Polycrystalline silicon directional solidifying method and device capable of improving impurity removal effect

A technology of directional solidification and polysilicon, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low recycling rate of waste, waste of energy and raw materials, and increase of manufacturing cost, so as to achieve good cost control and reduce waste , the effect of reducing the resection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

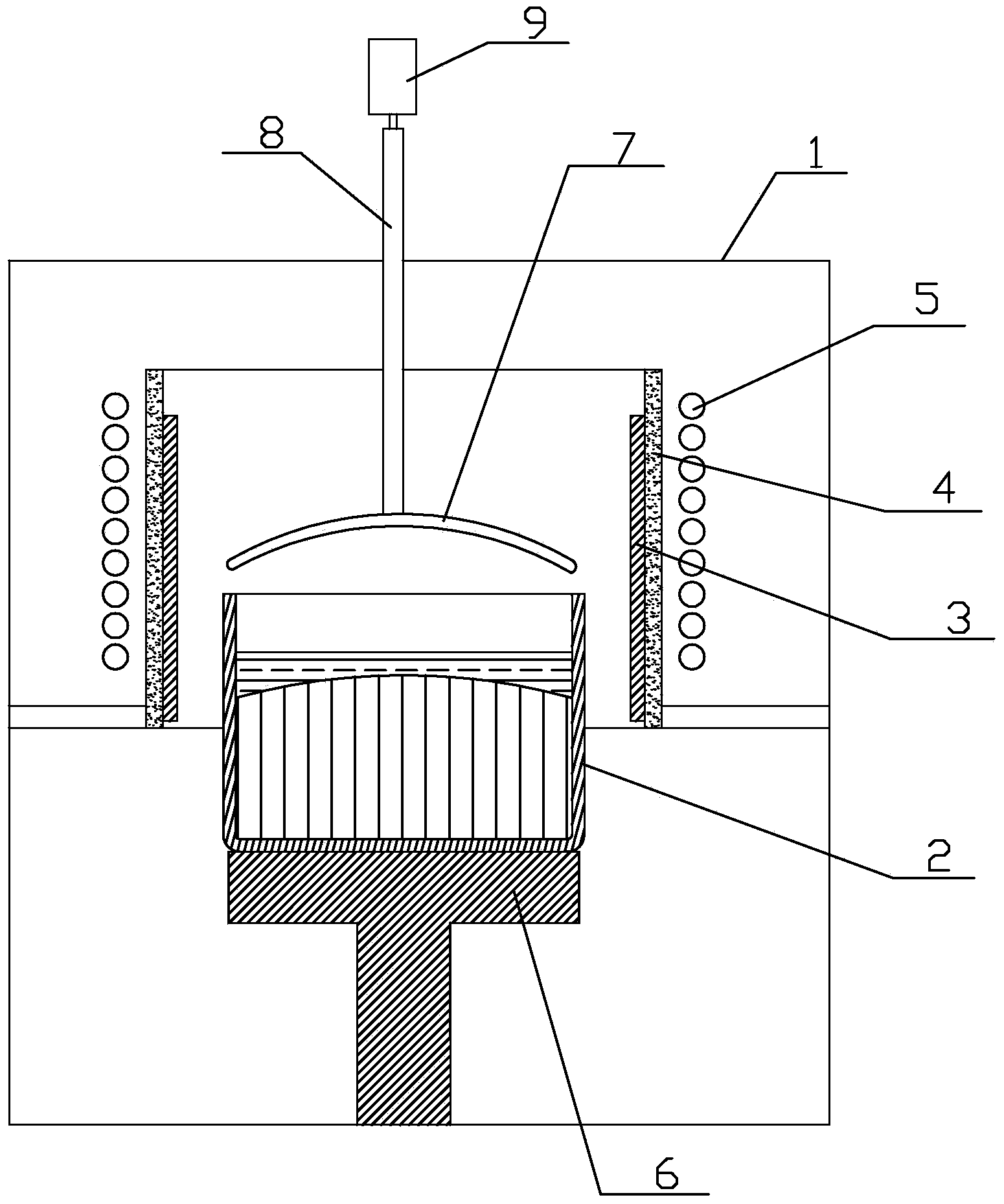

[0019] Such as figure 1 As shown, a polysilicon directional solidification device for improving the impurity removal effect includes a furnace body 1, a quartz crucible 2 is placed in the furnace body 1, and the outer wall of the quartz crucible 2 is surrounded by a graphite heating element 3 and a thermal insulation sleeve 4 sequentially from the inside to the outside. and the induction coil 5, the bottom of the quartz crucible 2 is provided with an ingot pulling mechanism 6 communicating with the bottom of the furnace body 1, a graphite tube 8 is vertically connected between the furnace body 1 and the heat preservation sleeve 4, and a graphite tube 8 is connected below the graphite tube 8 A curved graphite heater 7 is located between the insulation sleeve 4 and the quartz crucible 2 , and a drive mechanism 9 is connected to the graphite tube 8 located outside and above the furnace body 1 .

[0020] Wherein, the curved graphite heater 7 is convex. When the curved graphite he...

Embodiment 2

[0024] Adopt the device described in embodiment 1, carry out directional solidification:

[0025] (1) Put 500kg of industrial silicon in the quartz crucible 2, turn on the mechanical pump to evacuate the furnace body 1 to 800Pa, then turn on the Roots pump and continue to evacuate to 0.1Pa;

[0026] (2) Turn on the induction coil 5 to act on the graphite heating element 3 to raise the temperature of the silicon material in the quartz crucible 2 to 1500°C. After 10 hours, the silicon material is heated and melted to form a silicon melt;

[0027] (3) After 8 hours of heat preservation, turn off the Roots pump and the mechanical pump in turn. Fill the furnace body 1 with argon gas, and start the ingot pulling mechanism 6;

[0028] (4) Before the quartz crucible 2 is pulled down, place the thermocouple on the outer bottom of the quartz crucible 2 and place it in the air to monitor the temperature of the silicon melt and solid interface in real time. When the displayed temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com