Vane of stirring type wind power heating start device

A starting device and stirring technology, which is applied in wind power generation, wind turbines, engines, etc., can solve the problems of restricting the development of stirring wind heating technology and less research on the starting performance of stirring wind heating devices, and achieving a sweeping area reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

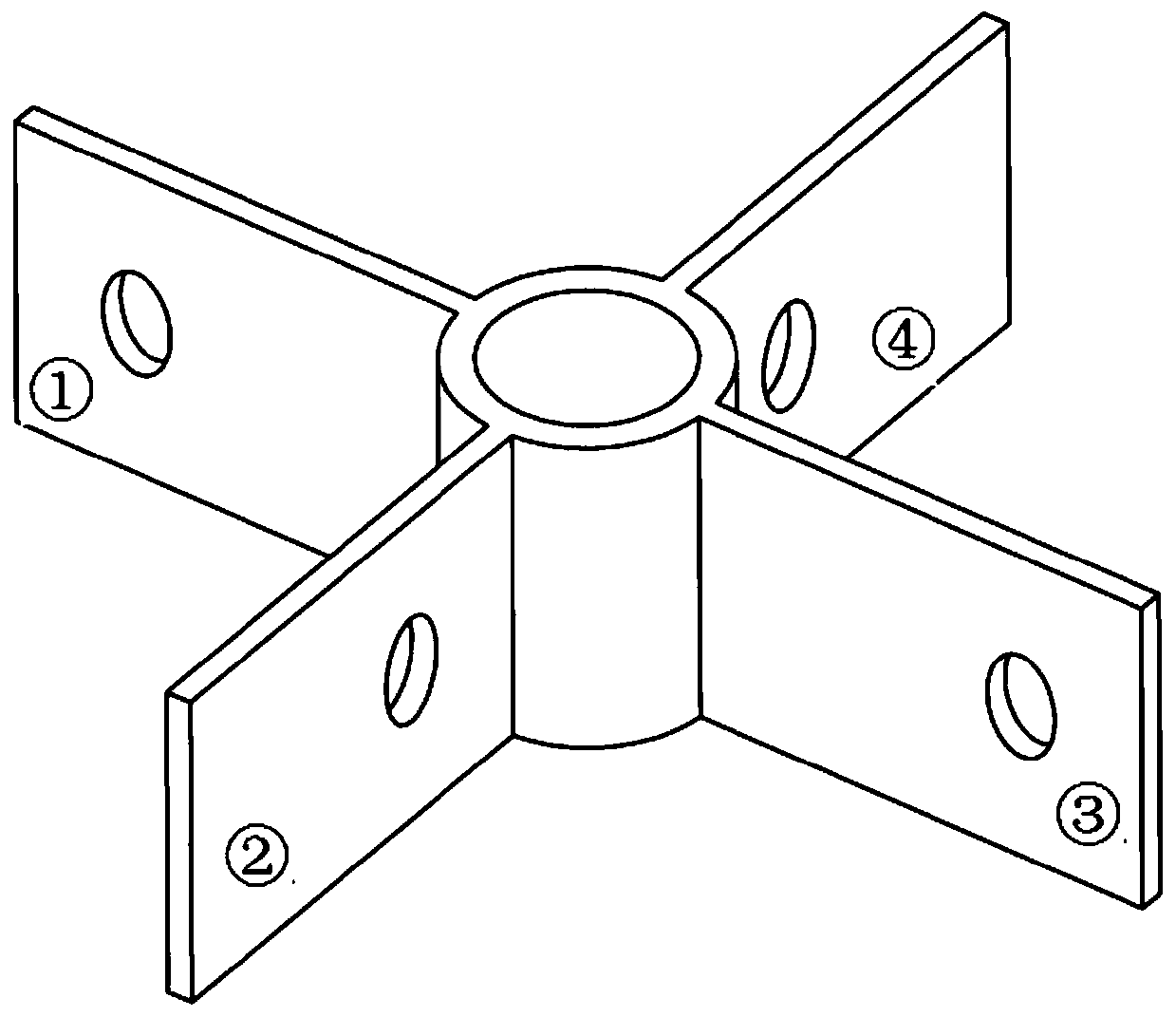

[0018] Such as figure 1 As shown, the blade of the stirring type wind energy thermal starting device of the present invention has a turbine-type straight blade made up of four blades. Since the sweeping area of the straight blades will increase the starting torque of the agitating wind energy thermal starting device, the four blades are marked as ① / ② / ③ / ④ counterclockwise, and the holes are staggered on the four straight blades, that is, the blade ① and ③ / are punched at the distance from the tip of the blade, while the blades ② and ④ are punched a little farther from the tip of the blade, and the center of the hole circle is located at 1 / 2 of the width of the blade. The hole can be a round hole or an oval hole.

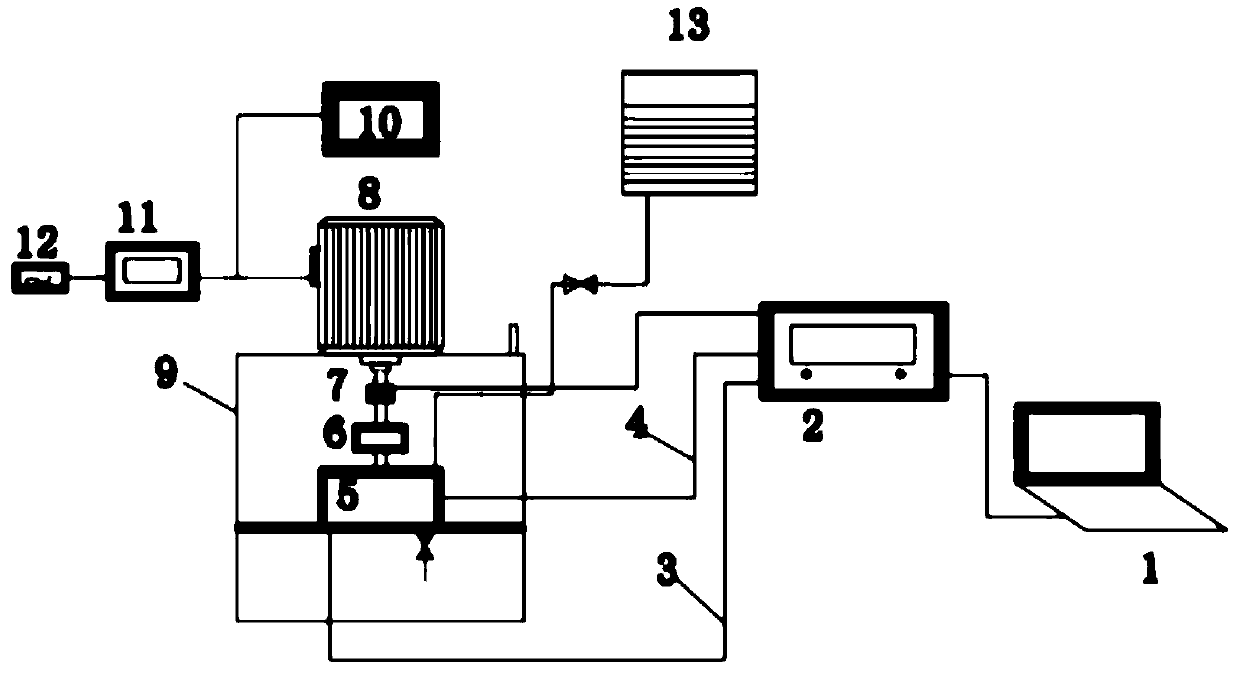

[0019] Such as figure 2 As shown, the indoor wind energy stirring heating device adopting the blade of the present invention includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com