Continuous preparation device for metal mobile phone shells

A technology for a mobile phone casing and a preparation device is applied in the field of continuous preparation devices for metal mobile phone casings, and can solve the problems of simple processing methods for mobile phone casings, inability to meet the needs of users, and inability of continuous preparation by the manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

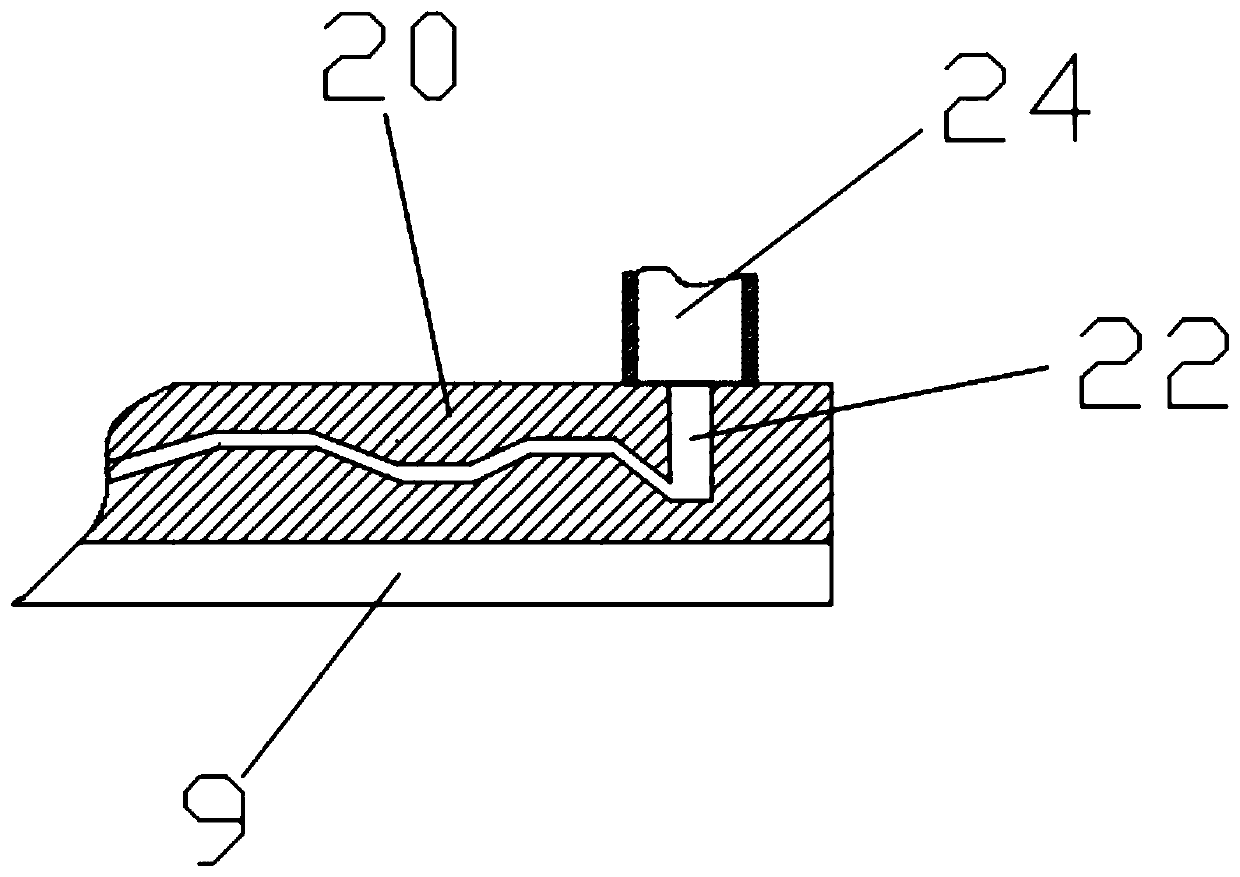

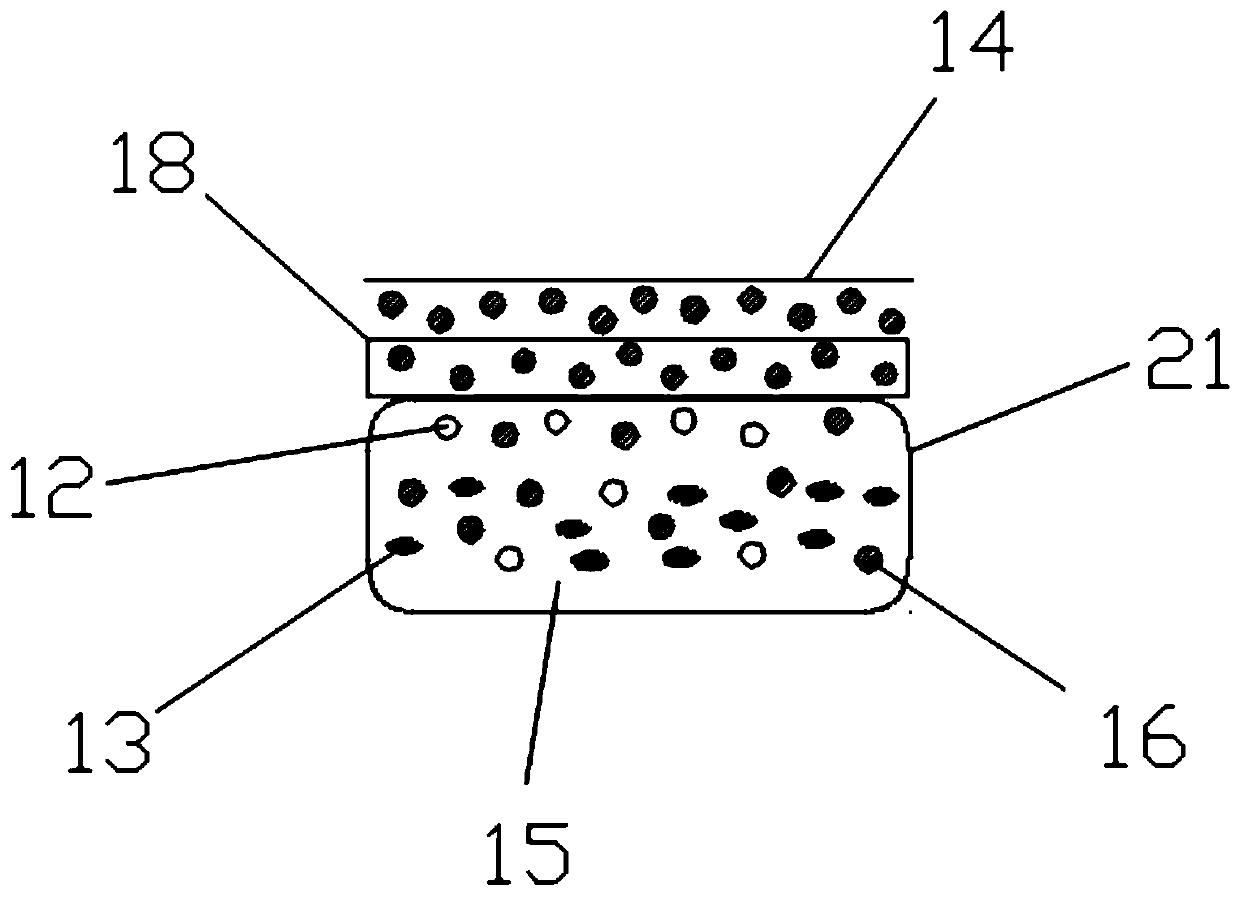

[0017] according to Figure 1-3 As shown, this embodiment proposes a continuous preparation device for metal mobile phone shells, including a stirring motor 2, a die-casting cavity 19 and a support frame 17, a feeding port 1 is arranged on the left side of the stirring motor 2, and the feeding port 1 is installed in a melting tank 3 On the lower side of the melting box 3, a melting box frame 4 is set, and the bottom of the melting box frame 4 is fixedly connected with the support frame 17, and the right side of the support frame 17 is provided with a heater 5, and the heater 5 is connected to the feeding pipe 6, and the upper side of the feeding pipe 6 Solenoid valve 7 is set, and solenoid valve 7 is connected with die-casting chamber 19, and the left side of die-casting chamber 19 is connected with cooling tank 8, and the lower end of cooling tank 8 is provided with coolant tank 23, and coolant tank 23 is fixedly connected with frame 9, and frame 9 The lower end of the column...

Embodiment 2

[0024] according to Figure 1-3 As shown, a continuous preparation device for a metal mobile phone shell provided in this embodiment includes a stirring motor 2, a die-casting cavity 19 and a support frame 17, and a feeding port 1 is arranged on the left side of the stirring motor 2, and the feeding port 1 is installed in a melting tank 3 On the lower side of the melting box 3, a melting box frame 4 is set, and the bottom of the melting box frame 4 is fixedly connected with the support frame 17, and the right side of the support frame 17 is provided with a heater 5, and the heater 5 is connected to the feeding pipe 6, and the upper side of the feeding pipe 6 Solenoid valve 7 is set, and solenoid valve 7 is connected with die-casting chamber 19, and the left side of die-casting chamber 19 is connected with cooling tank 8, and the lower end of cooling tank 8 is provided with coolant tank 23, and coolant tank 23 is fixedly connected with frame 9, and frame 9 The lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com