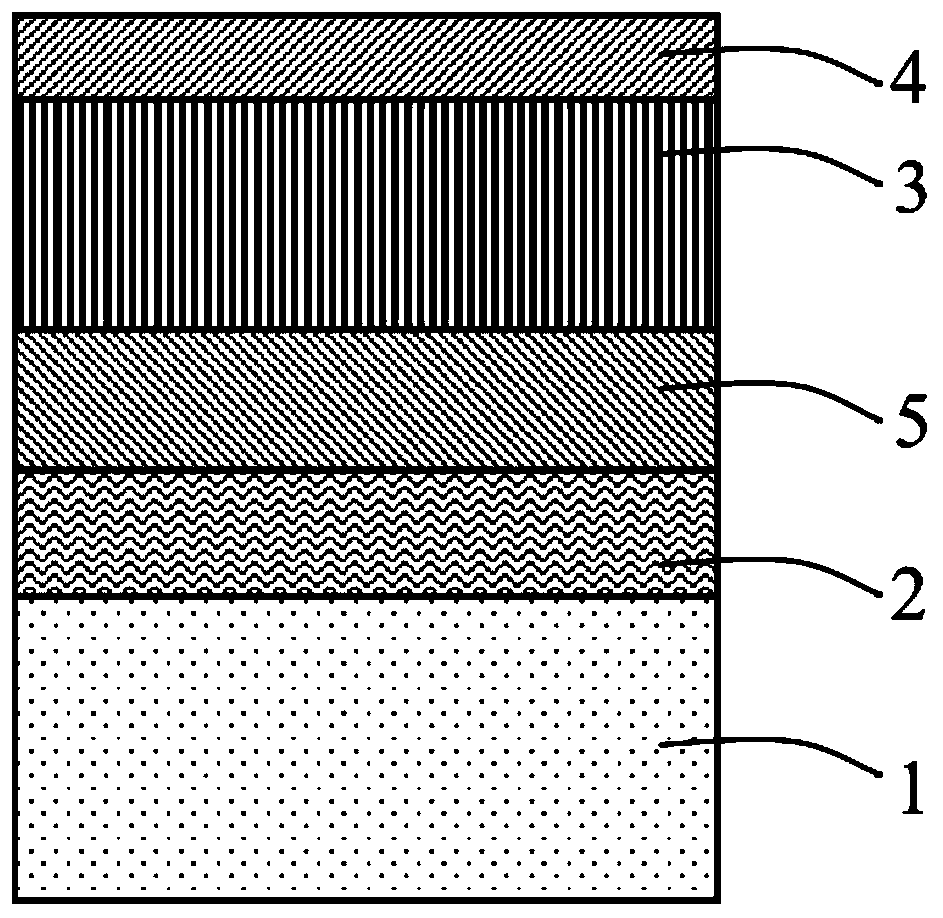

Yb modified CMAS prevention composite structure thermal barrier coating and preparing method thereof

A technology of thermal barrier coating and composite structure, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc., and can solve problems such as low thermal conductivity, easy expansion of coating cracks, and short thermal cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

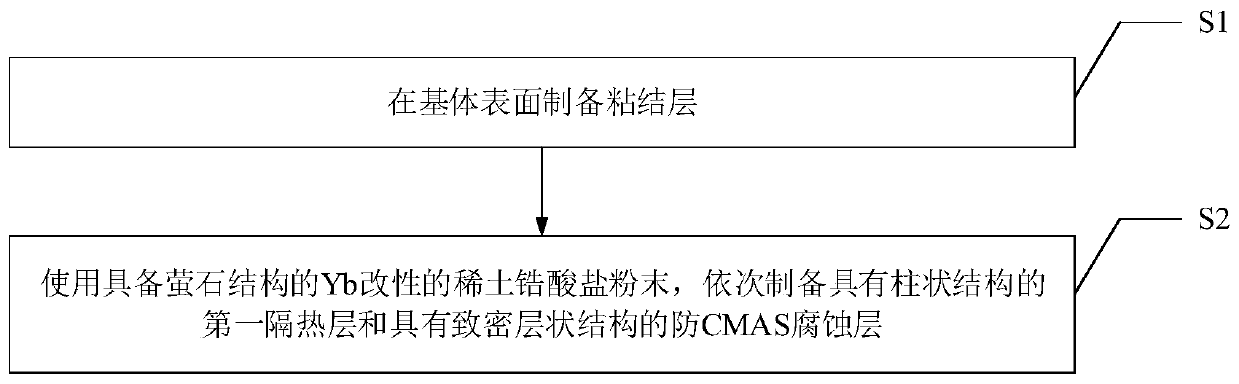

[0044] Based on the same inventive concept, the present invention also provides a preparation method of Yb modified anti-CMAS composite structure thermal barrier coating, such as figure 2 shown, including the following steps:

[0045] S1: preparing a bonding layer on the surface of the substrate;

[0046] Specifically, the substrate can be a superalloy substrate; before preparing the bonding layer, the surface of the superalloy substrate can be polished with sandpaper, then the polished superalloy substrate can be ultrasonically cleaned in alcohol or acetone, and finally the superalloy substrate The surface is pretreated by wet sandblasting to roughness Ra≤3; the bonding layer can be treated by one or more of multi-arc ion plating, low-pressure plasma spraying, magnetron sputtering, vapor phase infiltration, embedding infiltration, electroplating, and vapor phase deposition. A combination of the above methods is formed, and the formed bonding layer is subjected to vacuum hea...

Embodiment 1

[0065] The first step is to prepare single-phase fluorite structure ytterbium zirconate material and spray powder

[0066] (1) According to the chemical structural formula (Gd 1-x1 Yb x1 ) 2 Zr 2 o 7 and (Gd 1-x2 Yb x2 ) 2 Zr 2 o 7 , where, x1=0.2, x2=0.4, respectively weigh the high-purity oxide Gd 2 o 3 Powder, Yb 2 o 3 Powder and ZrO 2 Powder, two groups of weighed powders are mixed separately to obtain two kinds of mixed slurry;

[0067] (2) Put the above two kinds of mixed slurry into an oven to dry at a temperature of 60°C for 5h to 10h, then put it into a high-temperature furnace, and raise it to 1500°C in an air atmosphere for a high-temperature phase-forming reaction, and the reaction time For 15h, with furnace cooling, respectively (Gd 0.8 Yb 0.2 ) 2 Zr 2 o 7 and (Gd 0.6 Yb 0.4 ) 2 Zr 2 o 7 two materials;

[0068] (3) The above (Gd 0.8 Yb 0.2 ) 2 Zr 2 o 7 and (Gd 0.6 Yb 0.4 ) 2 Zr 2 o 7 The two materials were crushed by ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com