Variable structure turboshaft engine gas intake system

A turboshaft engine and air intake system technology, which is applied in the direction of engine components, machine/engine, turbine/propulsion device air intake, etc., can solve the problem of circumferential uneven sealing, difficulty, memory alloy does not meet the requirements, etc. problems, to achieve the effect of improving aerodynamic efficiency and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

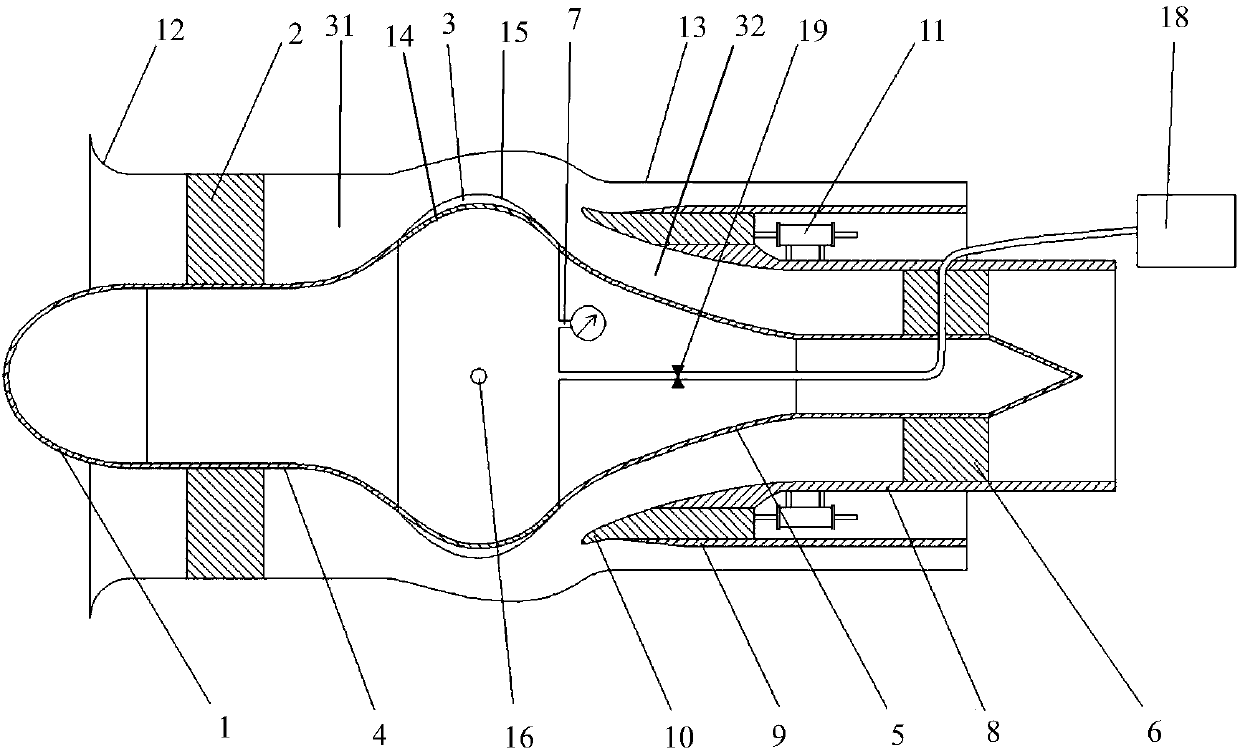

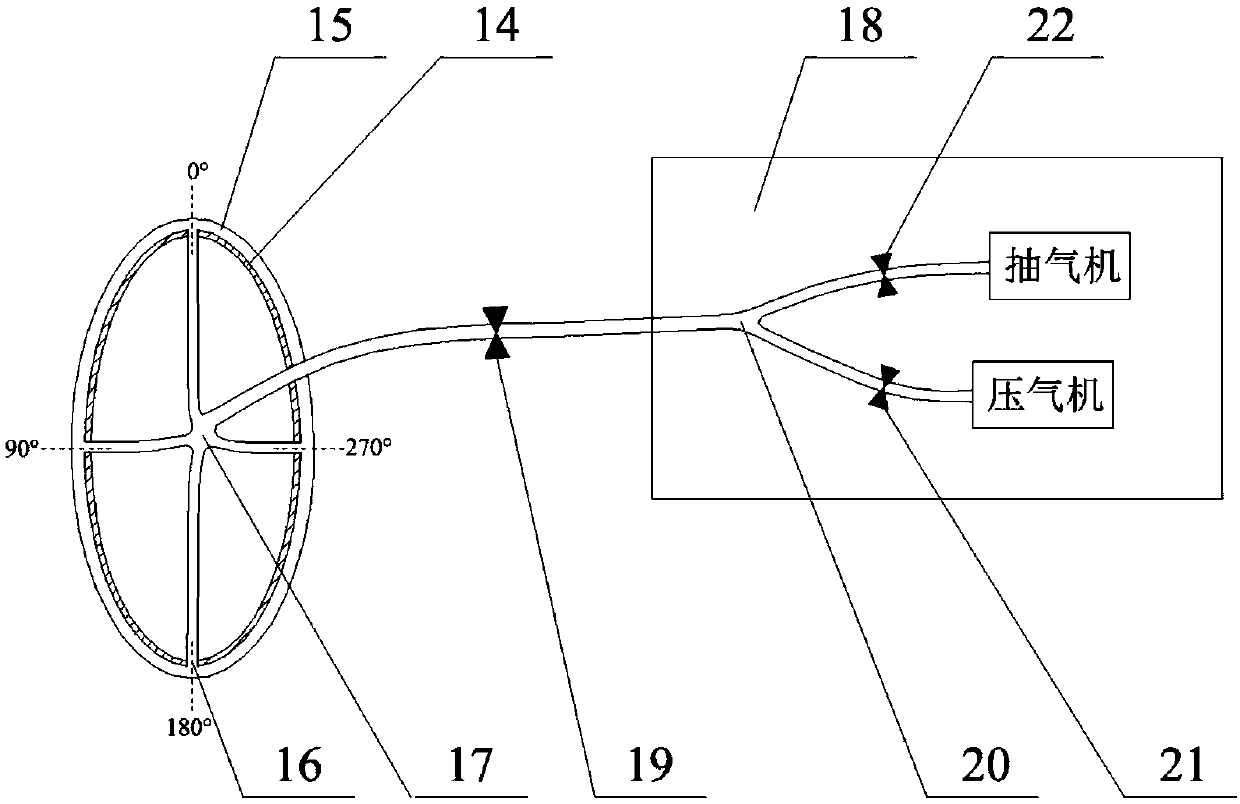

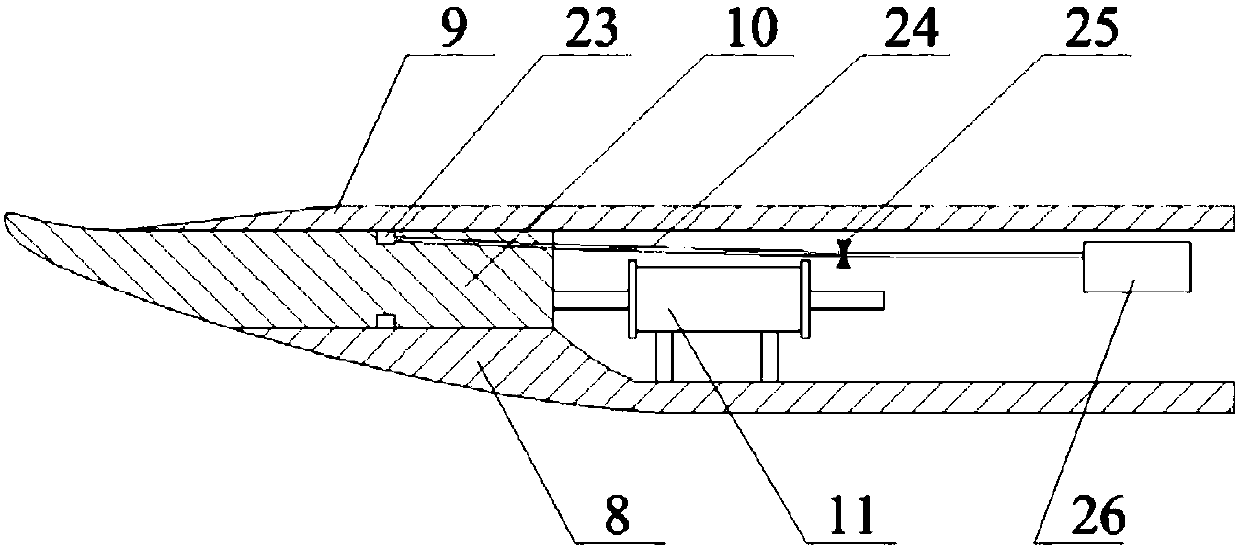

[0022] see figure 1 As shown, the invention discloses a turboshaft engine air intake device, which includes a center body assembly, a wedge assembly and a casing assembly. The casing assembly is the shell of the integral air intake device, including an outer cylinder 13 surrounding the central body assembly and a double-button lip section 12 located at the front of the outer cylinder 13 . The central body assembly includes a front fairing 1, an annular air chamber 3, a central body front section 4 extending forward from the annular air chamber, a central body rear section 5 extending backward from the annular air chamber, connecting and fixing the outer cylinder 13 and The front support section 2 of the front section 4 of the central body is connected and fixed to the outer cylinder 13 and the rear support section 6 and the pressure monitor 7 of the rear section 5 of the central body. Among them, the annular air chamber 3 adopts an integral structure, with a metal structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com