GH4169 alloy wide and flat billet structure homogenization forging process

A GH4169, uniform structure technology, applied in the field of forging, can solve the problems of poor structure uniformity, surface elongation, poor consistency, etc., to achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

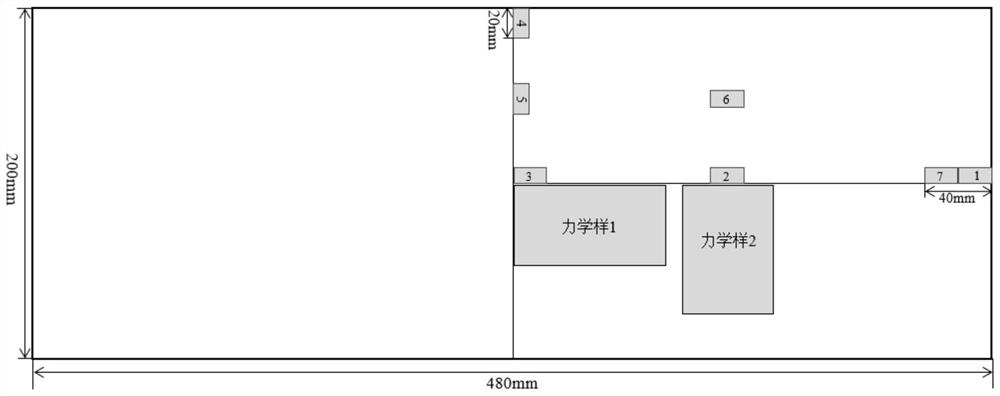

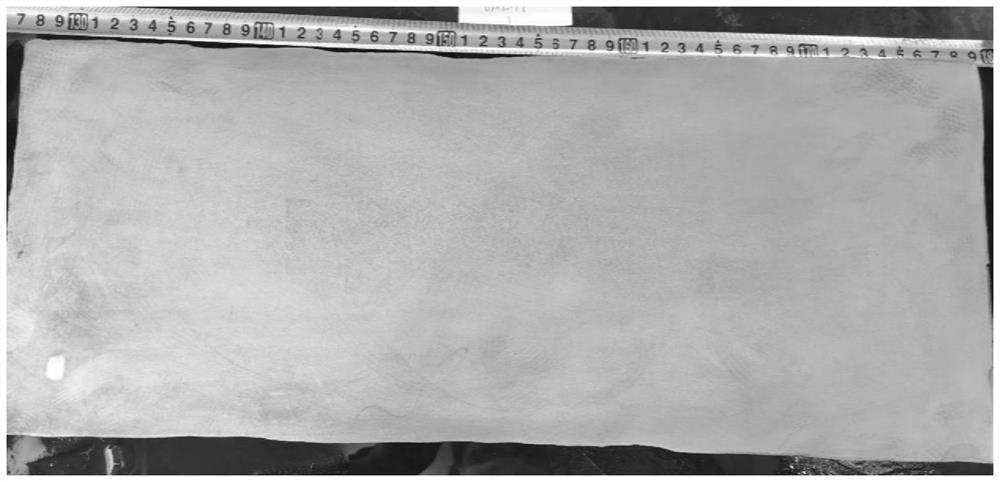

Image

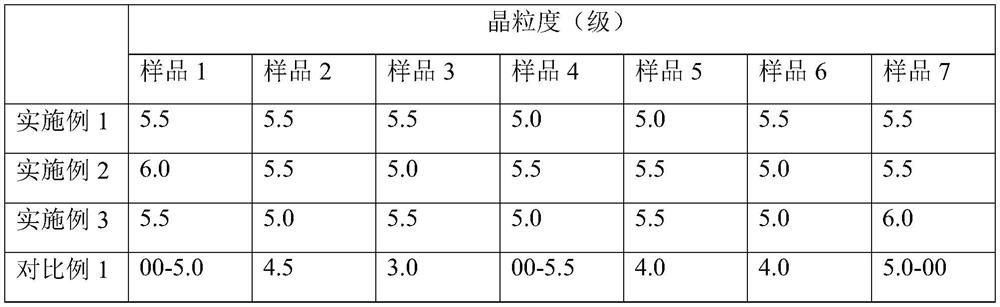

Examples

Embodiment 1

[0028] A GH4169 alloy wide slab microstructure homogenization forging process, specifically comprising the following steps:

[0029] Step A, heating a GH4169 alloy steel ingot with a diameter of 508mm to 1110°C, holding the temperature for 2.5 hours to make the ingot evenly heated through, then taking it out of the furnace, drawing it, and forging it to 450mm octagonal, so as to obtain a fire-forged billet;

[0030] Step B, continue to heat the first-fire forging billet to 1110°C, keep it warm for 1.5 hours to make the steel ingot evenly heated, and then take it out of the furnace, first upsetting to φ570mm, then drawing and forging to 450mm octagonal to obtain the second-fire forging billet;

[0031] Step C, heating the second-fire forged billet to 1090°C, holding it for 1.5 hours to make the steel ingot evenly heated through, and then upsetting the steel ingot to φ570mm to obtain a third-fire forged billet;

[0032] Step D, heating the three-fire forged billet to 1080°C, hol...

Embodiment 2

[0035] A GH4169 alloy wide slab microstructure homogenization forging process, specifically comprising the following steps:

[0036] Step A, heating a GH4169 alloy steel ingot with a diameter of 508mm to 1120°C, holding the temperature for 2 hours to make the ingot evenly heated through, then taking it out of the furnace, pulling it out, and then forging it to 445mm octagonal, so as to obtain a fire forged billet;

[0037] Step B, continue to heat the first-fire forging billet to 1120°C, keep it warm for 1.5 hours to make the steel ingot evenly heated, and then take it out of the furnace, first upsetting to φ565mm, then drawing and forging to 445mm octagonal to obtain the second-fire forging billet;

[0038] Step C, heating the second-fire forged billet to 1110°C, holding it for 1.5 hours to make the steel ingot evenly heated through, and then upsetting the steel ingot to φ565mm to obtain a third-fire forged billet;

[0039] Step D, heating the three-fire forged billet to 1090...

Embodiment 3

[0042] A GH4169 alloy wide slab microstructure homogenization forging process, specifically comprising the following steps:

[0043] Step A, heating a GH4169 alloy steel ingot with a diameter of 508mm to 1100°C, holding the temperature for 2 hours to make the ingot evenly heated through, then taking it out of the furnace, drawing it, and forging it to 445mm octagonal, so as to obtain a fire forged billet;

[0044] Step B, continue to heat the first-fire forging billet to 1100°C, keep it warm for 2 hours to make the steel ingot evenly heated, and then take it out of the furnace, first upsetting to φ565mm, then drawing and forging to 445mm octagonal to obtain the second-fire forging billet;

[0045] Step C, heating the second-fire forged billet to 1080°C, keeping it warm for 2 hours to make the steel ingot evenly heated through, and then upsetting the steel ingot to φ565mm to obtain a third-fire forged billet;

[0046] Step D, heating the three-fire forged billet to 1070°C, hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com