An automatic infusion bottle changing device

An automatic, bottle holder technology, applied in the field of medical devices, can solve the problems of slow bottle changing, mutual interference, and high equipment cost, and achieve the effect of fast bottle changing, ensuring work, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

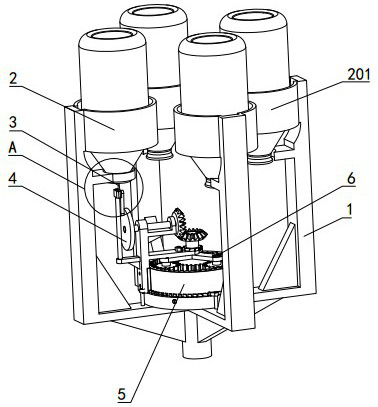

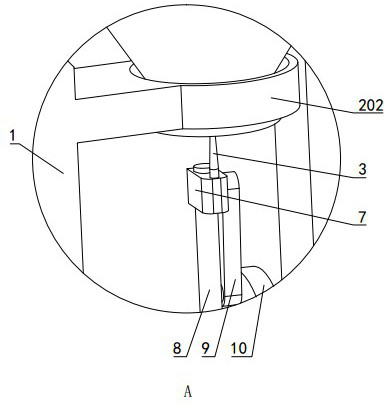

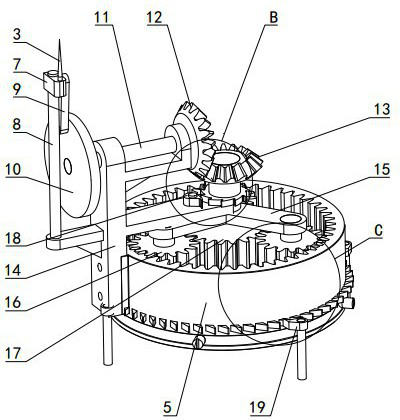

[0021] Figures 1~5 is the best embodiment of the present invention, the following is combined with the appendix Figures 1~5 The present invention will be further described.

[0022] An infusion automatic bottle changing device includes an infusion bottle holder 2 and a puncture needle 3 arranged on the lower side of the infusion bottle holder 2, and also includes a planetary gear train 6, a mounting frame 14 and a power device, and the mounting frame 14 is mounted on the planetary gear train 6. The puncture needle 3 is mounted on the mounting frame 14 in a lifting and lowering manner, and the puncture needle 3 is connected to the planetary carrier 15 of the planetary gear train 6 through the transmission mechanism, and moves with the planetary gear 5. The frame 15 rotates to move up and down, a lift lock mechanism 18 is arranged between the transmission mechanism and the planet carrier 15, a rotation lock mechanism 19 is connected to the ring gear 5, and the power unit is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com