Condensing glass evacuated medium-temperature collector tube

A glass vacuum, concentrating technology, applied in the field of solar energy utilization, can solve the problems of short working life, large investment in manufacturing equipment, high requirements for wind and corrosion resistance, and achieve various shapes and settings, improve optical energy density, and prolong working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

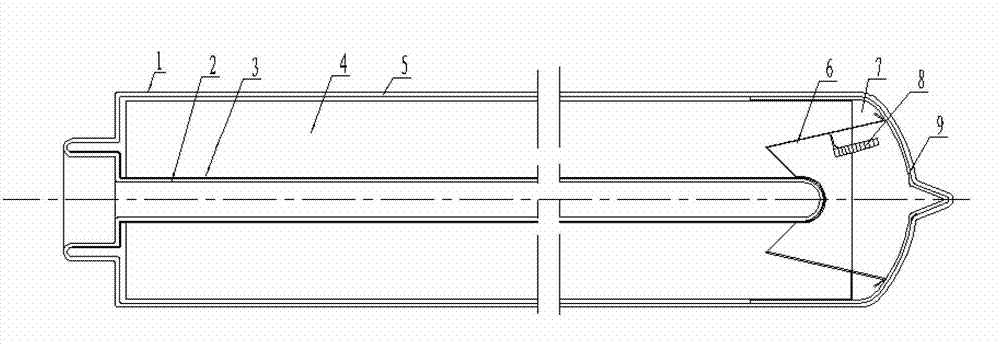

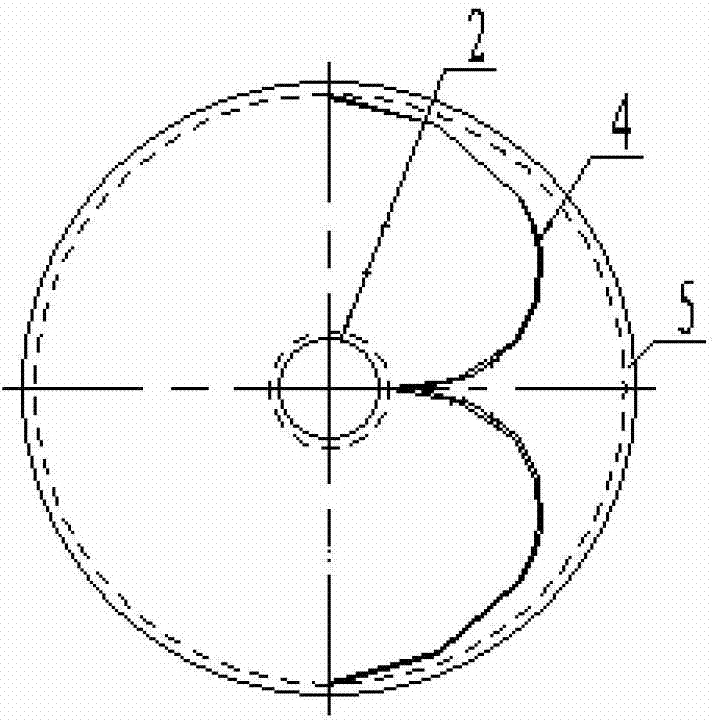

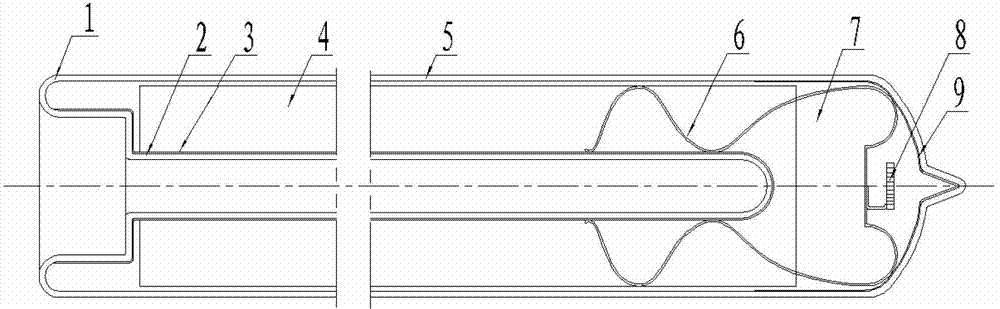

[0023] Such as figure 1 , figure 2 , image 3 As shown, the concentrating glass vacuum medium-temperature heat collection tube of the present invention has a structure in which a metal reflective condenser is built into the solar glass vacuum tube 1 . The solar glass vacuum tube 1 includes a glass cover tube 5, a glass inner tube 2 coated with a selective absorption coating 3 on the outer wall, a bracket 6 and a getter 8, and the material of the glass cover tube 5 and the glass inner tube 2 is preferably high boron The linear thermal expansion coefficient of silicon glass and high boron glass is (3.3±0.1)×10 -6 K, so it is also called borosilicate glass 3.3. The glass inner tube 2 is placed in the glass cover tube 5, supported by a bracket 6 at the bottom of the glass inner tube 2 and the glass cover tube 5, and the open end is welded and sealed. The interlayer is a vacuum layer, and the getter 8 is arranged on the bracket 6 to form a solar glass vacuum tube 1 . Preferab...

Embodiment 1

[0029] The outer diameter of the glass cover tube 5 is 102 mm, and the total length is 1500 mm or 1800 mm; the outer diameter from the distance from the opening end of the glass cover tube 5 to the opening end is 58 mm; the outer diameter of the glass inner tube 2 is 20 mm, and the distance from the opening end of the glass inner tube 2 is 70 mm The outer diameter to the open end is 58 mm, and the glass cover tube 5 and the glass inner tube 2 are made of borosilicate glass 3.3. The metal reflective concentrator 4 placed in the vacuum interlayer 7 is shaped like a trough concentrating paraboloid or other concave and curved concentrating surfaces, and is made of mirror polished aluminum sheet, mirror stainless steel sheet, or mirror tin iron sheet, with a thickness of 0.3mm-0.2mm , with a width of 98mm and a concentration ratio of 5, it is a concentrating glass vacuum medium-temperature heat collector with a large concentration ratio.

Embodiment 2

[0031]The outer diameter of the glass cover tube 5 is 70 mm, and the total length is 1500 mm or 1800 mm; the outer diameter from the distance from the opening end of the glass cover tube 5 to the opening end is 58 mm; the outer diameter of the glass inner tube 2 is 20 mm, and the distance from the opening end of the glass inner tube 2 is 50 mm The outer diameter to the open end is 58mm or 47mm, and the glass cover tube 5 and the glass inner tube 2 are made of borosilicate glass 3.3. The metal reflective concentrator 4 placed in the vacuum interlayer 7 is shaped like a trough concentrating paraboloid or other concave and curved concentrating surfaces, and is made of mirror polished aluminum sheet, mirror stainless steel sheet, or mirror tin iron sheet, with a thickness of 0.3mm-0.2mm , the width is 50mm or 62mm, and the concentration ratio is 3, which is a medium concentration ratio concentrating glass vacuum medium temperature heat collector.

[0032] The air-drying temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com