Windwheel of large-scale wind energy power device

A technology for a power plant and a wind turbine, which is applied to wind power generation, the configuration of installing/supporting wind turbines, wind turbines, etc. The effect of reducing the swept area and improving the efficiency of wind energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

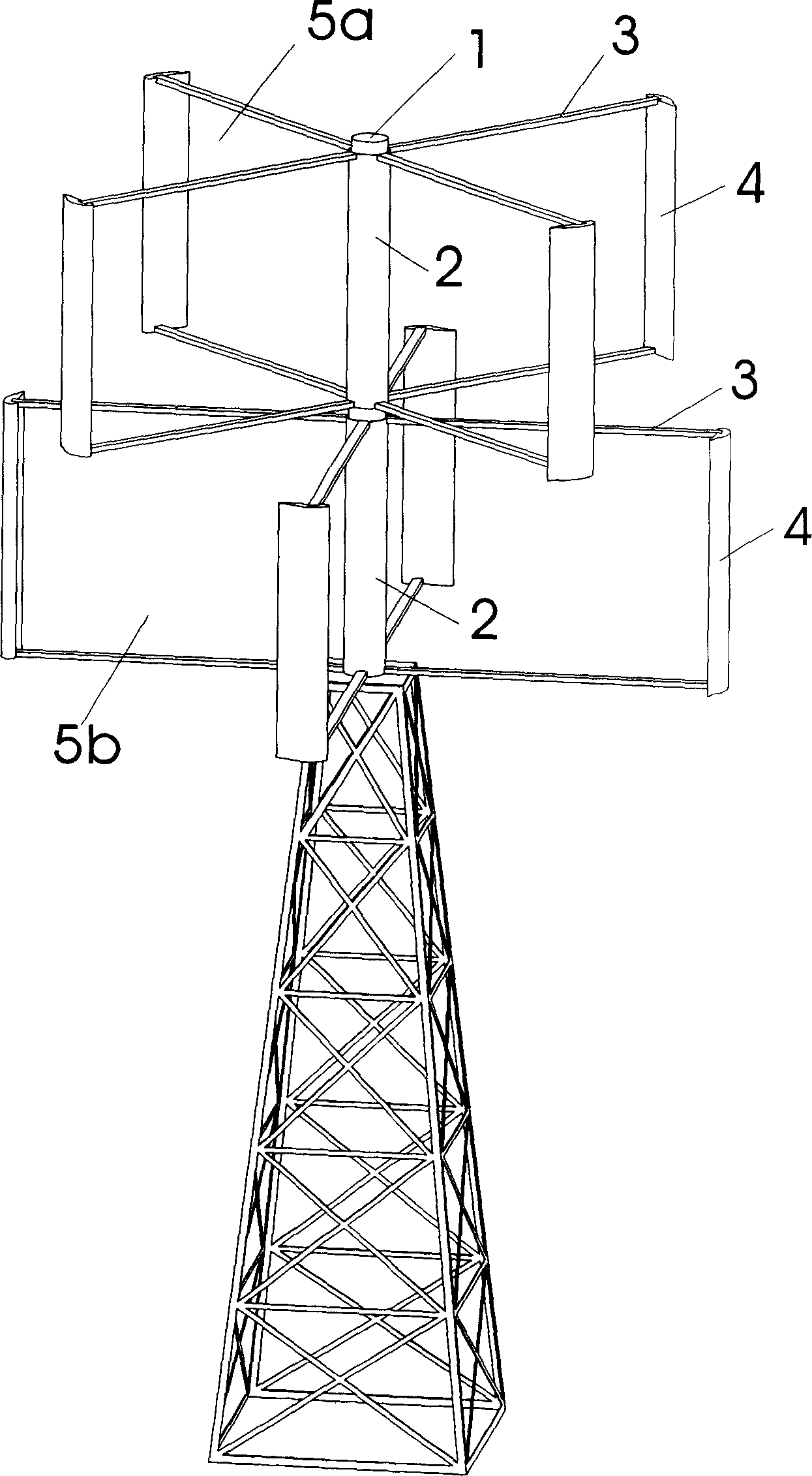

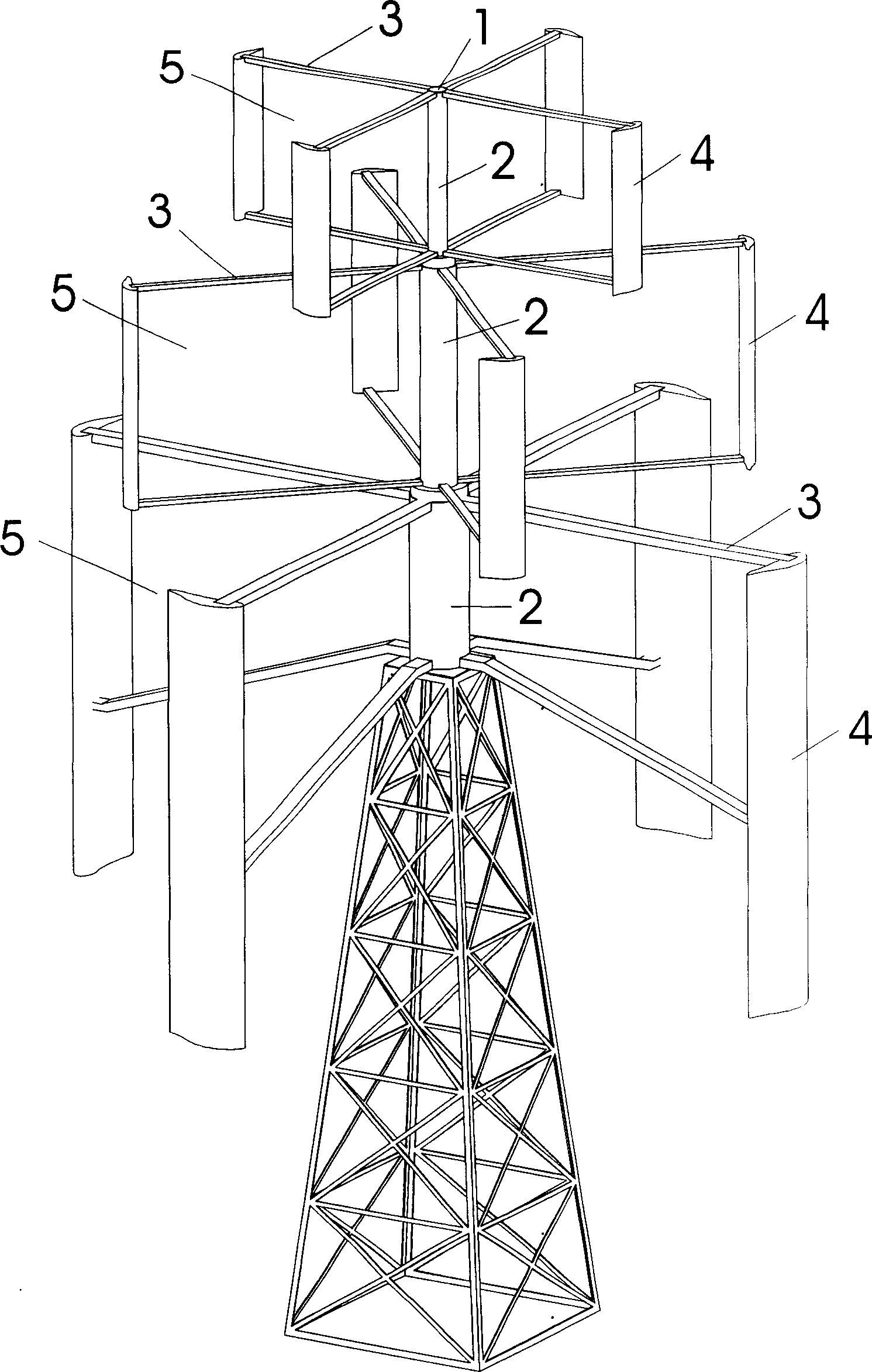

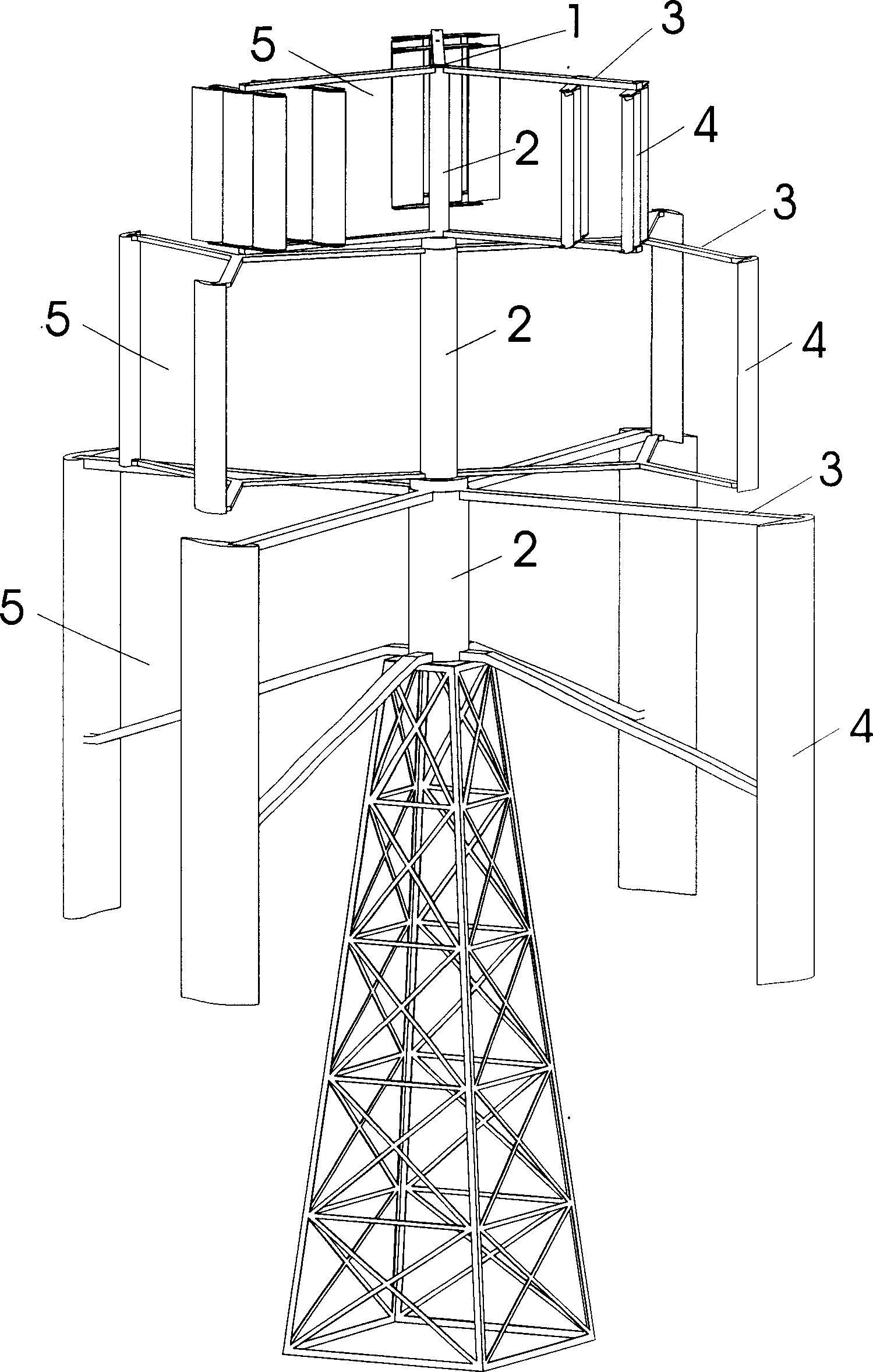

[0014] from figure 1 It can be seen from the figure that the wind wheel of a wind energy power plant according to the present invention is composed of a unit wind wheel 5a, a unit wind wheel 5b and a vertical shaft 1, and the shaft sleeve 2 is sleeved on the shaft sleeve 2. A cantilever 3 is connected, and a blade 4 is connected to the cantilever 3. The bushing 2, the cantilever 3 and the blade 4 form a unit wind wheel 5, and the unit wind wheel 5a and the unit wind wheel 5b are mounted on the vertical shaft 1 in series . There can be 2 to 50 unit wind wheels 5; the unit wind wheels 5 of each layer can be the same or different. A unit wind wheel 5 can have 2 to 16 cantilevers 3 . The included angle between the cantilevers 3 of different units of the wind wheel 5 constituting the wind wheel can be in the range of 0 to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com