Memory cell and operation method and preparation method thereof

A memory cell and voltage control technology, which is applied in the field of memory, can solve the problems of high operating voltage and slow access speed of Flash, and achieve the effects of low-cost manufacturing, increased bending degree, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

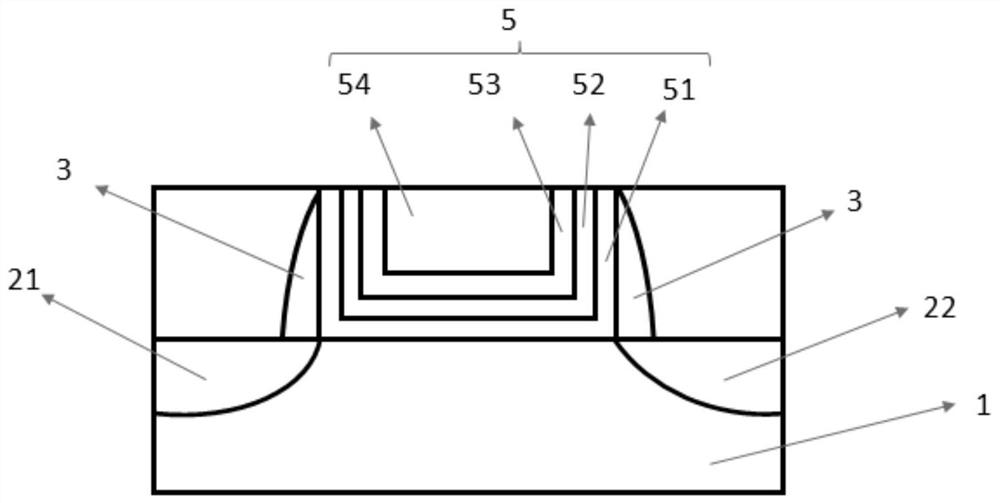

[0032] figure 1 is a schematic structural diagram of the storage unit in Embodiment 1 of the present invention;

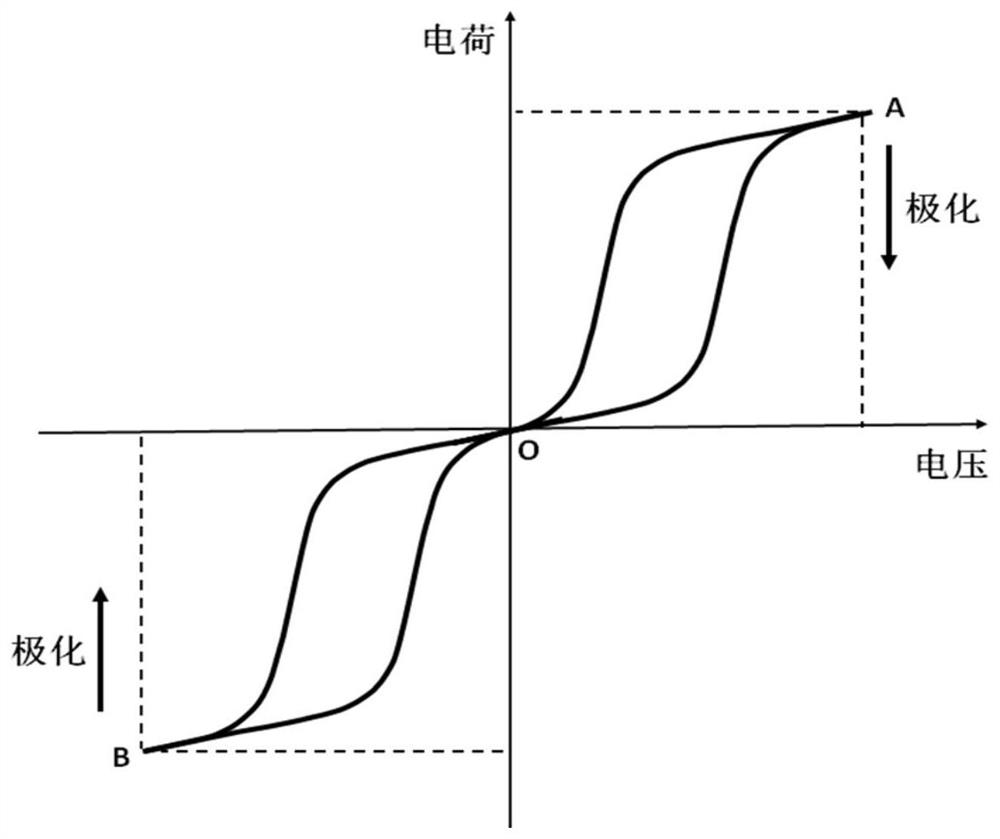

[0033] figure 2 is the polarization charge-voltage curve of the antiferroelectric thin film layer of Example 1 of the present invention.

[0034] Such as figure 1 and 2 As shown, this embodiment provides a memory cell, including: a substrate 1, a source 21 and a drain 22 disposed in the substrate 1, a stacked gate 5 and sidewalls 3; the stacked gate 5 is disposed on The upper surface of the substrate 1 between the source 21 and the drain 22 includes a tunnel oxide layer 51, a charge trapping layer 52, an antiferroelectric thin film layer 53 and a gate electrode 54 arranged sequentially from bottom to top; The gate electrode 54 is used to provide a voltage; the antiferroelectric thin film layer 53 is used to enhance the electric field on the tunnel oxide layer 51 under the action of the voltage, increasing the energy band of the tunnel oxide layer 51 Bending d...

Embodiment 2

[0042] This embodiment provides a method for operating a memory cell. During programming, first apply a positive control voltage on the gate electrode 54, and generate downward polarization in the antiferroelectric thin film layer 53 (control the polarity on the gate electrode 54). Turning the charge to positive corresponds to figure 2 point A in), at this time, a large electric field is generated in the tunneling oxide layer 51, so that the electrons in the substrate 1 tunnel through the tunneling oxide layer 51 to enter and stay in the charge trapping layer 52; then remove the control gate electrode Forward control voltage on 54, the polarization in the antiferroelectric thin film layer will be greatly reduced or reduced to 0, if it is an ideal antiferroelectric thin film, the polarization will be reduced to 0 corresponding figure 2 O point in , while retaining a large number of electrons in the charge trapping layer 52;

[0043] During erasing, a negative control voltage...

Embodiment 3

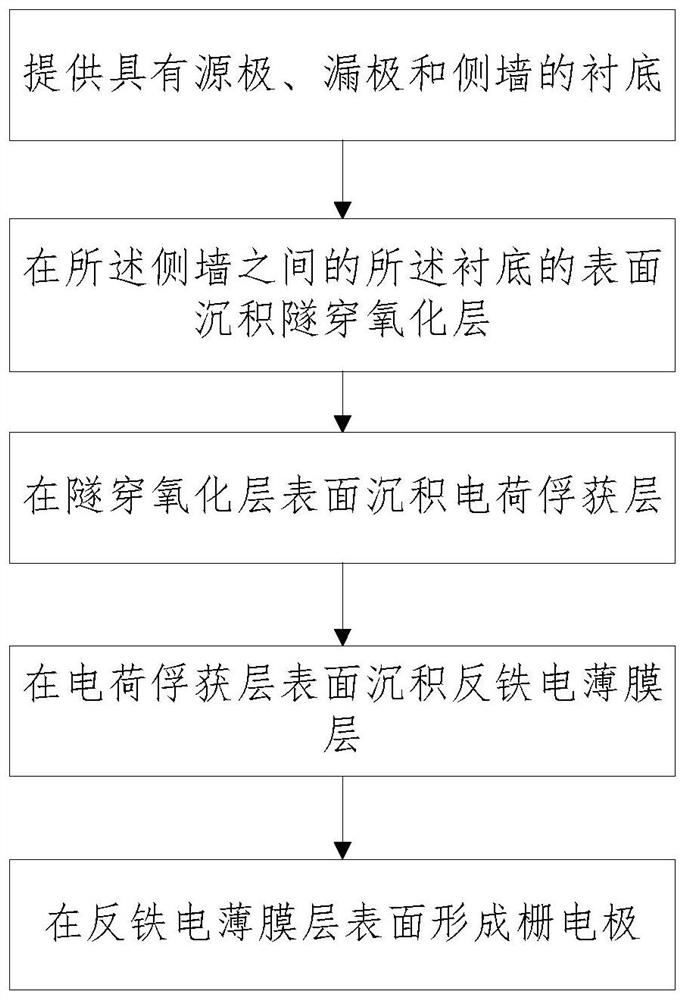

[0045] image 3 It is a flow chart of the manufacturing method of the storage unit according to Embodiment 3 of the present invention; Figure 4 It is a schematic diagram of the manufacturing process of the storage unit according to Embodiment 3 of the present invention.

[0046] Such as image 3 and Figure 4 As shown, the present embodiment provides a method for manufacturing a memory cell, providing a substrate 1 with a source 21, a drain 22 and a spacer 3 (such as Figure 4 a); Deposit a tunnel oxide layer 51 on the surface of the substrate 1 between the sidewalls 3 (such as Figure 4 b); Depositing a charge trapping layer 52 on the surface of the tunnel oxide layer 51 (such as Figure 4 c); Deposit an antiferroelectric film layer 53 on the surface of the charge trapping layer 52 (such as Figure 4 d); form a gate electrode 54 on the surface of the antiferroelectric thin film layer 53 (such as Figure 4 e).

[0047] The memory cell produced by the manufacturing meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com