Generating method cycloid tooth bevel gear grinding method

A cycloid bevel gear, forming technology, applied in the direction of components with teeth, belts/chains/gears, gear teeth, etc., can solve the problem that the processing efficiency cannot adapt to the finishing of large quantities of small and medium-sized gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment one, a kind of tooth grinding method of forming method cycloid bevel gear, it comprises the following steps:

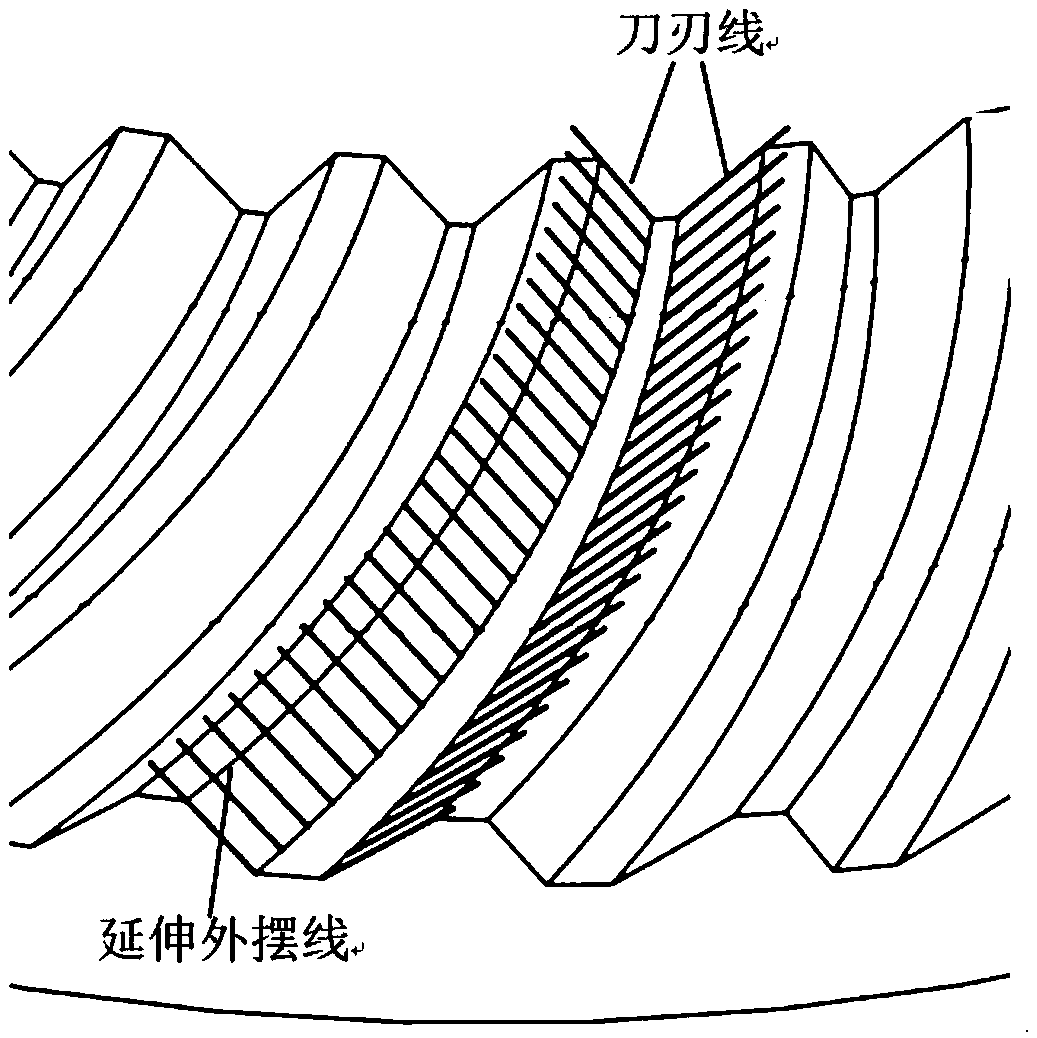

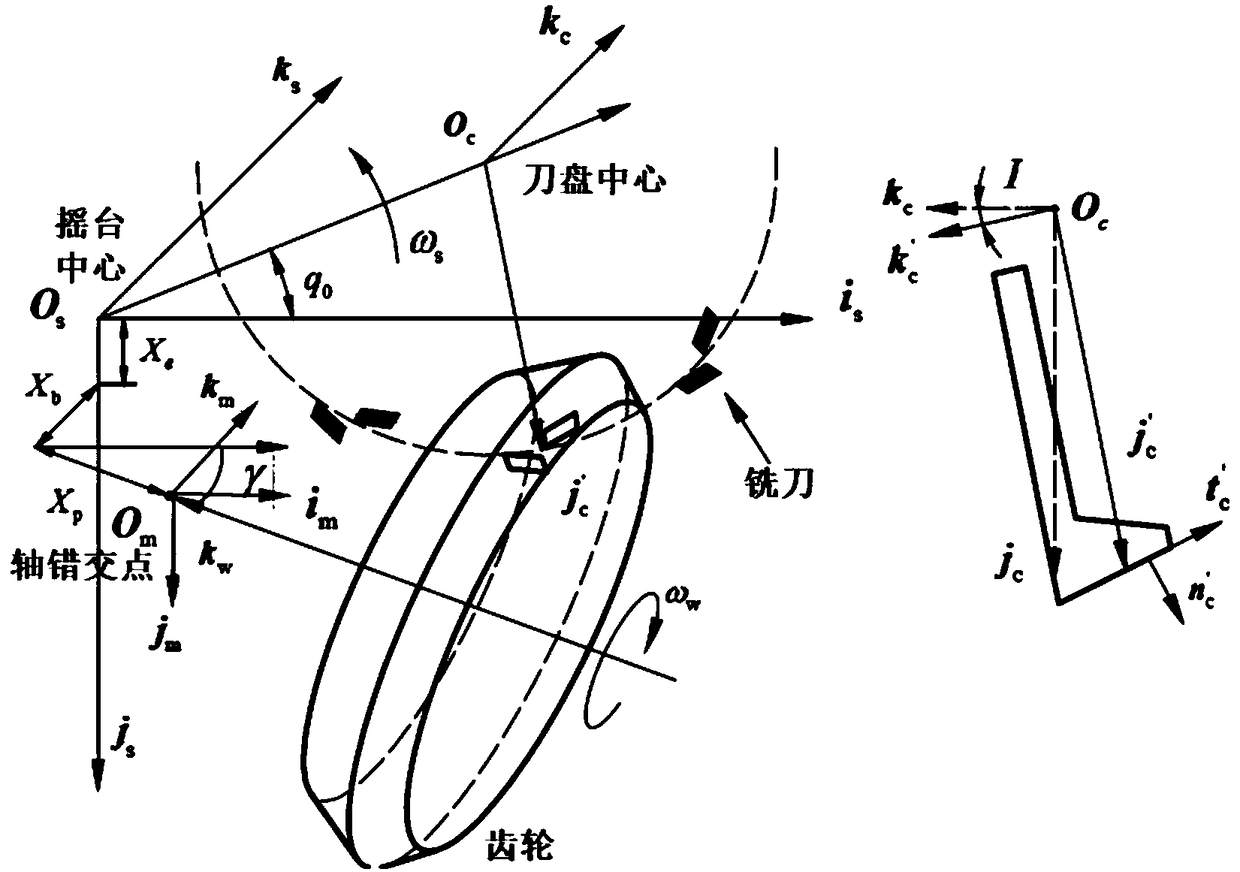

[0053] Step 1, the cycloidal bevel gear is processed by forming face hobbing method, see figure 2 The mathematical model of the face hobbing process shown by the forming method is used to establish a cycloidal bevel gear processing coordinate system group; the cradle coordinate system ∑ s ={O s , i s , j s , k s}, O s is the center of the cradle, i s o s j s is the plane of the cradle, k s The axis of the cradle points to the inside of the cradle; the cutterhead coordinate system Σ c ={O c , i c , j c , k c}, O c is the center of the cutterhead, i c o c j c on the top plane of the knife, j c is the direction from the center of the cutter head to the reference point of the cutting tooth on the cutting edge, k c The axis of the cutter head deviates from the plane of the top of the cutter; the gear coordinate system ∑ g ={O g , i ...

Embodiment 2

[0105] Example 2: Cycloidal bevel gears are manufactured by molding method, the basic parameters of which are shown in Table 1, and the machine tool adjustment parameters and cutter head parameters are shown in Table 2.

[0106] Table 1 Basic parameters of cycloidal bevel gears

[0107]

[0108] Table 2 Machine tool adjustment parameters and cutterhead parameters

[0109]

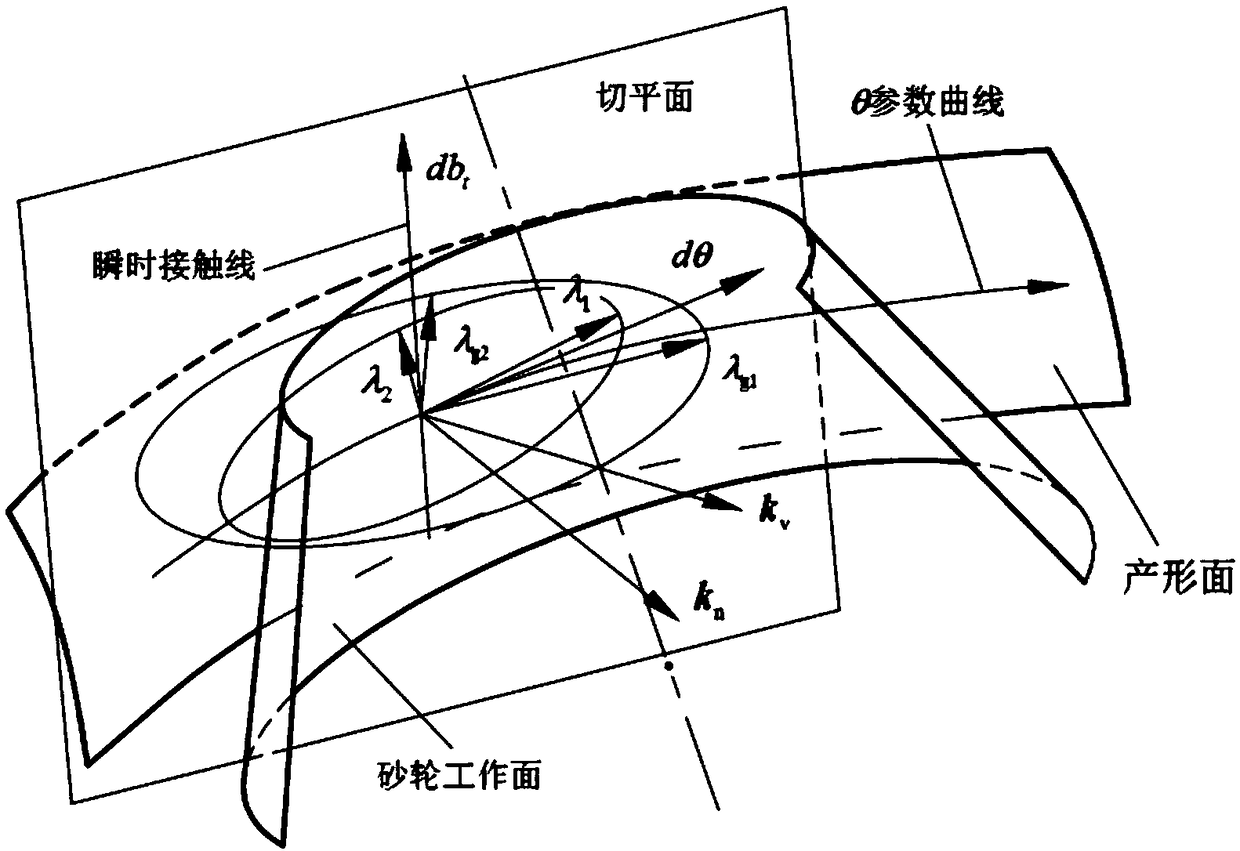

[0110] Using the surface equation of the cycloidal bevel gear, the parameters of the grinding wheel required for gear grinding can be designed, and the interference-free analysis and adjustment of the grinding wheel can be ensured. Depend on and Calculation, select the Δ value appropriately, and determine the pressure angle of the working face of the grinding wheel for gear grinding as The reference point radius is R g =77.2, grinding the convex surface of the cycloidal bevel gear with the grinding wheel on the inner side as the working surface. The tool position point calculated by the tool pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com