Method for welding and manufacturing weather-resistant suspension bridges with all welded steel structures and stiffening beams

A manufacturing method and weathering steel technology, applied in the field of steel structure manufacturing, can solve problems such as failure to meet design and use requirements, and achieve the effects of reduced manufacturing and installation accuracy, excellent quality, and simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

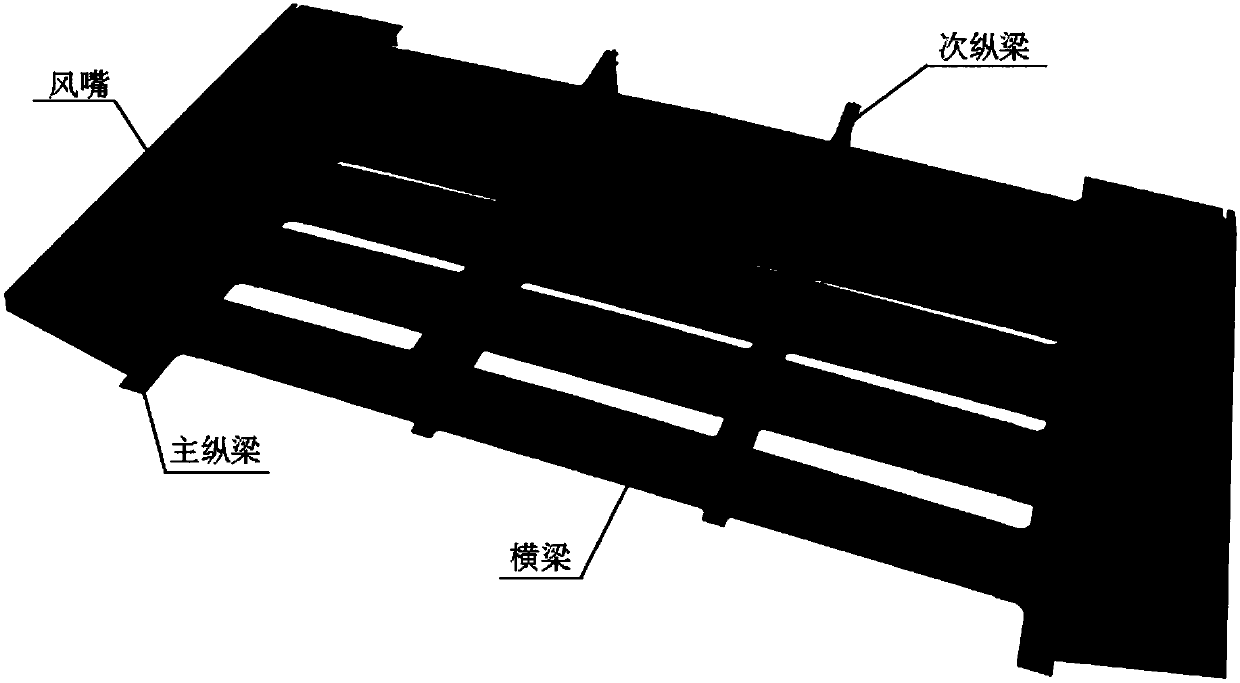

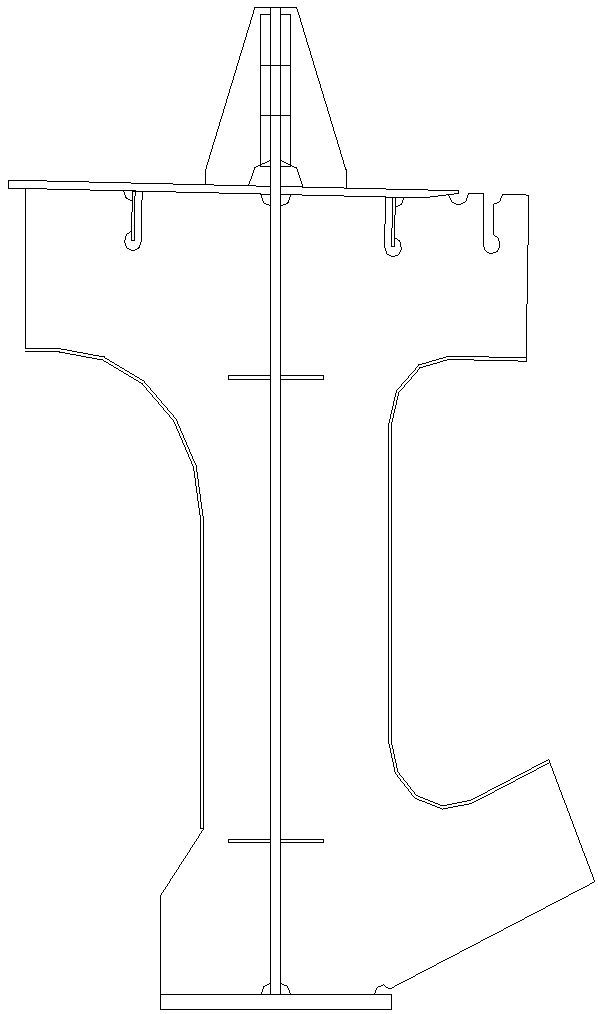

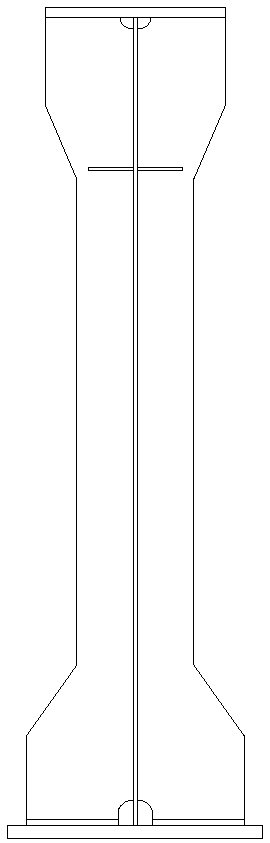

[0029] A welding manufacturing method of a weather-resistant all-welded steel structure stiffened beam suspension bridge, comprising the following steps:

[0030] Step 1: Make weather-resistant steel stiffened beam I-shaped members, box-shaped members, lug plate units and air nozzle units; Beveled fillet welds are welded by flux-cored CO2 gas shielded welding, and the rest of the leading welds are welded by submerged arc automatic welding; the tuyere plate unit is welded by flux-cored wire robotic automatic welding; the rest of the flat welds are semi-automatically welded by solid wire CO2 gas shielded welding Welding, vertical and supine welds are semi-automatically welded with CO2 gas protection for flux cored welds;

[0031] Step 2: After the rod is manufactured, remove surface oil, remove marks, remove splashes and other foreign objects on the rod, and then sandblast, store, and sprinkle water to accelerate corrosion;

[0032] Step 3: Assemble multiple weather-resistant s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com