Patents

Literature

49results about How to "Adequate insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

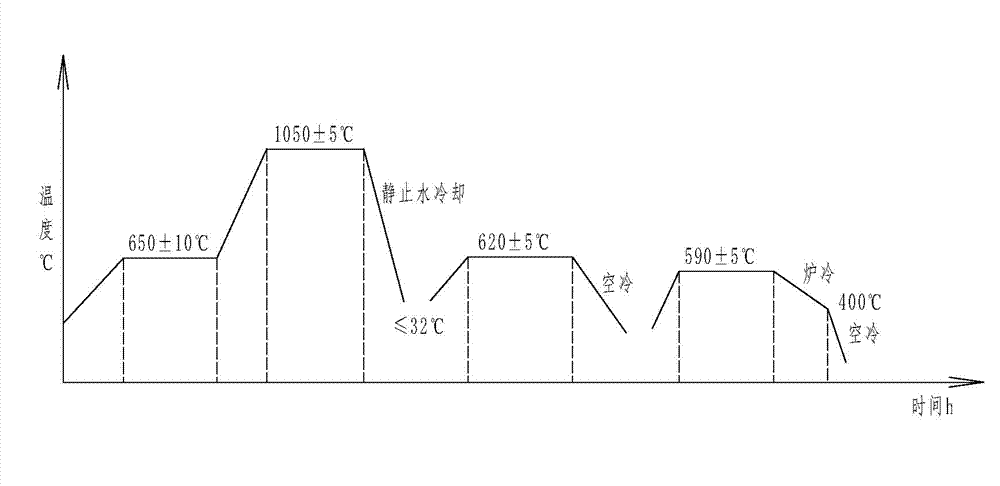

Process for manufacturing 17-4PH Martensite precipitation-hardening stainless steel forgings

The invention relates to a process for manufacturing 17-4PH Martensite precipitation-hardening stainless steel forgings. The process comprises the following steps of: quenching: firstly, raising the temperature of a workpiece to be 650 plus or minus 10 DEG C for carrying out heat preservation for the first time, raising the temperature of the workpiece to be 1,050 plus or minus 5 DEG C for carrying out heat preservation for the second time after the heat preservation for the first time is carried out for a long time, performing stationary air cooling on the workpiece in the water until the temperature of the workpiece is not more than 32 DEG C after the heat preservation for the second time is carried out for a long time; tempering for the first time: raising the temperature of the cooled workpiece to be 620 plus or minus 5 DEG C for carrying out heat preservation for the third time, and air-cooling the workpiece after the heat preservation for the third time is carried out for a long time; and tempering for the second time: raising the temperature of the workpiece subjected to the tempering for the first time to be 590 plus or minus 5 DEG C for carrying out heat preservation for the fourth time; furnace-cooling the workpiece after the heat preservation to be 400 DEG C after the heat preservation of the fourth time is carried out for a long time; and air-cooling the workpiece to prepare the forgings.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

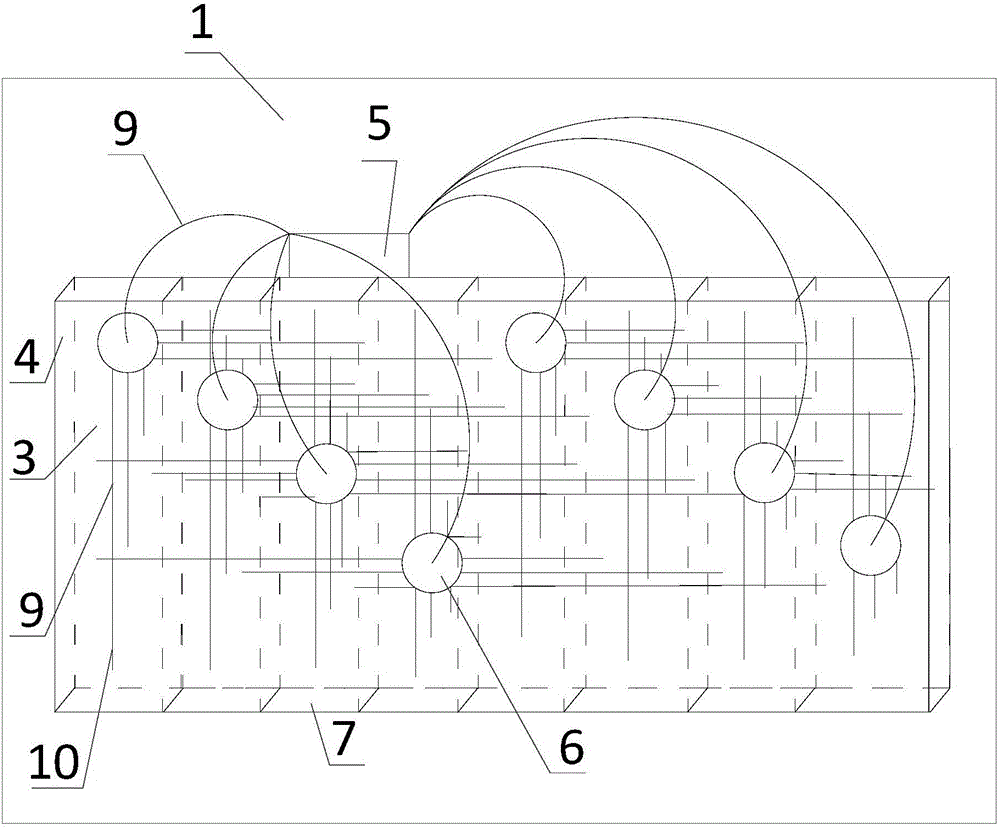

Forging process for preparing isotropic ultrahigh-strength heat-resistant magnesium alloy structural member

The invention discloses a forging process for preparing an isotropic ultrahigh-strength heat-resistant magnesium alloy structural member. Firstly, a cast ingot prepared through semi-continuous electromagnetic casting is subjected to homogenizing annealing, an ingot blank is formed through machining, the height direction of the cylindrical ingot blank and any two mutually perpendicular radial directions are used as the Z direction, the Y direction and the X direction correspondingly, 3-6 passes of heading are performed in the Z direction, the Y direction and the X direction, and the pass deformation amount is 20-40%; then the X direction or the Y direction is used as the axis, 2-6 passes of corner angle rolling compressing are performed, the pass deformation amount is 10-20%, intermediate annealing is performed, and the forging process is performed repeatedly once or twice; a forge piece is subjected to T6 treatment after forging is finished, and a final forge piece with the diameter being 450-650 mm and the height being 300-700 mm is obtained; as for both the height direction and the radial directions of the T6 state at the room temperature, the tensile strength is larger than or equal to 460 MPa, the yield strength is larger than or equal to 400 MPa, the ductility is larger than or equal to 4%, and the strength difference between the height direction and the radial directions is smaller than or equal to 10 MPa, and the ductility difference between the height direction and the radial direction is smaller than or equal to 0.5%; and as for both the height direction and the radial directions at the temperature of 200 DEG C, the tensile strength is larger than or equal to 350 MPa, and the ductility is larger than or equal to 6%.

Owner:CENT SOUTH UNIV

Casting mold coating and preparation method thereof

ActiveCN107470551AReasonable collocationAdequate insulationFoundry mouldsFoundry coresCollocationAdhesive

The invention provides casting mould coating. The casting mould coating is divided into bottom layer coating which coats the surface of a casting mould and outer layer coating which coats the surface of the bottom layer coating. The bottom layer coating and the outer layer coating each at least comprise refractory aggregate, adhesives and suspending agents, the main ingredients of the refractory aggregate contained in the outer layer coating are different from those of the refractory aggregate contained in the bottom layer coating, preferably, the refractory aggregate in the bottom layer coating simultaneously comprises zircon powder, titanium oxide, silicon carbide and kaolin, and the refractory aggregate in the outer layer coating simultaneously comprises mullite powder, bauxite clinker, talcum powder and silicon carbide. The casting mould coating is reasonable in ingredient collocation, the selected refractory aggregate of the casting mould coating can achieve a sufficient heat insulation effect, and can be well stripped after casting, and the refractoriness of the bottom layer coating and the refractoriness of the outer layer coating are matched in different levels so that the effect of the coating property can be achieved maximally.

Owner:唐山市鸿泉矿山机械有限公司

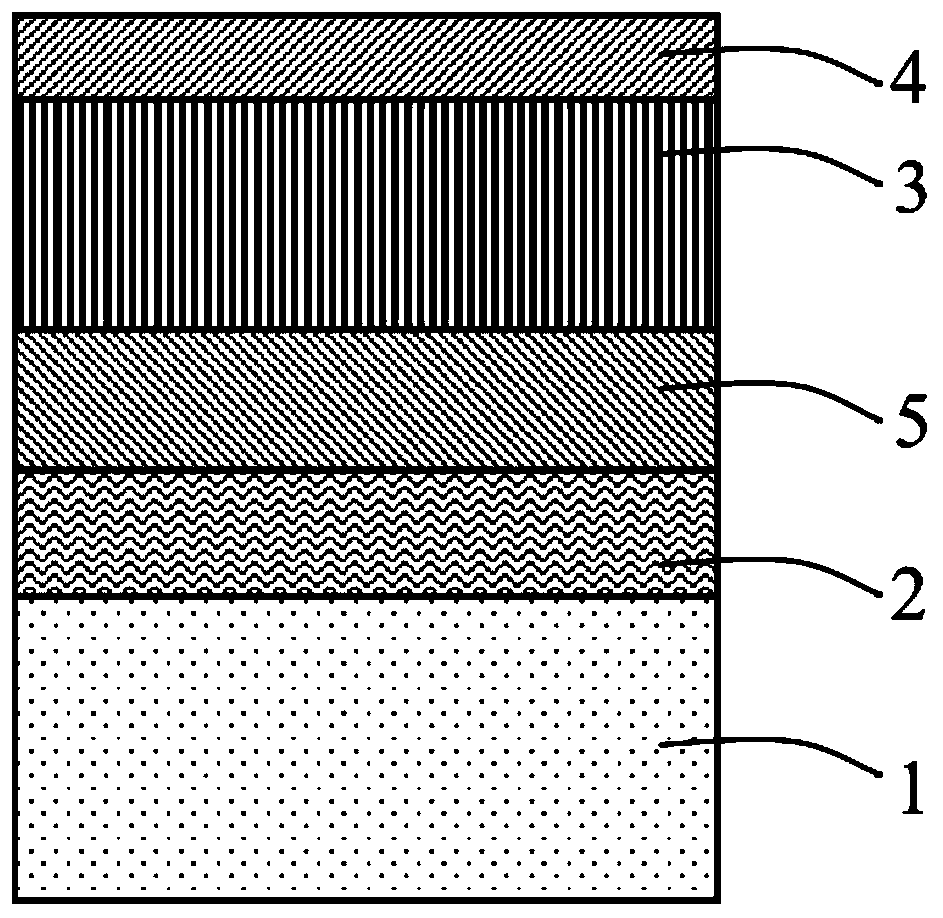

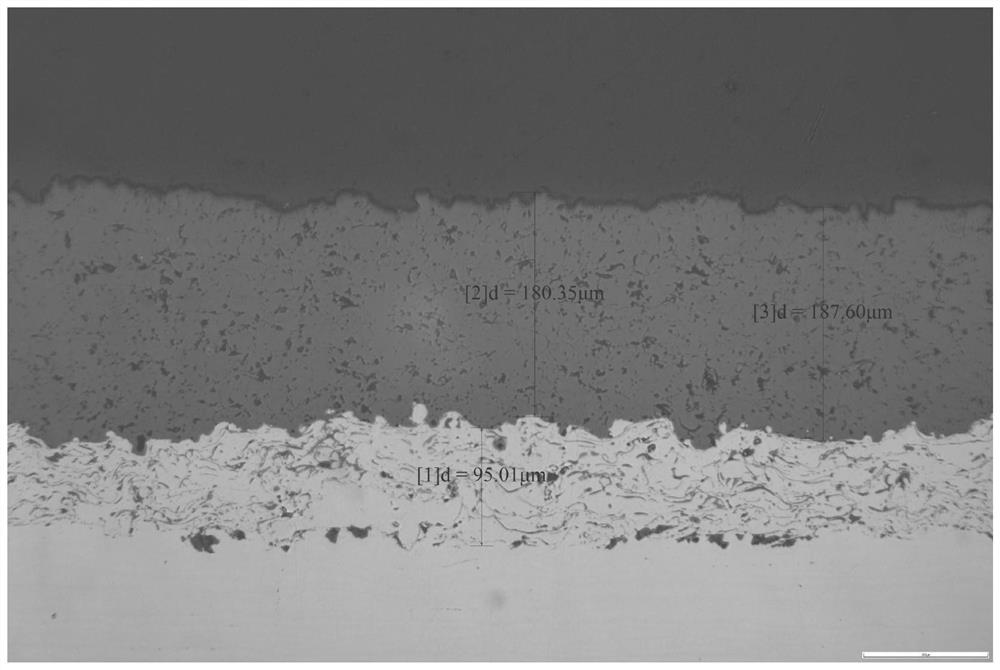

Yb modified CMAS prevention composite structure thermal barrier coating and preparing method thereof

ActiveCN111471998APrevent penetrationImprove thermal shock performanceMolten spray coatingSuperimposed coating processInsulation layerThermal break

The invention discloses an Yb modified CMAS prevention composite structure thermal barrier coating and a preparing method thereof. A CMAS corrosion prevention layer adopts Yb modified rare earth zirconate to form a compact layered structure, at the high temperature, the layered structure can have a reaction with CMAS to form a compact blocking layer, permeation of molten CMAS to the interior of the thermal barrier coating can be prevented, a first heat insulation layer adopts Yb modified rare earth zirconate to form a columnar structure, enough heat insulation performance and high strain tolerance can be provided for the thermal barrier coating, the thermal shock property of the thermal barrier coating is improved, the service life of the thermal barrier coating can be prolonged, the CMAScorrosion prevention layer and the first heat insulation layer are made of materials of the same elements, heat mis-match stress between the two layers can be relieved, combining strength of the two layers can be improved, the thermal barrier coating has the advantages of being low in heat conduction rate, stable in phase, high in combining strength, and high in sintering resisting capacity, the service life under the high-temperature service condition is long, combination strength between dual layers of ceramic can be high, and combination strength between a ceramic layer and a metal bondinglayer is high.

Owner:BEIHANG UNIV

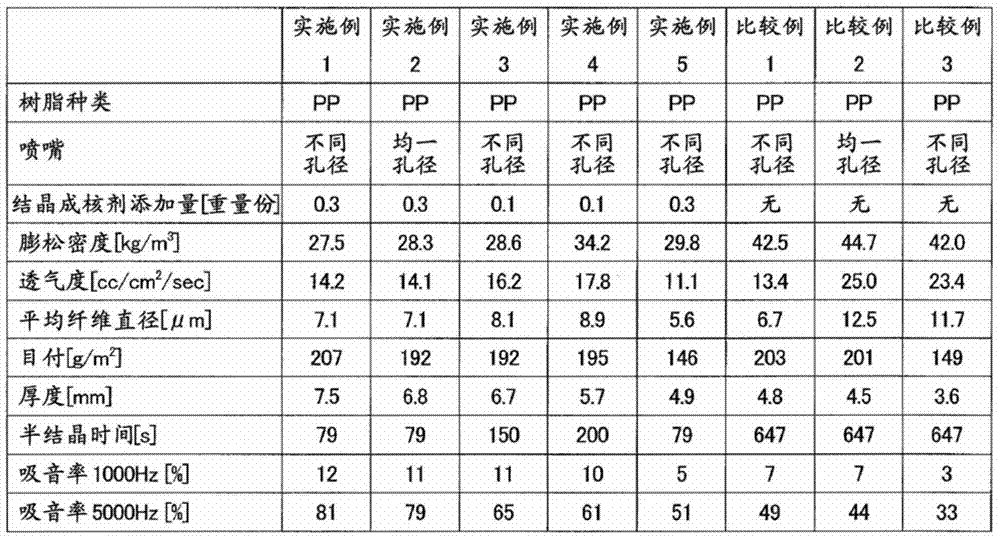

Melt-blown nonwoven fabric and use thereof

ActiveCN103842571ALow bulk densityLow costOther chemical processesLayered productsFiltrationFiber diameter

This melt-blown nonwoven fabric is formed of thermoplastic resin fibers having an average fiber diameter of 0.1-10 mum, and has a bulk density of 36 kg / m3 or less and an air permeability of 3-100 cc / cm2 / sec as measured by a Frazier type method at a weight of 200 g / m2. This melt-blown nonwoven fabric has a low bulk density and excellent sound absorption performance, oil absorption performance, heat insulation performance, dust collection performance and filtration performance. Since this melt-blown nonwoven fabric can be formed of a single kind of a resin composition, this melt-blown nonwoven fabric is able to be easily produced and have a uniform quality free from variation in the characteristics in comparison to the cases where mixed fibers or composite fibers composed of a plurality of kinds of resins are used. A sound absorbing material of the present invention can be obtained by an easy process and exhibits excellent sound absorption performance. Consequently, this sound absorbing material is suitable for use as a sound absorbing material for living environments or transportation means. In addition, the sound absorbing material of the present invention can be reduced in weight and thickness.

Owner:MITSUI CHEM INC

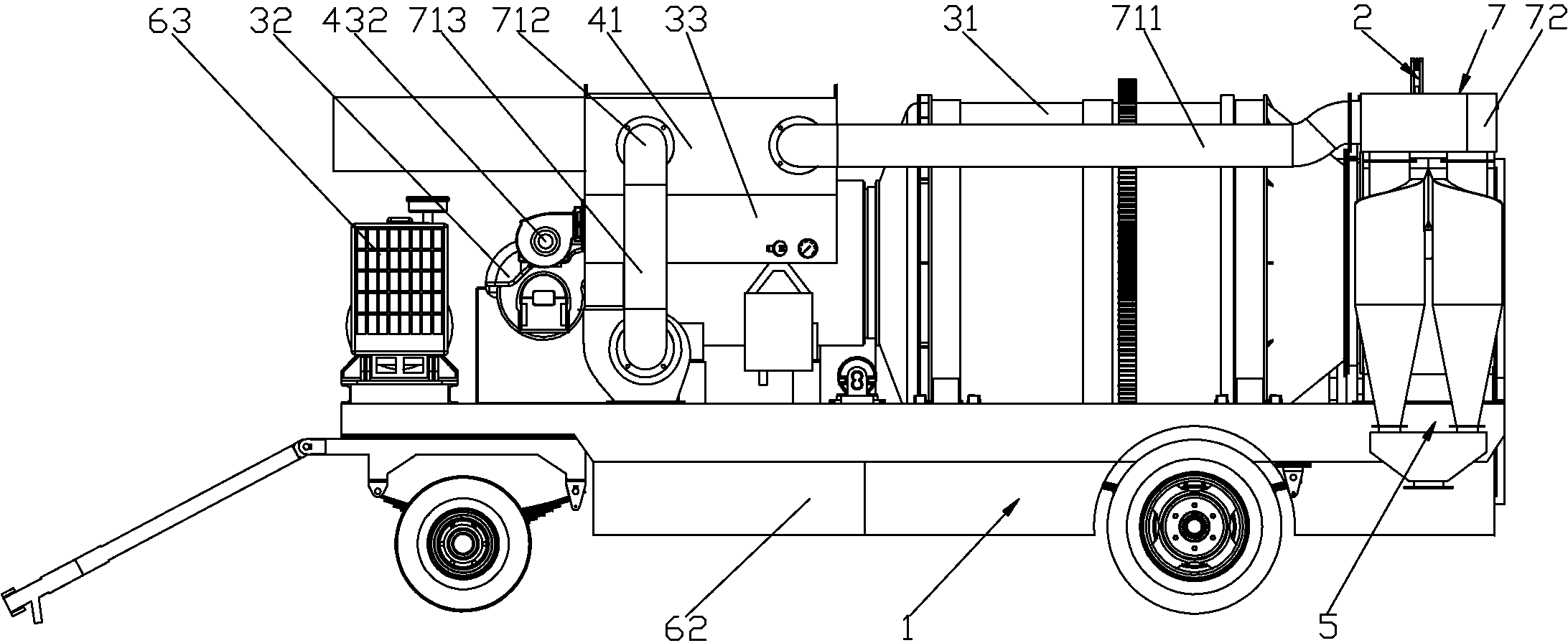

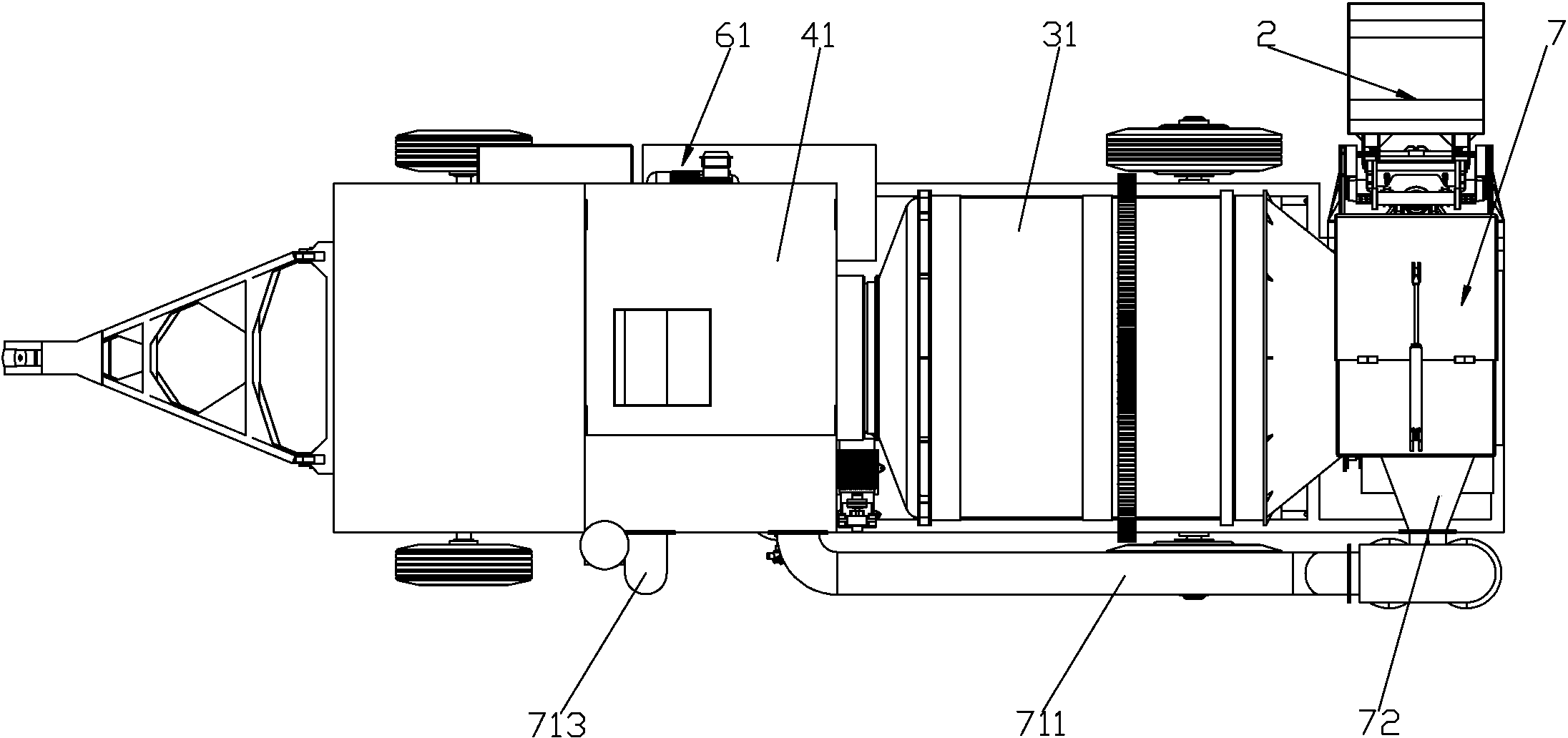

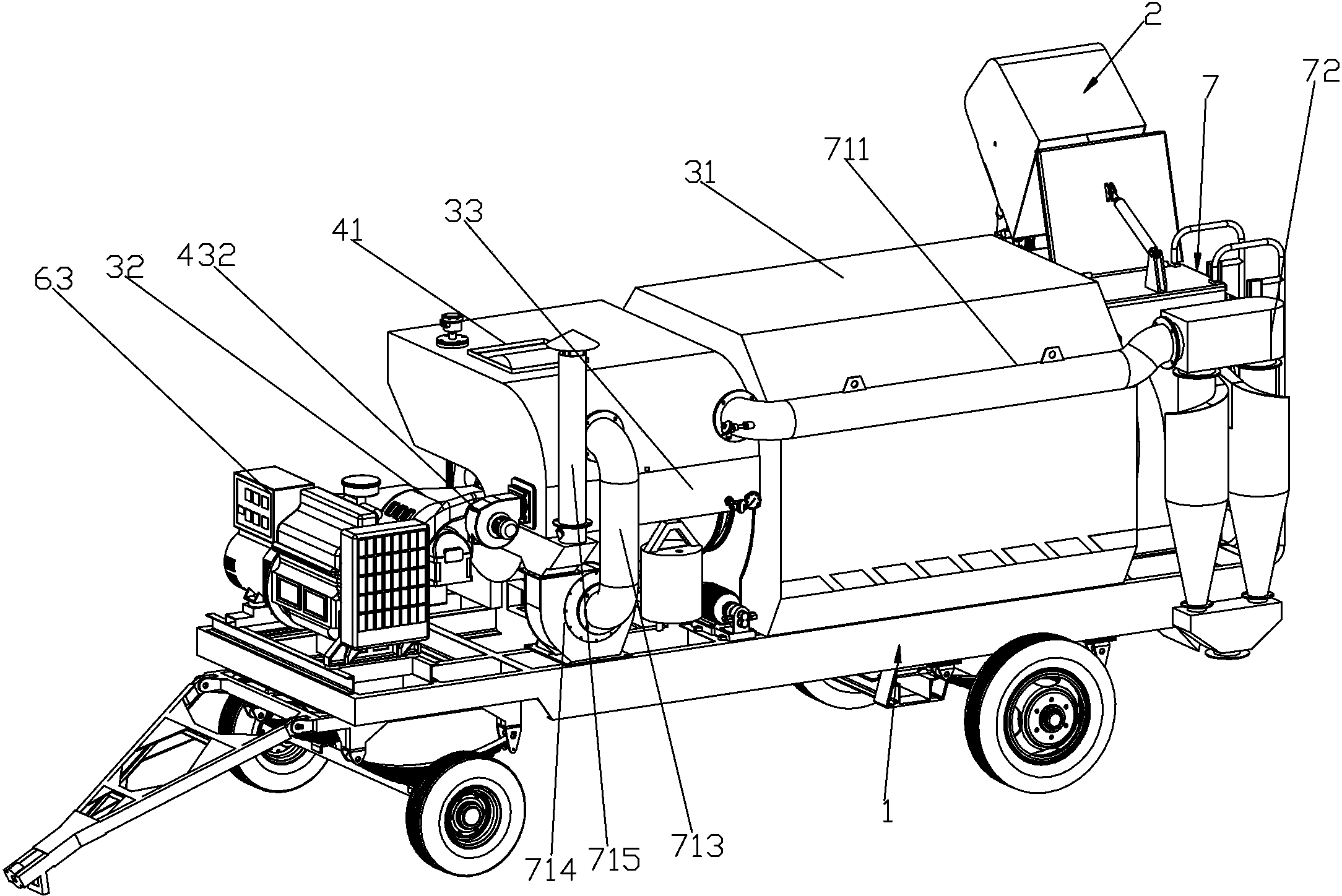

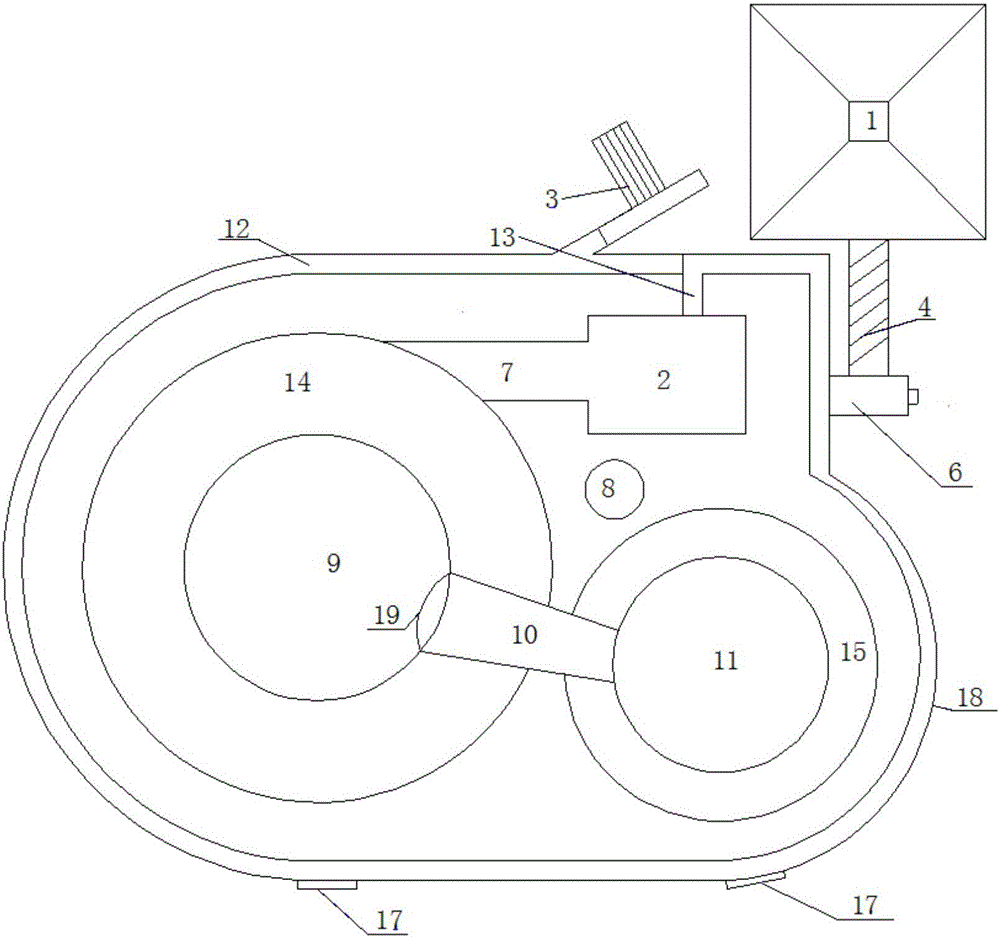

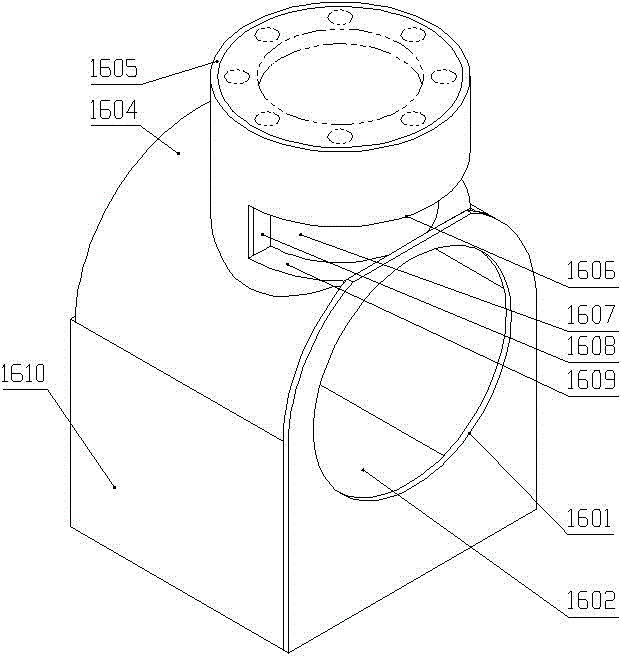

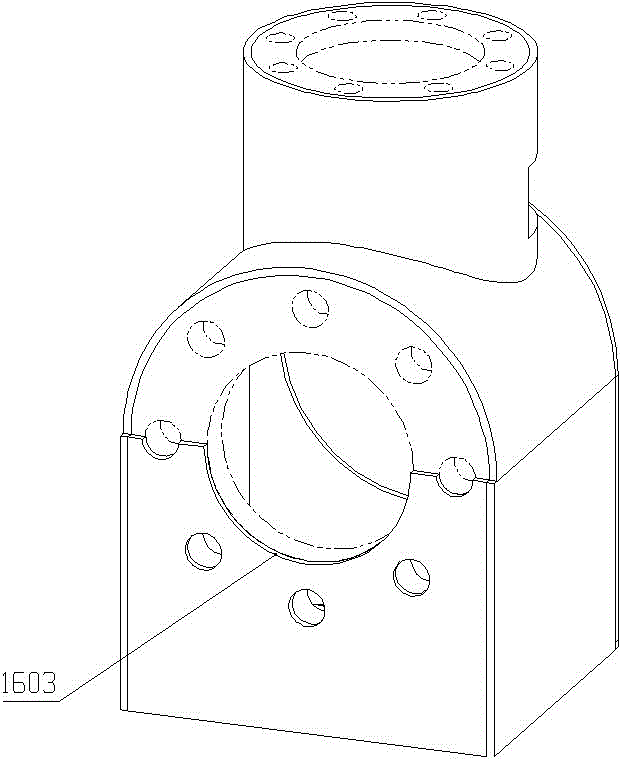

Moving type asphalt mixture regeneration equipment

The invention discloses moving type asphalt mixture regeneration equipment which comprises a rack, wherein a main combustor, a hot blast heater, a drying heating cylinder and an asphalt storage device are mounted on the rack; a tail gas conveying tube is connected to a tail gas outlet of the drying heating cylinder; the tail gas conveying tube is connected with the main combustor through a draft fan; at least one section of the tail gas conveying tube stretches into the asphalt storage device for preserving the heat. The equipment disclosed by the invention can move, is capable of regenerating an asphalt pavement surface rapidly and is high in efficiency; when being heated and preserved, a regenerated material and the asphalt do not contact with open fire, and then the quality is ensured; as an asphalt storage tank is arranged above the hot blast heater, the heat of the hot blast heater is sufficiently utilized to preserve the heat of the asphalt, and meanwhile, as a tail gas which is generated in heating is introduced into the asphalt storage tank, the residual heat of the tail gas is utilized to preserve the heat of the asphalt, the fuel is saved, and the heat utilization rate of the equipment is improved; as the tail gas is introduced to the main combustor for secondary combustion, secondary pollution is avoided; the weight of the regenerated material is weighted by using a pressure sensor, and the regenerated material is mixed with the asphalt in a grading manner, thereby obtaining a high-quality asphalt pavement material.

Owner:FUJIAN QUANCHENG MACHINERY

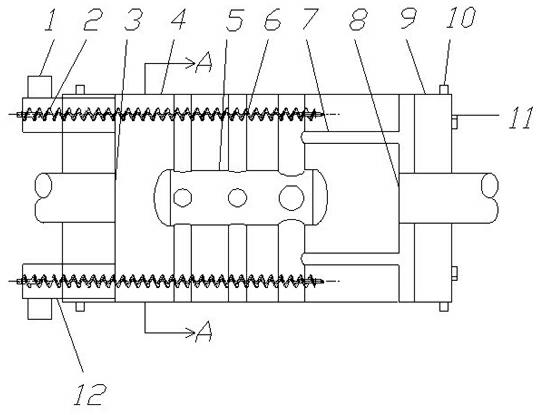

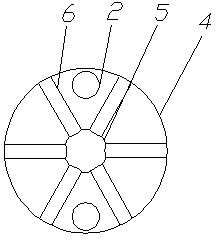

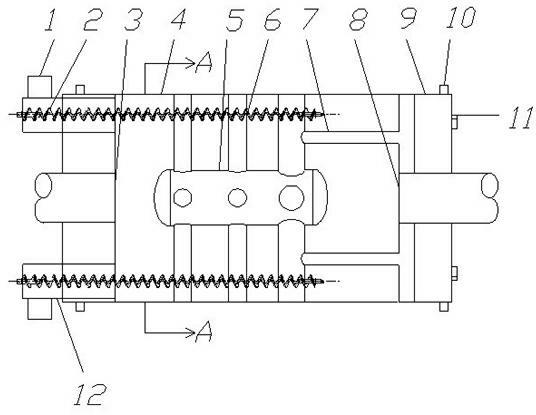

Apparatus for cracking papermaking waste residues

ActiveCN102367387AEasy to manufactureImprove stabilityLiquid hydrocarbon mixture productionThermal insulationHeating efficiency

The invention which relates to an apparatus for cracking papermaking waste residues belongs to the technical field of apparatuses for possessing the papermaking waste residues. The apparatus is characterized in that: the apparatus comprises an outer cylinder body and an inner cylinder body which is coaxially arranged in the inner cavity of the outer cylinder body, wherein a cracking gas outlet isarranged at one end of the outer cylinder body and a material inlet is arranged at the other end of the outer cylinder body; several thermal conduction tubes for communicating the inner cavity of theinner cylinder body with the outside of the outer cylinder body are radically arranged between the inner cylinder body and the outer cylinder body; two ends of the outer cylinder body are respectively provided with a thermal insulation layer; the outer wall of each thermal insulation layer is fixedly provided with a support roller with a supporting effect; a transmission gear which has a transmission connection with an outside driving unit is fixedly arranged on the end surface of each thermal insulation layer; a reinforced thermal conduction tube which has an annular structure is axially arranged between the thermal conduction tube close to the material inlet and the end surface of the outer cylinder body; and the reinforced thermal conduction tube is communicated with the thermal conduction tube close to the material inlet and the outside of the outer cylinder body. The apparatus of the invention, which has the advantages of high mechanical strength and high heating efficiency, has a perfect ash discharging system, and can continuously, safely and stably operate, is especially suitable for the high temperature cracking of waste plastic-contained papermaking waste residues.

Owner:仁精科技(昆山)有限公司

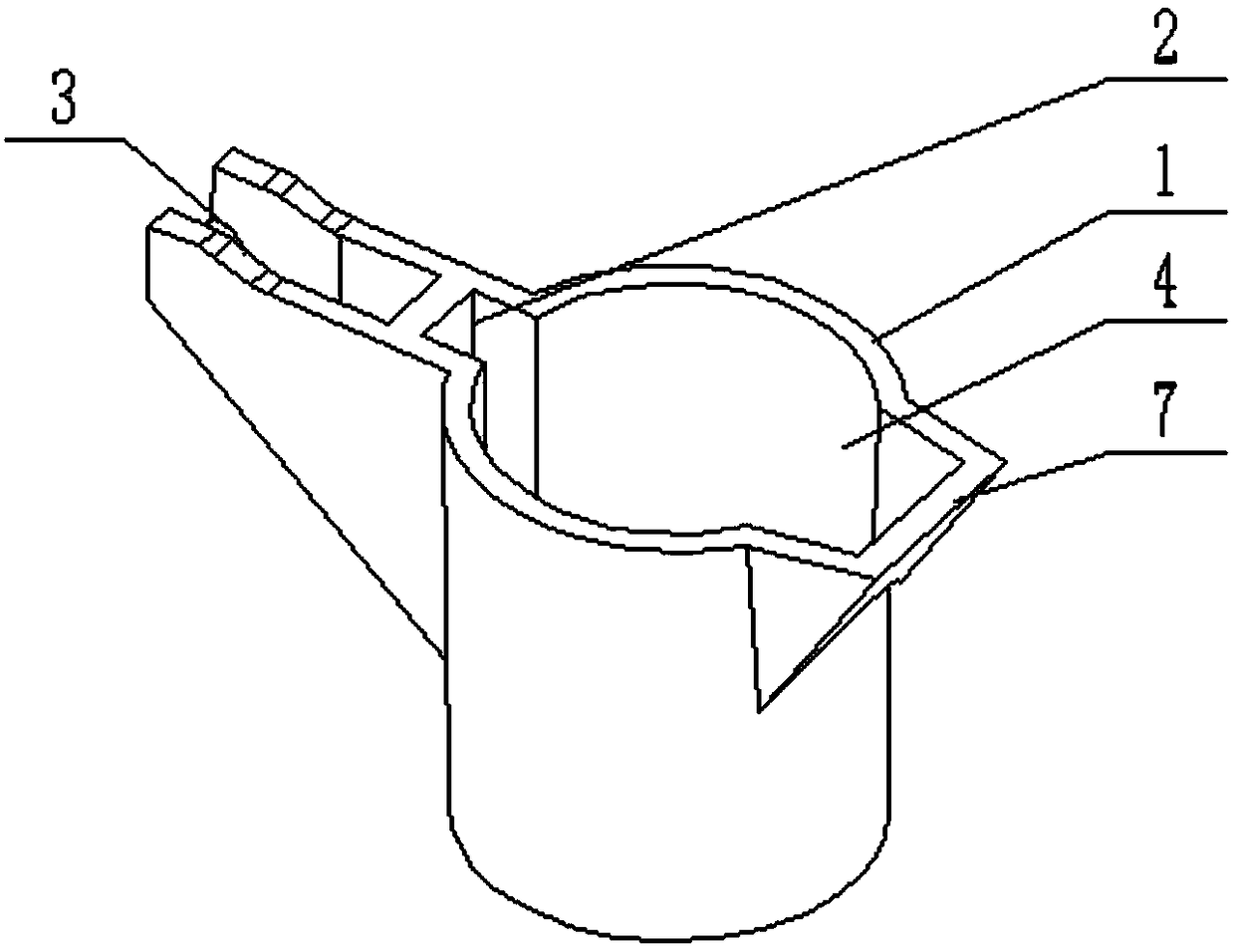

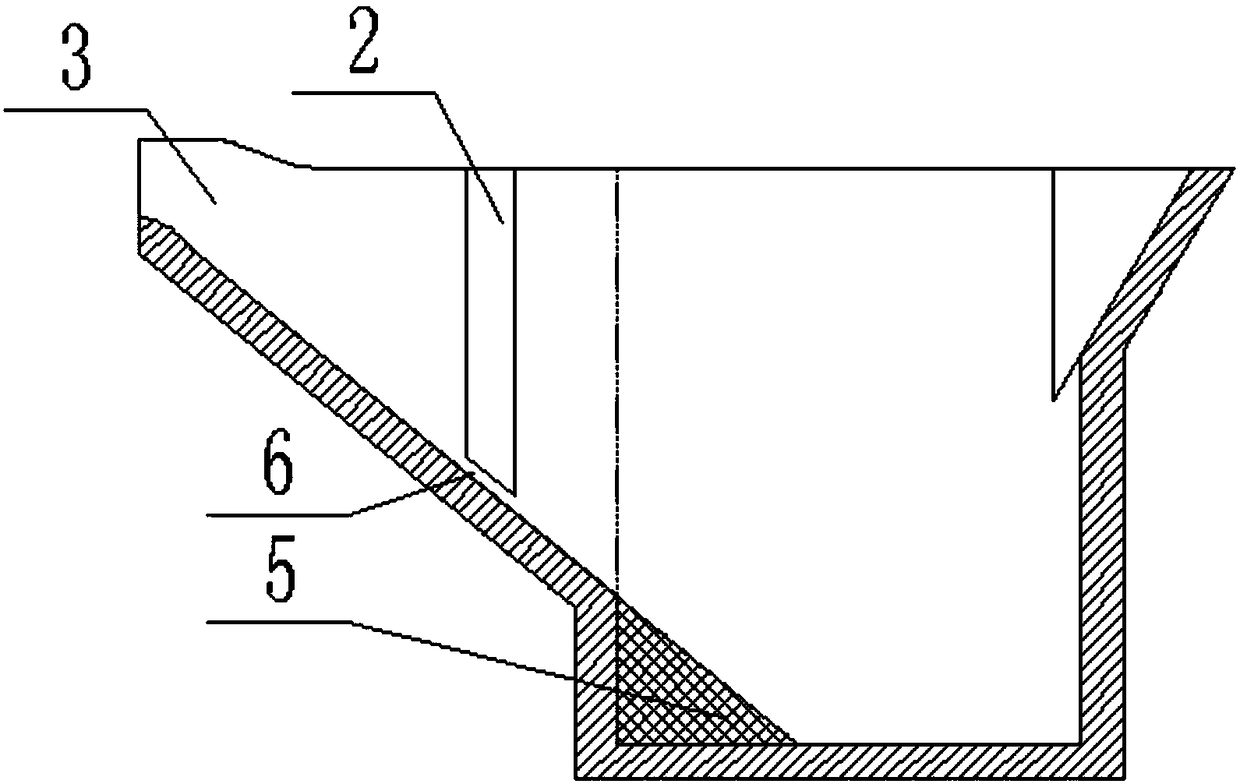

Pouring ladle beneficial to slag blocking

PendingCN109014158AImprove insulation effectAdequate insulationMelt-holding vesselsSlagMaterials science

The invention discloses a pouring ladle beneficial to slag blocking. The pouring ladle comprises a pouring barrel, a slag blocking plate, a ladle spout, a pouring groove and a water outlet. The pouring groove comprises a liquid storage groove and a liquid injection groove, the pouring barrel is of a hollow cylindrical structure, and the liquid storage groove is formed in the pouring barrel. The ratio of the diameter of the bottom of the liquid storage groove to the height of the pouring barrel is 1:2. The ladle spout is fixedly arranged on the pouring barrel, the liquid injection groove is formed in the ladle, the slag blocking plate is fixedly arranged in the ladle spout, and the water outlet is formed between the slag blocking plate and the bottom of the liquid injection groove. The liquid storage groove is communicated with the liquid storage groove through the water outlet. The pouring ladle beneficial to slag blocking is reasonable in shape and structure and better in heat preservation and slag blocking effect, and the pouring work can be facilitated.

Owner:广德亚太汽车智能制动系统有限公司

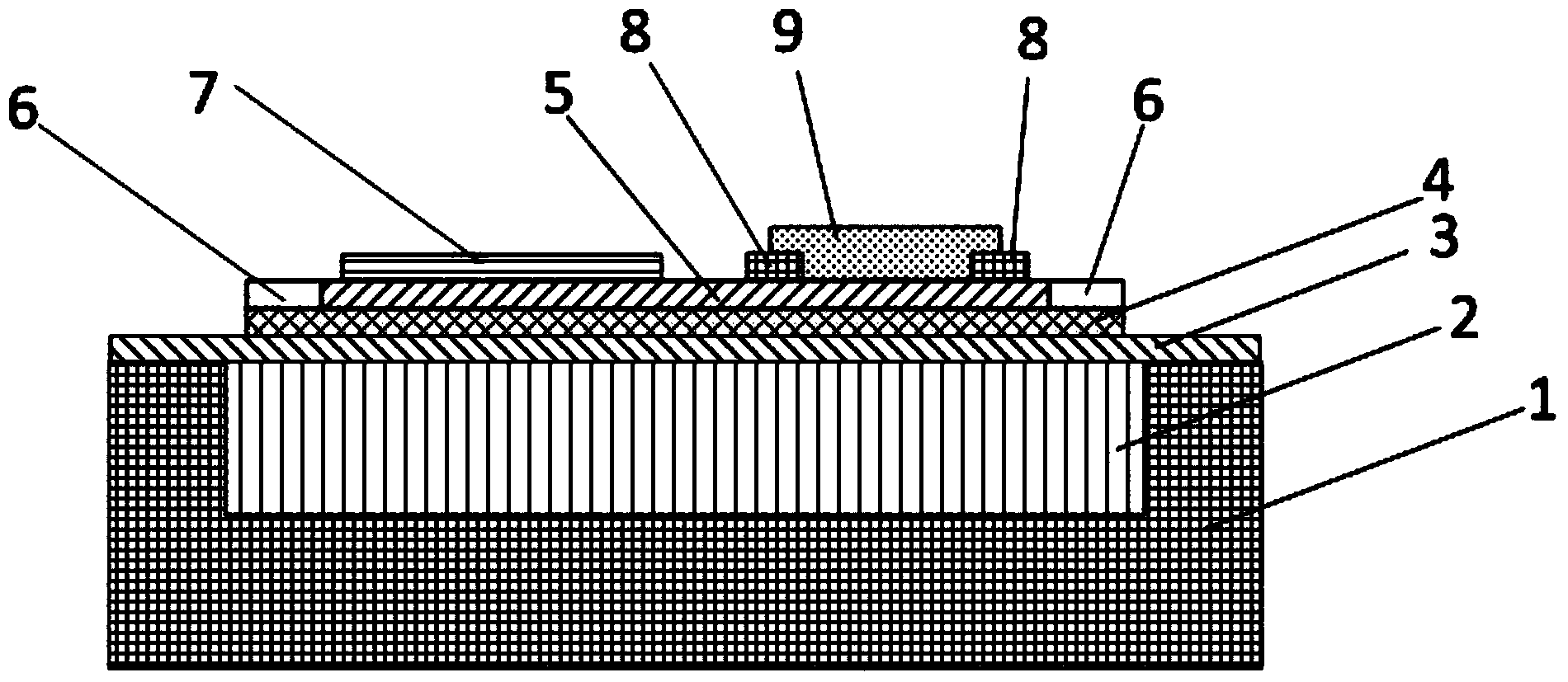

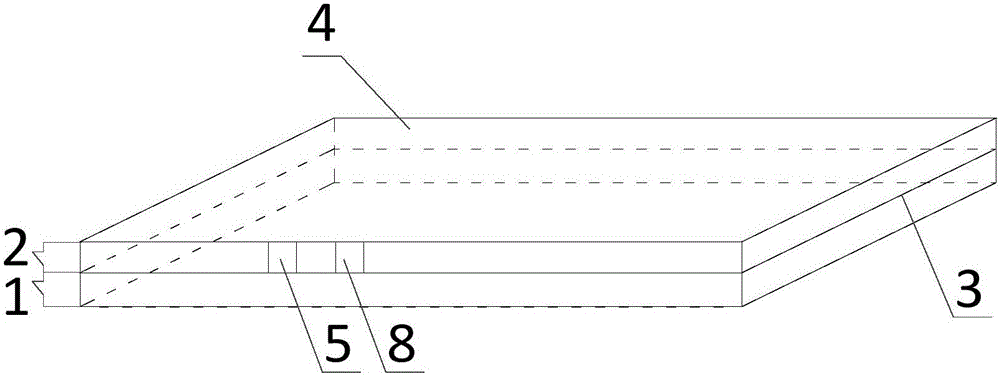

MEMS gas sensor with heat insulation groove and processing method thereof

ActiveCN104165902AStable supportInhibit sheddingDecorative surface effectsSolid-state devicesInsulation layerGas detector

The invention relates to the gas detection field, and discloses an MEMS gas sensor with a heat insulation groove and a processing method thereof. The MEMS gas sensor comprises a monocrystalline silicon substrate, a heat insulation groove, which is formed on the upper surface of the monocrystalline silicon substrate, has a certain depth, and comprises one or more groups of grooves, wherein each groove group comprises a plurality of parallel grooves; a lower insulation layer, which covers the heat insulation groove and the upper surface of the monocrystalline silicon substrate; and a heating layer and an upper insulation layer, which are arranged above the lower insulation layer. The heat insulation groove can stably support the lower insulation layer membrane, the heating plate and the upper insulation layer, and is capable of preventing the deformation of the lower insulation layer when the gas detector is operated at a high temperature so as to avoid the falling of the heating layer. At the same time, the groove surface of the heat insulation groove is covered by a silicon dioxide membrane, and thus the heat insulation performance of the groove is enhanced, so the energy consumption can be reduced, the detection sensitivity of the gas sensor is improved, and the service life of the gas sensor is also prolonged.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

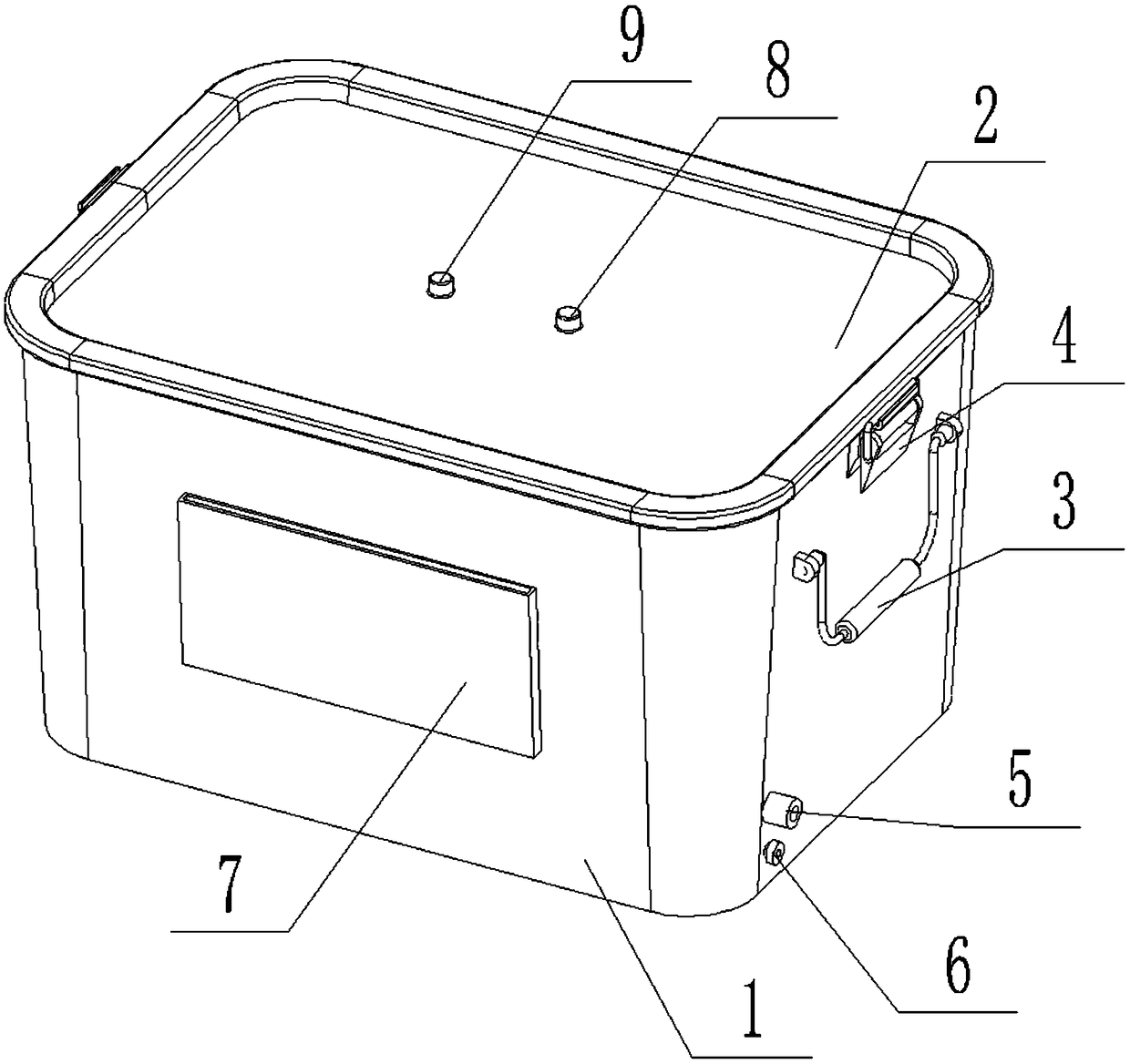

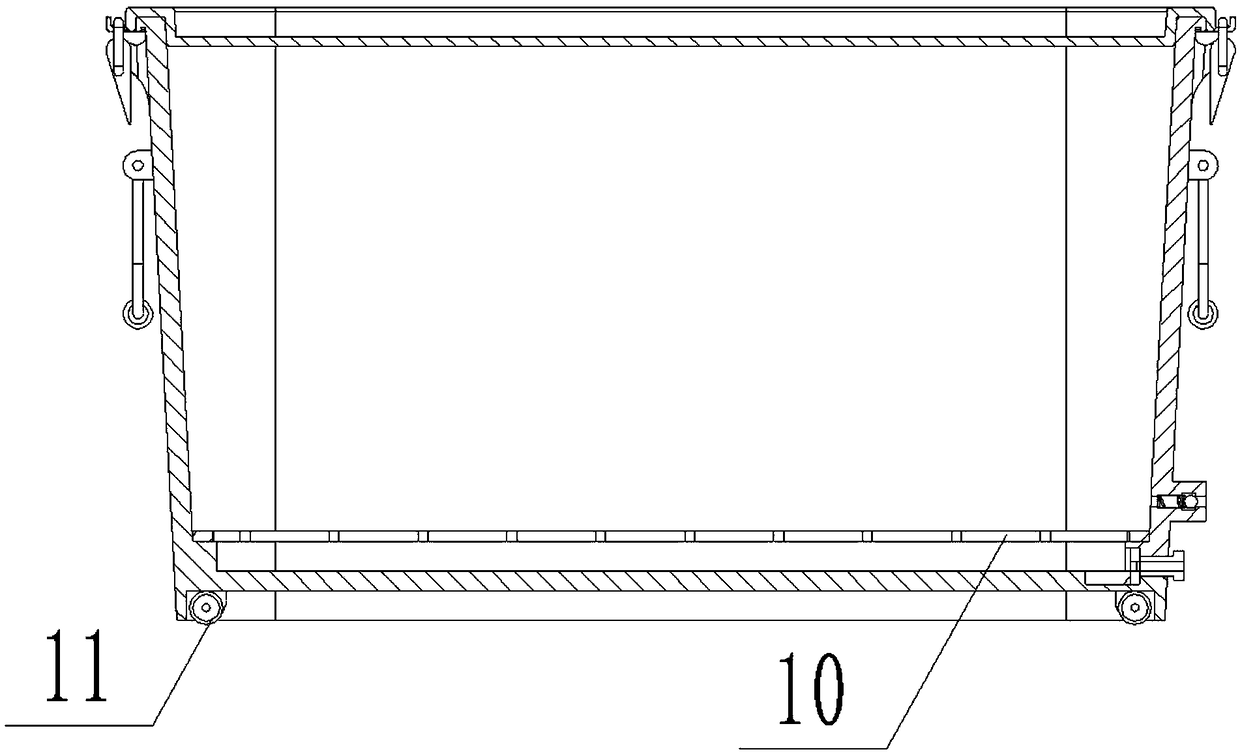

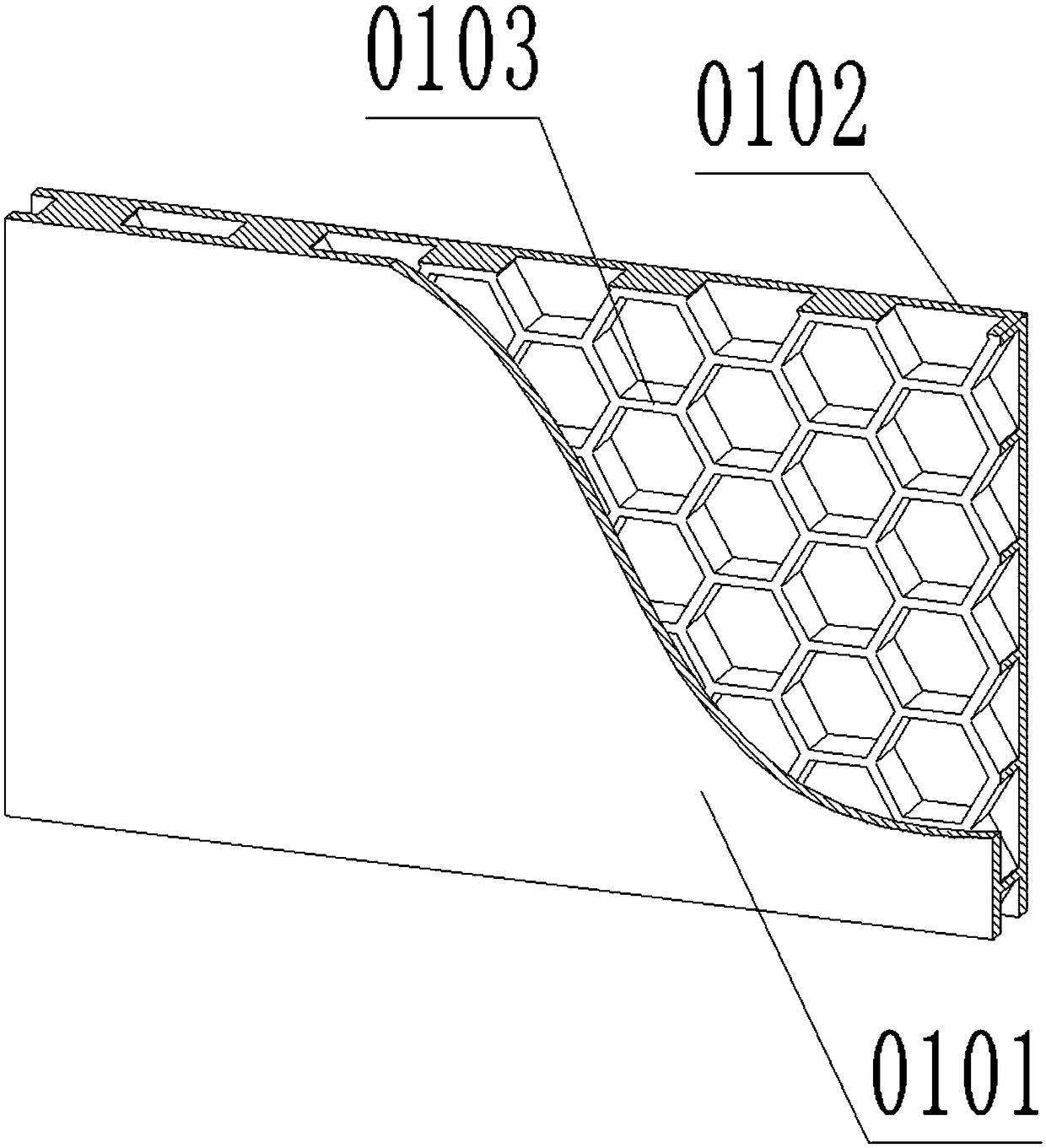

A fresh-keeping device for vegetables and fruits for logistics transportation

ActiveCN108891781AEasy to operateEasy to operate, high efficiency; simple by adopting honeycomb structureDomestic cooling apparatusLighting and heating apparatusEngineeringUltimate tensile strength

The invention provides a vegetable and fruit fresh-keeping device for logistics transportation, comprising a box body, an outer wall and a small wheel; The top cover of the box body is provided with aset of the box covers; A set of the portable handle is fixedly connected with the left and right end faces of the box body; At that top of the left and right end face of the box body are fixedly connected with a group of seal locking fasteners; The box body is pressed tightly with the box cover through the sealing lock buckle; A set of water outlet holes of the quick drain valve are arranged in the middle of the screw of the quick drain valve; A group of seal gaskets of the quick drain valve housing are arranged in the center of the quick drain valve housing. By adopting the honeycomb structure, the invention has sufficient strength and heat preservation performance while lightening the weight, and is light and handy for handling and transportation; The utility model has the advantages ofsimple structure, low cost, convenient operation, no additional equipment, reduced expenditure, simplified operation and convenient management, and is suitable for both long-distance logistics transportation and fresh-keeping of retailers.

Owner:浙江佳农果蔬股份有限公司

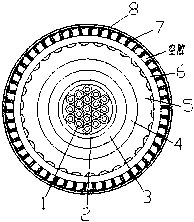

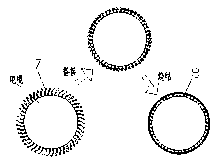

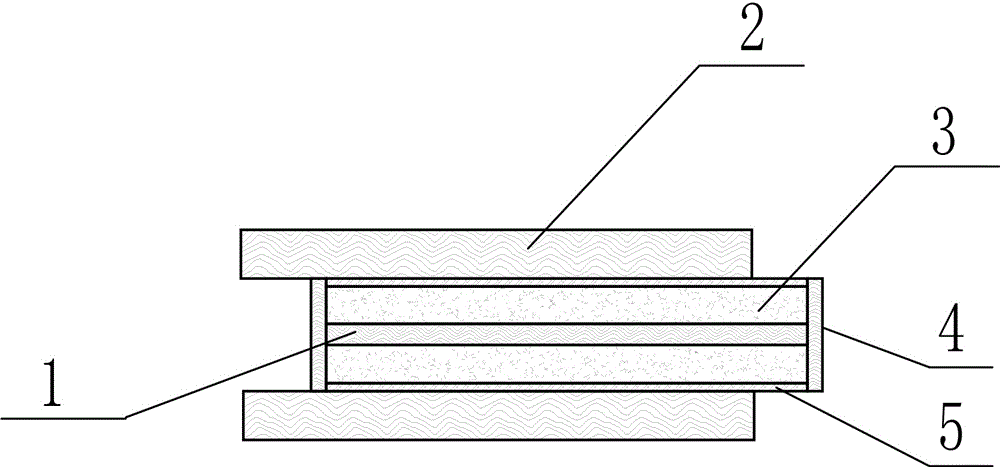

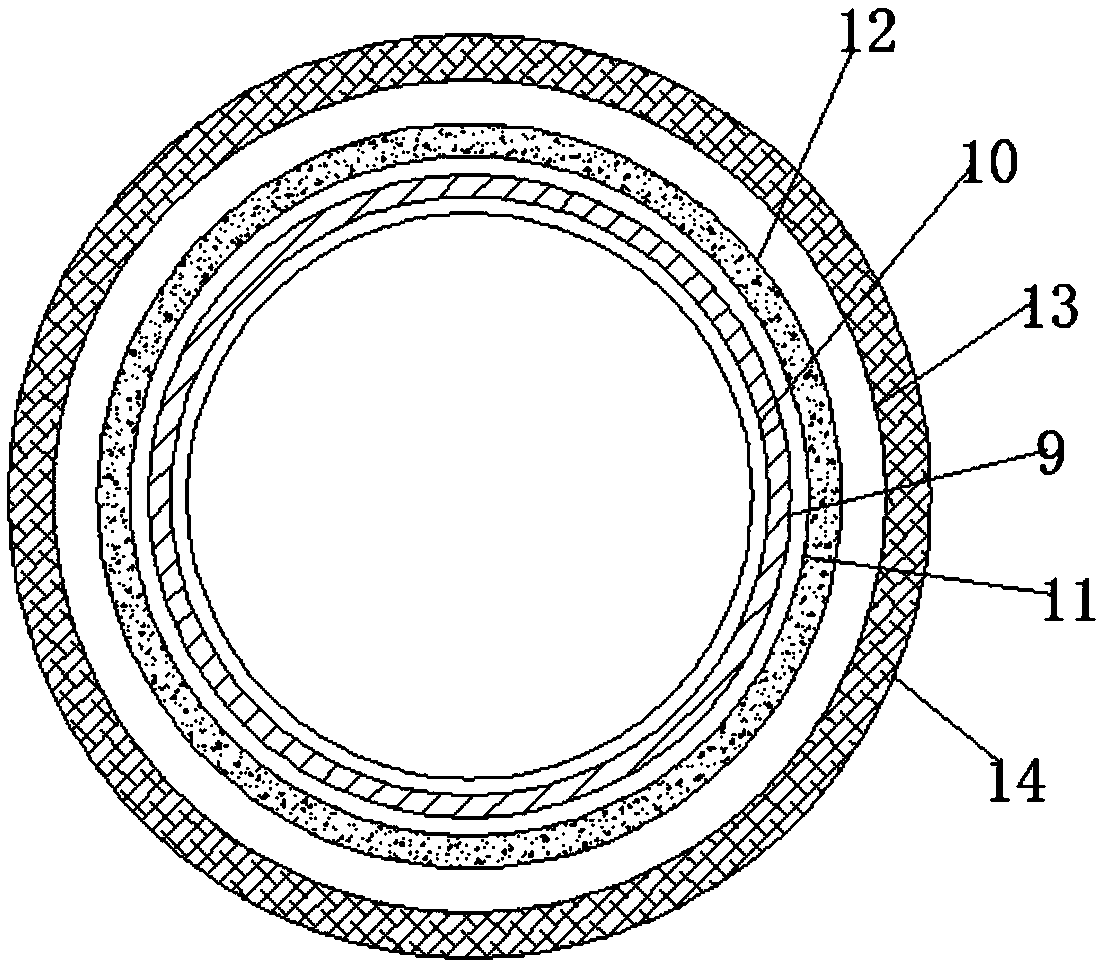

Special cable resistant to 1600 DEG C ultra-high temperature and flame scouring, and preparation method thereof

InactiveCN110911036AGuaranteed bending performanceImprove insulation performanceApparatus for heat treatmentFlexible cablesElectrical conductorComposite ceramic

The invention discloses a special cable resistant to 1600 DEG C ultra-high temperature and flame scouring. The cable sequentially comprises a conductor core, a polyimide composite insulating layer, asilicone rubber inner layer, an aerogel felt layer, a threaded pipe and a silicone rubber outer layer from inside to outside, wherein the silicone rubber outer layer is connected with a circle of silicone rubber composite ceramic layer through an L-shaped support, the conductor core is formed by concentrically stranding a plurality of strands of nickel-plated soft copper wires in the same direction, and the polyimide composite insulating layer is formed by winding a polyimide insulating film tape and then softening and sintering at high temperature; the aerogel felt layer is formed by windingaerogel felt belts in the same direction; and liquid nitrogen filled in threaded pipe. According to the novel special cable structure provided by the invention, a multiple heat insulation method of silicone rubber ceramization, air heat insulation, liquid nitrogen cooling, aerogel heat insulation and insulating film heat insulation is realized, the weight is light, the bending performance is relatively good, the installation and the use are convenient, the cable can resist the high temperature of 1600 DEG C, a large-current conduction state can be kept within 30 seconds, and the current is basically constant; the special cable can adapt to the ignition launching process of the rocket thruster.

Owner:安徽宏源特种电缆股份有限公司

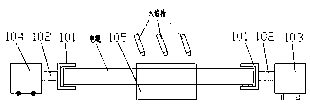

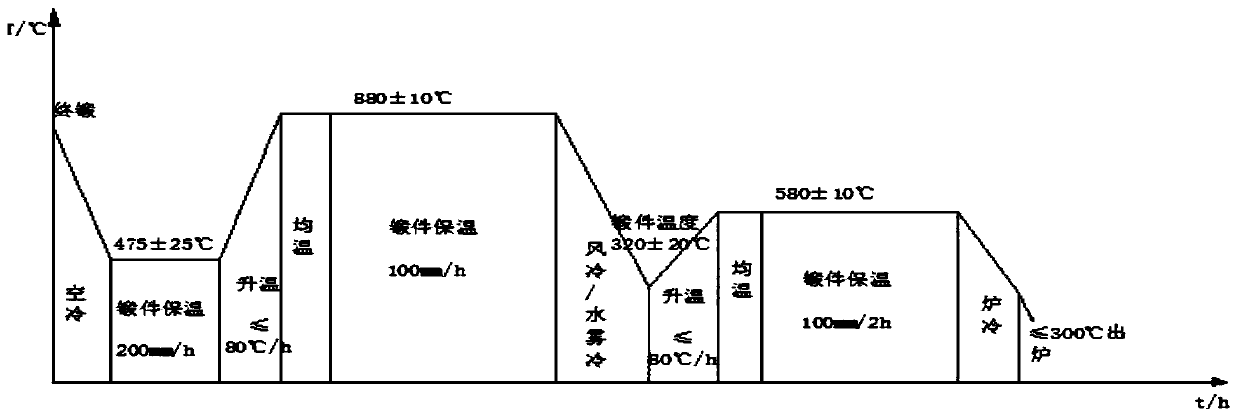

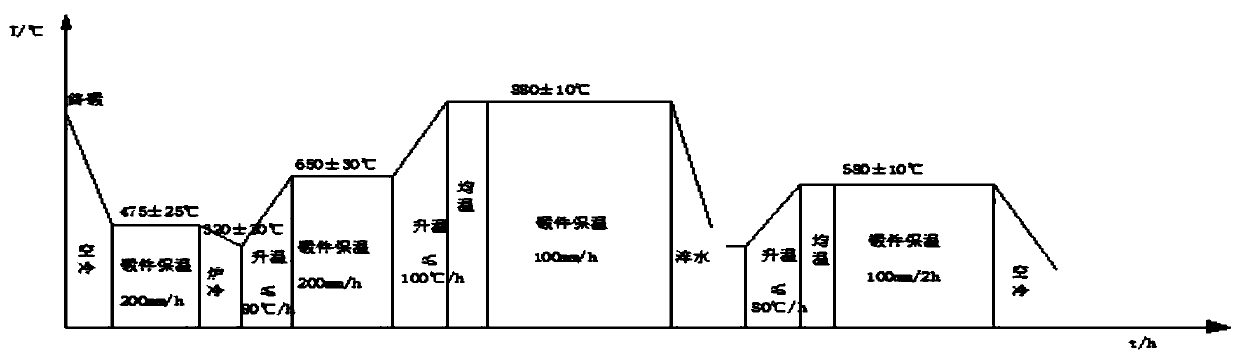

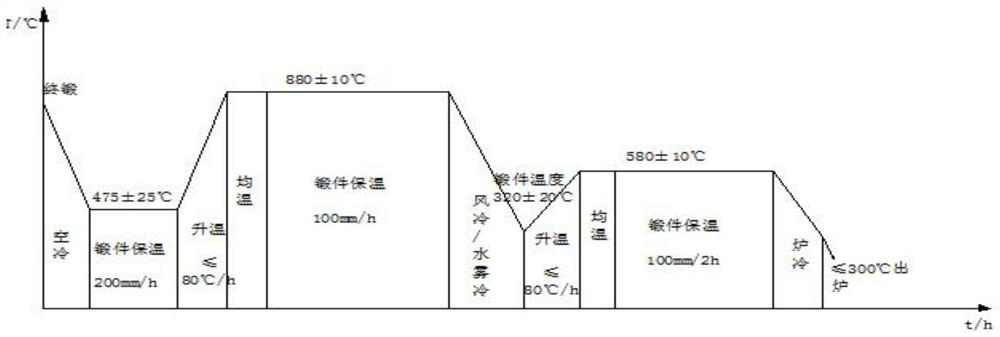

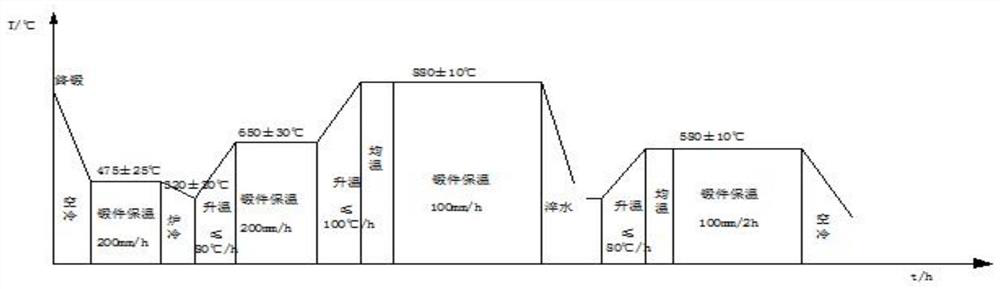

Motor shaft forging normalizing and tempering process

ActiveCN110306014AShorten heat treatment timeAdequate insulationFurnace typesHeat treatment furnacesElectric arc furnaceIngot

The invention provides a motor shaft forging normalizing and tempering process. The motor shaft forging normalizing and tempering process comprises the following steps of 1, adopting steel ingot whichis subjected to electric arc furnace smelting, external refining and vacuum degassing smelting as raw materials; 2, after forging, carrying out air cooling on a forged piece to 475DEG C+ / -25DEG C, and then loading the forged piece into a heat-treating furnace for temperature preserving; 3, if the forged piece is made of carbon manganese steel, directly entering the next step; if the forged pieceis made of alloy steel, carrying out furnace cooling to 320 DEG C+ / -20 DEG C, and then heating the forged piece to 650 DEG C+ / -30 DEG C at the temperature of no more than 80 DEG C per hour and then carrying out temperature preserving; 4, heating the forged piece in the heat-treating furnace to 880 DEG C+ / -10 DEG C at the temperature of 100 DEG C per hour and then carrying out uniform temperature;5, if the forged piece is made of the carbon manganese steel, after tapping, carrying out air cooling or water spray cooling to 320 DEG C + / -20 DEG C; if the forged piece is made of the alloy steel, after tapping, carrying out water quenching and cooling to the surface temperature of about 100 DEG C; 6, putting the forged piece into the furnace and heating to 580 DEG C + / -10 DEG C at the temperature of 80 DEG C per hour, and then carrying out heat preserving and closing the furnace; and 7, cooling the forged piece to 300 DEG C or below at the temperature of no greater than 100 DEG C per hour,and after tapping, carrying out air cooling to normal temperature.

Owner:陕西华威科技股份有限公司

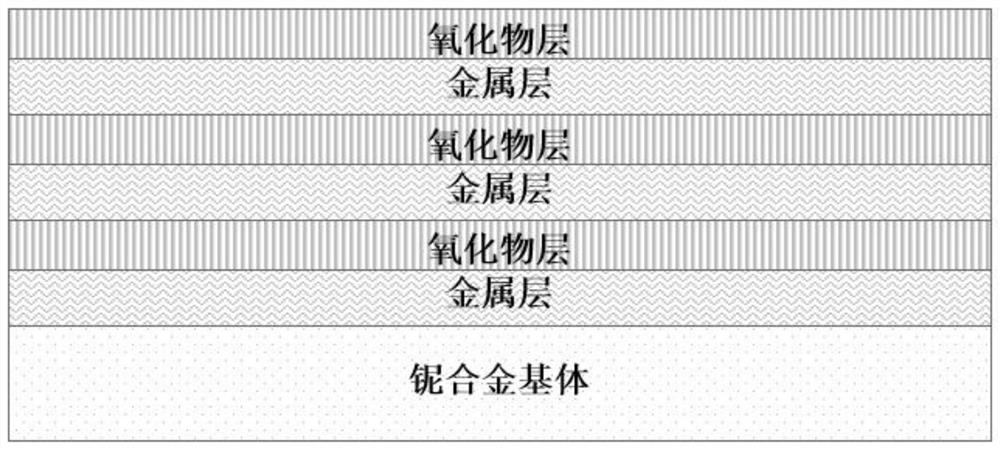

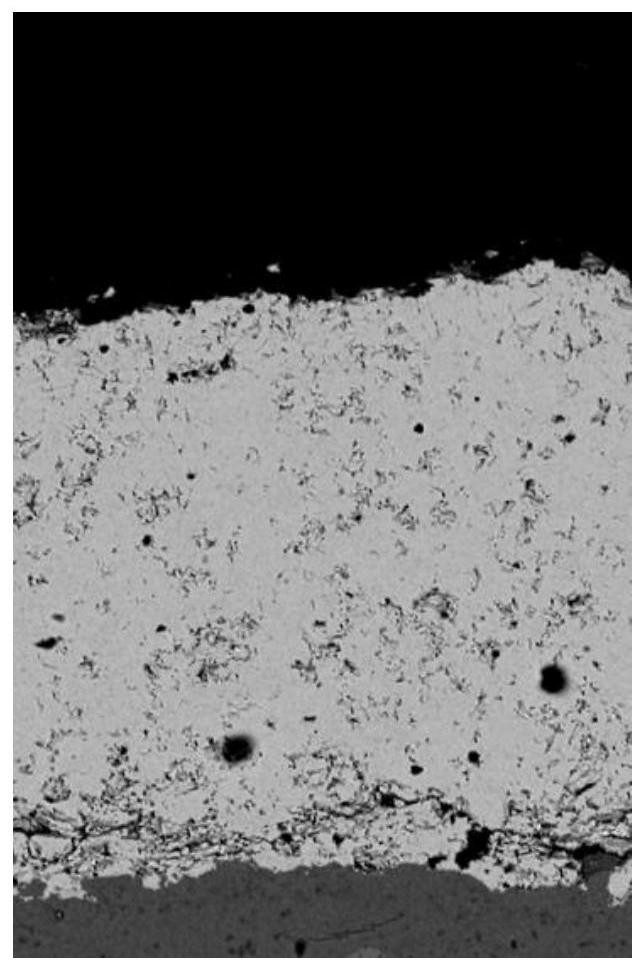

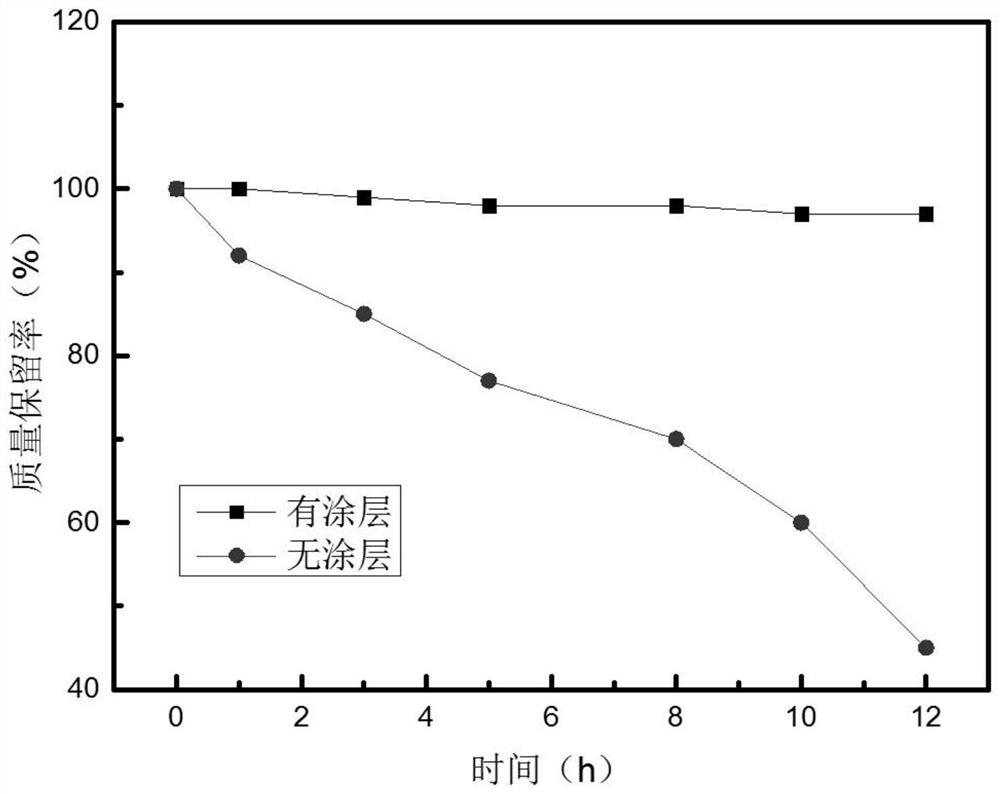

High-temperature-resistant, oxidation-resistant and ablation-resistant niobium alloy material and preparation method thereof

PendingCN114164428ALong-term service temperature increasesPush the limits of workSolid state diffusion coatingSuperimposed coating processOxidation resistantNiobium alloy

The invention discloses a high-temperature-resistant, oxidation-resistant and ablation-resistant niobium alloy material and a preparation method thereof, the high-temperature-resistant, oxidation-resistant and ablation-resistant niobium alloy material comprises a niobium-based alloy matrix, multiple layers of gradient coating materials are prepared on the niobium-based alloy matrix, each layer of gradient coating material is composed of a metal layer and an oxidation layer, and the total thickness of the metal layer is 40-300 microns. The working limit of a traditional niobium alloy material is broken through, and the high temperature resistance, oxidation resistance and ablation resistance of the niobium alloy material are improved; the long-term service temperature of the niobium-based alloy is increased to 2000 DEG C or above, and the working limit of a traditional niobium alloy material is remarkably improved.

Owner:KUNMING UNIV OF SCI & TECH

Combined ice box

ActiveCN106115085AEffective insulationImprove insulation reliabilityShock-sensitive articlesRigid containersEngineeringPhase-change material

The invention relates to a combined ice box. The combined ice box comprises a plurality of ice boxes, wherein the ice boxes are hollow structures which can accommodate a phase-change material; first accommodating grooves and second accommodating grooves are respectively formed in relative positions on the two relative side walls of the ice boxes; and the first accommodating groove in one of the two arbitrary adjacent ice boxes can be matched with the second accommodating groove in the other of the two arbitrary adjacent ice boxes, so that reagent accommodating grooves which can accommodate reagents are formed. According to the combined ice box, after the plurality of ice boxes are combined, the phase-change material can surround reagent containers and has a relatively large contact area with the reagent containers, so that heat of the reagents in the reagent containers can be fully preserved, and the stability and reliability of the heat preservation effect of the reagents are guaranteed; through combining the ice boxes with different numbers, the reagent accommodating grooves with different numbers can be obtained to accommodate the reagents with different numbers; and the ice box can be utilized as an ordinary insulating container, and the practicability is relatively high.

Owner:深圳好新鲜冷链科技有限公司

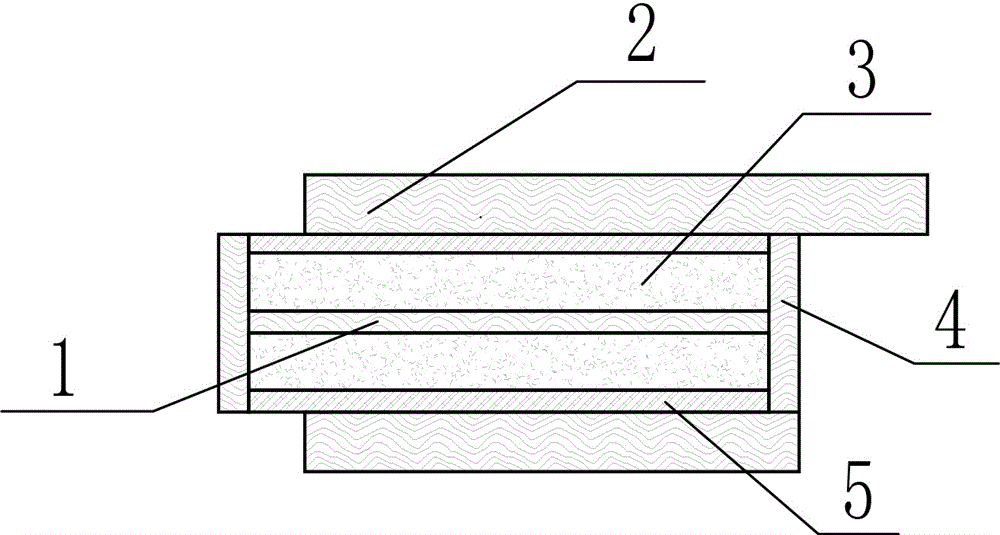

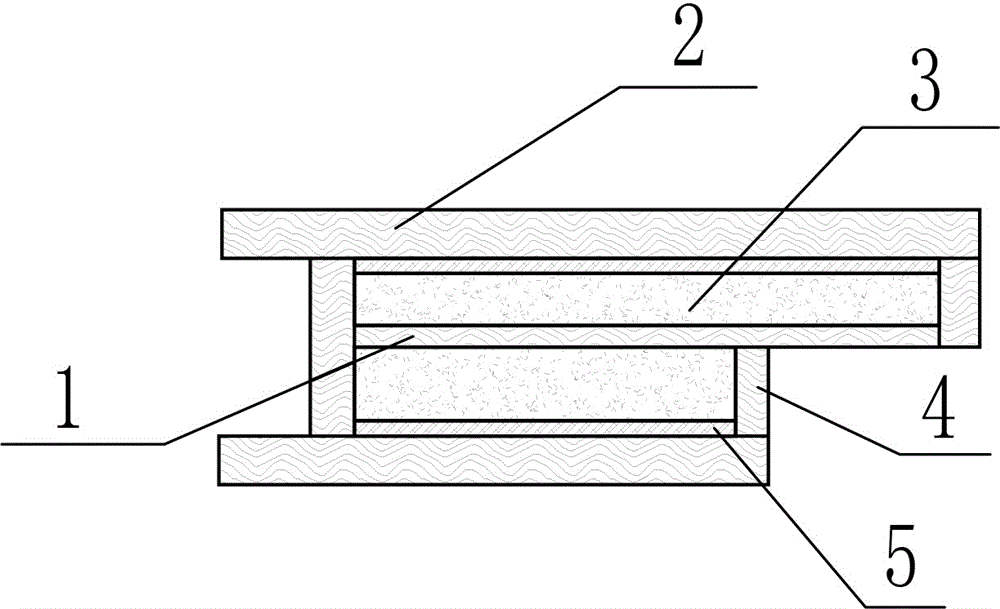

Multi-layer structure composite board manufactured by squeezing glue-free straw boards at high temperature

InactiveCN104989032ASolve the problem of not being suitable for interconnecting socketsSolve technical problemsBuilding componentsJoistEngineering

The invention discloses a multi-layer structure composite board manufactured by squeezing glue-free straw boards at a high temperature. The two large faces of a composite core board are each provided with a layer of composite outer layer wood board in a composite mode. The composite core board comprises a center skeleton board on the center layer. The two large faces of the center skeleton board are each provided with one layer of glue-free straw board in a composite mode. The outer large face of each glue-free straw board is provided with a fireproof board in a composite mode. A five-layer board formed by the glue-free straw boards, the fireproof boards and the center skeleton board has two opposite flush side faces. The two flush side faces are each provided with a layer of peripheral skeleton board in a composite mode. The two opposite side faces of the two composite outer layer wood boards are flush with the outer edges of the side faces of the peripheral skeleton boards on the same sides as the two composite outer layer wood boards. The composite board has the advantages of being free of glue and air pollution, low in density and light, has the enough connecting performance and strength, is good in flexibility and enables a wall to achieve self bearing, no joist is needed, deformation is avoided, the multi-layer structure composite board has the advantages of water resistance, impact resistance, radiation resistance and the like, and the service life of the board is as long as that of a building.

Owner:烟台金田科技有限公司

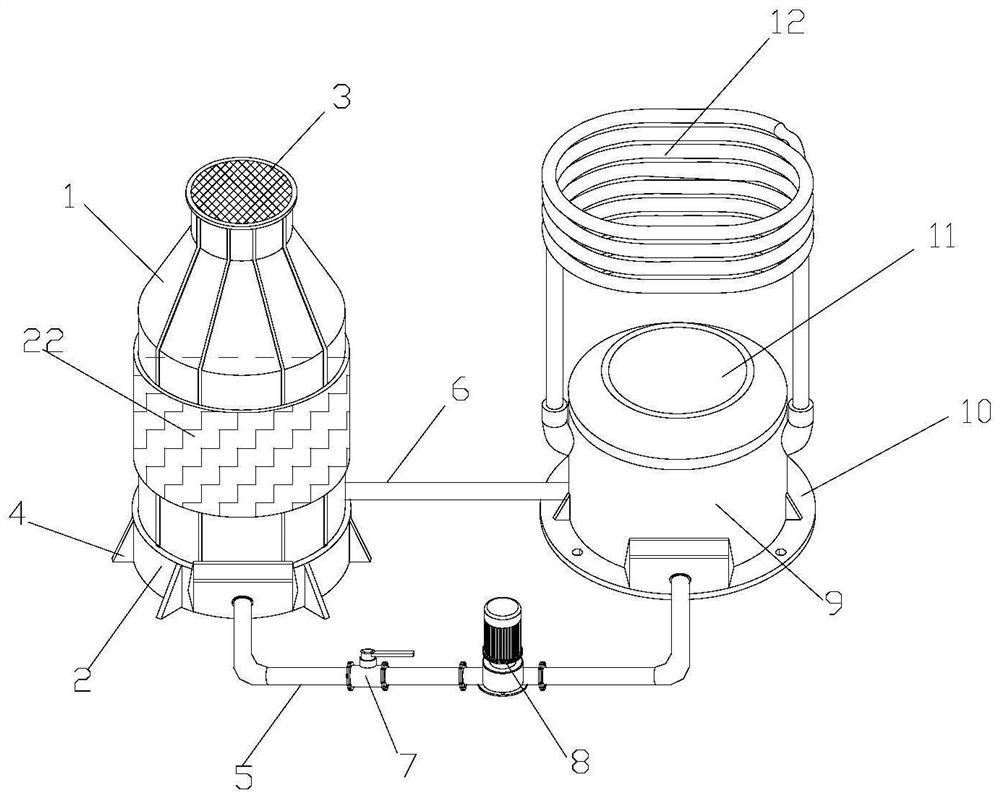

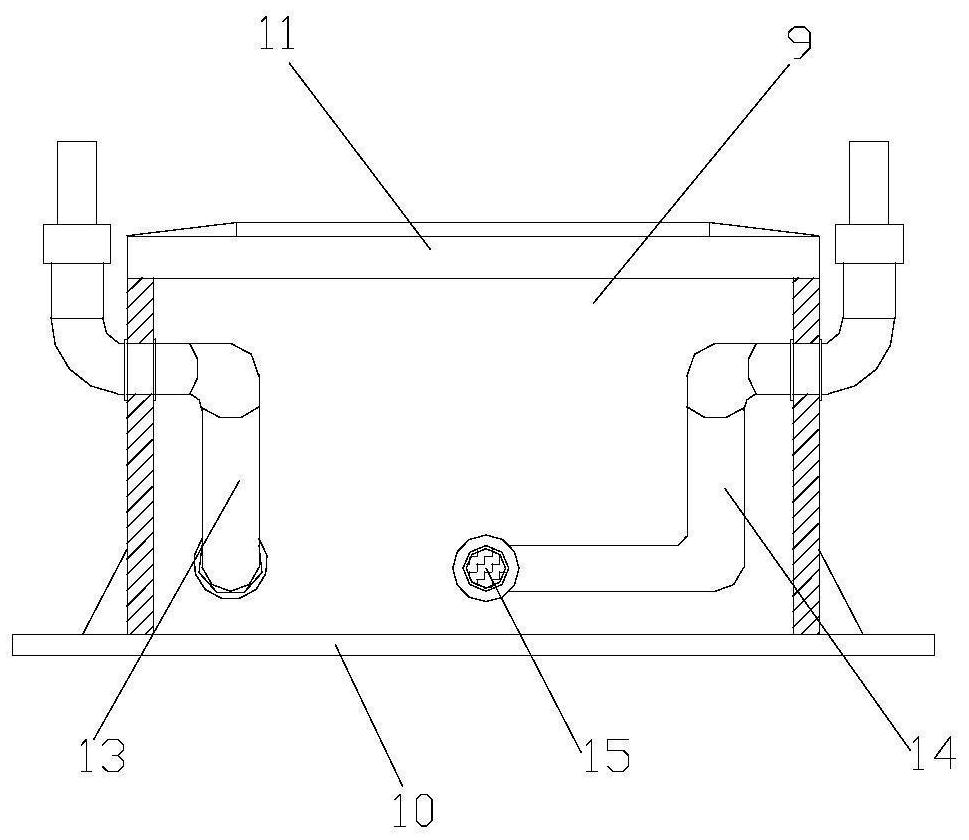

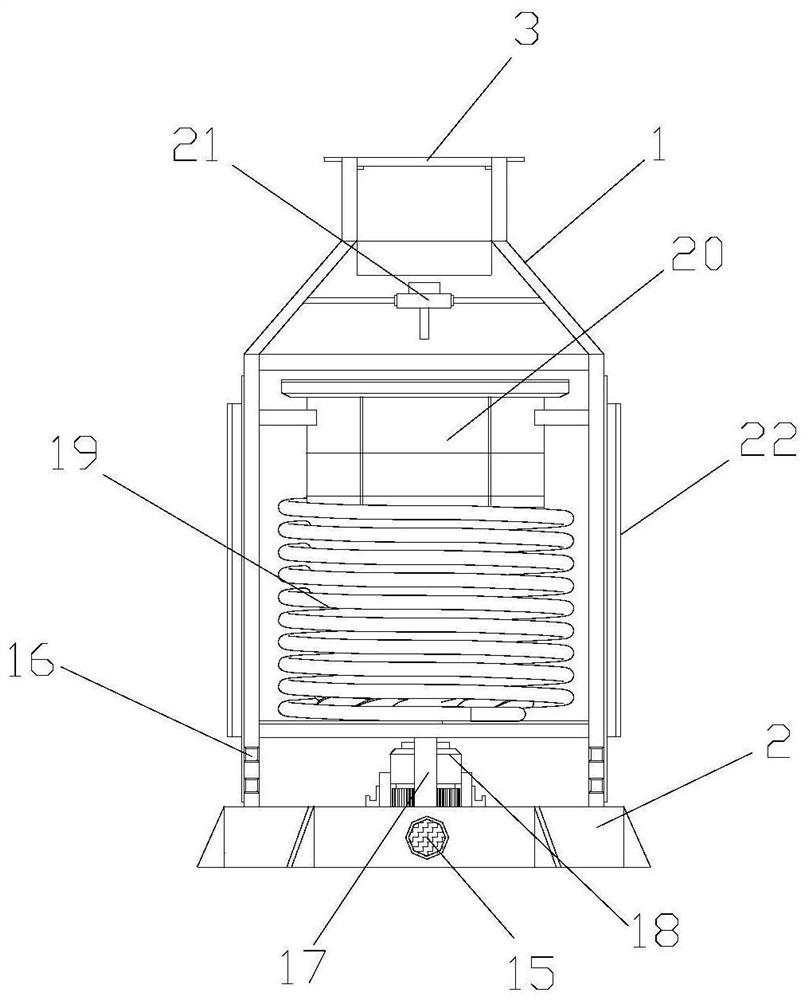

Biomass double-crucible aluminum melting furnace

InactiveCN105890356AAdequate insulationAvoid manual scooping of aluminumCrucible furnacesCombustion chamberCrucible

The invention discloses a biomass double-crucible aluminum melting furnace which comprises a biomass fuel bin and an air blower; a discharging port of the biomass fuel bin is communicated with a feeding port of a biomass combustion chamber through a feeding auger and a blanking pipe; an air outlet of the air blower is communicated with an air inlet of the biomass combustion chamber through a waste heat recovery cavity and a combustion air supply duct in sequence; a fire outlet of the biomass combustion chamber is communicated with a fire inlet of a melting crucible heating channel through a fire channel; a melting crucible is arranged at the center of the melting crucible heating channel and is communicated with a liquid aluminum using crucible through a liquid aluminum chute; the liquid aluminum using crucible is arranged at the center of a heat preservation crucible heating channel; a fire inlet of the heat preservation crucible heating channel is communicated with a fire outlet of the melting crucible heating channel through a flue gas channel; a flue gas port of the heat preservation crucible heating channel is communicated with a chimney. The biomass double-crucible aluminum melting furnace disclosed by the invention has the beneficial effects that the liquid aluminum temperature is stable, the use environment is improved, the heat preservation is performed by fully utilizing flue gas waste heat, and an energy-saving effect is achieved.

Owner:江苏七能生物质设备有限公司

Temperature self-regulating cold-proof clothing

ActiveCN105996219AFlexible movementLightweight and breathableGarment special featuresBatteries circuit arrangementsEngineeringThermal threshold

The invention provides temperature self-regulating cold-proof clothing, which comprises a jacket and lining which are in detachable connection, wherein the lining comprises a heating layer and a heat inductive layer which are mutually connected, as well as a processor which is connected to the heating layer and the heat inductive layer; the heat inductive layer is used for detecting temperature values; the heating layer is connected to the heat inductive layer and is used for receiving the temperature values detected by the heat inductive layer; the processor is used for receiving temperature values on different positions of the heat inductive layer, matching the temperature values with temperature thresholds on different positions, and controlling parts on the corresponding positions of the heating layer to heat. The clothing disclosed by the invention, which is light and thin, is suitable for summer and is convenient for movement, and meanwhile, the clothing, which is capable of keeping warm, is suitable for winter as well. The clothing disclosed by the invention has no need for a great amount of cotton fibers or down feathers; and the clothing is capable of closely covering a human body as the second skin of the human body, and the clothing is convenient for movement without barriers. The clothing, which is light and thin, can take both aesthetics and warm-keeping property into consideration even in the winter. In addition, the clothing, which is strong in air permeability, has no influence on sweat evaporation of a body surface.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

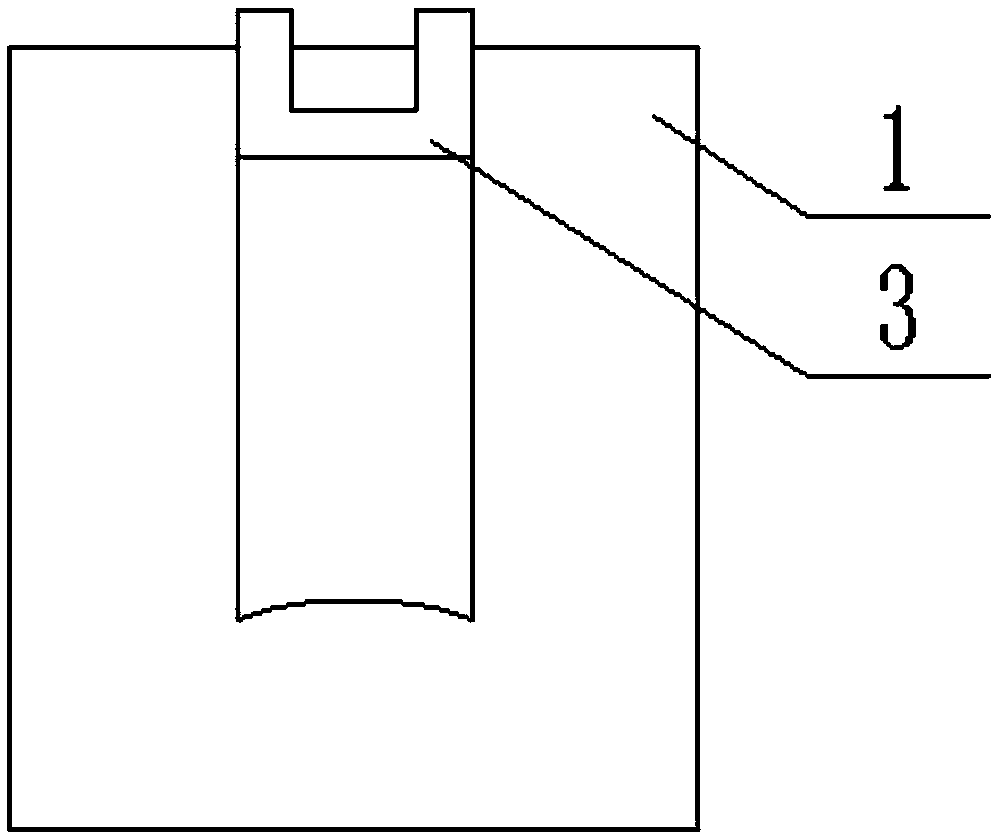

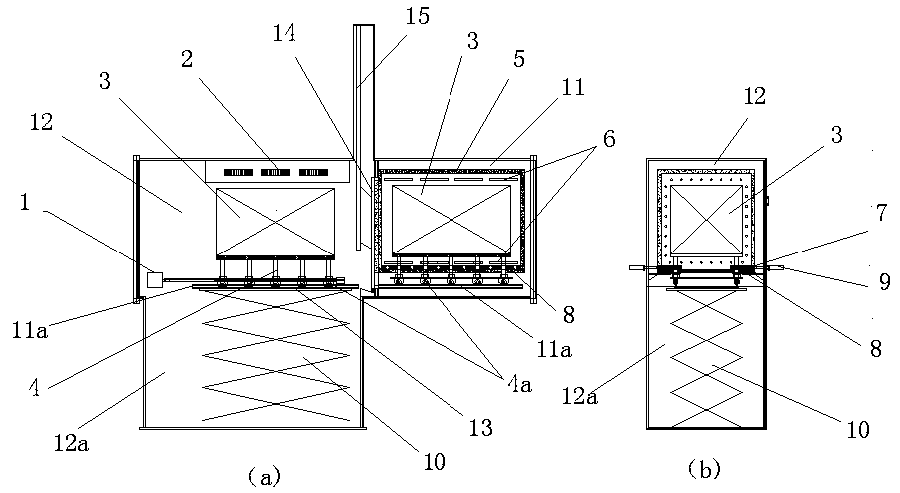

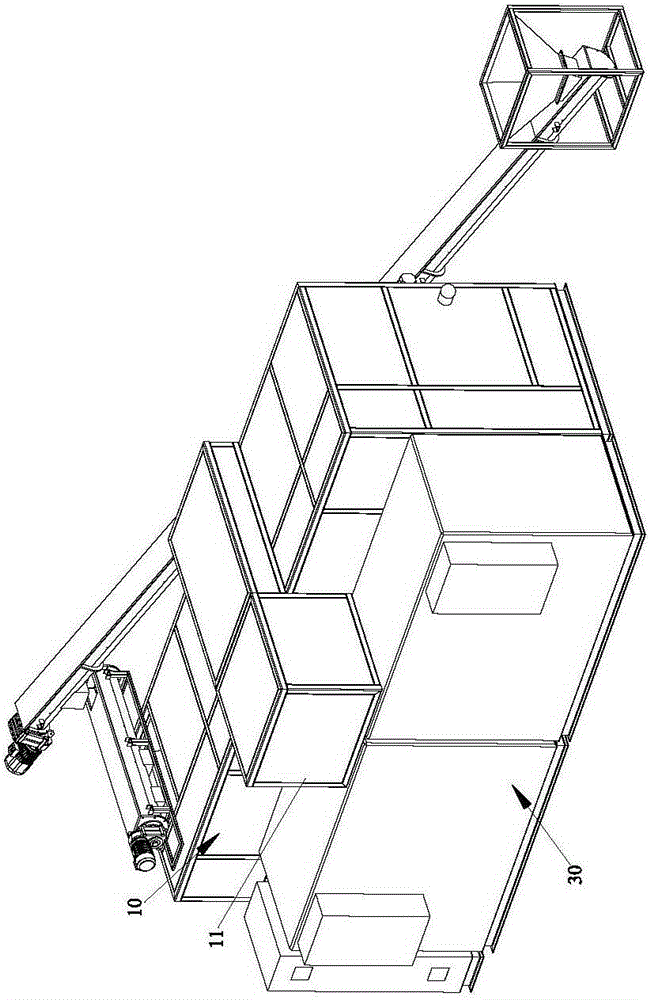

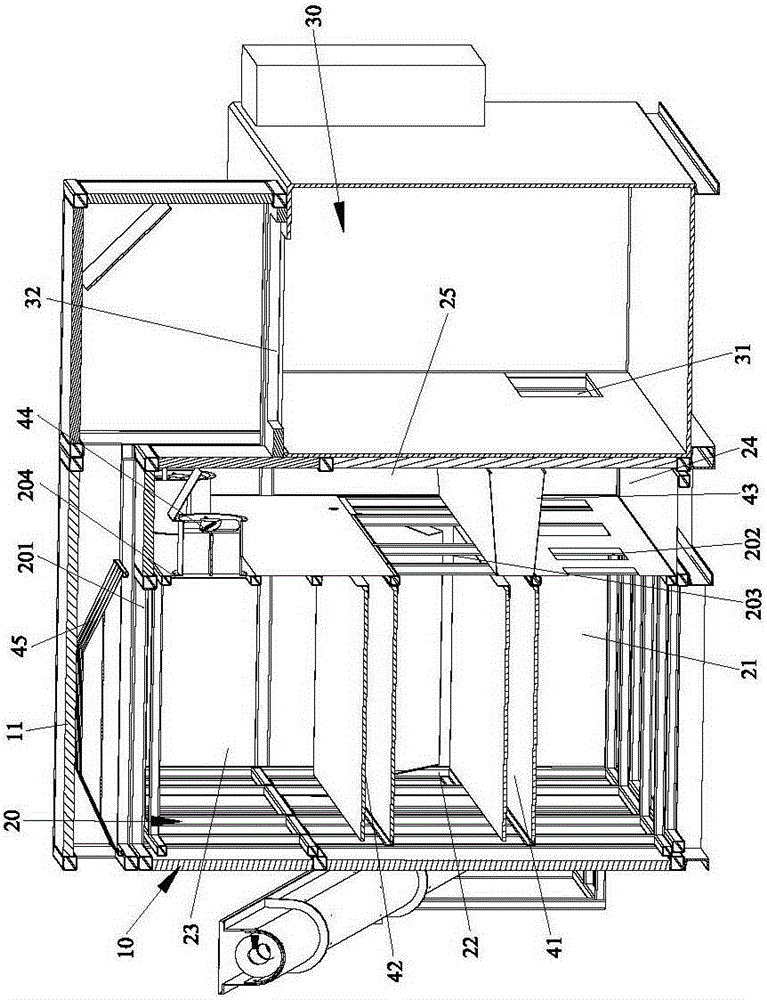

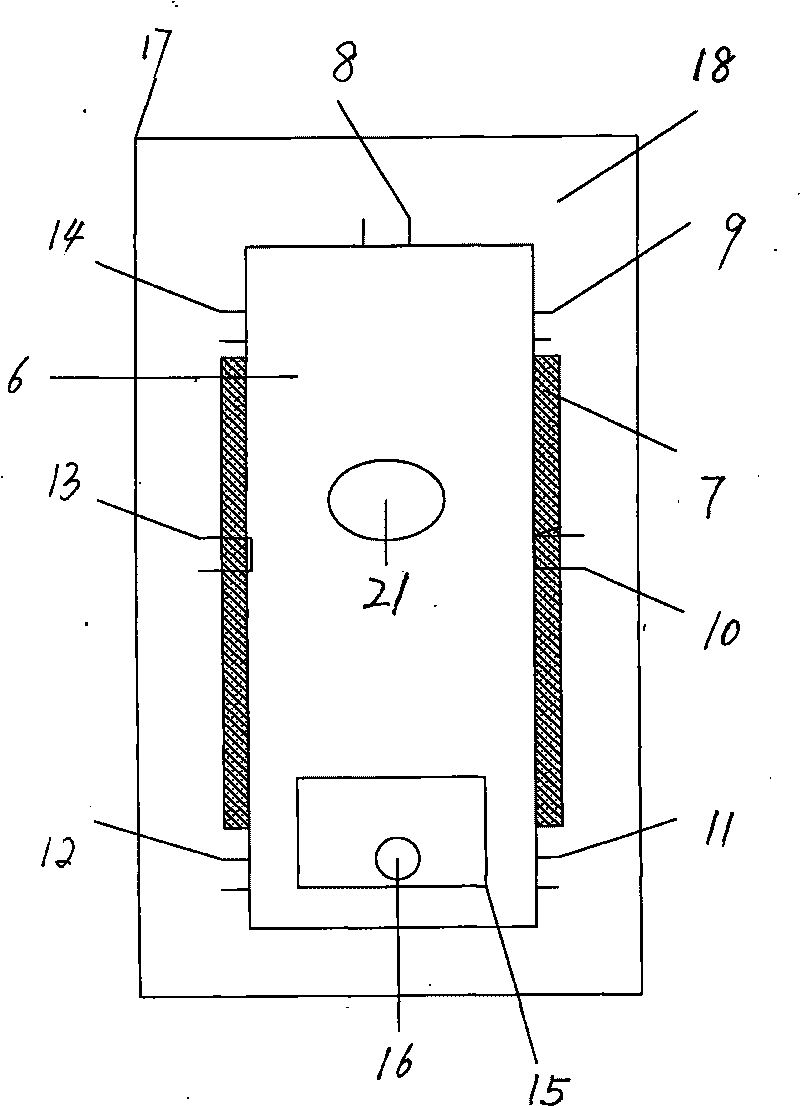

Heavy-loading large vacuum heat treatment furnace

InactiveCN110079653AEasy to moveAdequate insulationFurnace typesHeat treatment furnacesCooling chamberEngineering

The invention relates to a heavy-loading large vacuum heat treatment furnace. The heavy-loading large vacuum heat treatment furnace is mainly composed of a heating chamber and a cooling chamber; the heating chamber is of a square structure, a fixed heat preservation layer is arranged in the heating chamber, a plurality of heating pieces are arranged in the fixed heat preservation layer in an up-down mode, and a movable heat preservation layer is arranged above the heat preservation layer at the bottom of the fixed heat preservation layer; a hot air circulating device is arranged on the upper part of the cooling chamber, a rotary supporting plate is arranged in the middle of the cooling chamber, a quenching tank is arranged at the lower part of the cooling chamber, a lifting mechanism is arranged at the bottom of the quenching tank, and a rotary supporting plate is connected above the lifting mechanism; and rail grooves are formed in the middle of the movable heat preservation layer andthe rotary supporting plate, feeding trolleys can be borne on the rail grooves, the bottoms of the feeding trolleys are provided with movable rollers, the movable rollers linearly move on the rail grooves, and the heating chamber and the cooling chamber are connected through a movable door. According to the heavy-loading large-scale vacuum heat treatment furnace, a large-scale workpiece loading trolley can move between the heating chamber and the cooling chamber, the cooling speed is increased, and the hardenability of the quenching is improved.

Owner:苏州金言来真空炉业有限公司

Ceramic thermal barrier coating on surface of metal base body and application of ceramic thermal barrier coating in engine

ActiveCN111663092AHigh bonding strengthSufficient tensile shear strengthMolten spray coatingInternal combustion piston enginesMagnesium phosphatePtru catalyst

The invention discloses a ceramic thermal barrier coating on the surface of a metal base body and application of the ceramic thermal barrier coating in an engine, and belongs to the technical field ofceramic coatings. A bonding layer and the ceramic thermal barrier coating are sequentially prepared on the surface of the metal base body, wherein the preparation raw material of the ceramic thermalbarrier coating is Y2O3 powder and Zr2O3 powder, or the preparation raw material of the ceramic thermal barrier coating is gamma-Al2O3, a chromium magnesium phosphate binder and BN powder, or the preparation raw material of the ceramic thermal barrier coating is gamma-Al2O3 and SiO2. nH2O; and the ceramic thermal barrier coating is further coated with an oxidation catalyst, and the porosity of theoxidation catalyst is larger than that of the bonding layer. According to the ceramic thermal barrier coating on the surface of the metal base body and the application of the ceramic thermal barriercoating in the engine, the prepared ceramic thermal barrier coating is applied to the engine, and the oxidation catalyst added in the ceramic thermal barrier coating can utilize excessive hydrocarbonand carbon monoxide and oxidize the hydrocarbon before the hydrocarbon is converted into deposited carbon, so that the fuel enrichment during cold start is reduced, the emission of the hydrocarbon andthe carbon monoxide is reduced, and the preignition phenomenon caused by carbon deposition can be prevented.

Owner:上海亚域动力工程有限公司

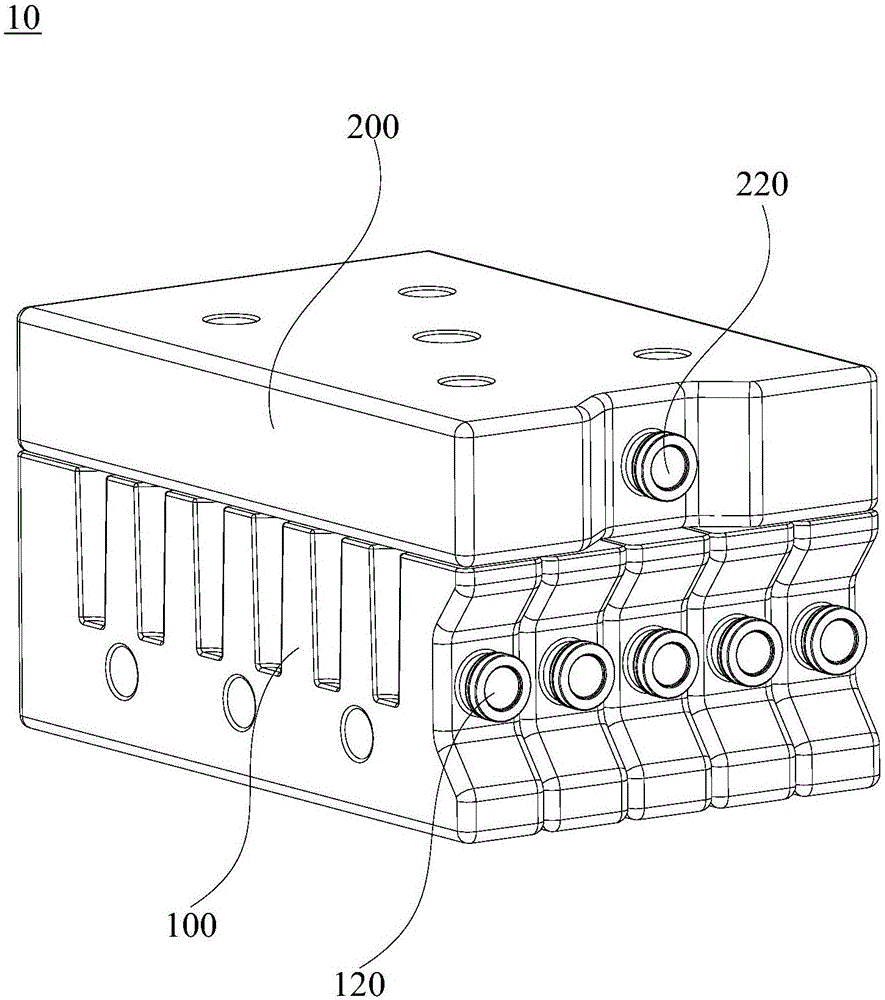

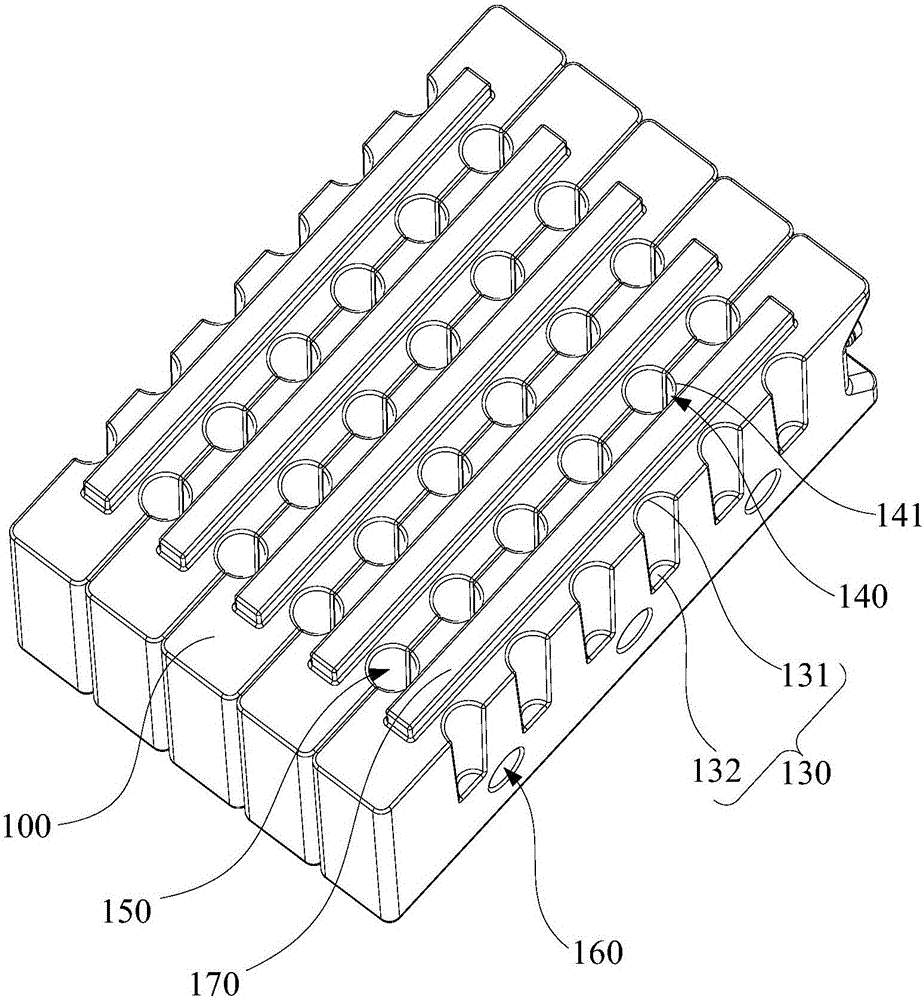

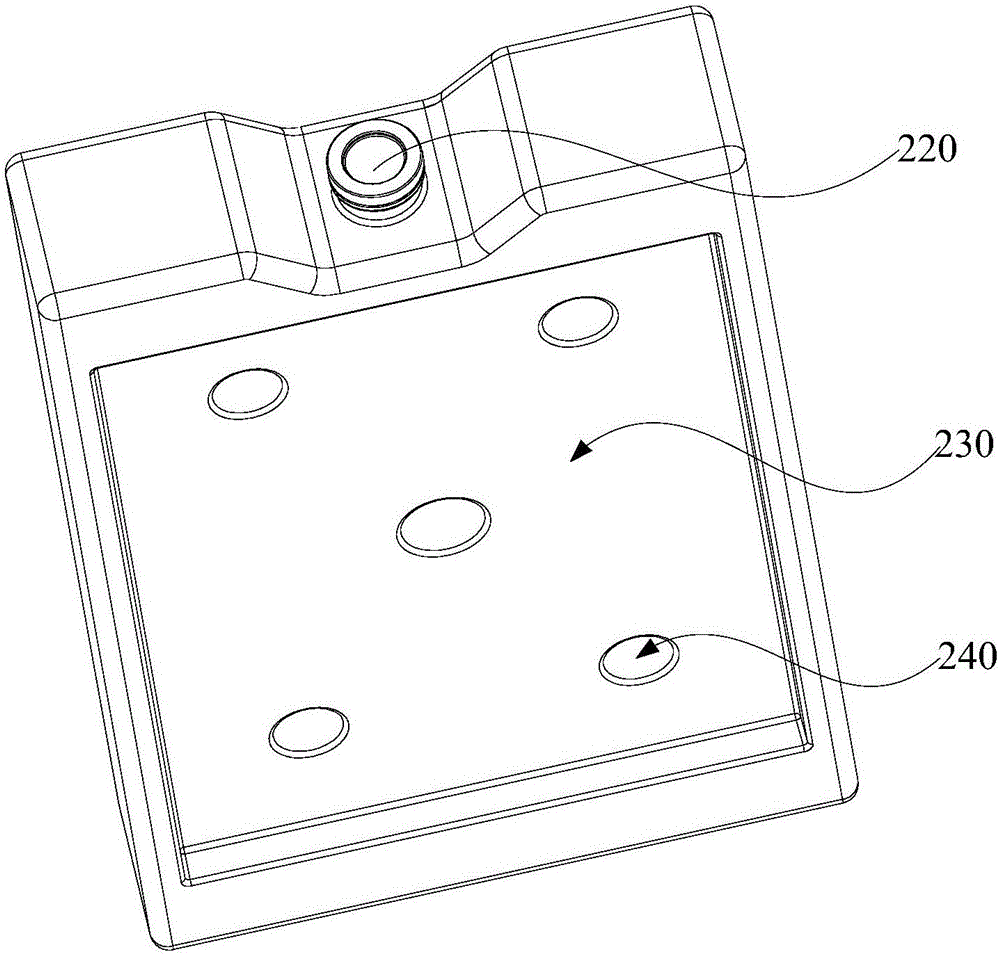

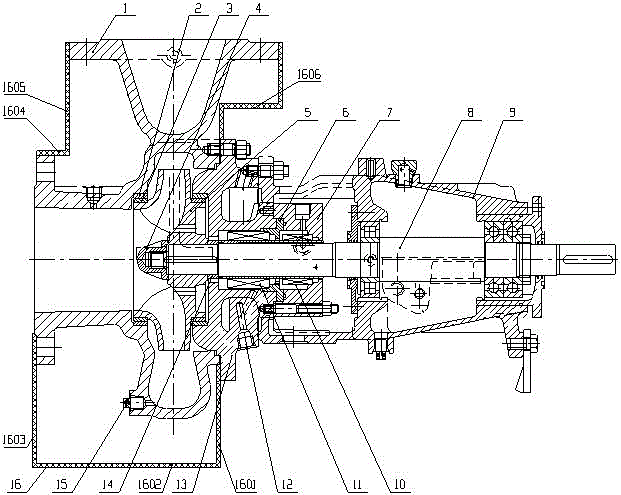

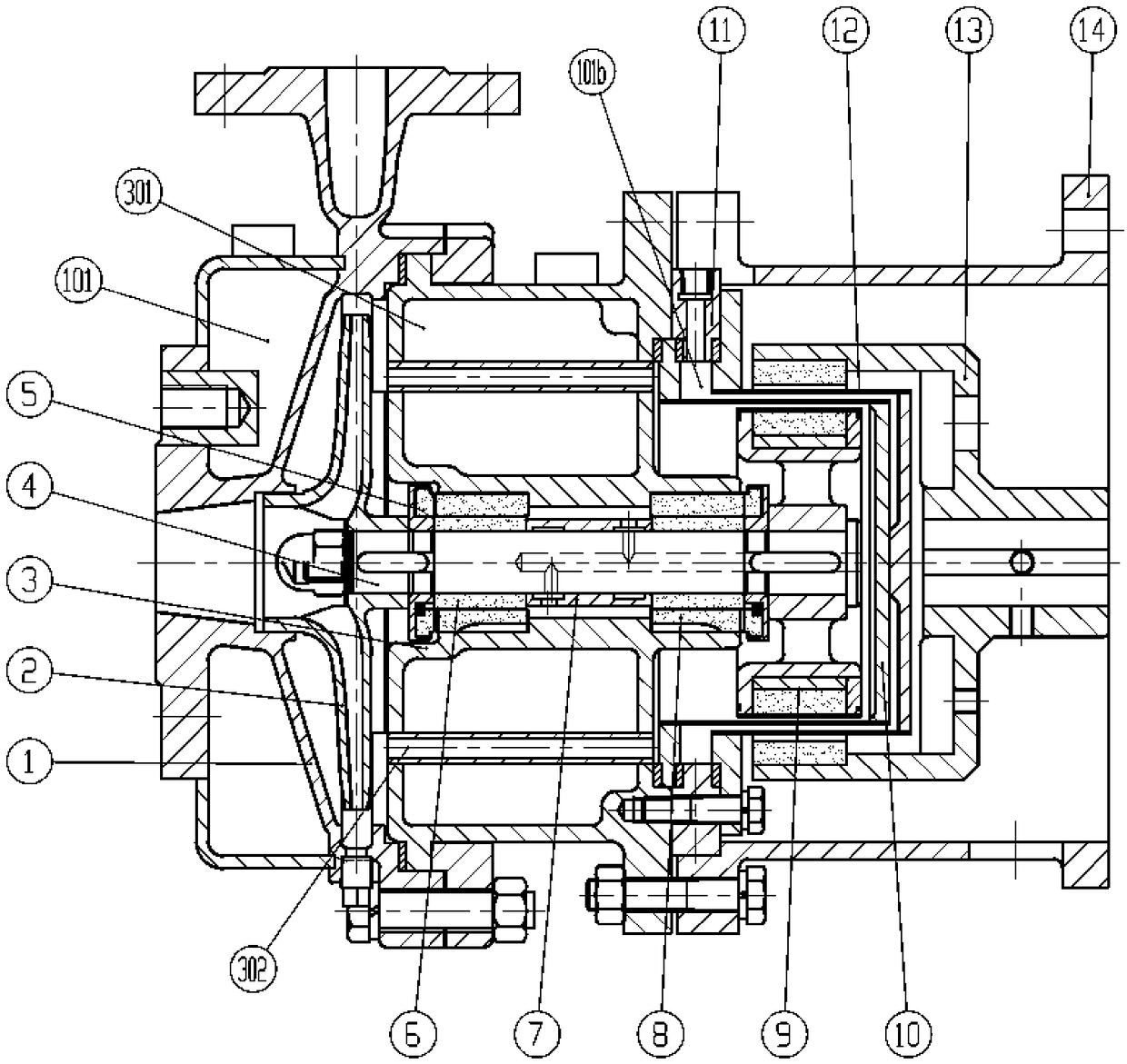

Petrochemical industry process pump

InactiveCN105298852AImprove efficiencyPrevent solidificationSpecific fluid pumpsPump componentsPetrochemicalEngineering

The invention relates to a petrochemical industry process pump. Two pump body insulating jackets are respectively arranged at the outer ring of an inlet section and the outer ring of an outlet section of a pump body, and adopt the all-surrounding structure; an insulating board C is mounted at the lower half part of a flange at the inlet section of the pump body, and the insulating board C is connected with an insulating board A through an insulating board B; a cylinder body insulating board A is a semicircle cylinder body and is arranged along the outer ring of the upper part of the flange at the inlet section of the pump body; a cylinder body insulating board B is a cylindrical cylinder body and arranged along the outer ring of the flange at the outlet section of the pump body, and the cylinder body insulating board B and the cylinder body insulating board A are in penetration; a rightwards-opened n shaped notch is formed in the right end of the cylinder body insulating board B; an insulating top board is arranged above the rightwards-opened n shaped notch; an insulating bottom board is arranged under the rightwards-opened n shaped notch; the insulating top board and the insulating bottom board are connected through a cylinder body insulating board C; two side surfaces of the cylinder body insulating board C are respectively in contact with the cylinder body insulating board B through an insulating sealing board. The petrochemical industry process pump disclosed by the invention is good in insulating effect and can effectively prevent media from solidifying.

Owner:季裕成

Air flue air distribution structure of heat pump drying machine

ActiveCN105222570AReasonable layoutAvoid churnDrying gas arrangementsDrying machines with progressive movementsSludgeProcess engineering

The invention discloses an air flue air distribution structure of a heat pump drying machine. The air flue air distribution structure comprises a shell, a drying chamber and a heat pump main engine. The shell is formed by packaging an insulation board. A lower conveying net belt and an upper conveying net belt are arranged in the drying chamber. First space is formed below the lower conveying net belt. Second space is formed between the upper conveying net belt and the lower conveying net belt. Third space is formed above the upper conveying net belt. A first air opening is formed in the top of the drying chamber. Second air openings, third air openings and fourth air openings are formed in the sided face of the drying chamber from bottom to top in sequence. An inner circulation air flue and an outer circulation air flue can be formed, the air flues are arranged reasonably and inlaid in the drying chamber, closed circulation is achieved, full heat preservation is achieved, heat is prevented from being lost, and the cost for manufacturing an outer independent air flue is omitted. In addition, dry air can be fully saturated to take away more water, the drying efficiency is improved, and the problem that sludge on the upper conveying net belt is dried unevenly is solved.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

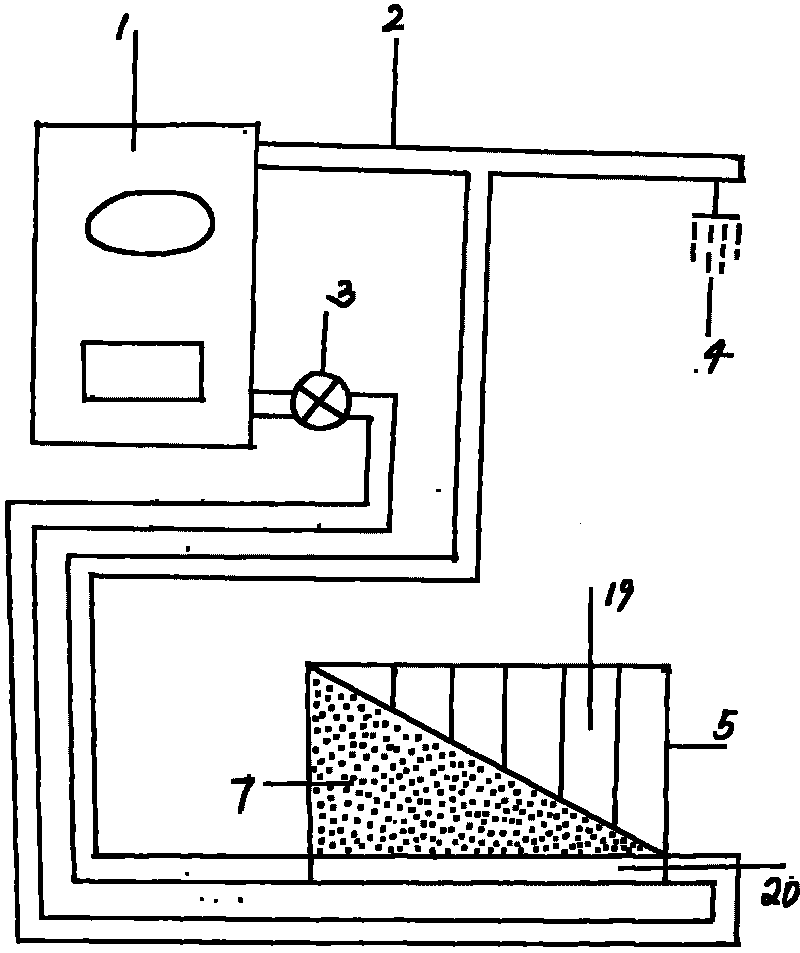

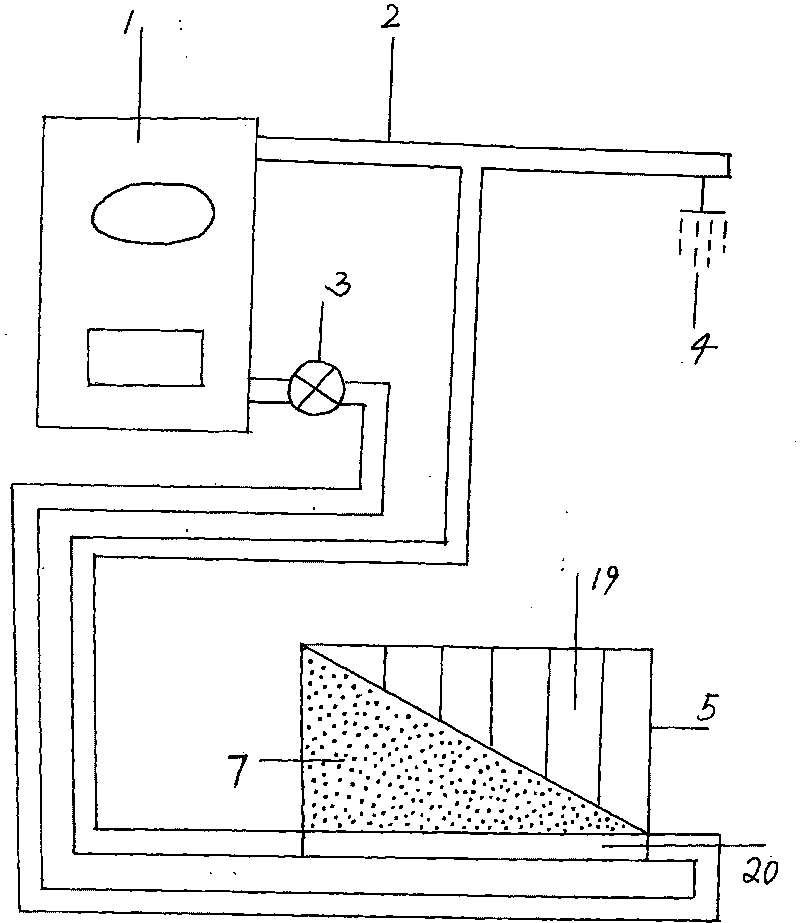

New-energy water-heat supply system

InactiveCN101726029AOvercoming the problems of heating with large volumes of waterEfficient water savingSpace heating and ventilation detailsWater heatersNew energyCirculating pump

The invention discloses a new-energy water-heat supply system. The system is formed by connecting a water heater consisting of a liner, a shell and new-energy superconducting liquid with a circulating pump, a nozzle and a radiator provided with the new-energy superconducting liquid through pipelines. The new-energy water-heat supply system has the advantages of solving the problems of using a large amount of water for heating, efficiently saving water, fully preserving heat, operating in 40 percent of state and efficiently saving power.

Owner:DALIAN GEBRO TECH DEV

Protective device for pressure pipeline

PendingCN109538882AEasy to useAvoid collisionPipe supportsFlanged jointsArchitectural engineeringSteel bar

The invention discloses a protective device for a pressure pipeline. The protective pipeline includes the pressure pipeline. Support steel bars are vertically welded to the outer side surface of the pressure pipeline. An outer protective steel pipe is vertically welded to the other end of each support bar. The pressure pipeline and the support steel bars are located in the cavity of the outer protective steel pipe. Connection flanges are fixedly welded to the two ends of the outer protective steel pipe. Connection part protective rings are arranged on the outer sides of the connection flanges.The connection part protective rings match the connection flanges. The connection part protective rings are connected to the outer side surface of the outer protective steel pipe. The protective device for a pressure pipeline has the advantages of simple structure, reasonable design, simple operation and convenient use. Through the arrangement of the outer protective steel pipe and the support steel bars, the protective device for a pressure pipeline is provided with a layer of vacuum zone between the pressure pipeline and the outer protective steel pipe under the coordination of the outer protective steel pipe and the support steel bars, which greatly protects the pressure pipeline. The protective device for a pressure pipeline has a broad application prospect.

Owner:NANJING HIGH DRIVE ELECTROMECHANICAL AUTOMATION EQUIP CO LTD

Novel heat-isolating board for building

InactiveCN103846998AAdequate insulationWood working apparatusFlat articlesFormaldehyde freeEngineering

The invention discloses a novel heat-isolating wall board and particularly relates to a light heat-isolating wall board for a building which is relatively low in heat transfer coefficient. The light heat-isolating wall board comprises the following components in percentage by weight: 95 percent of crushed plant straw, shrub branches and leaves, waste powder of processed wood boards and the like, and 5 percent of formaldehyde-free white latex which is special for a heat-isolating wood wall board. In use, mixed glue solution is sprayed onto crushed scrapes of crushed plant straw, shrub branches and leaves, waste powder of processed wood boards and the like; certain amount of components is placed in a frame model and is heated to the temperature of 200 DEG C to be thermally pressed and molded; after being de-molded, the molded product is placed at a ventilating dry place to be further aired to be dry.

Owner:王金山

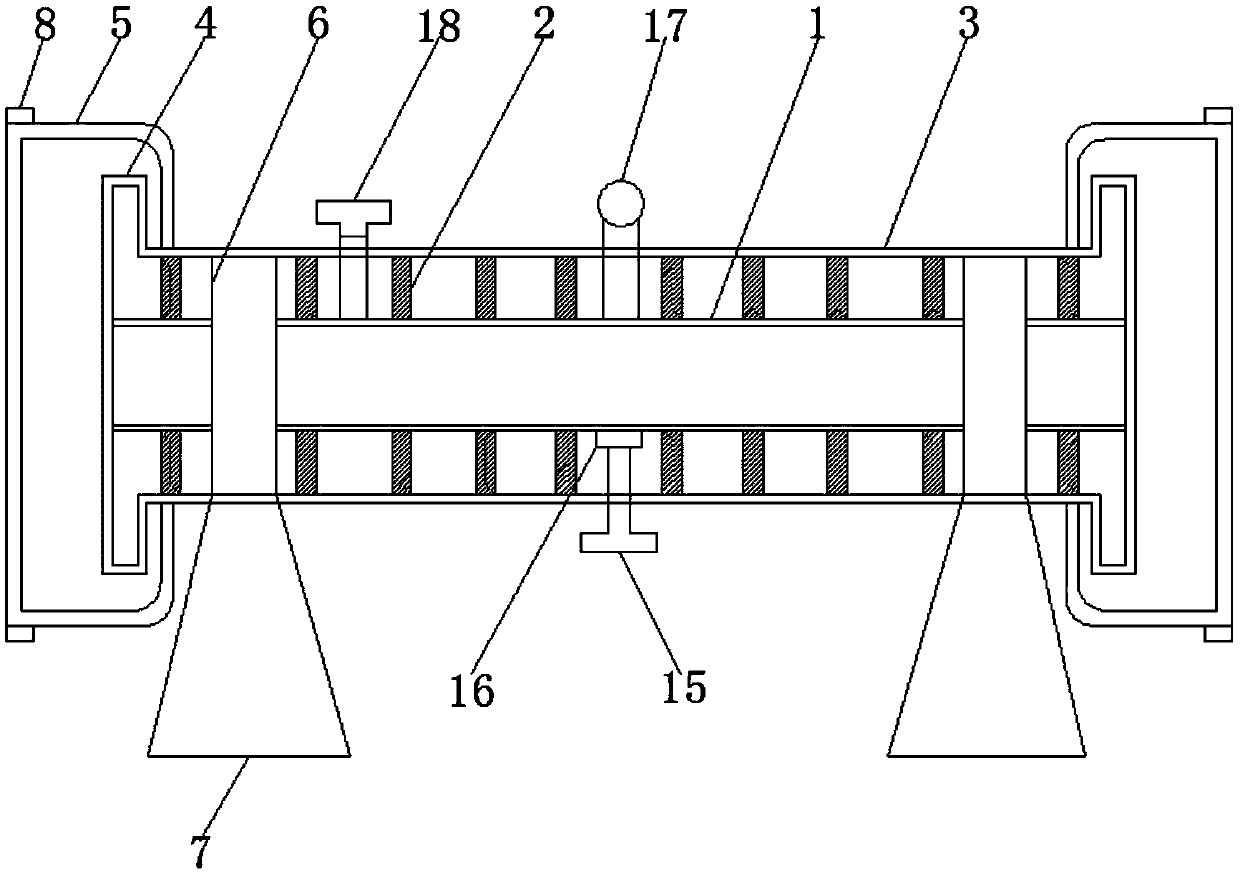

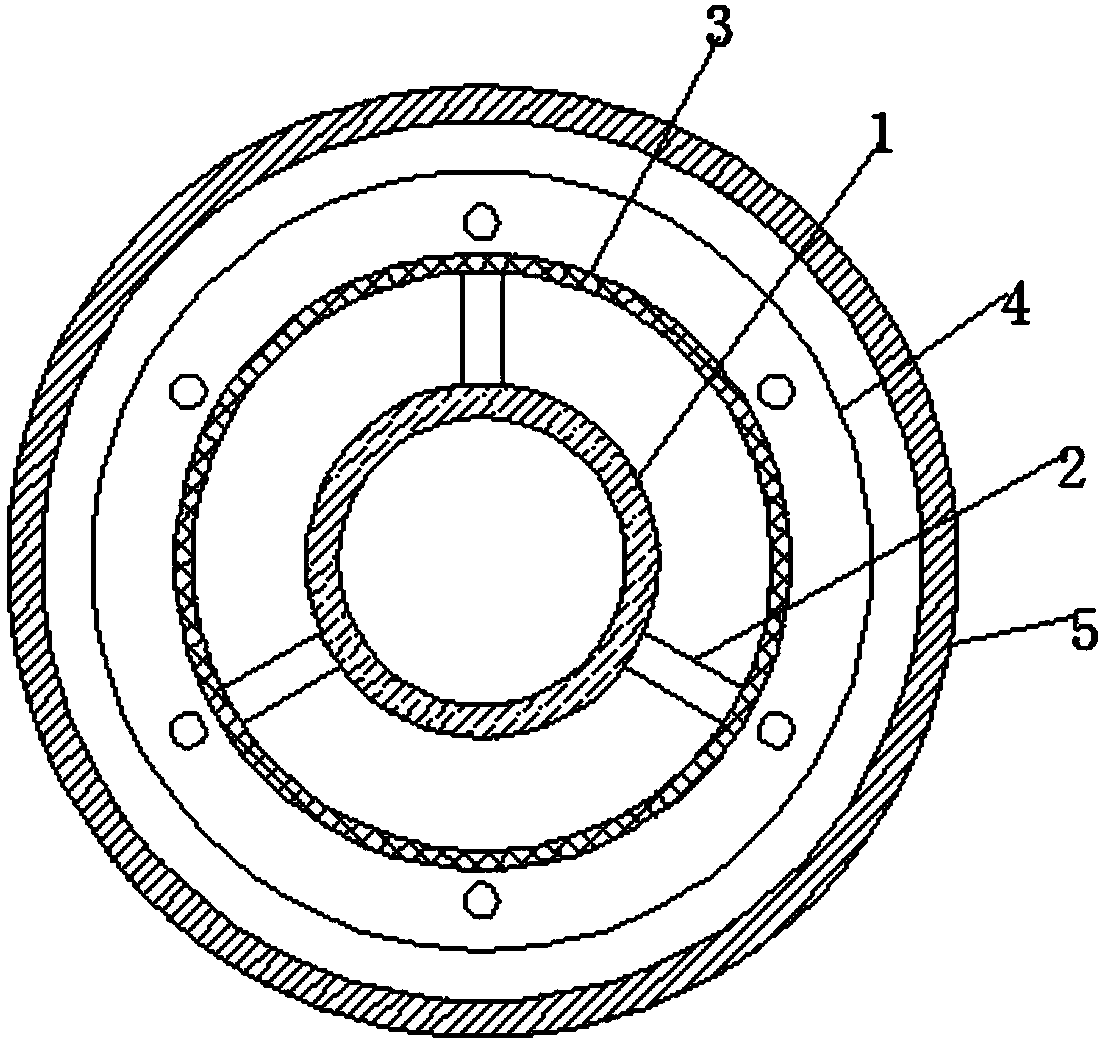

Heat insulation magnetic force pump with flow passage components wrapped totally

The invention provides a heat insulation magnetic force pump with flow passage components wrapped totally. The heat insulation magnetic force pump comprises a pump body, an impeller, an intermediate bearing body, a pump shaft, a thrust disk assembly, a shaft sleeve, a retaining sleeve, a bearing sleeve, an internal magnet rotor assembly, a spacer sleeve, an external magnet rotor assembly and a connecting frame. The periphery of the pump body is wrapped by a front heat insulation cavity formed by a metal jacket. The periphery of the intermediate bearing body is wrapped by an intermediate heat insulation cavity formed by a metal jacket. A circulating pipe is arranged on the intermediate bearing body. The circulating pipe penetrates through the intermediate heat insulation cavity to reach aninner cavity of an inner spacer sleeve body. The spacer sleeve comprises the inner spacer sleeve body and an outer spacer sleeve body. A flange ring is arranged between the inner spacer sleeve body and the outer spacer sleeve body. A rear heat insulation cavity is defined by the inner spacer sleeve body, the flange ring and the outer spacer sleeve body. The heat insulation magnetic force pump hasthe advantages of being sufficient in heat insulation, safe, reliable and good in circulation effect.

Owner:上海佰诺泵阀有限公司

A method of applying paint to a mold

ActiveCN107584082BImprove high temperature resistanceAlso sinterableFoundry mouldsFoundry coresPolymer scienceCasting mold

A kind of method for coating coating to casting mould, when coating coating to casting mold, be coated with 1-2 road primers on the surface of described casting mold earlier, every coating primer all carries out drying treatment, and then on The surface of the primer coating is coated with more than one outer layer of paint, and each outer layer of paint is dried. The main component of the refractory aggregate contained in the outer layer of paint is different from the main component of the refractory aggregate contained in the primer. Through the improvement of the paint coating method and the coordination of the fire resistance level of the primer and outer paint, the paint can not only play a sufficient heat insulation effect, but also achieve good peeling after casting, and the performance can exert the maximum effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Preparation method of light thermal insulating wallboard

The invention relates to a preparation method of a light thermal insulating wallboard, and specifically relates to a light thermal insulating wallboard with a low heat transfer coefficient for buildings. The light thermal insulating wallboard is composed of 95% of ground plant straws, shrub branches and leaves, wood board processing scraps and the like, and 5% of a formaldehyde-free white latex special for the thermal insulating wood wallboard by weight percentage. In use, the mixed solution glue is sprayed to scraps such as the ground plant straws, the shrub branches and leaves and the wood board processing scraps, and then the mixture is placed in a frame mold by a certain amount, and hot-press-molded at 200 DEG C by heating. Next, the demolded product is placed in a ventilated dry place for further air-drying.

Owner:牛雅丽

A normalizing and tempering process for motor shaft forgings

ActiveCN110306014BShorten heat treatment timeAdequate insulationFurnace typesHeat treatment furnacesElectric arc furnaceTempering

Owner:陕西华威科技股份有限公司

combination ice box

ActiveCN106115085BImprove practicalityAdequate insulationShock-sensitive articlesRigid containersEngineeringPhase-change material

The invention relates to a combined ice box. The combined ice box comprises a plurality of ice boxes, wherein the ice boxes are hollow structures which can accommodate a phase-change material; first accommodating grooves and second accommodating grooves are respectively formed in relative positions on the two relative side walls of the ice boxes; and the first accommodating groove in one of the two arbitrary adjacent ice boxes can be matched with the second accommodating groove in the other of the two arbitrary adjacent ice boxes, so that reagent accommodating grooves which can accommodate reagents are formed. According to the combined ice box, after the plurality of ice boxes are combined, the phase-change material can surround reagent containers and has a relatively large contact area with the reagent containers, so that heat of the reagents in the reagent containers can be fully preserved, and the stability and reliability of the heat preservation effect of the reagents are guaranteed; through combining the ice boxes with different numbers, the reagent accommodating grooves with different numbers can be obtained to accommodate the reagents with different numbers; and the ice box can be utilized as an ordinary insulating container, and the practicability is relatively high.

Owner:深圳好新鲜冷链科技有限公司

Soldering furnace waste heat treatment equipment based on convective heat exchange

ActiveCN112828412AStable deliveryStable and effective supply flow supportIncreasing energy efficiencyWaste heat treatmentHeat energyHeat treating

The invention discloses soldering furnace waste heat treatment equipment based on convective heat exchange. The equipment structurally comprises a closing cylinder, a bottom support, a dustproof net, a reinforcing plate, a liquid feeding pipe, a liquid return pipe, a hand valve, an oil pump, an oil guide bin, a bottom edge, a top cover, a heat exchange ring pipe, a liquid inlet connecting pipe, a liquid guide connecting pipe, heat conduction oil, heat dissipation holes, a liquid inlet pipe, a heat conveying mechanism, a heat conveying ring pipe, a heat storage mechanism, a heat detection probe and a heat insulation mechanism. The equipment has the following beneficial effects that after a heat exchange guide pipe makes contact with heat flow, heat is absorbed and exchanged through the heat conduction oil, heat is guided through the heat conveying mechanism after the heat conveying ring pipe absorbs the heat, the heat is dissipated after the heat is stored through the heat storage mechanism, preheating heat is provided for plates, the welding heat flow and waste heat can be effectively treated and recycled, the heat energy loss during operation is reduced, the heat utilization rate is increased, and the energy-saving effect is improved.

Owner:杭州余杭冠泰五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com