Patents

Literature

81results about How to "Increased form factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

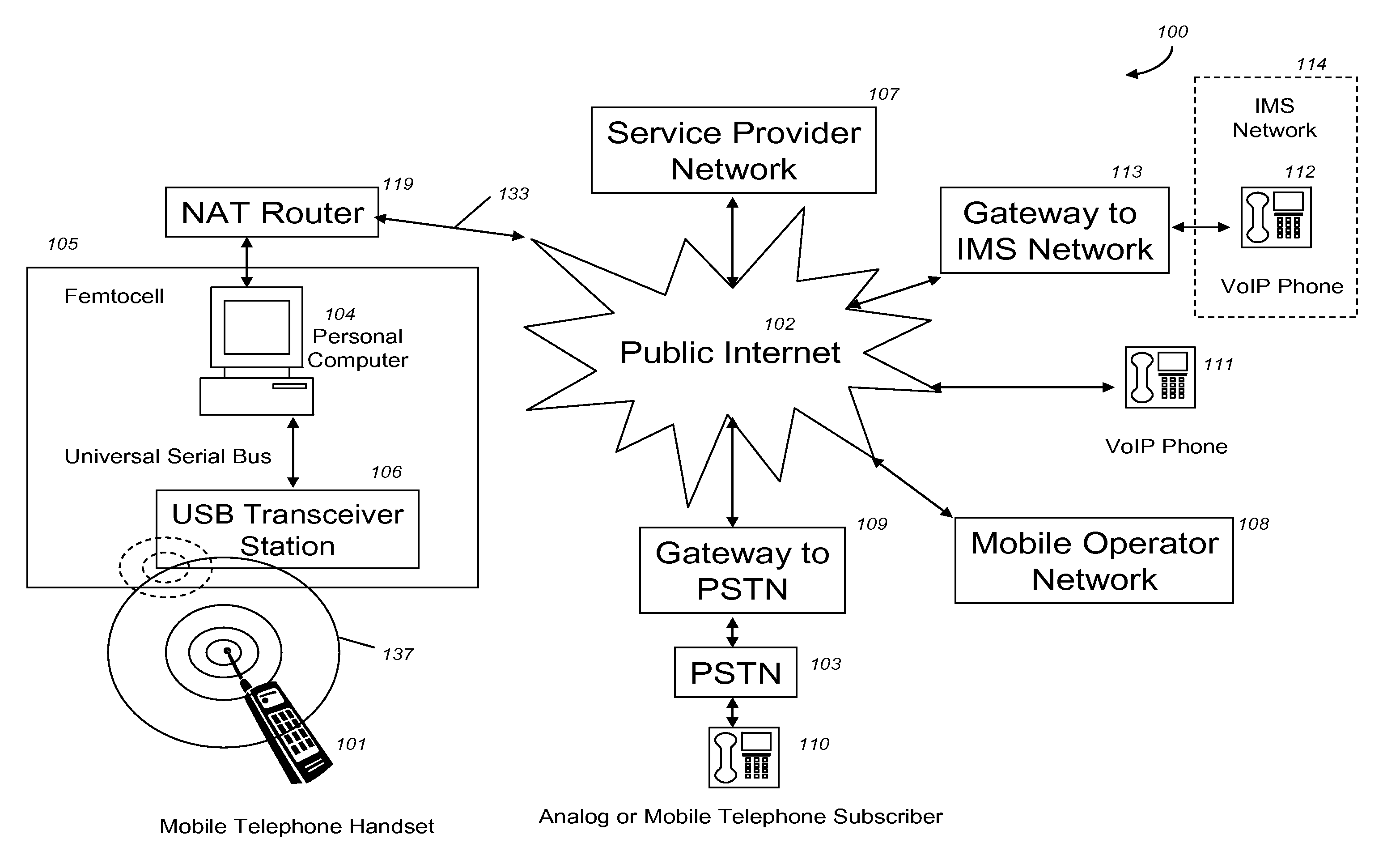

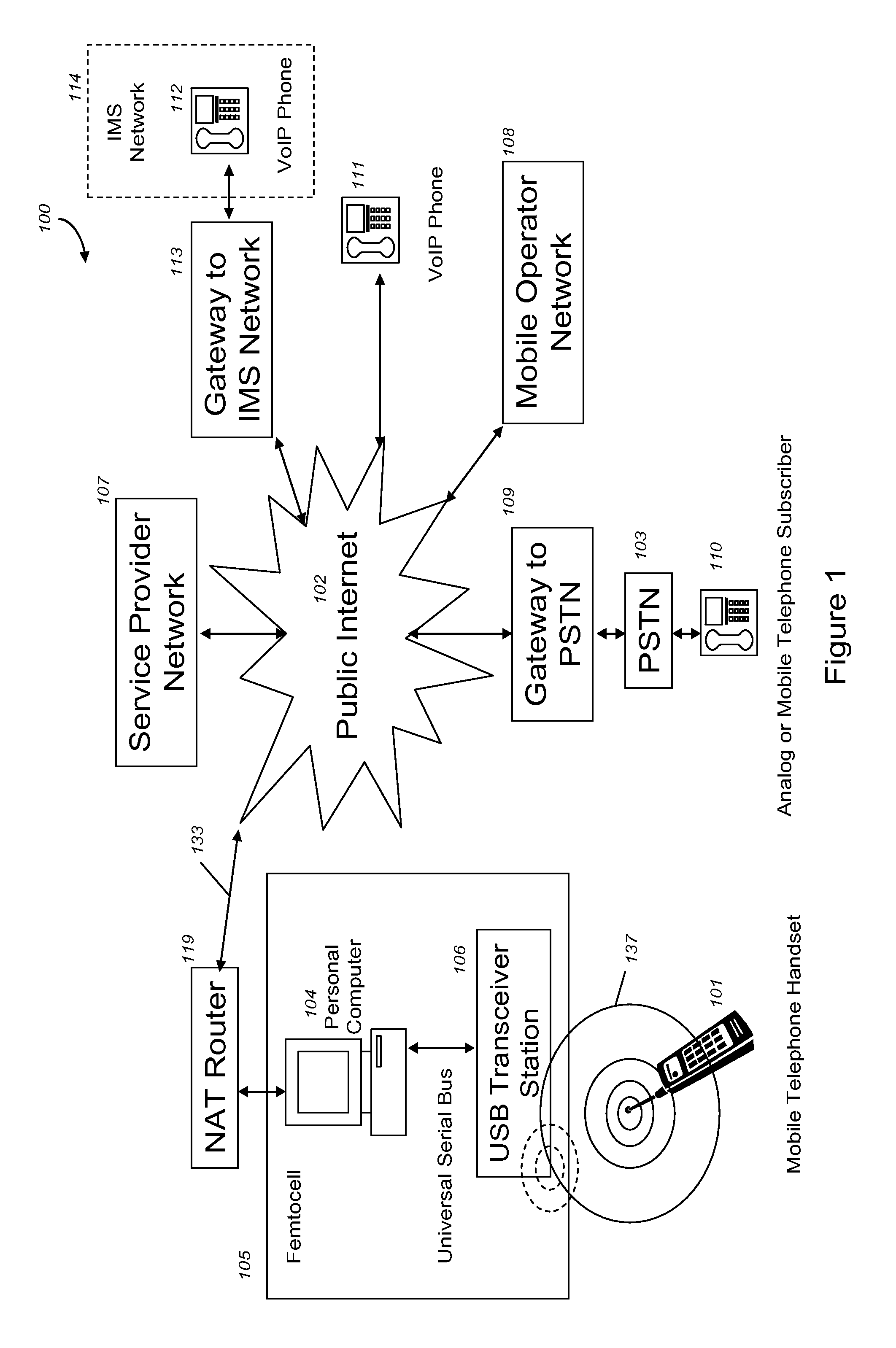

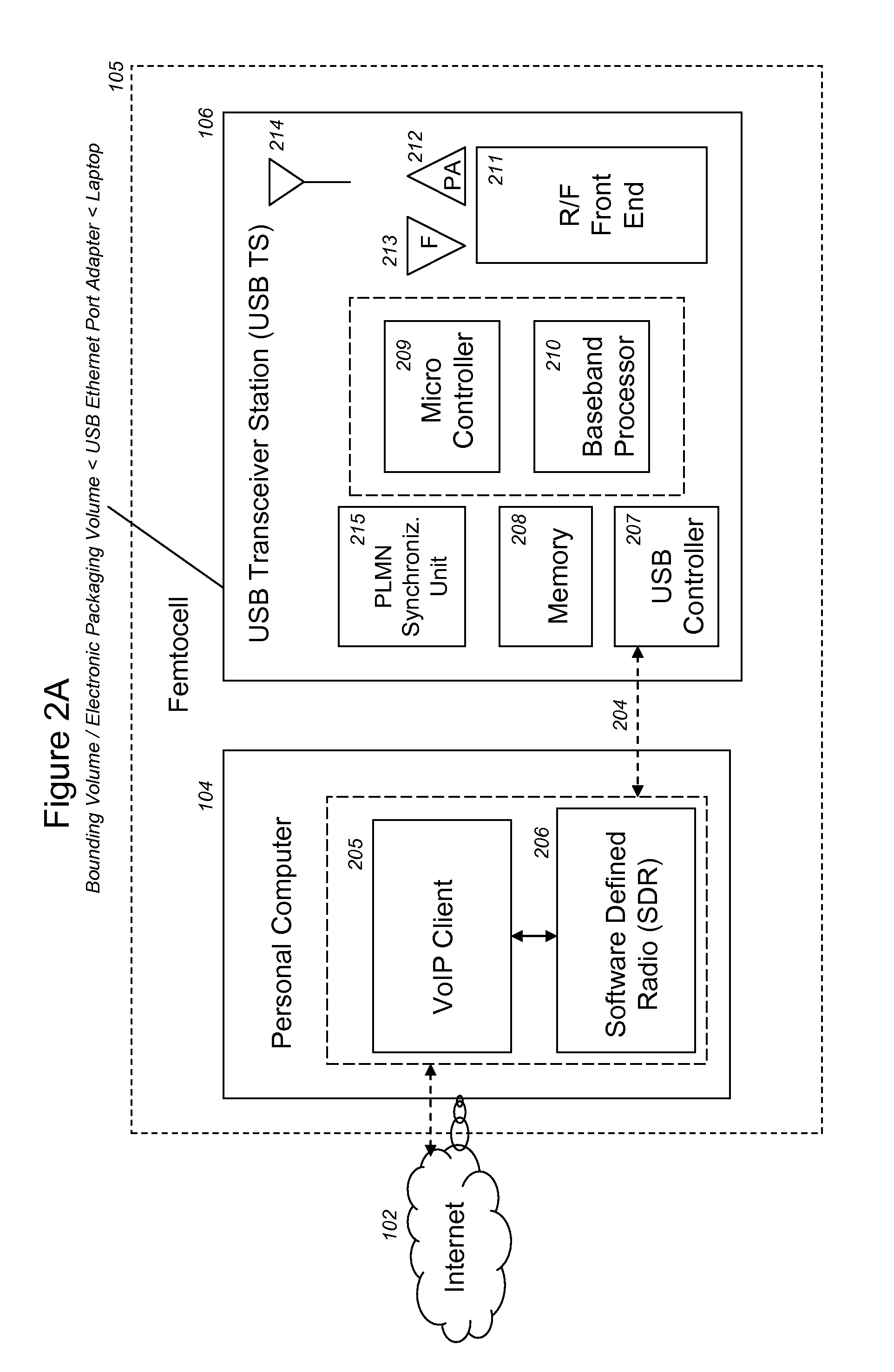

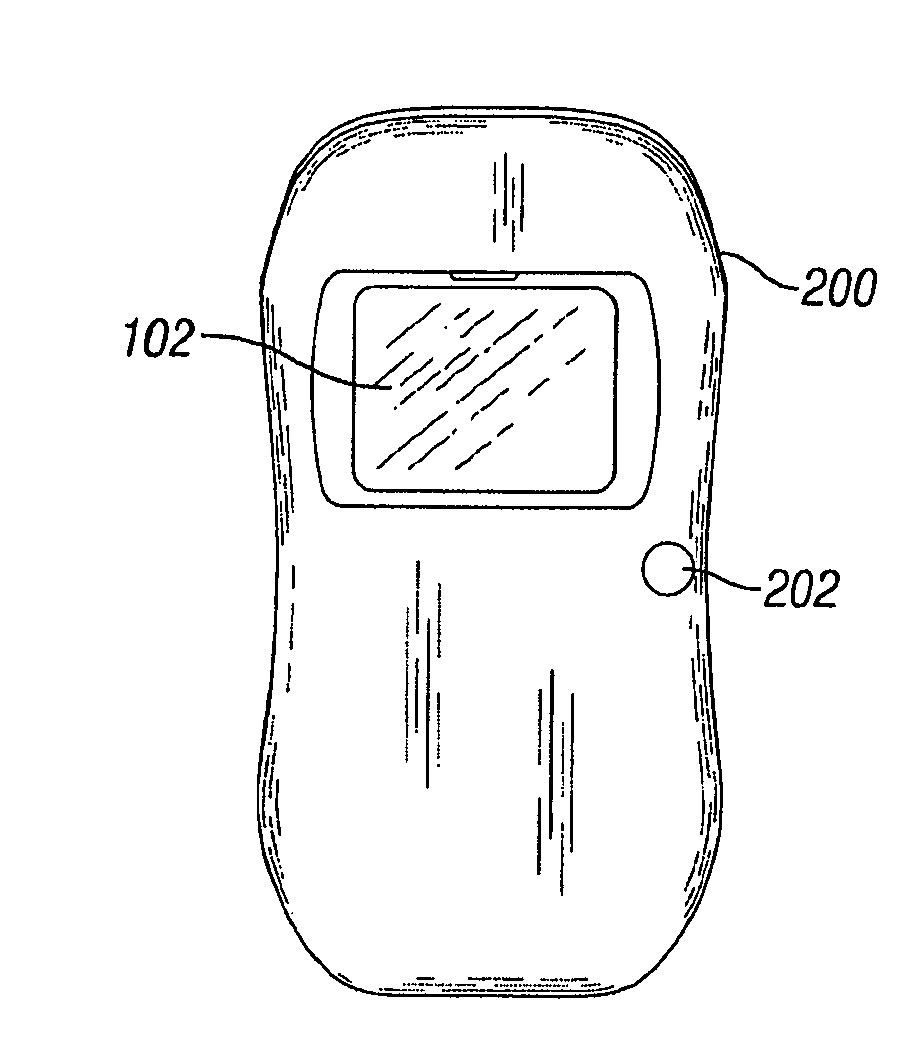

VoIP Enabled Femtocell with a USB Transceiver Station

InactiveUS20080244148A1High quality audioLow costNetwork topologiesSubstation equipmentMicrocontrollerRF front end

Telephone calls between a mobile station (MS) and the mobile network or PSTN are routed through the Internet via VoIP using a femtocell, as opposed to the traditional macrocellular network. The femtocell can comprise a USB Transceiver Station that is connected to a personal computer through a universal serial bus port, which provides both power and a multi-megabit per second connection between the personal computer and the USB transceiver station. The USB transceiver station can comprise a microcontroller to manage signaling between the RF front end / baseband processor and the personal computer, as well as a precise timing mechanism to assist the synchronization of femtocell timing with the surrounding macrocellular network, if it is present. The USB transceiver station can have a compact form factor that that facilitates a high degree of portability by the subscriber, such as being readily attachable to their keychain.

Owner:SMALL CELL INNOVATIONS

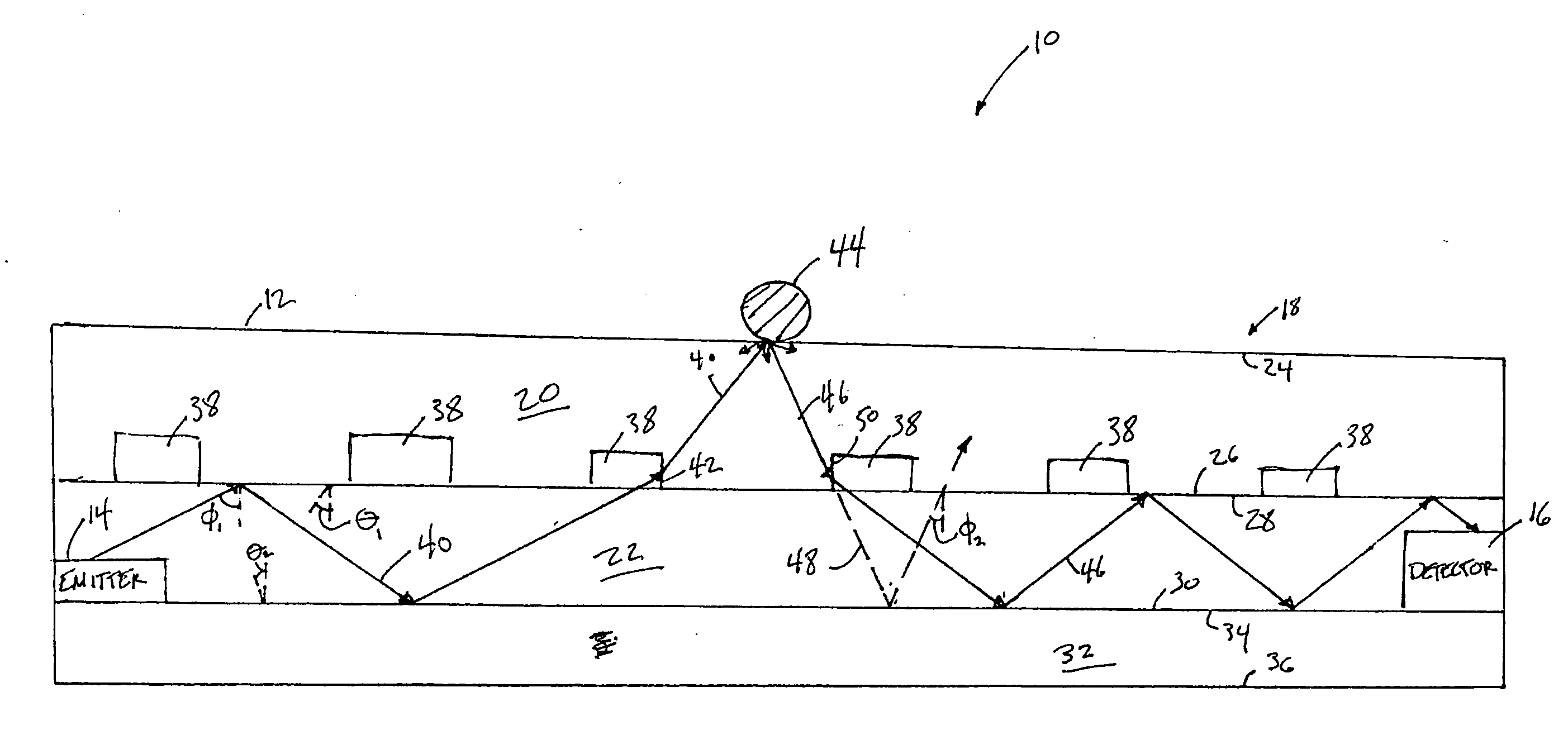

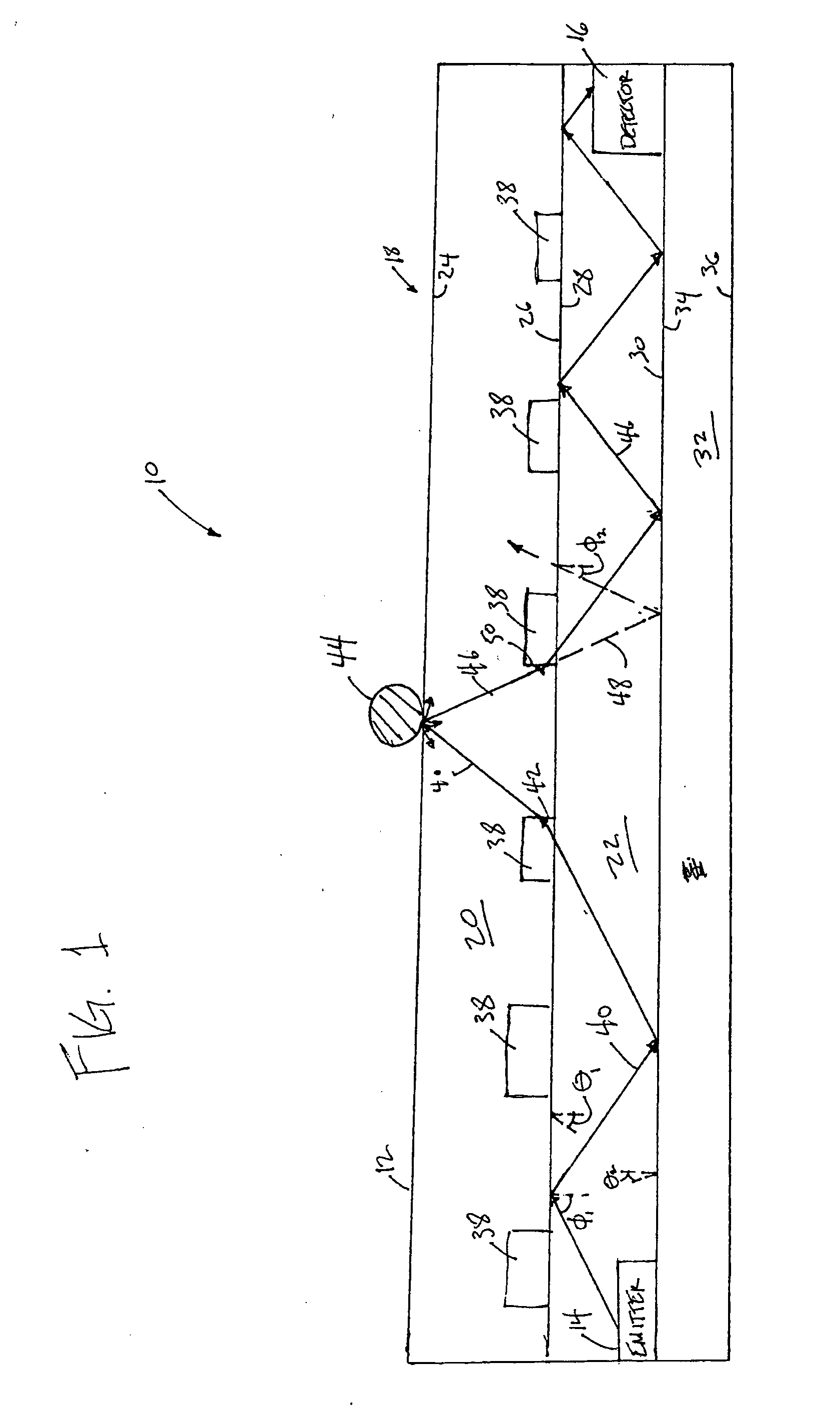

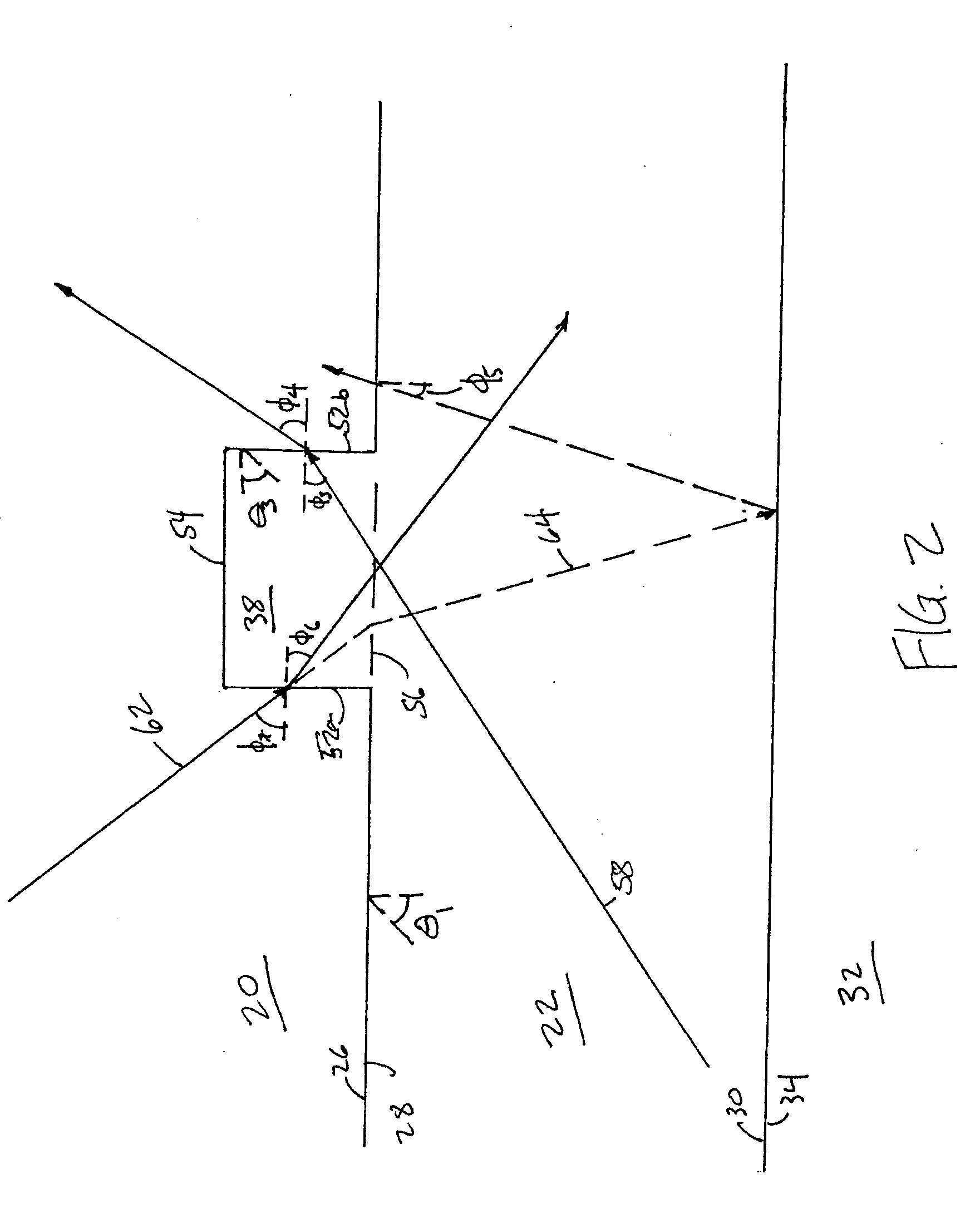

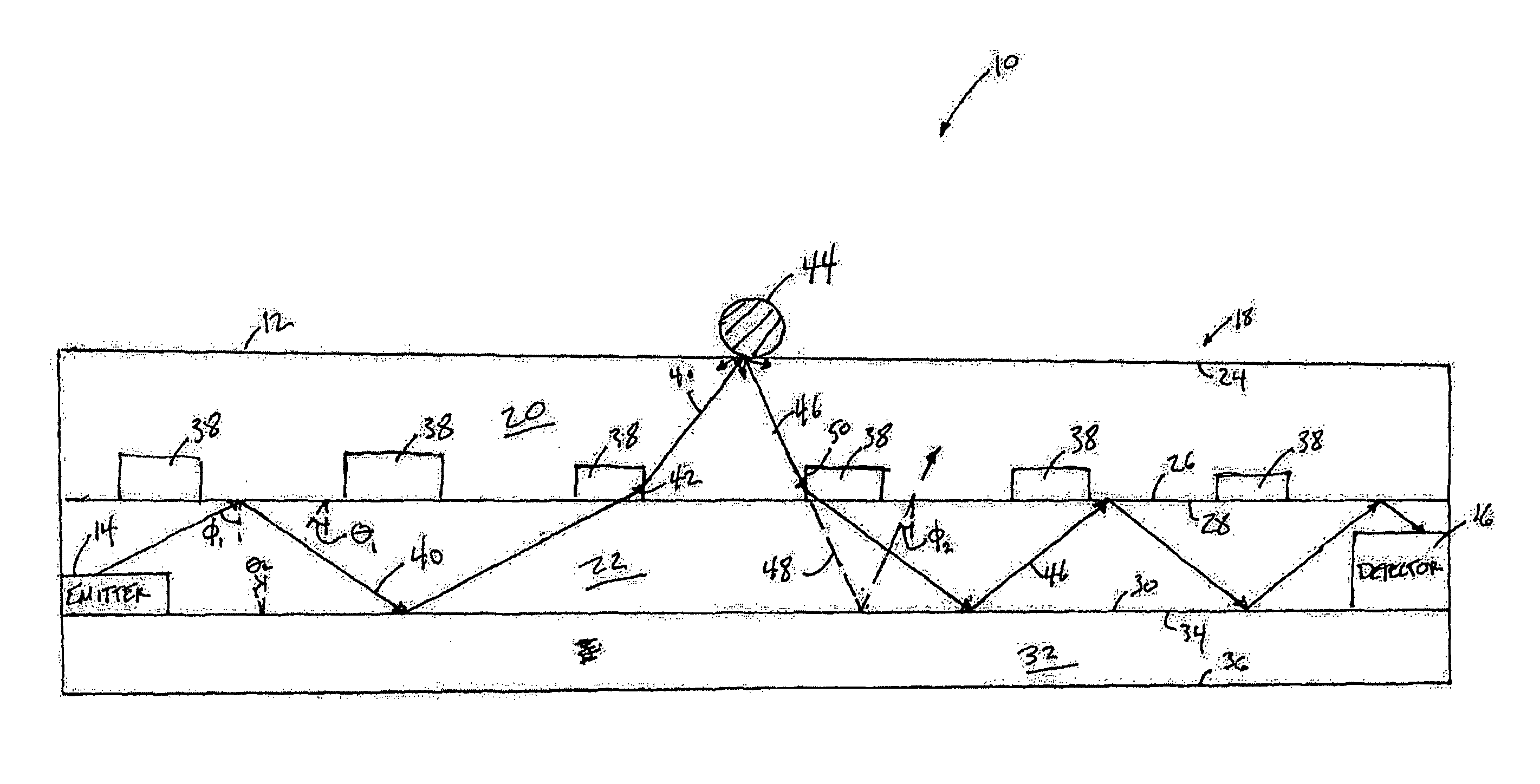

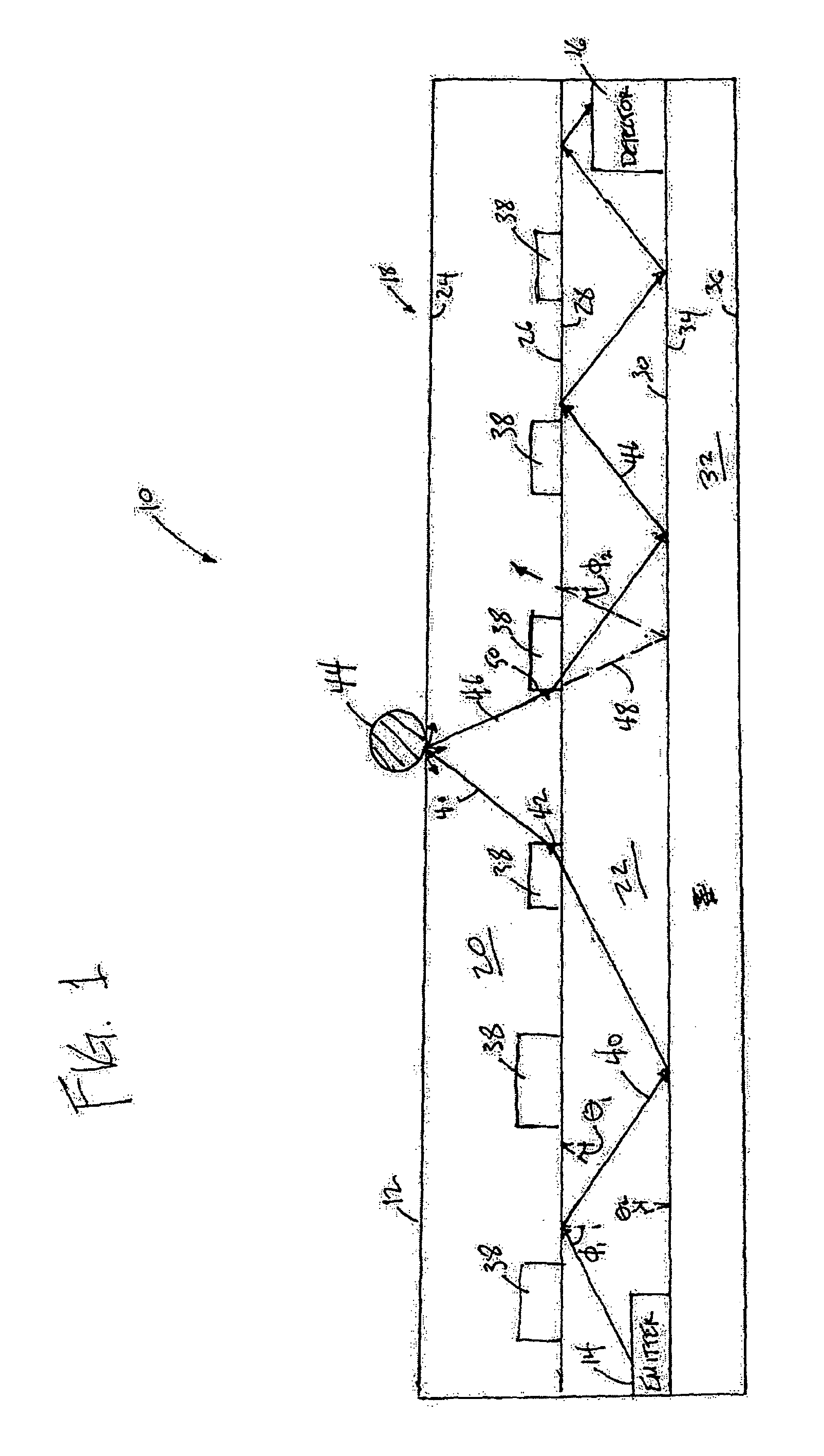

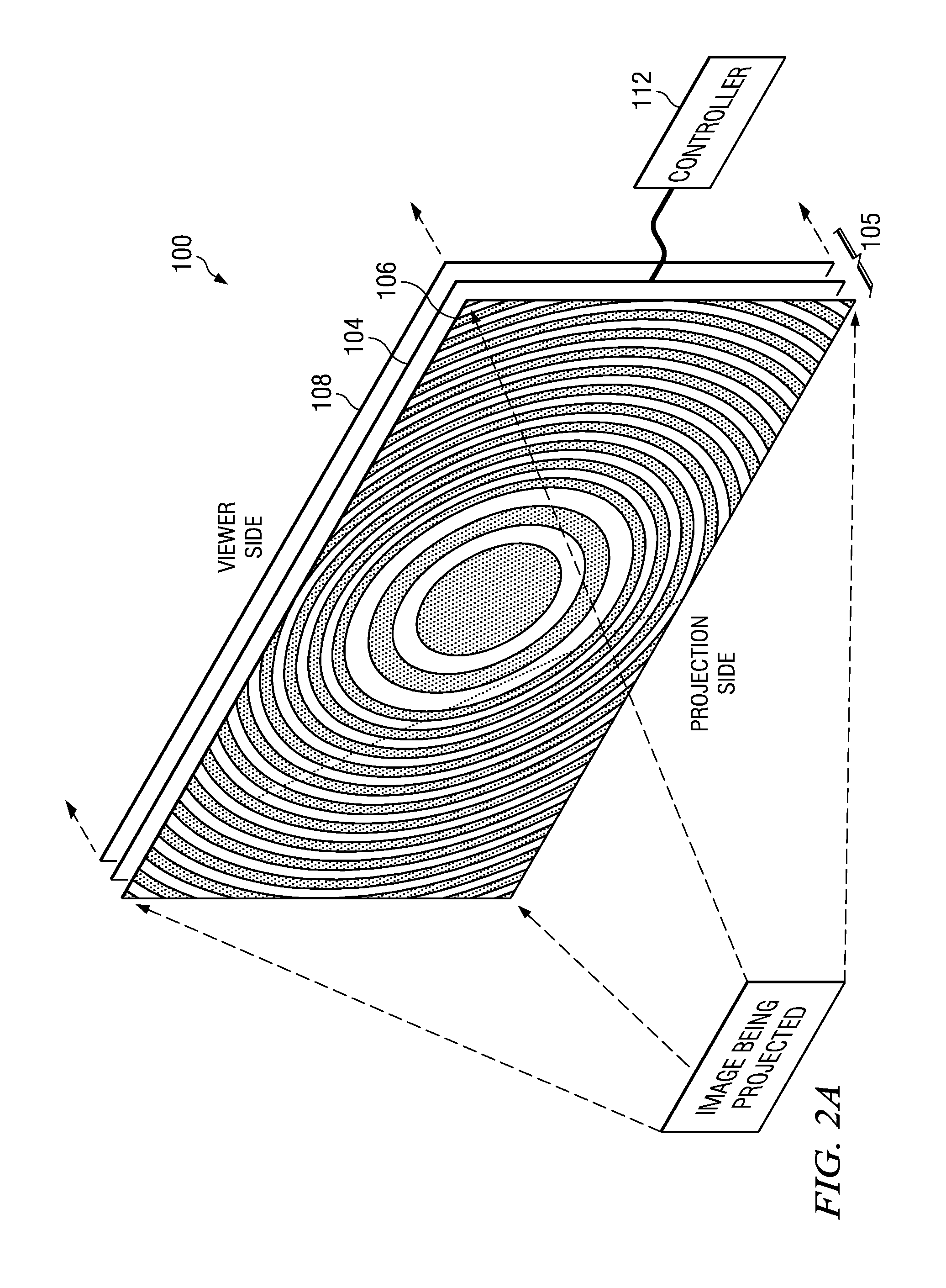

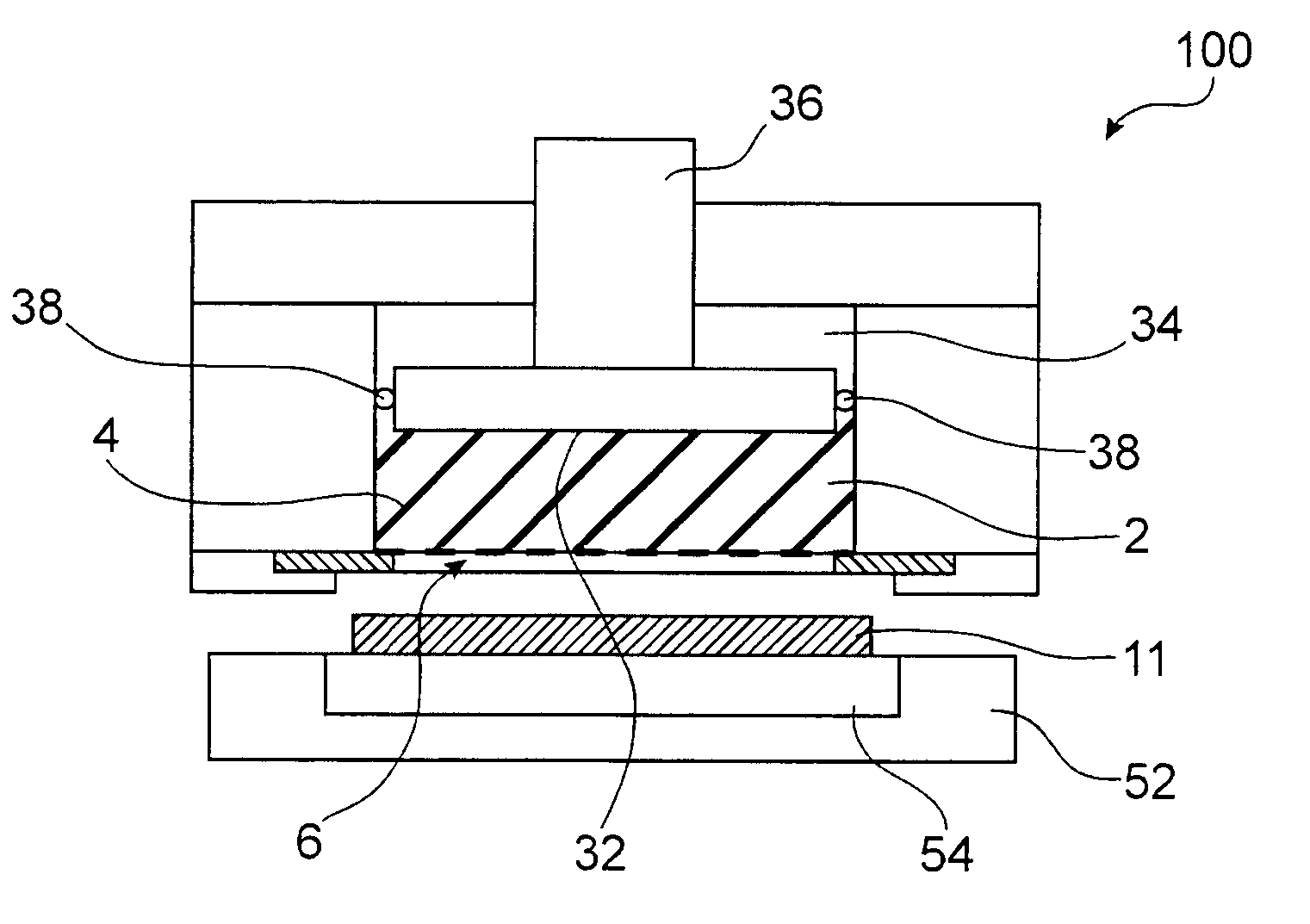

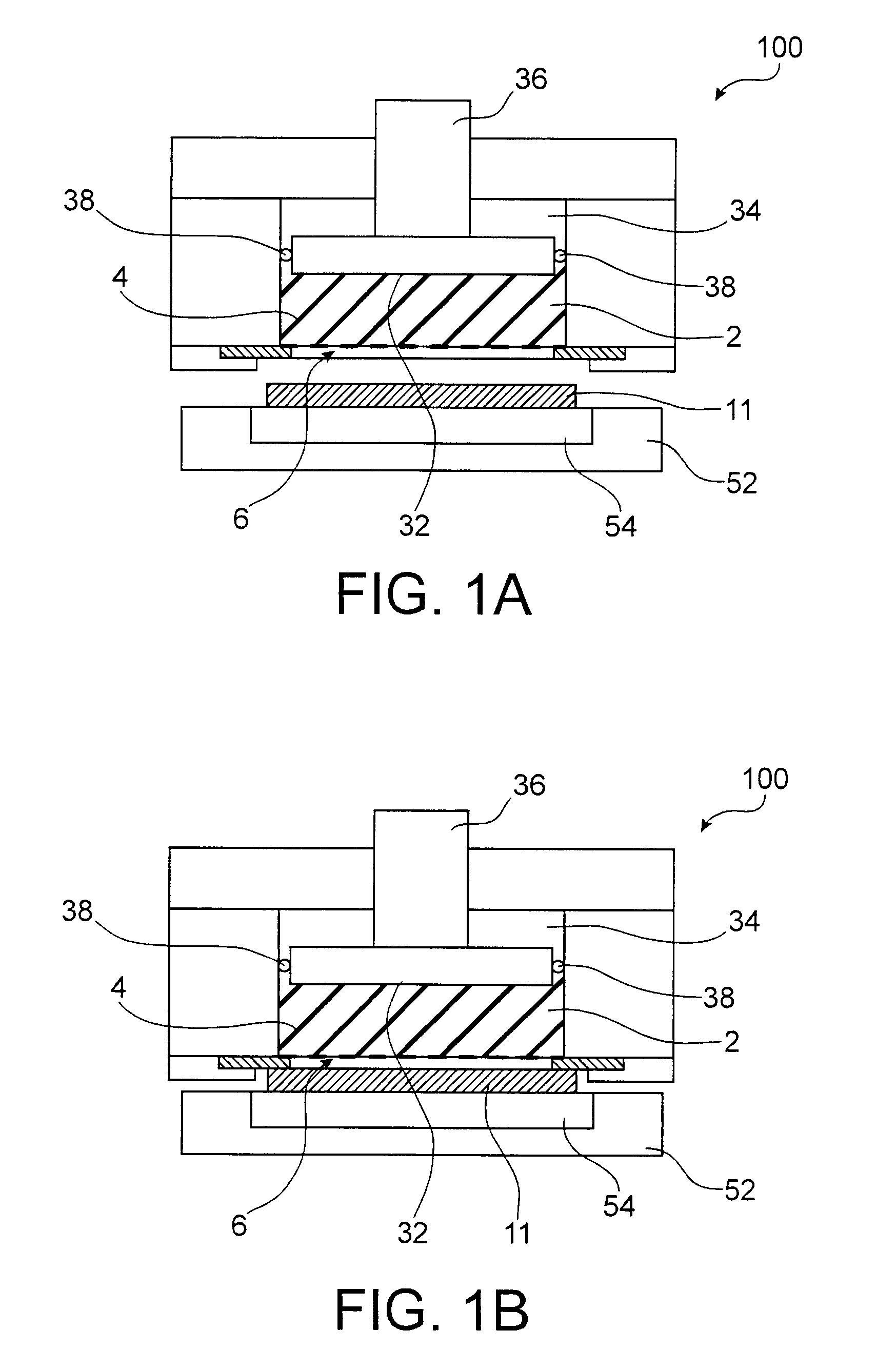

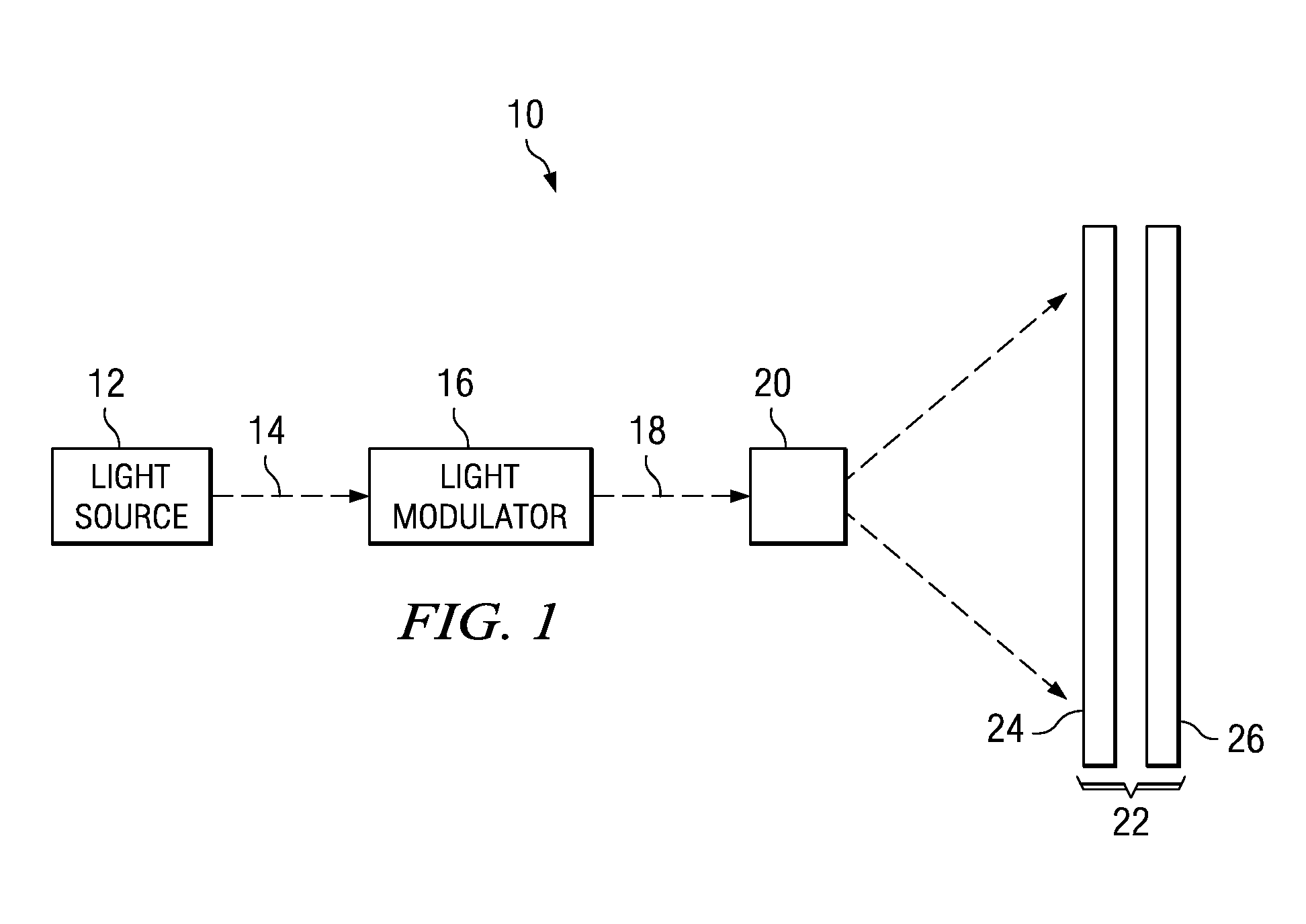

Optical touchpad system and waveguide for use therein

InactiveUS20080007541A1Easy to controlReduce Optical NoiseElectronic switchingInput/output processes for data processingInter layerRefractive index

An optical touchpad system that includes a waveguide having a plurality of waveguide layers. For example, the waveguide may include an intervening layer, a signal layer, and / or other layers. The intervening layer may be defined by a first surface, a second surface and a substantially transparent material having a first index of refraction disposed between the first and the second surface of the interface layer. The signal layer may be defined by a first surface, a second surface and a substantially transparent material having a second index of refraction that is greater than the first index of refraction.

Owner:O PEN

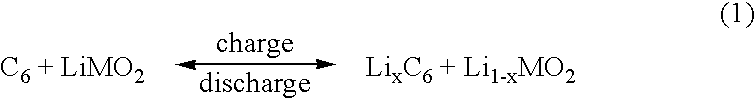

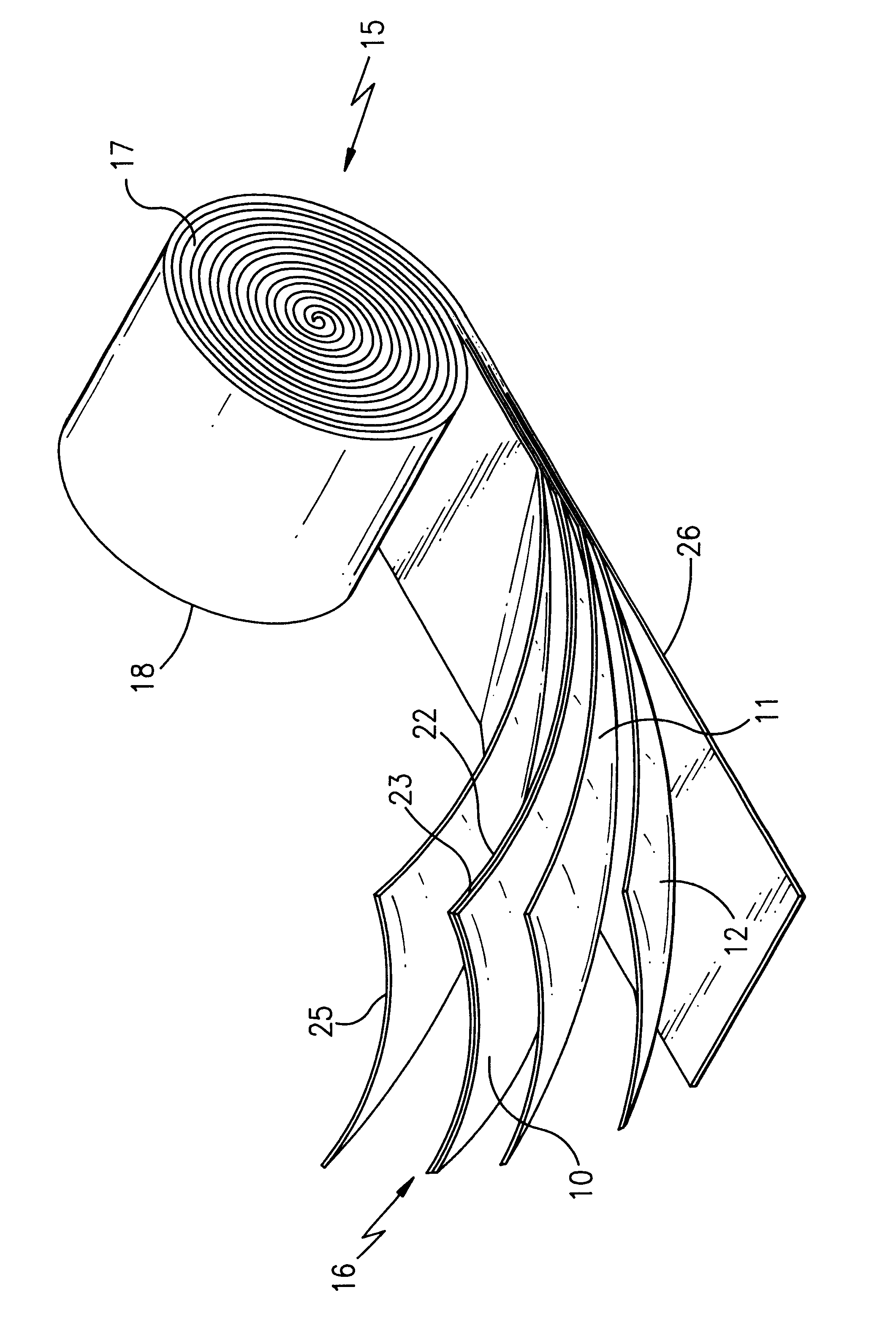

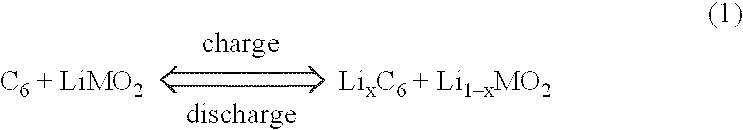

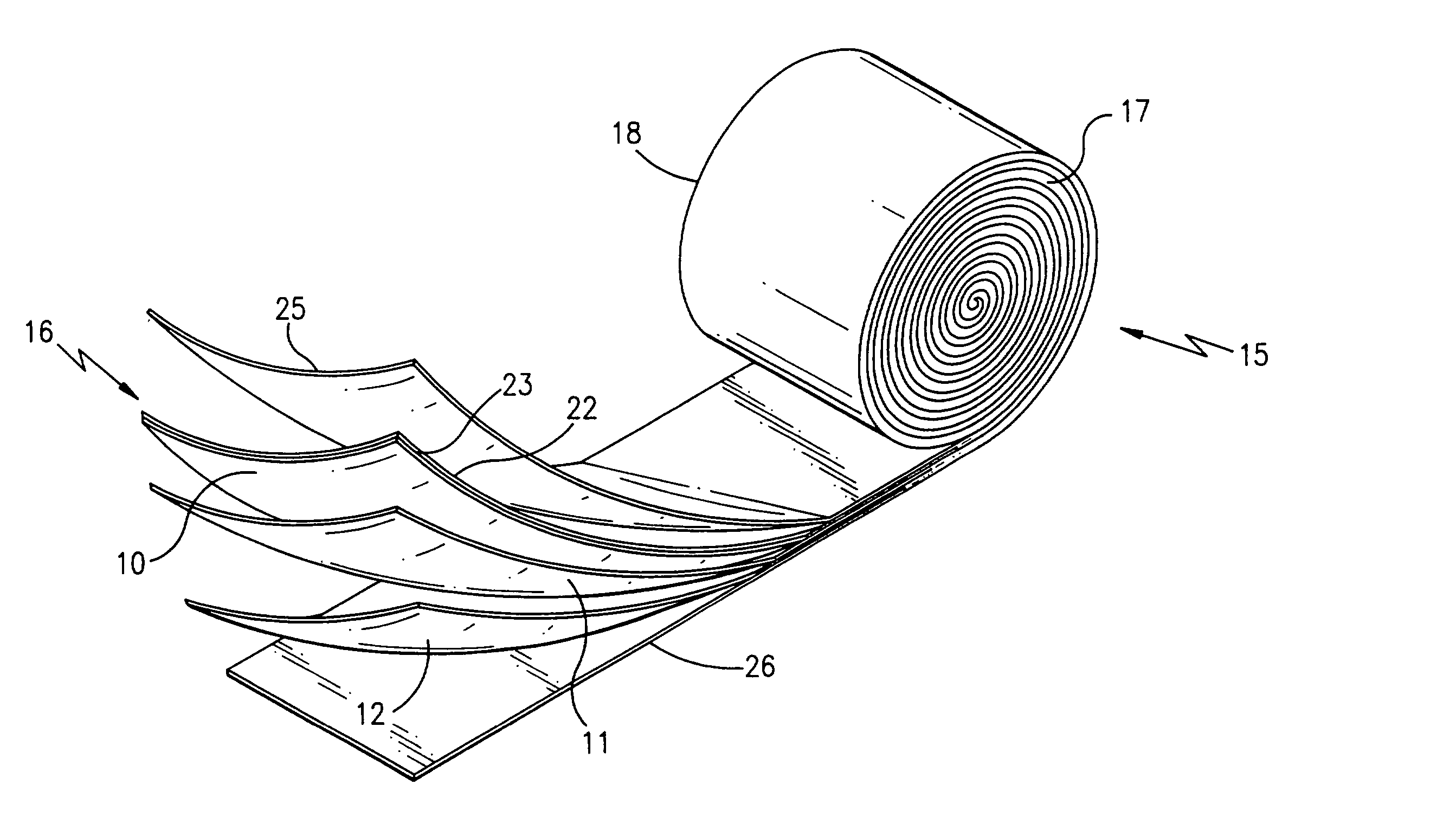

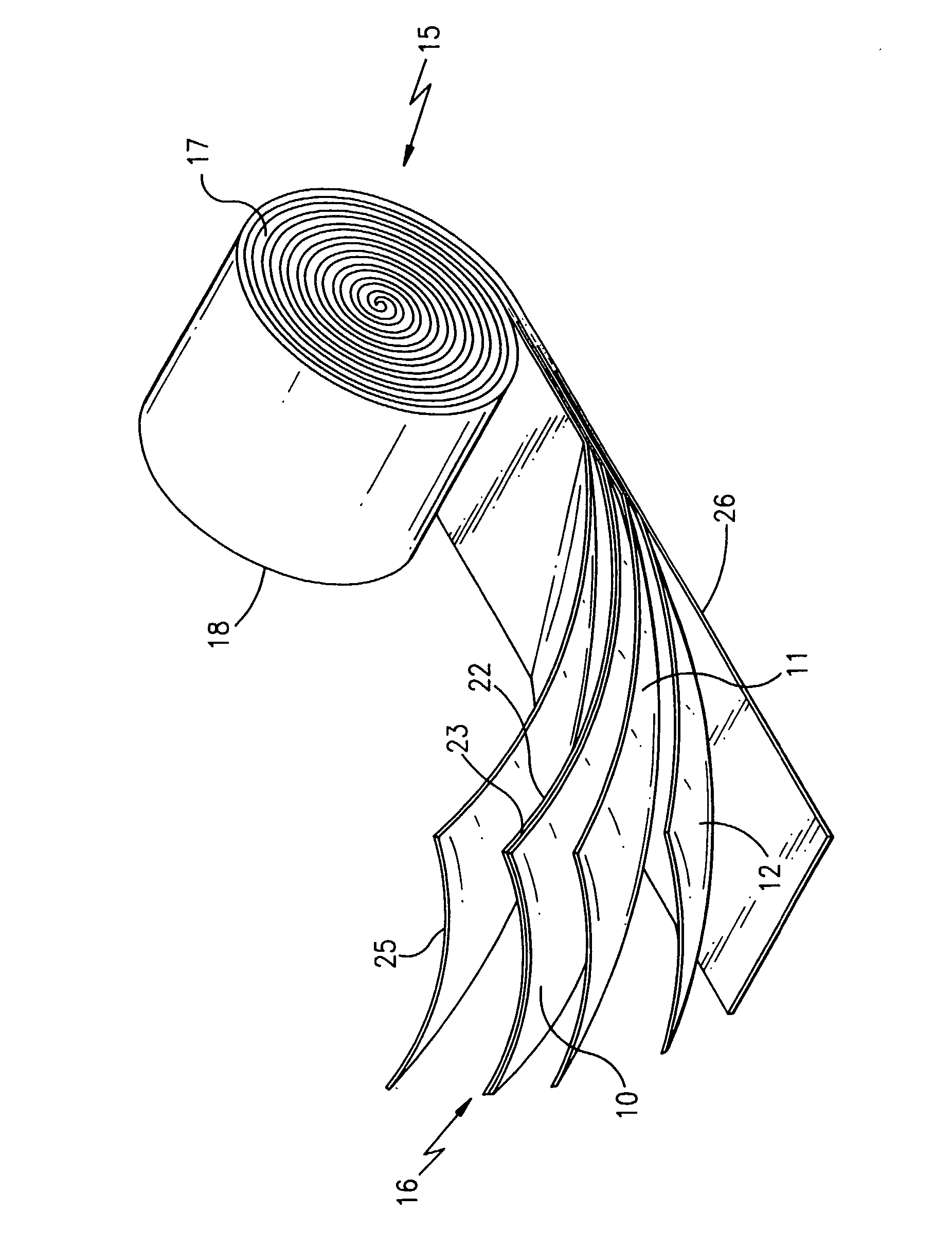

Lithium ion polymer electrolytes

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

Ionically conductive polymer electrolytes

InactiveUS20030091904A1Good flexibilityLower resistanceElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

Optical touchpad with three-dimensional position determination

InactiveUS8094136B2Easy to controlReduce Optical NoiseTransmission systemsCathode-ray tube indicatorsInformation opticsOphthalmology

An optical touchpad that may be able to provide accurate, reliable information about the position of an object in three-dimensions. The optical touchpad may enable a determination as to whether the object is engaged with the touchpad or hovering just above the touchpad. When the object is in contact with the optical touchpad, the optical touchpad may enable a determination of the force applied by the object to the optical touchpad. The optical touchpad may enable a determination of an object type of the object. These and other determinations of information related to the object may enhance the control provided by the touchpad system to the user as an electronic interface. The operation of the optical touchpad may further enable an enhanced frame rate, reduced optical noise in the optical signal(s) guided to the one or more sensors, augment the ruggedness of the optical touchpad, an enhanced form factor (e.g., thinner), and / or provide other advantages.

Owner:FLATFROG LAB

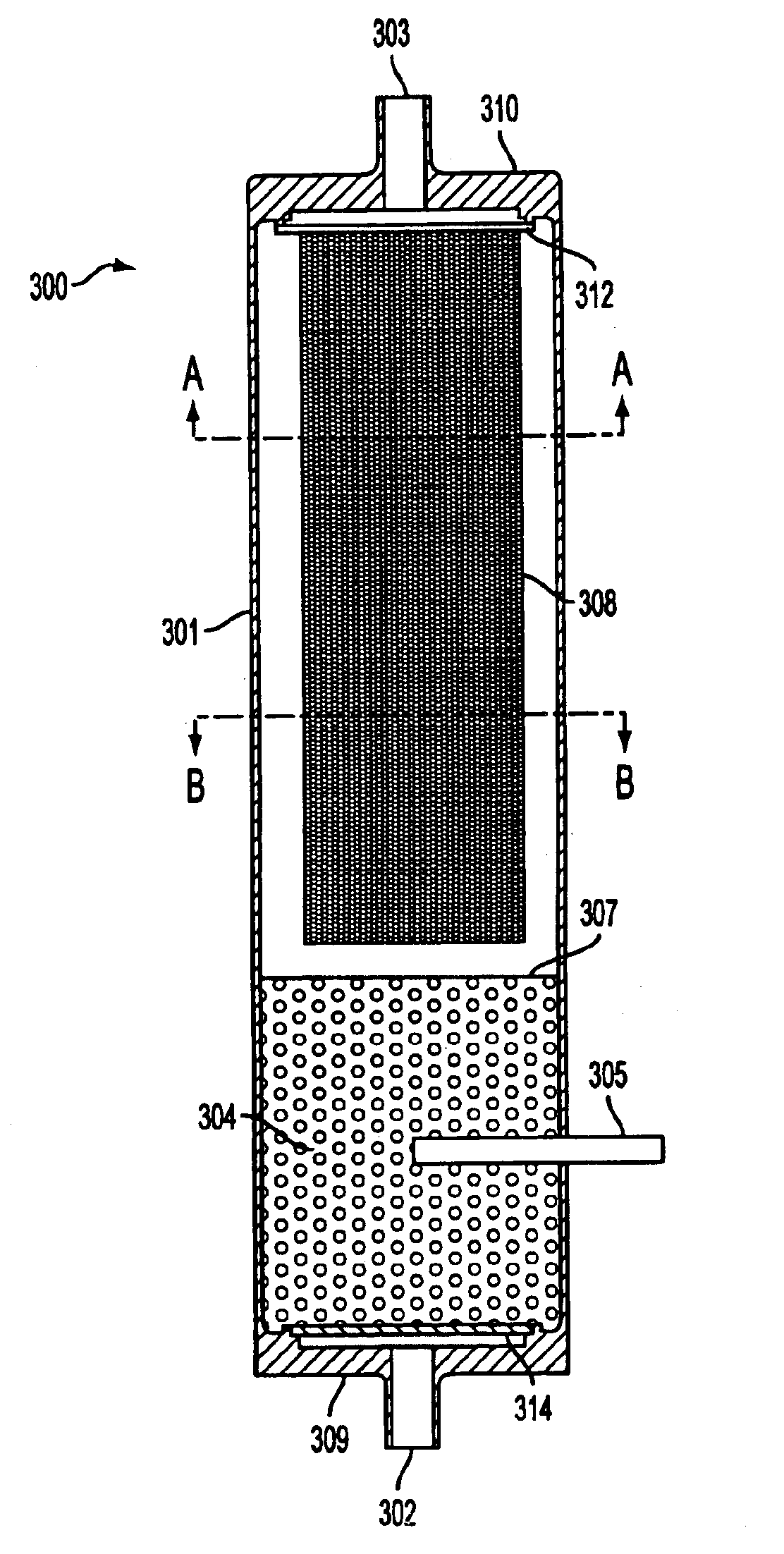

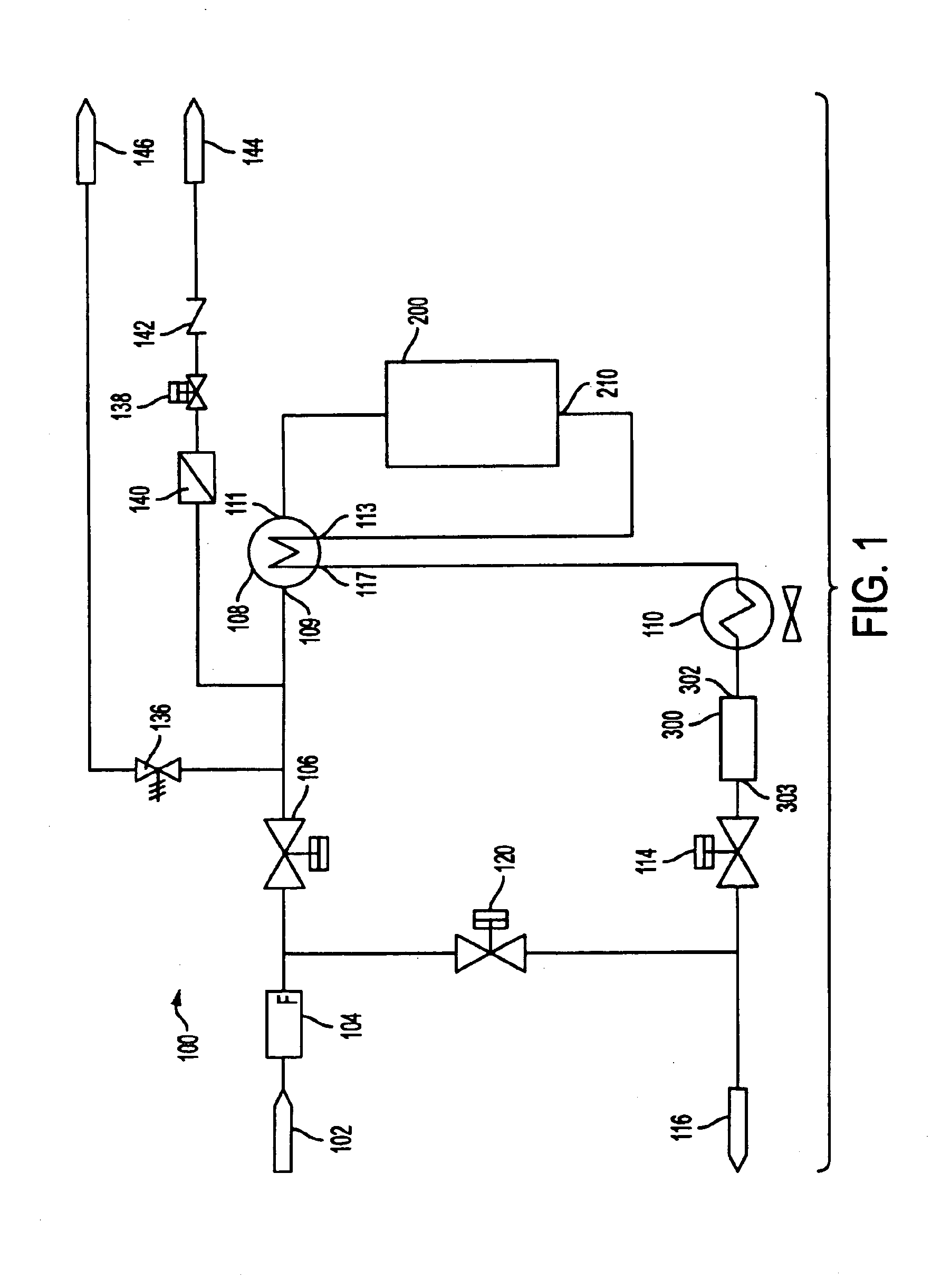

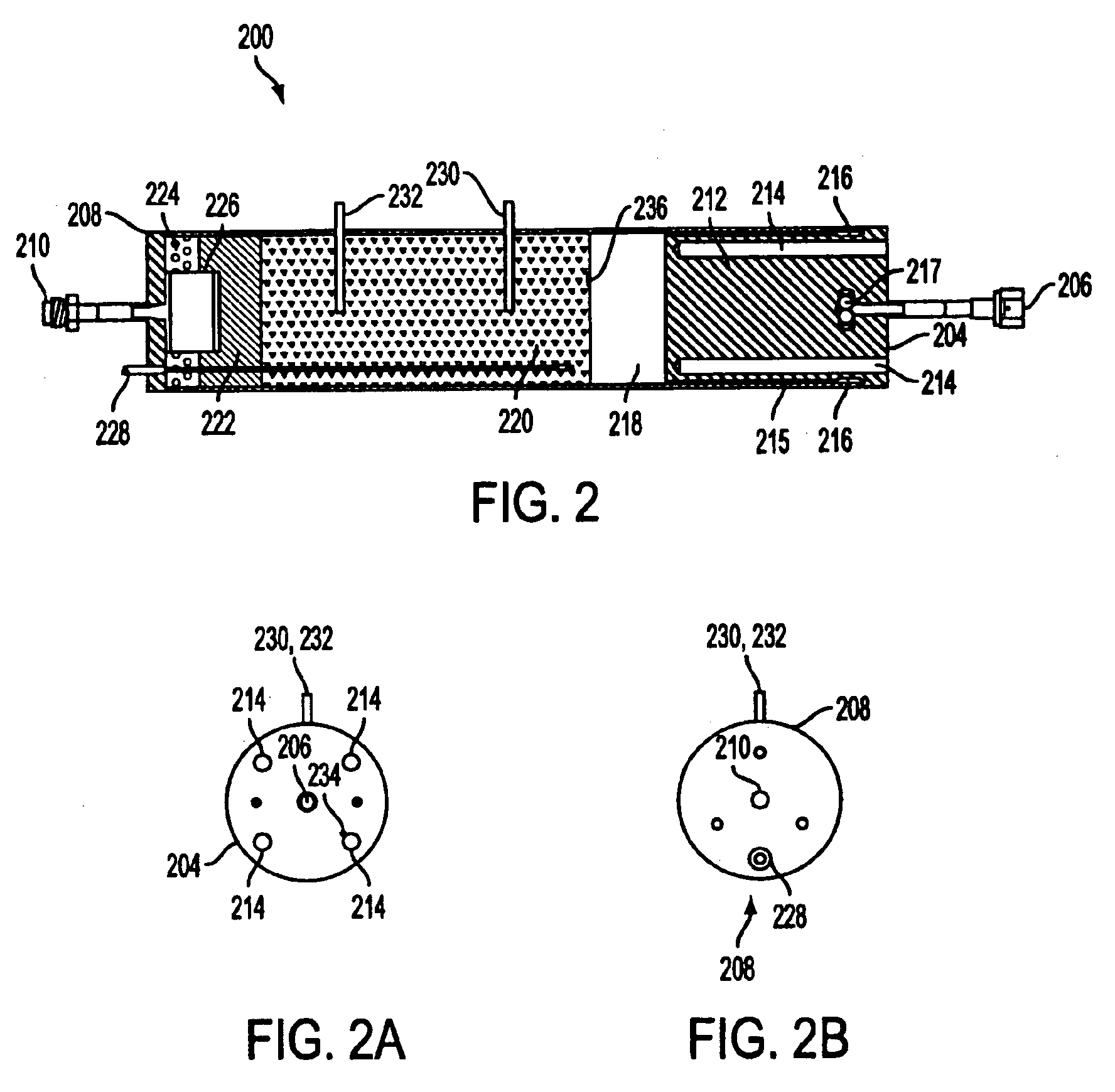

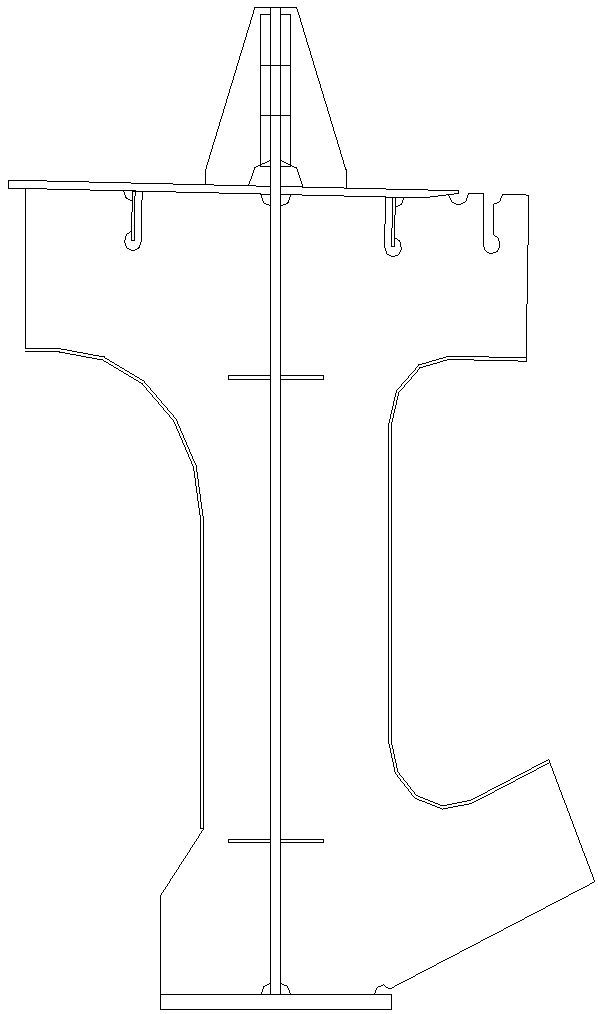

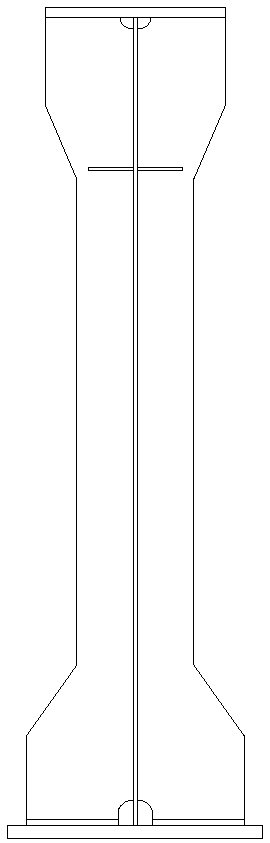

Gas purification system with an integrated hydrogen sorption and filter assembly

InactiveUS6890376B2Easy maintenanceManufacturing EaseCombination devicesNitrogen purification/separationThermal energyHydrogen

The present invention provides a gas purification system with improved efficiency, simpler construction, cost reductions, form factor improvements, and increased durability. The present invention provides cost and form factor improvements through fewer components overall and through utilizing multiple integrated components. Prior art gas purification systems are more bulky and complicated. The present invention achieves increased thermal efficiency through utilization of a regenerative heat exchanger to recapture a portion of the heat energy transferred to the gas during the purification process. Prior art purifiers lacked a regenerative heat exchanger. The present invention integrates the two components into one integrated heater and purification vessel assembly. The present invention integrates the two discrete components into one integrated hydrogen sorption and particle filter assembly. The integrated hydrogen sorption and particle filter assembly is also capable of operating at higher temperatures. This eases maintenance and manufacture. The resulting gas purification system is simpler through utilizing fewer components, smaller by utilizing fewer and integrated components, and reduced cost through fewer components, smaller components and through reduced manufacture labor requirements.

Owner:ENTEGRIS GP INC

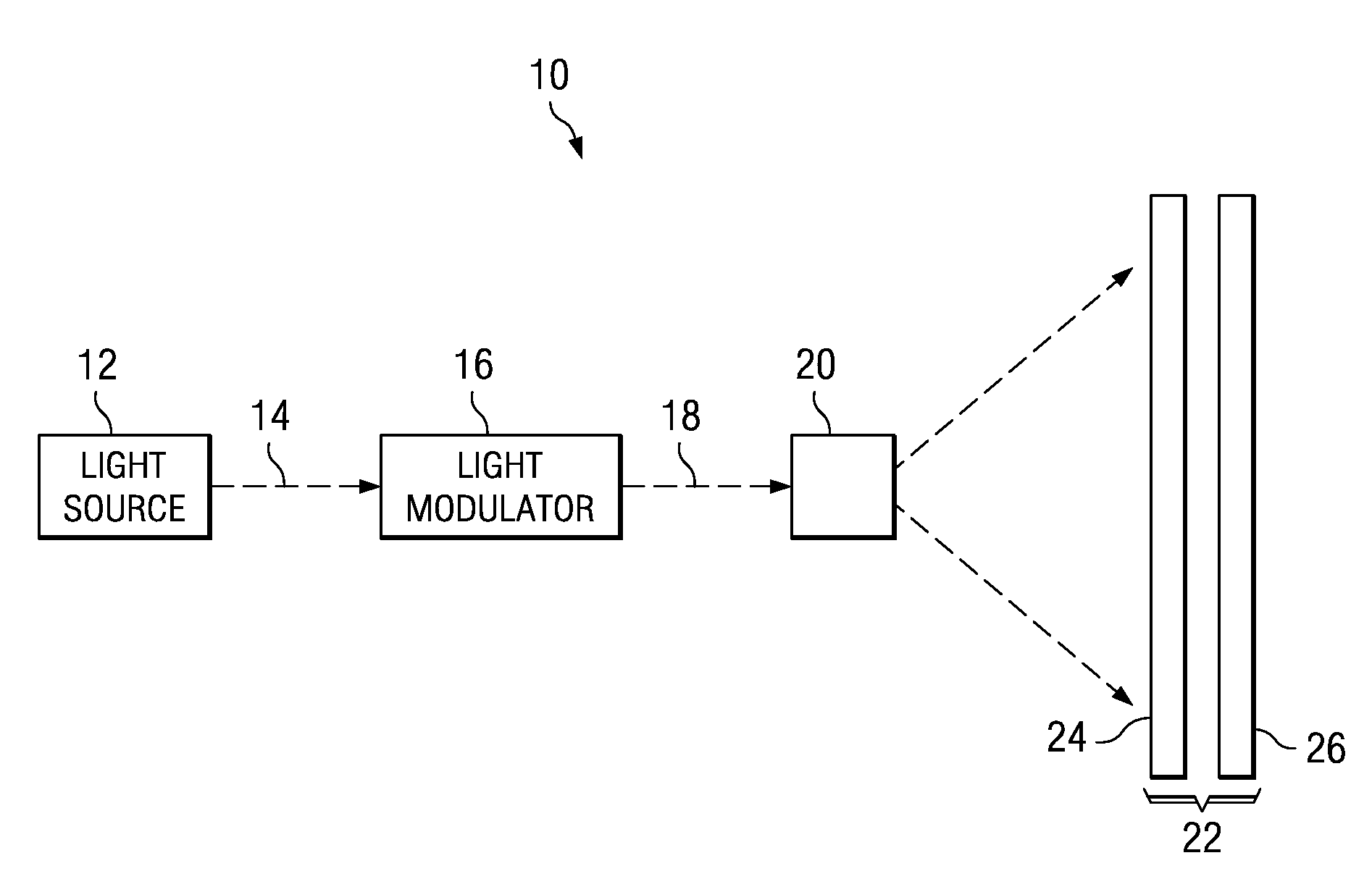

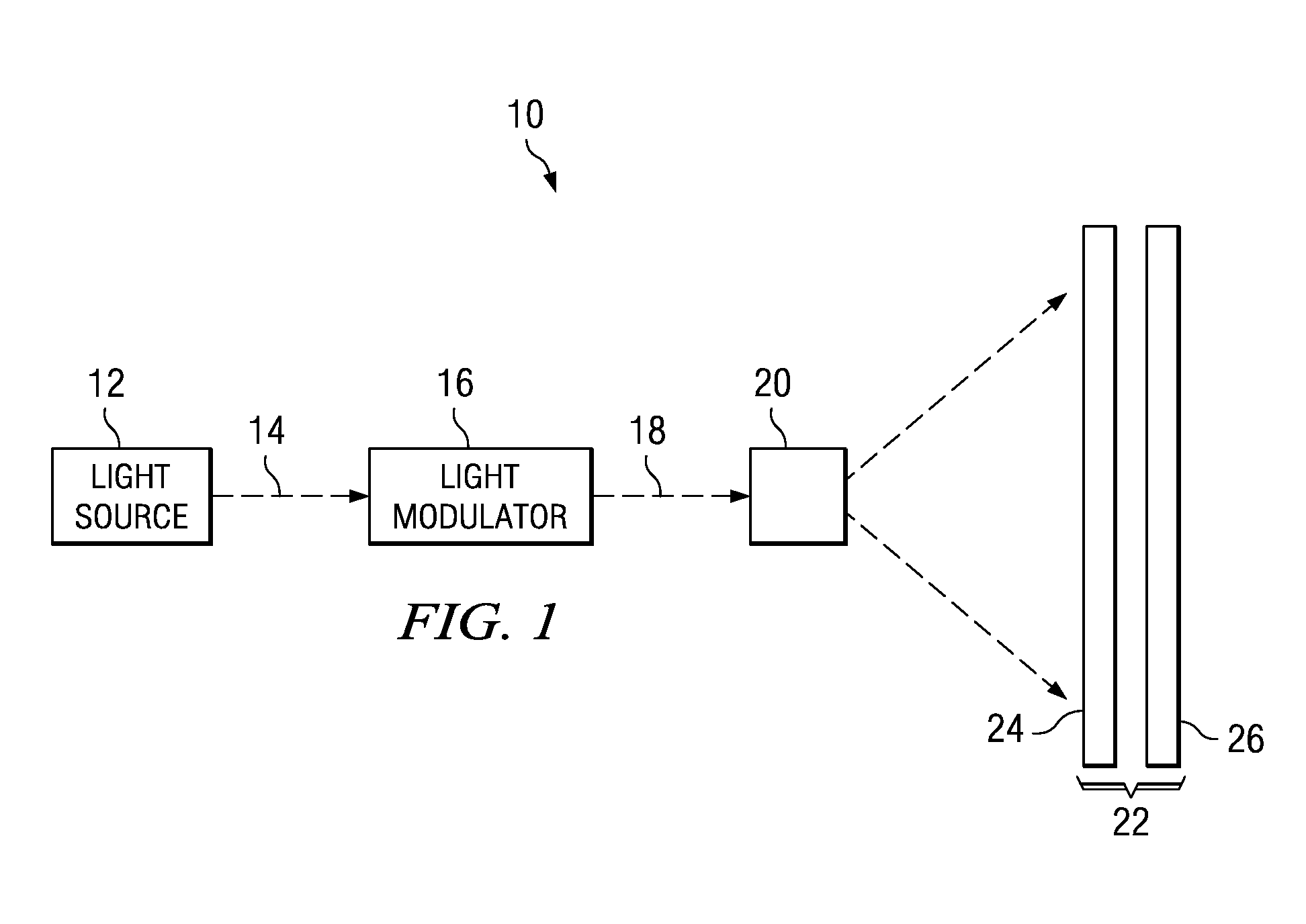

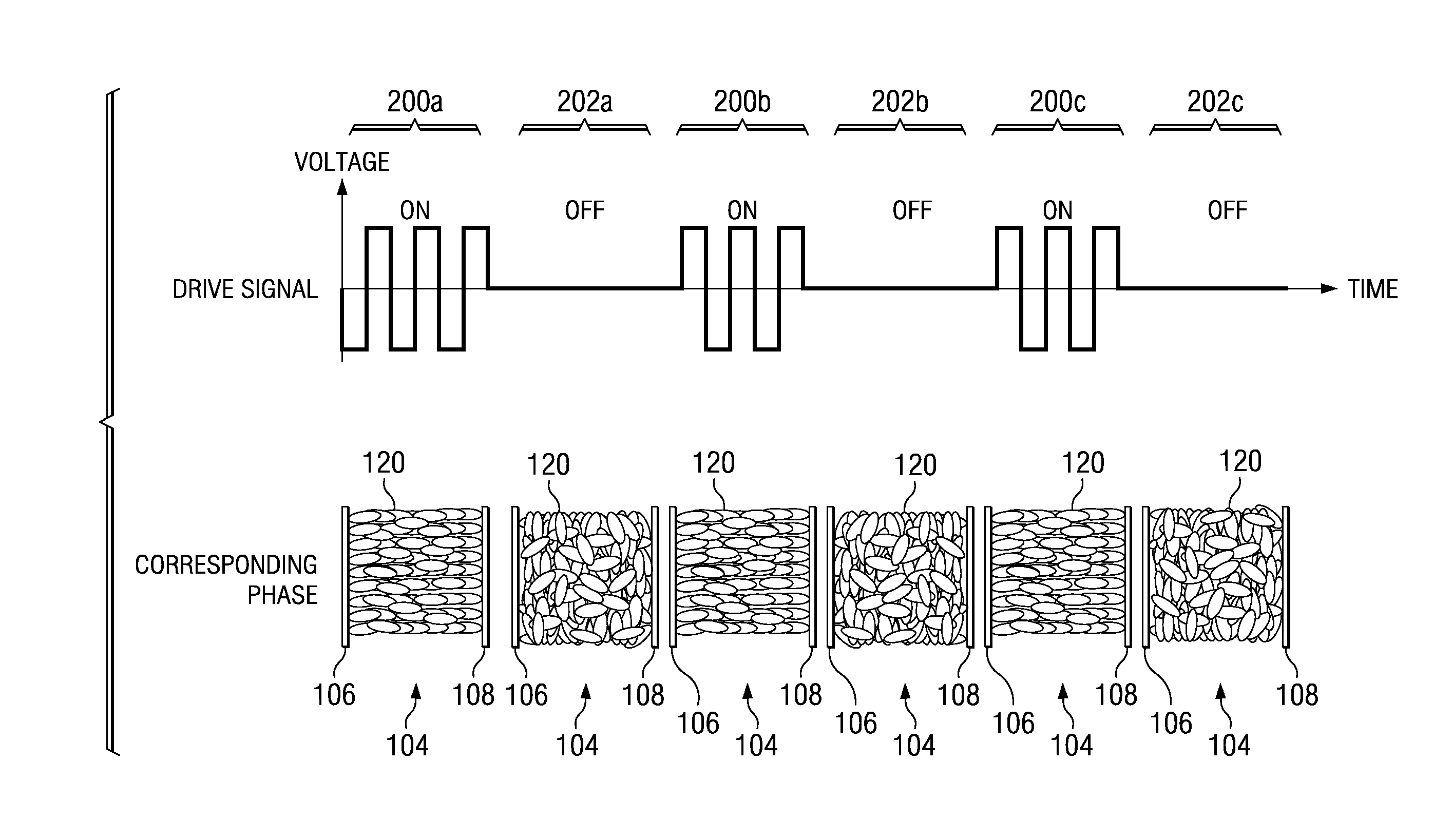

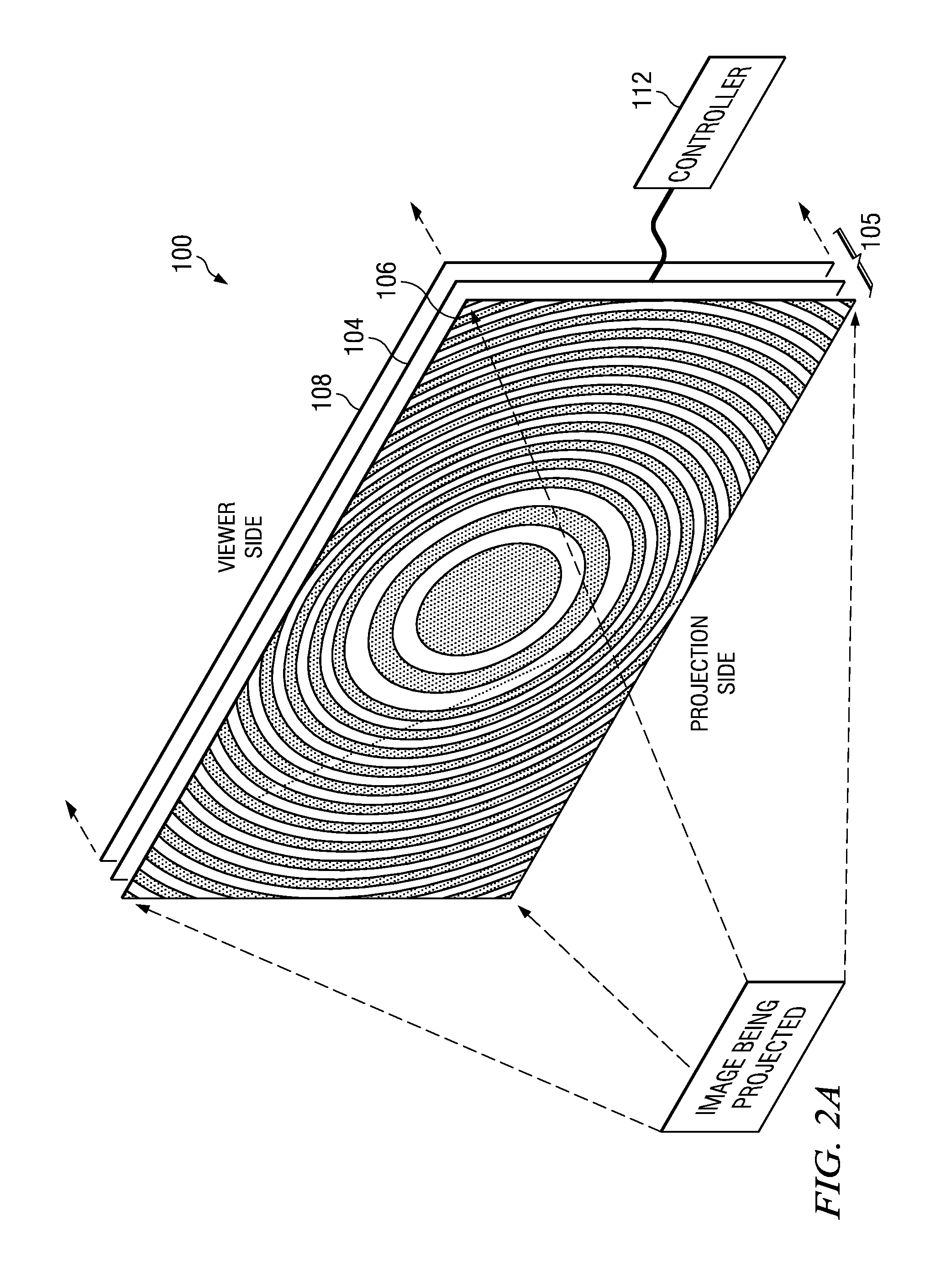

Method and apparatus for reducing speckle in coherent light

ActiveUS20090033814A1Speckle reductionReduce spatial coherenceStatic indicating devicesColor television detailsElectricityLight beam

According to one embodiment, a method for reducing speckle in an image produced from a coherent light source includes directing a beam of coherent light at an electrically controlled diffuser. An electrical signal is applied to the electrically controlled diffuser to produce an electrical field across the electrically controlled diffuser layer. At least one of an amplitude and a frequency of the electrical signal are varied to transition the controlled diffuser between a first state and a second state. The varied application of the electrical signal operates to reduce spatial coherence in an image projected through the electrically controlled diffuser.

Owner:TEXAS INSTR INC

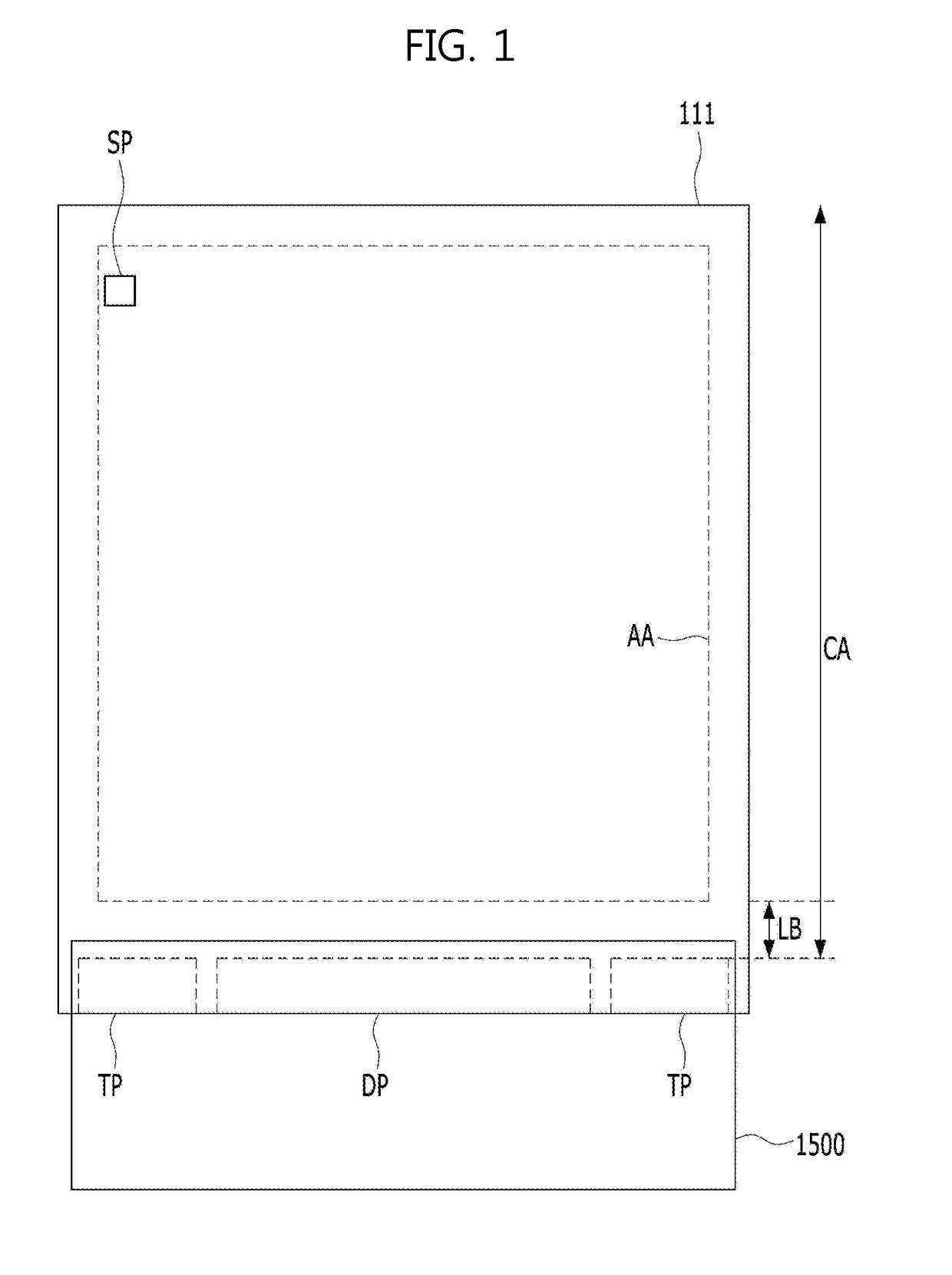

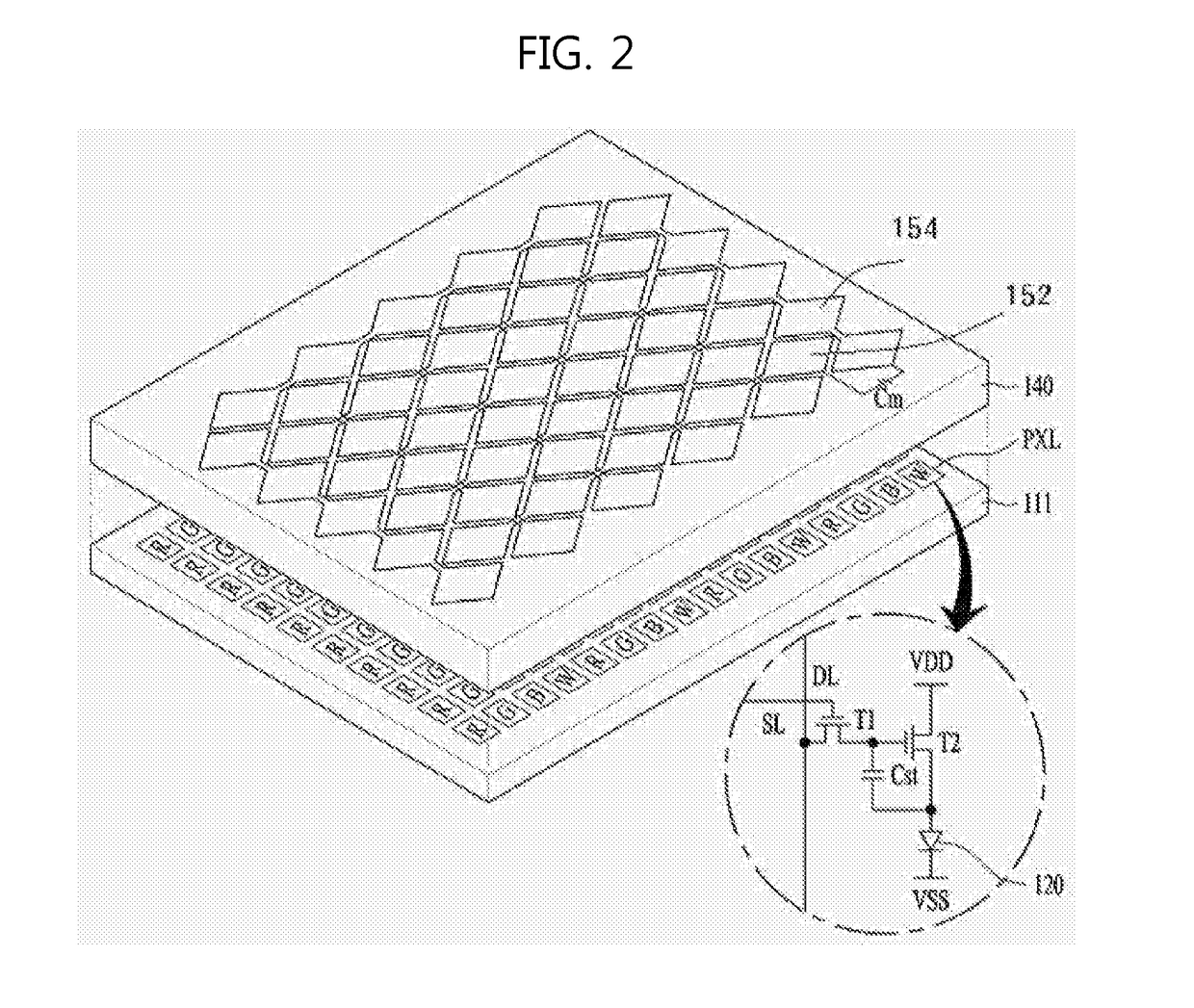

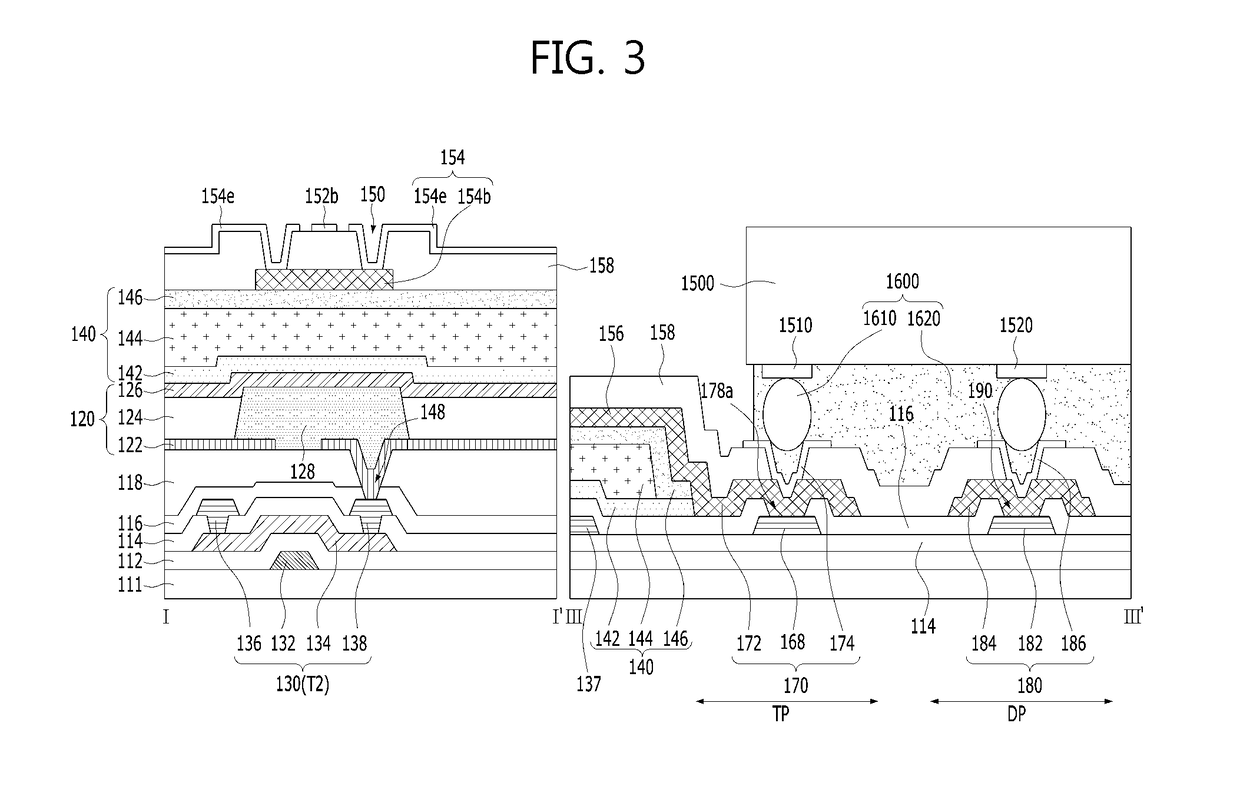

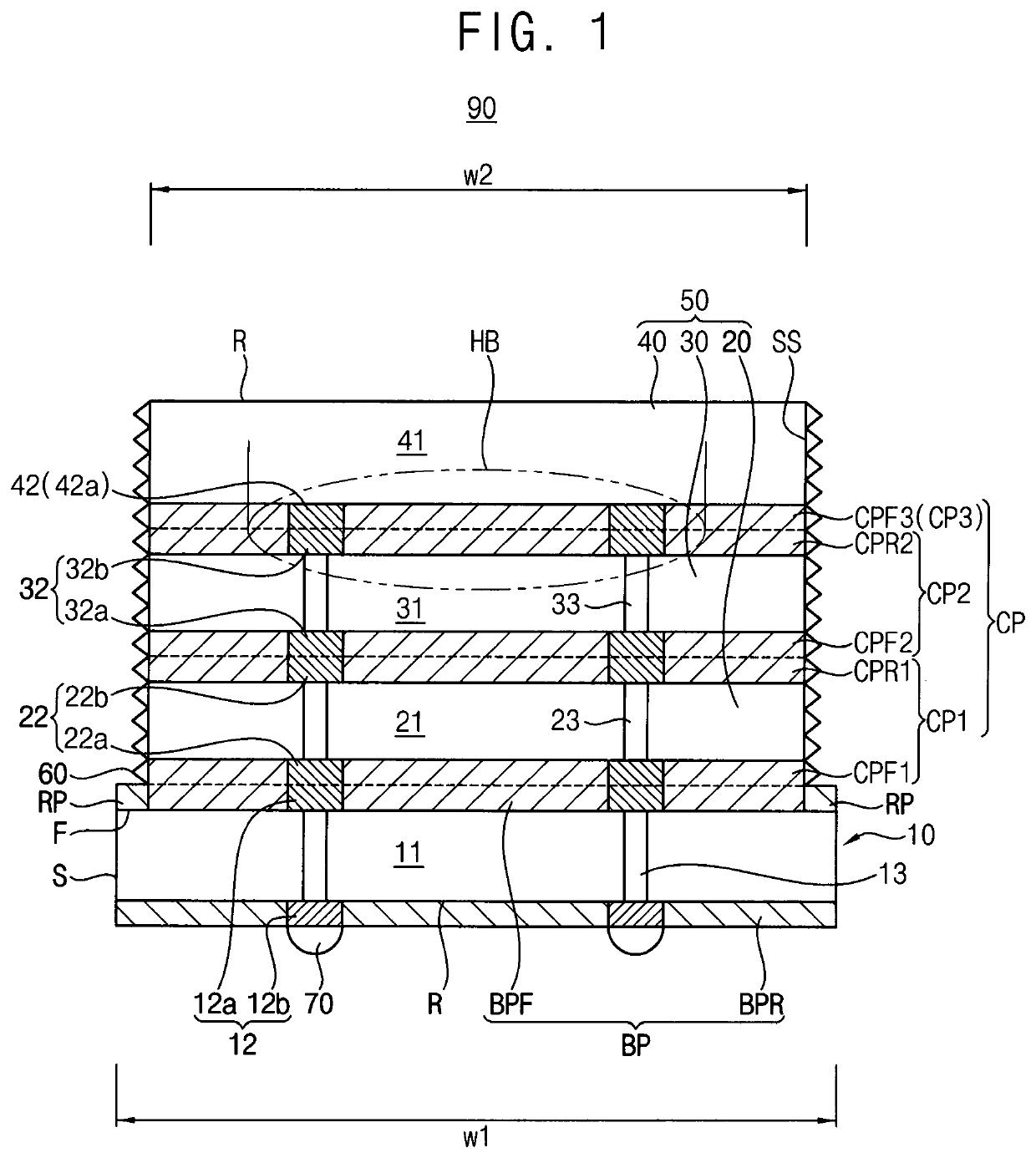

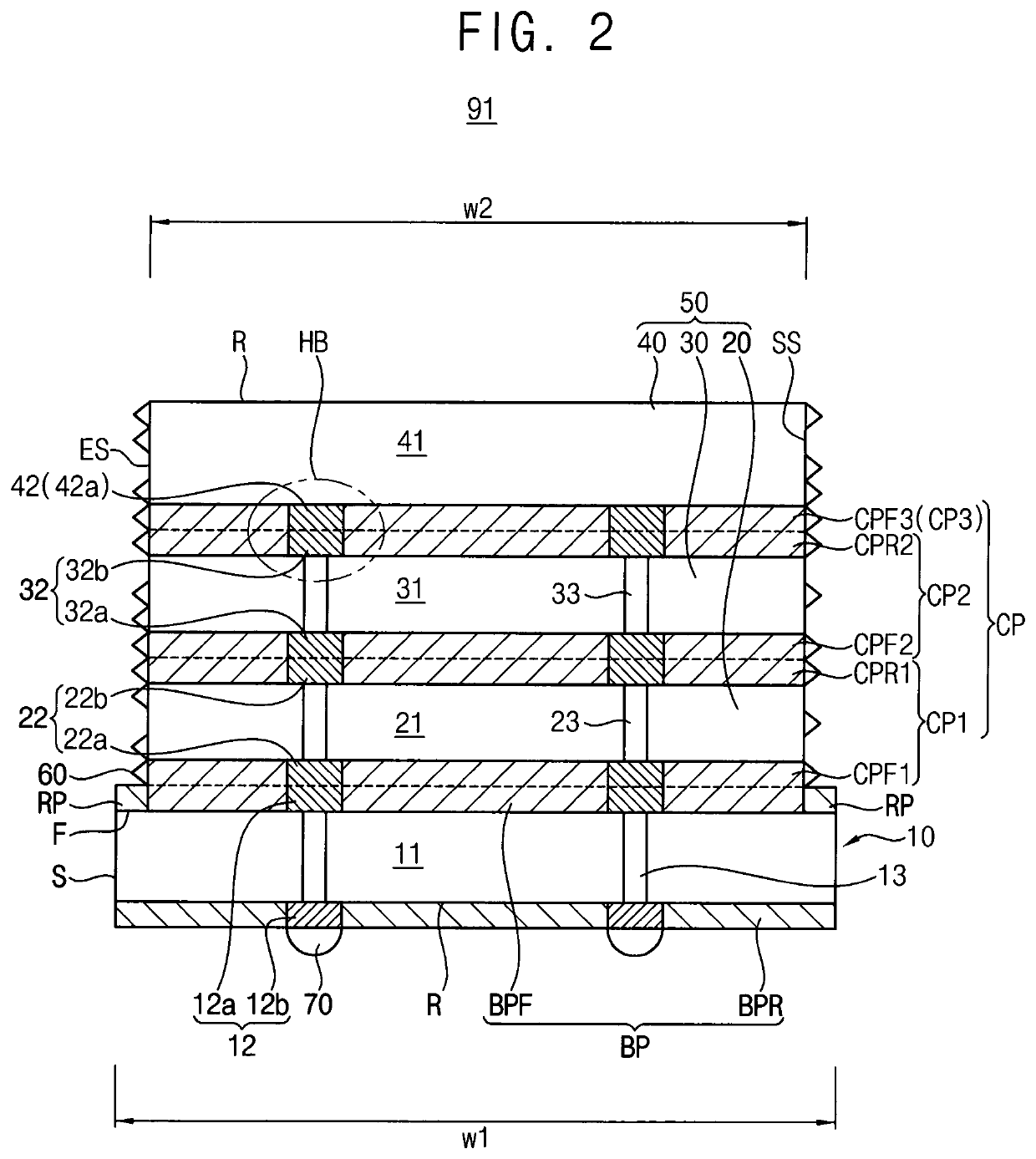

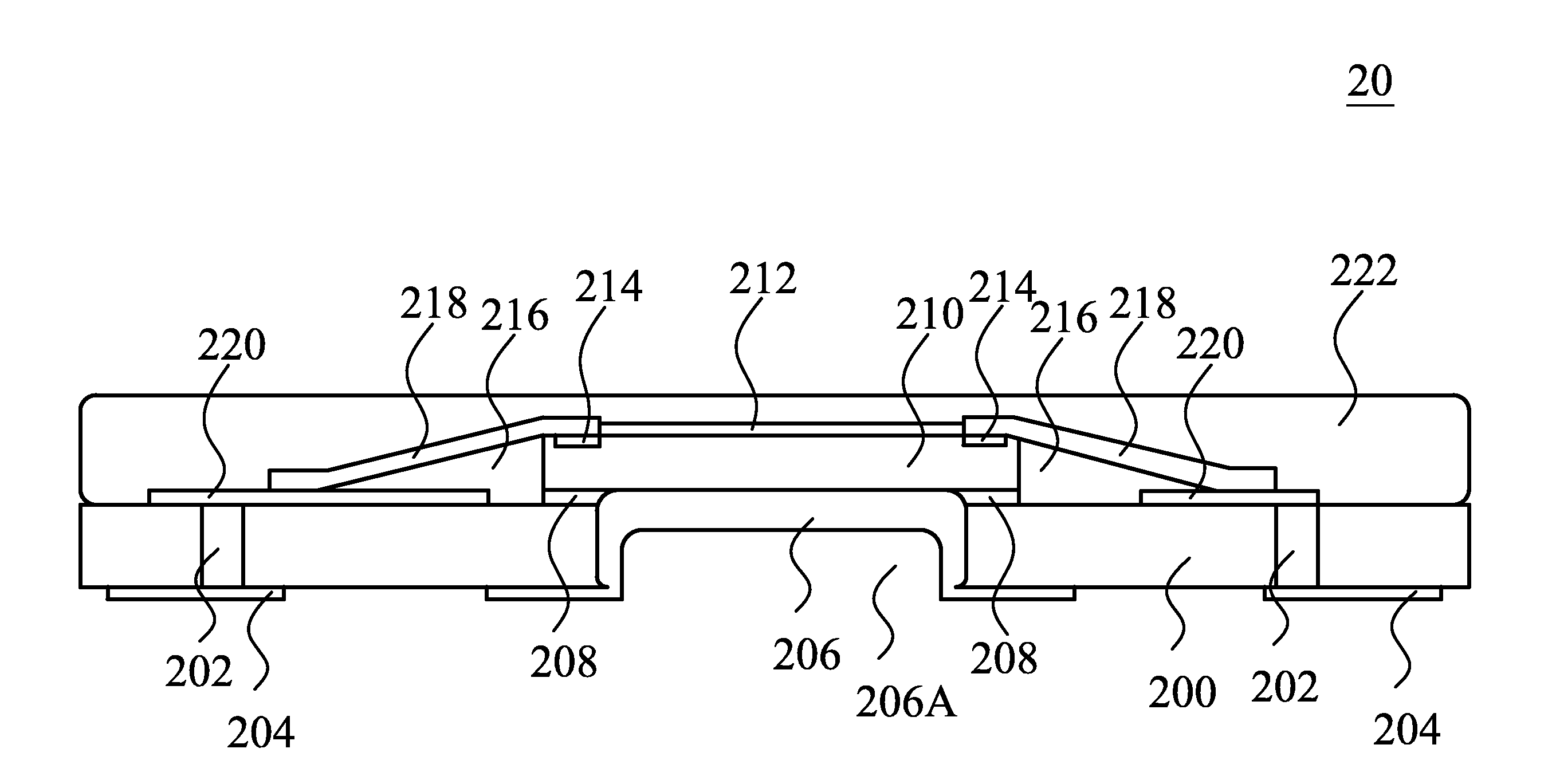

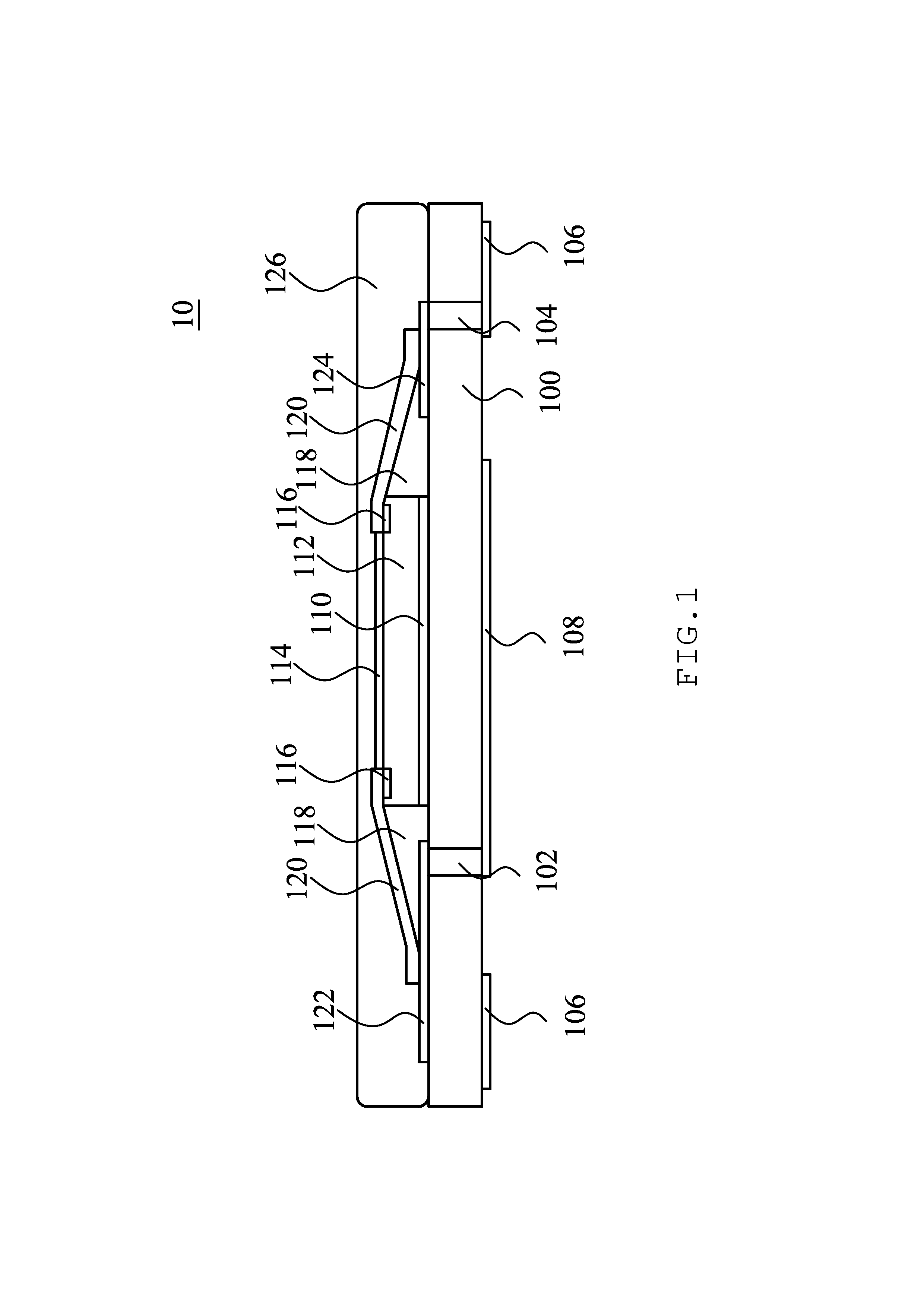

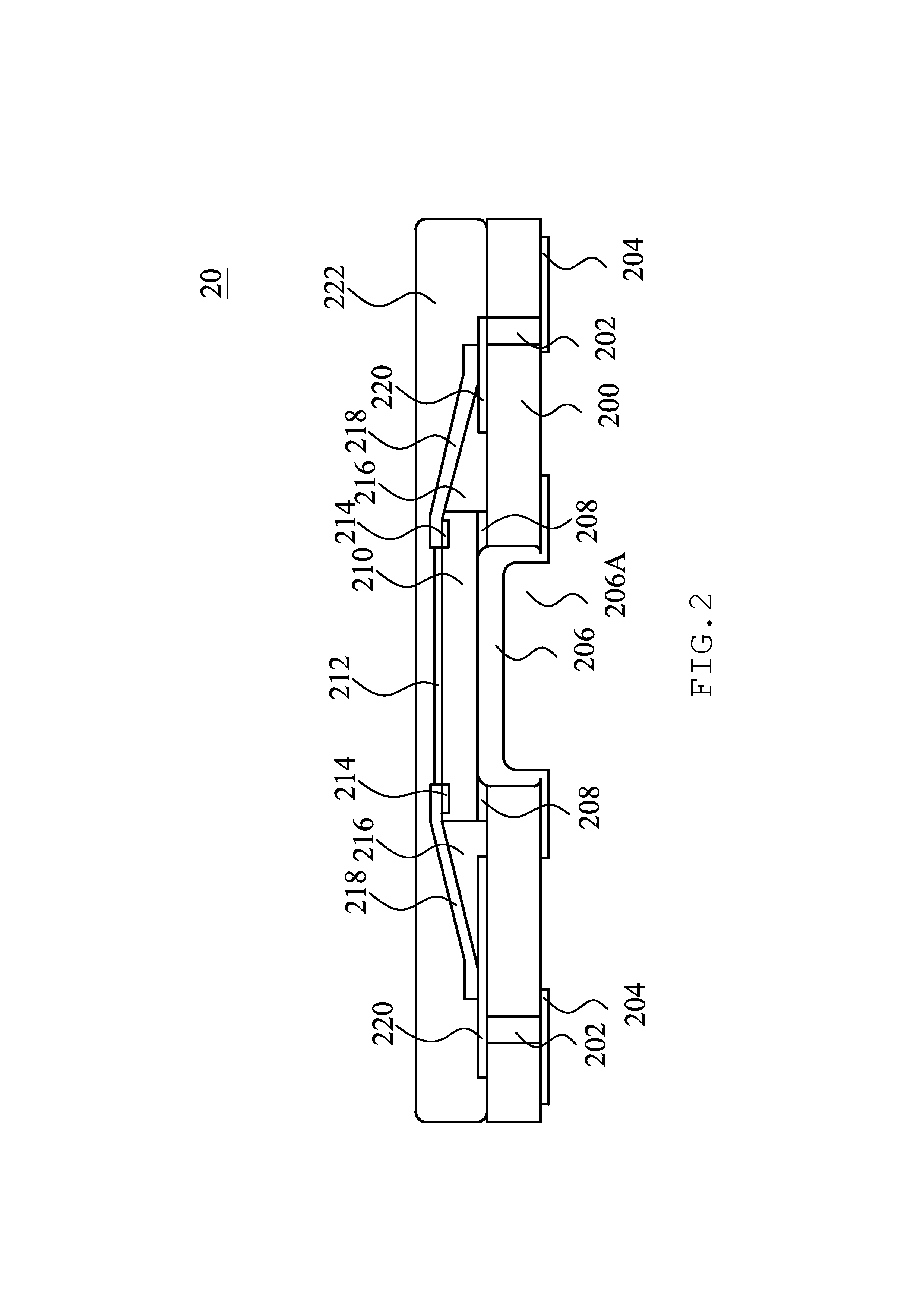

Organic light-emitting display device having touchscreen and method of manufacturing the same

ActiveUS20180358413A1Convenient ArrangementIncreased form factorFinal product manufactureSolid-state devicesDisplay boardDisplay device

Disclosed is an organic light-emitting display device having a touchscreen in which the configuration of a pad unit and a circuit board connected to the pad unit is simplified, resulting in bonding stability and an improved form factor of the device, and a method of manufacturing the same. In the organic light-emitting display device having the touchscreen in which a touch electrode is directly provided on an encapsulation layer, a touch pad and a display pad are disposed parallel to each other on the same side so as to be connected to a flexible printed circuit board with a difference in height therebetween. Thereby, increased bonding reliability and an increased effective display area are achieved.

Owner:LG DISPLAY CO LTD

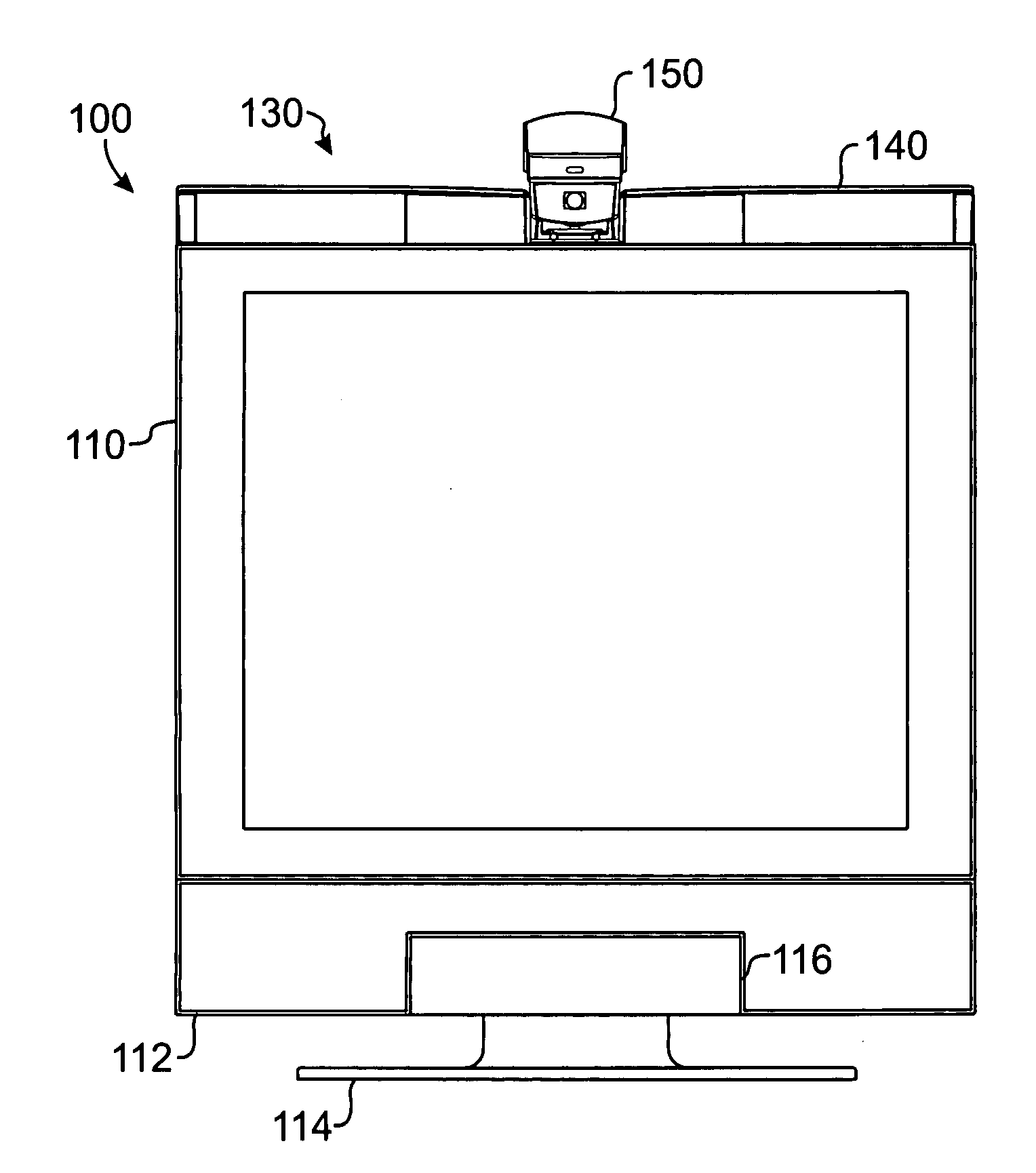

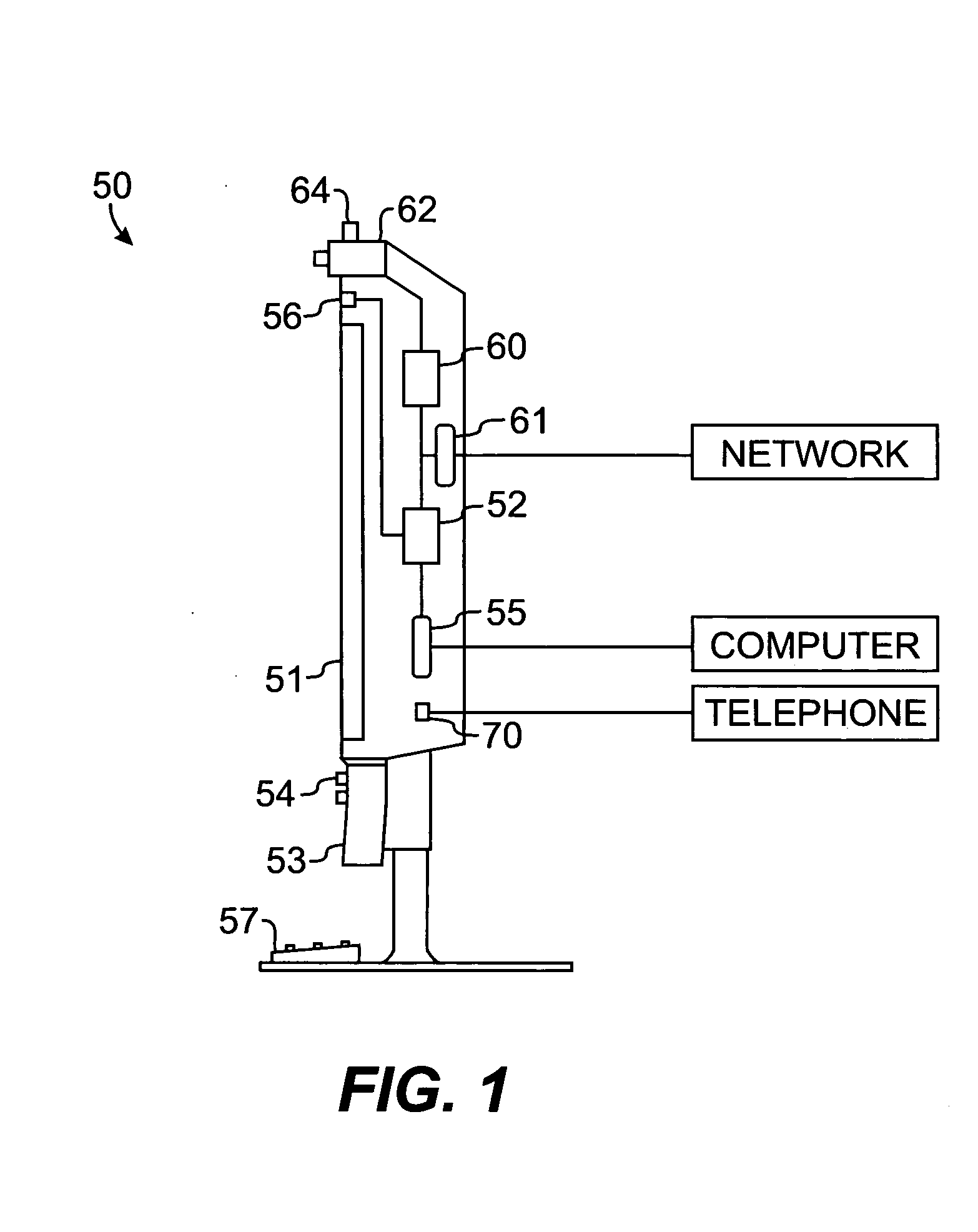

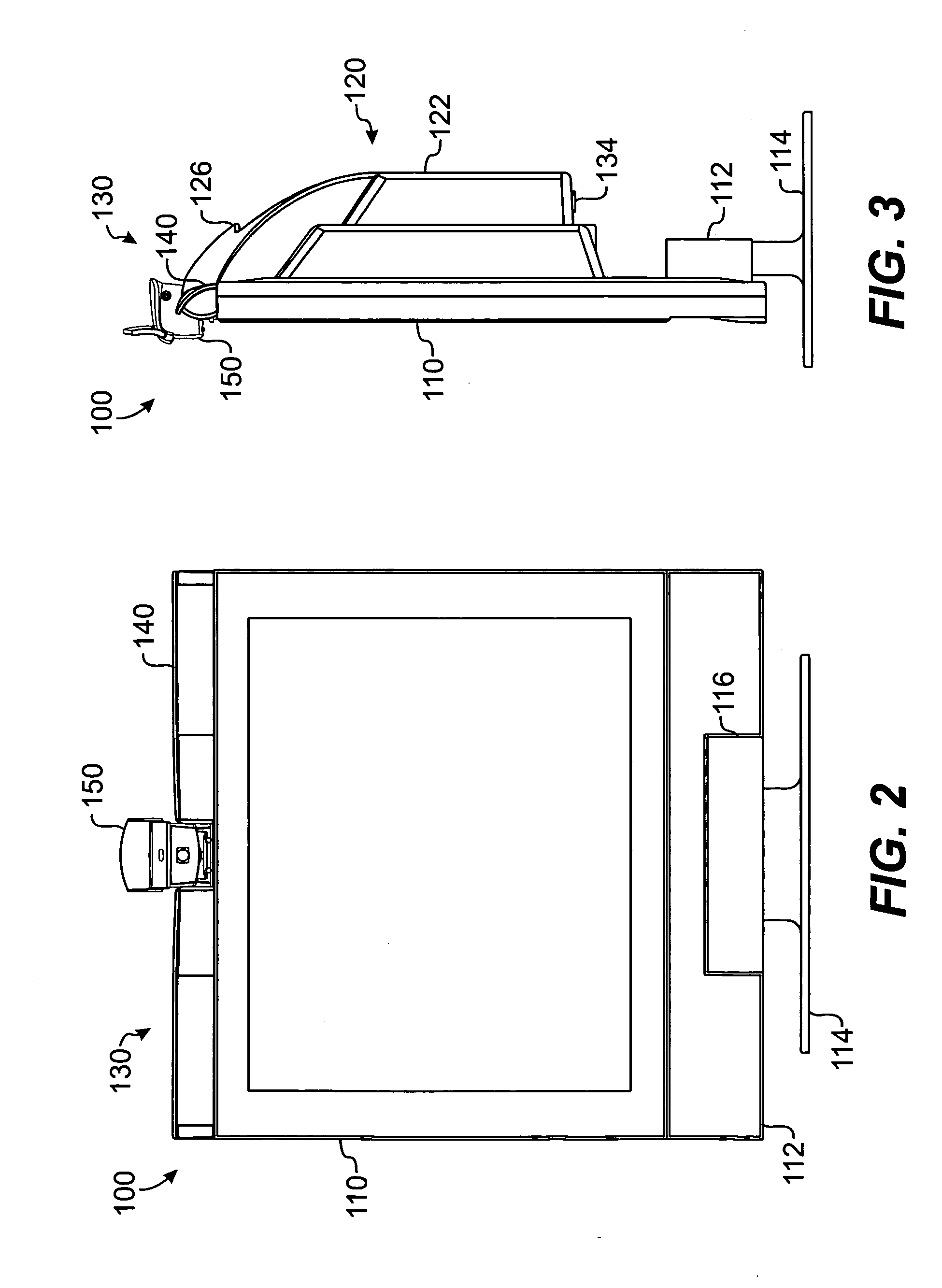

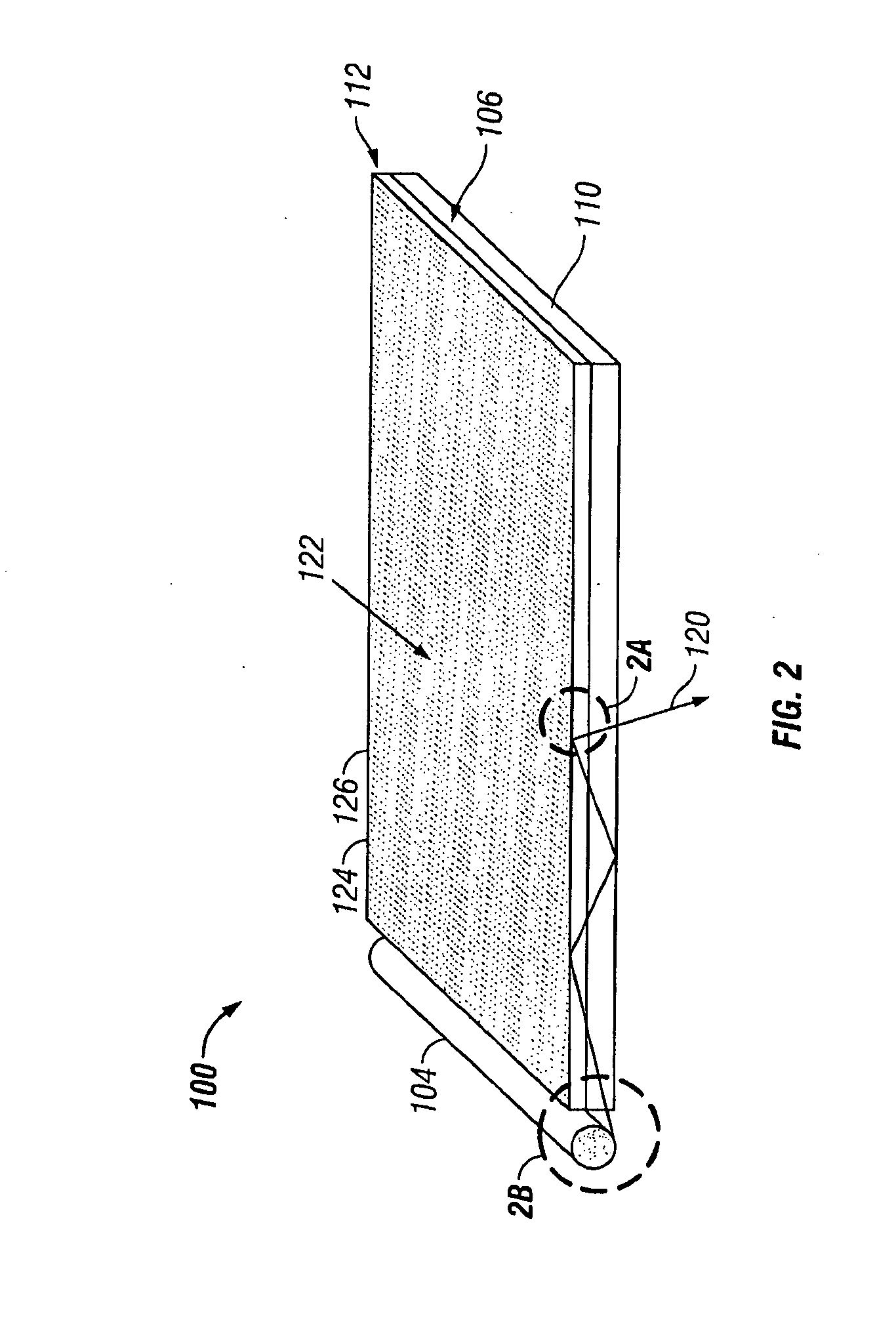

Integrated desktop videoconferencing system

ActiveUS20050231587A1Increased form factorTransducer detailsTwo-way working systemsComputer monitorDisplay device

Disclosed herein is a videoconferencing system that has been integrated into a flat panel display or computer monitor. The integration provides an improved form factor for the videoconferencing system. In addition, the integration offers the dual use as a computer monitor and as a videoconferencing system. The system includes a videoconferencing module attaching to a back of the flat panel display. The videoconferencing module has videoconferencing electronics that electronically connect to integral electronics of the display. The system also includes a microphone / camera module attaching to a top of the flat panel display. The microphone / camera module has a camera and microphone that both electronically connect to the videoconferencing electronics.

Owner:HEWLETT PACKARD DEV CO LP

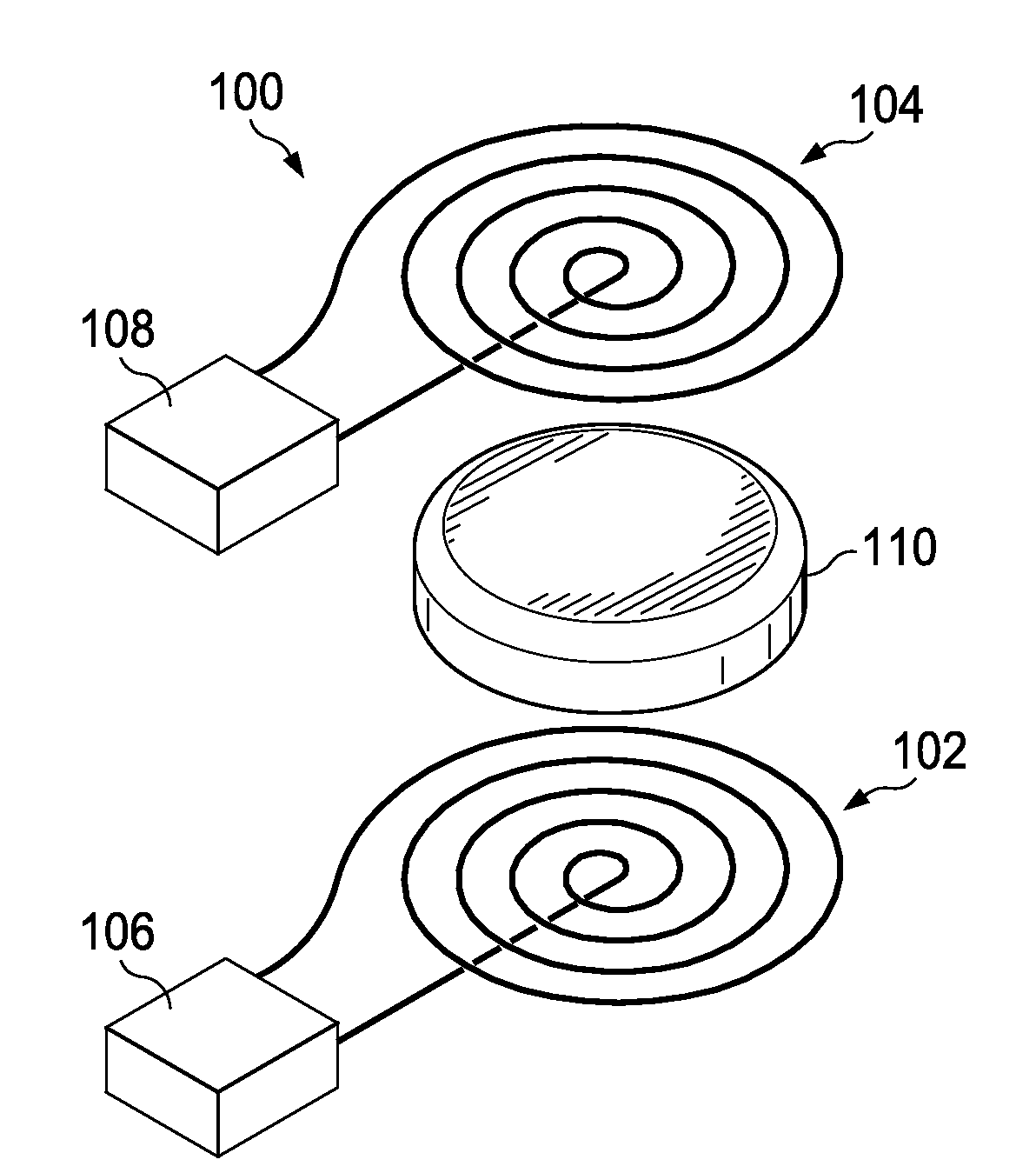

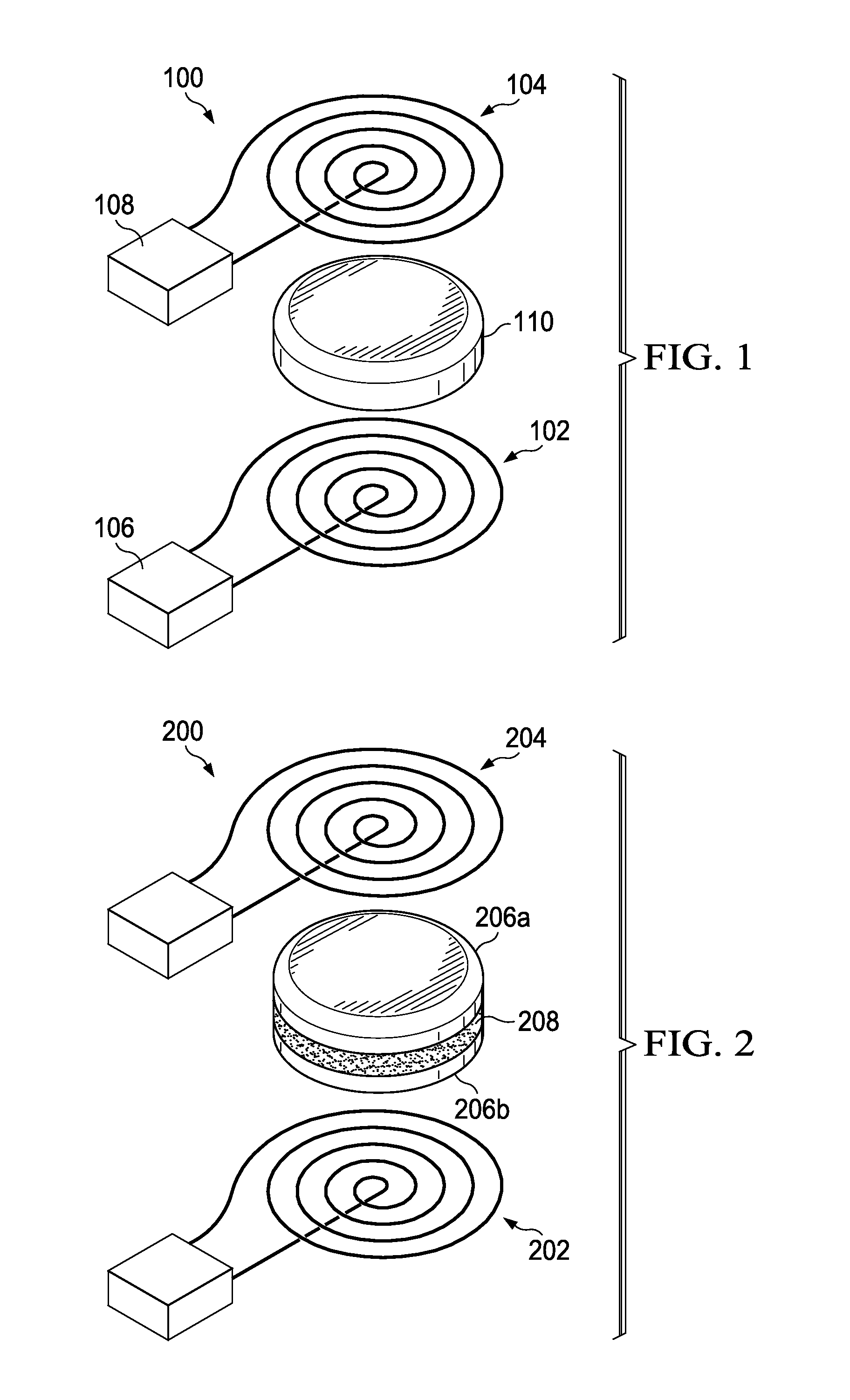

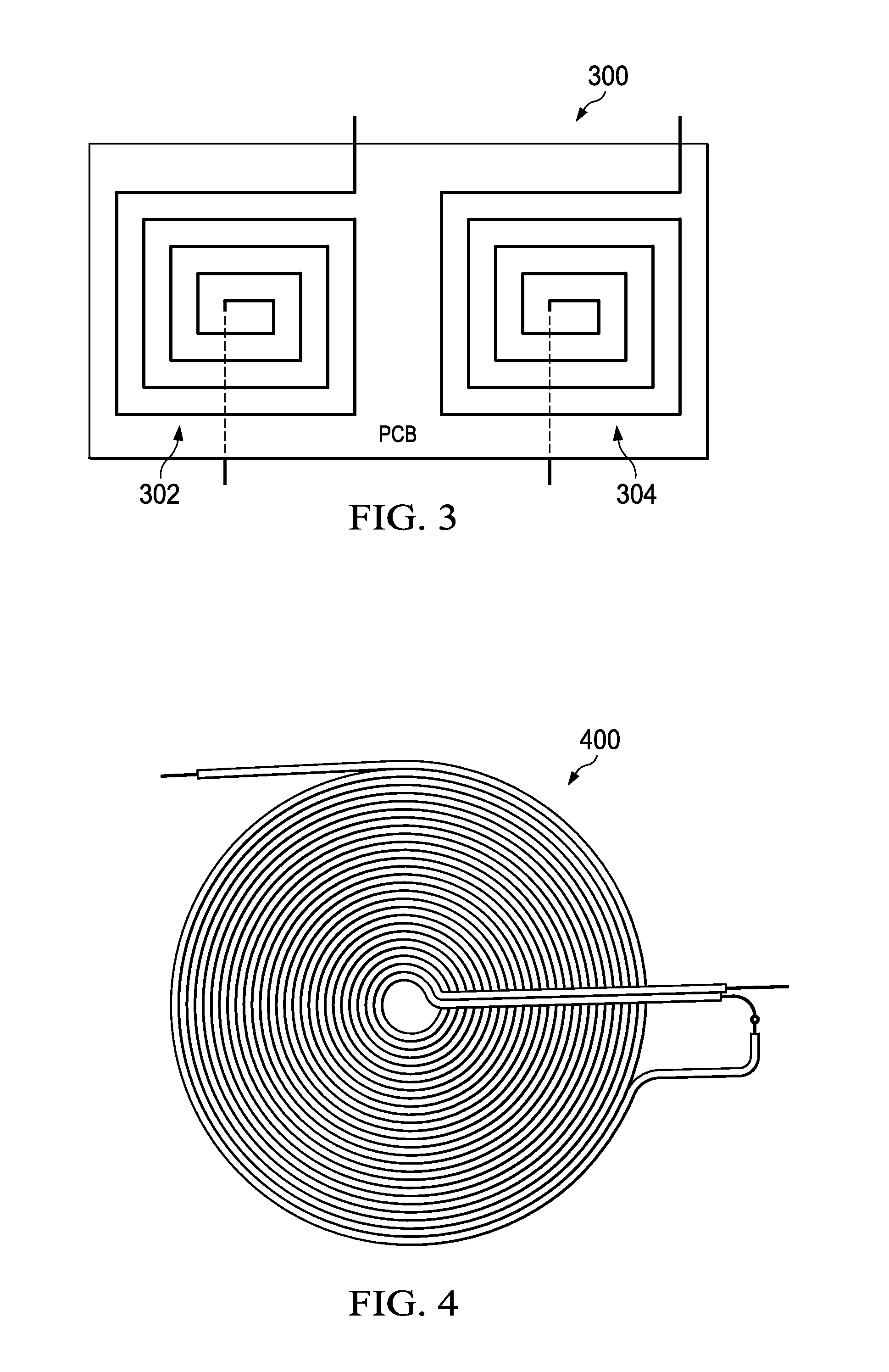

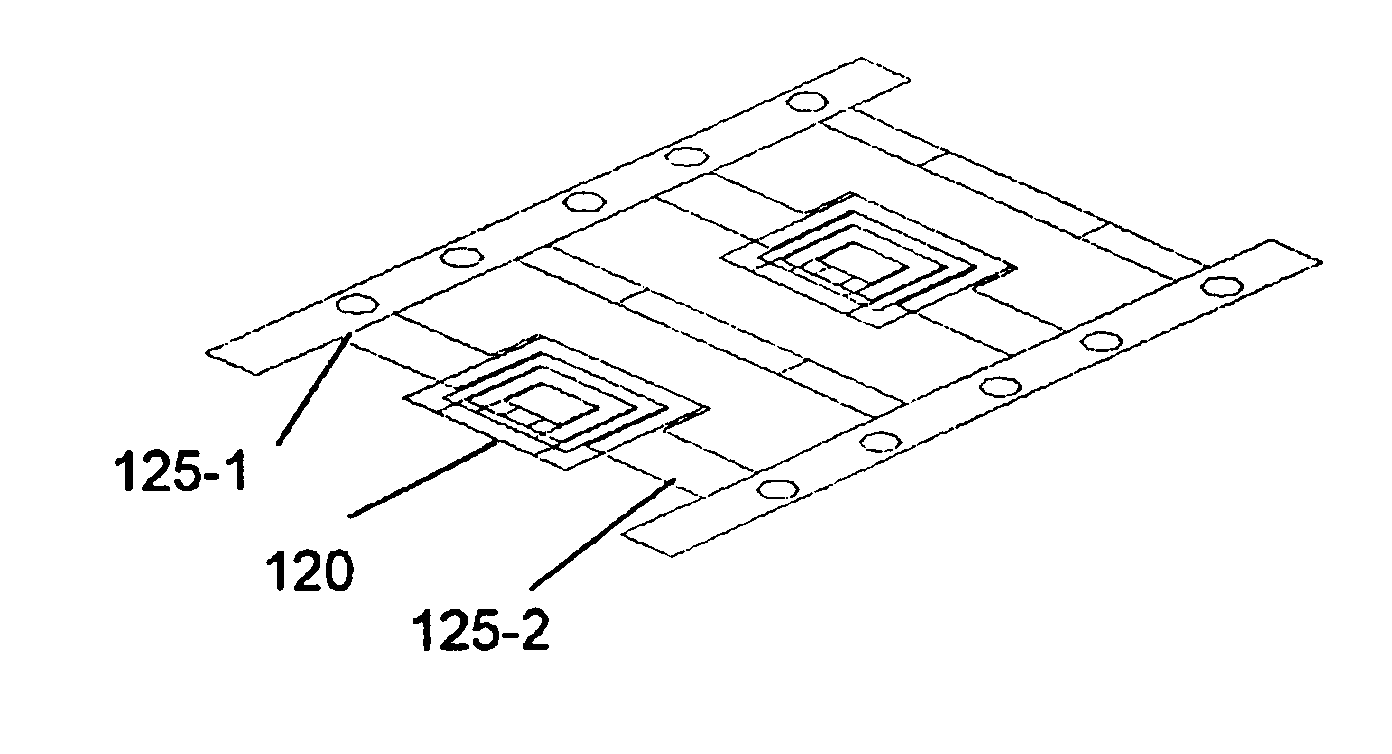

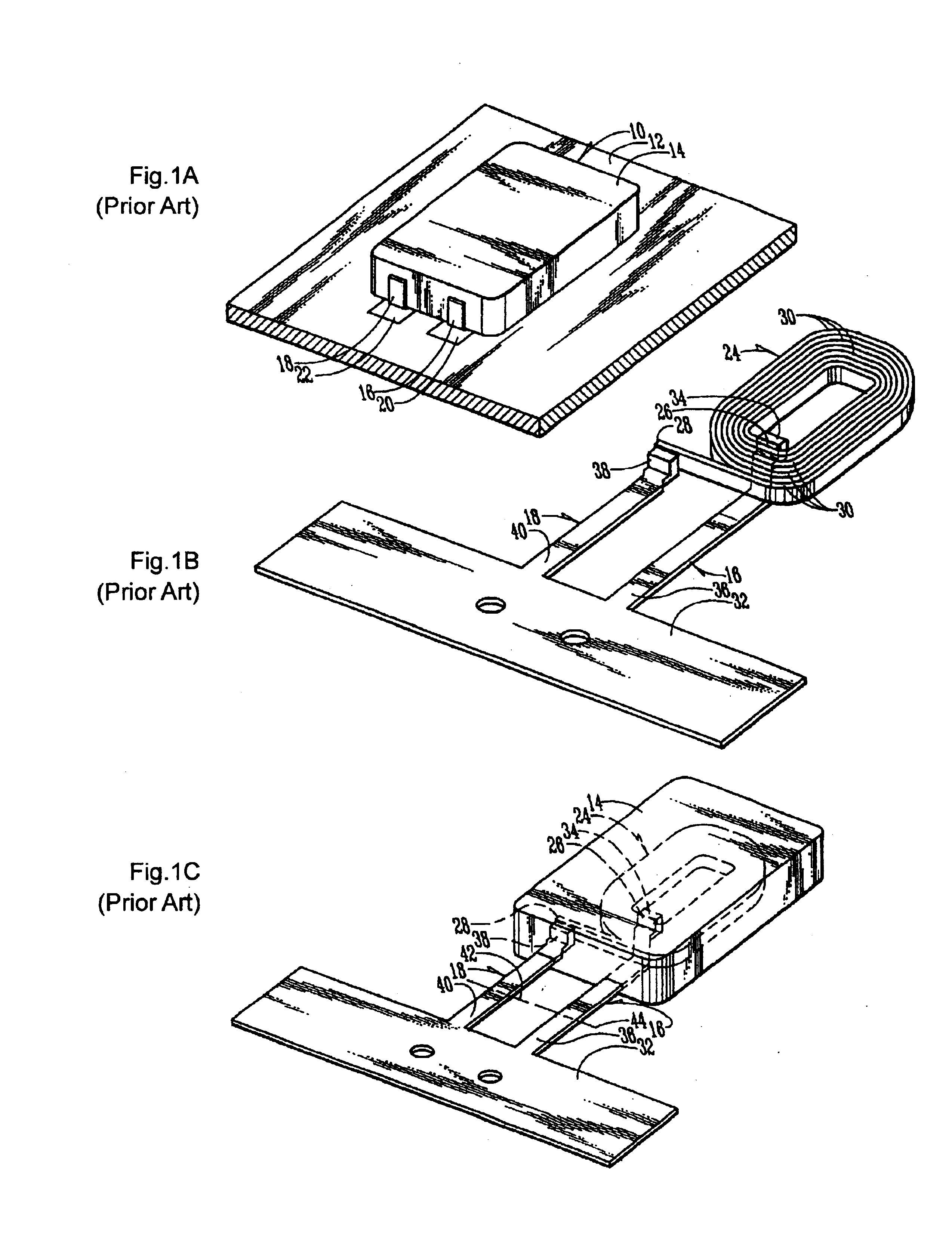

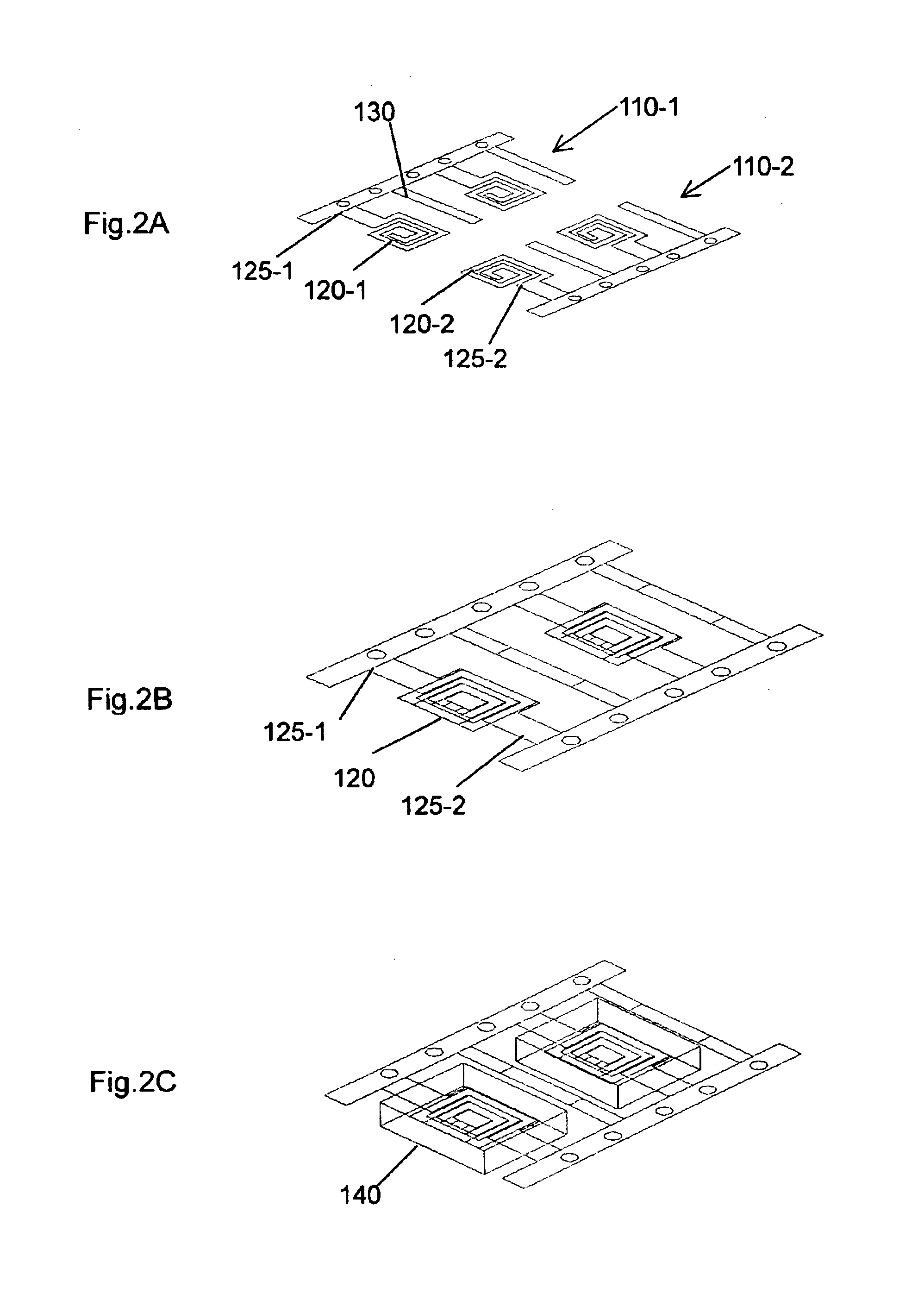

Multiple Coil System

InactiveUS20120104999A1Increased form factorLow costNear-field transmissionTransformersInductorTransmitter

Multiple coil systems and methods are disclosed in which transmitter and receiver inductors, or coils, are coupled in a configuration for wirelessly transferring data and / or power among them. In preferred implementations, the systems and methods are used for transmitting both power and data using pairs of coupled coils. One preferred aspect of the invention is that the coils are not permanently affixed in physical proximity to one another, but can be moved and / or interchanged.

Owner:TRIUNE IP

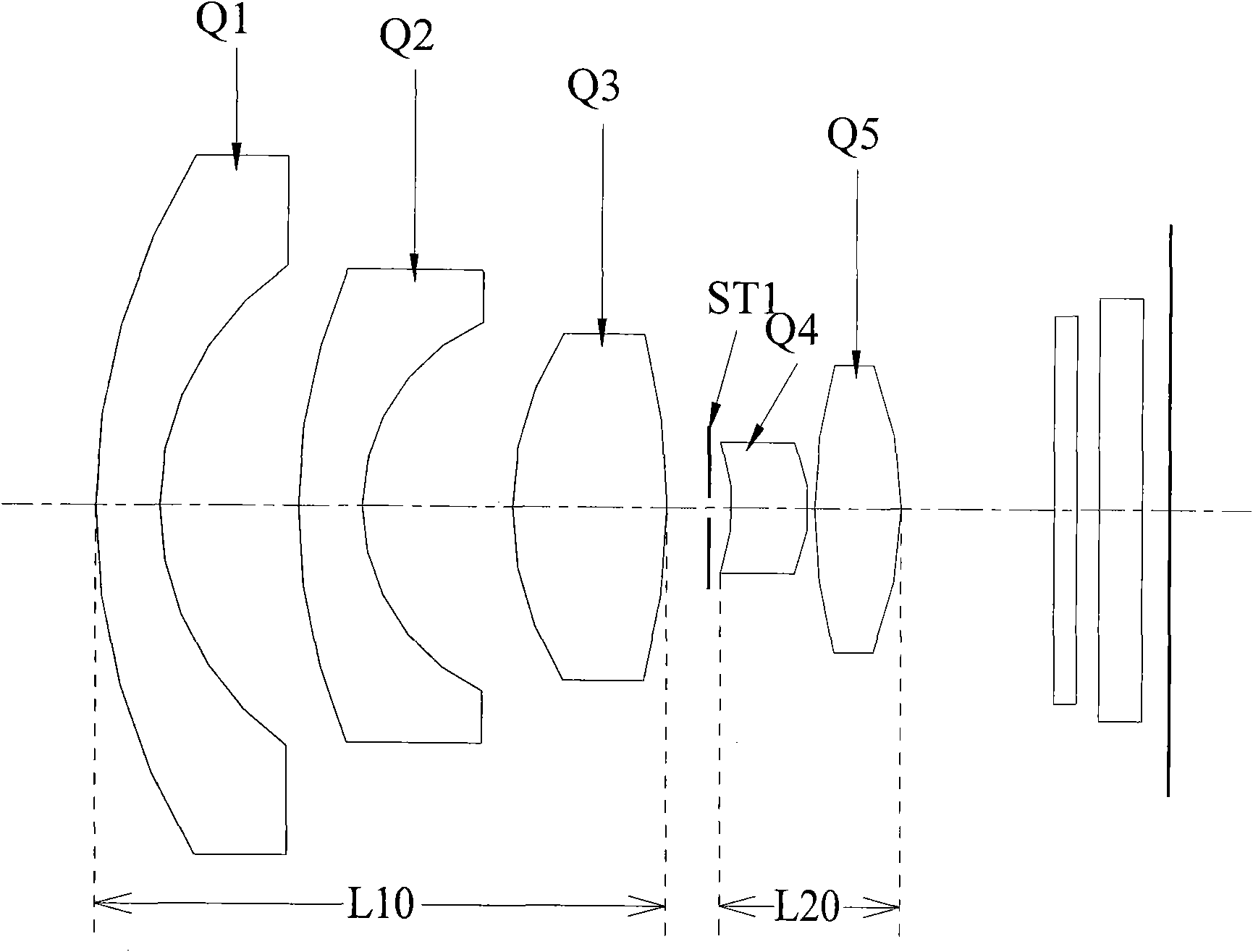

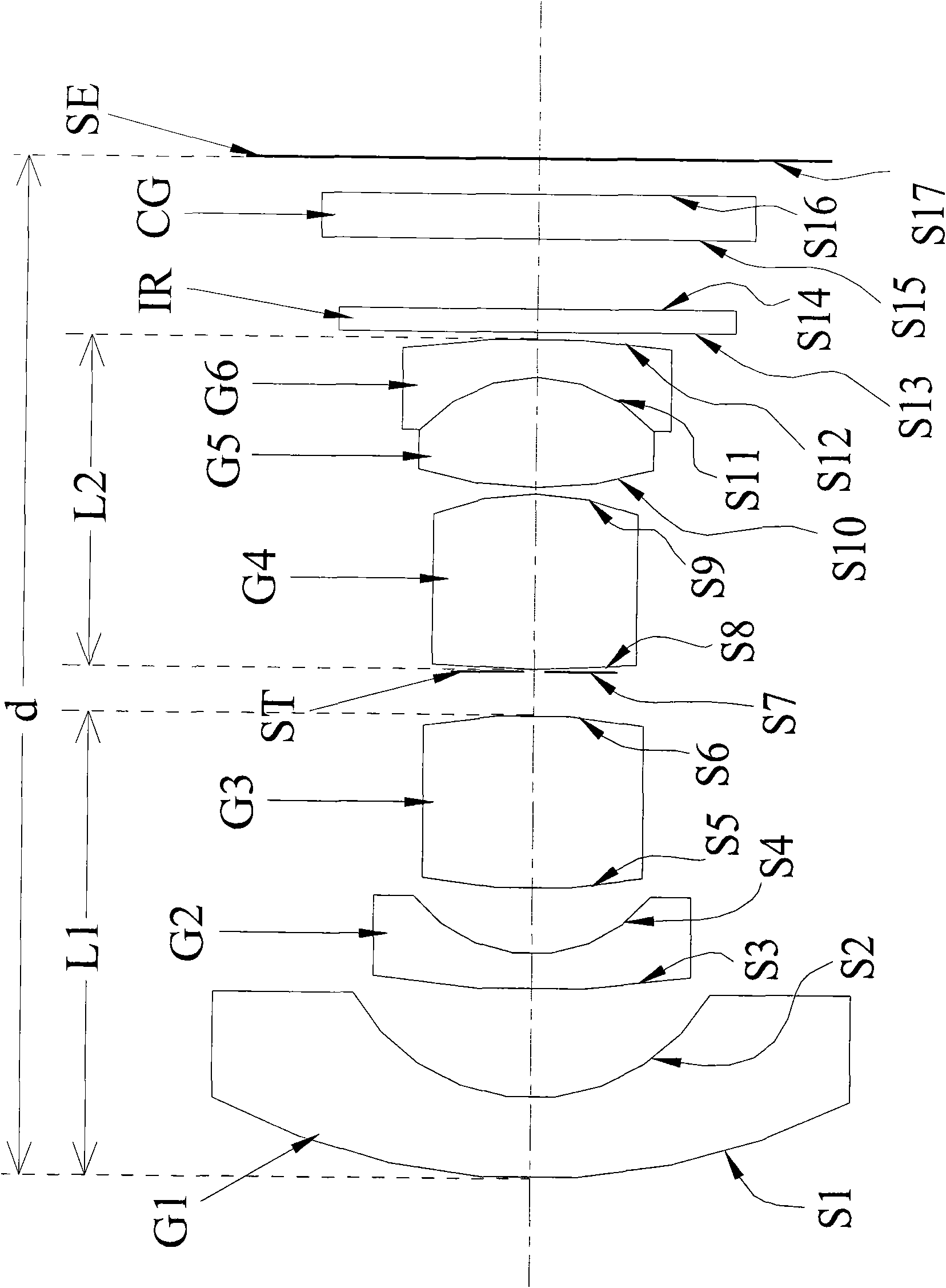

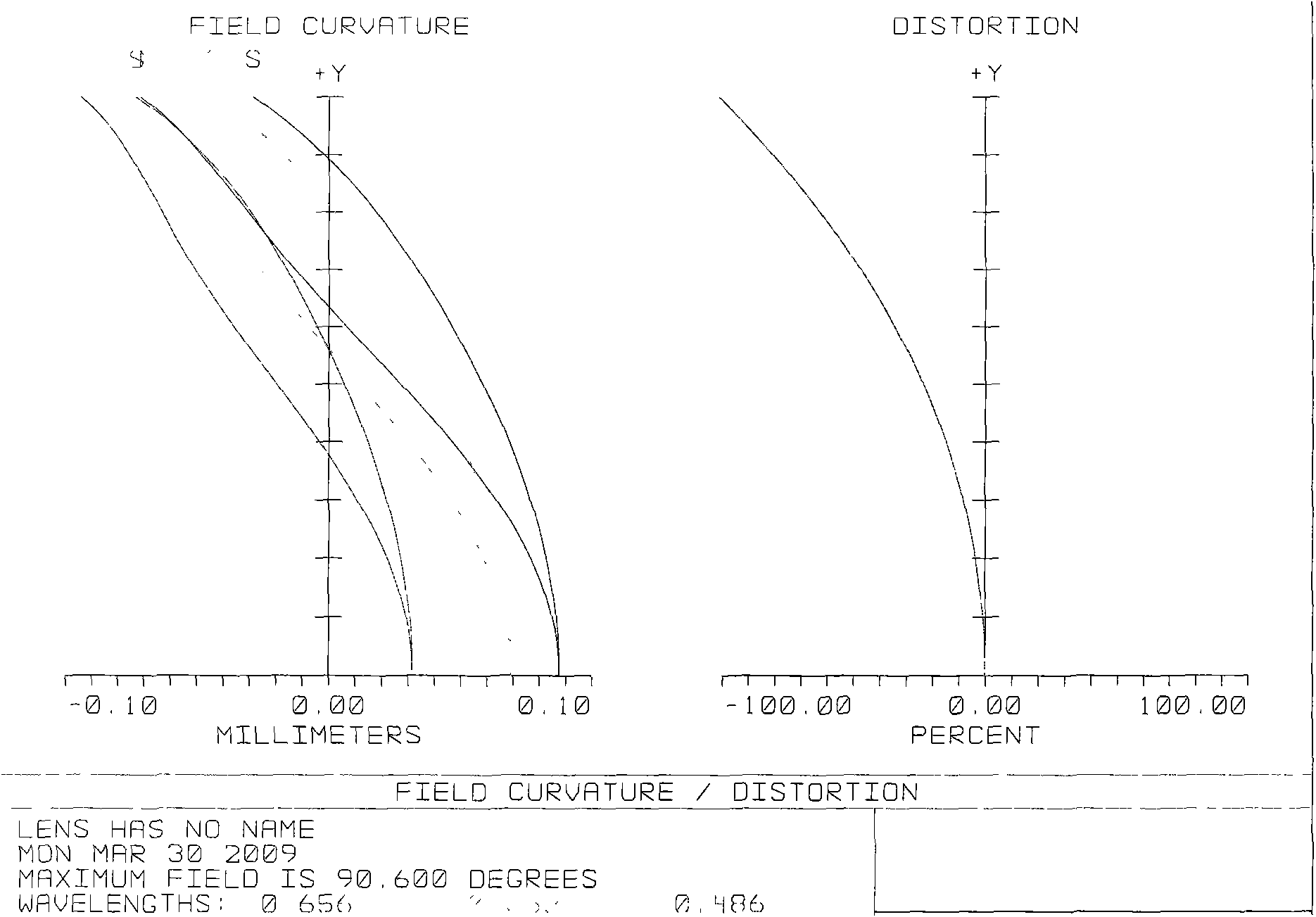

Wide-angle lens

InactiveCN101930111AIncrease the total lengthCompact structureOptical viewingOptical elementsImaging qualityLens plate

The invention discloses a wide-angle lens which comprises a first lens group with negative focus length, a diaphragm and a second lens group with positive focus length from an object, wherein the first lens group comprises a first lens with negative focus length, a second lens with negative focus length and a third lens with positive focus length; the second lens group comprises a fourth lens, a fifth lens and a sixth lens, the fourth lens is provided with positive focus length, and the fifth lens and the sixth lens have positive focus length after being glued; and the first lens group and the second lens group meet the following condition of -3<fL1 / fL2<-0.5, wherein fL1 expresses the combined focus length of the first lens group, and fL2 expresses the combined focus length of the second lens group. By adopting six full-glass lens structures, the invention has the advantages of compact structure, better machining manufacturability and low production cost. The wide-angle lens has better imaging quality under the condition of ensuring wide angle, and improves the imaging quality because the whole optical system enlarges the tolerance.

Owner:凤凰光学(广东)有限公司

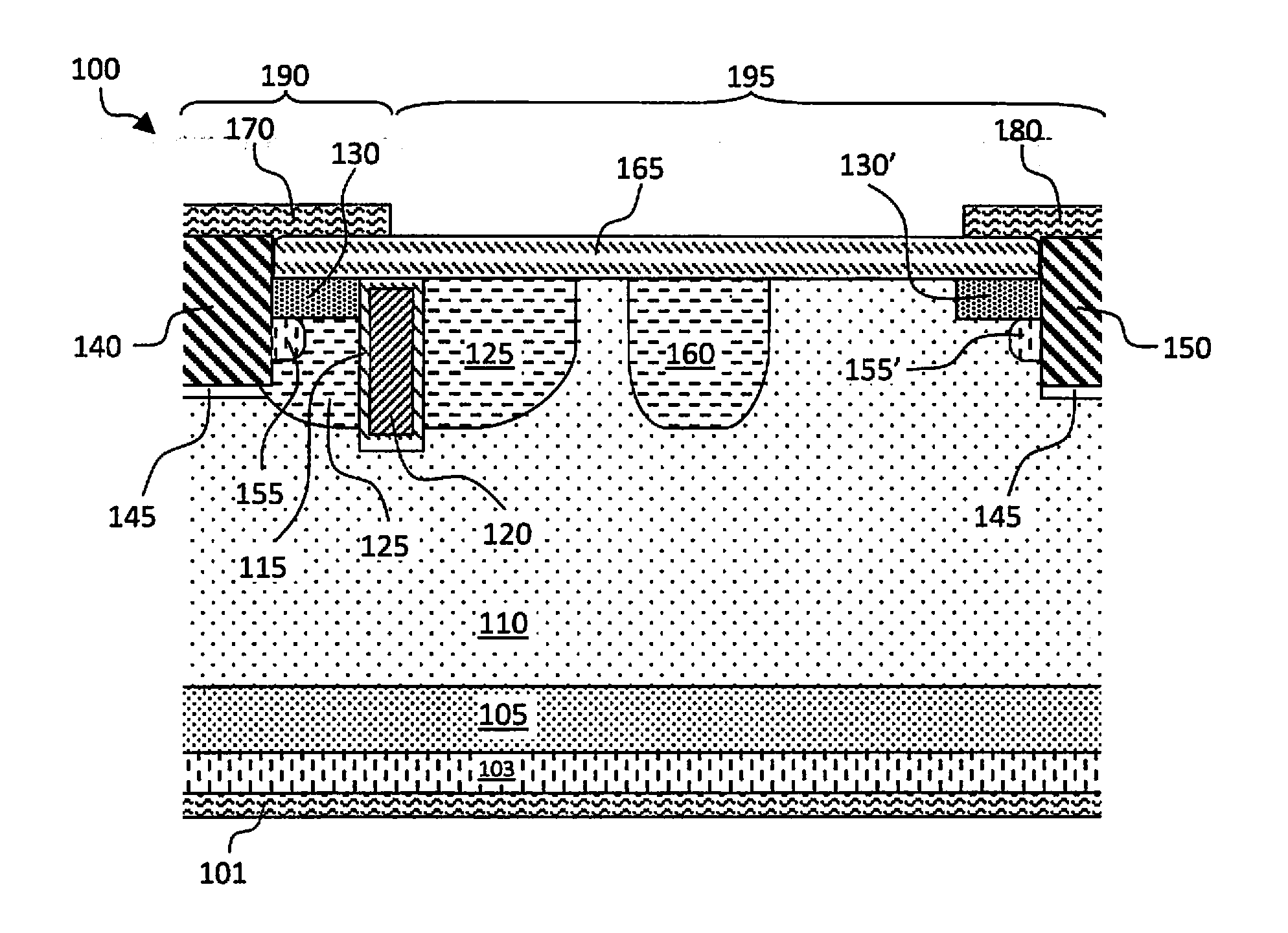

Configuration and method for manufacturing compact high current inductor coil

ActiveUS6879238B2Simple manufacturing processSmall heightTransformers/inductances casingsTransformers/inductances coils/windings/connectionsInductorInductance

This invention discloses a method for manufacturing an inductor by first press punching a first and a second layer of conductive plates into a first and second coil layers with a first and second inductor lead layers as single integrated layers. The manufacturing process further includes a step of overlapping and connecting the first and second coil layers to form an inductor. In a preferred embodiment, process of manufacturing further includes a step of mixing epoxy to bond with a highly magnetic material and pressure molding the bonding magnetic material around the coil layers to form an inductor.

Owner:CYNTEC

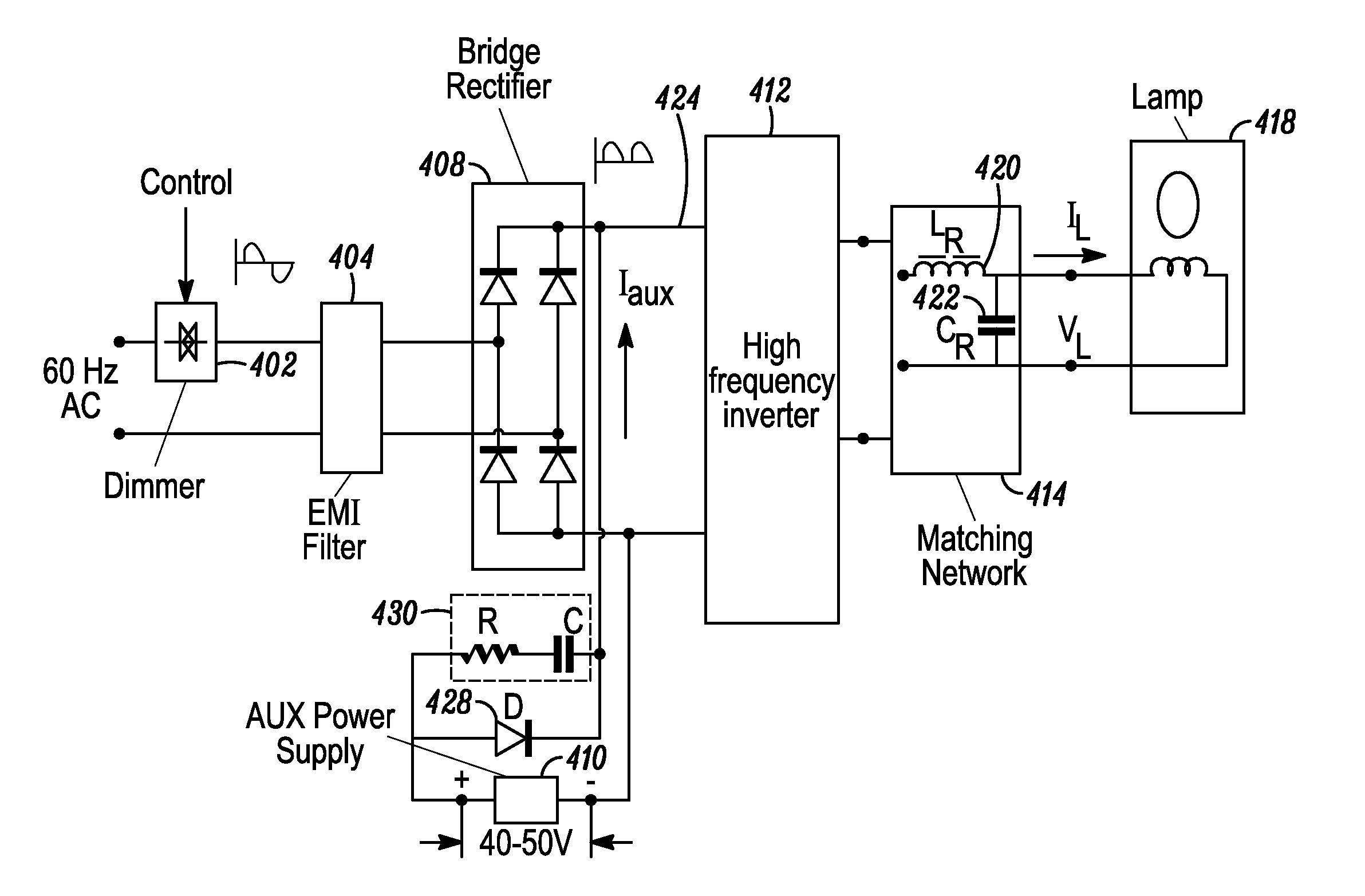

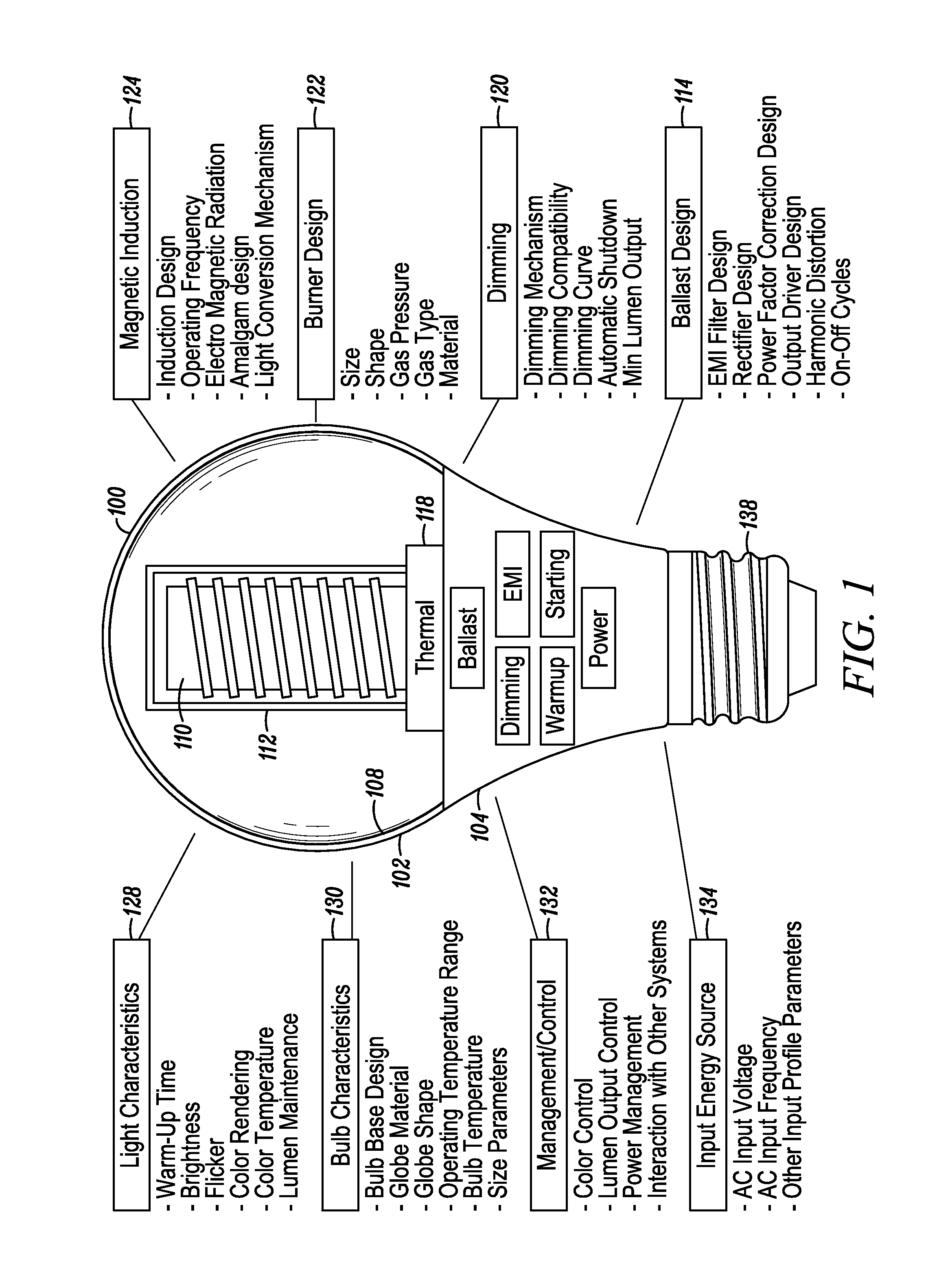

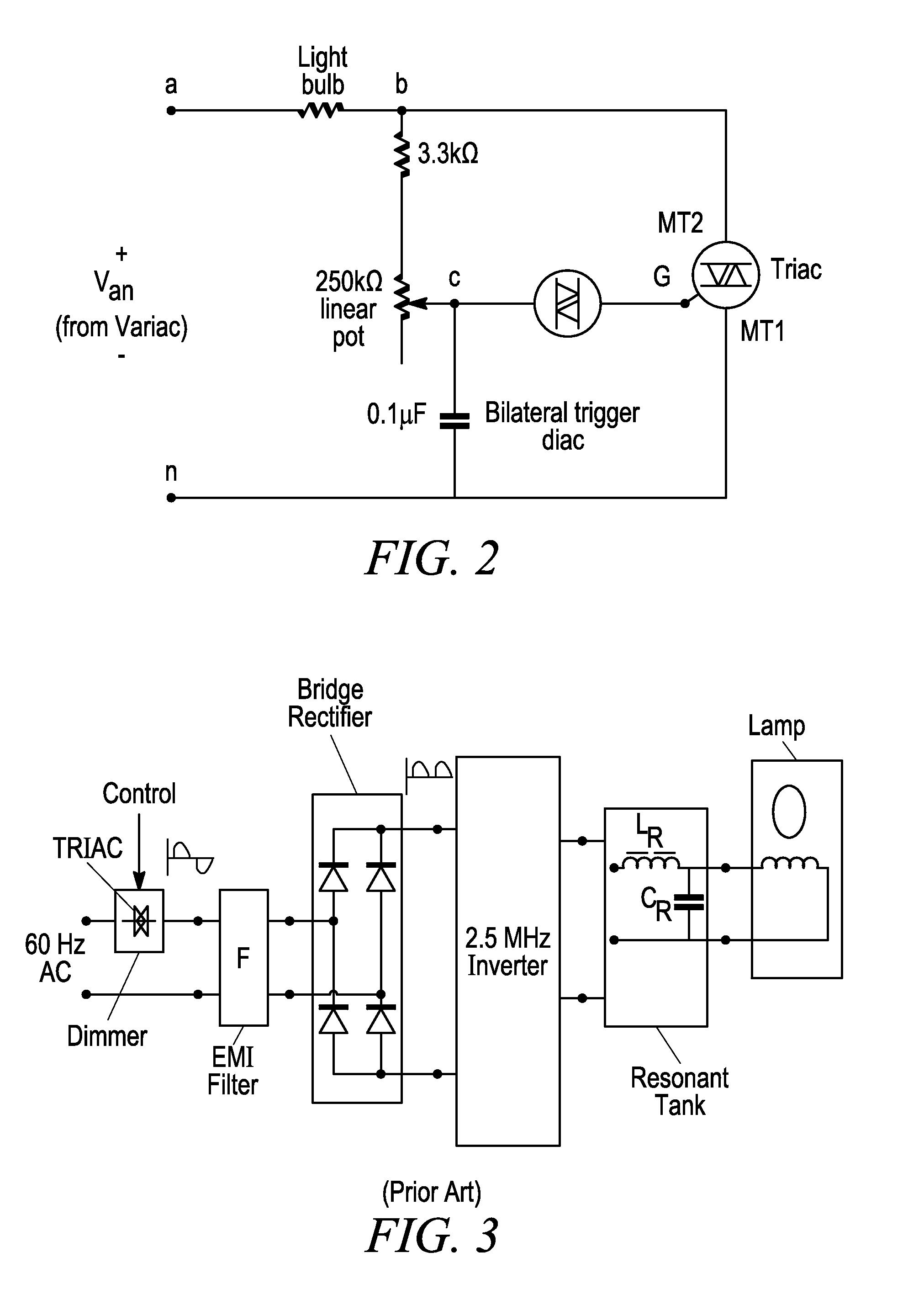

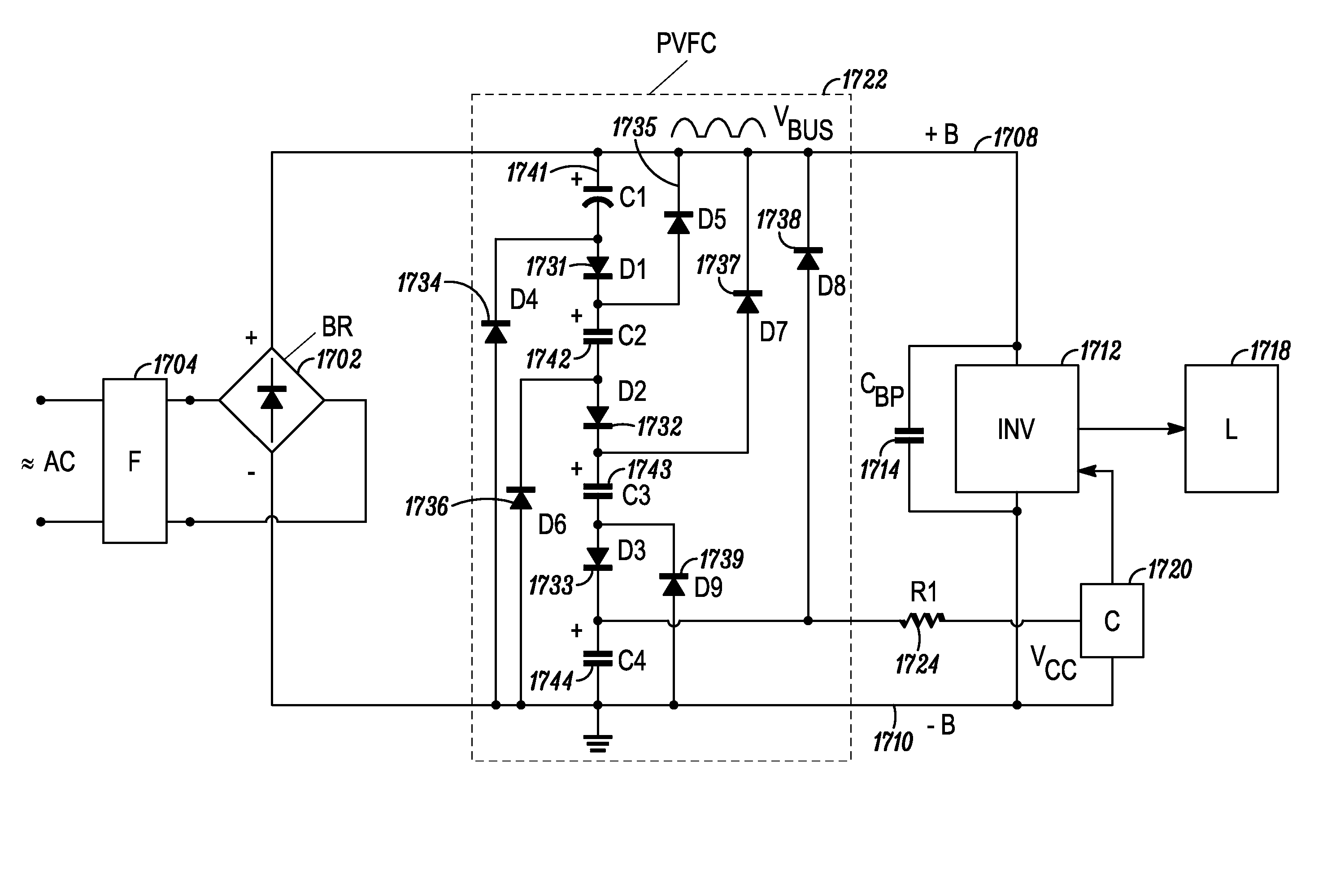

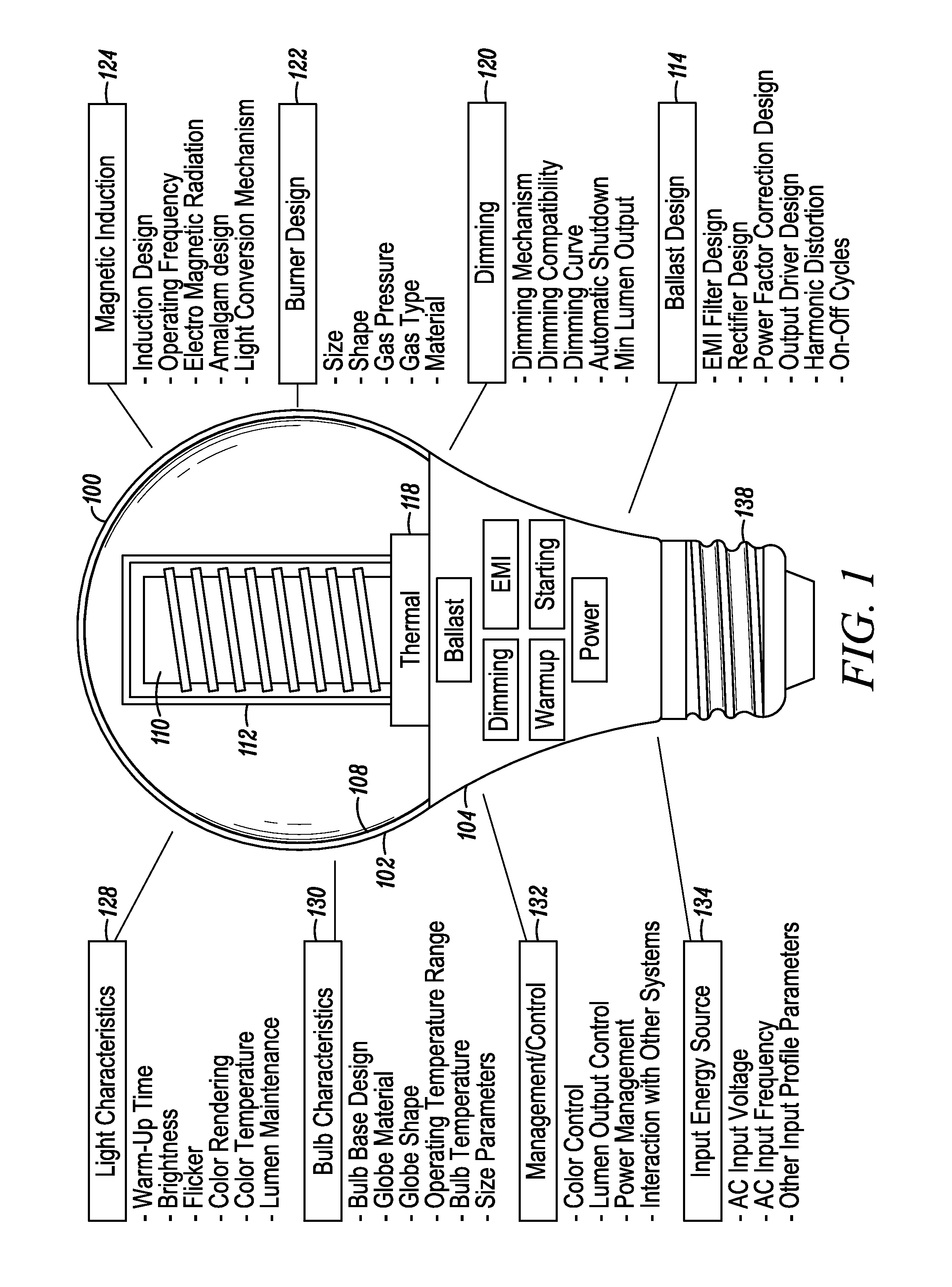

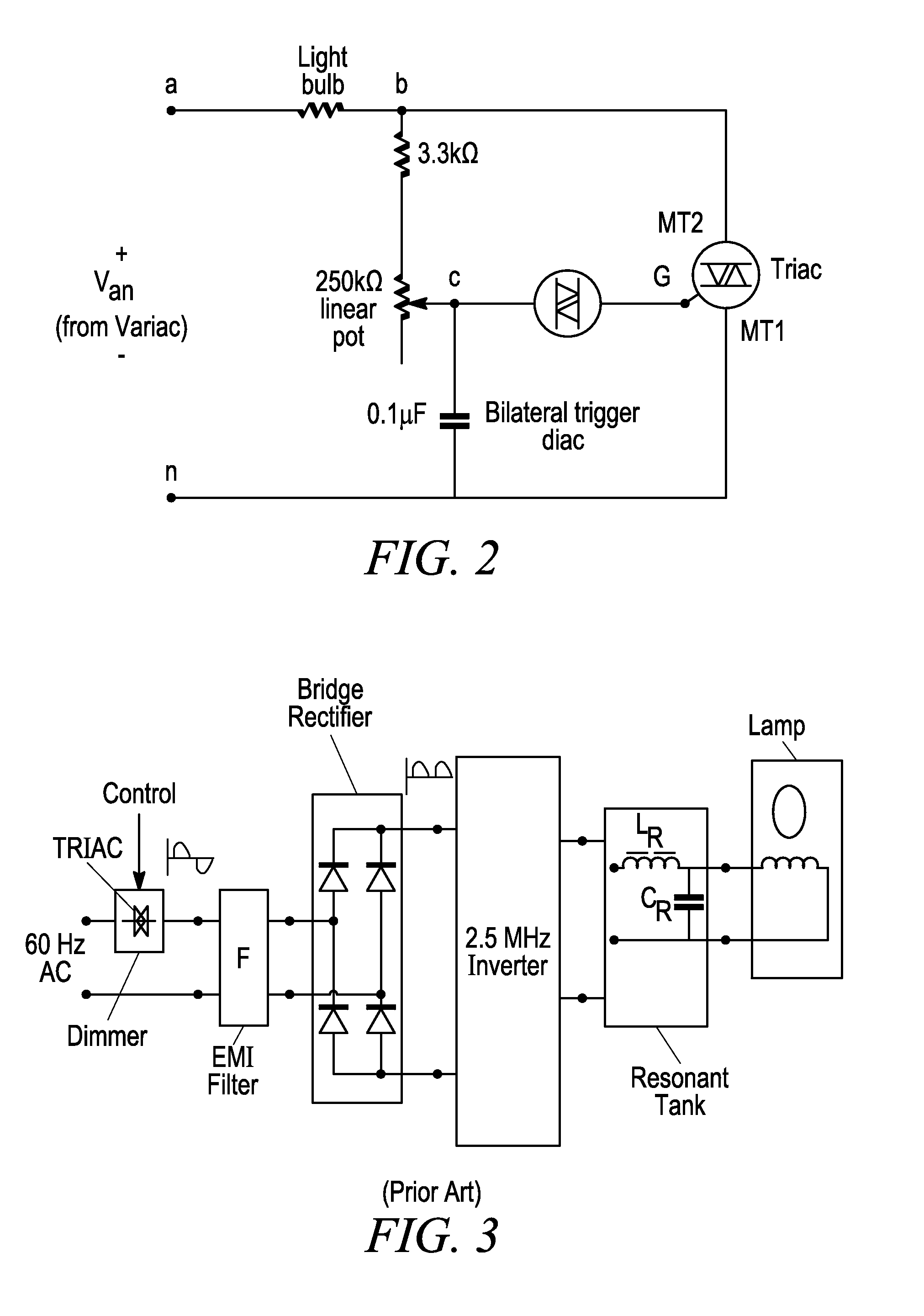

Electronic Ballast Having Improved Power Factor and Total Harmonic Distortion

ActiveUS20140145614A1Enhanced power factor correctionReduce power lossElectric discharge tubesElectric lighting sourcesTotal harmonic distortionPeak value

An electronic ballast for driving a gas discharge lamp includes an EMI filter, a bridge rectifier coupled to a DC bus without a conventional electrolytic capacitor, a passive valley fill circuit built as a network having 4 charge / discharge energy storage capacitors and 9 diodes (4C9C), and a resonant DC to AC high frequency inverter for powering gas discharge lamp. The 4C9D circuit divides the rectified peak voltage by four and the low output voltage of the circuit is used to provide continuous lamp operation. The result is a ballast having substantially improved power factor, total harmonic distortion, and current crest factor. The electronic ballast is provided with a dimming capability from a TRIAC based wall dimmer.

Owner:LUCIDITY LIGHTS

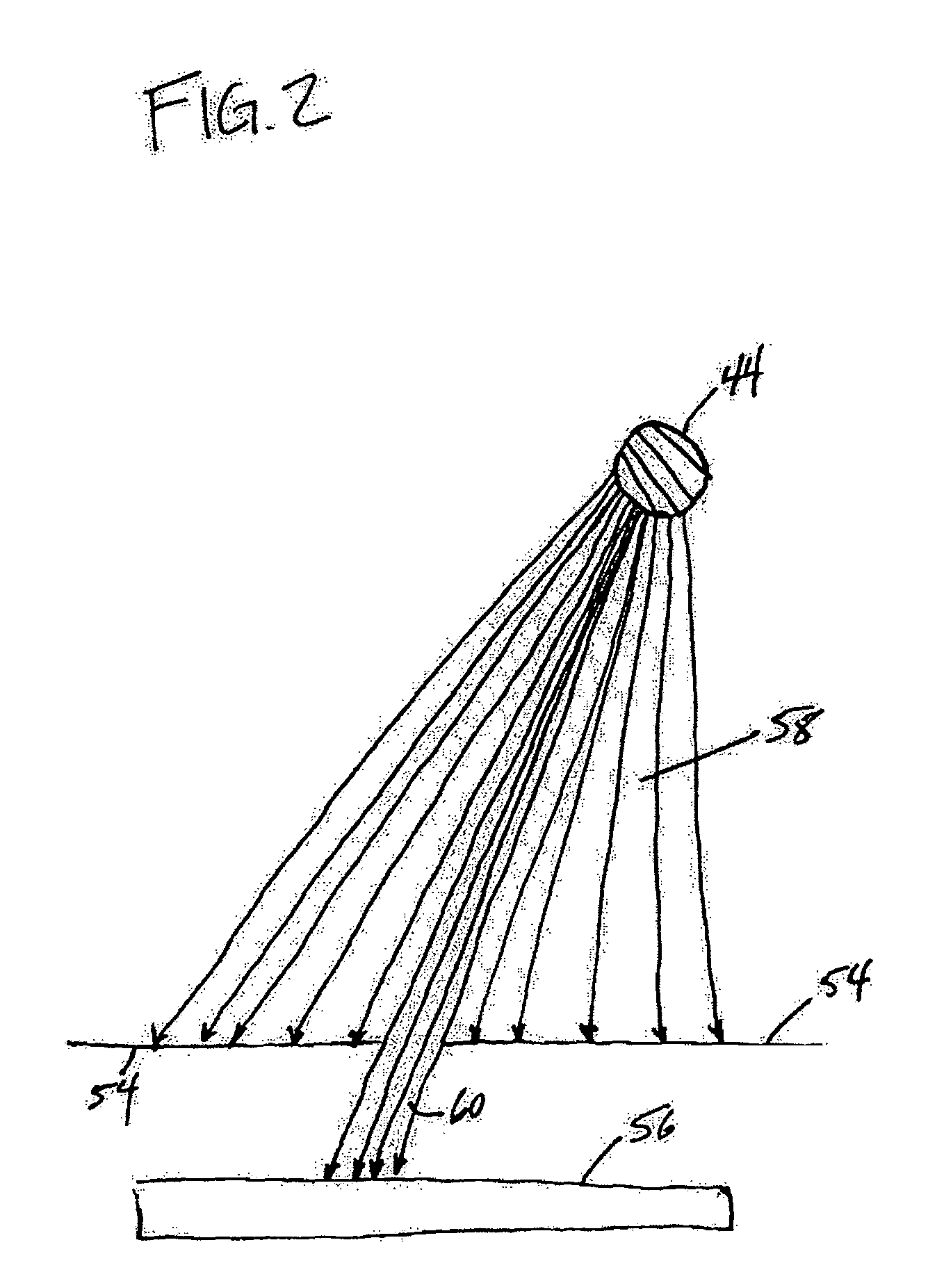

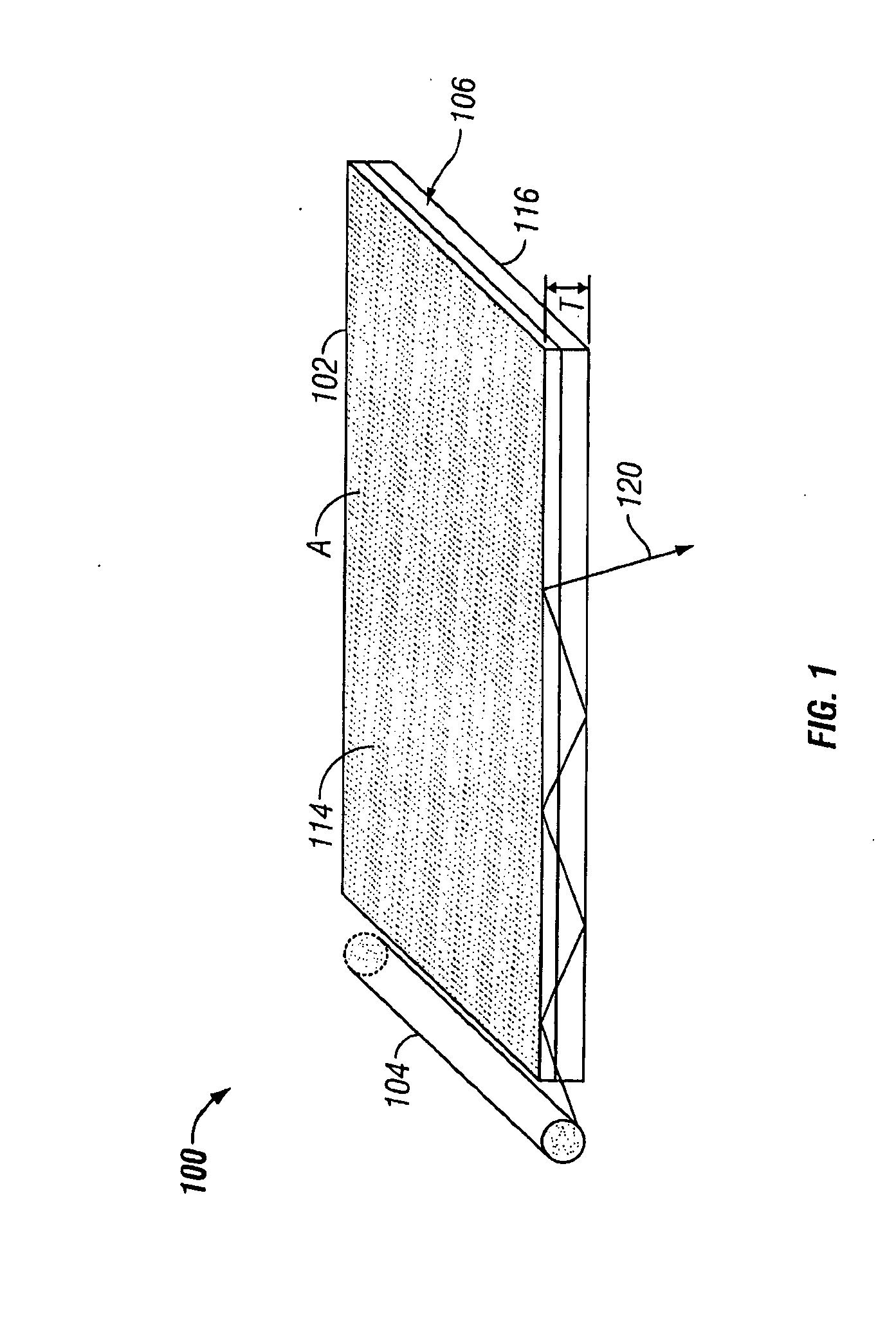

Luminaires comprising waveguides

InactiveUS20100157615A1Efficient dissipation of heatImprove form factorPoint-like light sourceLighting support devicesLight guideLight fixture

In certain embodiments, architectural lighting comprises a luminaire with a light source and a waveguide having forward and rearward surfaces. The waveguide can be disposed with respect to the light source such that light from the light source is input into the waveguide and guided therein. The waveguide can include a plurality of turning features that turn the light guided within the waveguide out the forward surface and one or more mounting fixtures for mounting the luminaire on an architectural structure. Some embodiments include a luminaire comprising a light source, a waveguide, turning features, and a lamp stand. Other embodiments are also described.

Owner:SNAPTRACK

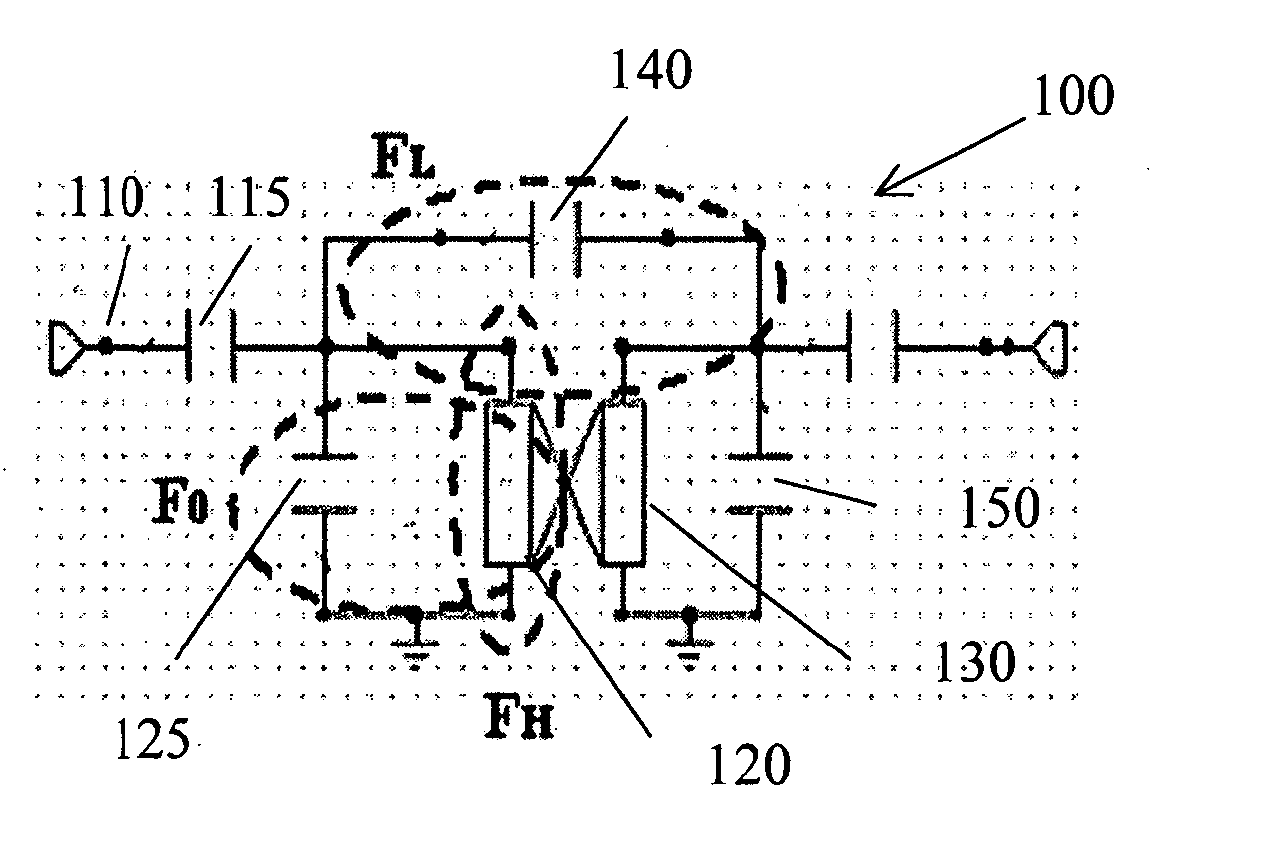

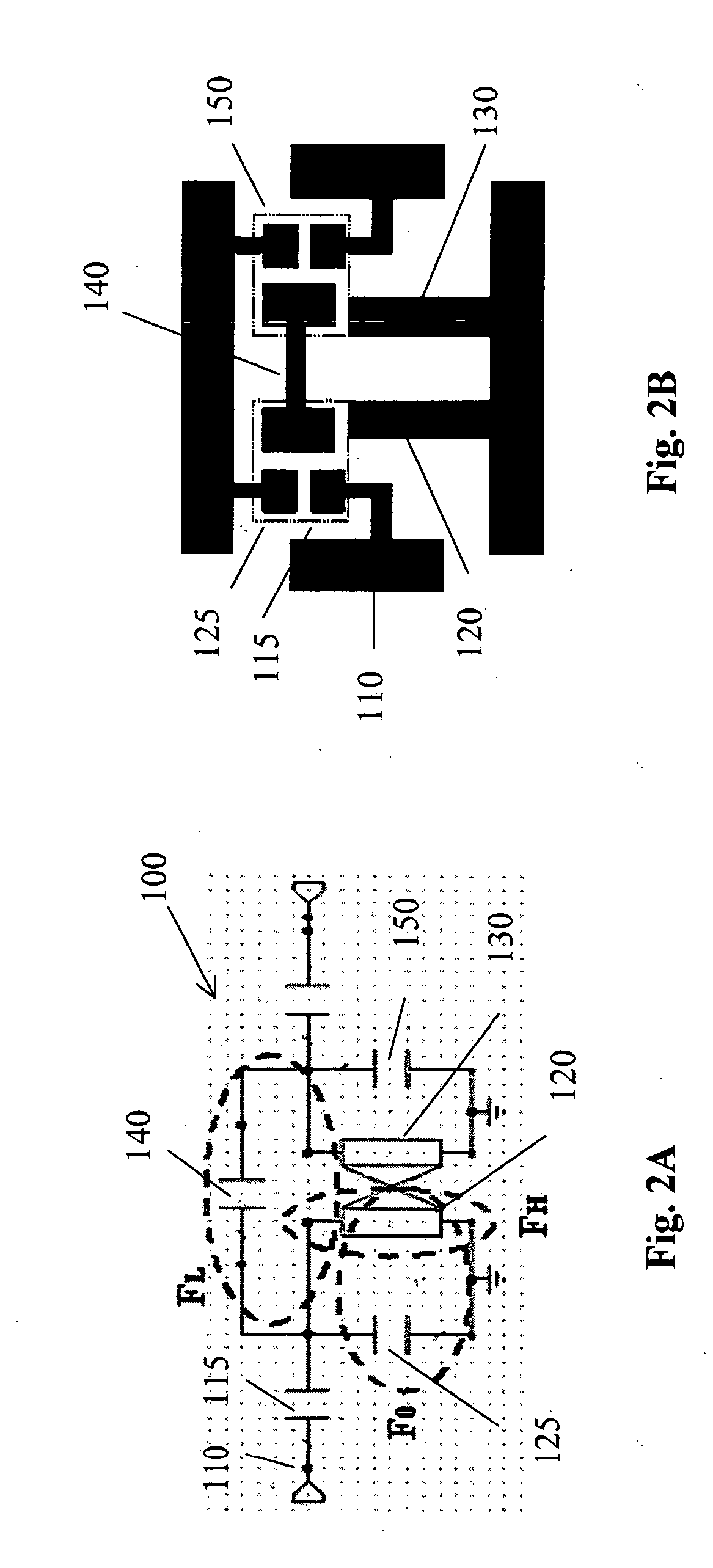

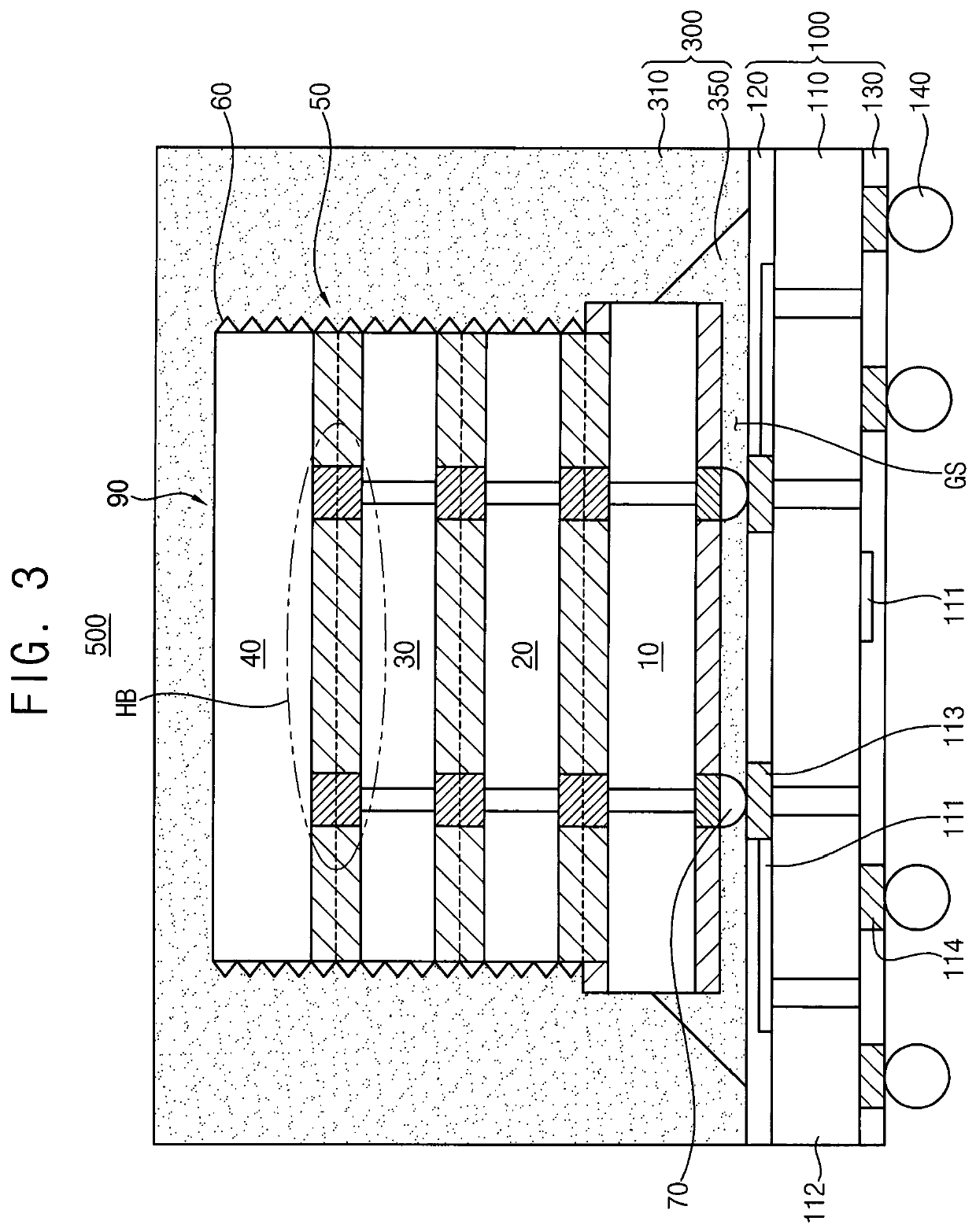

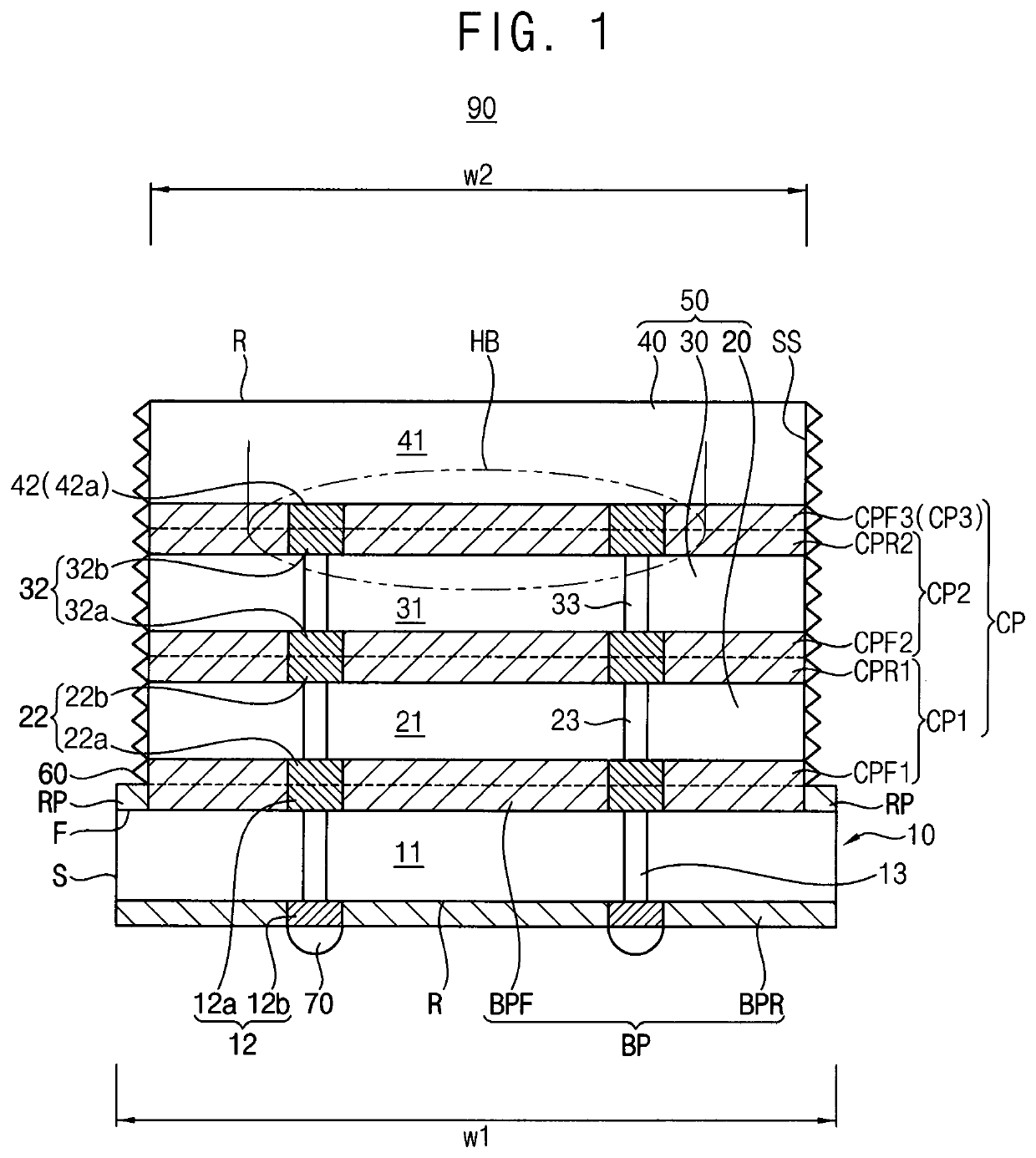

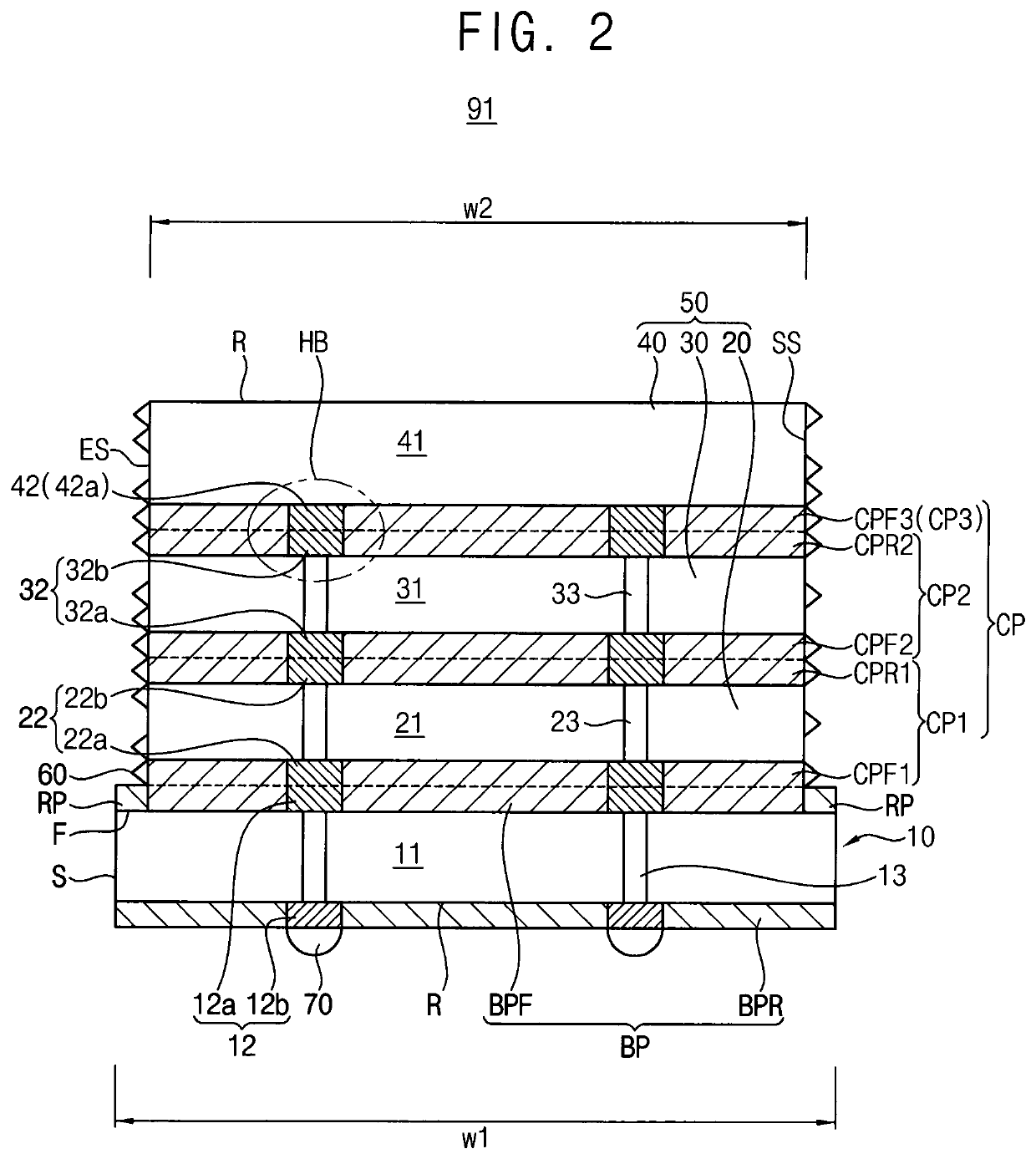

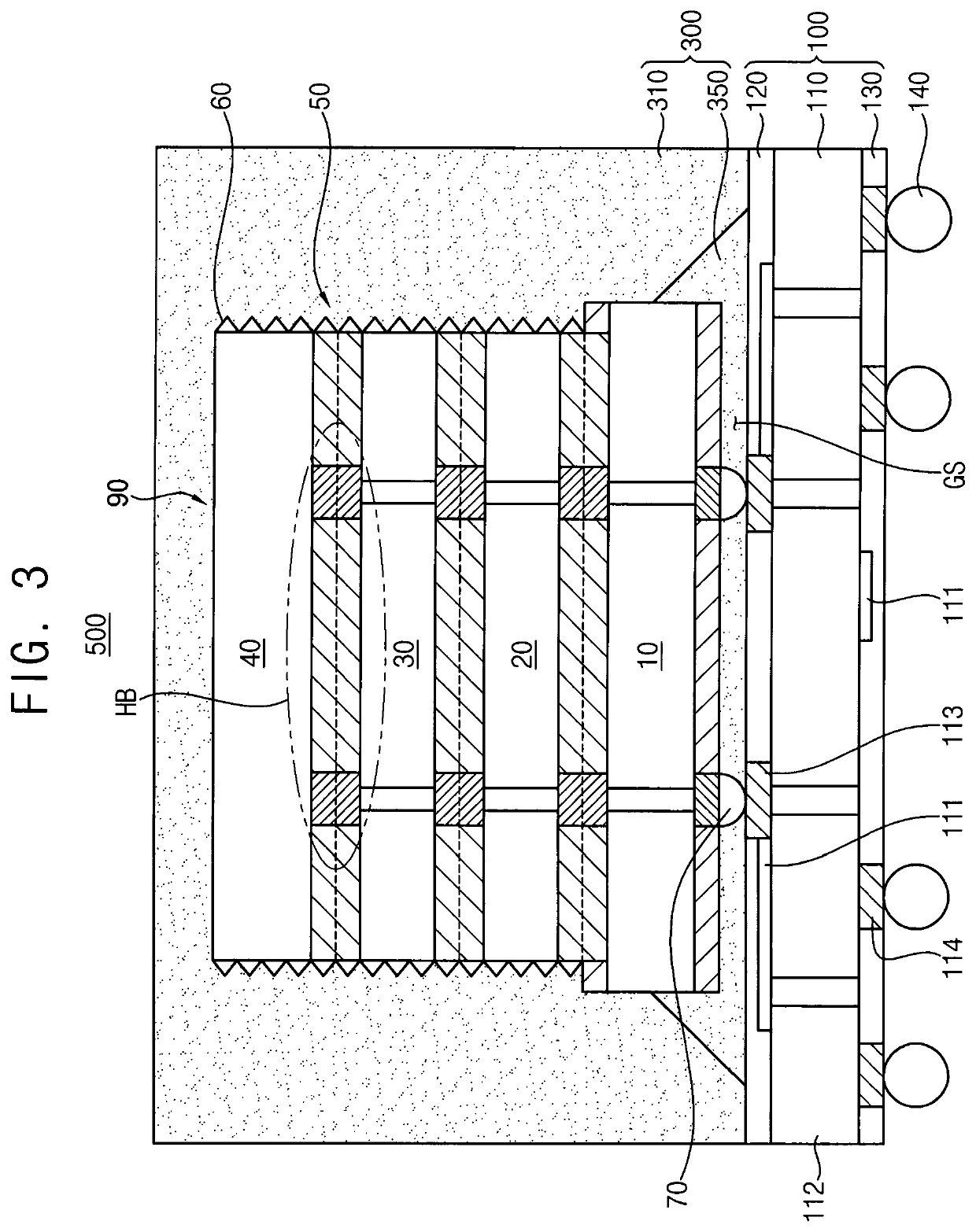

Circuits and manufacturing configurations of compact band-pass filter

InactiveUS20060077020A1Simple manufacturing processSmall heightWaveguidesBand-pass filterEngineering

A filter circuit that includes a thin film layer supported on a substrate serving as a medium layer for a capacitor formed between a top electrode layer and a bottom electrode layer formed above and below the thin film layer. The top electrode layer is patterned into microstrips for functioning as an inductor for the filter circuit.

Owner:CYNTEC

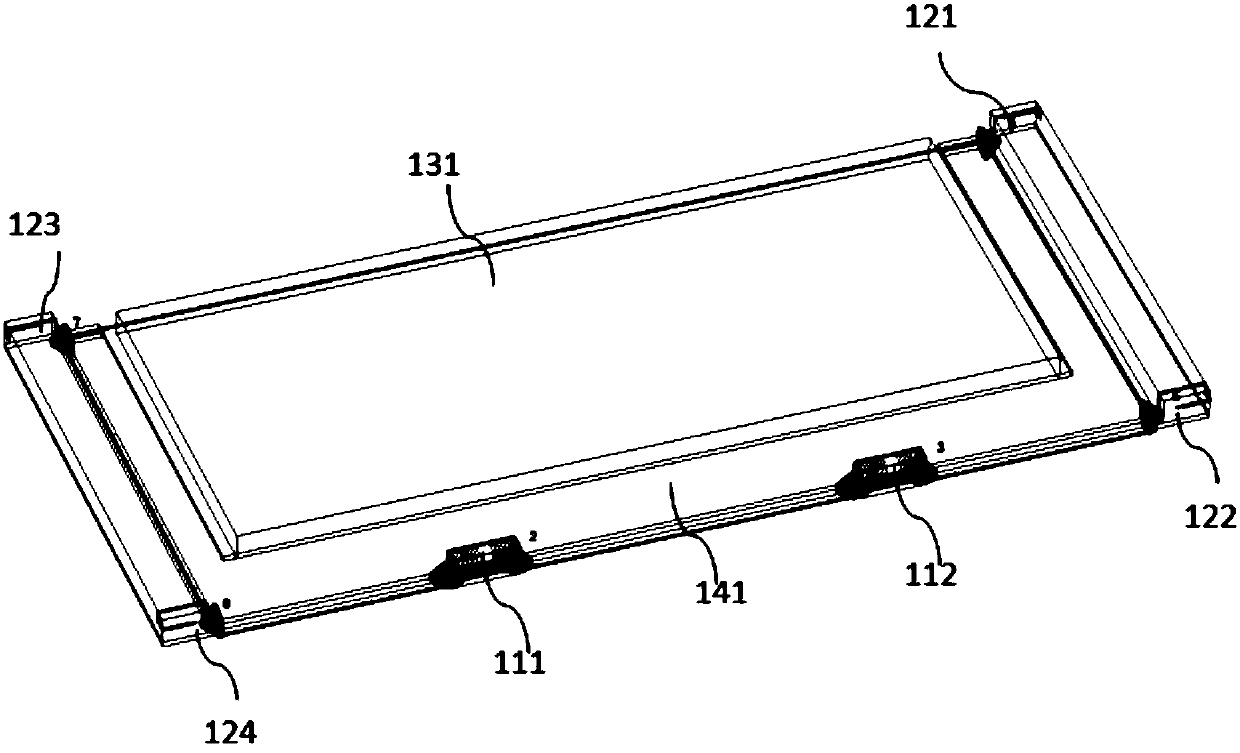

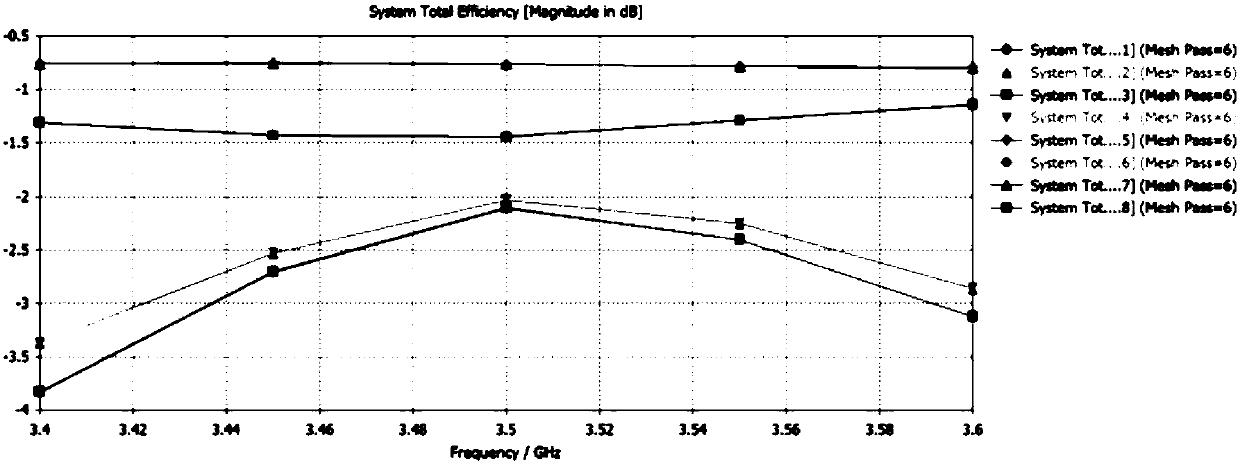

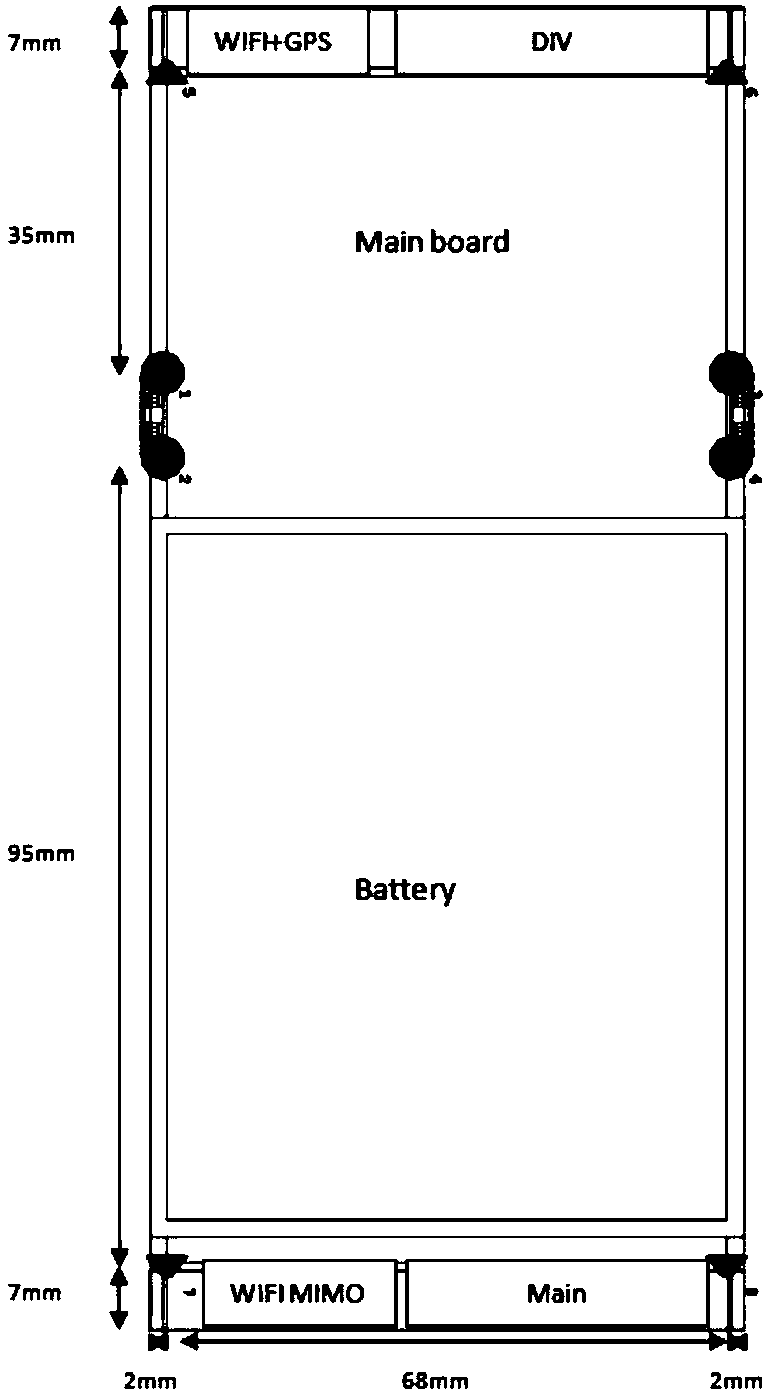

MIMO antenna system of terminal

InactiveCN107623176AReduce complexitySimple designSimultaneous aerial operationsRadiating elements structural formsMultiplexingMimo antenna

The invention provides a MIMO antenna system of a terminal. The system is composed of eight antennas that are divided into two groups, three groups or four groups of compact high-isolation antenna units; each compact high-isolation antenna unit group includes two antennas. When two groups of compact high-isolation antenna units are arranged, the two groups of compact high-isolation antenna units are arranged at the edge of a main board of the terminal at an interval; and the rest of four independent antennas are arranged at intervals by being far away from the main board in the terminal or inan antenna synchronization multiplexing manner based on the fixedly setting function inside the terminal. According to the MIMO antenna system, the space is saved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

Electronic ballast having improved power factor and total harmonic distortion

InactiveUS9161422B2Increase powerImprove power factorElectrical apparatusElectric light circuit arrangementTotal harmonic distortionPeak value

Owner:LUCIDITY LIGHTS

Die stack structure, semiconductor package having the same and method of manufacturing the same

ActiveUS20200135698A1Improve reliabilityImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor package

Owner:SAMSUNG ELECTRONICS CO LTD

Die stack structure, semiconductor package having the same and method of manufacturing the same

ActiveUS10886255B2Improve reliabilityImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor package

Owner:SAMSUNG ELECTRONICS CO LTD

Metallizing device and method

InactiveUS20100317147A1High viscosityReduce the ratioLiquid surface applicatorsScreen printersScreen printingEngineering

A metallization device configured to metallize a semiconductor device, including: a closed enclosure of variable volume configured to contain a metallization paste, a screen for screen printing forming a wall of the enclosure integral with the other walls of the enclosure, configured to be in contact with the semiconductor device during its metallization, and a mechanism applying uniform pressure over a mobile sealed wall of the enclosure opposite to the wall formed by the printing screen and reducing the volume of the enclosure. The volume reduction of the enclosure is configured to cause the metallization paste to uniformly pass through the printing screen.

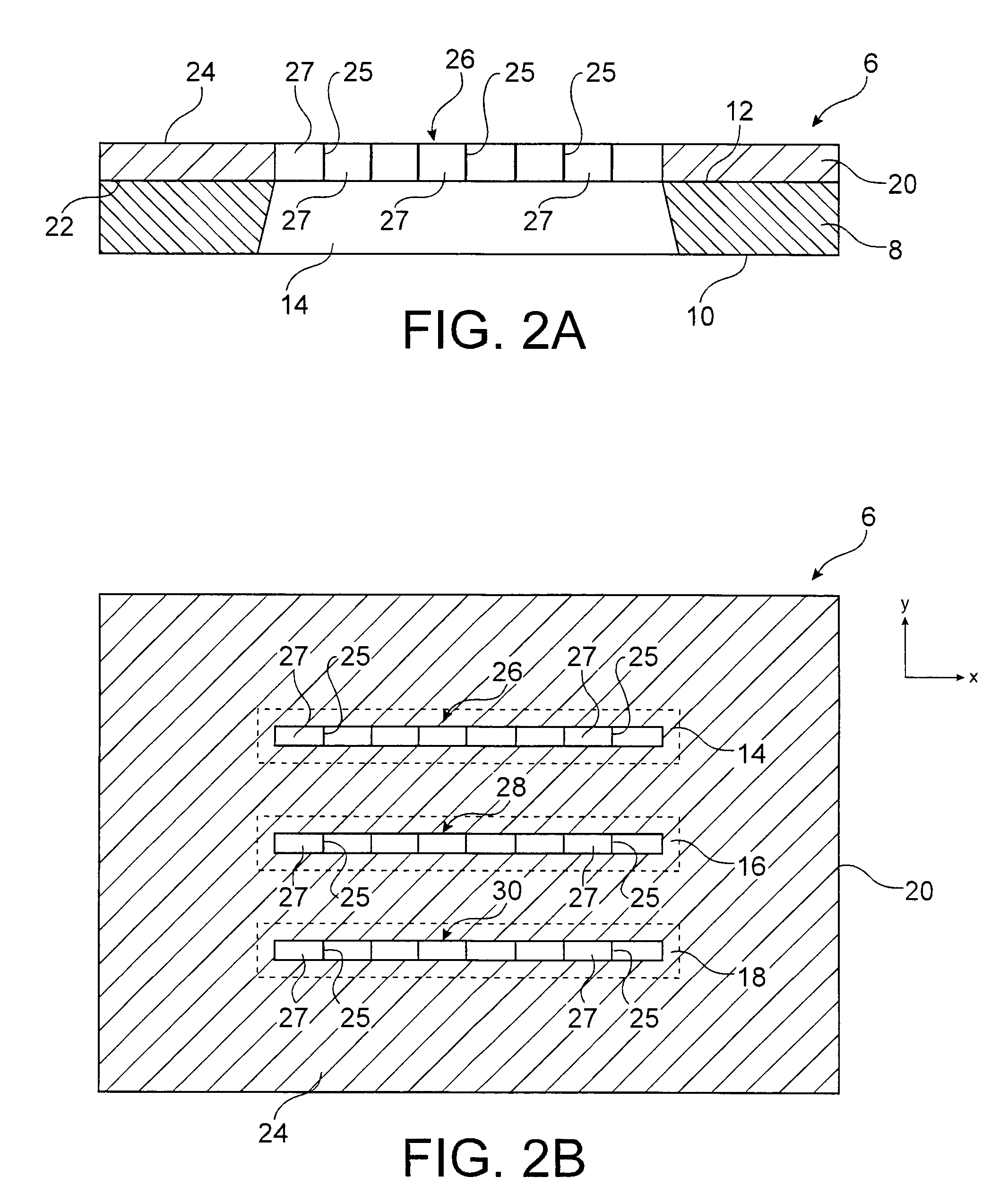

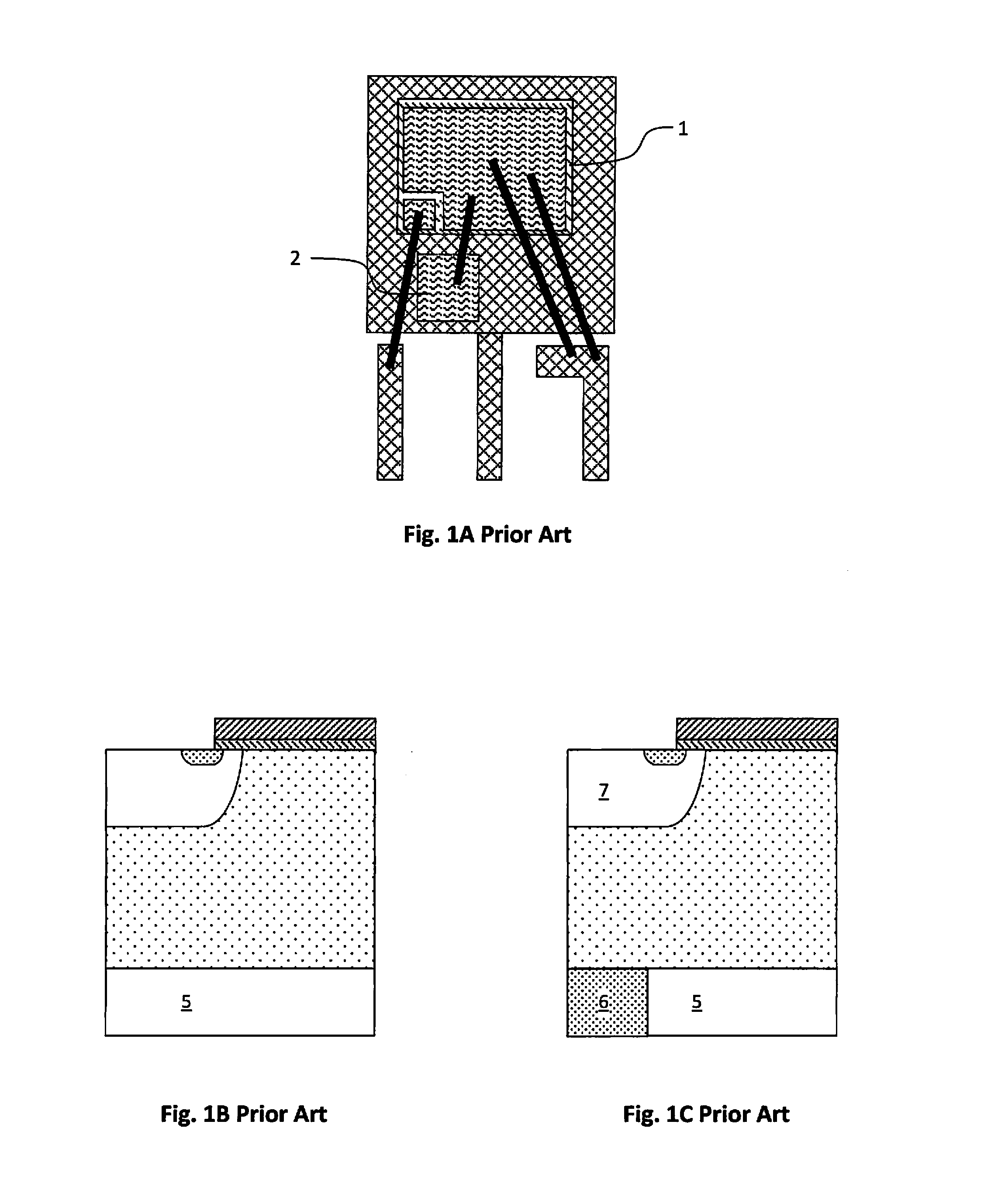

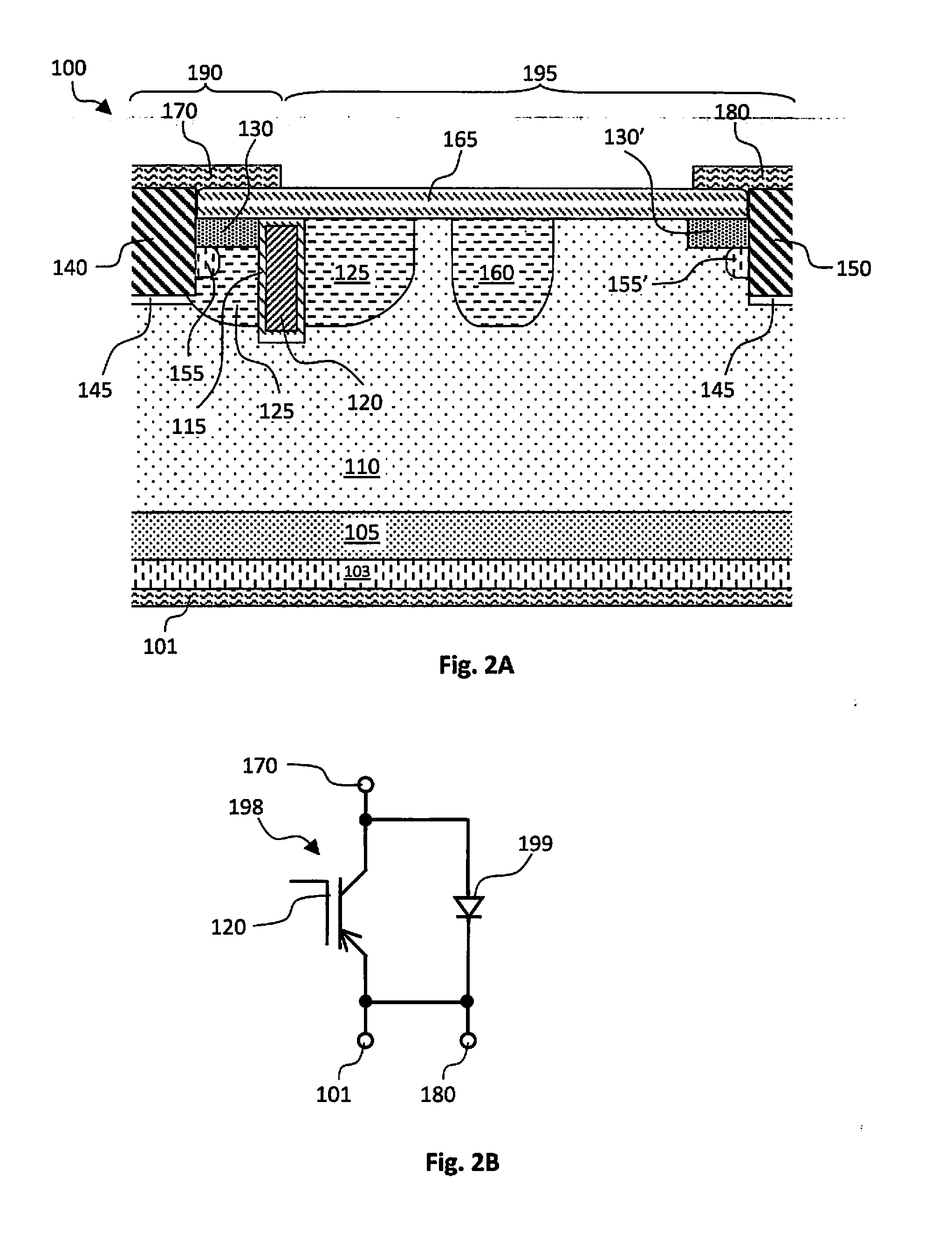

Monolithic IGBT and diode structure for quasi-resonant converters

ActiveUS20150035005A1Increased form factorIncrease production costTransistorSemiconductor/solid-state device detailsDevice formResonant converter

This invention discloses a semiconductor power device formed in a semiconductor substrate. The semiconductor power device further includes a channel stop region near a peripheral of the semiconductor substrate wherein the channel stop region further includes a peripheral terminal of a diode corresponding with another terminal of the diode laterally opposite from the peripheral terminal disposed on an active area of the semiconductor power device. In an embodiment of this invention, the semiconductor power device is an insulated gate bipolar transistor (IGBT).

Owner:ALPHA & OMEGA SEMICON INC

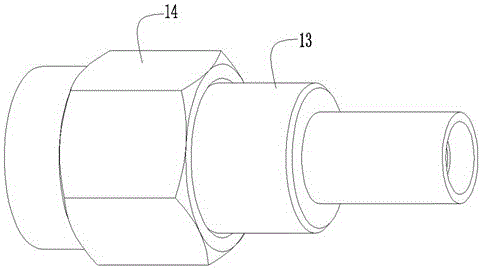

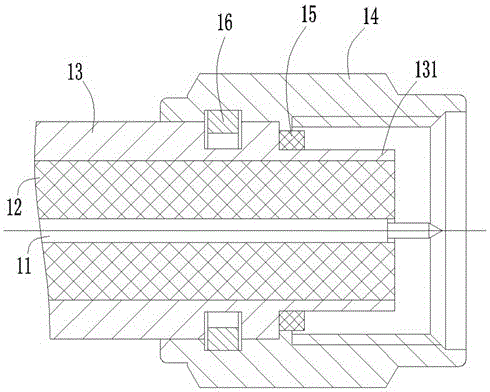

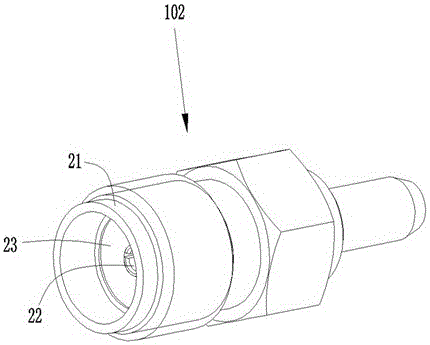

Coaxial connector and plug and socket thereof

ActiveCN105846258AIncreased form factorRetain mechanical propertiesCouplings bases/casesTwo-part coupling devicesEnvironmental resistanceElectrical conductor

The invention relates to the field of electrical connectors, in particular to a coaxial connector and a plug and a socket thereof. The coaxial connector comprises the plug and the socket, wherein the plug comprises an outer plug conductor and a connection nut; the connection nut is rotationally assembled on the outer plug conductor; the socket comprises an outer socket conductor; the outer plug conductor is provided with an insertion part which is used for inserting of the outer socket conductor; a set distance is formed between the outer wall surface of the insertion part and the inner wall surface of the connection nut; a thickening part is arranged on an outer layer of the insertion part; expansion parts matched with the thickening part are arranged in holes of the outer socket conductor and the connection nut; the set distance is the distance between the outer side surface of the thickening part and the inner wall surface of the expansion part in the hole of the connection nut; and an outer thread matched with the connection nut is formed in the outer socket conductor. By the coaxial connector, the strength, the reliability and the characteristic impedance can be improved under the condition of not increasing the boundary dimension of the SMA radio-frequency coaxial connector and reserving the mechanical property and the environmental resistance of the SMA connector.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

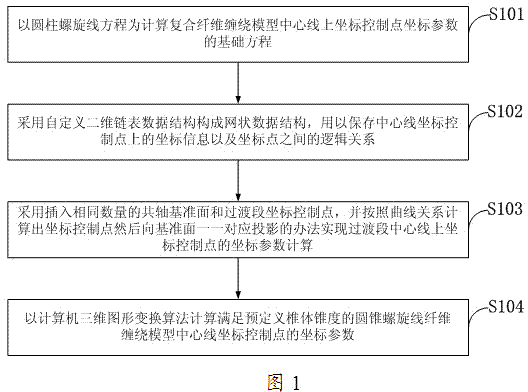

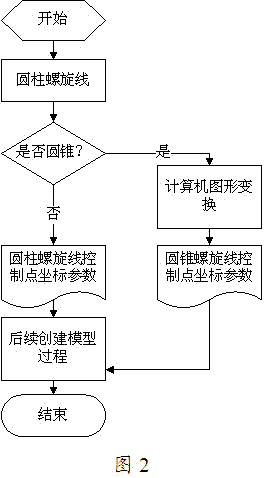

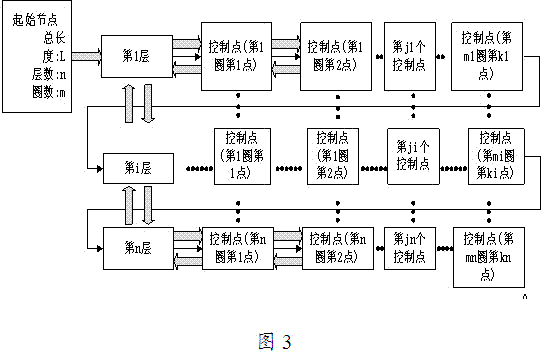

Construction method for taper-changeable composite fiber winding models

InactiveCN104504193ARealize the structureSimplify the design processSpecial data processing applications3D modellingThree-dimensional spaceDimensional modeling

The invention discloses a construction method for taper-changeable composite fiber winding models. According to the construction method, coordinates of positioning control points on winding fibers in a three-dimensional space are calculated according to a normalized curvilinear equation, and modeling of composite fiber winding products is realized by combining a three-dimensional modeling software solid feature operation method; the problems that mutual fiber interference among three-dimensional solid models of spring layer / striding circle positions during fiber winding simulation is caused and the control points need to be corrected to avoid the interference are solved; the construction method can construct the fiber winding models with any filament winding lengths, and the models have high similarity to actual fiber winding products; the fiber winding models have wide range of adaptability to taper of winding mandrel bodies and high dimensional accuracy. By the construction method, the fiber winding products as required can be automatically generated according to parameters inputted by users, and design efficiency is improved; fiber interference and intersection conditions, including spring layer intersection and circle change intersection, during winding of fibrous composite products can be simulated to the greatest extent; the three-dimensional models of the fiber winding products have high similarity to the actual products in terms of boundary dimension.

Owner:XIAN TECHNOLOGICAL UNIV

Electrical conduit

InactiveUS20040118589A1Increased form factorIncrease distanceTotally enclosed bus-bar installationsBusbarEngineering

The invention relates to an electrical busbar for transportation and distribution of electrical power comprising several parallel, metal conducting bars spaced out from one another inside a metal enclosure, each conducting bar having a cross-section of elongate shape. At least one conducting bar is provided with a thickness near to the centre of the cross-section of said conducting bar that is greater than thickness of at least one of the ends of the cross-section of said conducting bar.

Owner:SCHNEIDER ELECTRIC IND SAS

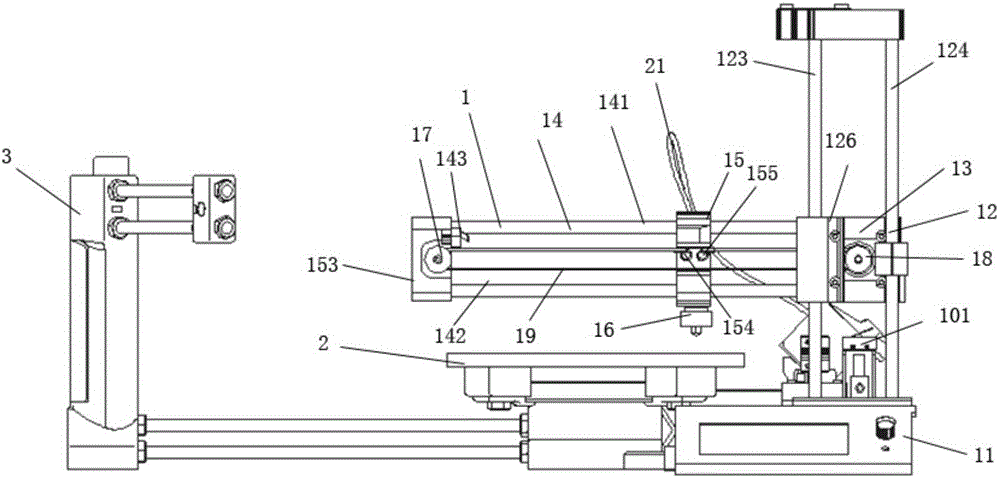

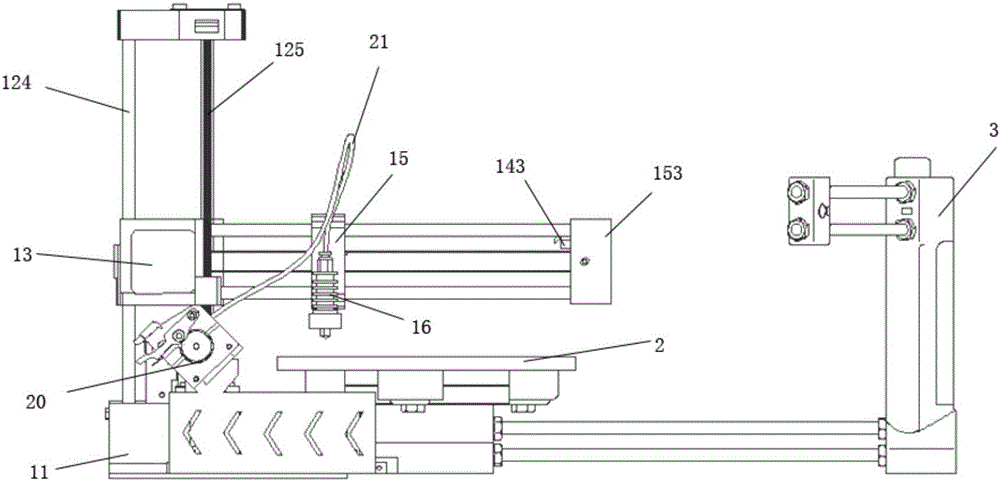

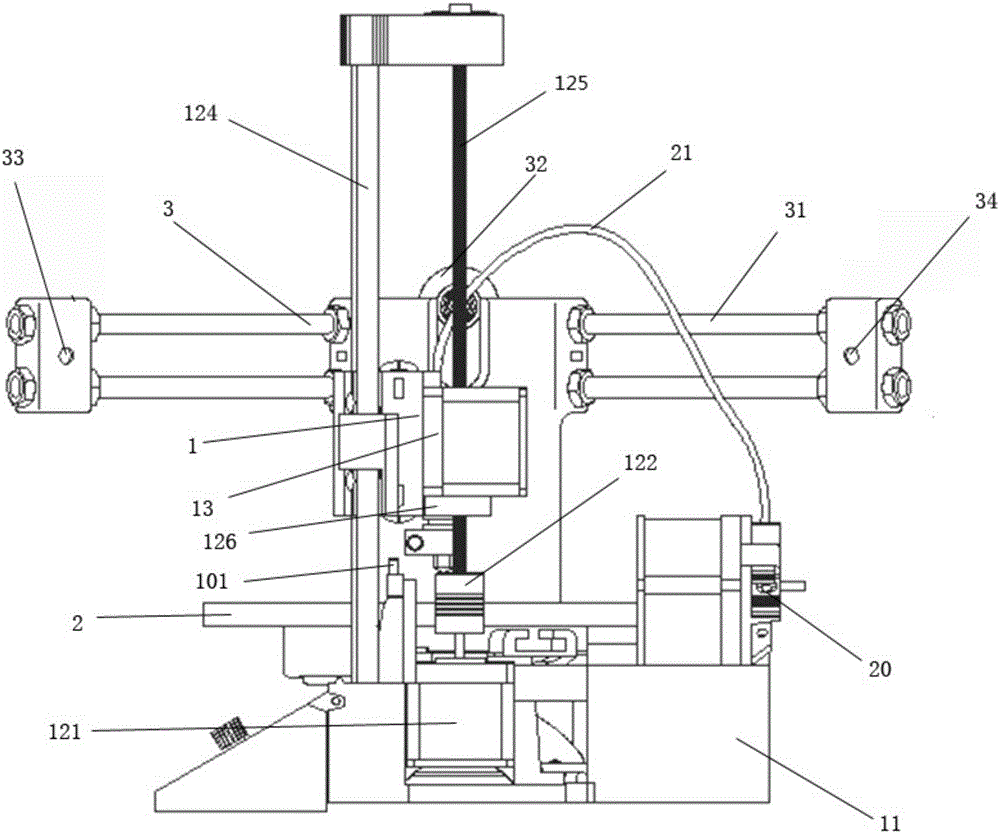

3D printing and scanning all-in-one machine

InactiveCN106313499ARealize the combinationIncrease profitAdditive manufacturing apparatus3D object support structuresEngineeringCantilever

The invention relates to a 3D printing and scanning all-in-one machine. The 3D printing and scanning all-in-one machine comprises printing equipment and further comprises a rotating platform and scanning equipment arranged at one side of the rotating platform. The printing equipment comprises a base arranged at the other side of the rotating platform, a vertical lifting device arranged on the base, a cantilever motor arranged on the vertical lifting device, a cantilever with one end connected with the vertical lifting device, a cantilever sliding block connected with the cantilever in a sliding mode, a printing head arranged on the cantilever sliding block, a first synchronous pulley, a second synchronous pulley and a synchronous belt. The first synchronous pulley is arranged at the other end of the cantilever. The second synchronous pulley is arranged at the position of the cantilever motor and is connected with a rotating shaft of the cantilever motor. The two ends of the synchronous belt wind across the first synchronous pulley and the second synchronous pulley separately and then are connected with the cantilever sliding block.

Owner:林子森

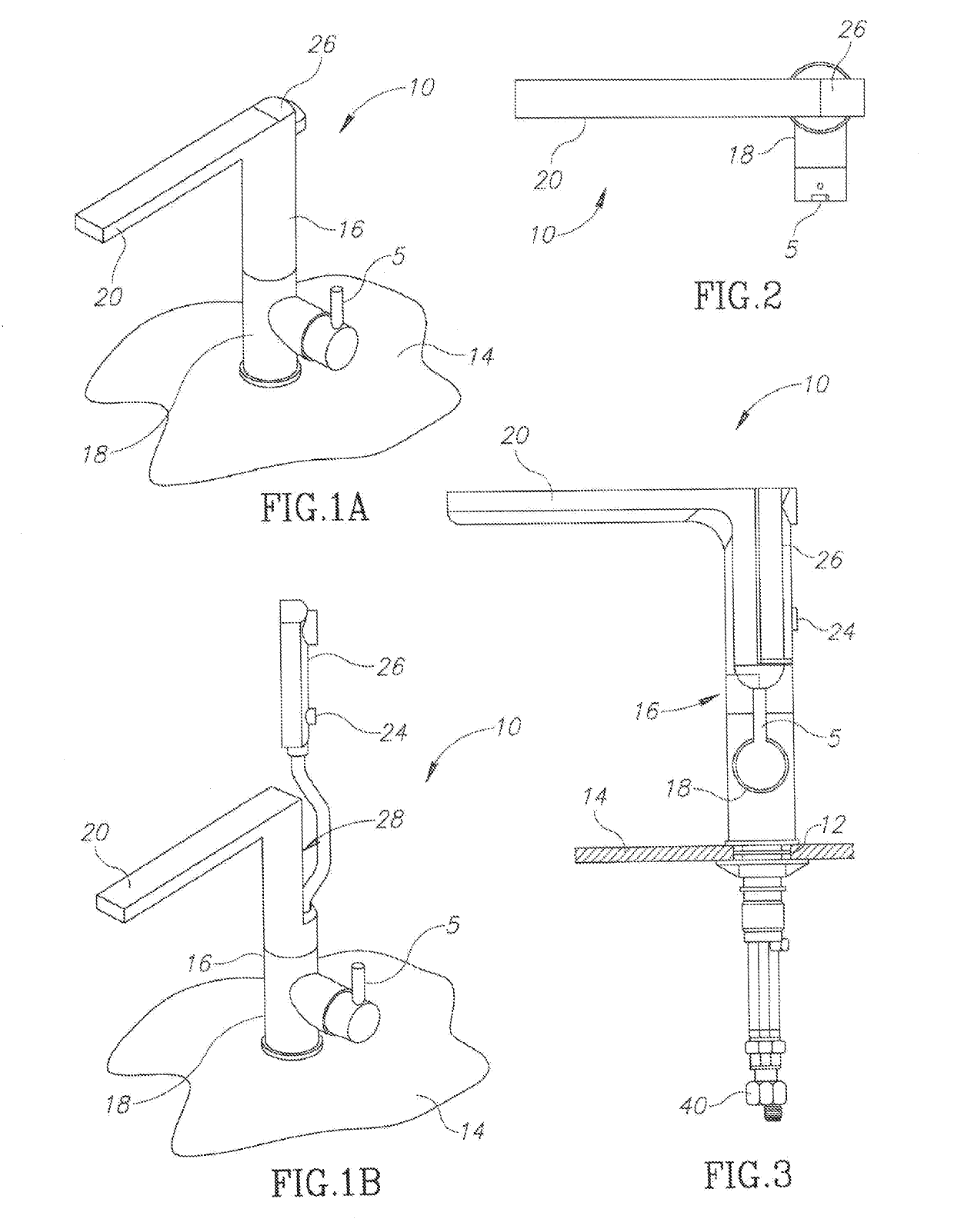

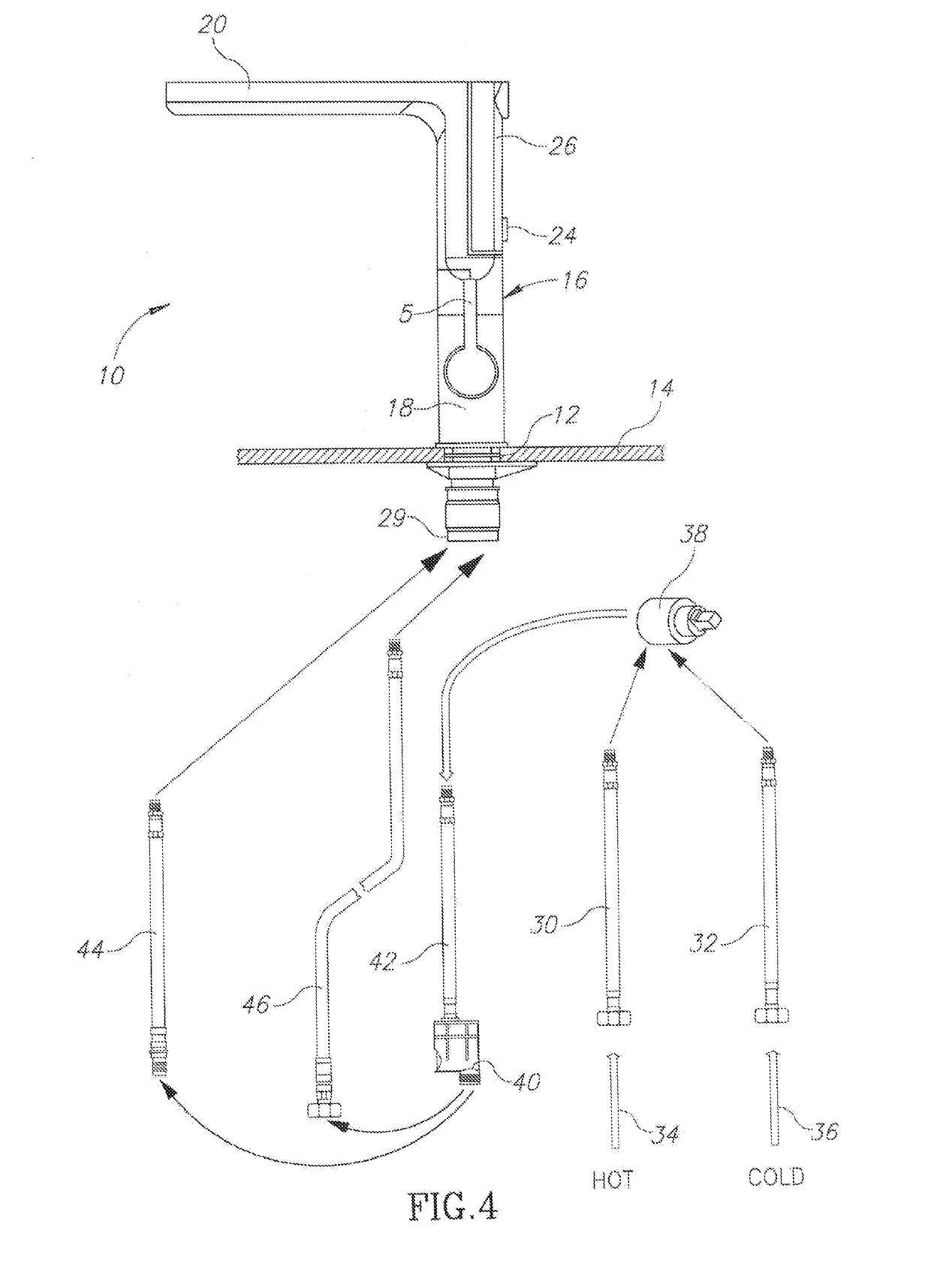

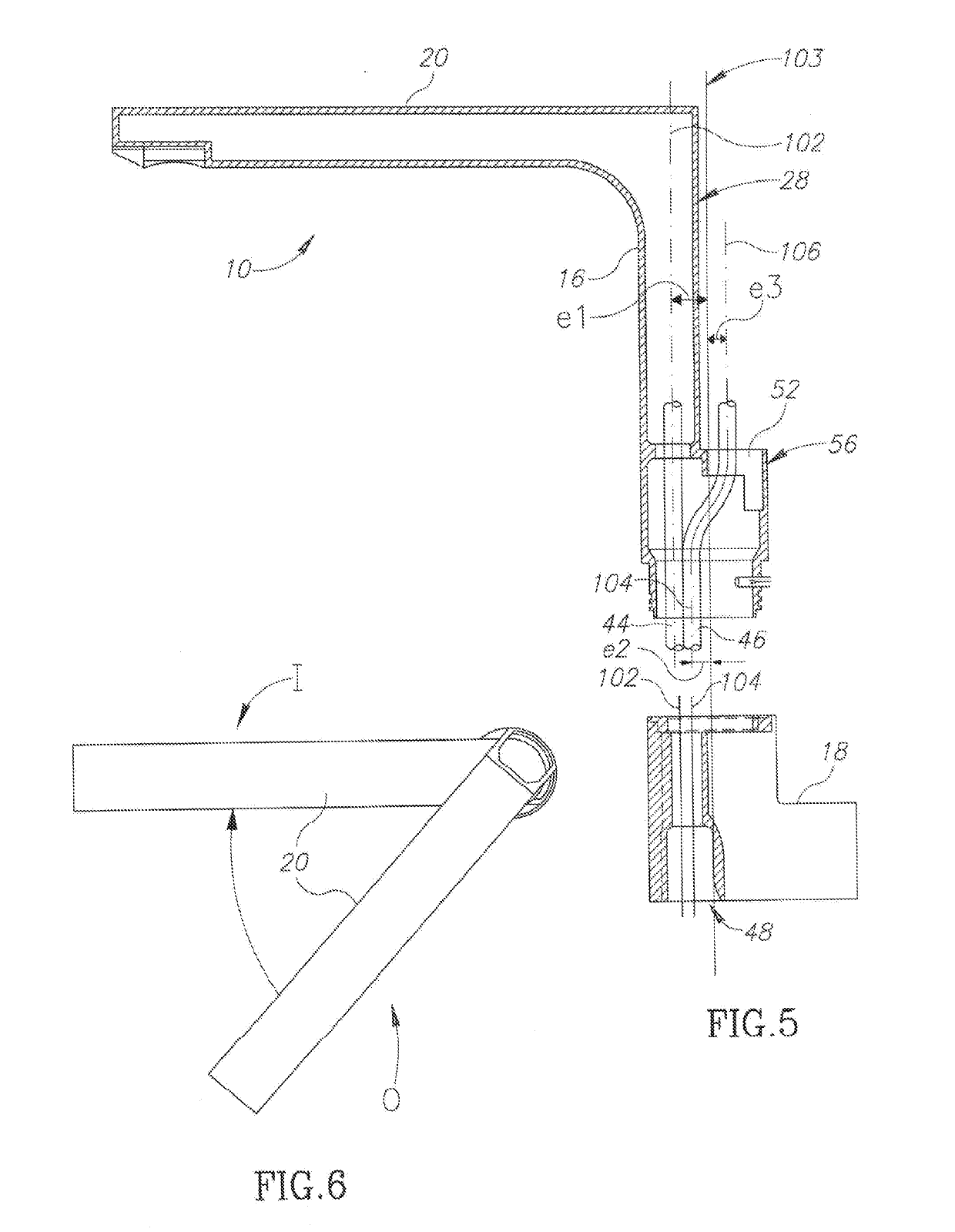

Mixer water faucet

ActiveUS20190145533A1Small sizeIncreased form factorDomestic plumbingMultiple way valvesEngineeringLateral movement

A mixer water faucet for installation through a bore in a work surface in proximity to a water supply, includes a stationary housing extending transversely through the bore; a faucet body mounted onto the housing, rotatable relative thereto; a main and auxiliary spouts extending from the housing; main and auxiliary supply hoses extending through the housing for conveying water to the main and auxiliary spouts, respectively; and a diverter for selectably directing a supply of water to the main and auxiliary spouts, wherein the main spout rotates about a rotation axis extending through the faucet body, the rotation causing a lateral movement and partial twisting of the auxiliary water supply hose with respect to the main water supply hose thereby to allow thereby to allow freedom of movement of the auxiliary spout and the auxiliary hose during extension and retraction thereof.

Owner:HAMAT SANITARY FITTINGS & CASTING LTD

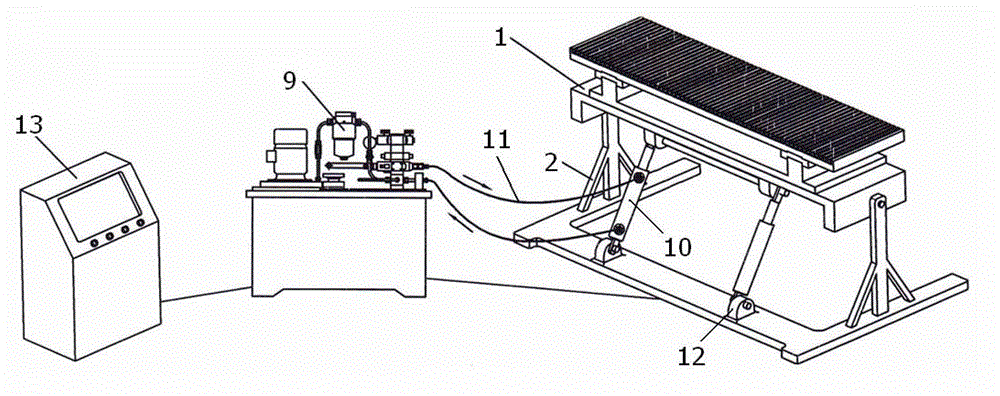

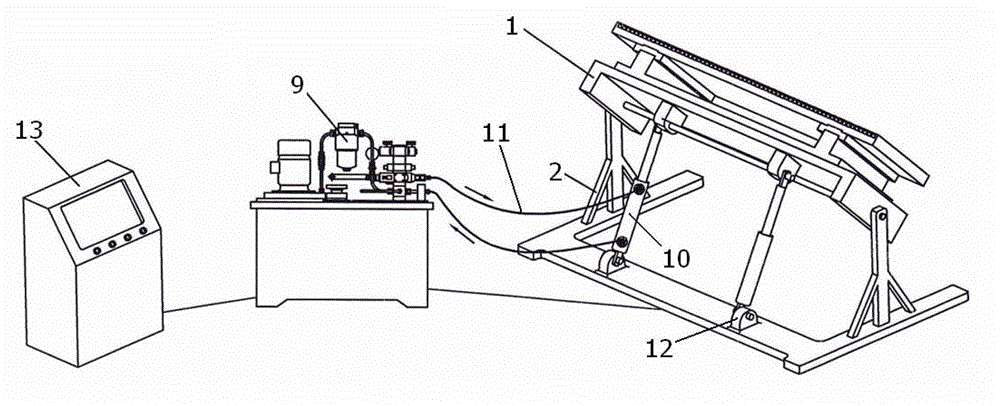

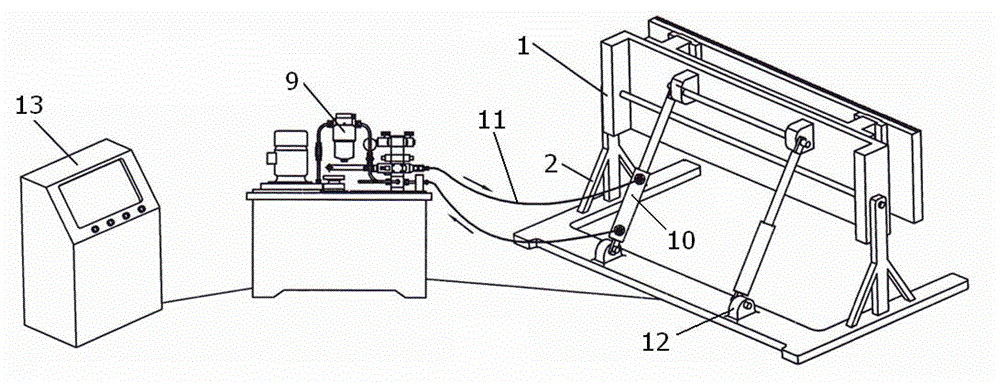

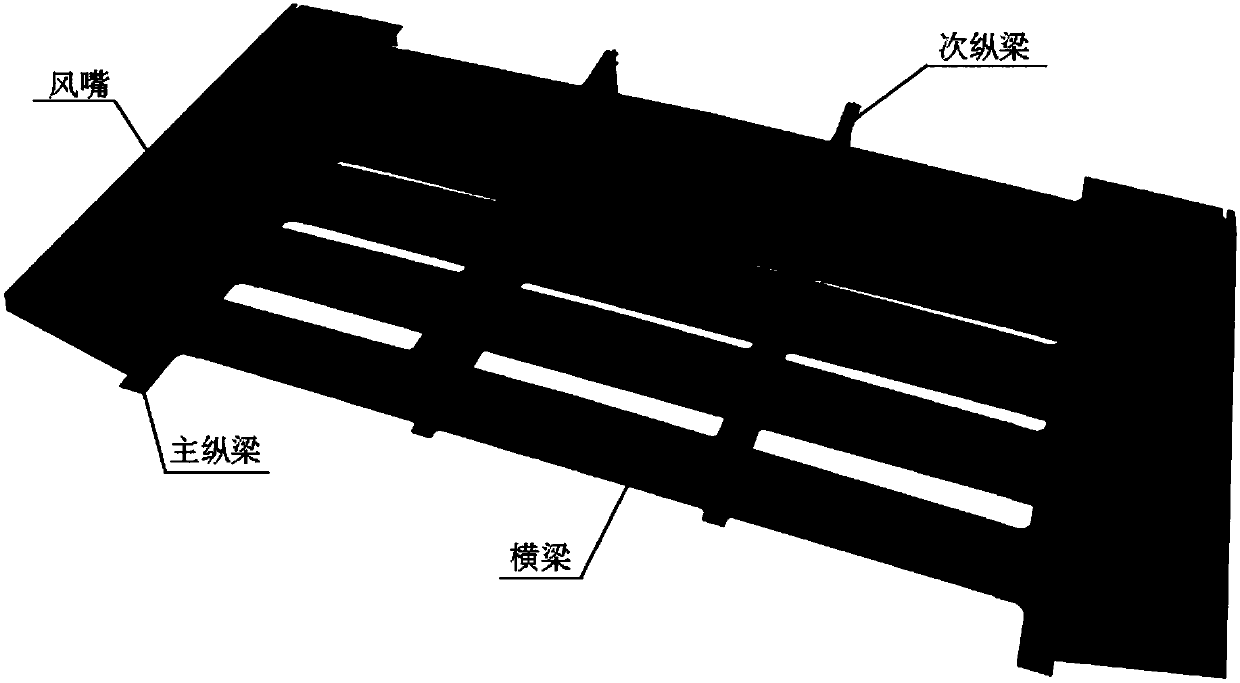

Novel braiding machine capable of achieving multi-structure conversion and multi-angle forming

The invention discloses a novel braiding machine capable of achieving multi-structure and multi-angle forming. The novel braiding machine comprises an adjustable braiding workbench, a braiding bed, a frame and a hydraulic lifting device, wherein the braiding bed is arranged on the adjustable braiding workbench and comprises a braiding rail and a yarn carrier; the hydraulic lifting device comprises a hydraulic pump station and an extensible upright post; the hydraulic pump station and the extensible upright post are communicated through a hydraulic pipe; one end of the extensible upright post is arranged at one side of the bottom surface of the adjustable braiding workbench, and the other end of the bottom surface of the adjustable braiding workbench is arranged on a base; and the adjustable braiding workbench is rotatably arranged on the frame. The novel braiding machine not only can achieve the braiding of three-dimensional multi-directional different structures, but also can carry out multi-angle braiding and forming such as horizontal braiding and forming and vertical braiding and forming according to the processing requirements.

Owner:YIXING HUAHENG HIGH PERFORMANCE FIBER WEAVING

Method for welding and manufacturing weather-resistant suspension bridges with all welded steel structures and stiffening beams

ActiveCN108031957AGuaranteed manufacturing and installation accuracyReduce welding distortionArc welding apparatusWelding/soldering/cutting articlesSequence controlWeather resistance

The invention discloses a method for welding and manufacturing weather-resistant suspension bridges with all welded steel structures and stiffening beams. The method has the advantages that the weather-resistant suspension bridges are welded by the aid of diversified welding materials and welding processes which are matched with weather-resistant steel, weld preheating and interpass temperatures are controlled, accordingly, the mechanical properties and the weather resistance of weld joint zones can be assuredly matched with parent metal, and coating-free service requirements of cold regions can be met; the diversified welding processes are used with one another, accordingly, the work efficiency can be greatly improved, and the construction periods can be shortened; measures such as full-cross-section weld joint position arrangement, groove designs, welding sequence control and inter-section port adjustment are adopted, accordingly, the manufacturing and mounting precision of the integral bridges can be guaranteed, and welding deformation can be reduced.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Method and apparatus for reducing speckle in coherent light

ActiveUS7956941B2Speckle reductionReduce spatial coherenceStatic indicating devicesColor television detailsElectricityLight beam

Owner:TEXAS INSTR INC

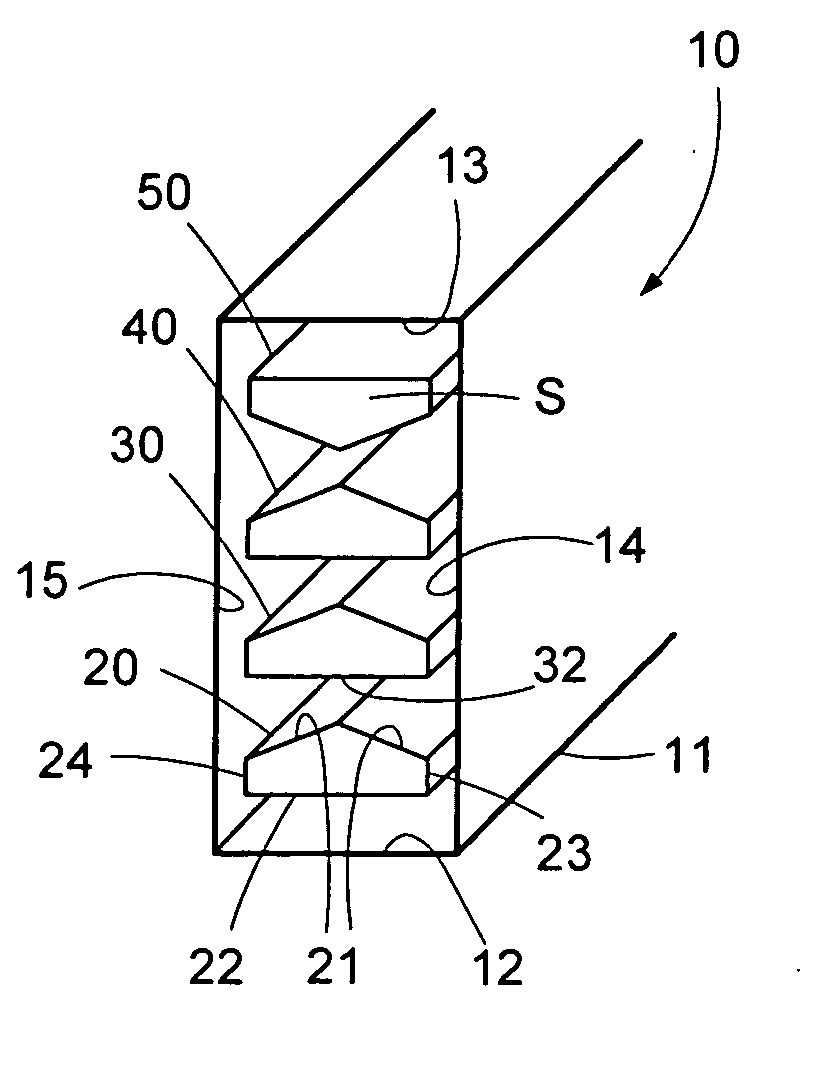

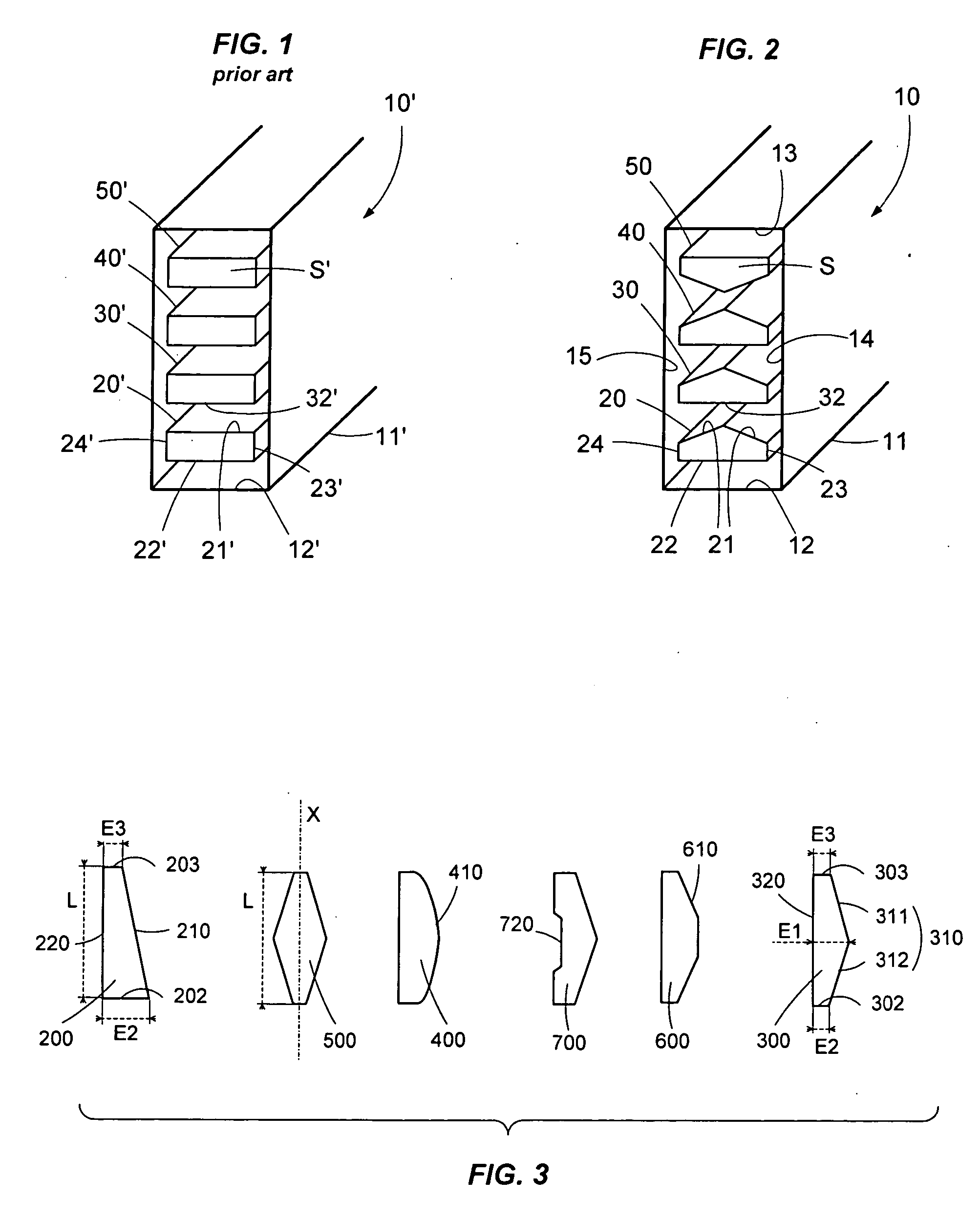

Semiconductor Device Package with Slanting Structures

InactiveUS20130181351A1Improving package form factorReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor package

A semiconductor device package structure includes a substrate with a via contact pad on top surface of the substrate, a terminal pad on bottom surface of the substrate and a conductive through hole through the substrate, wherein the conductive through hole electrically couples the via contact pad and the terminal pad on the substrate; a die having bonding pads thereon, wherein the die is formed on the top surface of the substrate; a slanting structure formed adjacent to at least one side of the die for carrying conductive traces; and a conductive trace formed on upper surface of the slanting structure to offer path between the bonding pads and the via contact pad.

Owner:KING DRAGON INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com