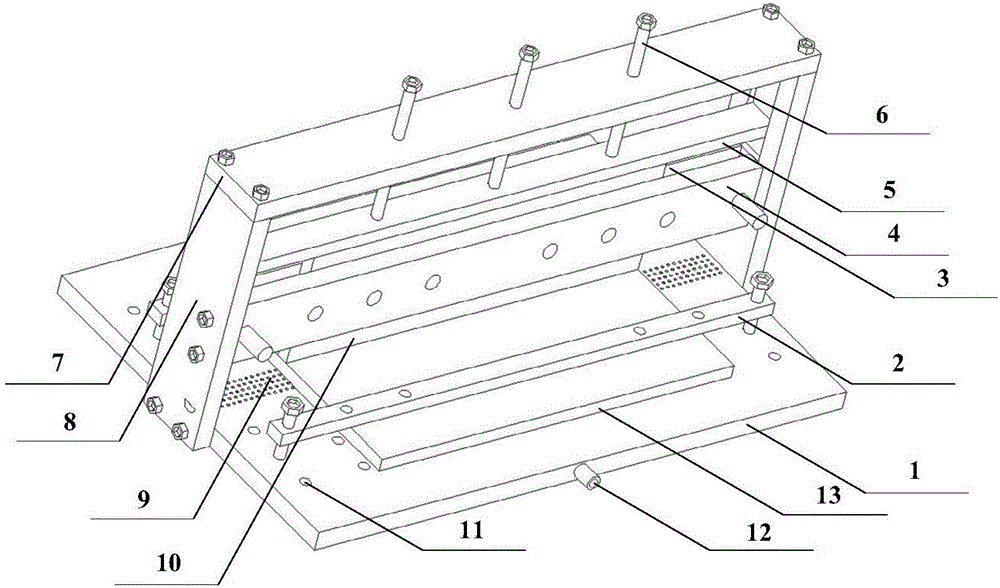

Clamp for laser hybrid welding of T-shaped connector

A hybrid welding and fixture technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve problems such as unsatisfactory, low operational feasibility, and inability to give down pressure to the web, achieving high practicability, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

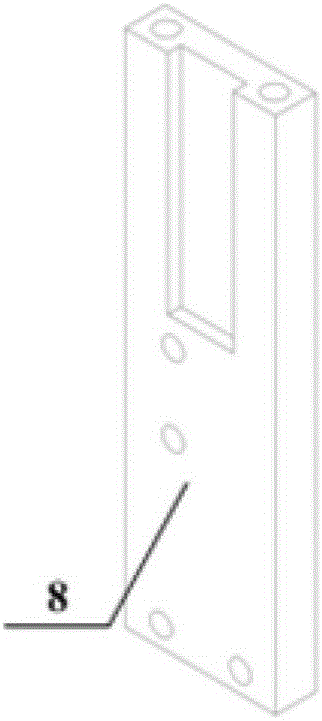

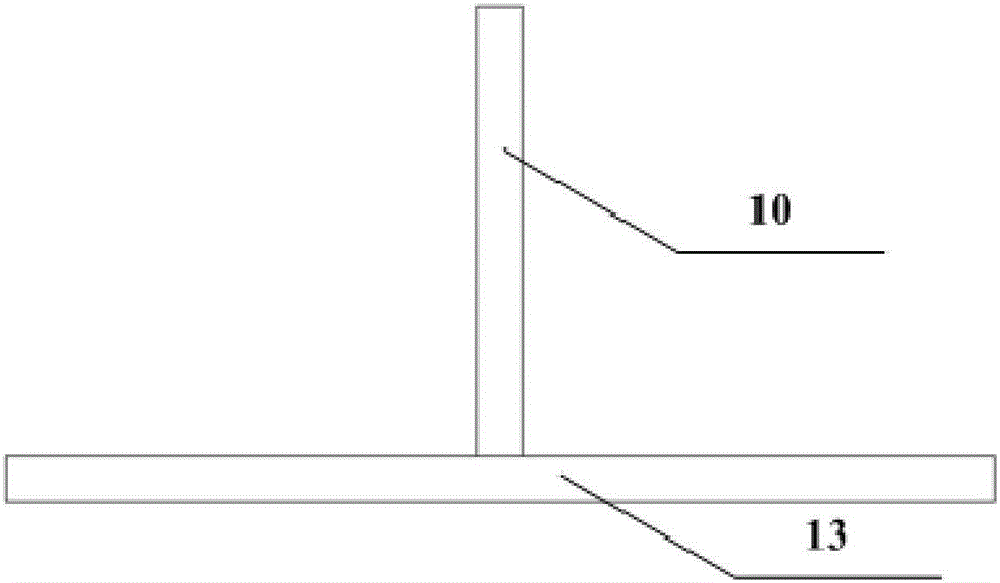

[0018] Use the flange 12 and web 9 of Q235B carbon steel, wherein the specification of the flange 12 is 200mm*100mm*16mm, and the specification of the web 9 is 200mm*100mm*16mm; place the flange 13 on the base 1, adjust its position, place the lower platen 2 on the wing plate 13, fix the lower platen 2 with compression bolts; place the web 9 on the wing plate 13, lift the upper platen 5 according to the height of the wing plate 13, and place the web 10 Under the upper platen 5; adjust the position of the web 10 so that it is close to the positioning baffle 3, and then tighten or loosen the bolts on both sides of the first positioning plate 4, so that the web 10 and the wing plate 13 are perpendicular to each other; Adjust the column bolts on the frame beam 7 to press the upper pressure plate 5 so that the web 10 is in close contact with the wing 13; mouth; during the welding process, the shielding gas is blown out from the air outlet 9 on the base 1 to protect the back of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com