Spiral type thrust engine

A screw-type engine technology, which is applied in the field of hot gas variable displacement engine devices, can solve the problems of complex engine systems, frequent maintenance, frequent repairs, large quality, and large volume, and achieve the effects of simple structure, low energy loss, and small mass and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

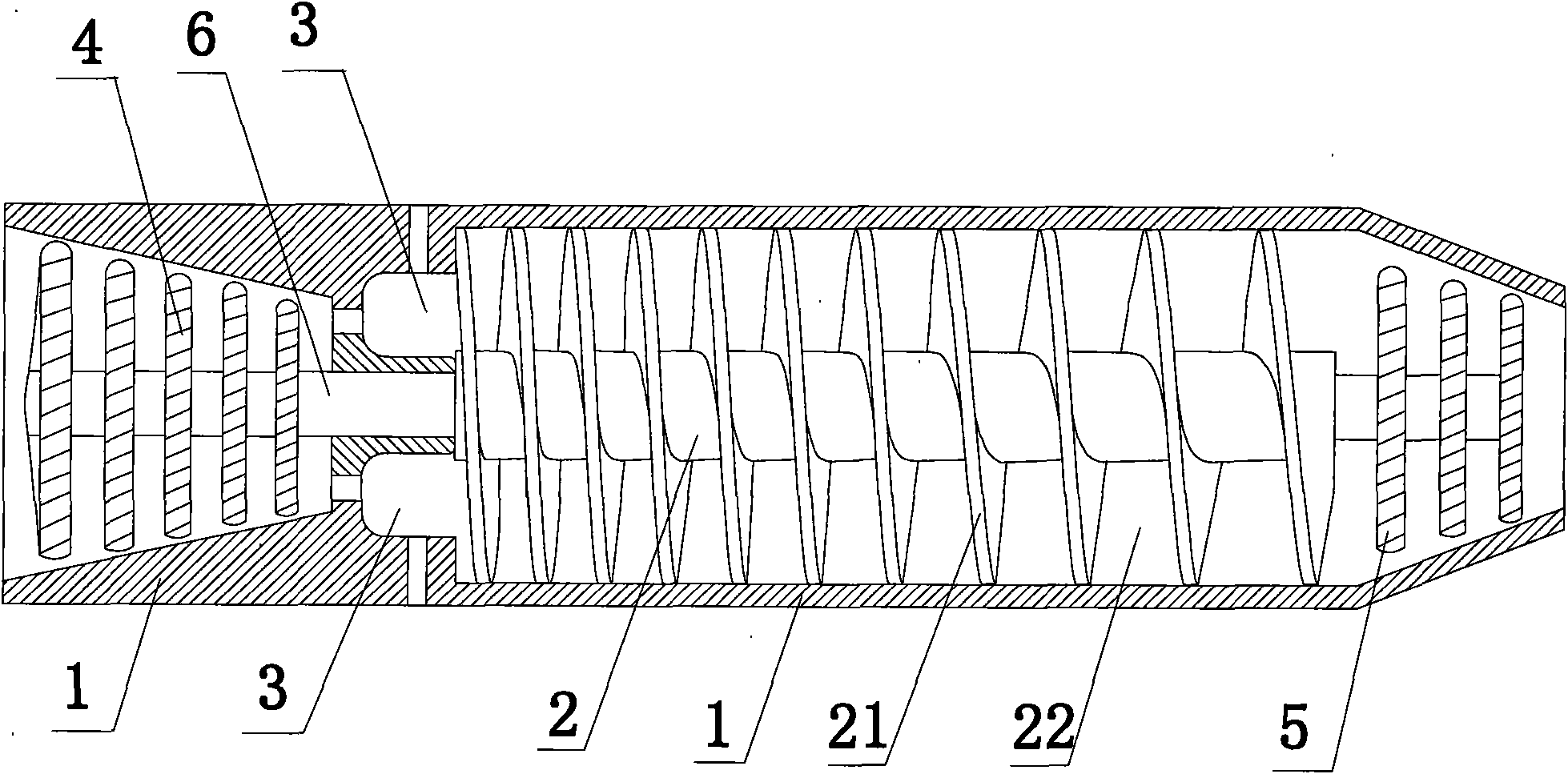

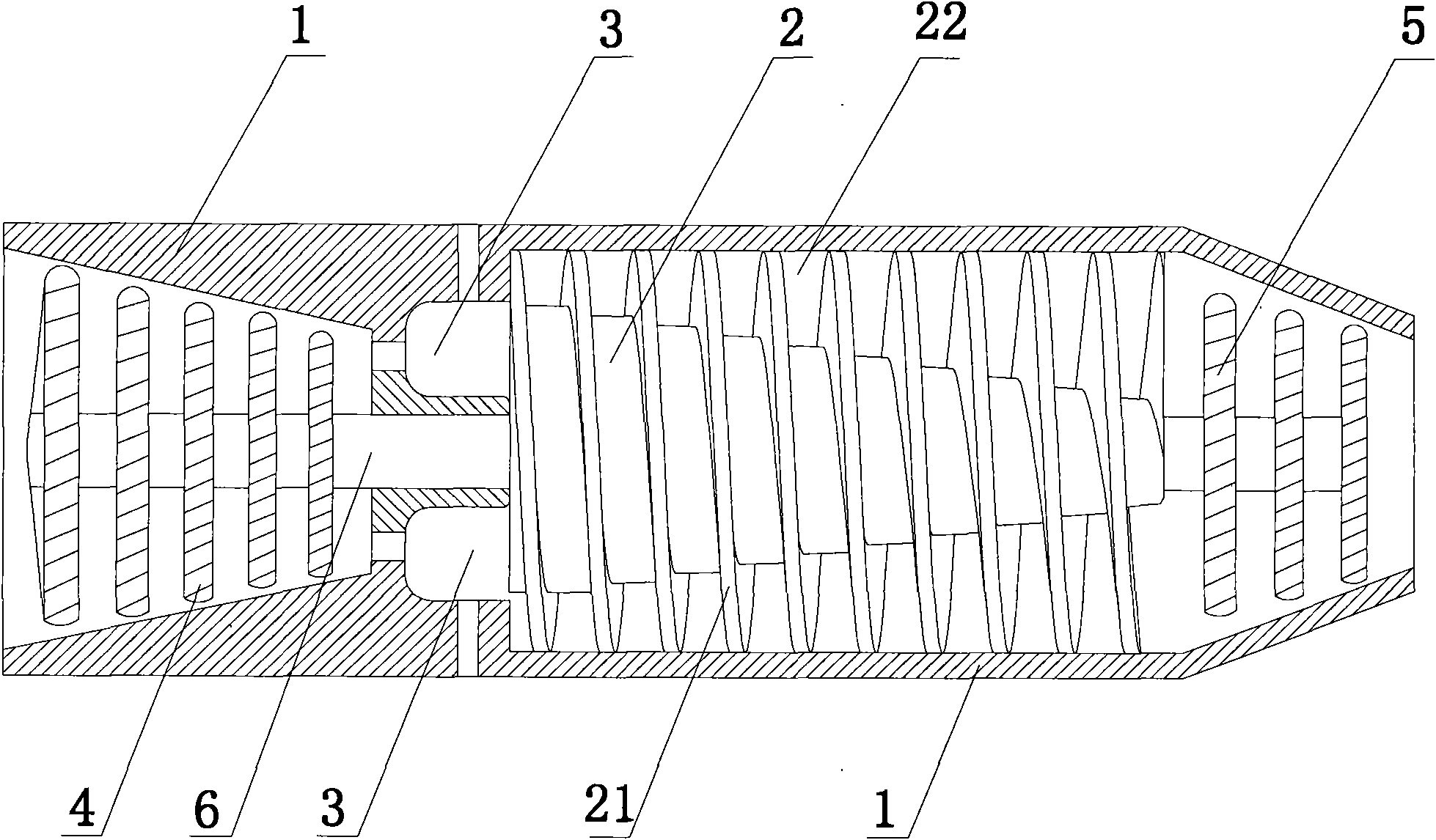

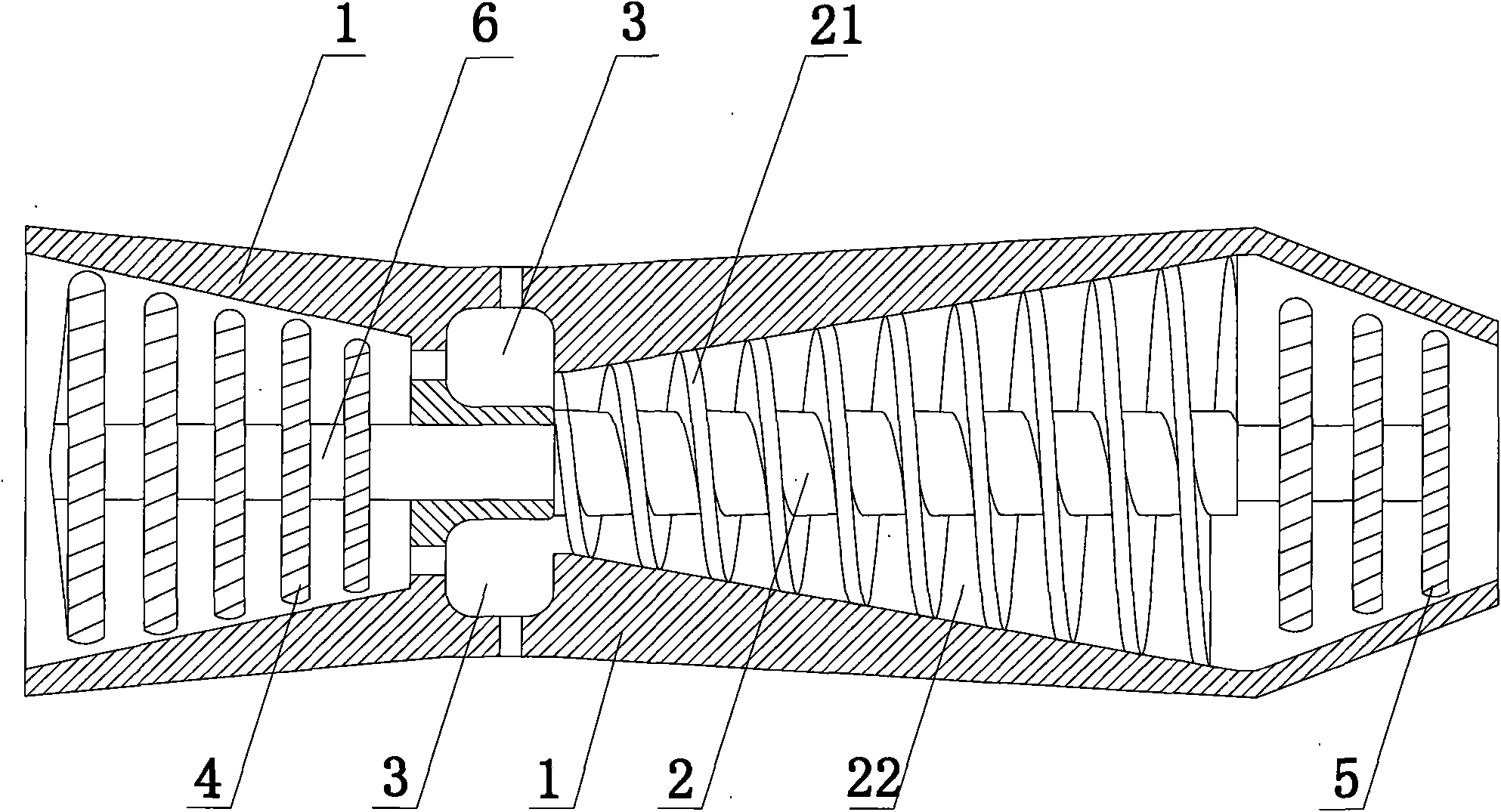

[0018] As an embodiment of the present invention, such as figure 1 As shown, a helical thrust engine includes an engine housing 1 and a high-pressure working medium generating device, and also includes a helical thrust generator fixed in the engine housing 1, and the high-pressure working medium generating device is a jet engine Combustion chamber, such as the combustion chamber 3 of the turbojet engine shown in this embodiment. The helical thrust generator is arranged between the combustion chamber 3 and the turbine 5, and the shaft 6 connecting the compressor 4 and the turbine 5 runs through the front and rear end faces of the helical thruster 2 shaft core 2 and is coaxial with it. The helical thrust generator includes a shaft core 2 and a helical blade 21 that is fixed on the side of the shaft core 2 and takes its shaft as the axis of rotation to advance helically along the axial direction from its front end to the rear end, and the inner edge of the helical blade 21 is ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com