Pipe Bending Forming Method of Flexible Hammer Ball Mandrel

A technology of bending forming and hammer ball, which is applied in the field of pipe bending and forming, can solve the problems of high friction between the mandrel and the inner wall of the pipe, large degree of bending, and excessive thinning of the wall thickness, so as to reduce inner wrinkling and outer cracking, and reduce production. The effect of high efficiency and controllable length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

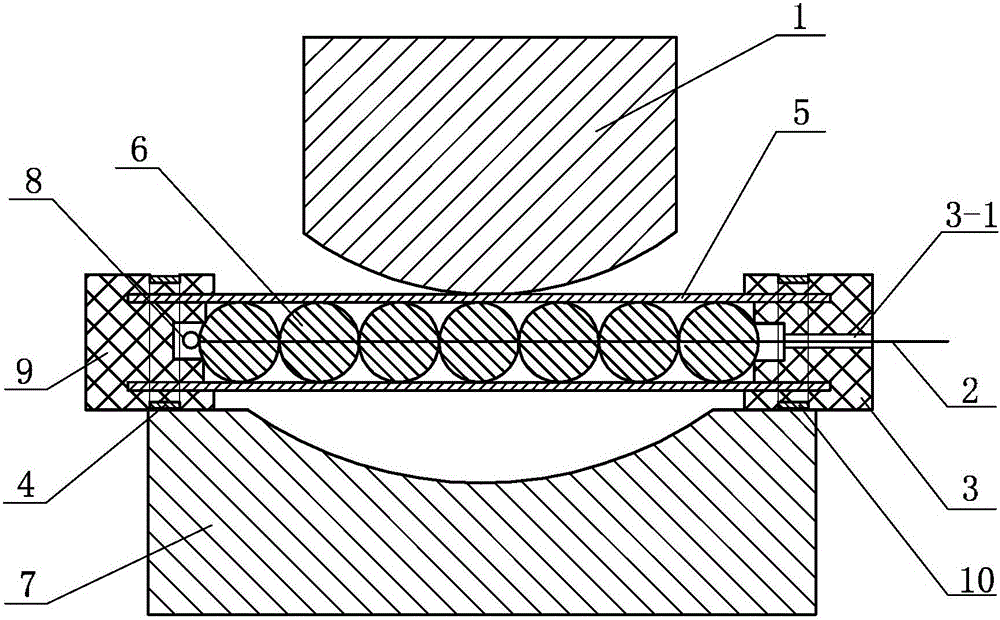

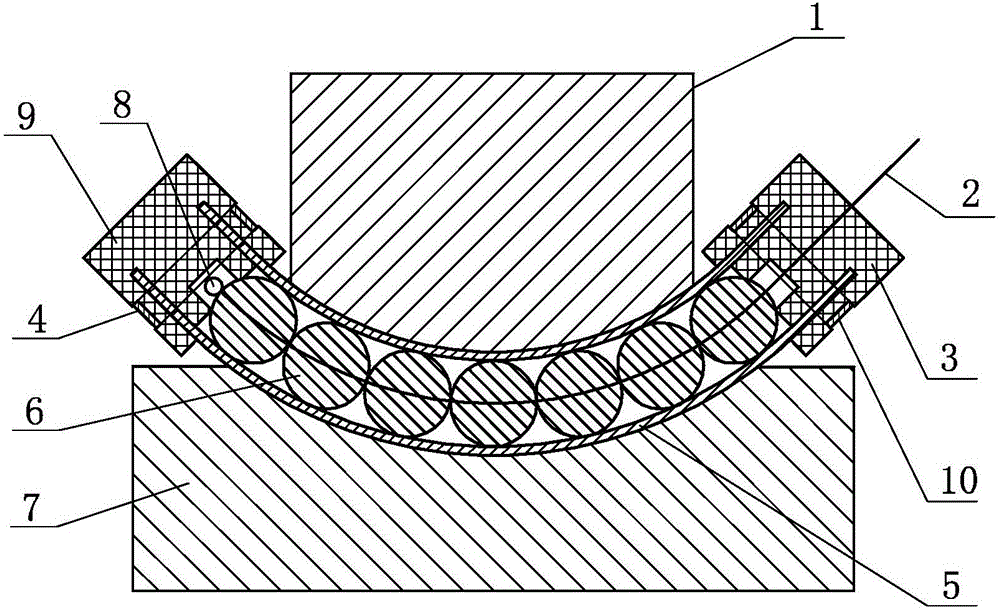

[0027] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this implementation mode, this implementation mode is realized through the following steps:

[0028] Step 1, use a rope 2 with a restraint ring 8 at one end to thread several balls 6 together to form a flexible hammer type mandrel;

[0029] Step 2, insert the assembled flexible hammer type mandrel into the inside of the pipe 5 to be bent;

[0030] Step 3, put the first rubber stopper 9 into one end of the pipe 5 to be bent (this end is the end of the restraining ring 8 of the rope 2), fix the first rubber stopper 9 with the first fastener 4, and fix the second rubber stopper 9 Put the plug 3 into the other end of the pipe 5 to be bent, and pass the rope 2 through the through hole 3-1 of the second rubber plug 3. After the mandrel is completely fixed, use the second fastener 10 to fasten the second rubber Plug 3 is fixed;

[0031] Step 4: Place the pipe 5 to be bent inserted into the flexible ham...

specific Embodiment approach 2

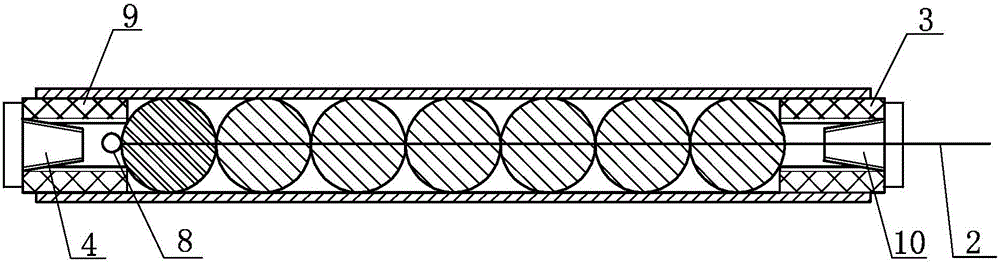

[0033] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. In this embodiment, the ball 6 is provided with a central through hole in step one. The central through hole is used for wearing the rope 2.

specific Embodiment approach 3

[0034] Specific implementation mode three: combination figure 1 , figure 2 and image 3 Describe this embodiment. In this embodiment, the diameter of the confinement ring 8 in step 1 is larger than the diameter of the central through hole. This design makes the confinement ring 8 play a constraining role. Other steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com