Preparation method of aluminum lithium alloy ingot

An aluminum-lithium alloy and ingot casting technology, which is applied in the field of aluminum alloys, can solve problems such as cracking, high risk of ingot cracking, and easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The embodiment of the present invention discloses a method for preparing an aluminum-lithium alloy ingot, comprising the following steps:

[0022] a) Melting the smelting raw material, the melted composition of the smelting raw material includes: 0-0.12wt% Si, 0-0.15wt% Fe, 2.4-4.6wt% Cu, 0-0.5wt% Mn, 0-0.8wt% Mg, 0-0.05wt% Cr, 0-0.05wt% Ni, 0-0.25wt% Zn, 0-0.15wt% Ti, 0.04-0.18wt% Zr, 0.7wt %~2.6wt% Li, 0.2wt%~0.7wt% Ag and the balance Al;

[0023] b) refining the melted raw materials to obtain a melt;

[0024] c) Transfer the melt to the holding furnace for sampling before the furnace, adjust the composition according to the composition results before the furnace, and then carry out vacuum refining after the adjustment;

[0025] d) Casting the refined melt, the casting speed is 25mm / min~35mm / min, the hydraulic pressure of the casting is 0.02MPa~0.08MPa, and the casting temperature is 710℃~750℃;

[0026] e) annealing the aluminum-lithium alloy ingot obtained in step...

Embodiment 1

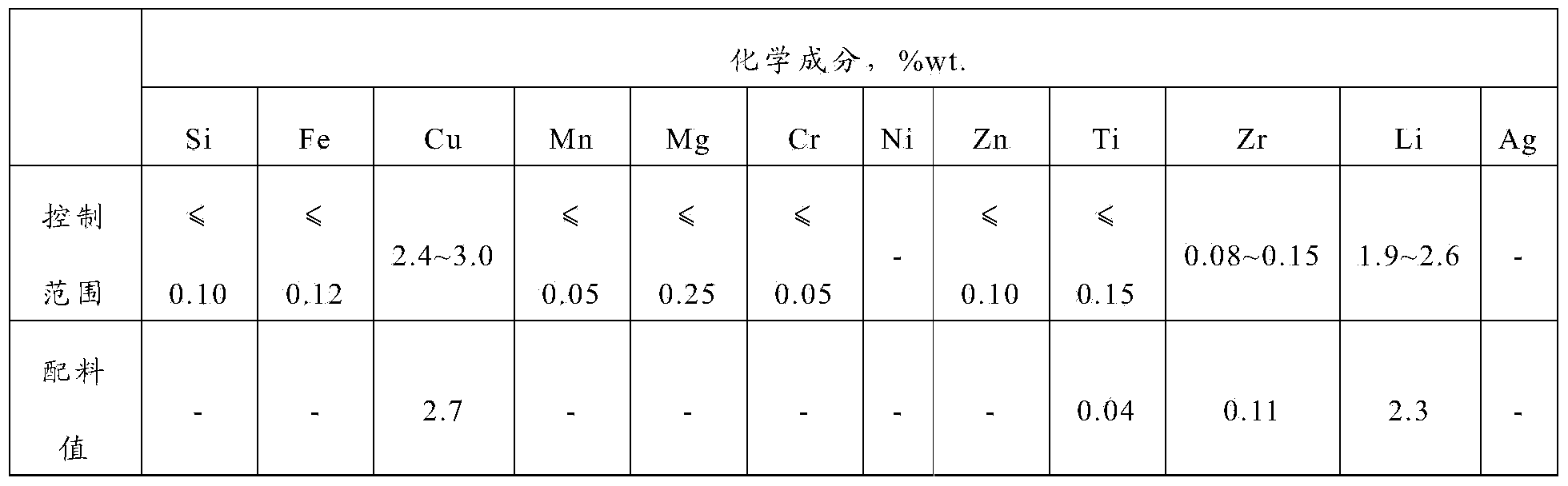

[0037] 1. Calculate the ingredients, determine the length of the ingot to be 3500mm according to the requirements of the issued production task, consider the oxidation and burning loss of 5%, the specification of the large-scale ingot is 420×1400mm, and the density of the alloy is assumed to be 2700kg / m 3 , then calculate the total feeding amount = 0.38×1.4×3.5×(1+5%)×2700≈5280kg. Then calculate the input amount of each metal, the chemical composition control range and batching value of alloy A are shown in Table 1:

[0038] Table 1 The chemical composition data table (wt%) of the aluminum-lithium alloy of this embodiment

[0039]

[0040] Notice:

[0041] ①The ingredient value is generally the middle value of the control range.

[0042] ② In order to refine the grain and prevent the ingot from cracking, generally add 0.04% Ti element

[0043] ③ When the aluminum-lithium alloy is prepared, the Cu element is added as a pure Cu plate, the Mn element is added as an Al-Mn in...

Embodiment 2

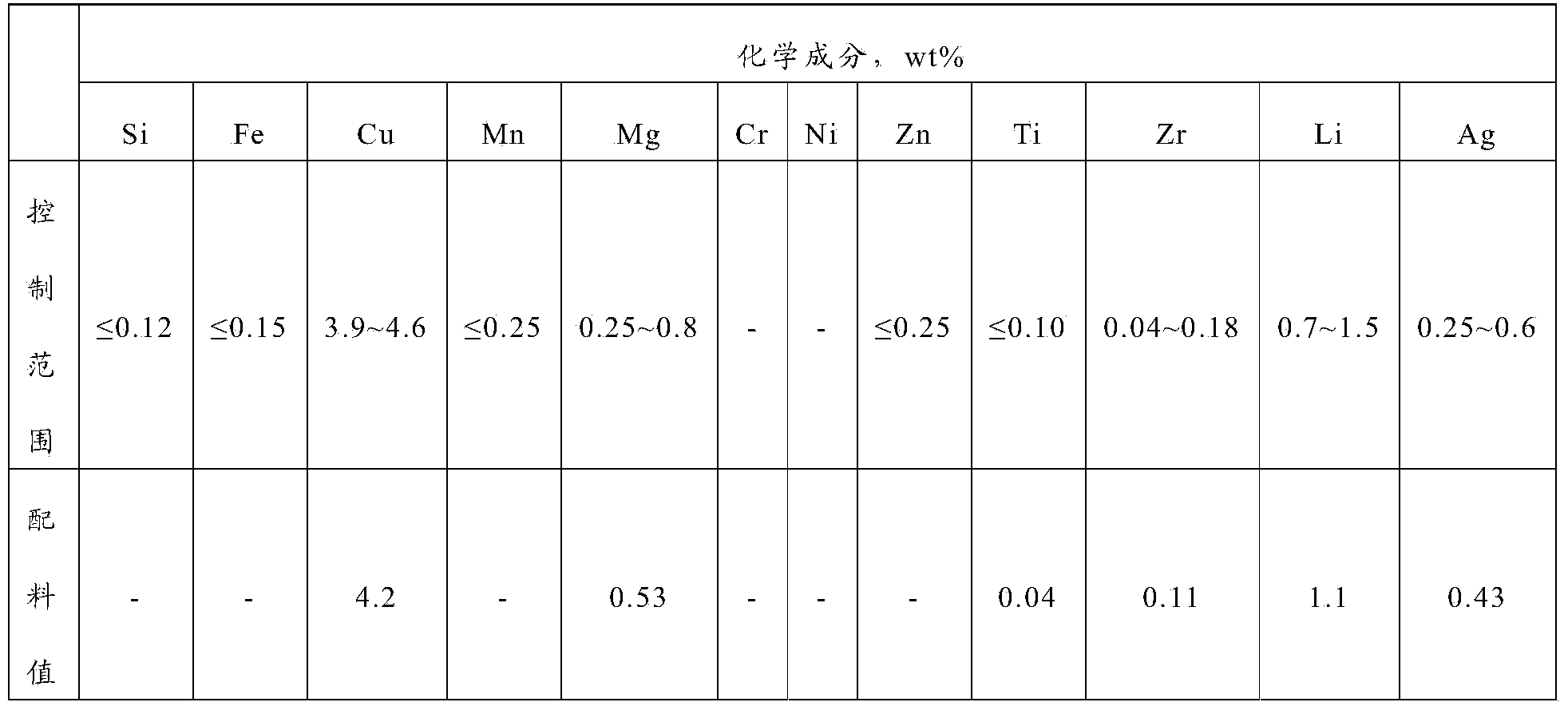

[0078] 1. Calculation. Determine the length of the ingot to be 3500mm according to the requirements of the issued production task. Considering the oxidation and burning loss of 5%, the specification of the large-scale ingot is 420×1400mm, and the density of the alloy is assumed to be 2700kg / m 3 , then calculate the total feeding amount = 0.38×1.4×3.5×(1+5%)×2700≈5280kg. Then calculate the input amount of each metal, the chemical composition control range and batching value of alloy B are shown in Table 2:

[0079] Table 2 The chemical composition data table (wt%) of the aluminum-lithium alloy of this embodiment

[0080]

[0081] Notice:

[0082] ①The ingredient value is generally the middle value of the control range.

[0083] ② In order to refine the grain and prevent the ingot from cracking, generally add 0.04% Ti element

[0084]③ When the aluminum-lithium alloy is prepared, the Cu element is added as a pure Cu plate, the Mn element is added as an Al-Mn intermediate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fracture toughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com