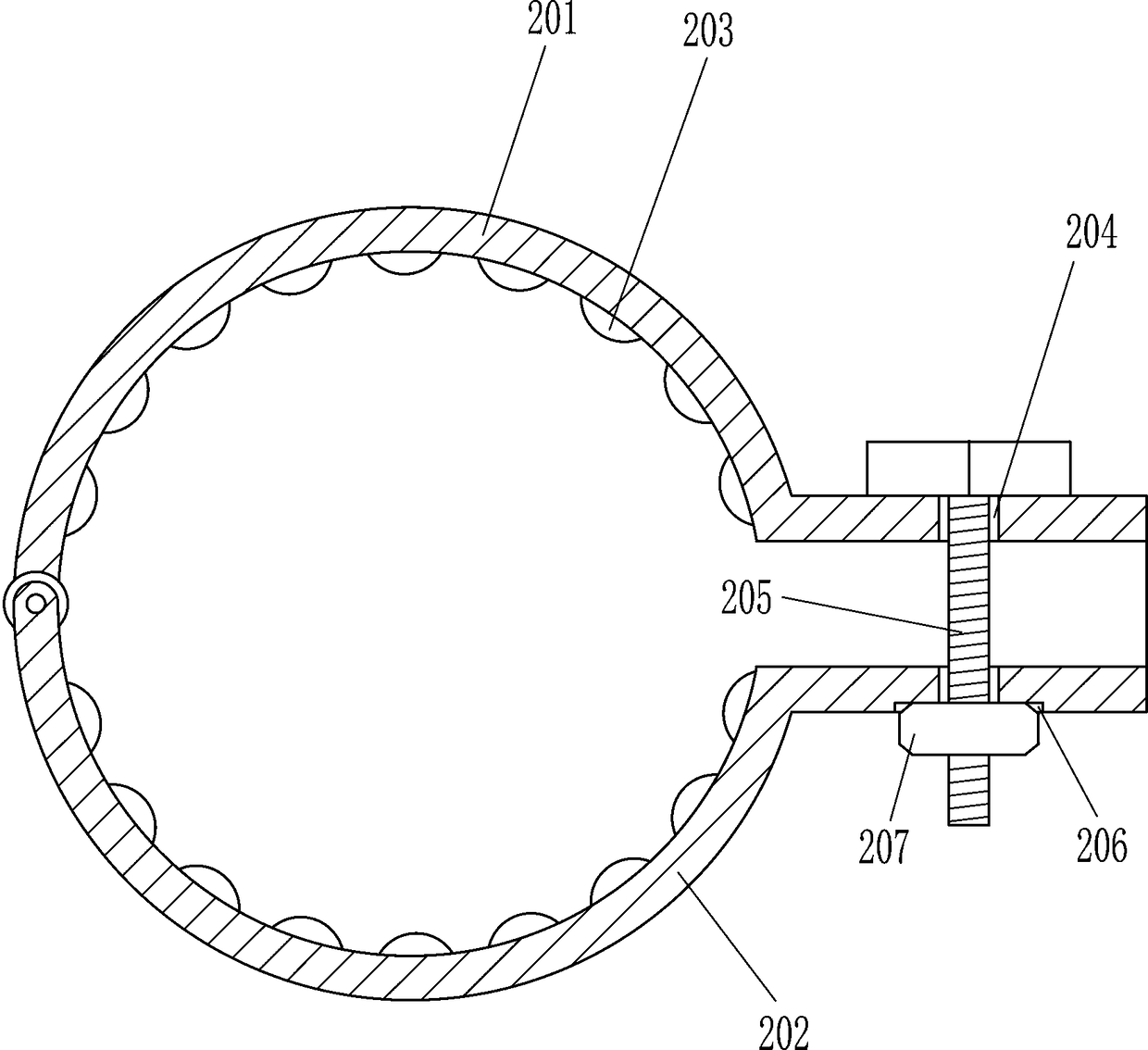

Rigid-flexible coupling bionic anti-sinking energy-saving buffer walking wheel

The invention provides a rigid-flexible coupling bionic anti-sinking energy-saving buffer walking wheel which comprises a spoke plate, walking wheel leg and foot single bodies and hip joint imitatingparts, and the spoke plate is connected with each walking wheel leg and foot single body through the hip joint imitating parts; a plurality of walking wheel leg and foot single bodies are distributedon the spoke plate in a circular array mode, and each walking wheel leg and foot single body is composed of a walking wheel leg and a walking wheel foot. Wild duck hind limbs are selected as bionic prototypes, and the biological assembly characteristics of rigid-flexible coupling of legs and feet of wild ducks and the constantly changing movement postures of the legs and the feet during movement are simulated. The legs of the walking wheels are bent and restored, so that the effects of energy conservation and buffering are achieved; the toe webs at the feet of the walking wheel are actively opened and closed, so that the ground contact area is changed, and the anti-sinking and anti-sideslip effects are achieved. The rigid-flexible coupling walking wheel leg-foot single bodies actively change the moving posture and the ground contact area, so that the trafficability and traction performance of the walking wheel on soft grounds such as mudflat, muddy and marsh are improved.

Owner:JIANGSU UNIV

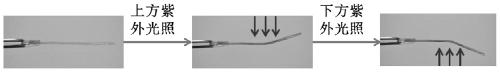

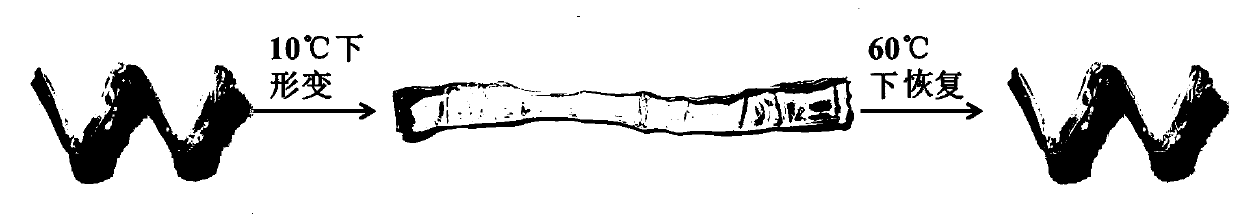

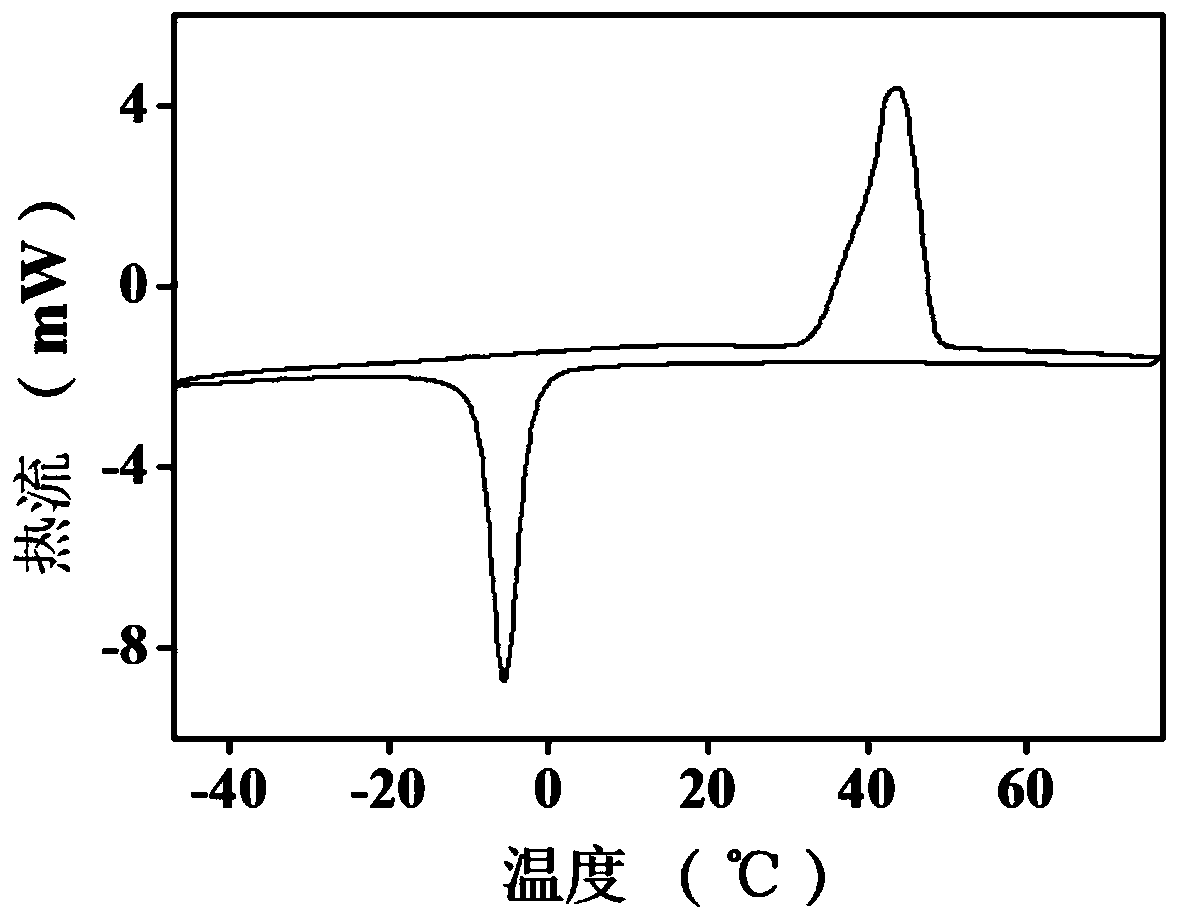

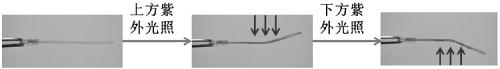

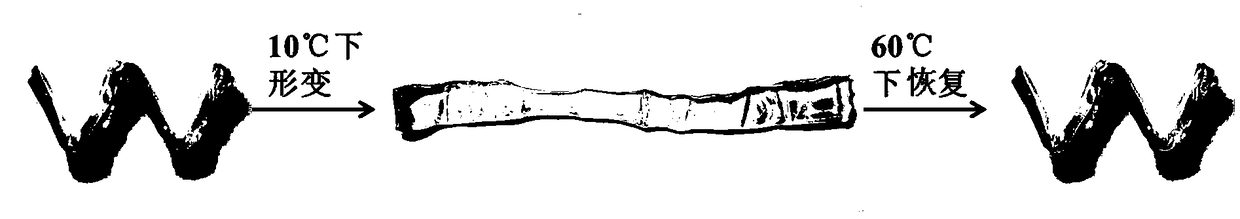

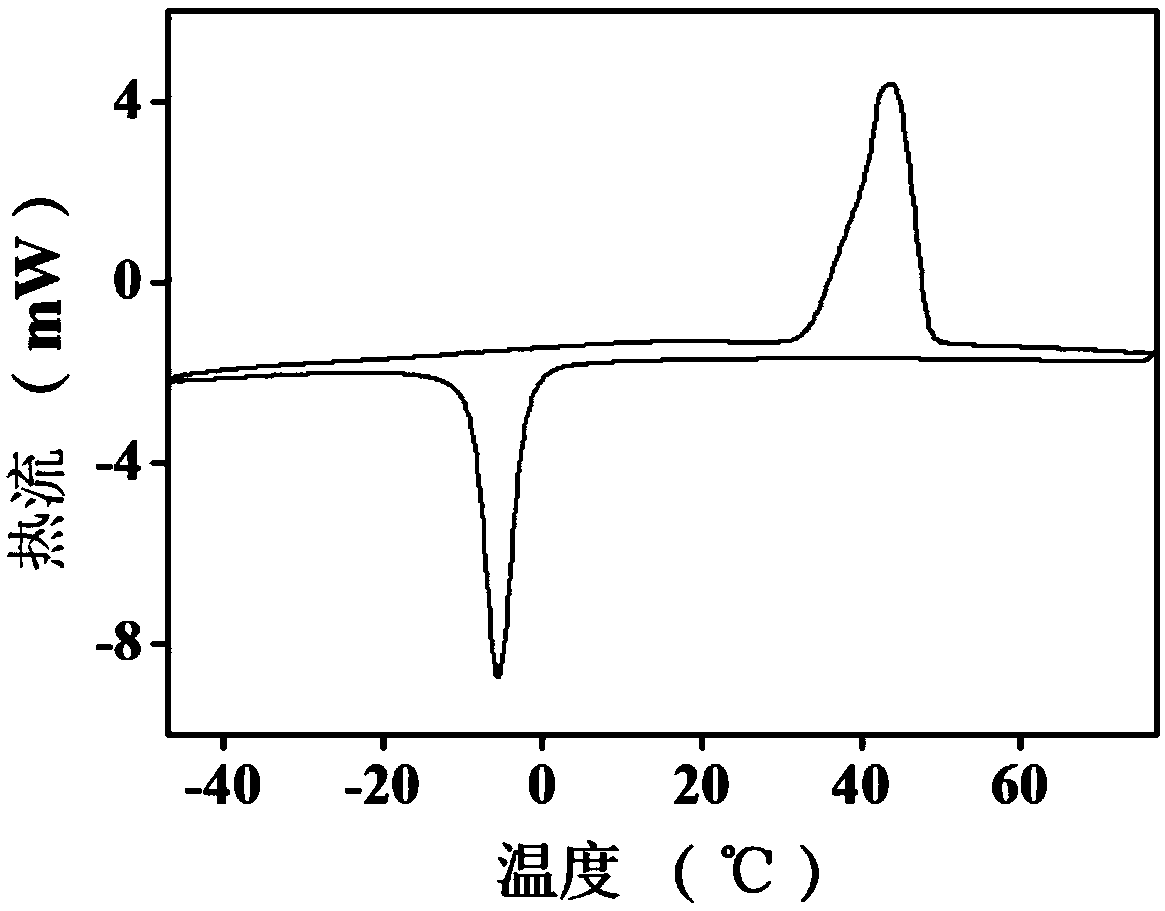

A kind of phototropic shape memory polymer material, its preparation method and application

The invention belongs to the technical field of flexible intelligent driving materials and particularly relates to a phototropic shape memory polymer material integrating photo-response and temperature response and preparation and application methods thereof. The phototropic shape memory polymer material is a polyurethane elastomer material in a double-crosslinked net structure and is prepared bytaking polycaprolactone diol as a chain extender, tetrahydroxy functionalized hexaaryl biimidazole molecular switches as dynamic crosslinking points and polyols as fixed crosslinking points to performcrosslinking reaction with isocyanate. The phototropic shape memory polymer material can present rapid deformation response under ultraviolet radiation and temperature driving to achieve good phototropic properties and is reversible in deformation under temperature driving, thereby solving the technical problem that intelligent photo-driven materials can achieve driving effects only when the thickness is reduced to a micron scale or are slow in driving response, irreversible or the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Pipe Bending Forming Method of Flexible Hammer Ball Mandrel

InactiveCN103752666BThere is no problem of mutual interferenceUniform deformationEngineeringFastener

The invention relates to a pipe bending method, in particular to a bending method of pipes with a flexible chained-ball mandrel and solves the problem that high bending degree in the existing process of bending pipes having a mandrel causes mutual interference. The method includes: 1, threading a plurality of balls with a rope having a restraint ring at one end; 2, inserting a combined flexible chained-ball mandrel into a pipe to be bent; 3, placing a first rubber plug into one end of the pipe to be bent, fastening the first rubber plug through a first fastener, placing a second rubber plug into the other end of the pipe to be bent, and fastening the second rubber plug through a second fastener; 4, placing the pipe to be bent, onto a female die, and driving a male die to move down by a press until the pipe to be bent is bent; 5, after bending, loosening the first fastener, the second fastener, the first rubber plug and the second rubber plug to obtain a bent pipe. The bending method of pipes with one flexible chained-ball mandrel is applicable to pipe bending.

Owner:HARBIN UNIV OF SCI & TECH

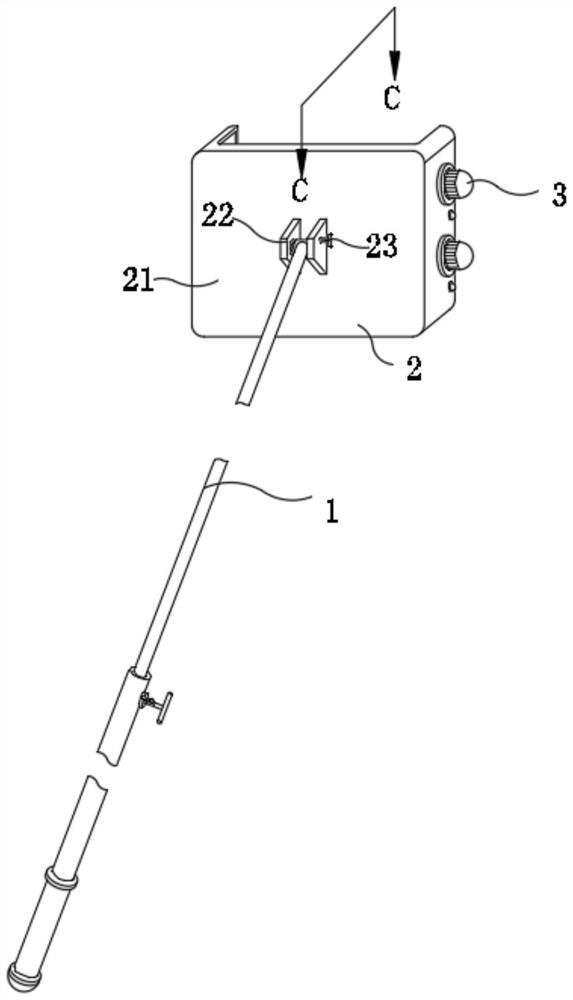

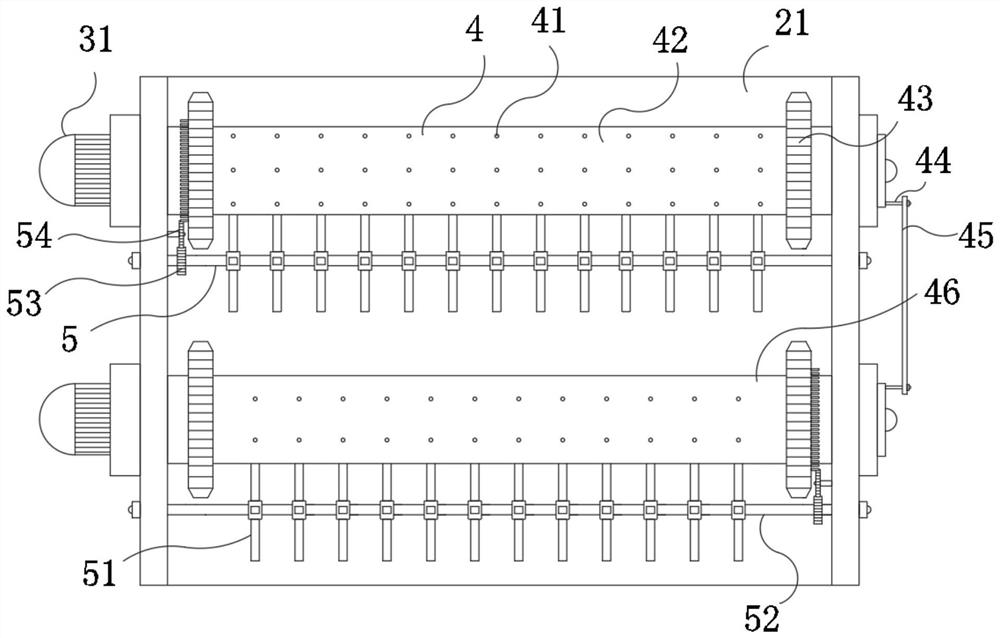

Wall plastering slurry throwing tool

The invention provides a wall plastering slurry throwing tool. The wall plastering slurry throwing tool comprises a supporting rod, a connecting mechanism, a feeding mechanism, a spraying mechanism and an accelerating mechanism, wherein the spraying mechanism comprises through holes, a first roller, ratchet wheels, a limiting rod, a rotating rod and a second roller, the two ends of the first roller and the two ends of the second roller are fixedly connected with the ratchet wheels, and the through holes are formed in the side wall of the first roller and the side wall of the second roller at equal intervals; the limiting rod is installed at one end of the first roller and one end of the second roller, and the limiting rod is rotationally connected with the rotating rod; the accelerating mechanism comprises scrapers, a fixing shaft, a first gear and a second gear, the multiple scrapers with the arc-shaped side walls are symmetrically installed on the side wall of the fixing shaft, and the elastic scrapers are slidably connected with the first roller, the second roller and the through holes. The tool further comprises a driving mechanism. The wall plastering slurry throwing tool hasthe advantages that slurry throwing is uniform, the labor amount of people is reduced, and cement slurry waste is avoided.

Owner:ZHEJIANG WANHUA CONSTR

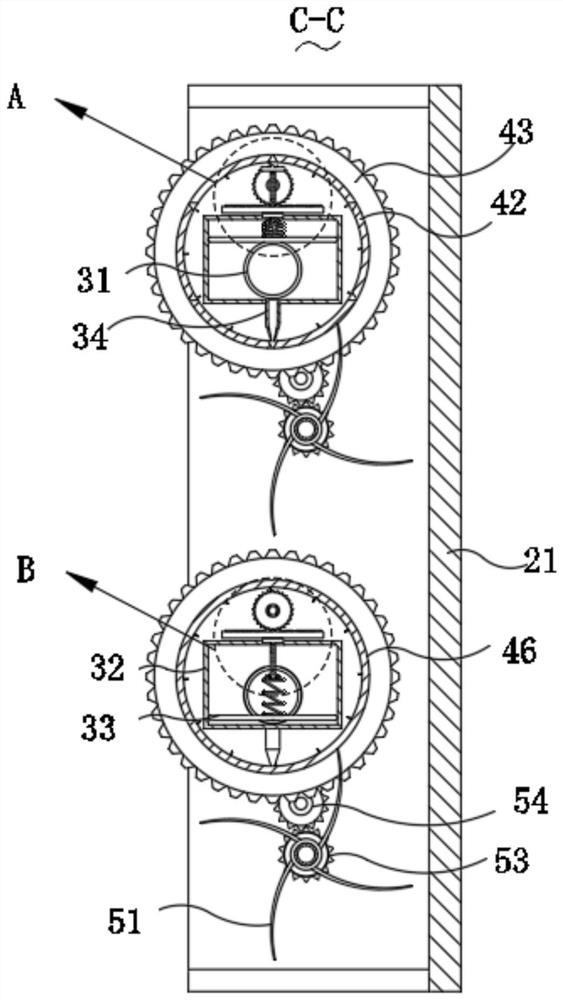

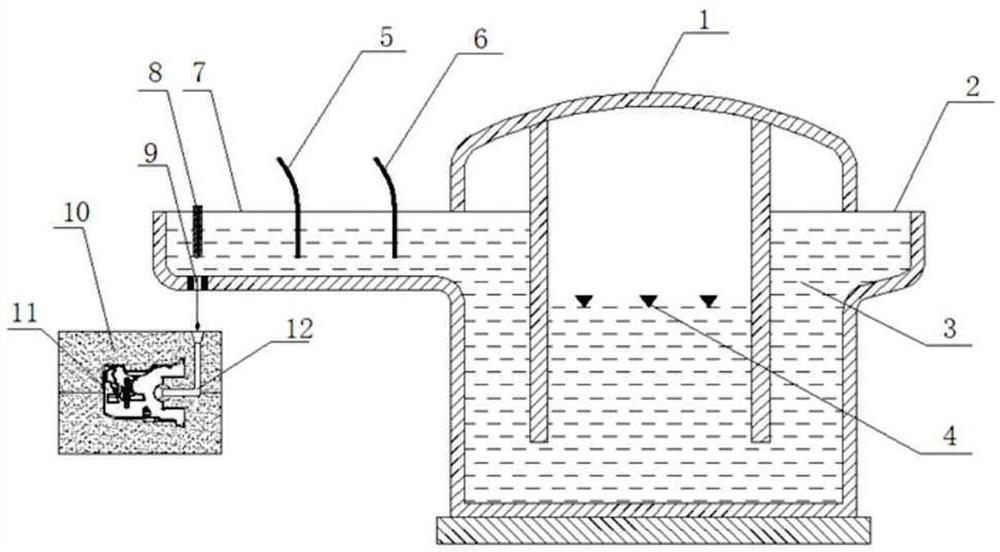

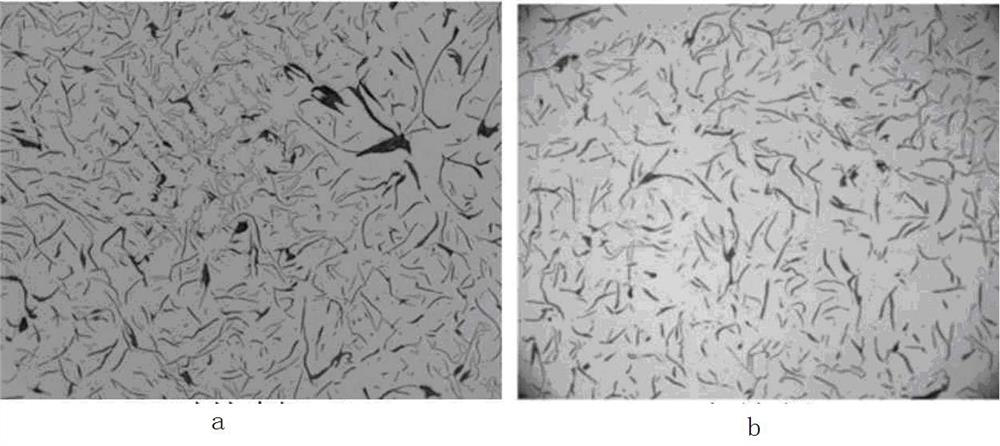

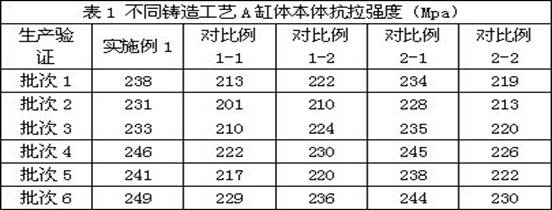

Low-cost casting process for improving performance of engine cylinder body and cylinder cover casting

ActiveCN114517270AHighly curvedShorten the lengthProcess efficiency improvementTemperature controlCylinder block

The invention relates to the fields of pig iron processing, metal casting, iron or steel smelting and the like, in particular to a casting process for improving the performance of an engine cylinder body and cylinder cover casting. Comprising the following steps that when molten iron is conveyed to an iron tapping groove of the heat preservation pouring furnace from the interior of the heat preservation pouring furnace in a pressed mode, double-line wire feeding inoculation is started in the iron tapping groove, and the molten iron subjected to wire feeding inoculation is poured; in the pouring process, the temperature is controlled to be 1400-1420 DEG C, the pouring speed is 18-23 kg / s, and the adding amount of a wire feeding inoculation wire is 0.14-0.16% of the mass of poured molten iron; and after pouring is finished, a cylinder body and cylinder cover casting with improved performance can be obtained. The molten iron comprises the following components in percentage by mass: 3-3.5% of C, 1.7-2.3% of Si, 0.4-1.0% of Mn, less than or equal to 0.08% of P, 0.05-0.12% of S, 0.3-1.0% of Cu, 0.15-0.45% of Cr, less than or equal to 0.4% of Mo, less than or equal to 0.15% of Sn and the balance of trace elements and Fe; according to the double-wire feeding inoculation, a first wire feeding inoculation wire is arranged at the position 245-255 mm away from a water outlet of the tapping groove; and a second wire feeding inoculation line is arranged at a position 445-455mm away from the water outlet of the tapping groove.

Owner:ASIMCO INT CASTING CO LTD SHANXI

Display screen assembly and electronic equipment

PendingCN113079237AEasy to bendHighly curvedTelephone set constructionsStructural engineeringFlexible display

The invention discloses a display screen assembly and electronic equipment. The display screen assembly comprises a flexible cover plate and a flexible display panel, at least part of the flexible cover plate covers the flexible display panel; and the flexible display panel comprises a supporting layer and a functional layer, the functional layer is located between the supporting layer and the flexible cover plate, a plurality of first stress grooves distributed side by side are formed in the side, away from the functional layer, of the supporting layer, and the flexible display panel can be bent and deformed at least at any first stress groove. According to the flexible display panel, the first stress grooves distributed side by side are formed in the flexible display panel, stress generated when the display screen assembly is bent and folded can be eliminated or reduced, small-radius folding and curling can be achieved, and meanwhile the foldable and bending deformation capacity of the display screen assembly is achieved.

Owner:VIVO MOBILE COMM CO LTD

Phototropic shape memory polymer material and preparation and application methods thereof

The invention belongs to the technical field of flexible intelligent driving materials and particularly relates to a phototropic shape memory polymer material integrating photo-response and temperature response and preparation and application methods thereof. The phototropic shape memory polymer material is a polyurethane elastomer material in a double-crosslinked net structure and is prepared bytaking polycaprolactone diol as a chain extender, tetrahydroxy functionalized hexaaryl biimidazole molecular switches as dynamic crosslinking points and polyols as fixed crosslinking points to performcrosslinking reaction with isocyanate. The phototropic shape memory polymer material can present rapid deformation response under ultraviolet radiation and temperature driving to achieve good phototropic properties and is reversible in deformation under temperature driving, thereby solving the technical problem that intelligent photo-driven materials can achieve driving effects only when the thickness is reduced to a micron scale or are slow in driving response, irreversible or the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Animal excrement collecting device for veterinarians

The invention discloses an animal excrement collection device for veterinarians, and belongs to the technical field of excrement collection. The animal excrement collecting device for the veterinariancomprises a collecting cylinder, a collecting part, a folding structure, a compressing structure and a limiting structure. The collecting part is arranged on the upper end surface of the collecting cylinder; the collecting part can be closed and opened relative to the collecting cylinder; the collecting part can be used for collecting solid excrement and liquid excrement in a folded state; the compression structure is slidably connected to the inner wall, close to the lower end, of the collection cylinder, and dynamic seal is formed between the compression structure and the inner wall of thecollection cylinder. When the collecting part is folded, a sealed storage space is formed among the lower part of the collecting part, the upper part of the compression structure and the inside of thecollecting cylinder; after the collecting part is folded, relatively dry and liquid excrement is stored in the sealed storage space; through the cooperative use of the collection part, the folding structure and the compression structure, solid excrement and liquid excrement can be collected at the same time, the excrement is not prone to leakage in the transportation process, and the collection cylinder and the collection part are easy to clean.

Owner:宁夏农林科学院动物科学研究所

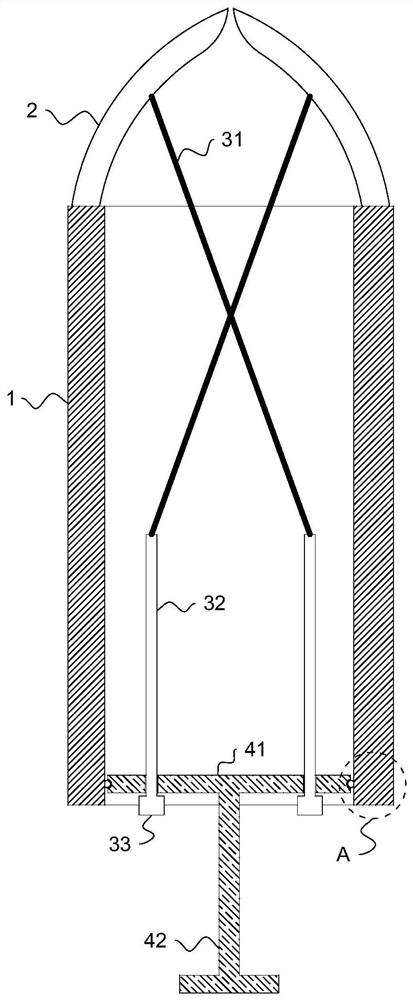

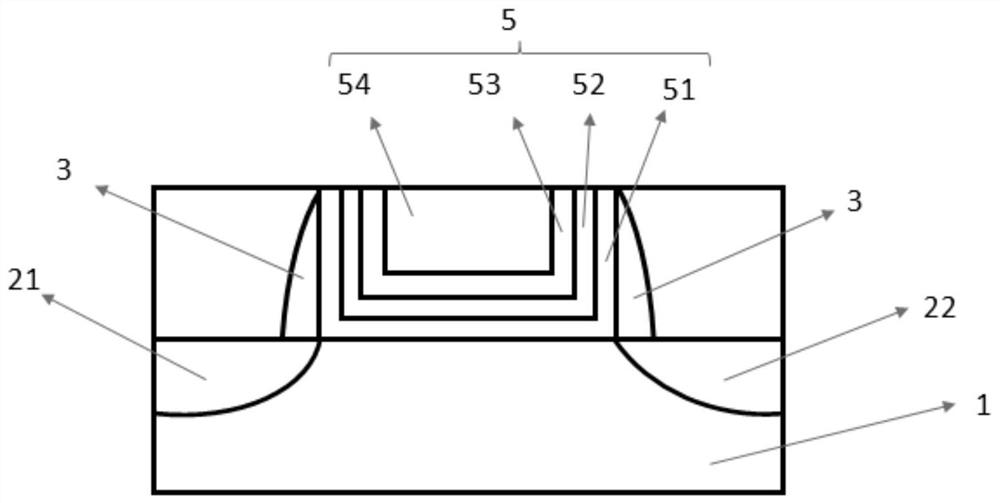

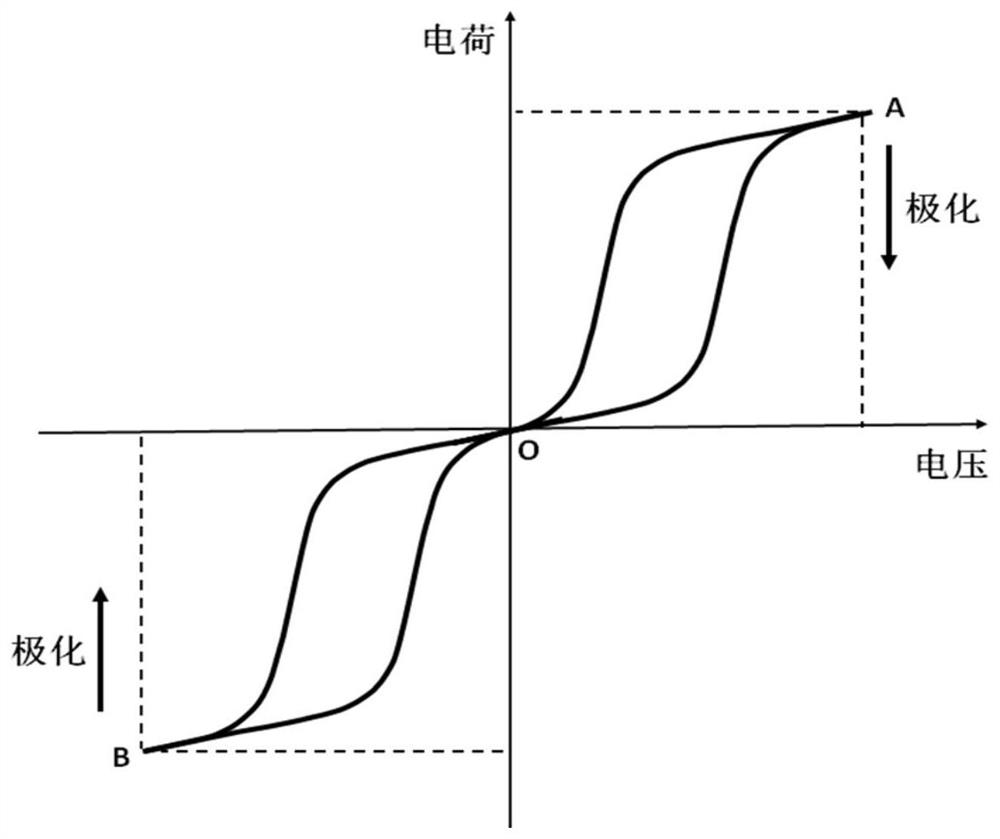

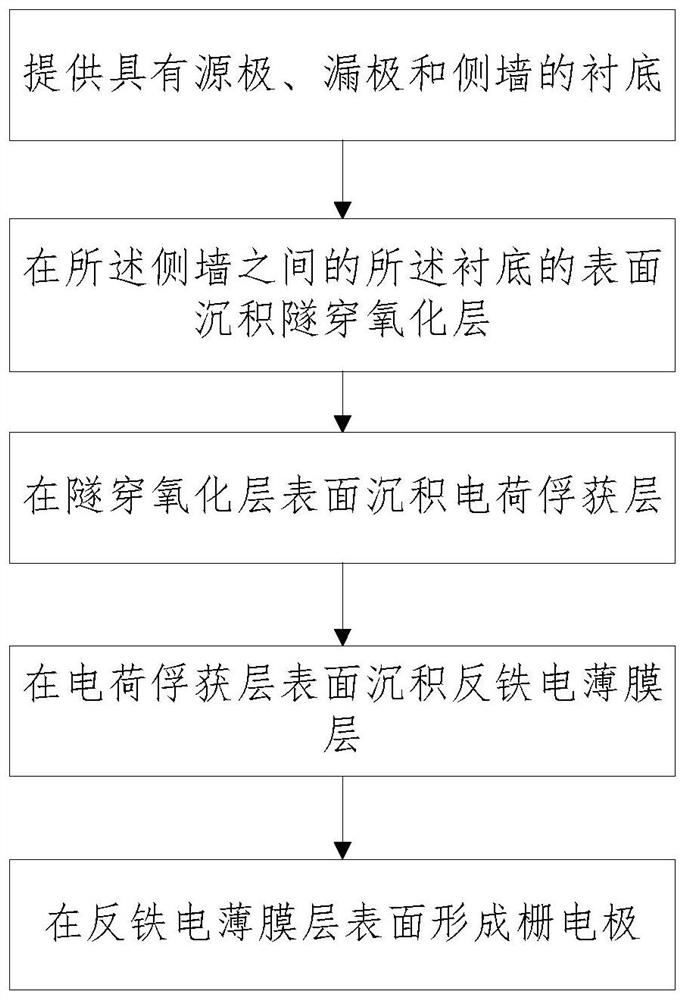

Memory cell and operation method and preparation method thereof

PendingCN111799271AHighly curvedImprove tunneling efficiencySolid-state devicesSemiconductor devicesMemory cellFerroelectric thin films

The invention relates to a memory cell and an operation method and a preparation method thereof, and the memory cell comprises a substrate, a source electrode and a drain electrode which are arrangedin the substrate, a stacked gate and a side wall. The stacked gate is arranged on the substrate between the source electrode and the drain electrode and comprises a tunneling oxide layer, a charge trapping layer, an anti-ferroelectric film layer and a gate electrode which are sequentially arranged along the direction far away from the substrate. The gate electrode is used for providing a control voltage. The antiferroelectric film layer is used for enhancing an electric field on the tunneling oxide layer under the action of the control voltage and increasing the bending degree of an energy band of the tunneling oxide layer. The charge trapping layer is used for trapping charge storage information injected from the substrate. The storage unit is low in working voltage, high in access speedand low in power consumption.

Owner:XIANGTAN UNIV

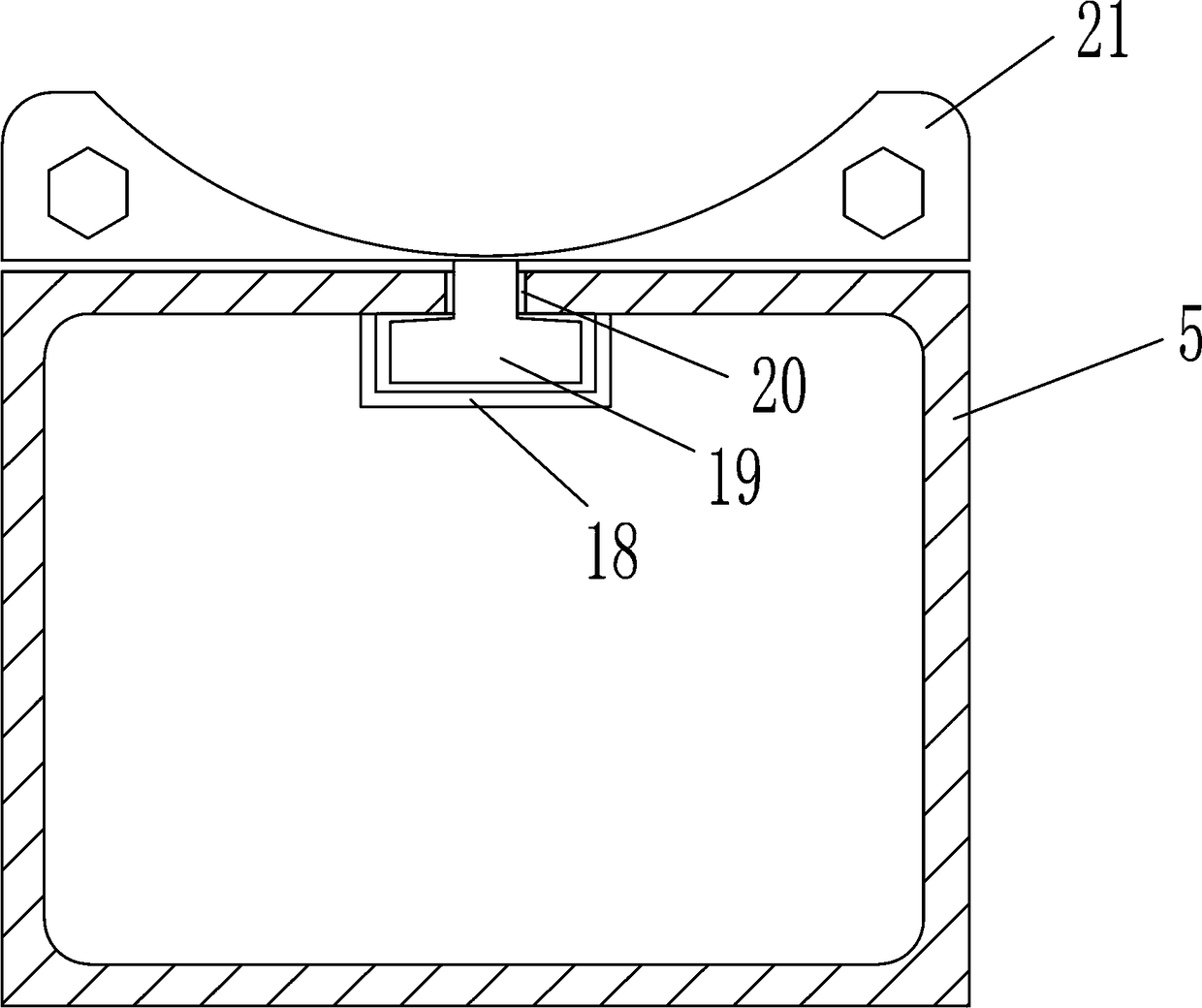

Hot straightening die for first gear and second gear shifting fork

InactiveCN106890895AHigh thermal correction accuracyLess likely to cause personal injuryShaping toolsEngineeringCounterbore

The invention discloses a thermal correction mold for a one-two shift fork, which belongs to the field of mold design technology, and includes an upper mold, a lower mold, an upper mold groove, a lower mold groove, and a fixed boss. The base bodies of the upper mold and the lower mold are uniform. It is a cuboid, the upper mold groove is located on the lower surface of the upper mold, the lower mold groove is located on the upper surface of the lower mold, the upper mold groove and the lower mold groove are arranged symmetrically front and rear, and the fixed boss is arranged on the left-right symmetrical line of the upper surface of the lower mold One at the front and one at the front and back, and fixed counterbores are set at the corresponding positions of the upper mold. When the upper mold and the lower mold are closed, the fixed boss and the counterbore are embedded and installed. High, the first and second gear shift fork heat correction mold disclosed by the present invention has good safety, the upper mold and the lower mold are conveniently fixed, the thermal correction accuracy of the parts is high, the bending degree of the upper mold groove and the lower mold groove is large, and the first and second gears The shift fork is placed between the upper mold and the lower mold at high temperature for thermal correction processing, and the forming efficiency is high.

Owner:CHANGLI FORGING

Restorer for half-paralyzed patient

The invention relates to a restorer, in particular to a restorer for a half-paralyzed patient. According to the technical problem, the restorer for the half-paralyzed patient, which can prevent body fatigue and improve recovery efficiency, is provided. The restorer comprises chair support rods, a fixing device, a bracket, a first rotating rod, a first gear, a first hollow support plate, a second gear, a third gear, a fixing plate, a pressing block and the like. The chair support rods are connected with the bracket through the fixing device. The upper part of the front side of the bracket is rotatably connected with the first rotating rod, the first rotating rod is connected with the first gear, and the first hollow support plate is connected with the first gear. According to the invention,the recovery of patients with different heights can conveniently use the device for recovery by moving a first arc-shaped clamp plate to a suitable position from left to right. By holding a first handle by hand, a fourth gear rotates clockwise, so that the leg part of the half-paralyzed patient can swing up to a right position, and the leg part of the half-paralyzed patient can be bent for recovery.

Owner:SECOND AFFILIATED HOSPITAL OF COLLEGE OF MEDICINEOF XIAN JIAOTONG UNIV

Anti-static teflon wire

InactiveCN113488257AIncrease frictionReduce shakingFlexible cablesFlexible conductorsAdhesive glueEngineering

The invention provides an anti-static teflon electric wire, and relates to the technical field of teflon electric wires. The anti-static teflon electric wire is composed of an outer layer, a teflon layer, a glue layer, an insulating layer, a wire core shielding layer and a wire core body; the teflon layer is fixedly installed on the inner side of the outer layer, the glue layer is fixedly installed on the inner side of the teflon layer, and the insulating layer is fixedly installed on the inner side of the glue layer. An insulating layer is fixedly installed on the inner side of the glue layer, a wire core shielding layer is fixedly installed on the inner side of the insulating layer, and a wire core body is installed in the wire core shielding layer. According to the invention, through the arrangement of the ferrule, the convex particles and the hexagonal blocks, the friction force of the outer layer can be increased, the shaking amplitude of the cable in an electric appliance is reduced, the wear degree is further reduced, the service life is prolonged, and actual use is facilitated; meanwhile, the buffer pad is arranged between the outer layer and the teflon layer, so that when the outer layer is bent, the teflon layer can be prevented from being bent excessively through the buffer pad, and the service life of the teflon layer is further prolonged.

Owner:湖北宇辰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com