Aluminium piston of IC engine and its casting method

A technology for internal combustion engines and pistons, applied in the directions of pistons, mechanical equipment, engine components, etc., can solve the problems that the thermal conductivity, overall strength and wear resistance of aluminum pistons have not been greatly improved and improved, and achieve good hardness and wear resistance. Good performance, uniform and fine metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

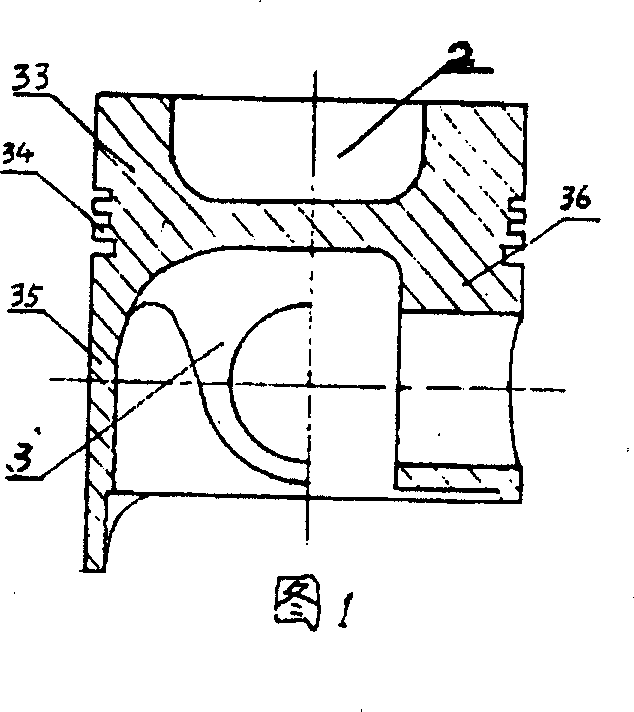

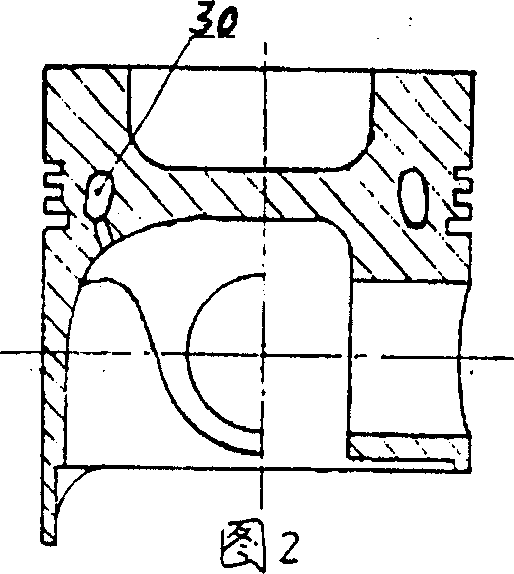

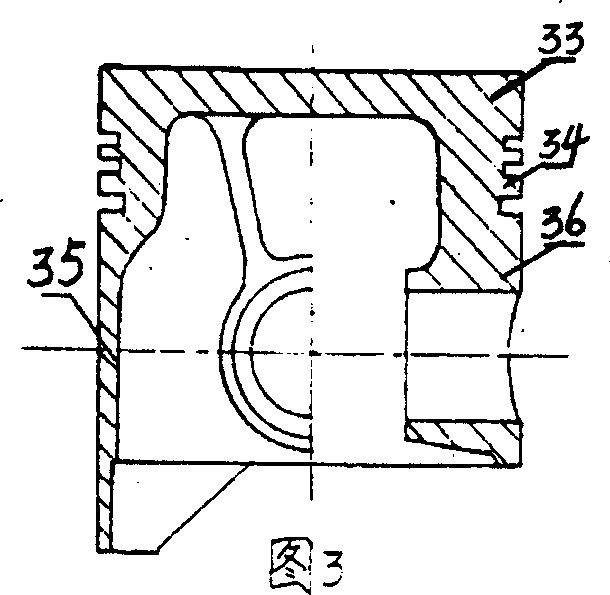

[0050] As shown in Fig. 1, Fig. 2, Fig. 3, the internal combustion engine (reciprocating) aluminum piston of prior art comprises piston head 33, piston groove 34, piston pin hole seat 3 and piston skirt 35 etc. Representative of the following three structural forms. Fig. 1 is common diesel engine piston, and combustion chamber 2 is arranged on the top, for the structure and strength needs of head 33, groove portion 34 and pin hole seat top 36, its head 33, groove portion 34 and pin hole seat top 36 (this The three are here a whole, the same below) The thickness of the section (including the transverse section and the longitudinal section, the same below) is 5-5- 7 times. Fig. 2 is a supercharged diesel engine piston, which has an internal cooling oil chamber 30 to accelerate the cooling effect of the piston head and groove, but the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com