3D printing and scanning all-in-one machine

A 3D printing and all-in-one machine technology, applied in the field of 3D printing, can solve the problems of multiple costs and large space occupied by equipment, and achieve the effect of improving utilization rate and reducing volume size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

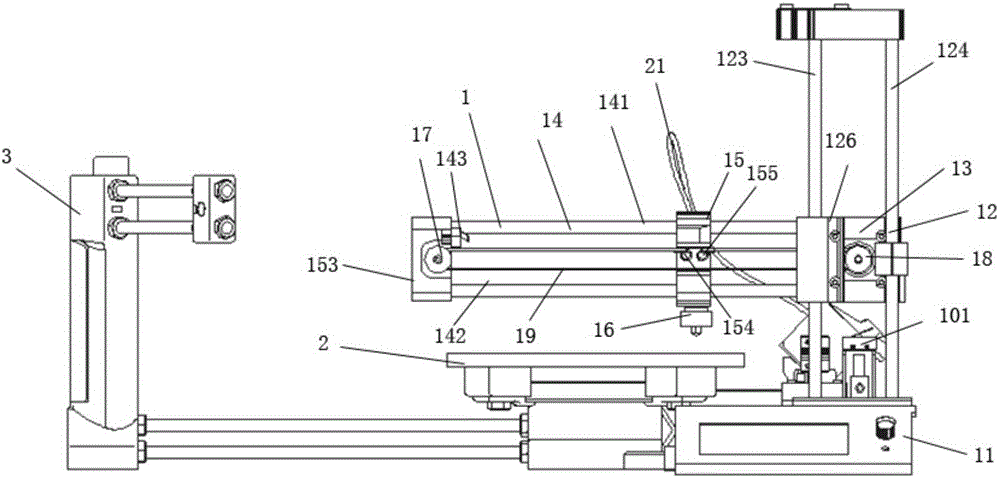

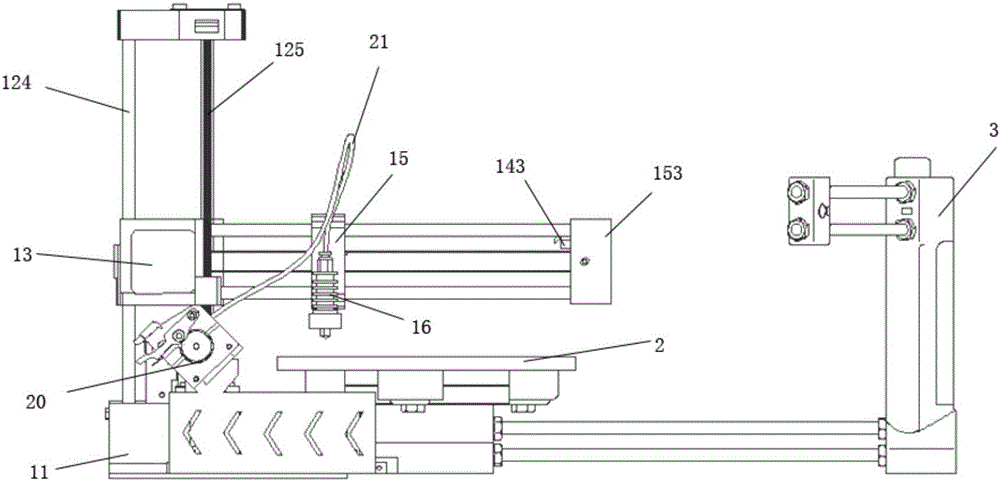

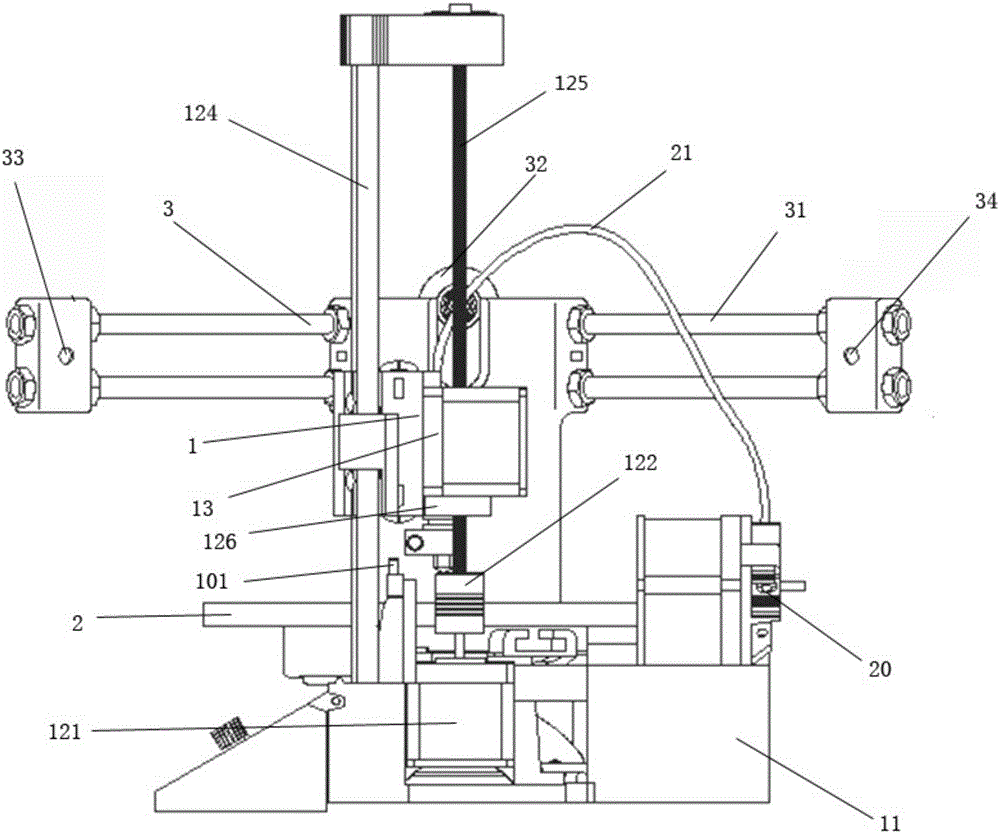

[0031] like Figures 1~5 As shown, the 3D printing and scanning all-in-one machine includes a printing device 1, a rotating platform 2 and a scanning device 3 arranged on one side of the rotating platform 2; wherein the printing device 1 includes a base arranged on the other side of the rotating platform 2 11. A vertical lifting device 12 arranged on the base 11, a cantilever motor 13 arranged on the vertical lifting device 12, a cantilever 14 connected to the vertical lifting device 12 at one end, a cantilever slider 15 slidably connected to the cantilever 14, The print head 16 on the slider 15 and the first synchronous pulley 17, the second synchronous pulley 18 and the synchronous belt 19; wherein the first synchronous pulley 17 is arranged at the other end of the cantilever 14; the second synchronous pulley 18 is arranged at the cantilever motor 13, and the second synchronous pulley 18 is connected to the rotating shaft of the cantilever motor 13; the two ends of the synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com