Patents

Literature

42results about How to "Enough deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-alloy high-strength large-diameter thick-walled seamless steel pipe and manufacturing method thereof

ActiveCN105586532AGuaranteed mechanical performance indexEnough deformationSteelmakingRefining (metallurgy)

The invention relates to the technical field of metallurgy, and provides a low-alloy high-strength large-diameter thick-walled seamless steel pipe and a manufacturing method thereof. The method comprises the steps of steelmaking, wherein smelting and refining are performed to obtain target molten steel, and ingot casting is performed on the target molten steel to obtain static ingots; pipe billet forging, wherein forging and annealing are performed on the static ingots to obtain pipe billets; pipe rolling, wherein the pipe billets are heated inside an annular furnace at the temperature of 1230-1270 DEG C, holes are formed after heating is performed, and rolling forming is performed through a pipe mill; normalizing heat treatment, wherein normalizing heat treatment is performed on rolled and formed steel pipes, the normalizing furnace discharge pipe temperature is 920-940 DEG C in the normalizing heat treatment process, and the cooling mode is the air-cooling or air-cooling and mist spraying mode. The steel pipe produced through the manufacturing method is uniform in texture, good in performance and capable of achieving high-strength and excellent subzero 20 DEG C low-temperature toughness, in addition, by adopting the simplified production technology, the production efficiency can be improved, the production cost can be lowered, and meanwhile the steel pipe has the good using safety due to the low yield ratio.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

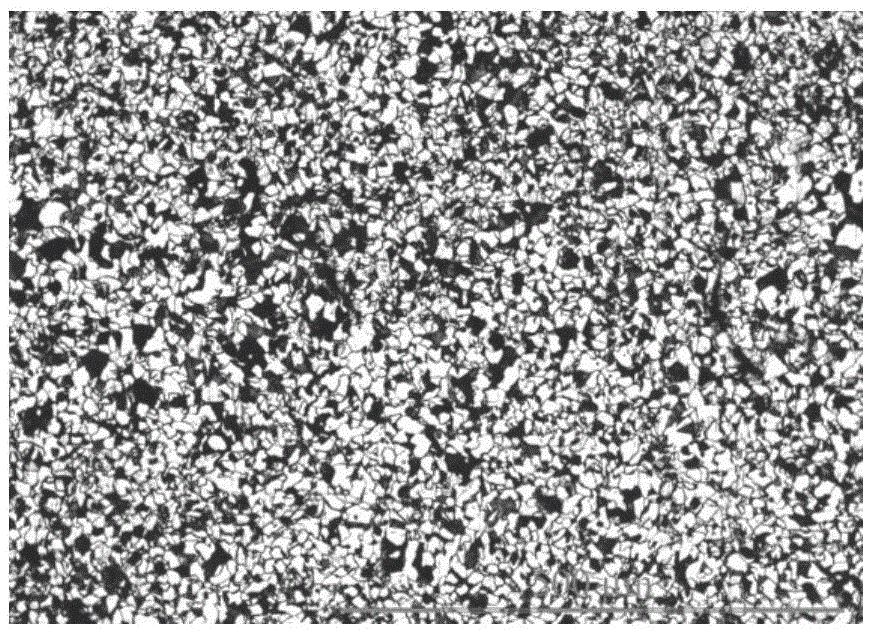

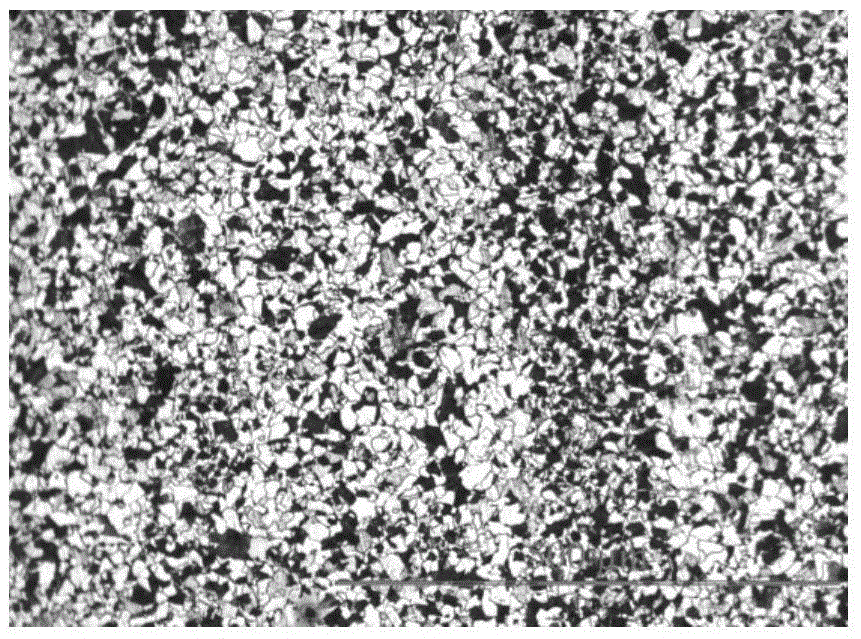

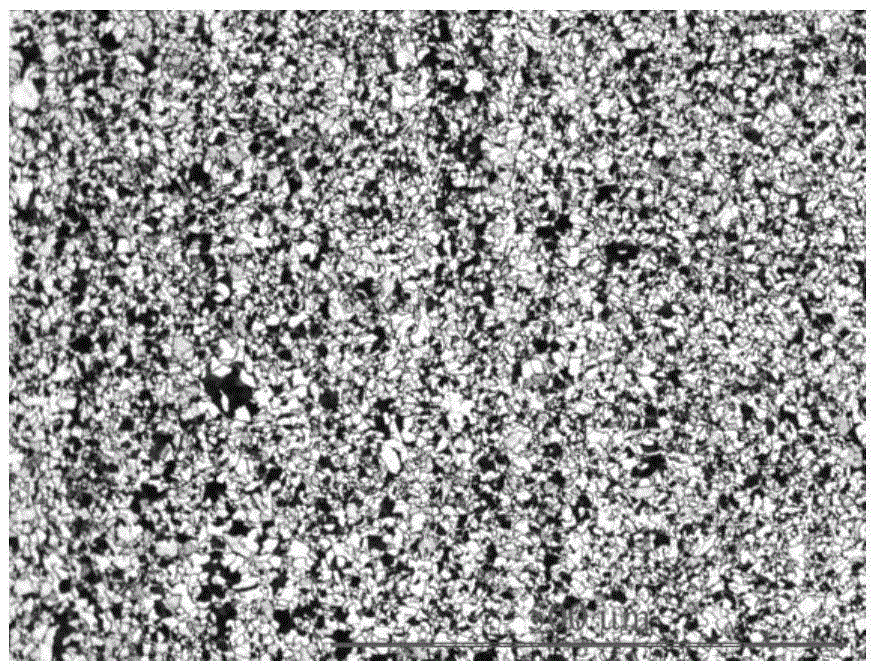

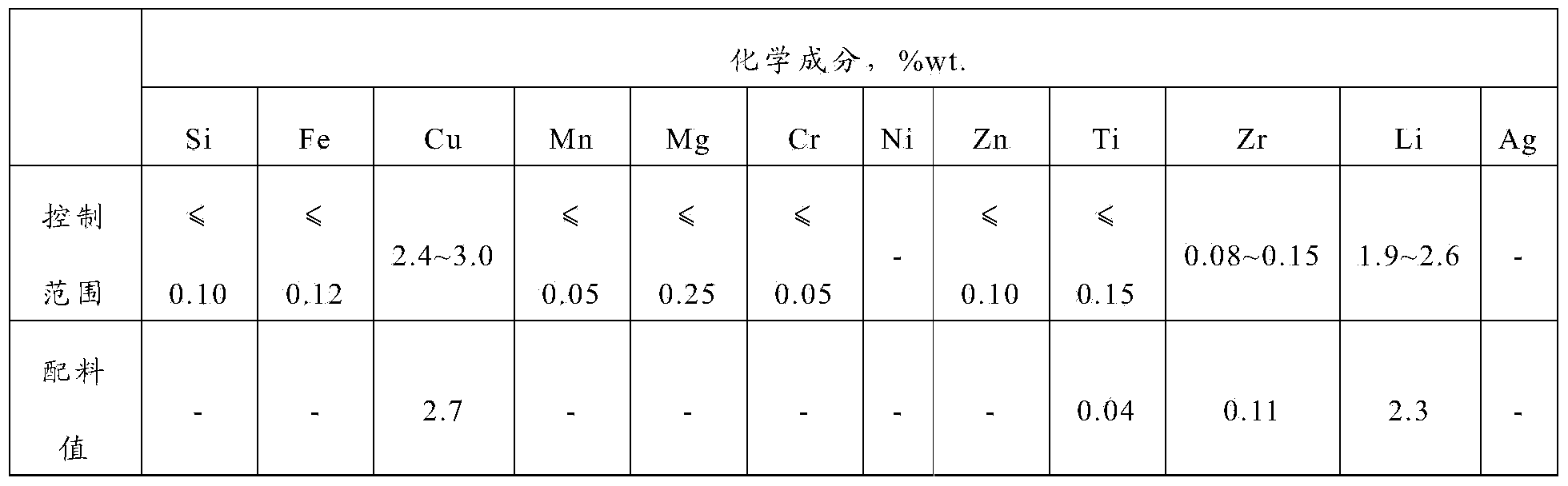

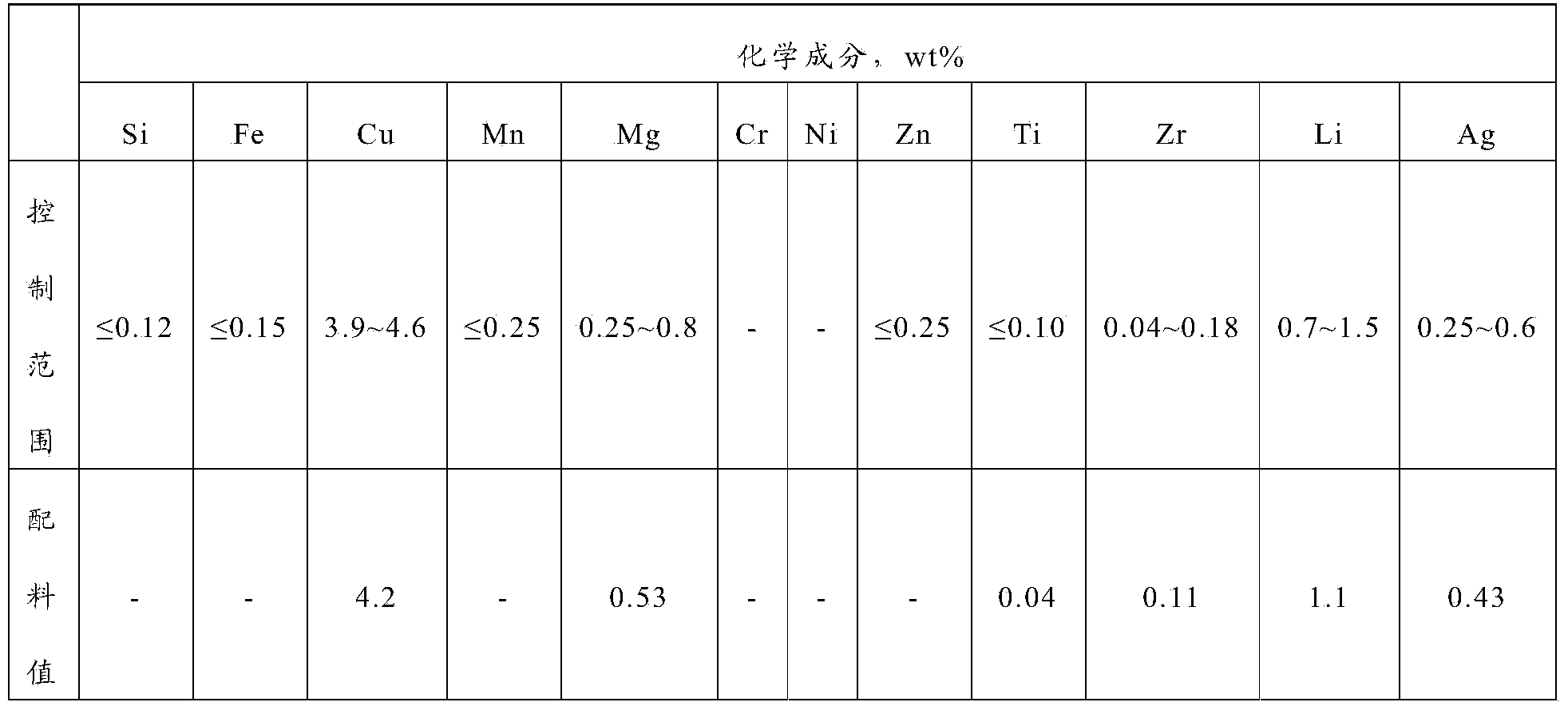

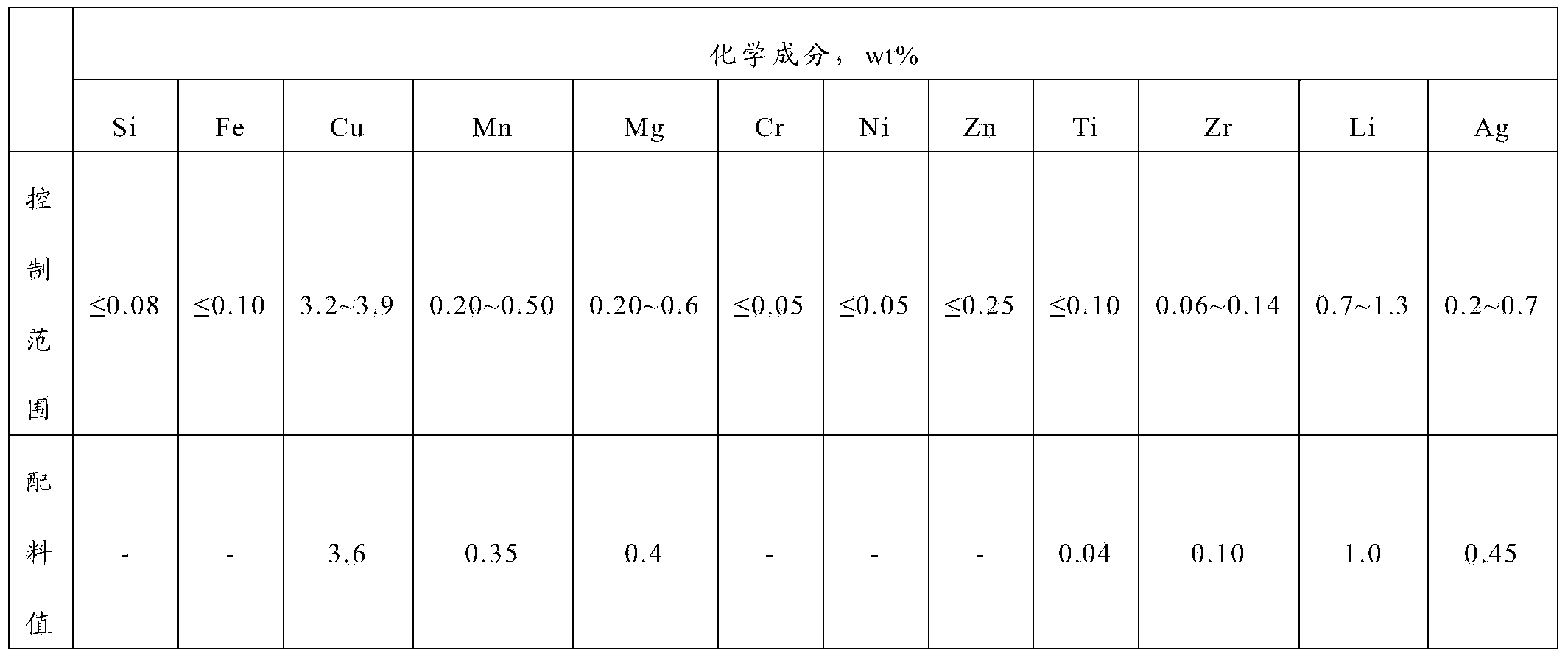

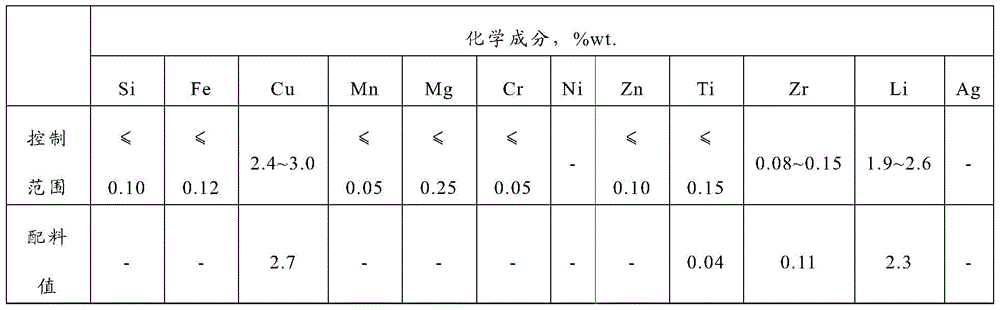

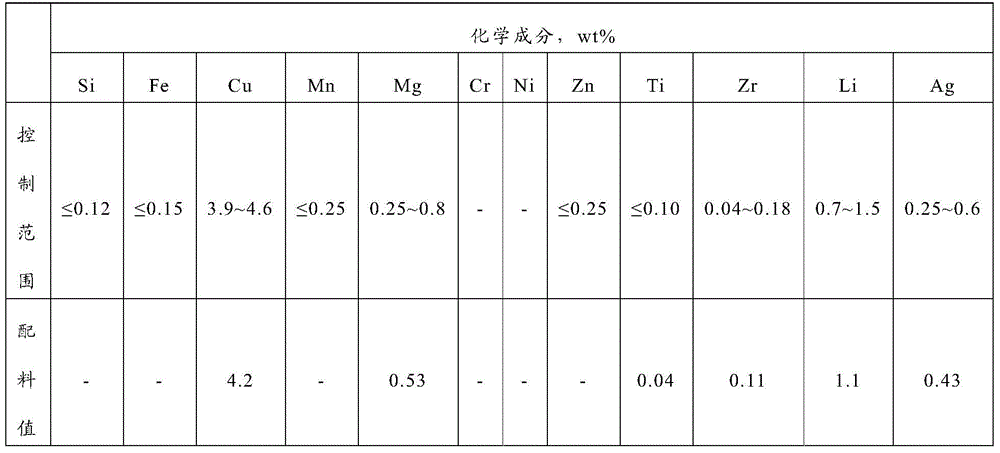

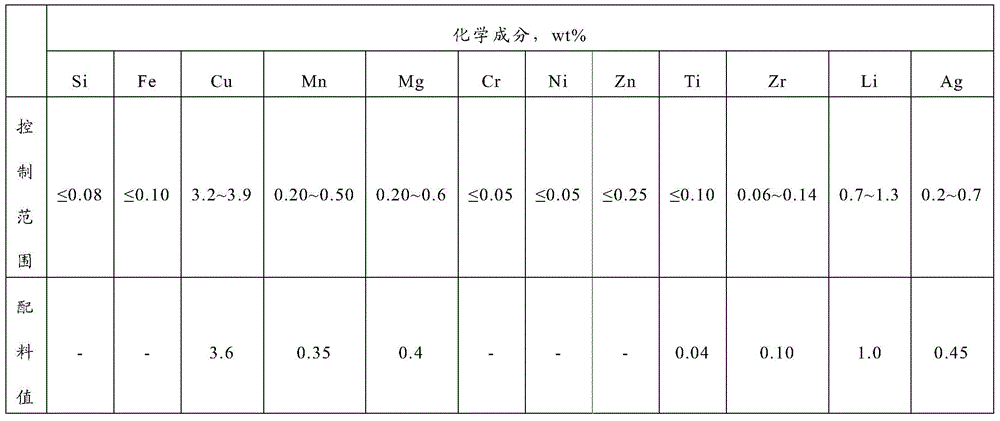

Preparation method of aluminum lithium alloy ingot

The invention provides a preparation method of an aluminum lithium alloy ingot. The preparation method comprises the following steps: (a) melting raw materials for smelting; (b) refining the raw material after being melted to obtain a melt; (c) transferring the melt to a holding furnace for sampling before smelting, and then carrying out vacuum refining; (d) casting the melt after being refined, wherein the speed of casting is 25-35 mm / min, the water pressure of casting is 0.02-0.08 MPa, and the temperature of casting is 710-750 DEG C; (e) annealing an obtained aluminum lithium alloy ingot to obtain the aluminum lithium alloy ingot. The dimensions of the aluminum lithium alloy ingot prepared by the invention can reach (400-500) mm * (1200-1500) mm. Experimental results show that the breaking tenacity of the large-specification aluminum lithium alloy ingot prepared by the invention when the thickness is 100 mm is 32-35 MPa * m<1 / 2>.

Owner:SOUTHWEST ALUMINUM GRP

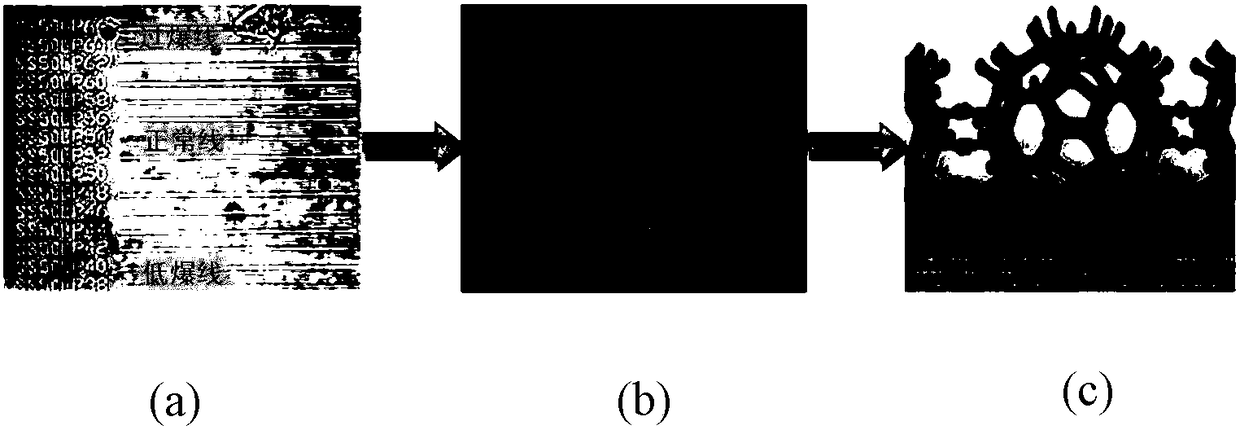

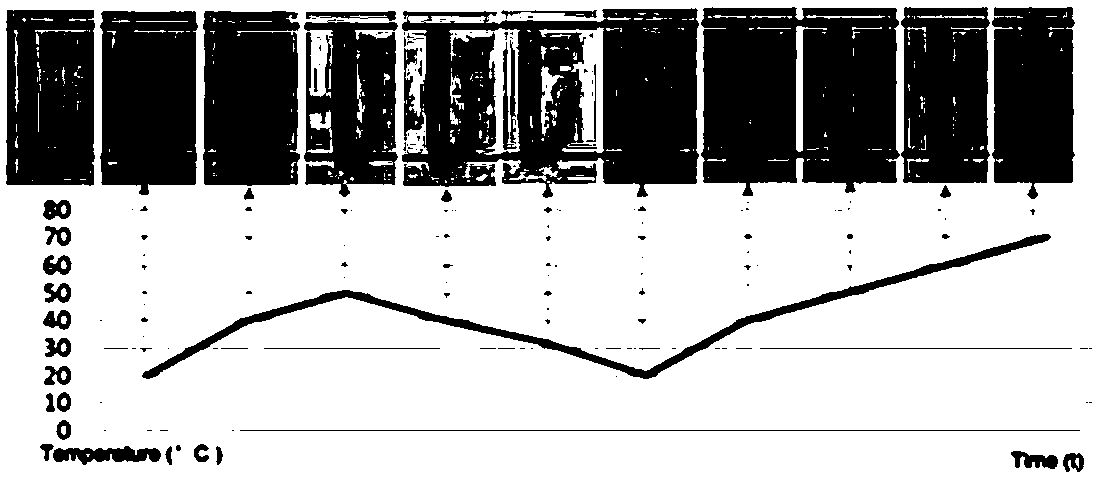

Copolymer gel, 4D micro-nano printing material, and printing test method

ActiveCN108546312AExcellent photocurabilityNo residueDiagnosticsMicrobiological testing/measurementCross-linkMicro nano

The invention discloses a copolymer gel, a 4D micro-nano printing material, and a printing test method. The copolymer gel comprises: reactants comprising a functional monomer N-isopropyl acrylamide and acrylic acid; a cross-linking agent DPEPA; a photosensitizer triethanolamine; and a photoinitiator EMK. According to the present invention, the hydrogel-based 4D micro-nano printing material especially has good photocuring performance and good heterogeneous swelling property to two-photon 780 nm femtosecond laser, can print complex three-dimensional micro-nano structures with submicron precisionin photoresists without supporting materials, and can achieve the controlled deformation from three-dimensional to three-dimensional by designing the local difference in the structure under the stimulation of the pH value, the organic solvent and the temperature.

Owner:PEKING UNIV

Forging process for preparing isotropic ultrahigh-strength heat-resistant magnesium alloy structural member

The invention discloses a forging process for preparing an isotropic ultrahigh-strength heat-resistant magnesium alloy structural member. Firstly, a cast ingot prepared through semi-continuous electromagnetic casting is subjected to homogenizing annealing, an ingot blank is formed through machining, the height direction of the cylindrical ingot blank and any two mutually perpendicular radial directions are used as the Z direction, the Y direction and the X direction correspondingly, 3-6 passes of heading are performed in the Z direction, the Y direction and the X direction, and the pass deformation amount is 20-40%; then the X direction or the Y direction is used as the axis, 2-6 passes of corner angle rolling compressing are performed, the pass deformation amount is 10-20%, intermediate annealing is performed, and the forging process is performed repeatedly once or twice; a forge piece is subjected to T6 treatment after forging is finished, and a final forge piece with the diameter being 450-650 mm and the height being 300-700 mm is obtained; as for both the height direction and the radial directions of the T6 state at the room temperature, the tensile strength is larger than or equal to 460 MPa, the yield strength is larger than or equal to 400 MPa, the ductility is larger than or equal to 4%, and the strength difference between the height direction and the radial directions is smaller than or equal to 10 MPa, and the ductility difference between the height direction and the radial direction is smaller than or equal to 0.5%; and as for both the height direction and the radial directions at the temperature of 200 DEG C, the tensile strength is larger than or equal to 350 MPa, and the ductility is larger than or equal to 6%.

Owner:CENT SOUTH UNIV

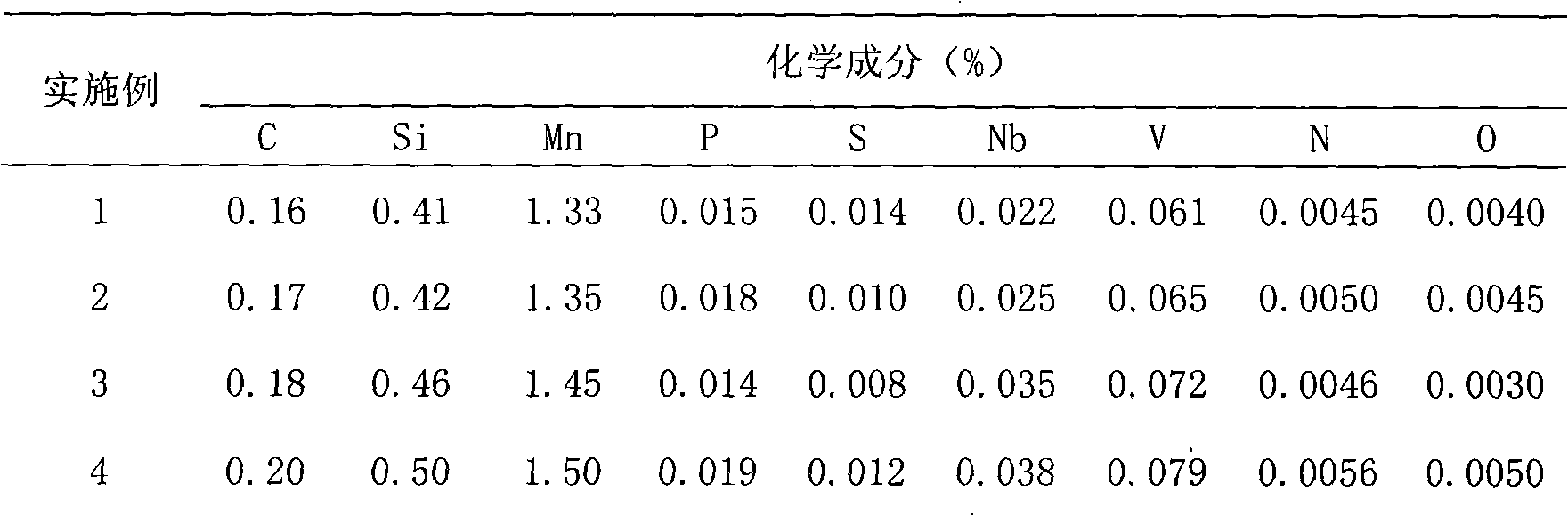

Anti-seismic H-type steel and production method thereof

InactiveCN102021474AMeet needsGuaranteed to be fully fusedTemperature control deviceChemical compositionRoom temperature

The invention discloses anti-seismic H-type steel which comprises the following chemical components in percentage by weight: 0.16-0.20 percent of C, 0.4-0.5 percent of Si, 1.3-1.5 percent of Mn, 0.06-0.08 percent of V, 0.02-0.04 percent of Nb, less than or equal to 0.025 of P, less than or equal to 0.015 of S, less than or equal to 100ppm of N, less than or equal to 100ppm of O, and the balance of Fe and impurity elements. A production method of the anti-seismic H-type steel comprises the procedures of heating, rolling and cooling and is characterized in that the heating temperature is 1210 DEG C-1250 DEG C; the rolling technique is as follows: the controlled rolling temperature at unrecrystallized areas is less than or equal to 950 DEG C, the accumulated deformation for passes is 50-70%, and the final rolling temperature is controlled to be 820 DEG C-880 DEG C; and after rolling, air cooling is carried out by utilizing a cold bed until the temperature of the product is room temperature.

Owner:MAANSHAN IRON & STEEL CO LTD

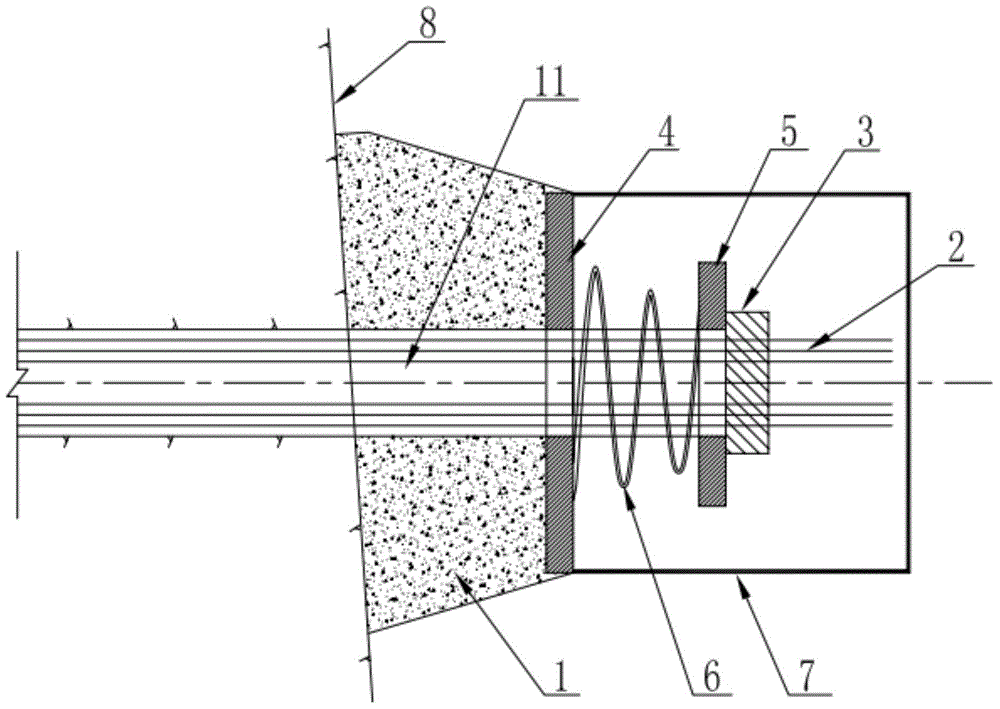

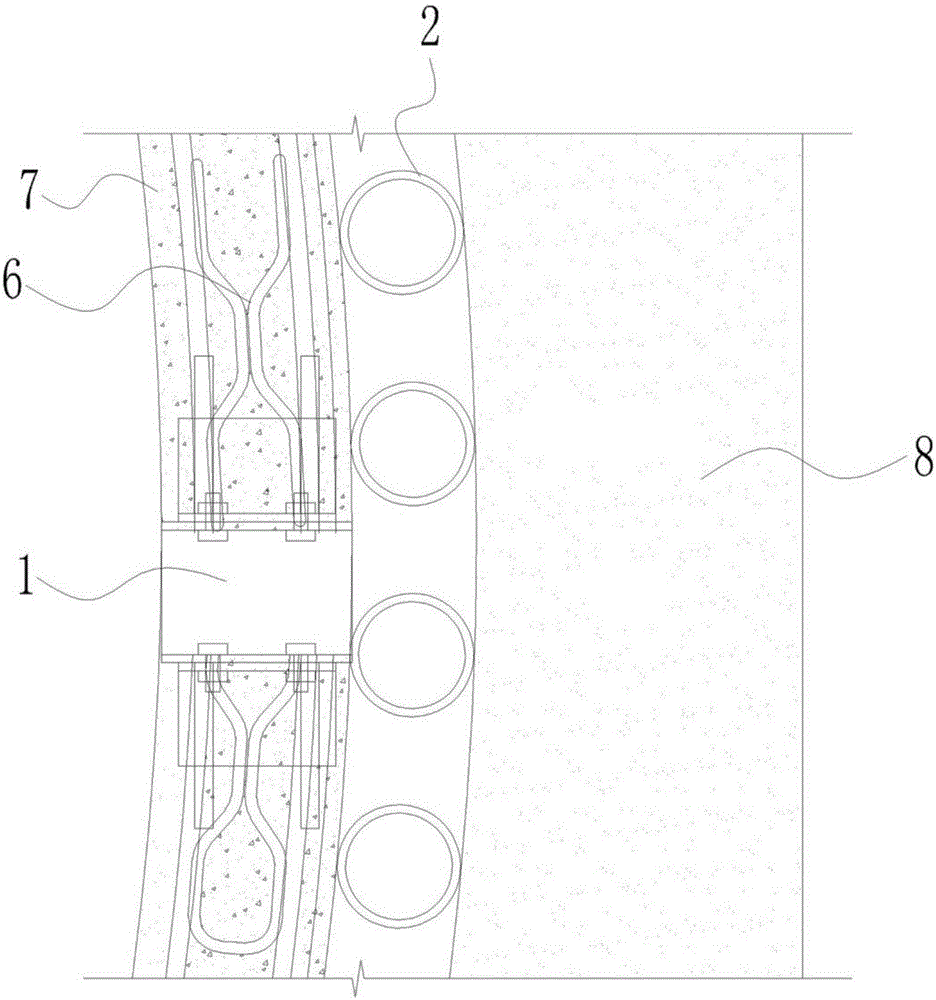

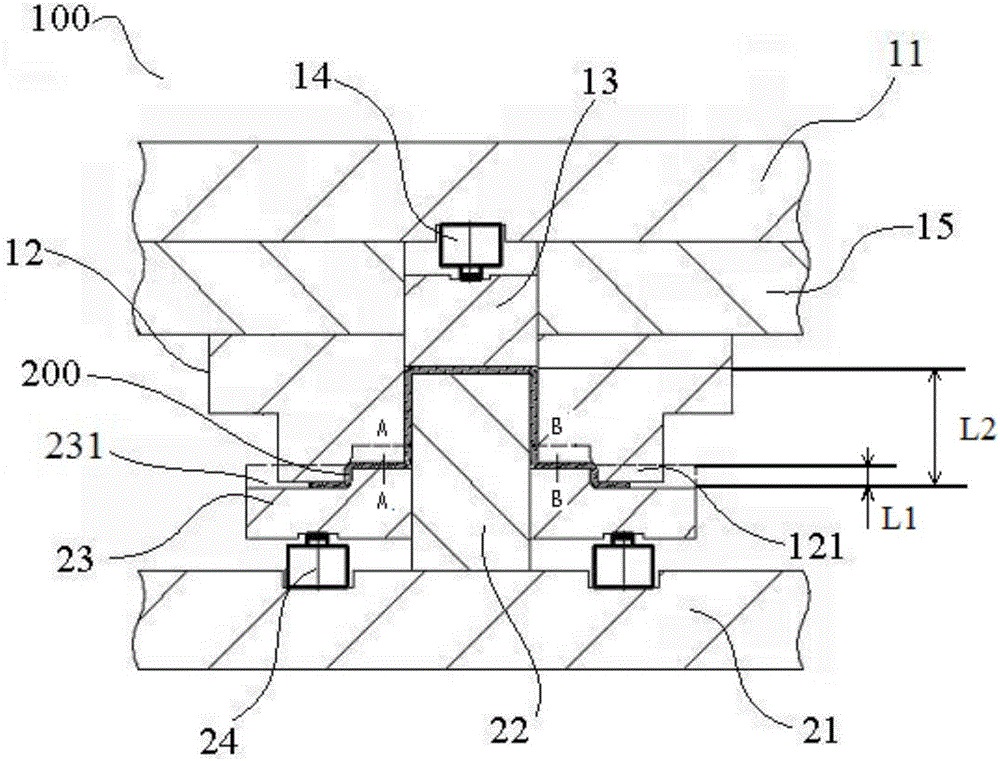

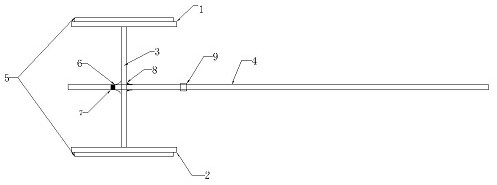

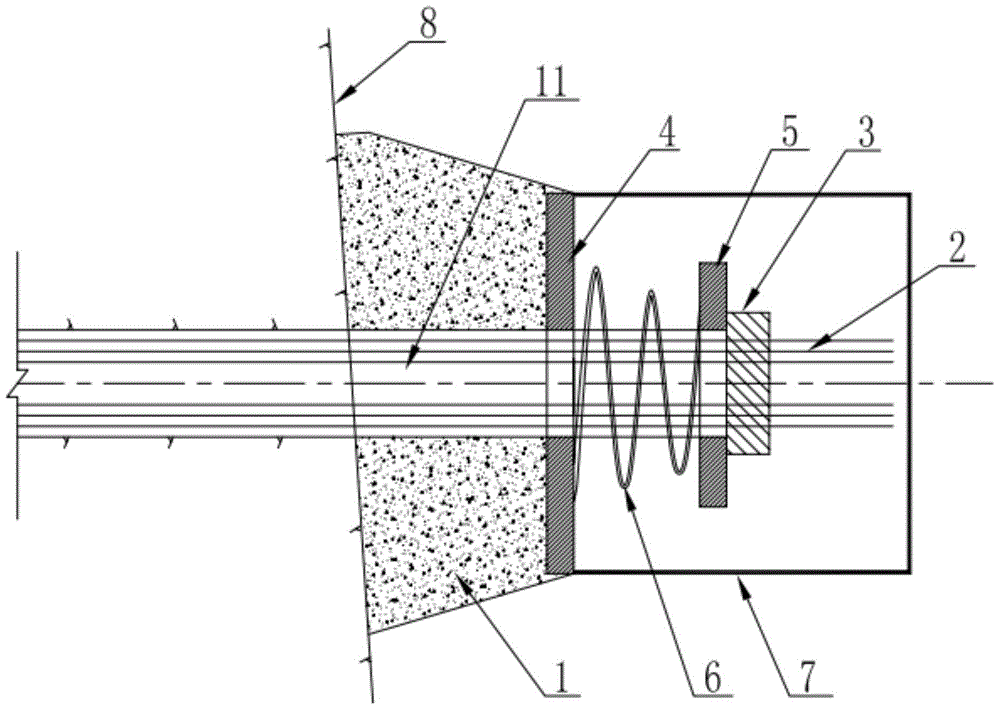

Anchorage pier structure suitable for surrounding rock deformation

ActiveCN104480935AAvoid instabilityRealize adaptive adjustmentBulkheads/pilesEngineeringSelf adaptive

The invention discloses an anchorage pier structure suitable for surrounding rock deformation, belonging to the field of building construction. The anchorage pier structure suitable for surrounding rock deformation comprises an anchorage pier, a steel strand and an anchorage device, wherein one end of the steel strand penetrates through a locking hole on the anchorage pier and is locked on the anchorage pier through the anchorage device; the anchorage pier structure further comprises a first anchorage plate, a second anchorage plate and an elastic part, wherein the first anchorage plate and the second anchorage plate are arranged between the anchorage pier and the anchorage device; the steel strand penetrates through the lock hole in the anchorage pier, then penetrates through the first anchorage plate and the second anchorage plate in sequence, and is finally connected to the anchorage device; the elastic part is arranged between the first anchorage plate and the second anchorage plate. The self-adaptive regulation of the anchorage pier structure during surrounding rock deformation is realized, so that enough anchorage force can be provided at an initial anchorage stage, and therefore, the surrounding rocks are prevented from being unstable; meanwhile, enough deformation can be reserved for being adaptive to the great deformation condition which possibly appears in later-stage surrounding rocks. Besides, the anchorage rope is prevented from being stretched and pulled for the second time.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

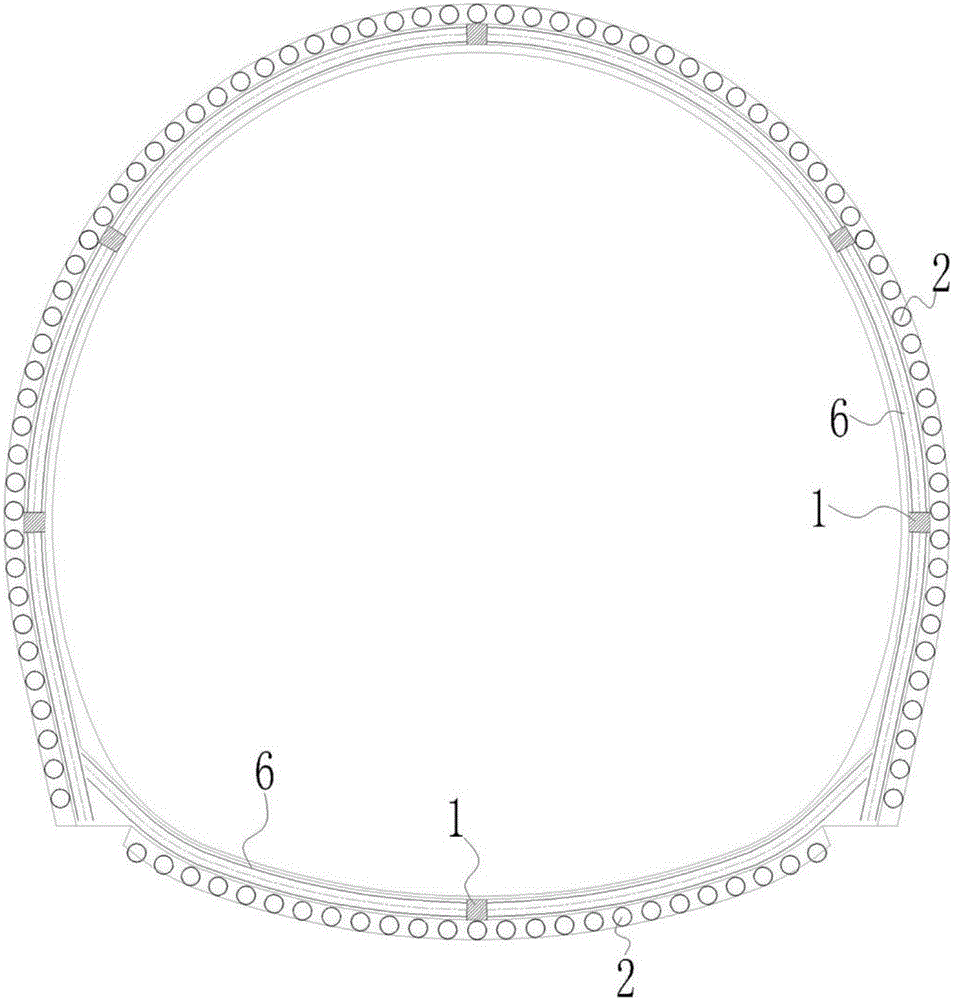

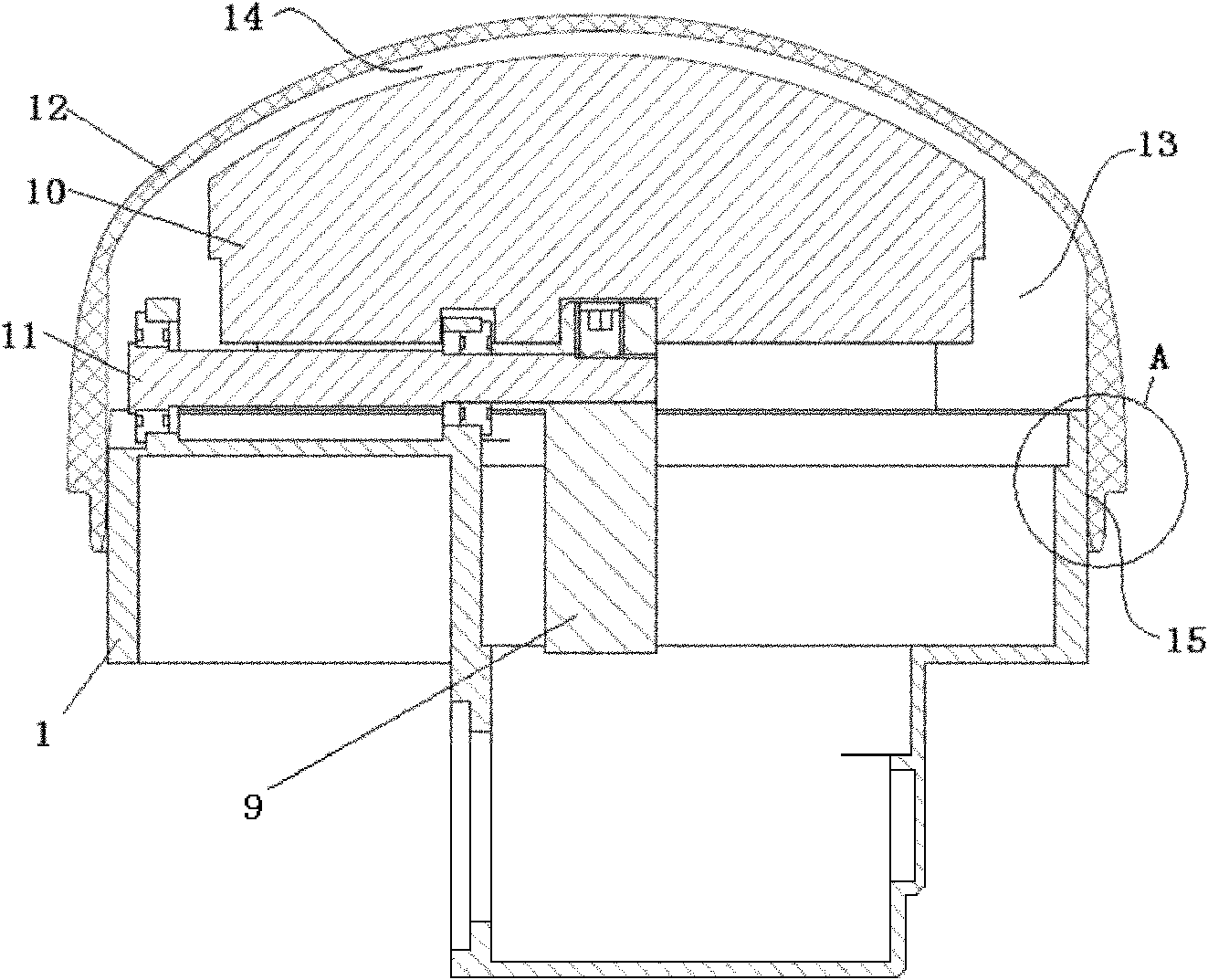

Large-stroke combined damper utilizing post-peak performance of materials

ActiveCN107524457AAvoid repeated replacementLow costUnderground chambersTunnel liningSnubberEngineering

The invention provides a large-stroke combined damper utilizing the post-peak performance of materials. The large-stroke combined damper comprises a circumferential damper and a radial damper, and the circumferential damper and the radial damper are arrayed around the inner side of a tunnel to form a ring; the circumferential damper is fixedly installed in the tunnel, and the deformation direction is in the circumferential direction of the tunnel; the radial damper is fixedly installed in the tunnel, and the deformation direction is in the radial direction of the tunnel; the circumferential damper is positioned on the inner side of the radial damper. Supporting and deformation can not only be provided in the circumferential direction of the tunnel, but also can be provided in the radial direction of the tunnel, stress of the tunnel is effectively released, so that the tunnel structure is more stable and reliable.

Owner:仇文革

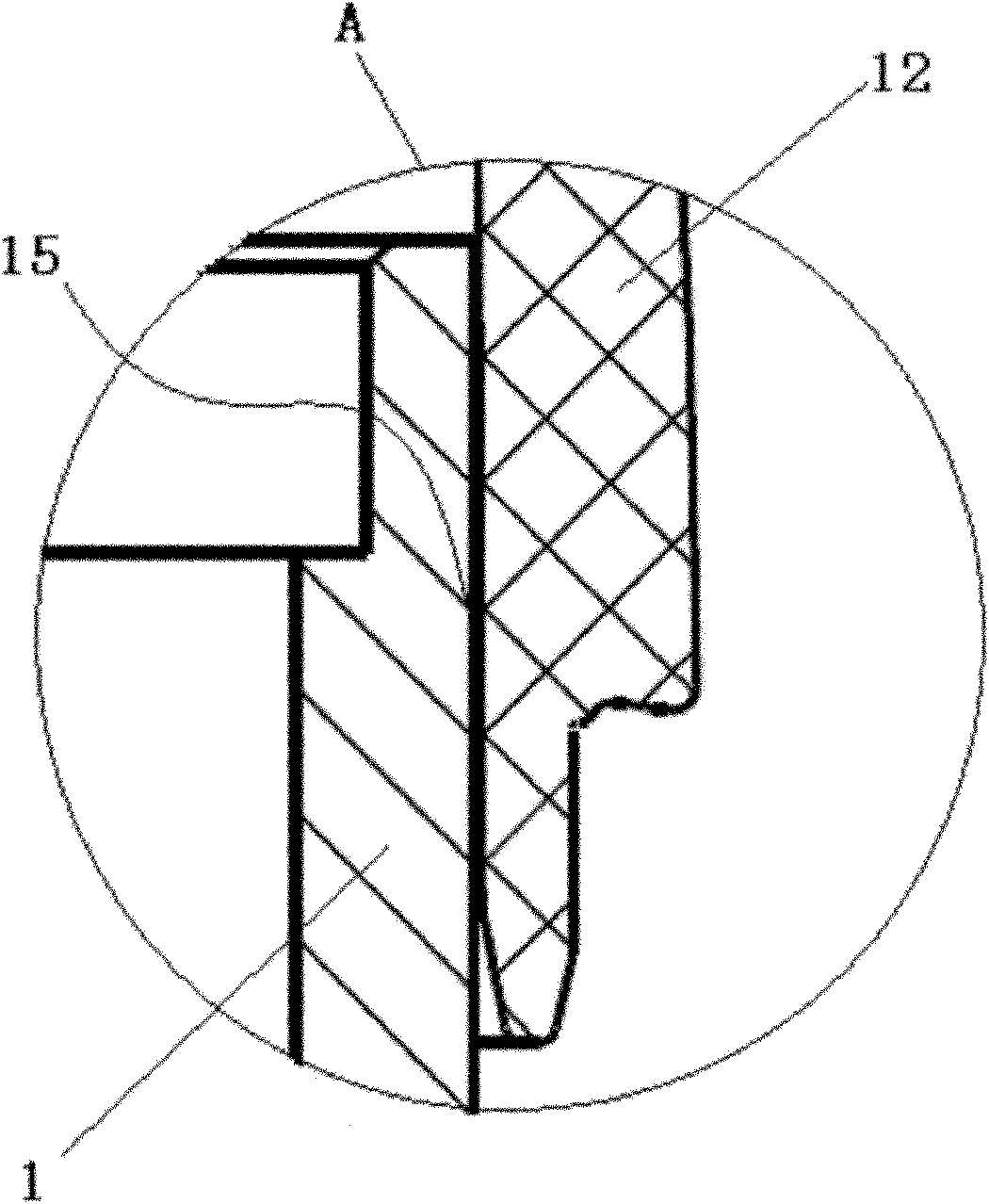

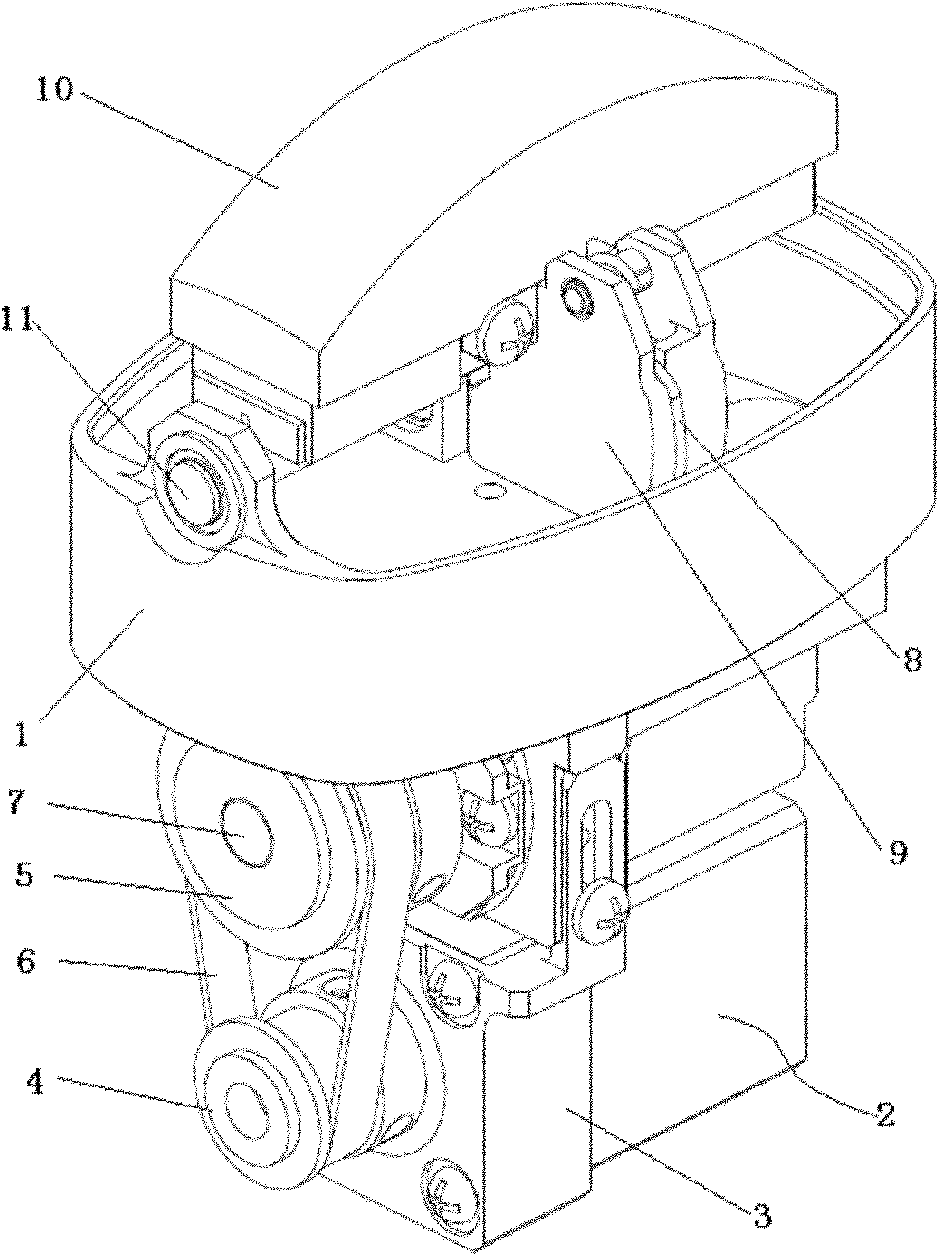

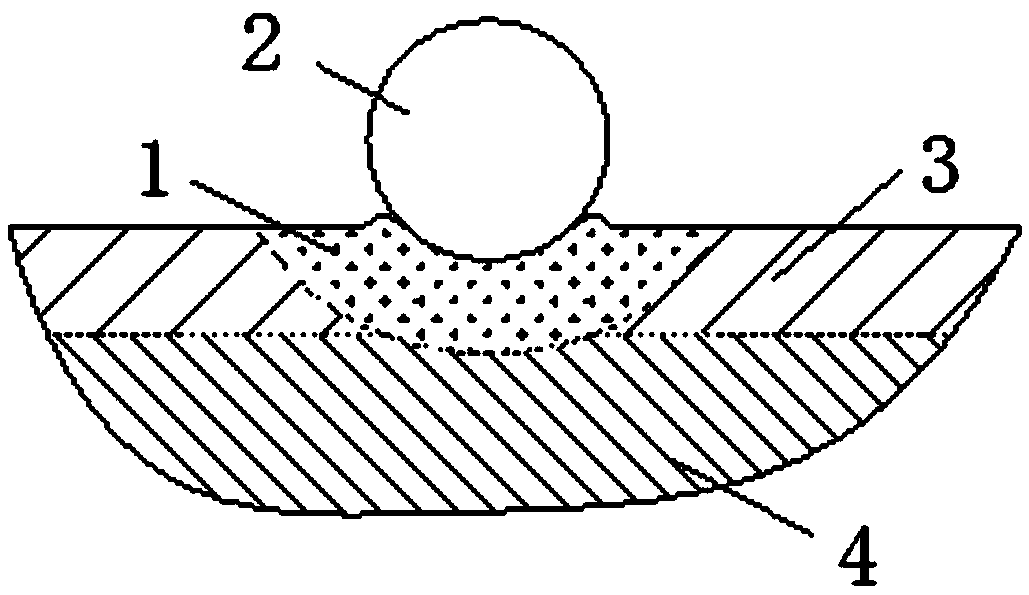

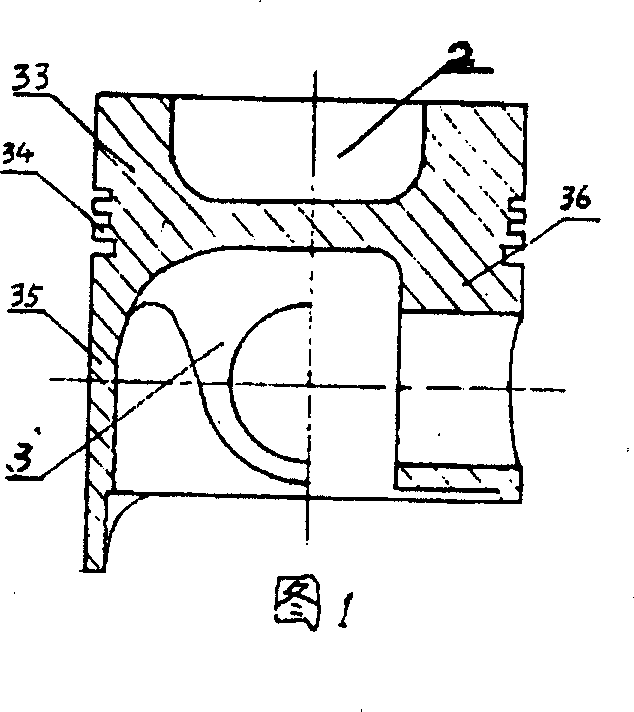

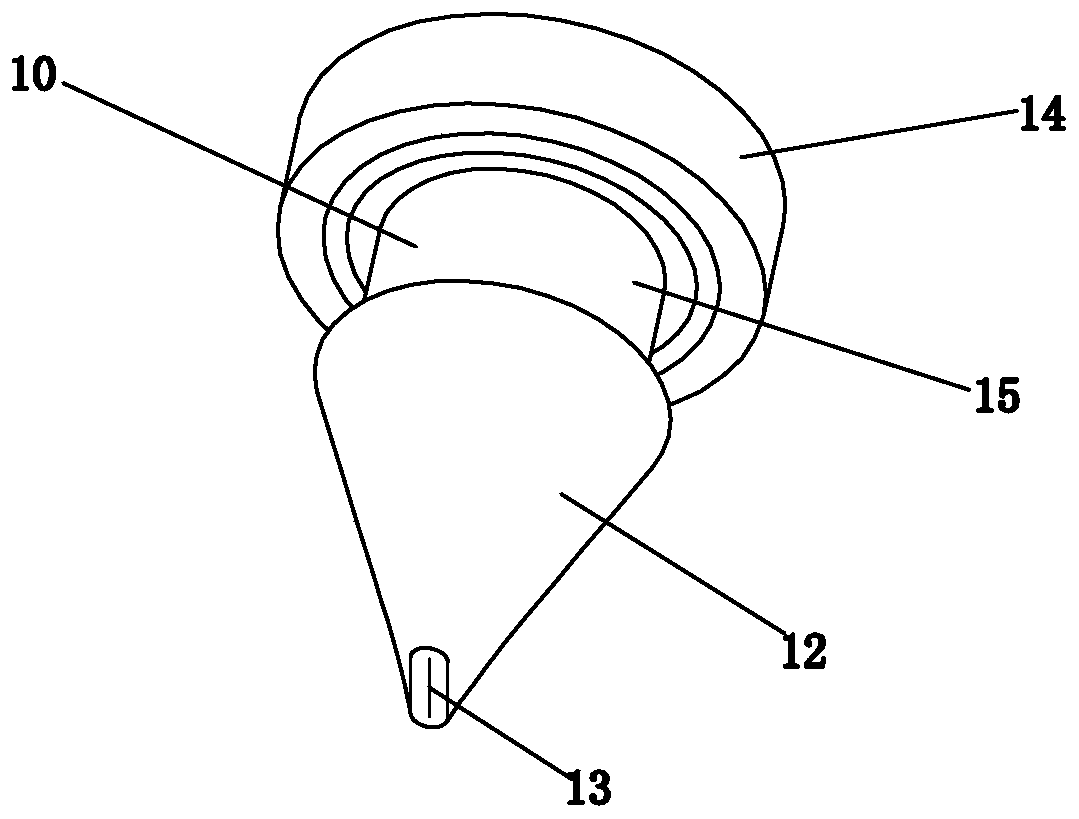

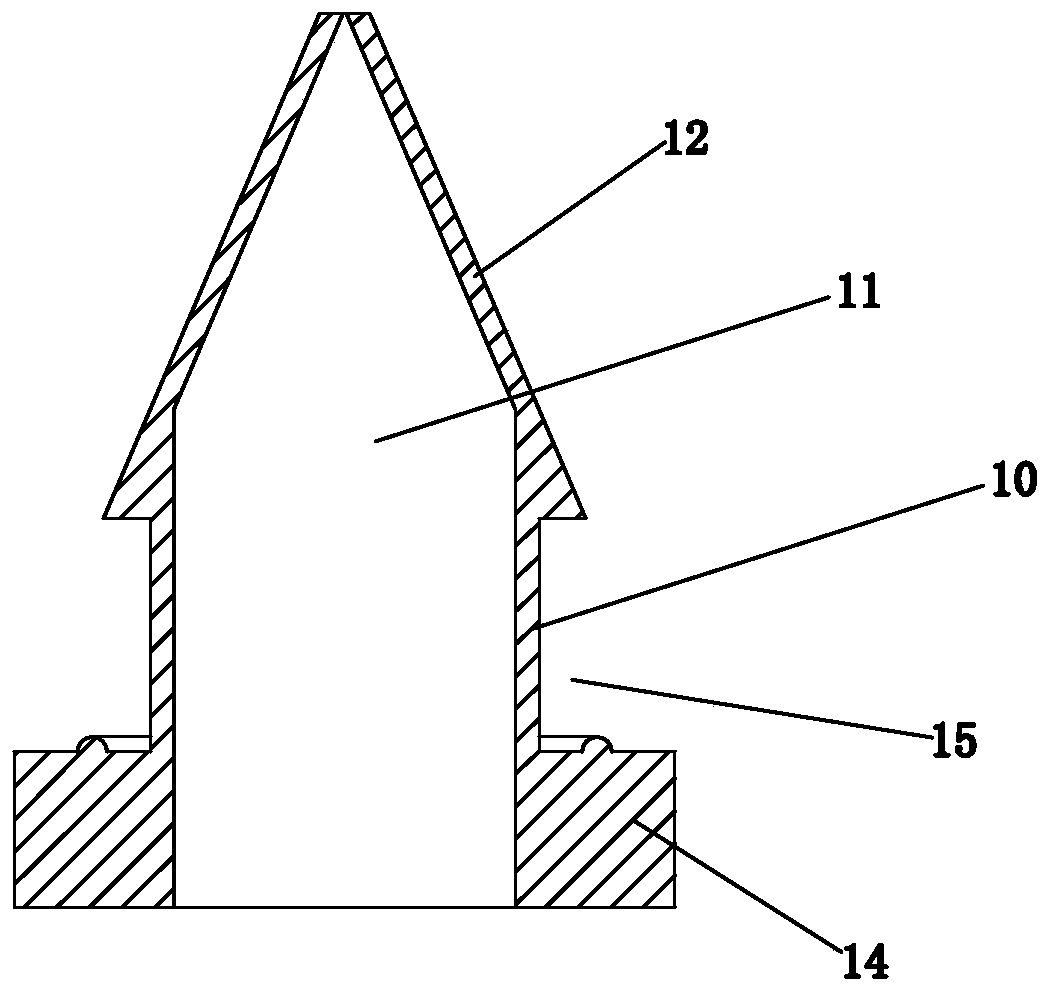

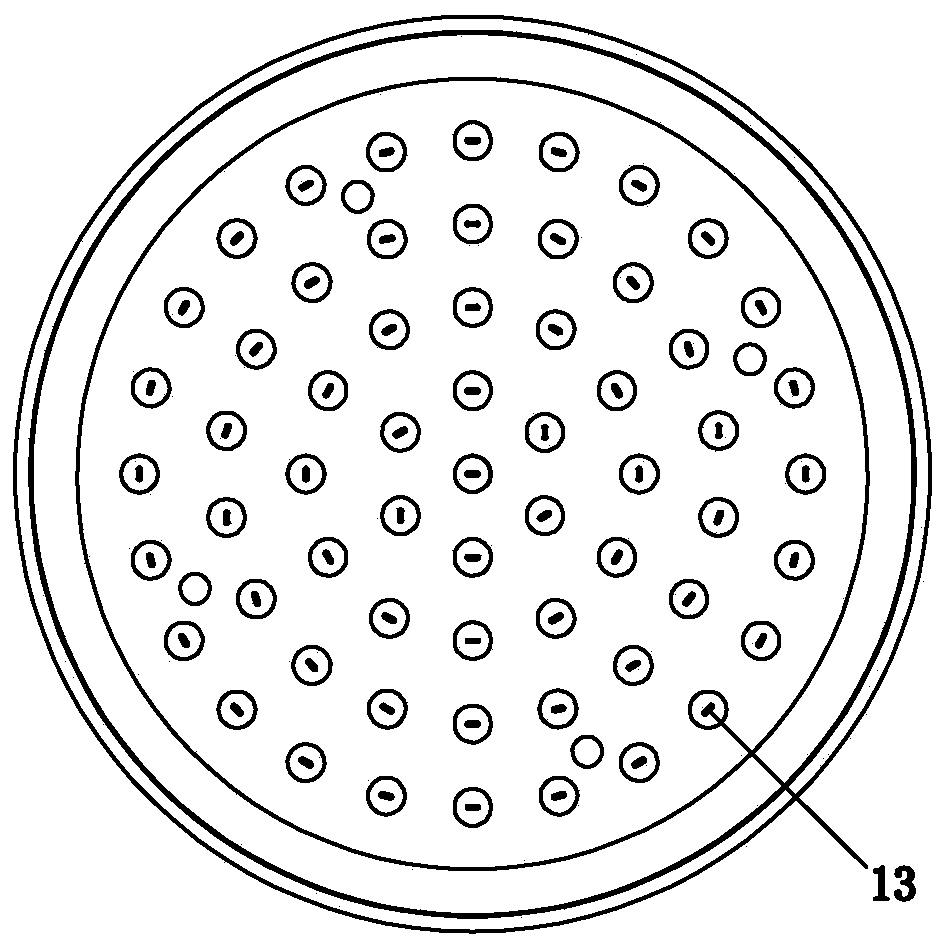

Three-dimensional (3D) mechanical probe

ActiveCN102370497AEnough deformationGuaranteed sealing performanceUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsEngineering

The invention discloses a three-dimensional (3D) mechanical probe, which comprises a sound window, a base, a restraining body and an elastic sealing ring, wherein the sound window and the base are fixedly connected and form a sealed space, the sound window is provided with a first matching wall, the base is provided with a second matching wall, the first matching wall is sheathed with the second matching wall, the sealing ring is arranged between the first matching wall and the second matching wall and is tightly pressed to deform, and the restraining body limits the deformation of the sound window. Through the sealing ring with the compression deformation quantity between the first matching wall and the second matching wall, the sealing between the sound window and the base can be effectively ensued, the coupling liquid seepage is prevented, through the arrangement of the restraining body, the sound window is prevented from deforming through being expanded by the sealing ring, the sufficient deformation quality of the sealing ring is ensued, and the sealing performance between the base and the sound window is further ensured.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

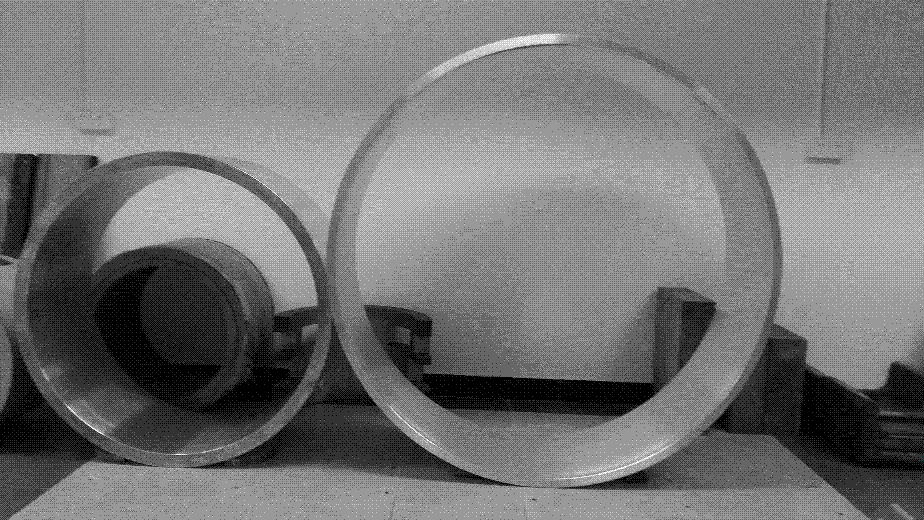

Forging and rolling integrated manufacturing process of large-diameter ultrahigh-strength high temperature resisting magnesium alloy shell part

The invention discloses a forging and rolling integrated manufacturing process of a large-diameter ultrahigh-strength high temperature resisting magnesium alloy shell part. The manufacturing process comprises the following steps in sequence: semi-continuous electromagnetic casting; machining of an ingot blank; uniform annealing; multi-directional free forging; mechanical perforation; annular rolling; and T6 thermal treatment. The dimension of the prepared shell part is as follows: the outer diameter Phi is 600 mm to 1700 mm; the wall thickness is 35 mm to 100 mm; the height is 300 mm to 700 mm; the T6-state room-temperature tangential and height-direction tensile strength is larger than or equal to 470 MPa; the elongation rate is larger than or equal to 5%; the tangential and height-direction tensile strength at the temperature of 200 DEG C is larger than or equal to 350 MPa; and the elongation rate at the temperature of 200 DEG C is larger than or equal to 7%. A product prepared by the process disclosed by the invention has the characteristics of large size, no cracks, ultrahigh room-temperature strength, excellent heat resistance and the like, and the process disclosed by the invention can provide a qualified magnesium alloy shell part for the fields such as aeronautics and astronautics.

Owner:CENT SOUTH UNIV

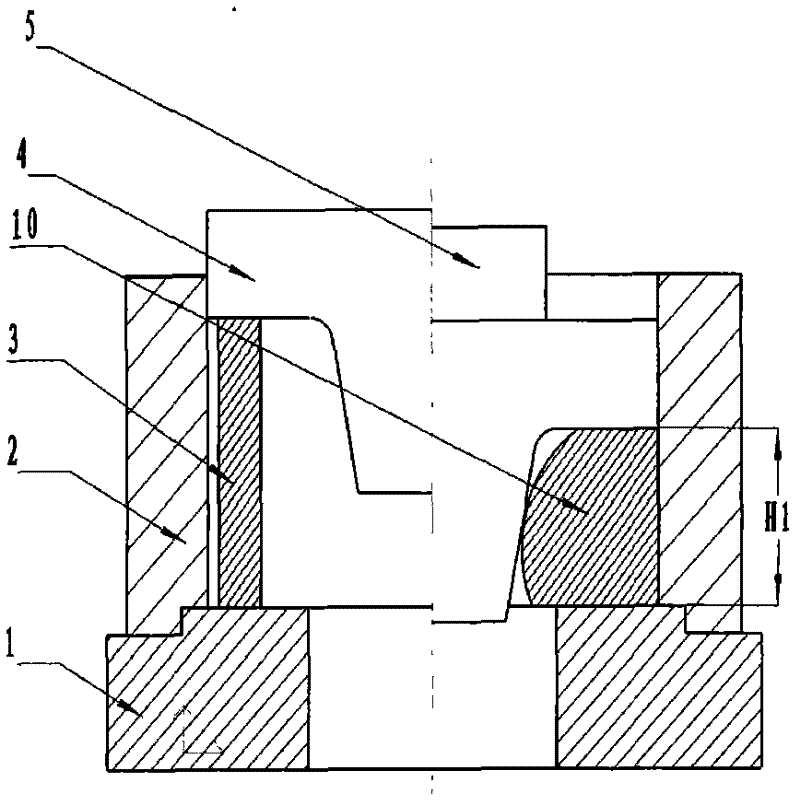

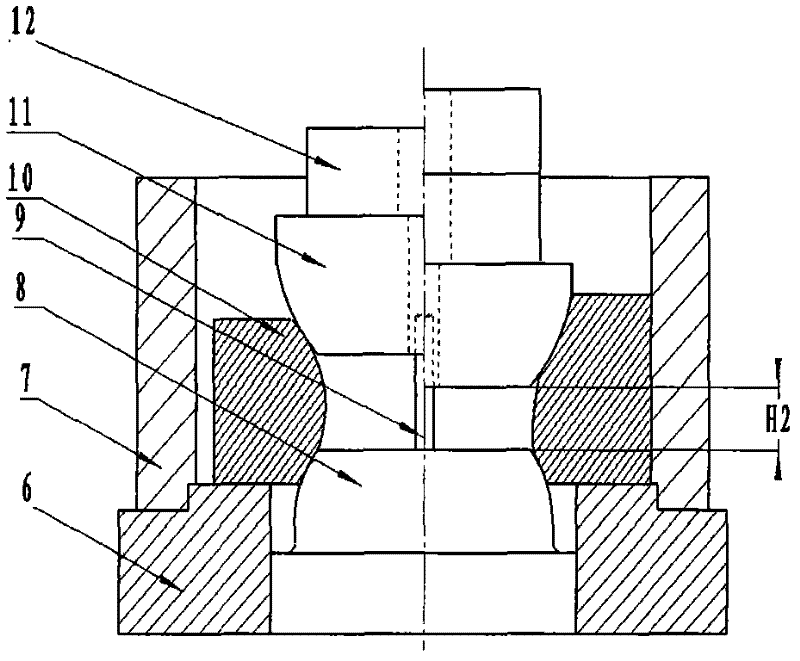

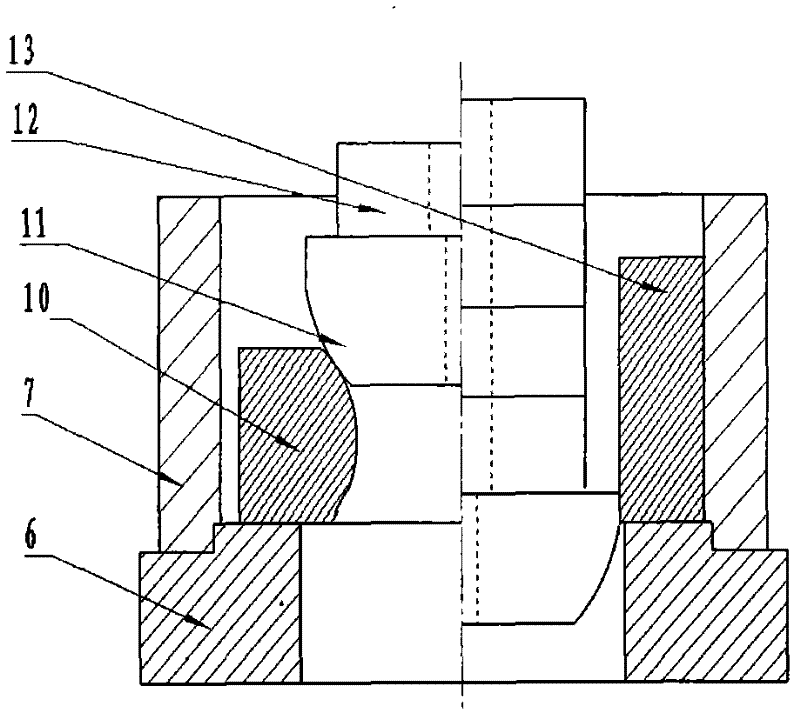

Die structure

InactiveCN104550454AForce of small rounded cornersEnough deformationShaping toolsMechanical engineeringEngineering

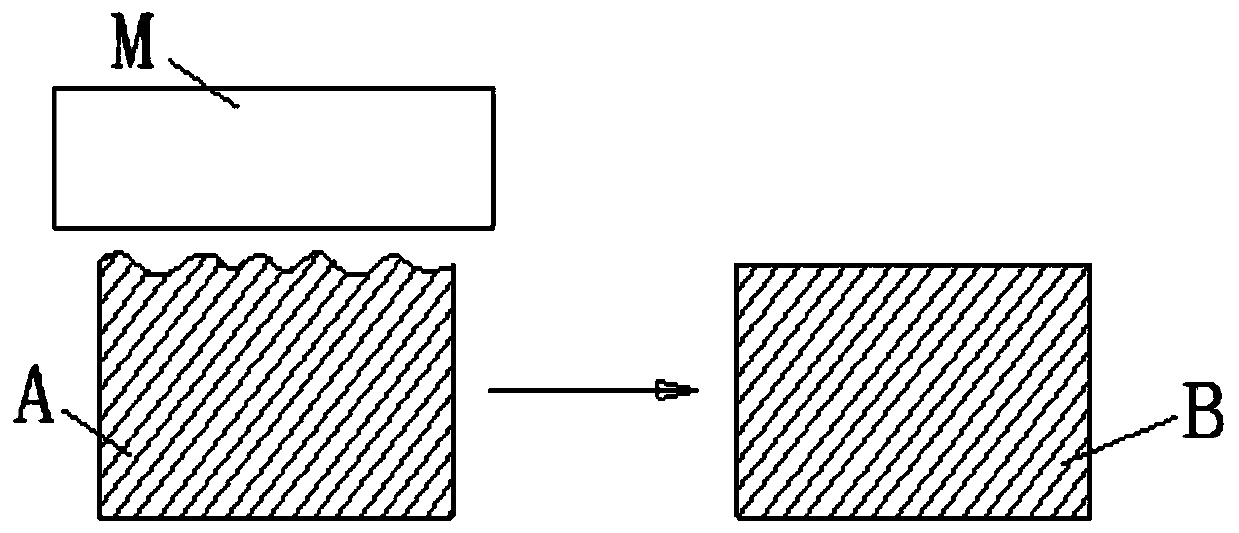

The invention discloses a die structure comprising a female die component and a male die component. The male die component is arranged under the female die component and comprises a die holder, a male die arranged on the die holder and a pressing plate. The pressing plate penetrates the male die to be vertically movably arranged on the die holder. The distance of the vertical movement of the pressing plate is less than stretching depth of a workpiece. As the female component moves downwards to be matched with the pressing plate, the pressing plate and the female component synchronously move downwards, and preset deformation occurs to the edge of the workpiece. According to the arrangement, as the distance of the vertical movement of the pressing plate is less that vertical height of the sidewall of the workpiece stamped, the workpiece is applied with low acting force by a fillet of the female die component, the enough deformation occurs to the sidewall of the workpiece, and accordingly stress is uniformly distributed on the inner and the outer surfaces of the workpiece without curling and springs back.

Owner:BEIQI FOTON MOTOR CO LTD

Titanium ingot forging and broadening process

ActiveCN102513490AWell organized edgesGood edge shapeMetal-working apparatusTitaniumProduct property

The invention discloses a titanium ingot forging and broadening process. The titanium ingot forging and broadening process is characterized in that the process comprises the following steps of: erecting a titanium ingot with a diameter D below a forging press and forging downwards until the diameter of the upset titanium ingot is less than or equal to 1.2D; flatly placing the upset titanium ingot on a lower anvil of the forging press so that the axis of the titanium ingot in a length direction is vertical with the axis of a press operation vehicle; rolling the upset titanium ingot and controlling the width of the titanium ingot to be 1.2-1.3 times as much as the width of a final continuously-rolled titanium ingot product; rotating the transversely-rolled titanium ingot for 90 degrees so that the axis of the titanium ingot in the length direction is parallel to the axis of the press operation vehicle; vertically drawing out one end of the titanium ingot through clamping of an operation vehicle of the forging press; alternatively forging along a thickness direction and a width direction of the titanium ingot until the requested thickness and width are obtained, namely manufacturing the continuously-rolled titanium ingot. With the adoption of the titanium ingot forging and broadening process, the continuously-rolled titanium ingot with the width more than or equal to 1.5D can be produced, so that the need of the continuously-rolled titanium ingot with the width more than or equal to 1500mm is satisfied. And the product properties are good.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

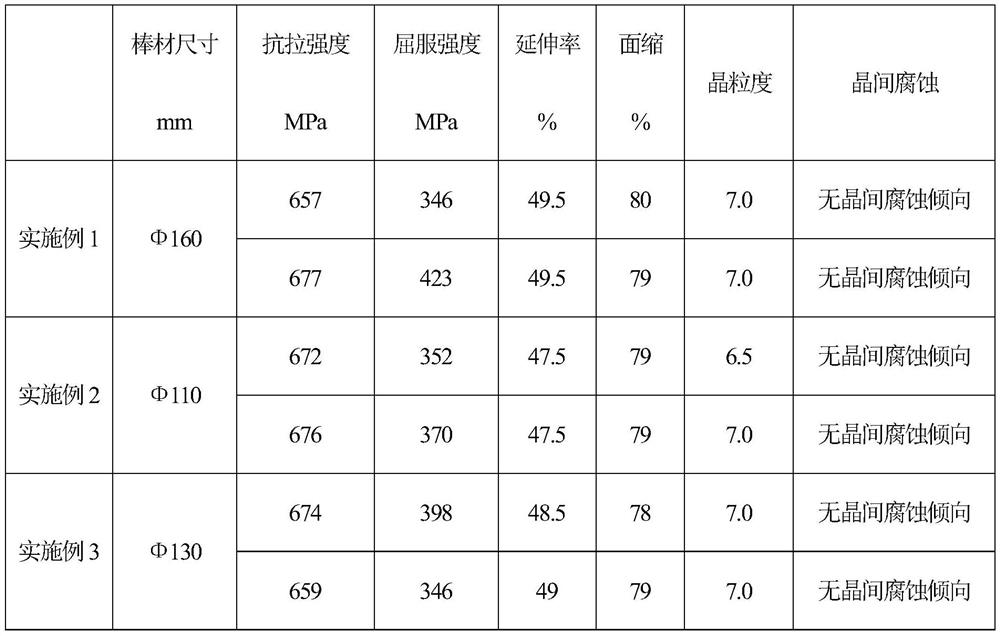

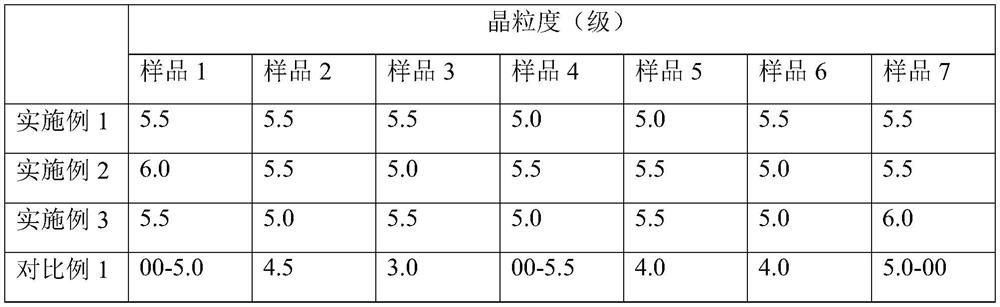

Austenitic stainless steel, fine-grain large-specification bar and preparation method and application of fine-grain large-specification bar

PendingCN112877611AIncrease manufacturing costGuaranteed stabilityAustenitic stainless steelPetrochemical

The invention discloses austenitic stainless steel. The stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.030% of C, less than or equal to 0.01% of S, less than or equal to 0.02% of P, less than or equal to 1.00% of Si, less than or equal to 2.00% of Mn, 0.14-0.22% of N, 17.50-19.50% of Cr, 9.50-12.50% of Ni, and the balance Fe and other inevitable impurities. The invention further discloses a large-specification bar prepared from the stainless steel and a preparation method and application of the large-specification bar, the austenitic stainless steel large-specification bar with the diameter not smaller than 100 mm has good intergranular corrosion resistance, the tensile strength is not lower than 600 MPa, and the grain size can reach the level 6 or even finer. The austenitic stainless steel large-specification bar can be applied to the aerospace field with high requirements for strength, toughness and corrosion resistance, and can also be applied to the fields of petroleum, chemical engineering, energy and power.

Owner:宝武特种冶金有限公司

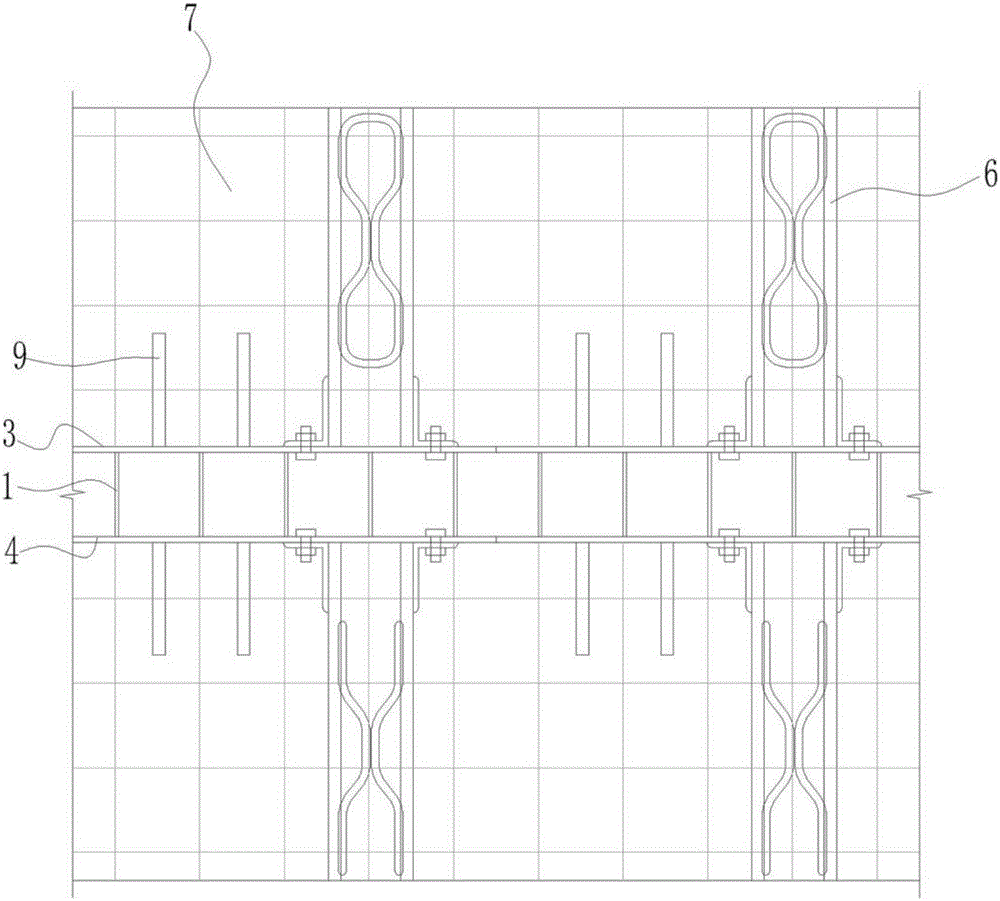

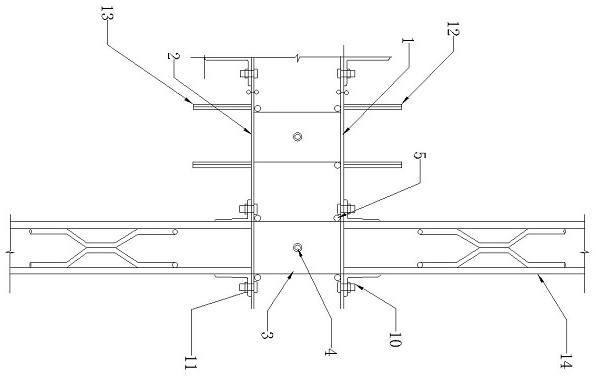

Supporting and anchoring integrated resistance-limiting energy-consuming large-deformation tunnel primary supporting structure and construction method

InactiveCN112282799AReduce radial pressureGuaranteed deformationUnderground chambersTunnel liningLarge deformationRock bolt

The invention discloses a supporting and anchoring integrated resistance-limiting energy-consuming large-deformation tunnel primary supporting structure, and belongs to the field of tunnel construction. The primary supporting structure is composed of a steel grating and an anchor rod and damper integrated structure; the anchor rod and damper integrated structure comprises a resistance limiting steel plate and an anchor rod support; a damper is composed of an upper connecting plate, a lower connecting plate, stiffening ribs and the resistance limiting steel plate; an anchoring hole is reservedin the center of the resistance limiting steel plate; and the resistance limiting steel plate is arranged between the two connecting plates and is parallel to surrounding rock. The primary supportingstructure achieves active and passive combined supporting of a deeply-buried soft rock large-deformation tunnel, allows the generation of certain deformation amount of the surrounding rock, and releases radial and circumferential stress of the surrounding rock of the tunnel.

Owner:LIAONING TECHNICAL UNIVERSITY

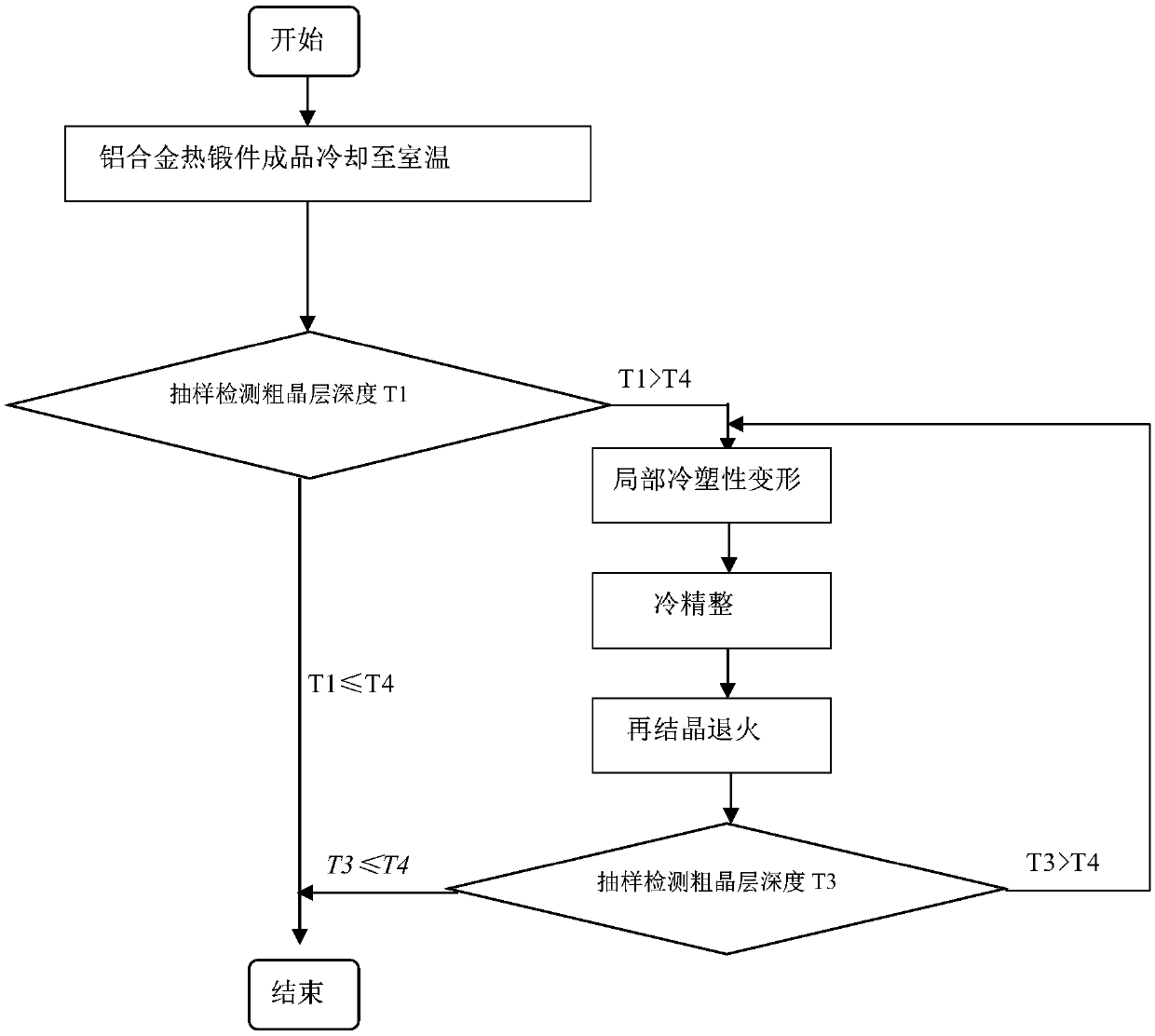

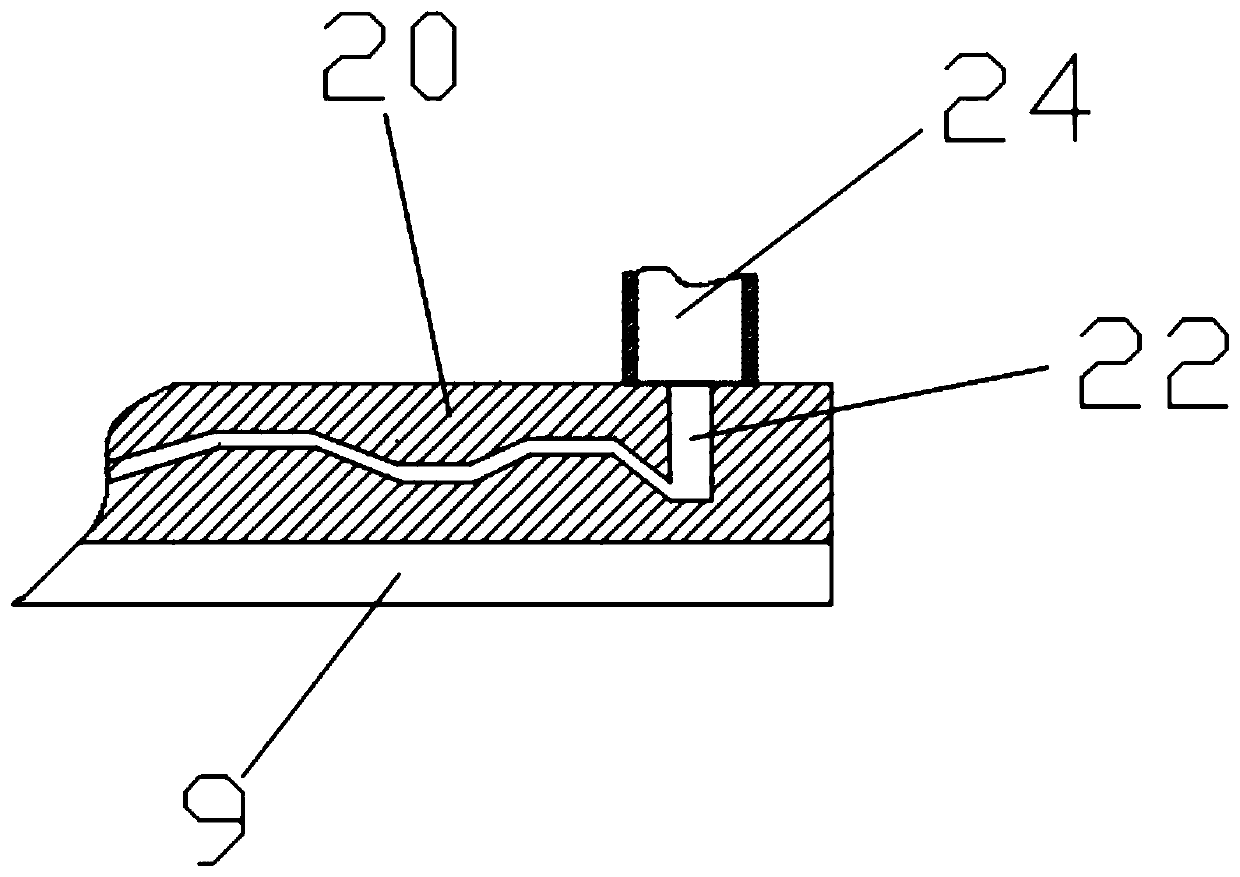

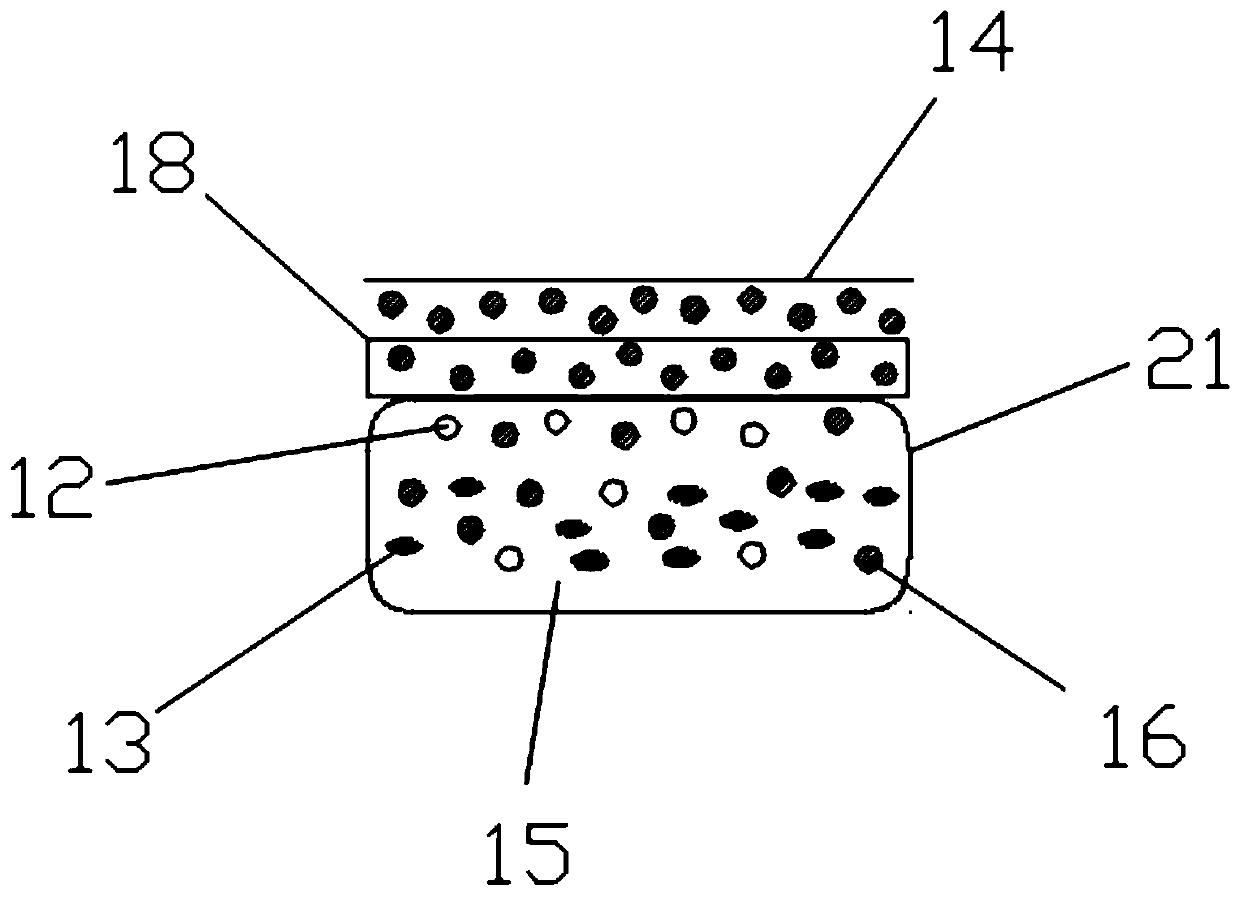

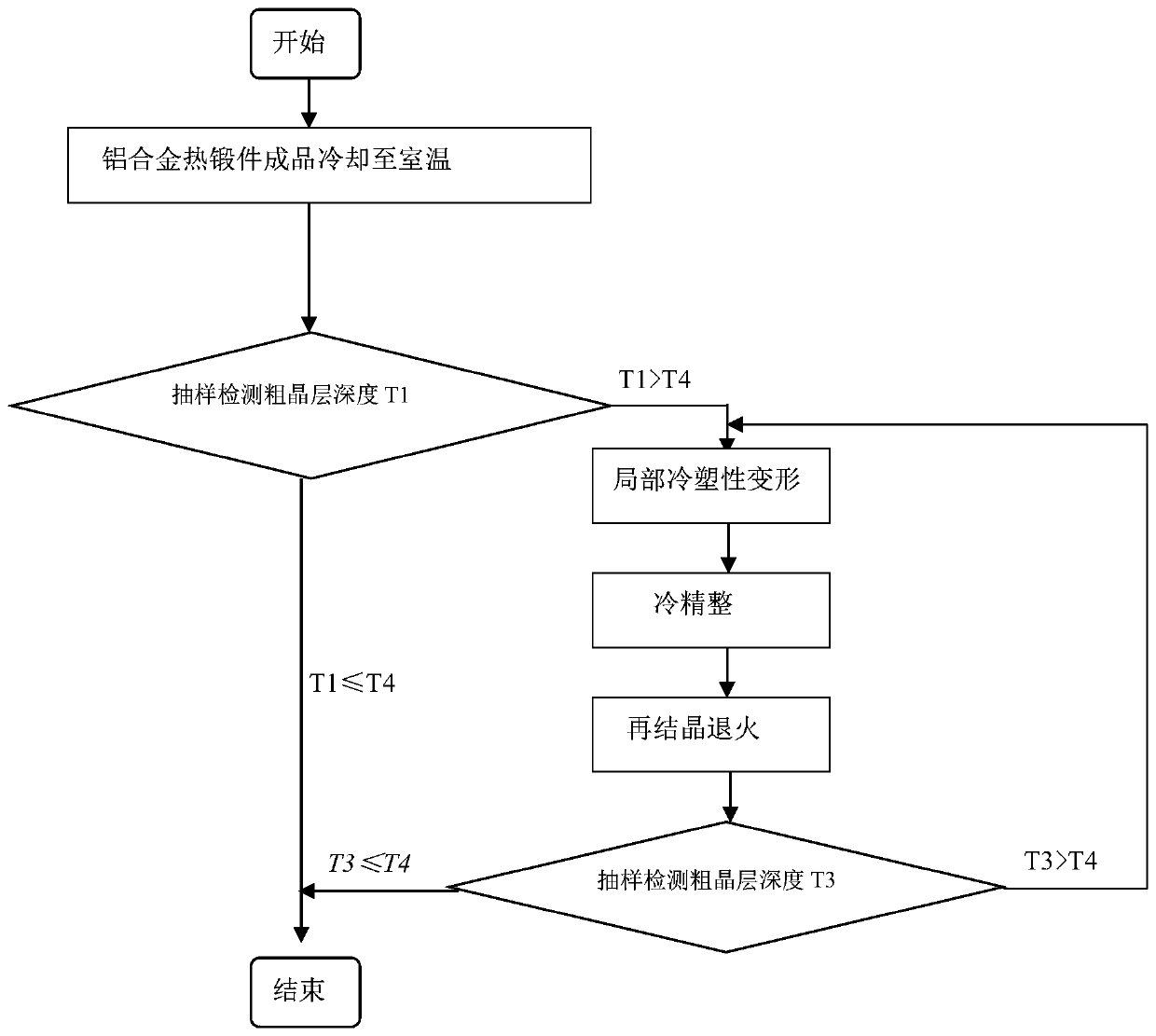

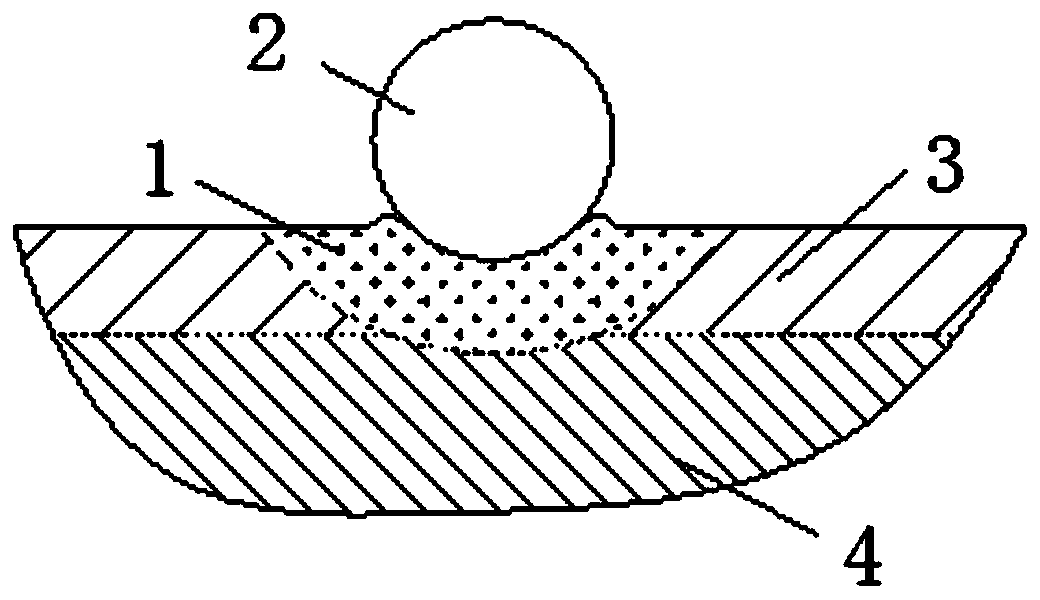

Method for reducing depth of coarse grain layer of surface of aluminum alloy hot forging part

The invention relates to the technical field of metal forging, in particular to a method for reducing the depth of a coarse grain layer of the surface of an aluminum alloy hot forging part. The methodcomprises the following steps that (S1) the aluminum alloy hot forging finished product is cooled to room temperature; (S2) sampling detecting of the depth of the coarse grain layer is carried out; (S3) if the measured depth of the coarse grain layer exceeds an acceptable depth, local cold plastic deformation is carried out; (S4) cold finishing is carried out; (S5) recrystallization annealing iscarried out; and (S6) sampling detecting of the depth of the processed coarse grain layer is carried out. The method for reducing the depth of the coarse grain layer of the surface of the aluminum alloy hot forging part has the beneficial effects that the local cold plastic deformation and cold finishing processes of surface metal are increased after a conventional aluminum alloy hot forging process, the cold plastic deformation enables the coarse grain layer to obtain sufficient deformation amount, and grain refinement of the coarse grain layer is achieved through the recrystallization annealing, so that the effect of reducing the depth of the coarse grain layer of the aluminum alloy hot forging part can be achieved without removing materials; and waste of the materials and scrap of forging parts caused by coarse grain defects are reduced, the qualification rate of the aluminum alloy hot forging part is improved, and the dimensional accuracy of the forging part is further increased through the cold finishing process.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

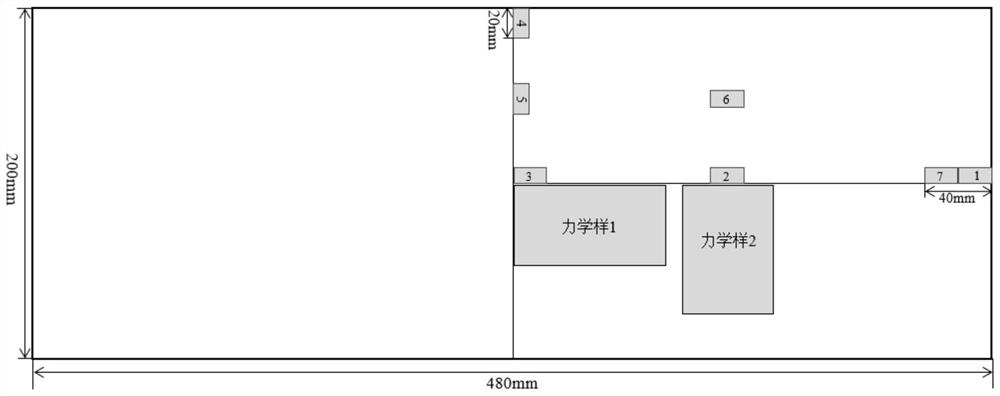

A kind of preparation method of aluminum-lithium alloy ingot

The invention provides a preparation method of an aluminum lithium alloy ingot. The preparation method comprises the following steps: (a) melting raw materials for smelting; (b) refining the raw material after being melted to obtain a melt; (c) transferring the melt to a holding furnace for sampling before smelting, and then carrying out vacuum refining; (d) casting the melt after being refined, wherein the speed of casting is 25-35 mm / min, the water pressure of casting is 0.02-0.08 MPa, and the temperature of casting is 710-750 DEG C; (e) annealing an obtained aluminum lithium alloy ingot to obtain the aluminum lithium alloy ingot. The dimensions of the aluminum lithium alloy ingot prepared by the invention can reach (400-500) mm * (1200-1500) mm. Experimental results show that the breaking tenacity of the large-specification aluminum lithium alloy ingot prepared by the invention when the thickness is 100 mm is 32-35 MPa * m<1 / 2>.

Owner:SOUTHWEST ALUMINUM GRP

Method for forging annular cylinder by aid of electroslag remelted hollow blank

InactiveCN102581189AHigh material utilizationUniform deformationMetal-working apparatusMicrostructureControllability

A method for forging an annular cylinder by the aid of an electroslag remelted hollow blank belongs to the technical field of hot forming of annular cylinder forgings. The method is characterized by including the process steps: firstly, performing closed upsetting for the electroslag remelted hollow blank by a set upsetting die on a press to reach the height set in a process; secondly, performing expanding extrusion composite deformation for the upset blank by a set expanding extrusion die on the press; and thirdly, performing shrinkage deformation for the blank after expanding extrusion by a set shrinkage die on the press to meet the requirement of a finished forging on size. The method has the advantages that firstly, materials can be saved and cost can be reduced as compared with the prior art; secondly, in-die forming is adopted, high controllability is achieved, materials are in pressure stress during deformation and can be prevented from cracking, and original defects in a casting blank can be forged; and thirdly, remarkable shearing strain can be generated in the blank by means of in-die upsetting deformation, expanding extrusion composite deformation and shrinkage deformation, dendritic crystal in the electroslag cast blank can be broken to obtain thin and smooth microstructures, and the quality of the materials is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

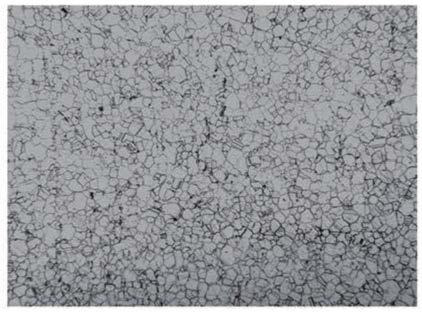

Nickel-based superalloy for missile launching device and manufacturing process of nickel-based superalloy for missile launching device

InactiveCN109628797AImprove product mechanical properties and use requirementsGood product performanceBatch productionSmelting process

The invention discloses a nickel-based superalloy for a missile launching device and a manufacturing process of the nickel-based superalloy for the missile launching device. The purposes of effectively solving the problem of low tensile strength and plasticity at 650 DEG C-700 DEG C, meeting the comprehensive performance requirements of the operating environment at instantaneous high temperature and high strength, and realizing industrial batch production are reached. According to the technical scheme, the nickel-based superalloy is selected, and tungsten, molybdenum and other strong solid solution elements are added; the best element ratio and a narrower composition range are designed for the chemical composition of nickle-chromium-molybdenum-tungsten alloy on the basis of the cost and comprehensive performance requirements; and reasonable smelting process and processing process are carried out. The nickel-based superalloy for the missile launching device and the manufacturing processof the nickel-based superalloy for the missile launching device have the beneficial effect that (1) the control of the composition determines the good thermal workability of the alloy, the deformation temperature range is relatively wide, the plastic thermal deformation is found at 950 DEG C-1160 DEG C, one-heating-number rolling is adopted for a finished square flat material, and the sufficientdeformation amount is retained to enable the product to achieve uniform microstructure; and (2) the tensile strength of the alloy at 700 DEG C is 1000 MPa-1200 MPa, the elongation after break is 16%-25%, the section shrinkage rate is 16%-30%, and a good verification result is obtained after long term use.

Owner:FUSHUN SPECIAL STEEL SHARES

Titanium ingot forging and broadening process

The invention discloses a titanium ingot forging and broadening process. The titanium ingot forging and broadening process is characterized by comprising the steps that a titanium ingot with a diameter D stands upright under a forging press, and forging downwards is carried out until the diameter of the upset titanium ingot is less than or equal to 1.2 D; the upset titanium ingot is placed flat ona lower anvil of the forging press, the axis in the lengthwise direction of the titanium ingot is enabled to be perpendicular to the axis of an operation vehicle of the press, the upset titanium ingot is rolled, and the width of a titanium blank is controlled to be 1.2 to 1.3 times the width of a final continuous rolled titanium blank product in actual production; and the horizontally rolled titanium blank is rotated by 90 degrees, so that the axis in the lengthwise direction of the titanium blank is parallel to the axis of the operation vehicle of the press, one end of the titanium blank isclamped by the operation vehicle of the forging press for longitudinal elongation, forging is alternately carried out in the thickness direction and the width direction of the titanium blank until therequired thickness and width are obtained, and thus the continuous rolled titanium blank is obtained. According to the titanium ingot forging and broadening process, the continuous rolled titanium blank with the width of more than or equal to 1.5 D can be produced to meet the requirement of the continuous rolled titanium blank with the width of more than or equal to 1500 mm, and the product is good in performance.

Owner:付旭升

Titanium ingot forging broadening technology

The invention discloses a titanium ingot forging and widening process, which is characterized in that it comprises: erecting a titanium ingot with a diameter D under a forging press, forging and pressing it downward until the diameter of the upset titanium ingot is ≤ 1.2D; The rough titanium ingot is placed flat on the lower anvil of the forging press, so that the axis of the length direction of the titanium ingot is perpendicular to the axis of the press operating vehicle, and the titanium ingot after upsetting is rolled. In actual production, the width of the titanium billet is controlled to be the final continuous rolling 1.2 to 1.3 times the width of the titanium billet product; rotate the titanium billet after horizontal rolling by 90 degrees so that the longitudinal axis of the titanium billet is parallel to the axis of the press operating vehicle, and the operating vehicle of the forging press holds one end of the titanium billet for longitudinal Pull out and alternately carry out forging along the thickness direction and width direction of the titanium billet until the required thickness and width are obtained, that is, the continuous rolling titanium billet is obtained. By adopting the invention, continuous rolling titanium billet with width ≥ 1.5D can be produced to meet the requirement of continuous rolling titanium billet with width ≥ 1500mm; the product performance is good.

Owner:侯霞

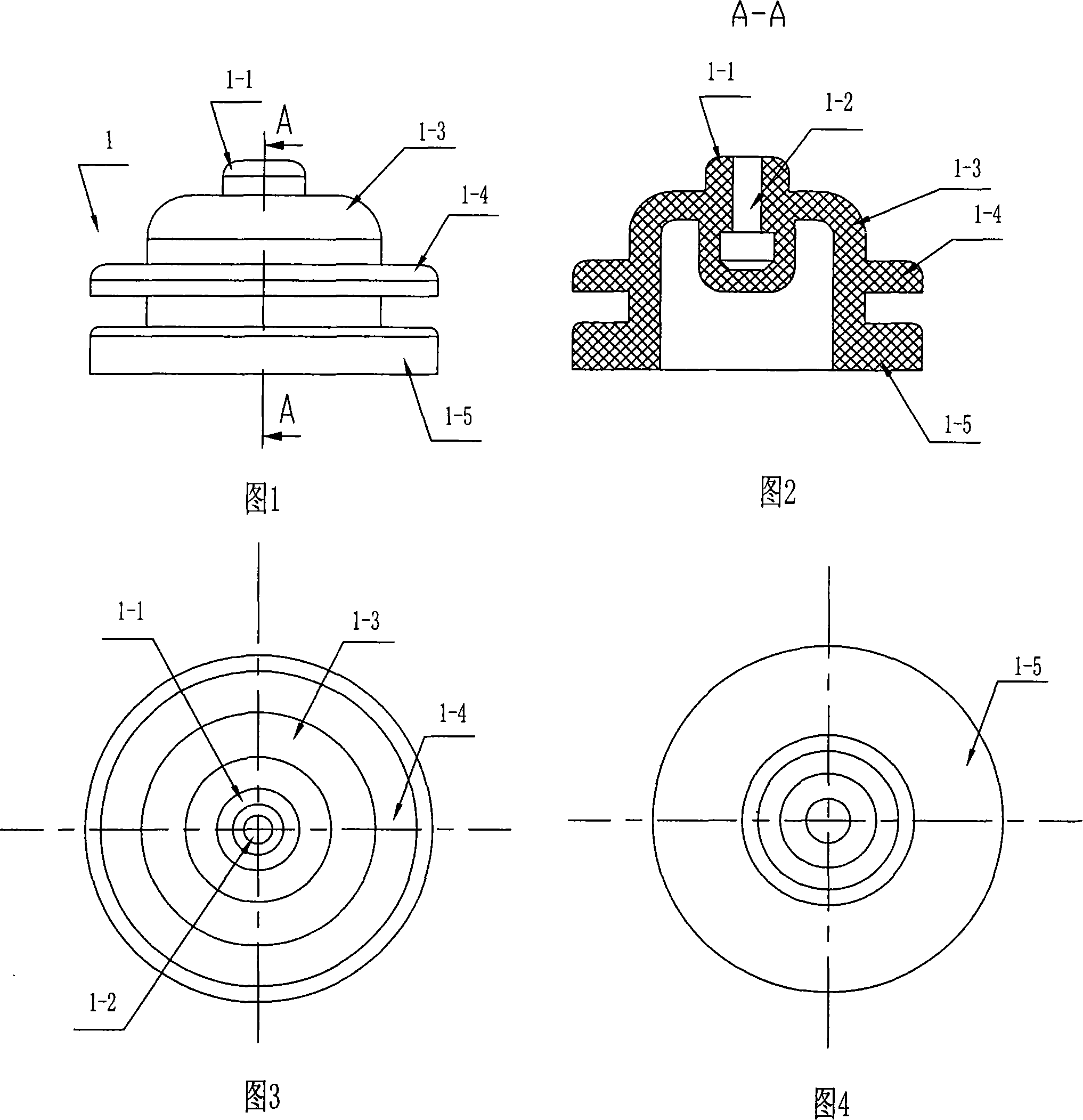

Antivibration pad for vehicle disc loading device

InactiveCN101089416AAvoid the hidden danger of leakageSolve the lack of spaceSpringsRecord carrier turntablesIn vehicleEngineering

The present invention relates to a vibration-absorbing pad for vehicle disk loading device. Said vibration-absorbing pad is made up by using high-damping rubber cover with cavity body. The lower end if said rubber cover has a cavity body, and the upper end of said rubber cover is circular table, the shaft core of said circular table is equipped with a shaft sheath, and the periphery of circular table of said rubber cover has the curved shoulder portion. Said invention utilizes the improvement of rubber cover structure and form to make the rubber cover have the feature of spring, so that it not only can absorb the energy produced by high-frequency vibration, but also can absorb the energy produced by flow-frequency vibration.

Owner:XINKE PRECISION MACHINERY CHANGZHOU CITY

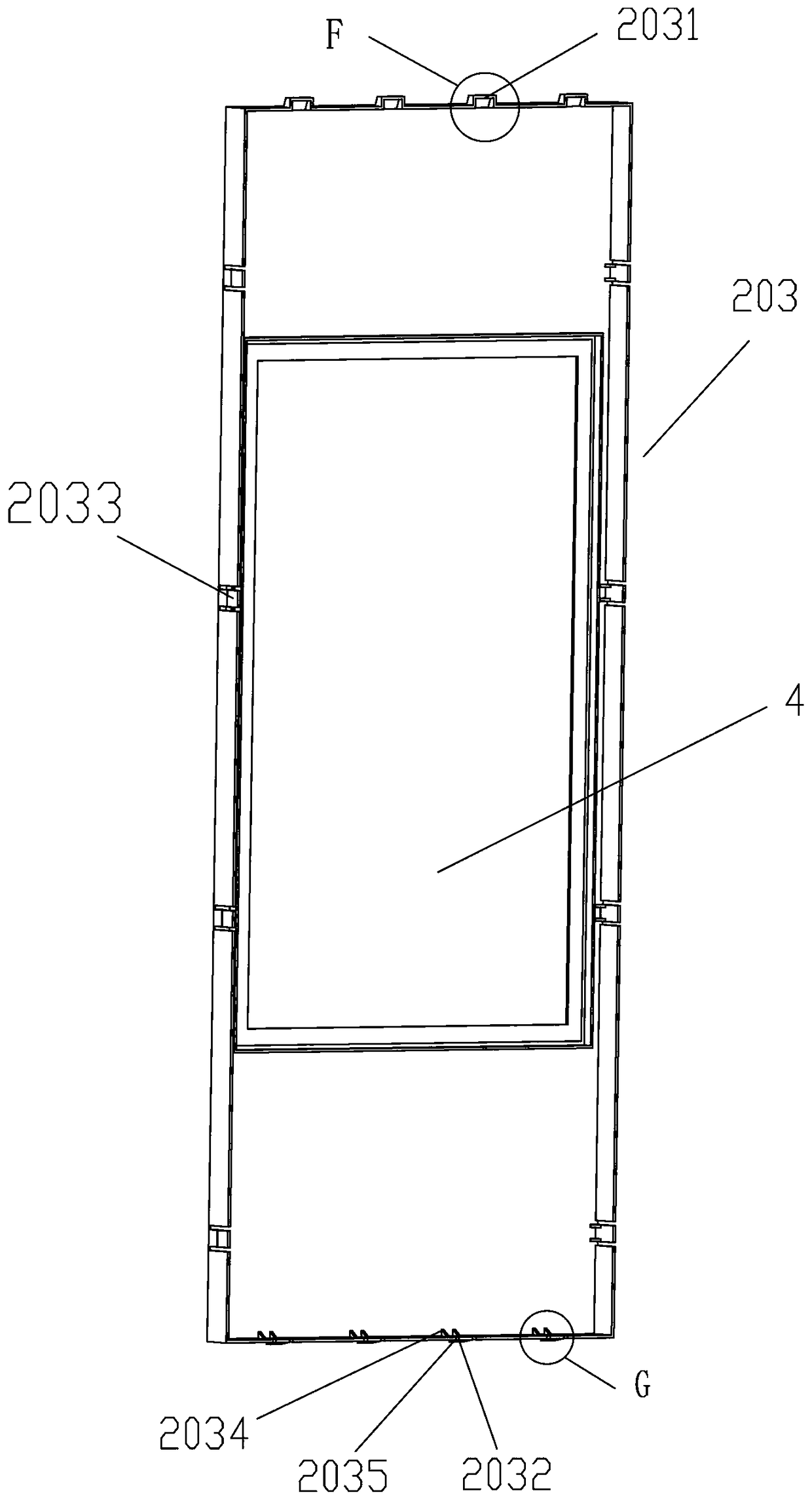

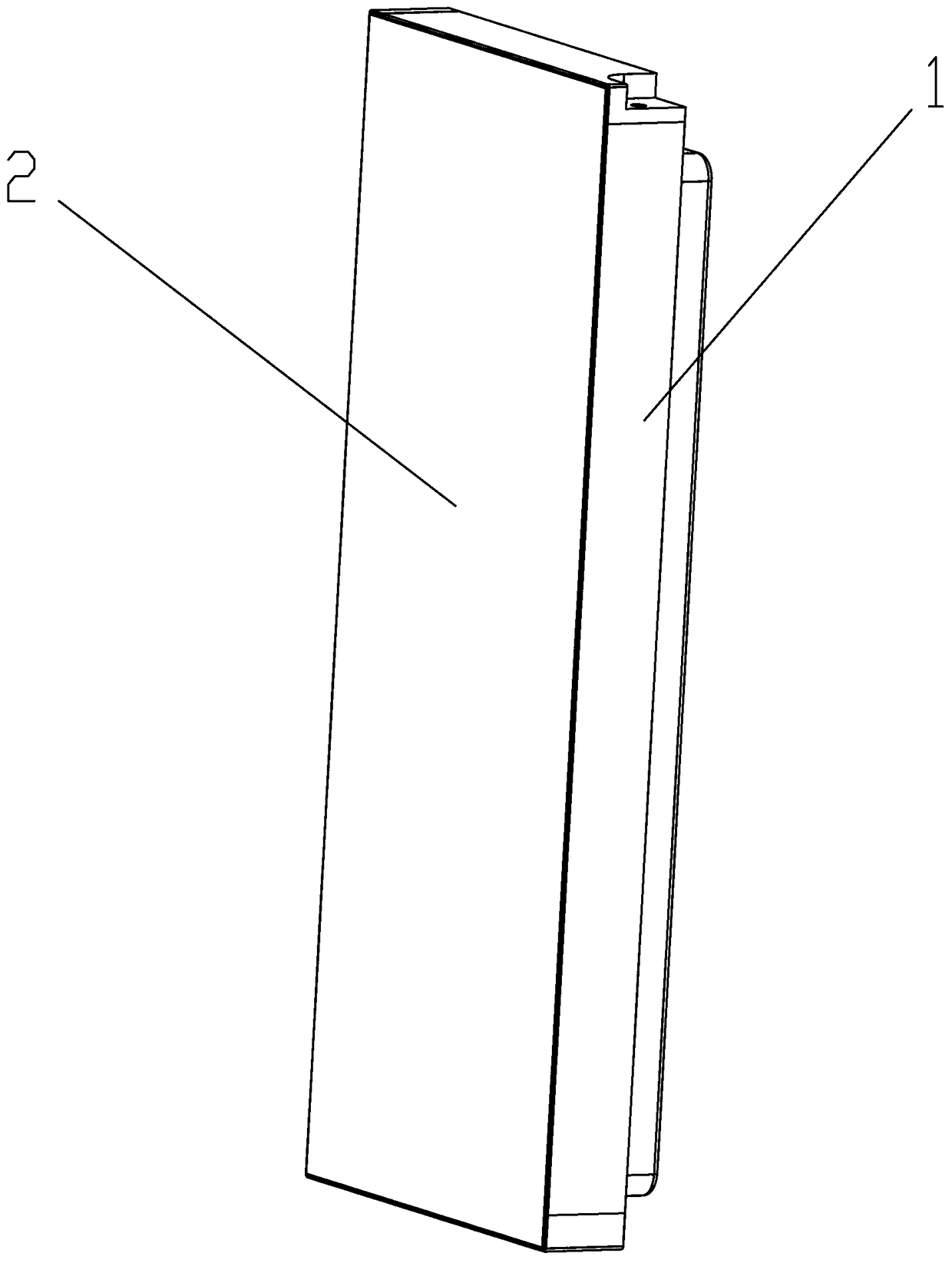

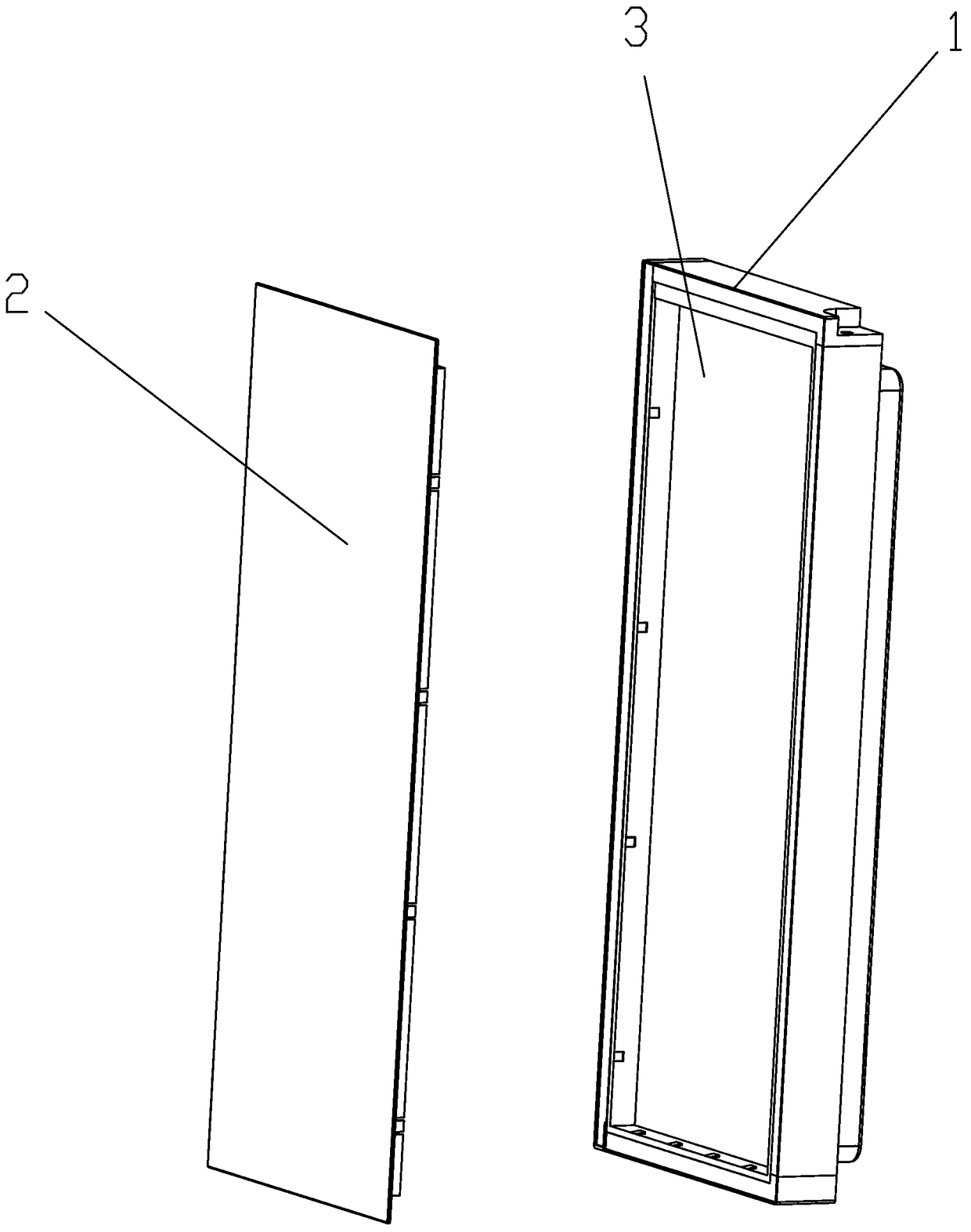

Display screen assembly connecting structure for household electrical appliance products

PendingCN109323530AEasy to installEasy to disassembleLighting and heating apparatusWing arrangementsEngineeringMachining

The invention discloses a display screen assembly connecting structure for household electrical appliance products. The display screen assembly connecting structure comprises a door foaming assembly and a display screen assembly, the door foaming assembly is provided with an installing port, and the display screen assembly is assembled into the installing port. The display screen assembly connecting structure is characterized in that the upper portion of the display screen assembly is in slope buckling connection with the upper portion of the inner wall of the installing port of the door foaming assembly, and the lower portion of the display screen assembly is in buckling connection with the lower portion of the inner wall of the installing port of the door foaming assembly. According to the display screen assembly connecting structure for the household electrical appliance products, slope buckles are arranged on the display screen assembly and the door foaming assembly, when disassembling and assembling are conducted, screen assembly assembling and disassembling are more convenient through the slope buckles, great convenience is achieved and time is better saved compared with themethod of screwing and unscrewing screws with tools, and the machining precision is lower than that required by the screws in the machining production process.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Continuous preparation device for metal mobile phone shells

The invention provides a continuous preparation device for metal mobile phone shells. The device is characterized in that by starting a stirring motor, shell metal solid pieces in mobile phone shell shapes are put into a die-casting mould from a feeding hole, and then die-casting materials, with melting points lower than that of the shell metal solid pieces, of the metal solid pieces are injectedinto the die-casting mould for die casting, so that inner surface structural parts of the mobile phone shells are made of the die-casting materials, the shell metal solid pieces are used as the outersurfaces of the mobile phone shells, and then the mobile phone shells are manufactured; and by means of the continuous preparation device for the metal mobile phone shells, raw materials in a molten state are injected into a moulding cavity, and the moulding cavity is of a multi-corner design, so that it is guaranteed that the materials generate enough deformation when passing through the mouldingcavity, grains are refined, and the metal mobile phone shells can be continuously prepared by continuously adding raw materials. According to the device, the problem that an existing mobile phone shell machining mode is simple, and the continuous preparation cannot be carried out through the manufacturing method is solved.

Owner:江苏杰邦电子科技有限公司

A Method for Reducing the Depth of Coarse Grain Layer on the Surface of Aluminum Alloy Hot Forging

The invention relates to the technical field of metal forging, in particular to a method for reducing the depth of a coarse grain layer of the surface of an aluminum alloy hot forging part. The methodcomprises the following steps that (S1) the aluminum alloy hot forging finished product is cooled to room temperature; (S2) sampling detecting of the depth of the coarse grain layer is carried out; (S3) if the measured depth of the coarse grain layer exceeds an acceptable depth, local cold plastic deformation is carried out; (S4) cold finishing is carried out; (S5) recrystallization annealing iscarried out; and (S6) sampling detecting of the depth of the processed coarse grain layer is carried out. The method for reducing the depth of the coarse grain layer of the surface of the aluminum alloy hot forging part has the beneficial effects that the local cold plastic deformation and cold finishing processes of surface metal are increased after a conventional aluminum alloy hot forging process, the cold plastic deformation enables the coarse grain layer to obtain sufficient deformation amount, and grain refinement of the coarse grain layer is achieved through the recrystallization annealing, so that the effect of reducing the depth of the coarse grain layer of the aluminum alloy hot forging part can be achieved without removing materials; and waste of the materials and scrap of forging parts caused by coarse grain defects are reduced, the qualification rate of the aluminum alloy hot forging part is improved, and the dimensional accuracy of the forging part is further increased through the cold finishing process.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

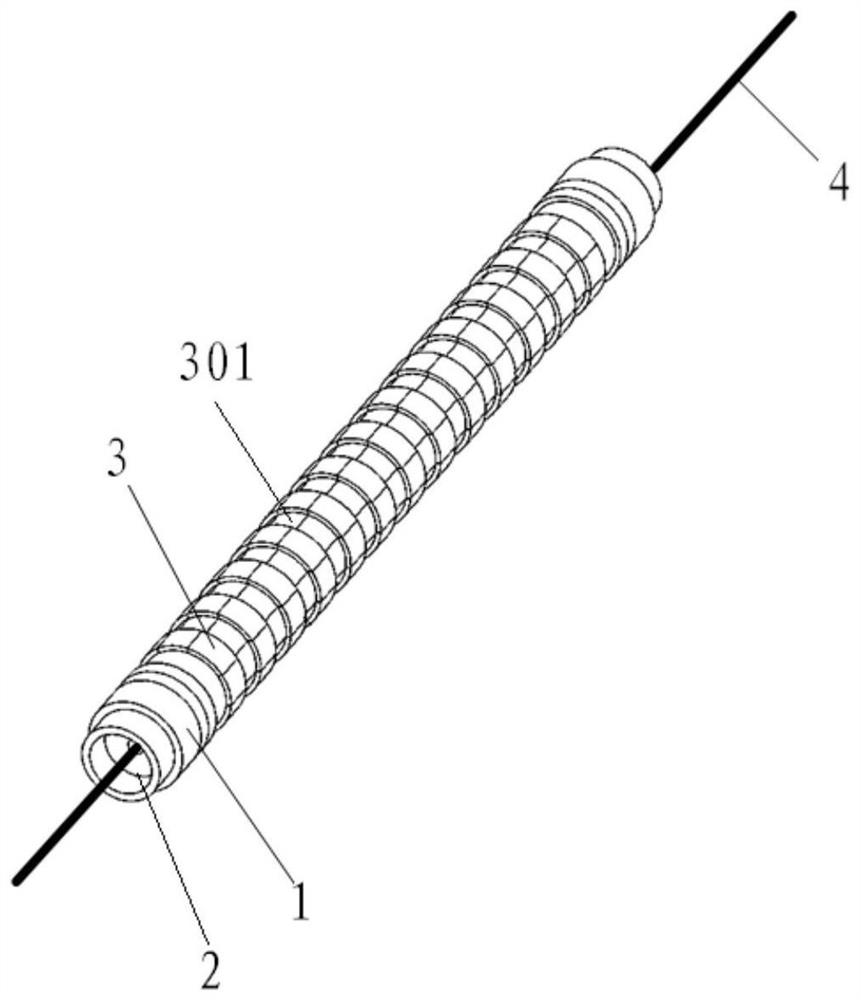

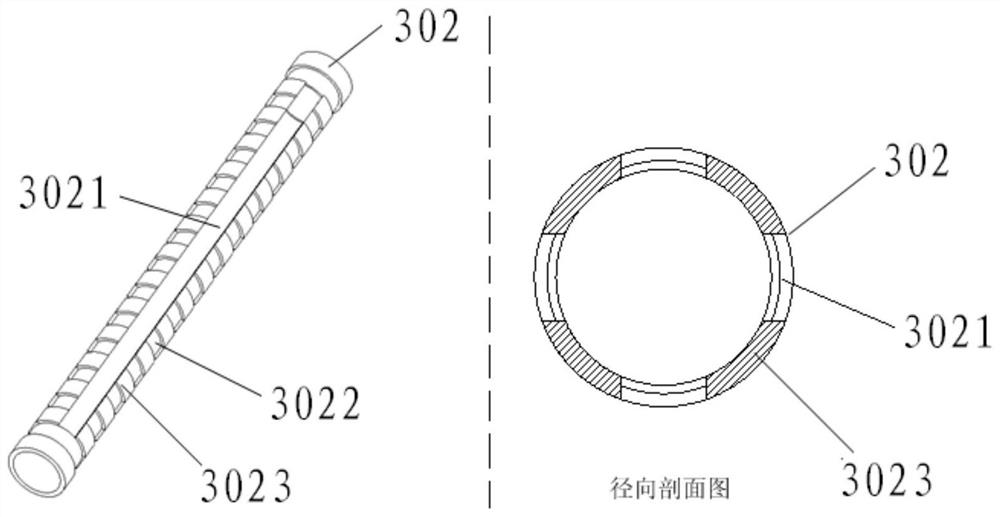

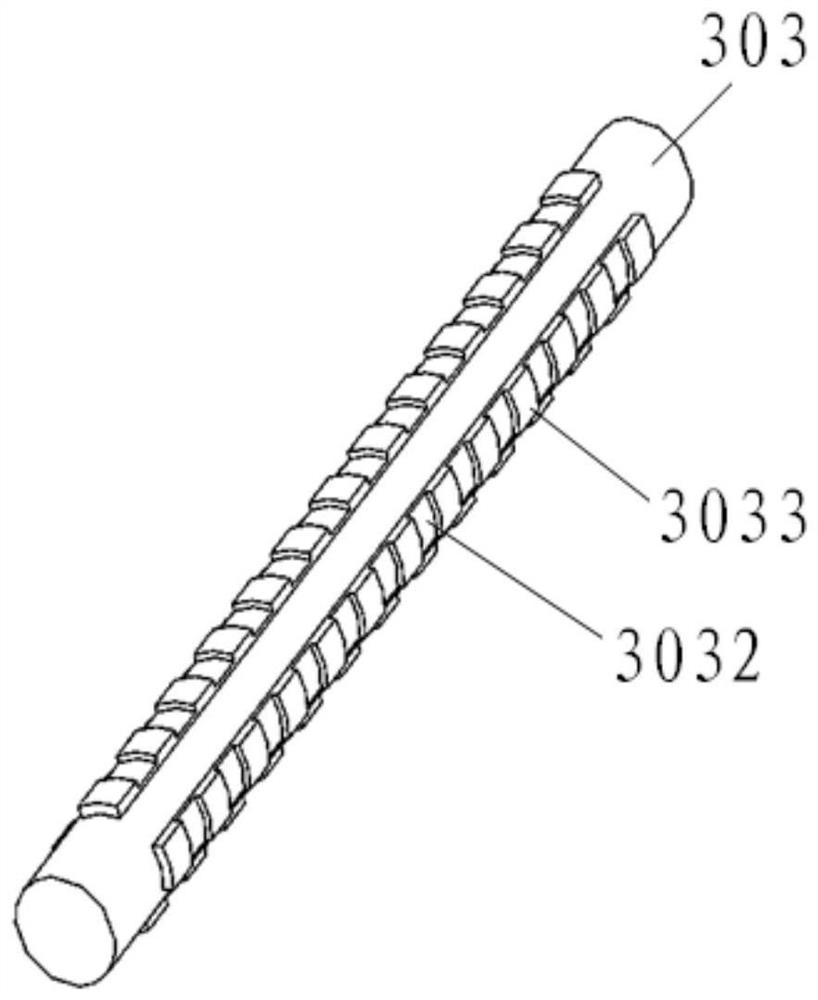

A bamboo fiber laser hydrophone packaging structure and assembling method thereof

ActiveCN108151865BFlat Frequency ResponseHigh sensitivitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansAcousticsSilicone oil

The invention discloses a packaging structure of a bamboo-shaped fiber laser hydrophone, an assembly method thereof, and a processing method of a bamboo-shaped elastic cylinder; wherein, the packaging structure includes: a pair of end covers, a pair of Elastic diaphragm, bamboo-shaped elastic tube and active optical fiber; the outer surface of the bamboo-shaped elastic tube is provided with multiple circular grooves; the inside of the bamboo-shaped elastic tube is filled with silicone oil; a pair of elastic diaphragms are respectively glued on Both ends of the bamboo-shaped elastic tube; a pair of end caps are respectively arranged on both ends of the bamboo-shaped elastic tube; an air cavity structure is formed between the end cap and the elastic diaphragm; the active optical fiber is located on the central axis of the bamboo-shaped elastic tube The two ends of the active optical fiber pass through the pair of end caps respectively. The packaging structure of the bamboo-shaped fiber laser hydrophone described in the present invention ensures that the fiber laser hydrophone has a flat frequency response and high sensitivity in the low frequency band while satisfying the need to reduce the size.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Large-diameter ultra-high-strength high-temperature-resistant magnesium alloy shell parts forging-rolling integrated preparation process

The invention discloses a forging and rolling integrated manufacturing process of a large-diameter ultrahigh-strength high temperature resisting magnesium alloy shell part. The manufacturing process comprises the following steps in sequence: semi-continuous electromagnetic casting; machining of an ingot blank; uniform annealing; multi-directional free forging; mechanical perforation; annular rolling; and T6 thermal treatment. The dimension of the prepared shell part is as follows: the outer diameter Phi is 600 mm to 1700 mm; the wall thickness is 35 mm to 100 mm; the height is 300 mm to 700 mm; the T6-state room-temperature tangential and height-direction tensile strength is larger than or equal to 470 MPa; the elongation rate is larger than or equal to 5%; the tangential and height-direction tensile strength at the temperature of 200 DEG C is larger than or equal to 350 MPa; and the elongation rate at the temperature of 200 DEG C is larger than or equal to 7%. A product prepared by the process disclosed by the invention has the characteristics of large size, no cracks, ultrahigh room-temperature strength, excellent heat resistance and the like, and the process disclosed by the invention can provide a qualified magnesium alloy shell part for the fields such as aeronautics and astronautics.

Owner:CENT SOUTH UNIV

Low-alloy high-strength large-diameter thick-wall seamless steel pipe and manufacturing method thereof

The invention relates to the technical field of metallurgy, and provides a low-alloy high-strength large-diameter thick-walled seamless steel pipe and a manufacturing method thereof. The method comprises the steps of steelmaking, wherein smelting and refining are performed to obtain target molten steel, and ingot casting is performed on the target molten steel to obtain static ingots; pipe billet forging, wherein forging and annealing are performed on the static ingots to obtain pipe billets; pipe rolling, wherein the pipe billets are heated inside an annular furnace at the temperature of 1230-1270 DEG C, holes are formed after heating is performed, and rolling forming is performed through a pipe mill; normalizing heat treatment, wherein normalizing heat treatment is performed on rolled and formed steel pipes, the normalizing furnace discharge pipe temperature is 920-940 DEG C in the normalizing heat treatment process, and the cooling mode is the air-cooling or air-cooling and mist spraying mode. The steel pipe produced through the manufacturing method is uniform in texture, good in performance and capable of achieving high-strength and excellent subzero 20 DEG C low-temperature toughness, in addition, by adopting the simplified production technology, the production efficiency can be improved, the production cost can be lowered, and meanwhile the steel pipe has the good using safety due to the low yield ratio.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Anchor Pier Structure Suitable for Surrounding Rock Deformation

ActiveCN104480935BAvoid instabilityRealize adaptive adjustmentBulkheads/pilesSelf adaptiveBuilding construction

The invention discloses an anchorage pier structure suitable for surrounding rock deformation, belonging to the field of building construction. The anchorage pier structure suitable for surrounding rock deformation comprises an anchorage pier, a steel strand and an anchorage device, wherein one end of the steel strand penetrates through a locking hole on the anchorage pier and is locked on the anchorage pier through the anchorage device; the anchorage pier structure further comprises a first anchorage plate, a second anchorage plate and an elastic part, wherein the first anchorage plate and the second anchorage plate are arranged between the anchorage pier and the anchorage device; the steel strand penetrates through the lock hole in the anchorage pier, then penetrates through the first anchorage plate and the second anchorage plate in sequence, and is finally connected to the anchorage device; the elastic part is arranged between the first anchorage plate and the second anchorage plate. The self-adaptive regulation of the anchorage pier structure during surrounding rock deformation is realized, so that enough anchorage force can be provided at an initial anchorage stage, and therefore, the surrounding rocks are prevented from being unstable; meanwhile, enough deformation can be reserved for being adaptive to the great deformation condition which possibly appears in later-stage surrounding rocks. Besides, the anchorage rope is prevented from being stretched and pulled for the second time.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

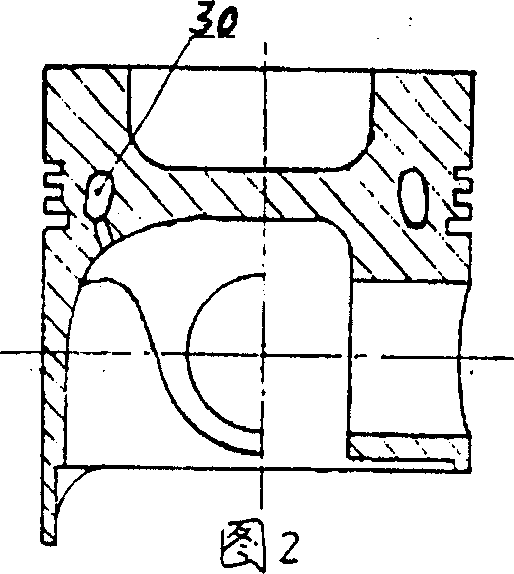

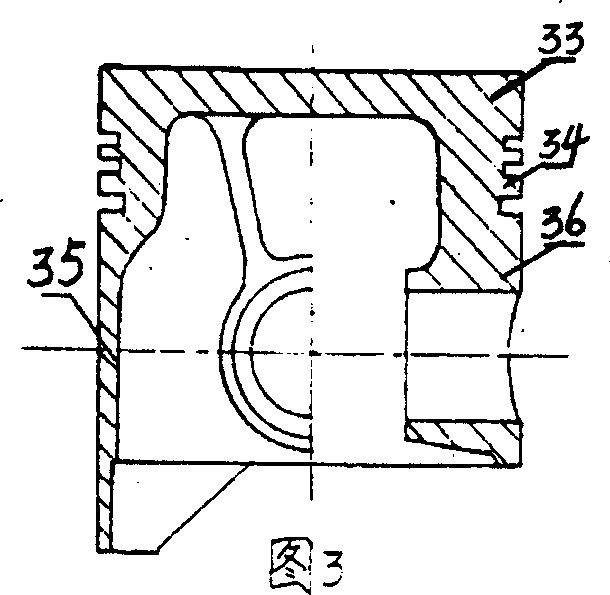

Aluminium piston of IC engine and its casting method

InactiveCN1152189CImprove rigidityHigh strengthMachines/enginesPistonsDie castingInternal combustion engine

The invention discloses an aluminium piston of internal-combustion engine. Assembling part is made of aluminium alloy material inserted in head part, grooved part and upper part of pinhole seat of piston. The assembling part and piston are die cast as an integral part. The assembling part acts as a uniform contracting element that makes entities with larger thickness such as head part, grooved part and upper part of pinhole seat of piston delaminate or thinning down when die-casting. Thus the thickness of cross section of above said parts is close to the thickness of wall thickness of piston skirt so that when die-casting, each cross section of the integral piston is solidified nearly at same time. The characteristics of the casting method are that each piston is shaped by two times of die-casting i.e. first is to cast the uniform contracting elements, second is to cast integrated piston. The invented method has advantages of good heat conductivity, high integral strength, good wear-resistance, long service life, lower cost and high production efficiency.

Owner:刘毅

GH4169 alloy wide and flat billet structure homogenization forging process

PendingCN114309409AGuaranteed uniformityEnough deformationMetal-working apparatusAlloy steelMechanical properties of carbon nanotubes

The invention relates to the technical field of forging, in particular to a GH4169 alloy wide and flat billet structure homogenizing forging process, which comprises the following steps of: performing five-heating-number forging on a GH4169 alloy steel ingot, controlling the heating temperatures of a first heating number and a second heating number to be 1100-1120 DEG C, controlling the heating temperatures of a third heating number and a fourth heating number to be 10-20 DEG C lower than the forging temperature of the first heating number, and controlling the forging temperature of the third heating number and the fourth heating number to be 10-20 DEG C lower than the forging temperature of the first heating number; the heating temperature of the fifth heating number is 20-30 DEG C lower than that of the fourth heating number; the forging deformation of the first heating number is 15-20%, and the forging deformation of the second heating number to the fifth heating number is larger than or equal to 30%. According to the GH4169 alloy wide and flat blank forged through the forging technology, the core radius edge structure is uniform, the grade difference does not exceed the first grade, the mechanical property is excellent, and the mechanical properties in different directions are consistent.

Owner:AVIC SHANGDA METAL REGENERATION TECH

Water outlet nozzle structure and kitchen and bathroom product using same

The invention discloses a water outlet nozzle structure and a kitchen and bathroom product using the sane. The water outlet nozzle structure comprises a water outlet nozzle body provided with a water passing cavity; the water outlet nozzle body is provided with an assembling part and an elastic deformation part, and the elastic deformation part is not deformed when no water pressure exists so as to quickly close the water passing cavity; and when water pressure is applied, the elastic deformation part deforms to quickly open the water passing cavity. Since the water outlet nozzle body is provided with the elastic deformation part, when no water pressure exists, the elastic deformation part does not deform so as to close the water passing cavity; when water pressure exists, the elastic deformation part deforms to open the water passing cavity; when a switch of the kitchen and bathroom product is in a non-water pressure state, the elastic deformation part can quickly deform to close the water passing cavity so as to stop water instantly, and the phenomenon of water dripping and leaking is avoided; and when the switch of the kitchen and bathroom product is opened instantly in a water pressure state, the elastic deformation part can quickly deform so as to open the water passing cavity and achieve quick water outlet.

Owner:XIAMEN LOTA INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com