A supercritical carbon dioxide cogeneration system and operation method

A carbon dioxide, cogeneration technology, applied in joint combustion mitigation, steam engine installations, machines/engines, etc., can solve the problems of 50℃-140℃, difficult to match the heat release curve, difficult to use the exhausted steam, etc. The effect of reducing the temperature of the working fluid, reducing the heat exchange temperature difference at the hot end, and improving the energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

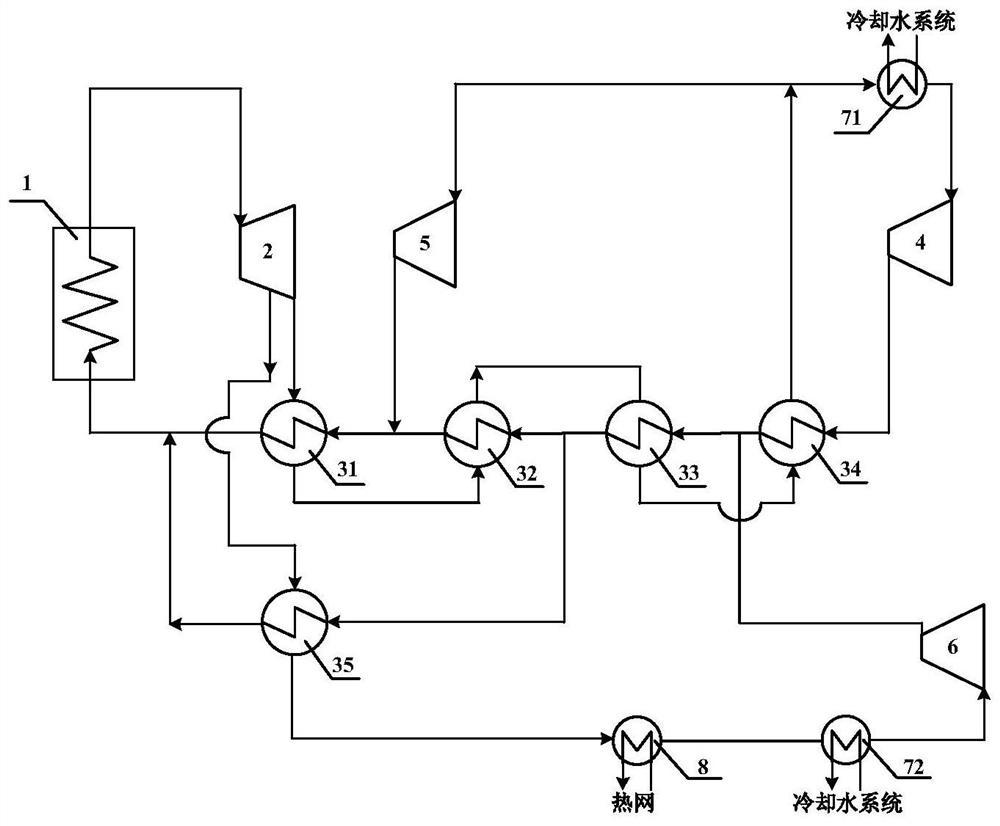

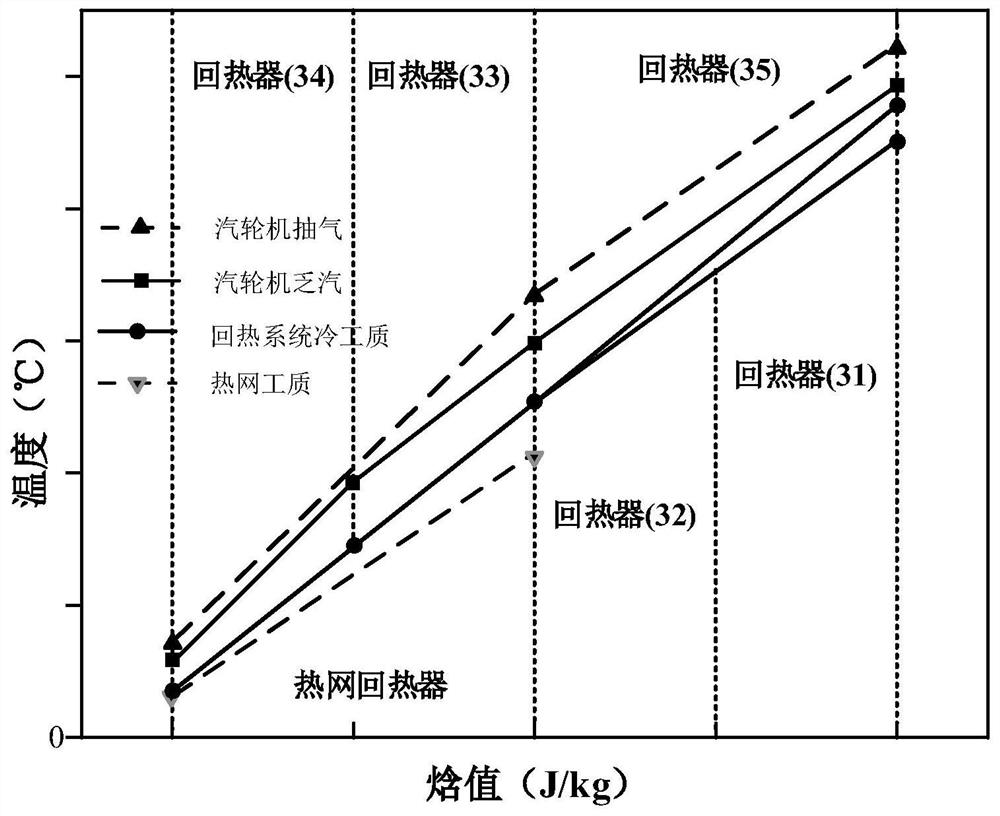

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] working principle

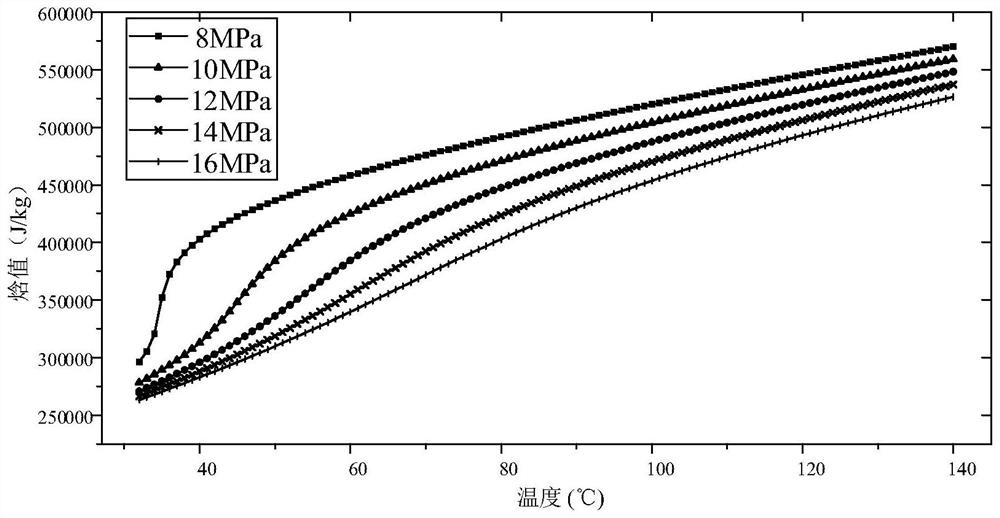

[0031] The curve of enthalpy value and temperature change of carbon dioxide working medium under different pressures is as follows: figure 1 As shown, in the supercritical carbon dioxide system, the exhaust steam pressure of the turbine is mostly below 10MPa. At this time, when the temperature of the working fluid is higher than 60°C, the heat release is slow. Irreversible loss, most of the waste heat required for heating is between 50°C and 140°C, and it is difficult to utilize exhaust steam in this temperature range, so the heat supply of supercritical carbon dioxide coal-fired power generation system is different from that of traditional high back pressure heating units. When the carbon dioxide pressure is high, the heat release curve is linear and easy to match, so it is a relatively reasonable and simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com