Novel braiding machine capable of achieving multi-structure conversion and multi-angle forming

A multi-angle, multi-structure technology, applied in the direction of woven fabrics, textiles and paper making, can solve problems such as labor-intensive, high manufacturing costs, and small equipment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

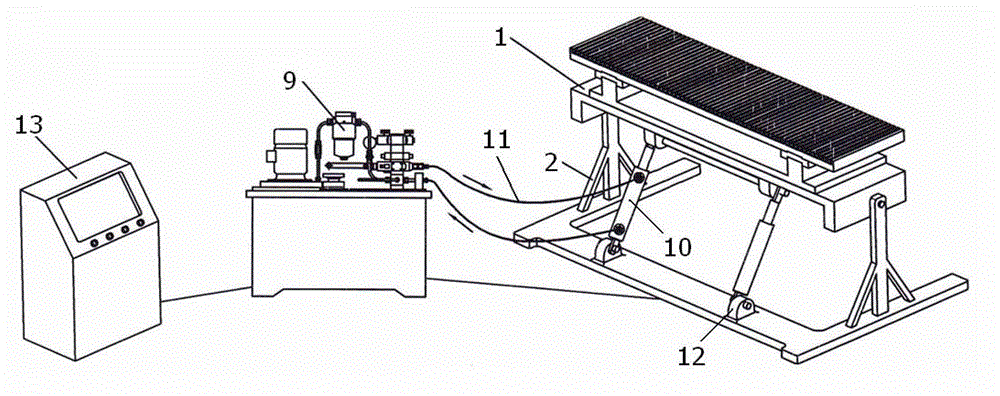

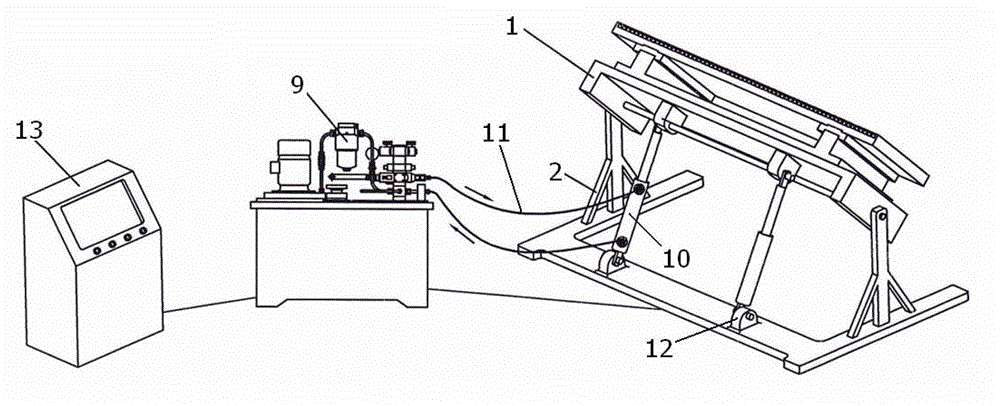

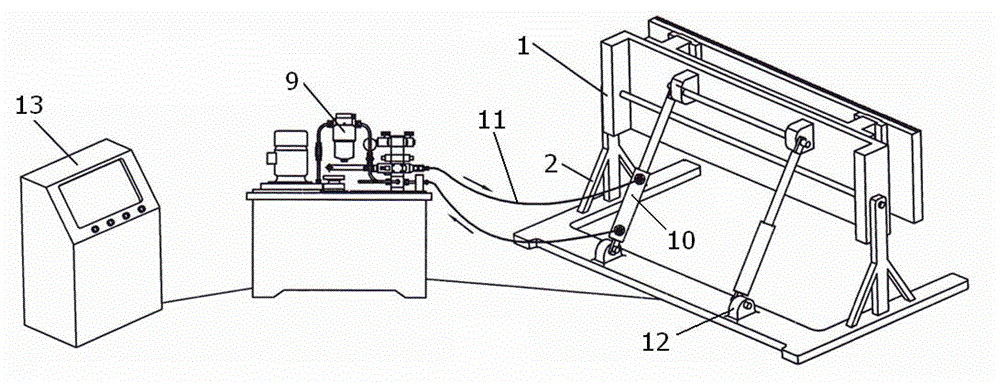

[0029] A new knitting machine that can realize multi-structure conversion and multi-angle forming, including an adjustable knitting table 1, a braiding disc, a frame 2 and a hydraulic lifting device, and the knitting disc is set on the adjustable knitting table 1 , the knitting disk includes a knitting track 3 and a yarn carrier 4, and the knitting track 3 is fixed on the sliding bar 6 by a plurality of T-shaped blocks 5 at equal intervals, and then a plurality of sliding bars 6 are arranged side by side and The T-shaped blocks 5 are aligned with each other, and the yarn carrier 4 is arranged between two adjacent T-shaped blocks 5 of each slide bar 6; there is a gap 7 between the adjacent two slide bars 6, and the adjacent There is a gap between the yarn hanging hooks 8 of the two yarn carriers 4 (such as Figure 4shown); the hydraulic lifting device includes a hydraulic pump station 9 and a telescopic column 10, and the hydraulic pump station 9 and the telescopic column 10 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com