Multi-layer structure composite board manufactured by squeezing glue-free straw boards at high temperature

A glue-free straw, multi-layer structure technology, applied in building components, building structures, buildings, etc., can solve problems such as the inability to fully display the lightweight characteristics of straw boards, physical injuries to construction workers, and damage to the health of occupants. To achieve the effect of sound insulation and fire resistance, excellent impact resistance, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

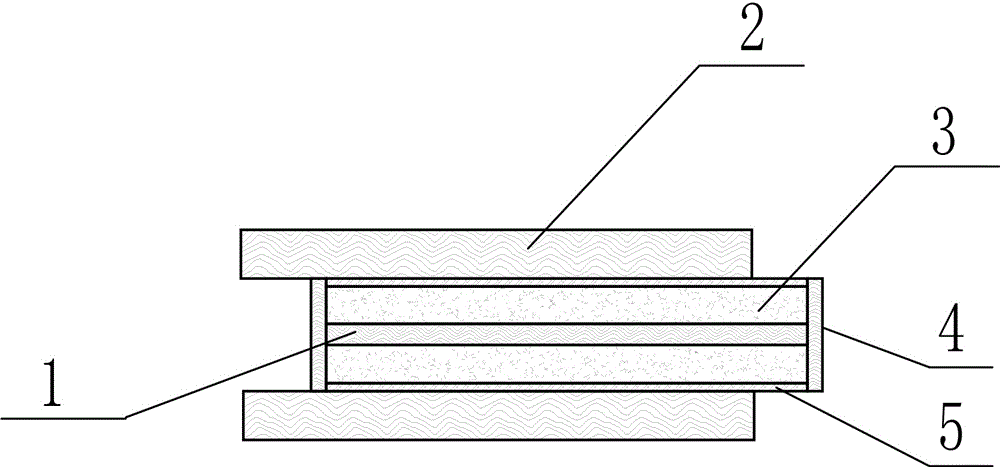

[0022] Such as figure 1 , the present embodiment includes a composite core board, each of the two large surfaces of the composite core board is composited with a layer of composite outer wood board 2 .

[0023] The composite core board includes a central skeleton board 1 located at the center layer, a layer of non-adhesive straw board 3 is compounded on each of the two large surfaces of the central skeleton board 1 , and a layer of fireproofing board 3 is compounded on the outer large surface of the non-glue straw board 3 . plate 5. The same side surface and the same end surface of the five-layer board are all flush, and a layer of peripheral skeleton board 4 is respectively compounded on the two side surfaces and the two end faces of the five-layer board.

[0024] The large surfaces of the two-layer composite outer wood boards 2 are parallel to each other and the side faces are flush with the outer edges of the side faces of the peripheral skeleton boards 4 on the same side....

Embodiment 2

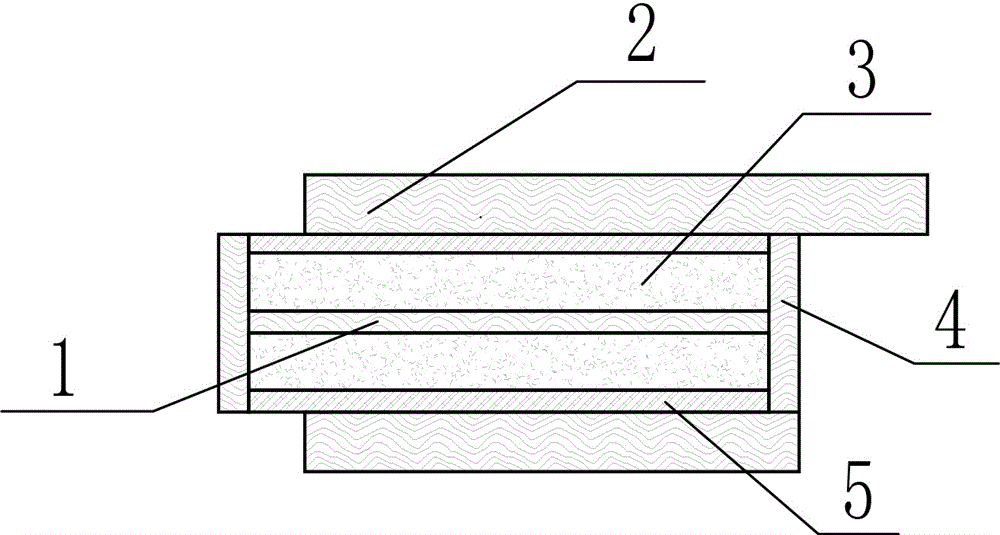

[0027] Such as figure 2 , the present embodiment includes a composite core board, each of the two large surfaces of the composite core board is composited with a layer of composite outer wood board 2 .

[0028] The composite core board includes a central skeleton board 1 located at the center layer, a layer of non-adhesive straw board 3 is compounded on each of the two large surfaces of the central skeleton board 1 , and a layer of fireproofing board 3 is compounded on the outer large surface of the non-glue straw board 3 . plate 5. The same side surface and the same end surface of the five-layer board are all flush, and a layer of peripheral skeleton board 4 is respectively compounded on the two side surfaces and the two end faces of the five-layer board.

[0029] The large surfaces of the two-layer composite outer wood boards 2 are parallel to each other and the side faces are flush with the outer edges of the side faces of the peripheral skeleton boards 4 on the same side...

Embodiment 3

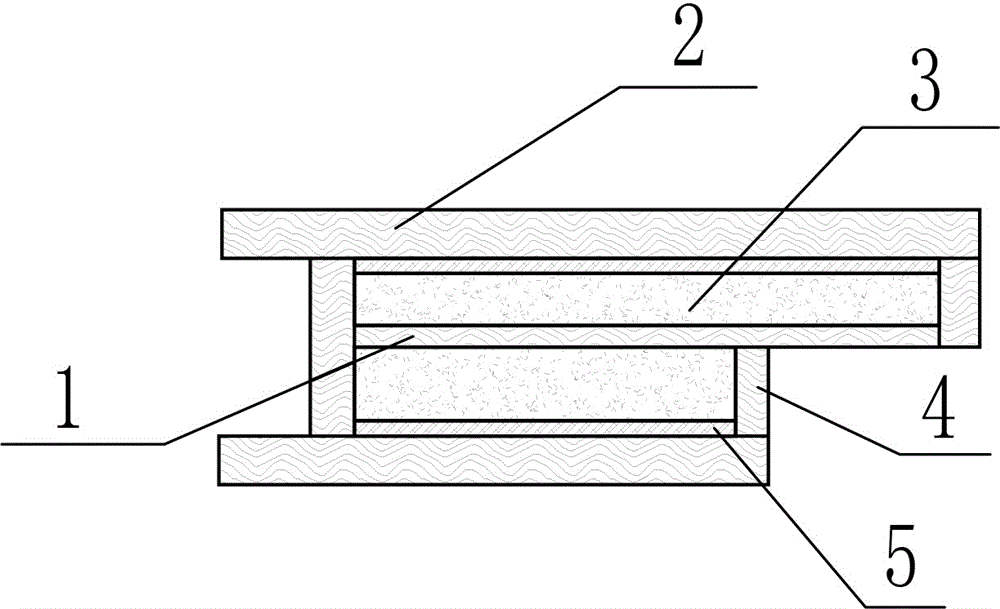

[0032] Such as image 3 , the present embodiment includes a composite core board, each of the two large surfaces of the composite core board is composited with a layer of composite outer wood board 2 .

[0033] The composite core board includes a central skeleton board 1 located at the center layer, a layer of non-adhesive straw board 3 is compounded on each of the two large surfaces of the central skeleton board 1 , and a layer of fireproofing board 3 is compounded on the outer large surface of the non-glue straw board 3 . plate 5. The same side of the five-layer board is flush, and a peripheral skeleton board 4 is compounded on two sides of the five-layer board respectively. The left ends of the five-layer boards are flush with each other, and a peripheral skeleton board 4 is compounded on the left ends of the five-layer boards. One of the glue-free straw boards 3 and the side fireproof board 5 are aligned with the right end of the central skeleton board 1 to form a longer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com