Patents

Literature

64results about How to "Avoid repeated replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

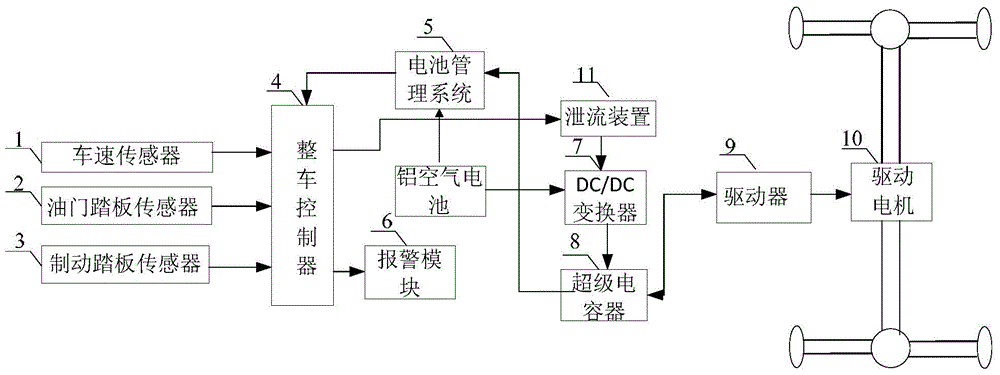

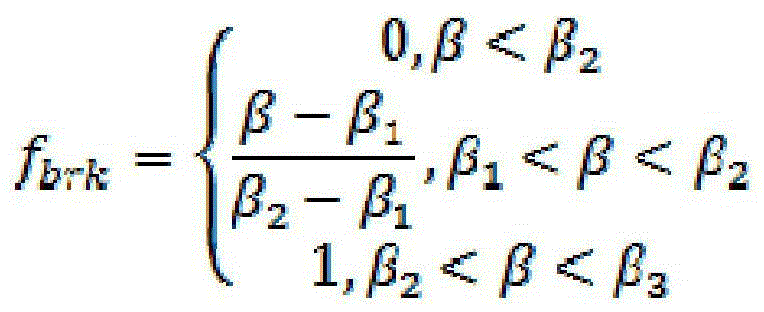

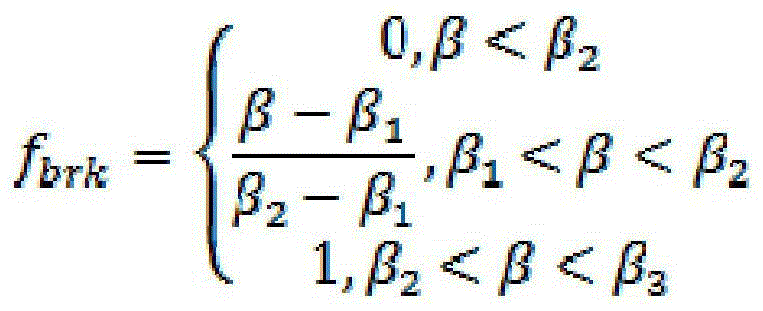

Energy distribution device and energy distribution method of compound energy sources of urban electric bus

ActiveCN104960429AAvoid repeated replacementMeet power needsVehicular energy storageElectric energy managementEnergy sourceDriving range

The invention provides an energy distribution device and an energy distribution method of compound energy sources of an urban electric bus, relates to the configuration and the energy management method of compound energy sources of electric cars, and solves the problem of poor power characteristics caused by the fact that the existing electric vehicles adopt aluminum air batteries. According to the invention, by formulating the corresponding energy distribution method, energy of the compound energy sources is reasonably allocated, the energy of the aluminum air batteries is saved, and the aluminum air batteries do not need to be replaced repeatedly, so that the requirement of users for the driving range of electric vehicles is met, and the requirement for power of the urban electric bus most of the time is also met. The energy distribution device and the energy distribution method of the compound energy sources of the urban electric bus are suitable for distribution of compound energy sources of urban electric buses.

Owner:TSINGHUA UNIV

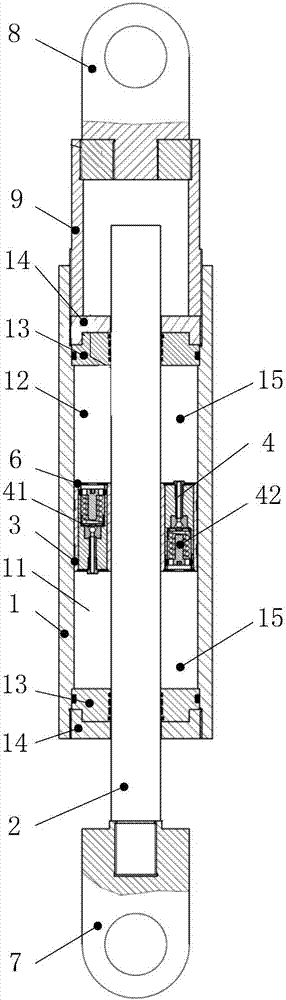

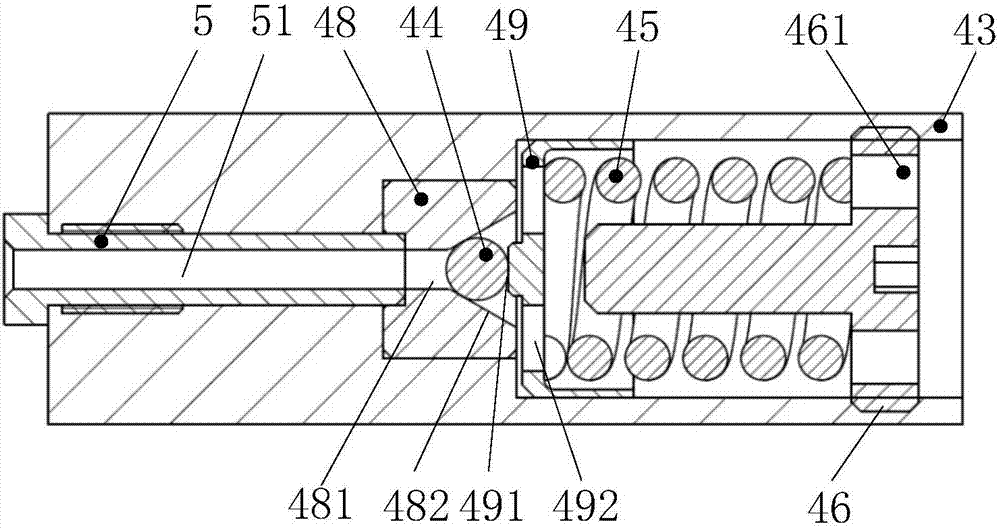

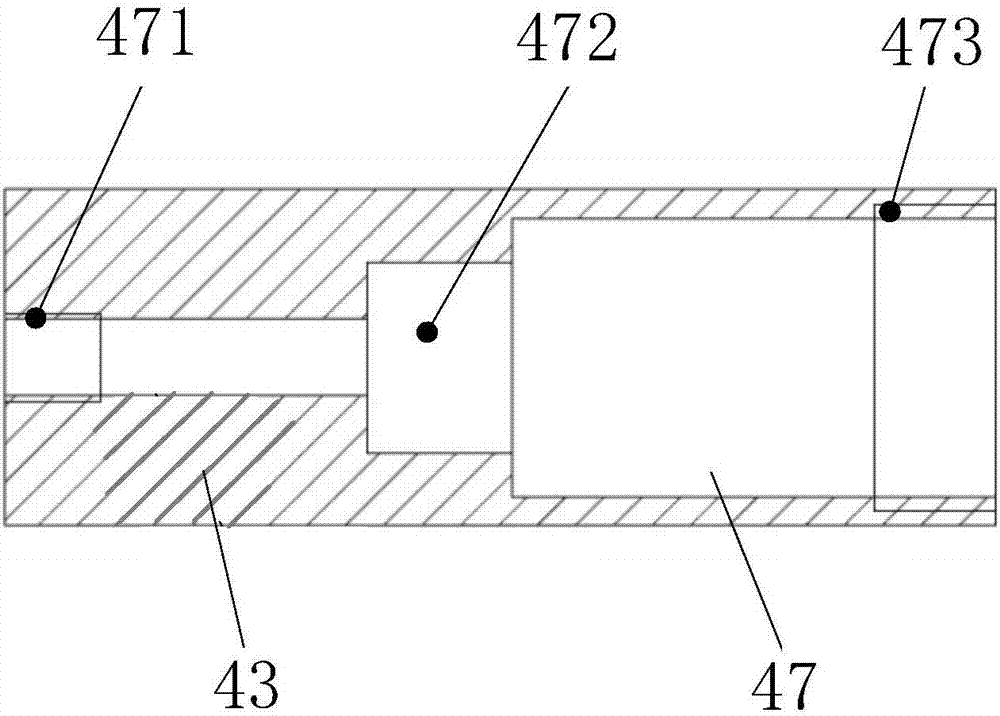

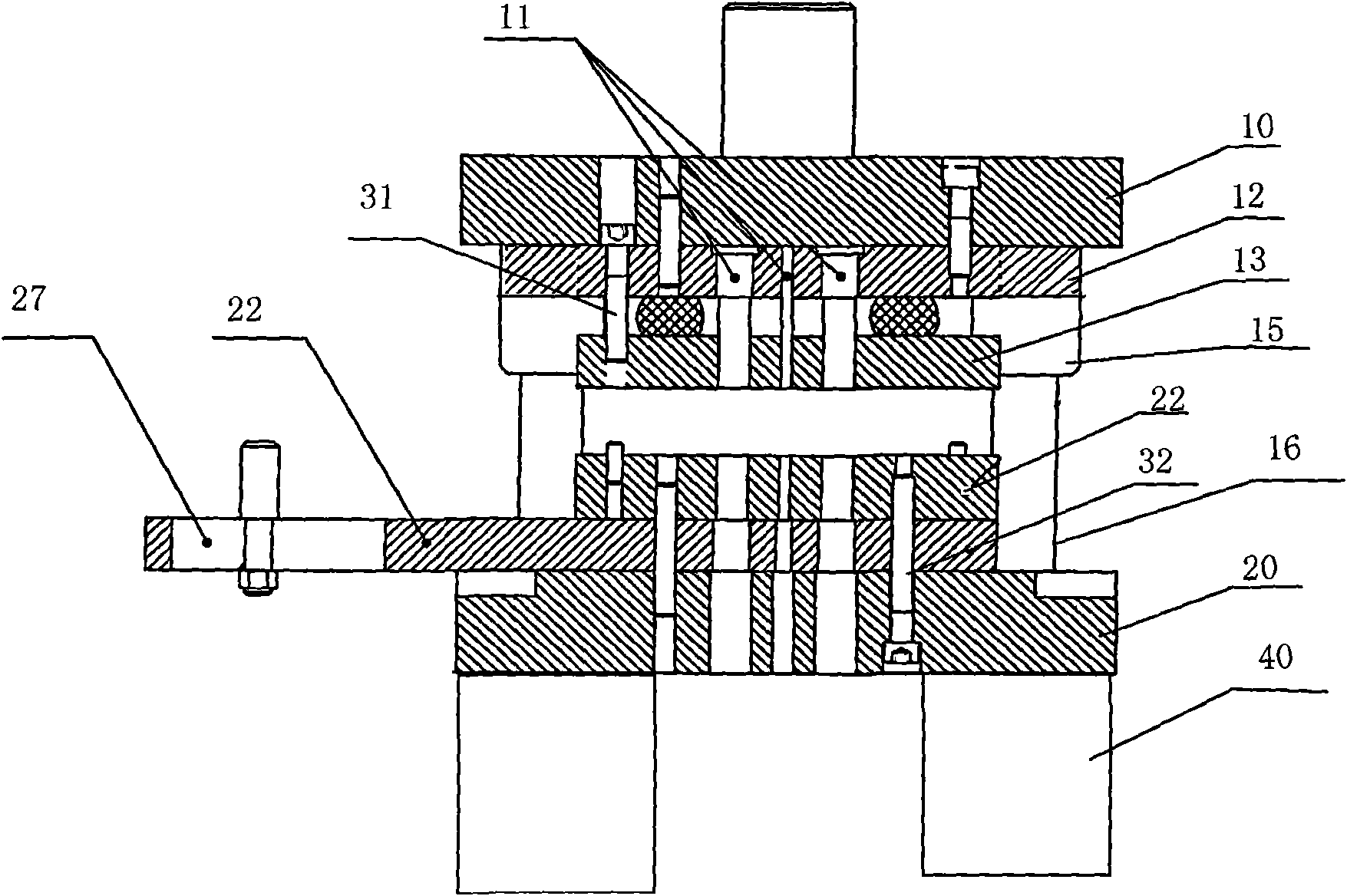

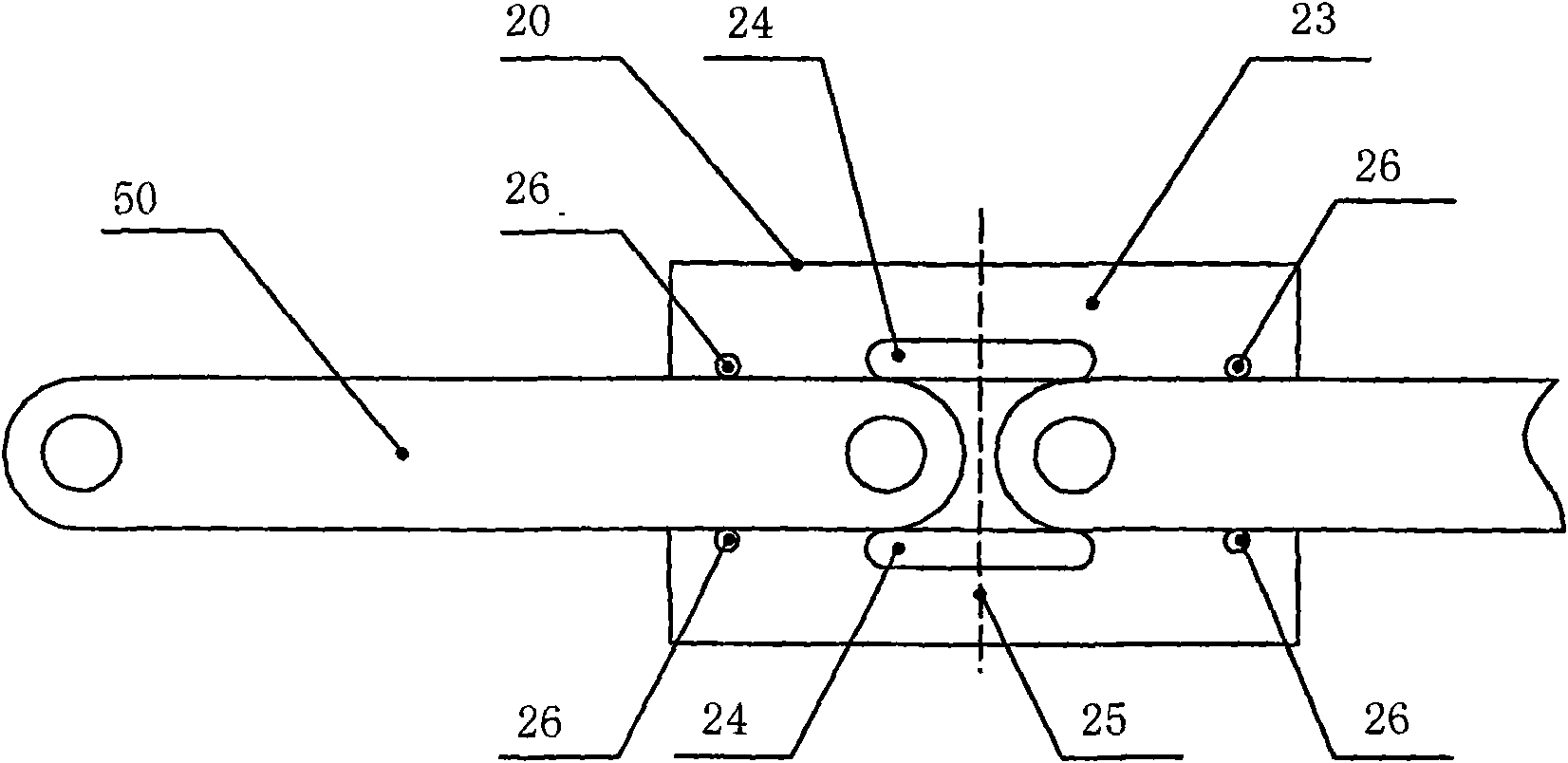

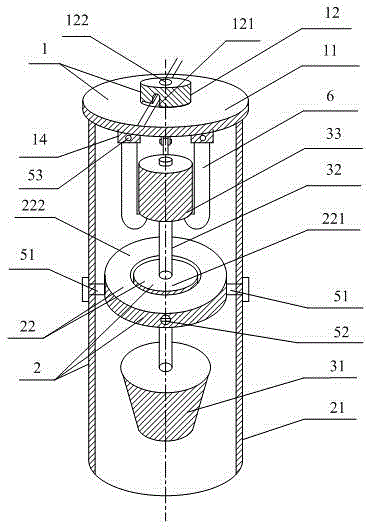

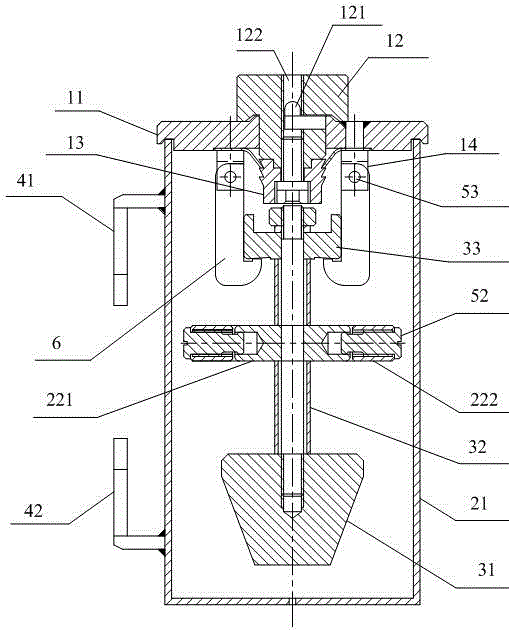

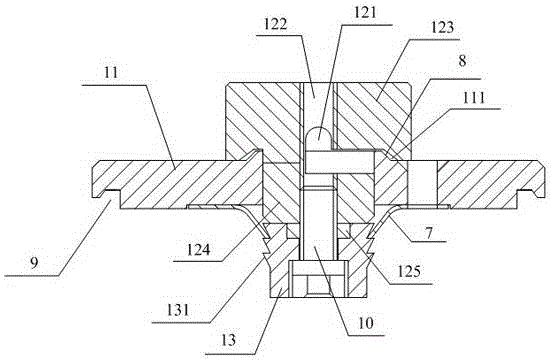

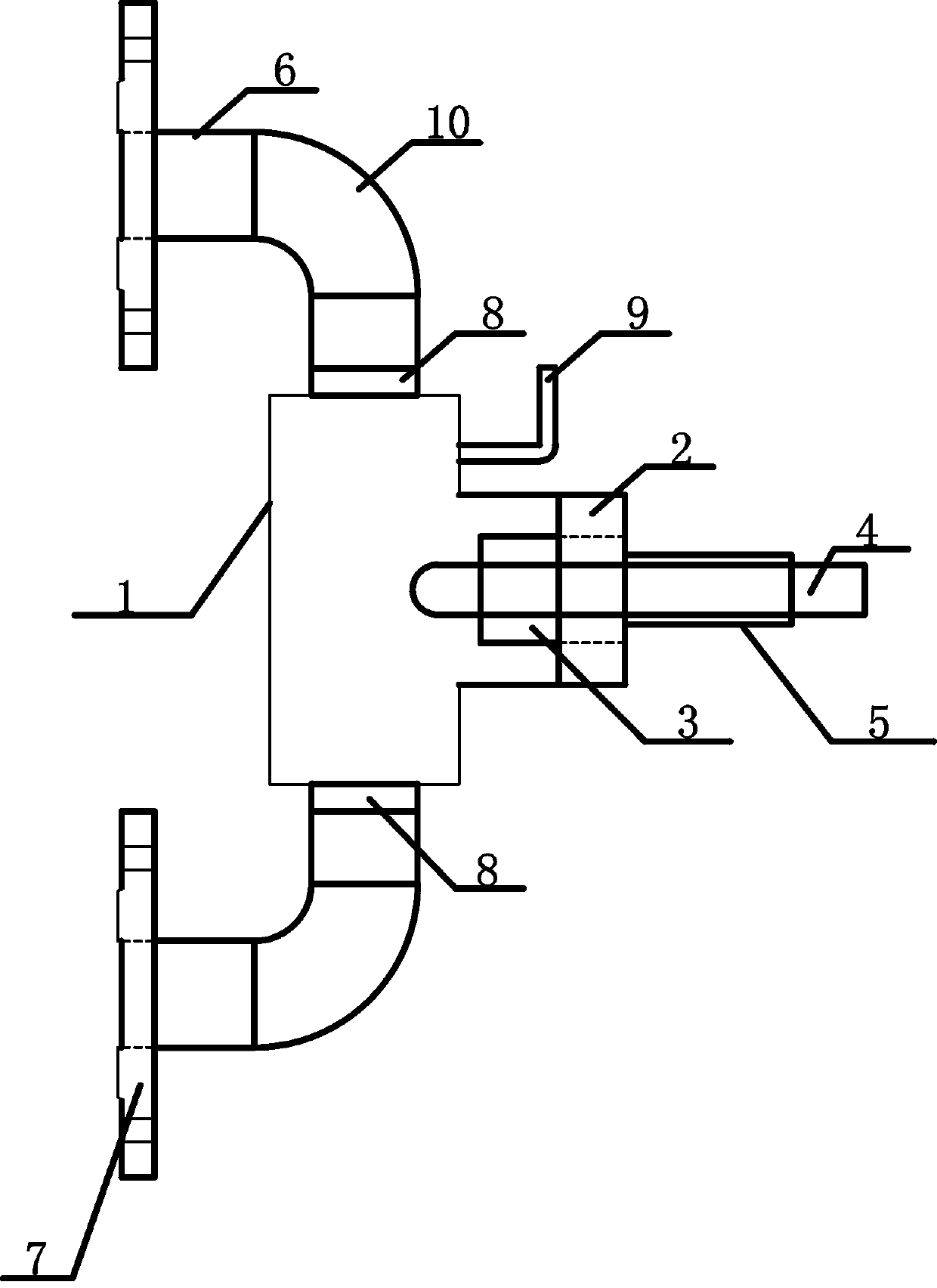

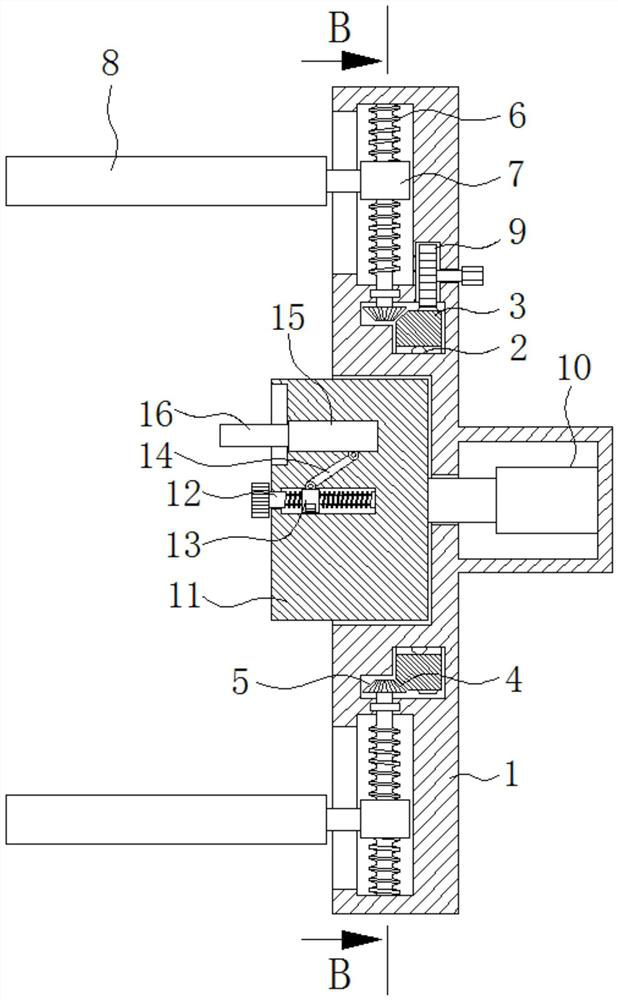

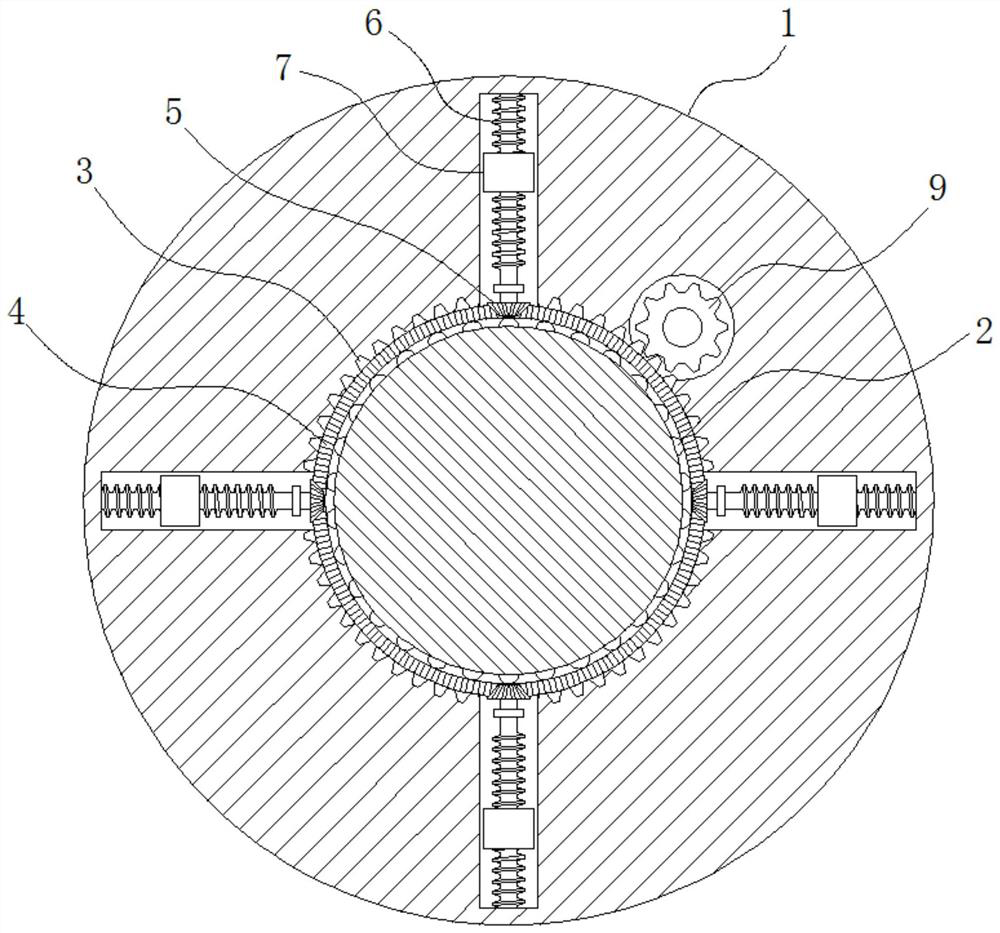

Viscous damper with hydraulic fusing function

ActiveCN107152486AImprove work efficiencyLow maintenanceSpringsNon-rotating vibration suppressionPistonViscous medium

The invention provides a viscous damper with a hydraulic fusing function. The viscous damper comprises a cylinder, a piston rod and a piston; the piston is mounted in the cylinder for dividing the cylinder into a first cavity and a second cavity; viscous mediums are filled in the first cavity and the second cavity; and the piston is provided with a first one-way valve for allowing the viscous mediums to flow from the first cavity to the second cavity and a second one-way valve for allowing the viscous medium to flow from the second cavity to the first cavity. The viscous damper has the advantages of high working efficiency and low maintenance cost.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

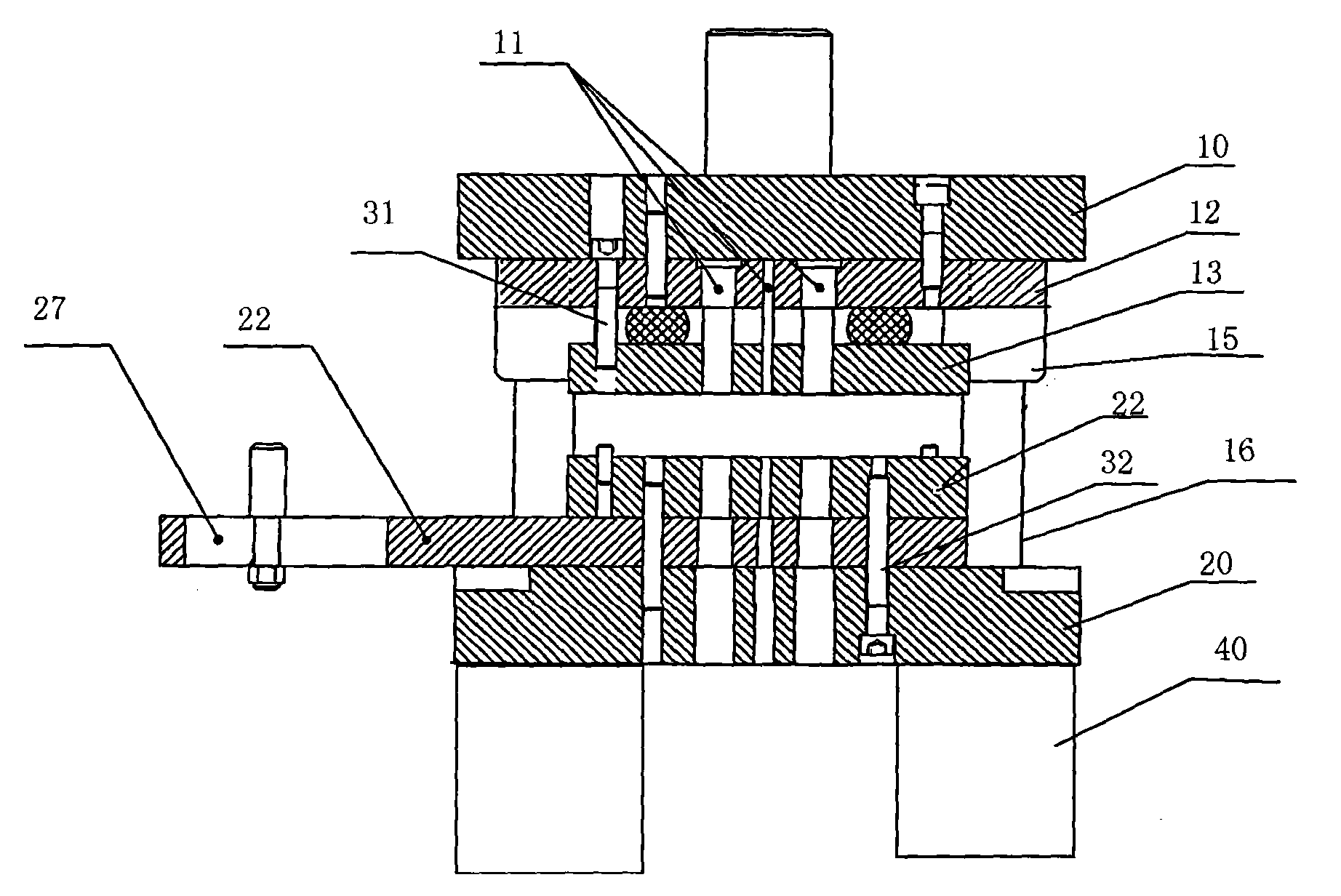

Blanking extrusion die for soldering lug

The invention discloses a blanking punch die for a soldering lug, comprising a terrace die, an upper padding plate blank, a striper plate and a concave die. The die also comprises a die pad arranged under the concave die and a second guide pin which is penetrated among a lower die base, the die pad and the striper plate, wherein at least one side of the die pad is protruded outside the concave die; an upper die base is provided with a guide sleeve and a sleeve column which are fixedly connected with the upper die base and the lower die base; the guide sleeve and the sleeve column are connected by adopting a rolling mode; and a chute is arranged on the part of the lower padding plate blank, which is protruded out from the concave die, and support parallels are arranged on the bottom of the lower die base. By mounting the second guide pin, the blanking punch die can produce two product blanking terminals in one punching stroke so as to improve the utilization ratio and production efficiency of punching plates; meanwhile, in the punching stroke, a strip plate is fed along a slide rail; after primary punching, the strip plate is moved towards one direction; and after the strip is moved for a certain distance, the strip plate is punched once again. Therefore, the punching process for a product with different lengths avoids repeatedly changing dies to ensure simple and quick operation.

Owner:昆山凯意工模具配套有限公司

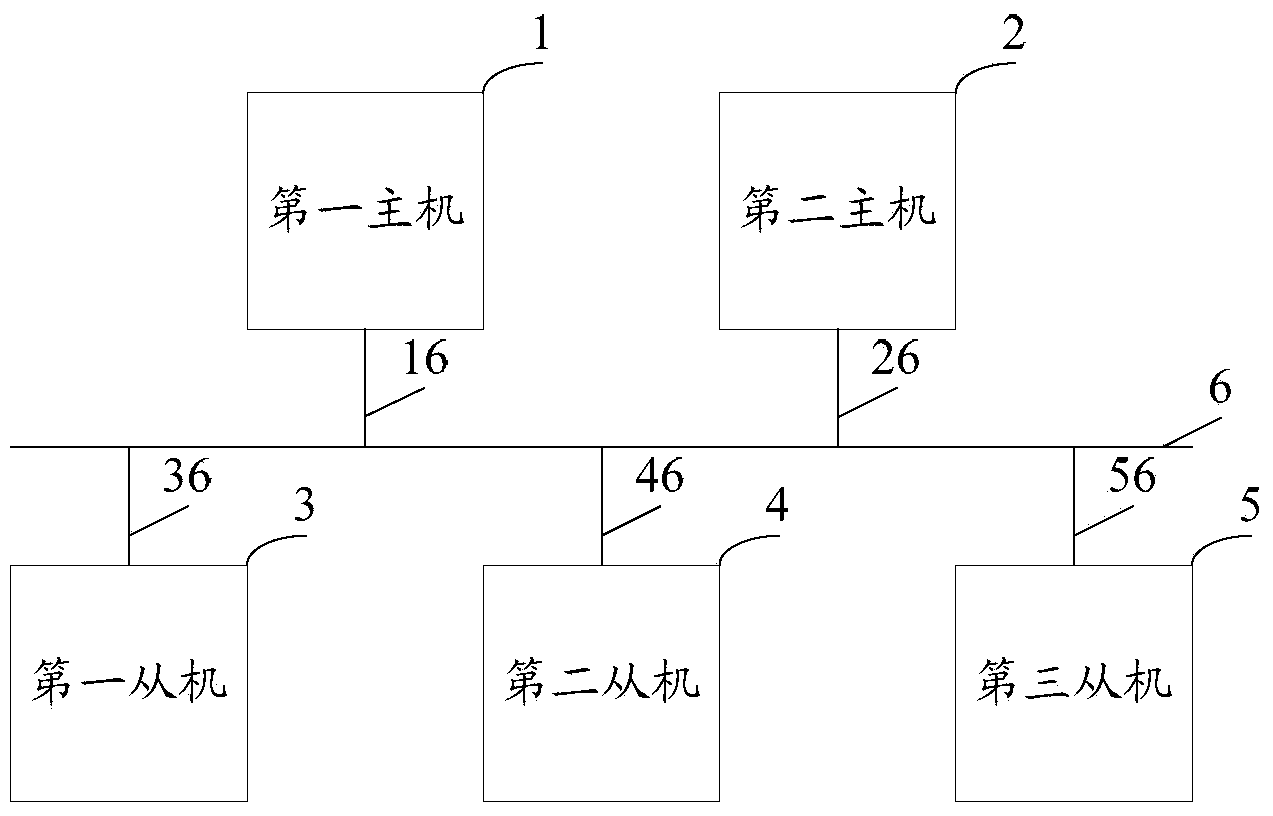

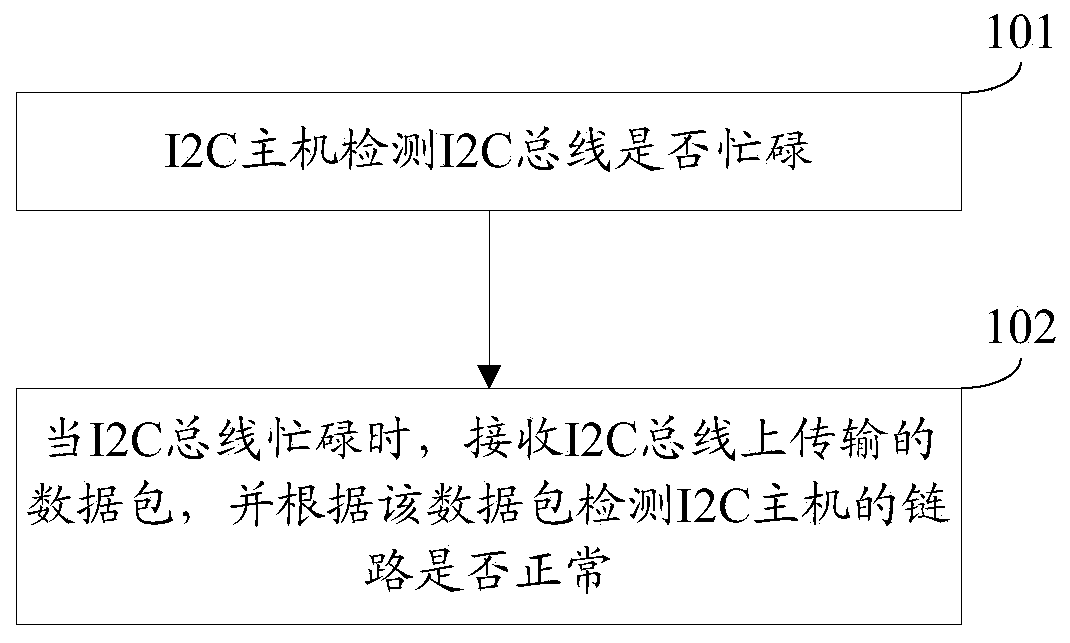

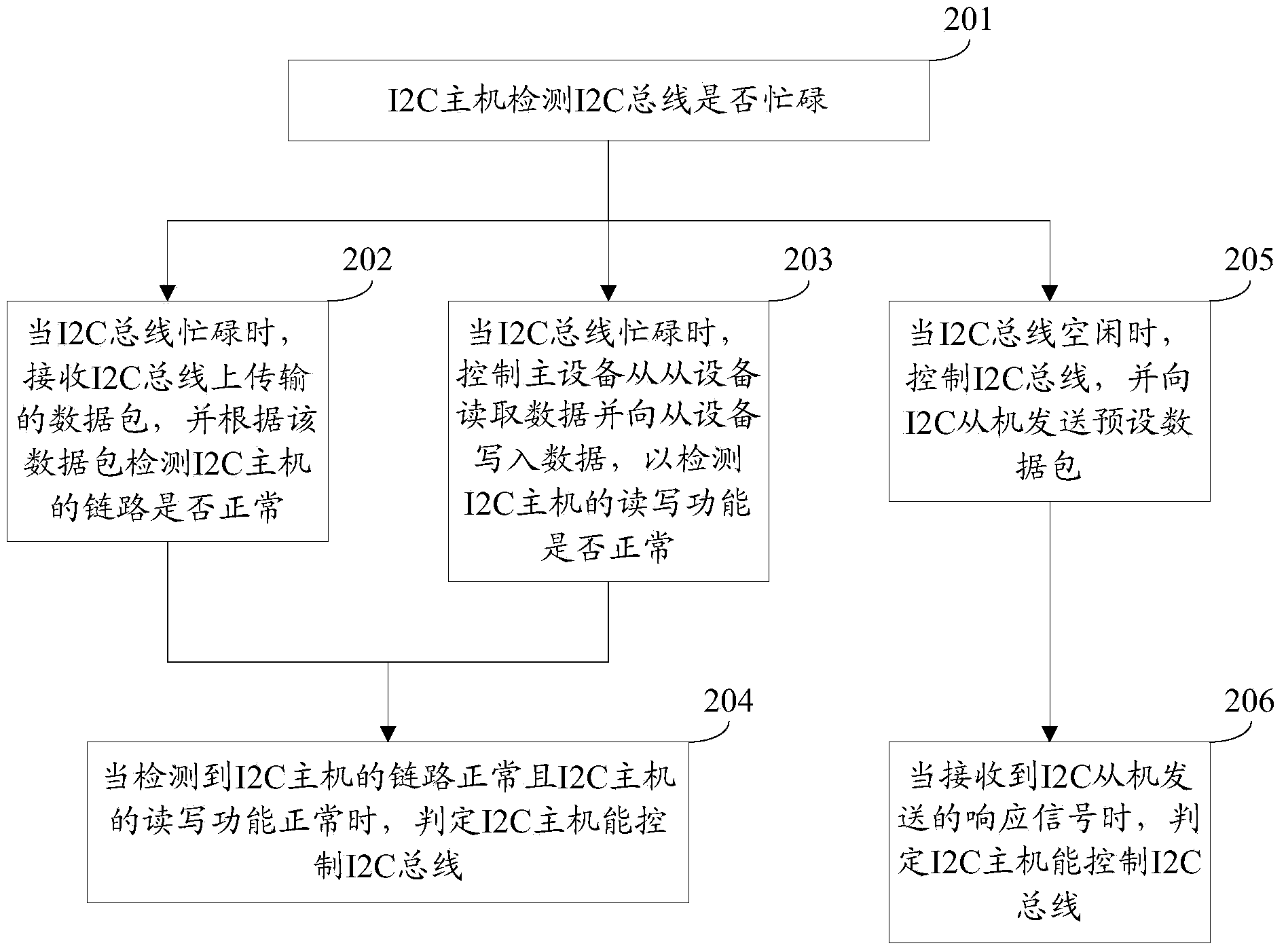

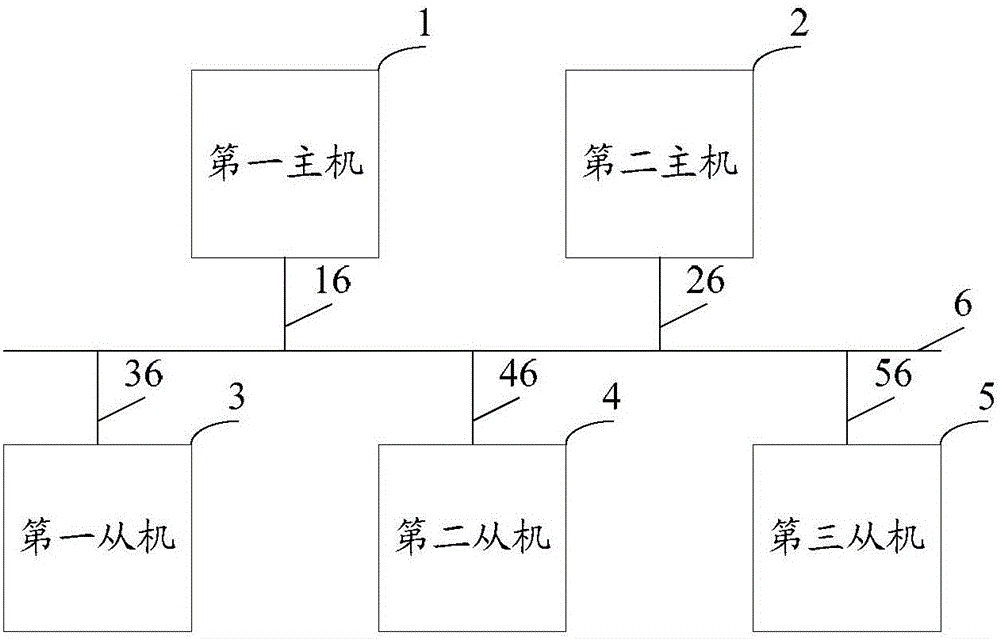

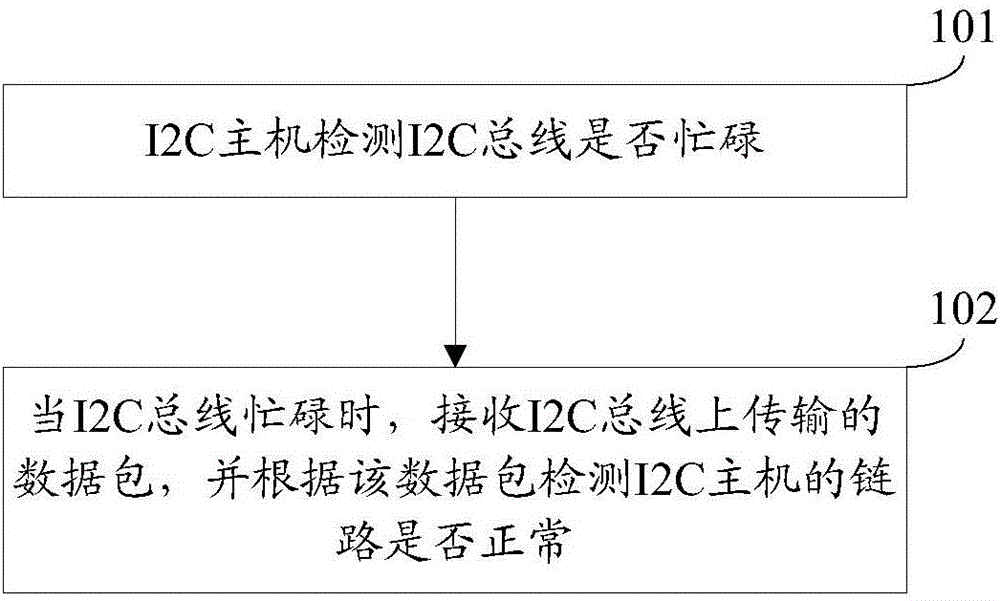

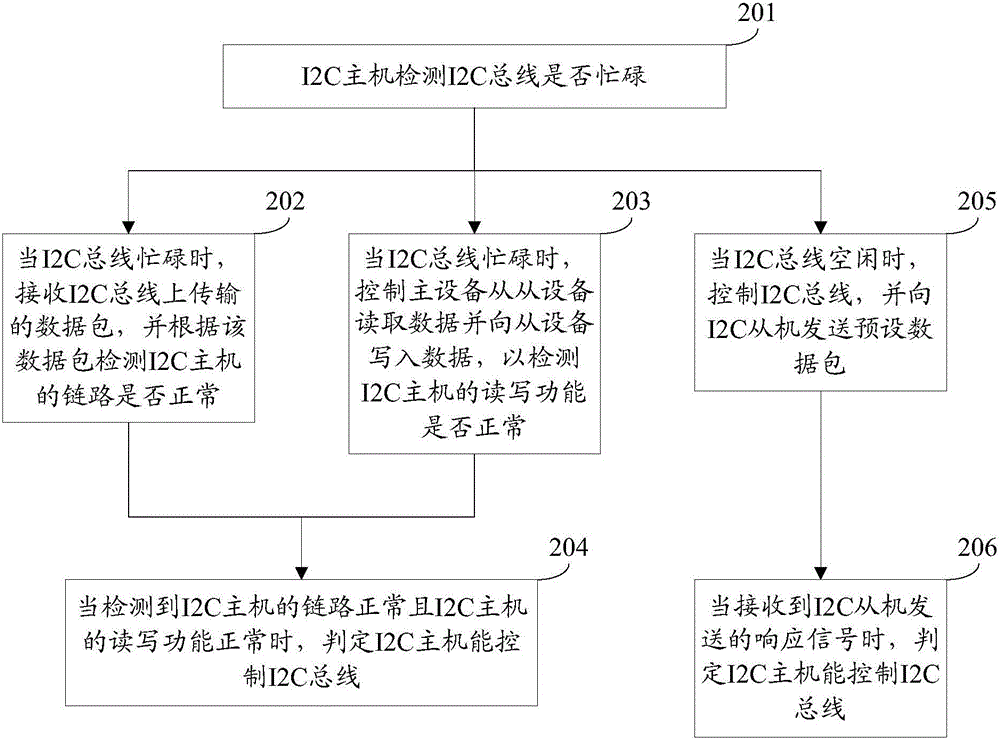

Self-inspection method and device of inter integrated circuit host and host

ActiveCN103530215AAvoid repeated replacementError detection/correctionNetwork packetIntegrated circuit

The invention discloses a self-inspection method and device of an inter integrated circuit host and the host, and belongs to the technical field of communication. The method comprises the steps that the I2C host detects whether an I2C bus is busy; when the I2C bus is busy, data packets transmitted on the I2C bus are received, and whether a link of the I2C host is normal is detected according to the data packets. According to the method, when the I2C bus is busy, the data packets transmitted on the I2C bus are received, whether the link of the I2C host is normal is detected according to the data packets, and therefore it is not necessary to wait to conduct self-inspection of the I2C host when the I2C bus is free, self-inspection can be conducted in real time, and the problem that when the I2C host waits for self-inspection, the I2C host controlling the I2C bus at present breaks down and cannot be replaced by a spare I2C host, and therefore the I2C host controlling the I2C bus is changed repeatedly is solved.

Owner:XFUSION DIGITAL TECH CO LTD

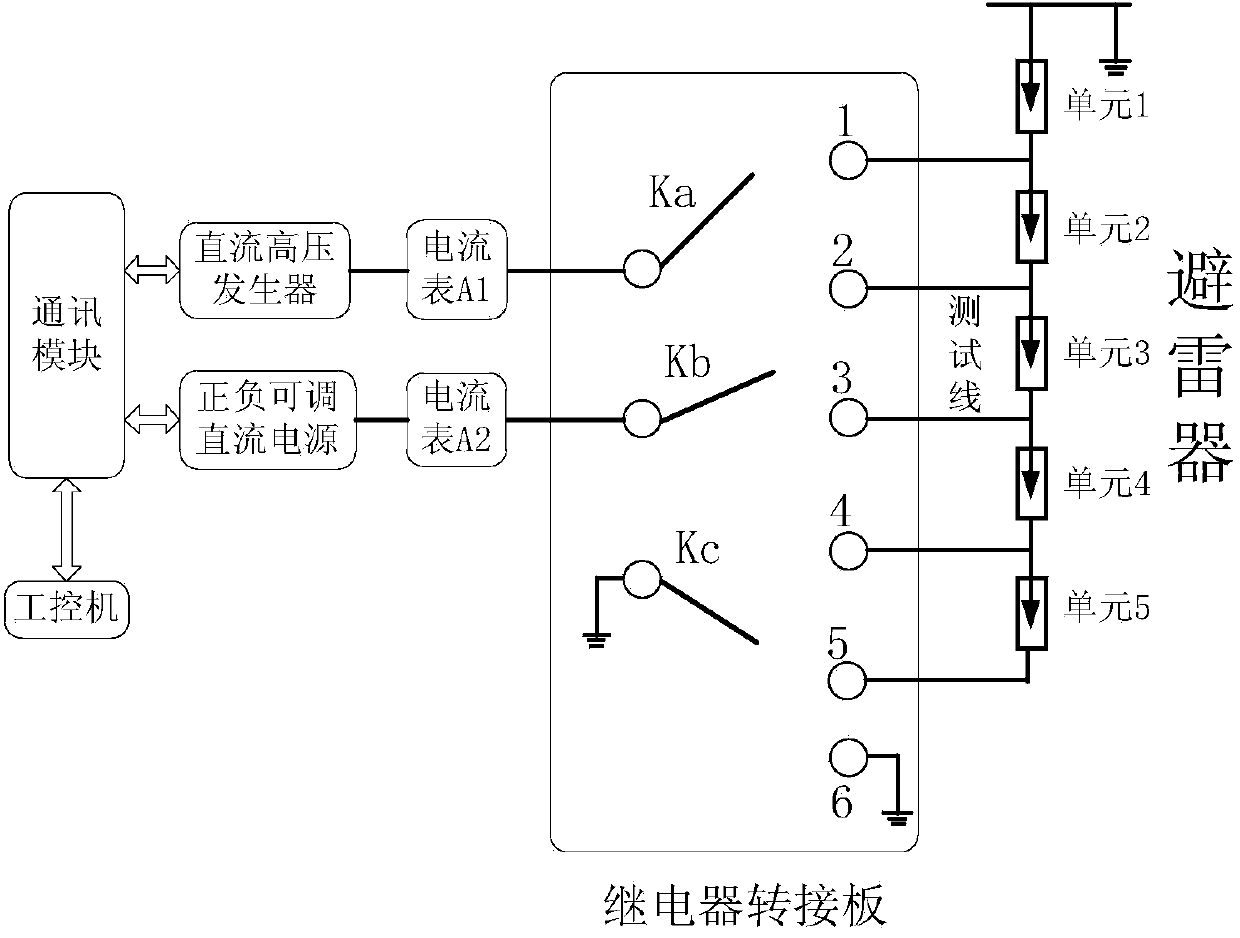

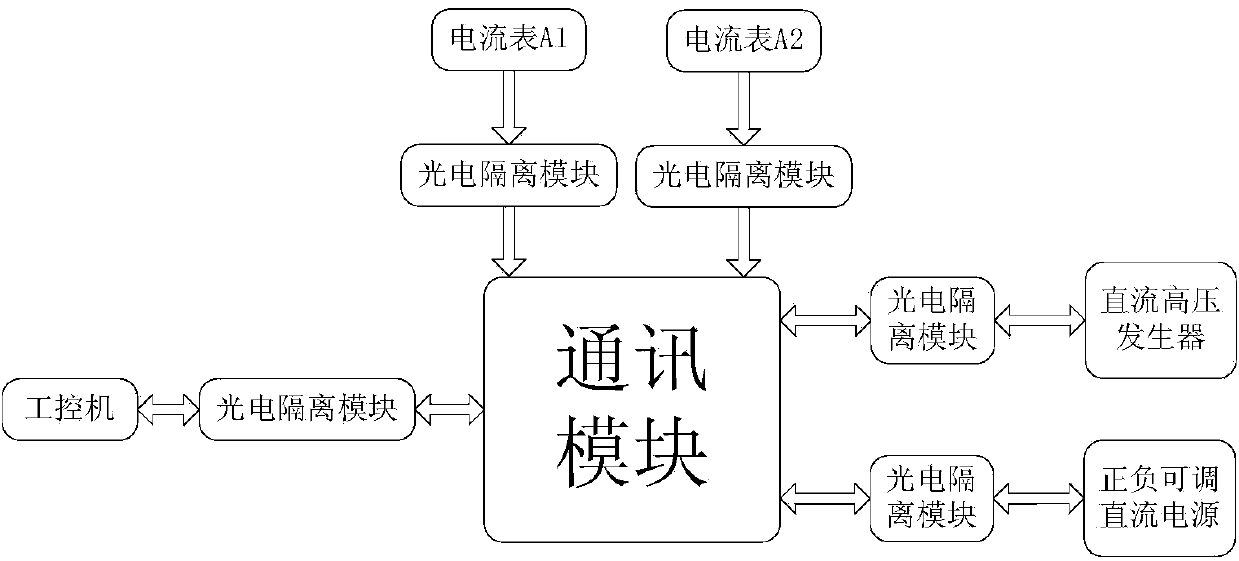

One-step wiring device and method for testing 1000kV lightning arrester reference voltage and leakage current

ActiveCN103630729AEasy wiringAvoid repeated wiring changesCurrent/voltage measurementElectrical testingVoltage referencePersonal computer

The invention discloses a one-step wiring device and a one-step wiring method for testing 1000kV lightning arrester reference voltage and leakage current. The device comprises an industrial personal computer, a communication module, a direct-current high-voltage generator, a positive and negative adjustable direct-current power supply, an ampere meter A1, an ampere meter A2 and a relay adapter board, wherein the industrial personal computer is connected with the direct-current high-voltage generator and the positive and negative adjustable direct-current power supply through the communication module to realize data communication, the direct-current high-voltage generator and the positive and negative adjustable direct-current power supply are respectively and serially connected with the ampere meters and then are connected with relays on the relay adapter board, and the relay adapter board is connected with a tested lightning arrester through a testing line. The method provided by the invention has the advantages that the wiring is convenient to perform, the testing items of all lightning arrester units can be completed through one-step wiring, the repetitive replacement of wires is avoided, the time of power outage is shortened, the time and the labor are saved and the application prospect is good.

Owner:STATE GRID CORP OF CHINA +2

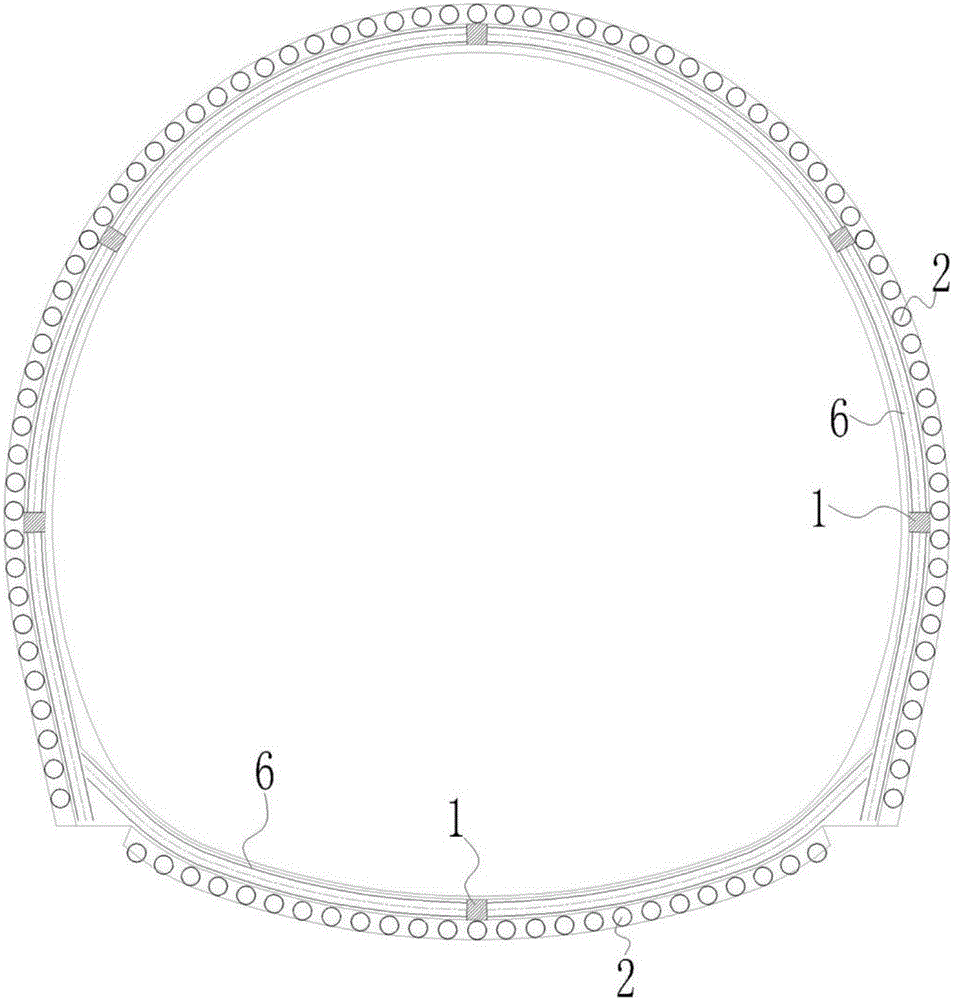

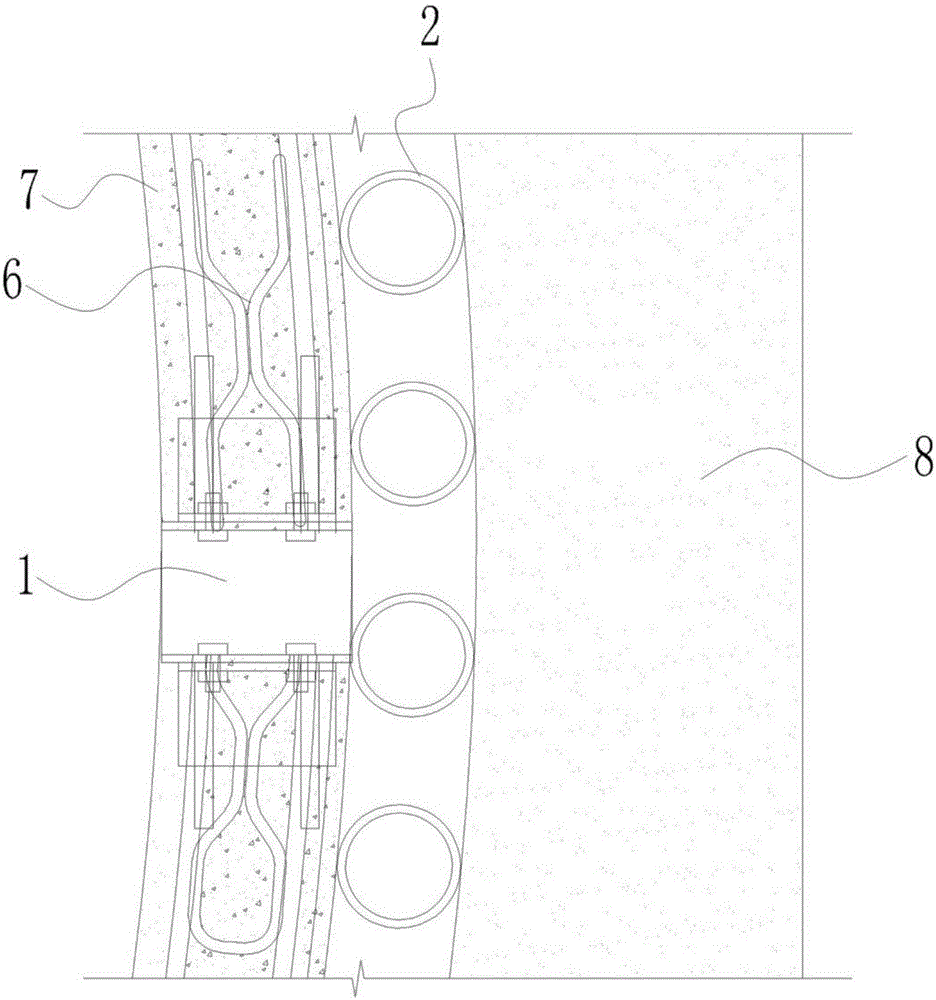

Large-stroke combined damper utilizing post-peak performance of materials

ActiveCN107524457AAvoid repeated replacementLow costUnderground chambersTunnel liningSnubberEngineering

The invention provides a large-stroke combined damper utilizing the post-peak performance of materials. The large-stroke combined damper comprises a circumferential damper and a radial damper, and the circumferential damper and the radial damper are arrayed around the inner side of a tunnel to form a ring; the circumferential damper is fixedly installed in the tunnel, and the deformation direction is in the circumferential direction of the tunnel; the radial damper is fixedly installed in the tunnel, and the deformation direction is in the radial direction of the tunnel; the circumferential damper is positioned on the inner side of the radial damper. Supporting and deformation can not only be provided in the circumferential direction of the tunnel, but also can be provided in the radial direction of the tunnel, stress of the tunnel is effectively released, so that the tunnel structure is more stable and reliable.

Owner:仇文革

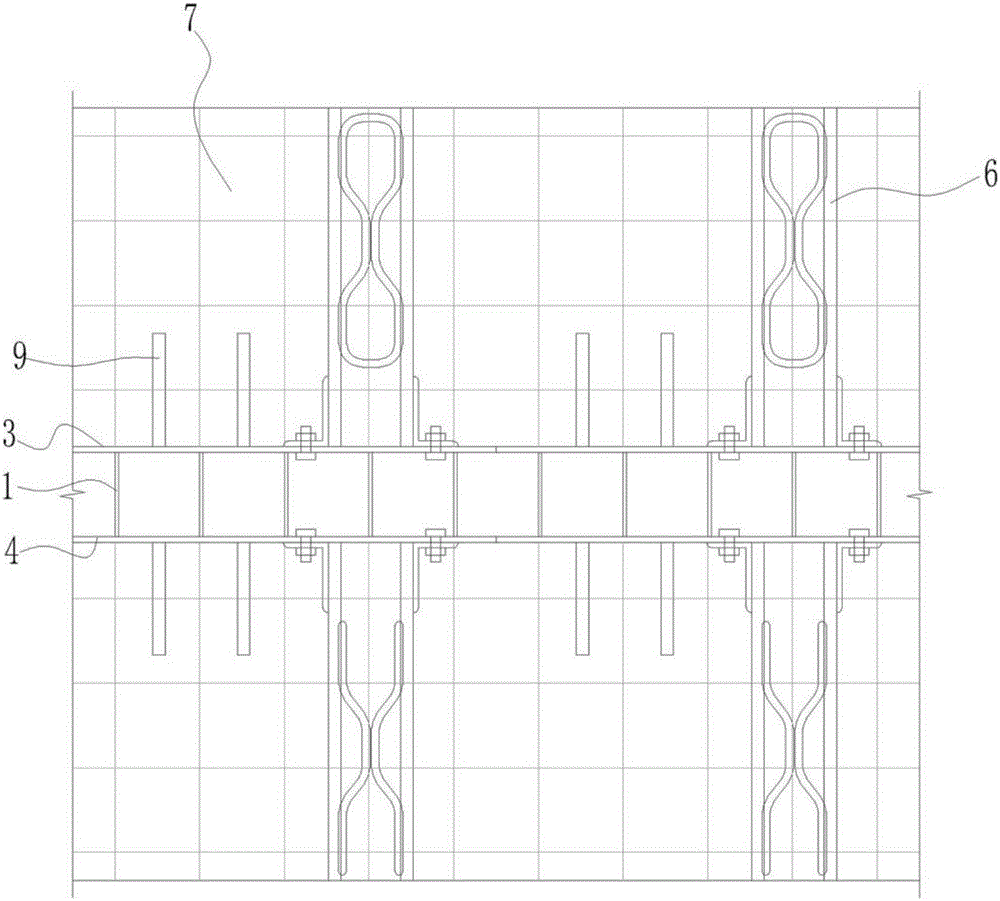

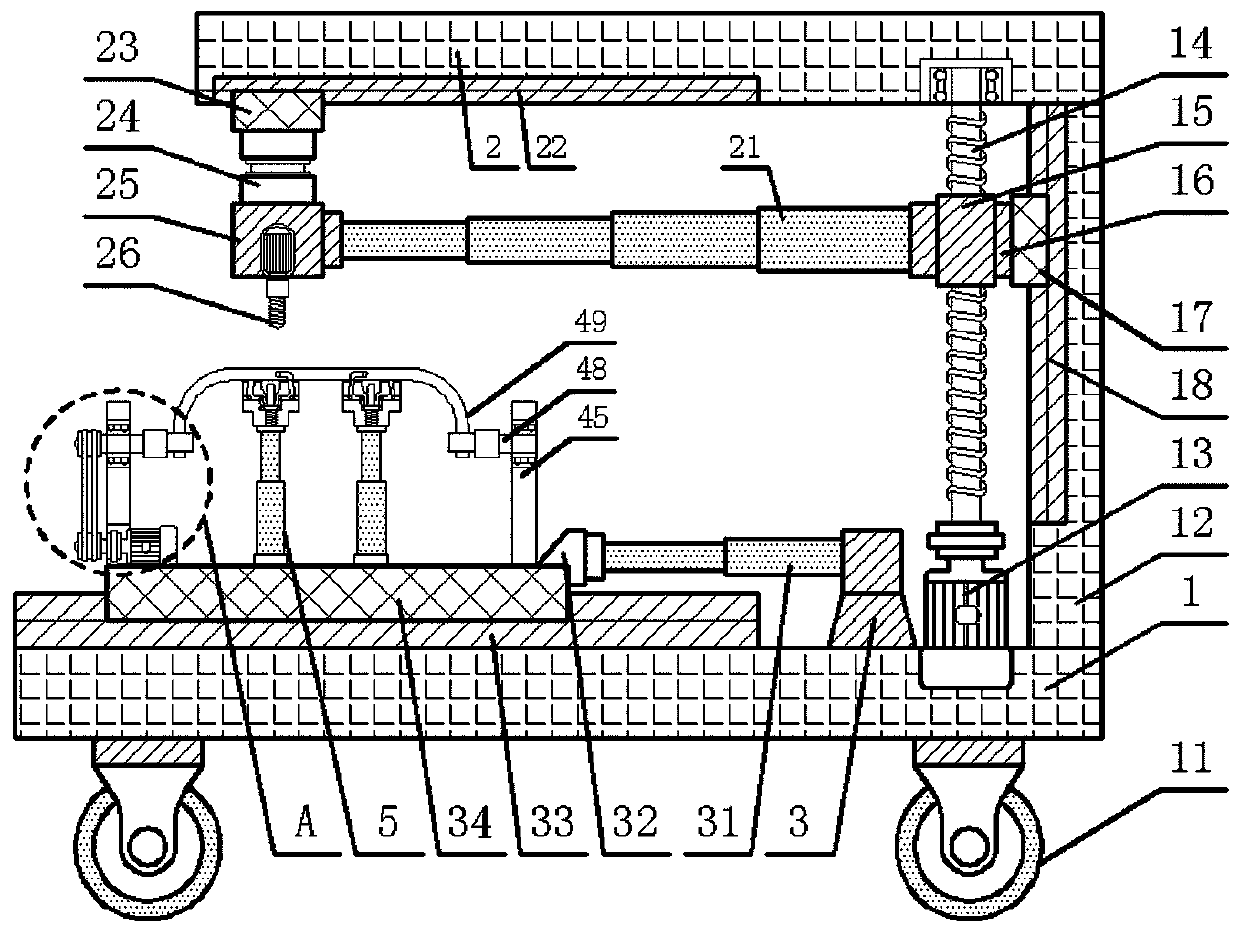

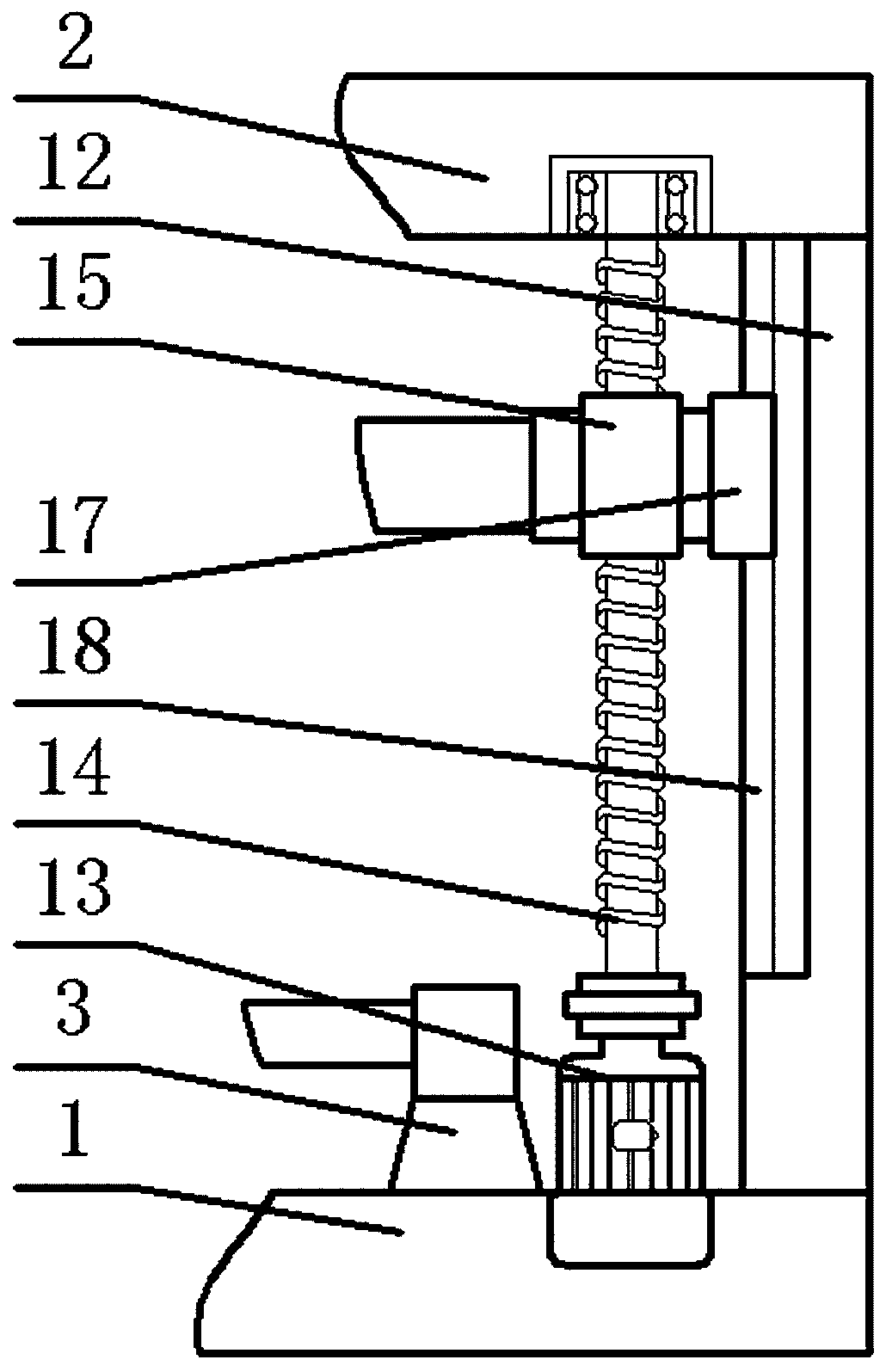

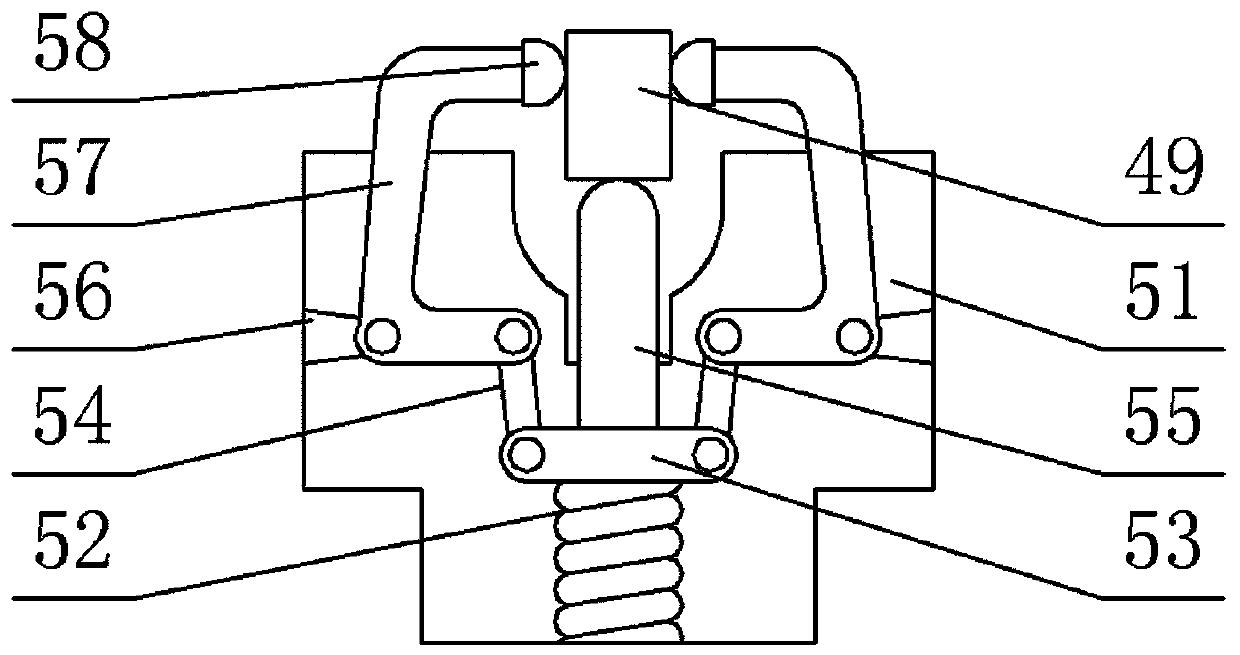

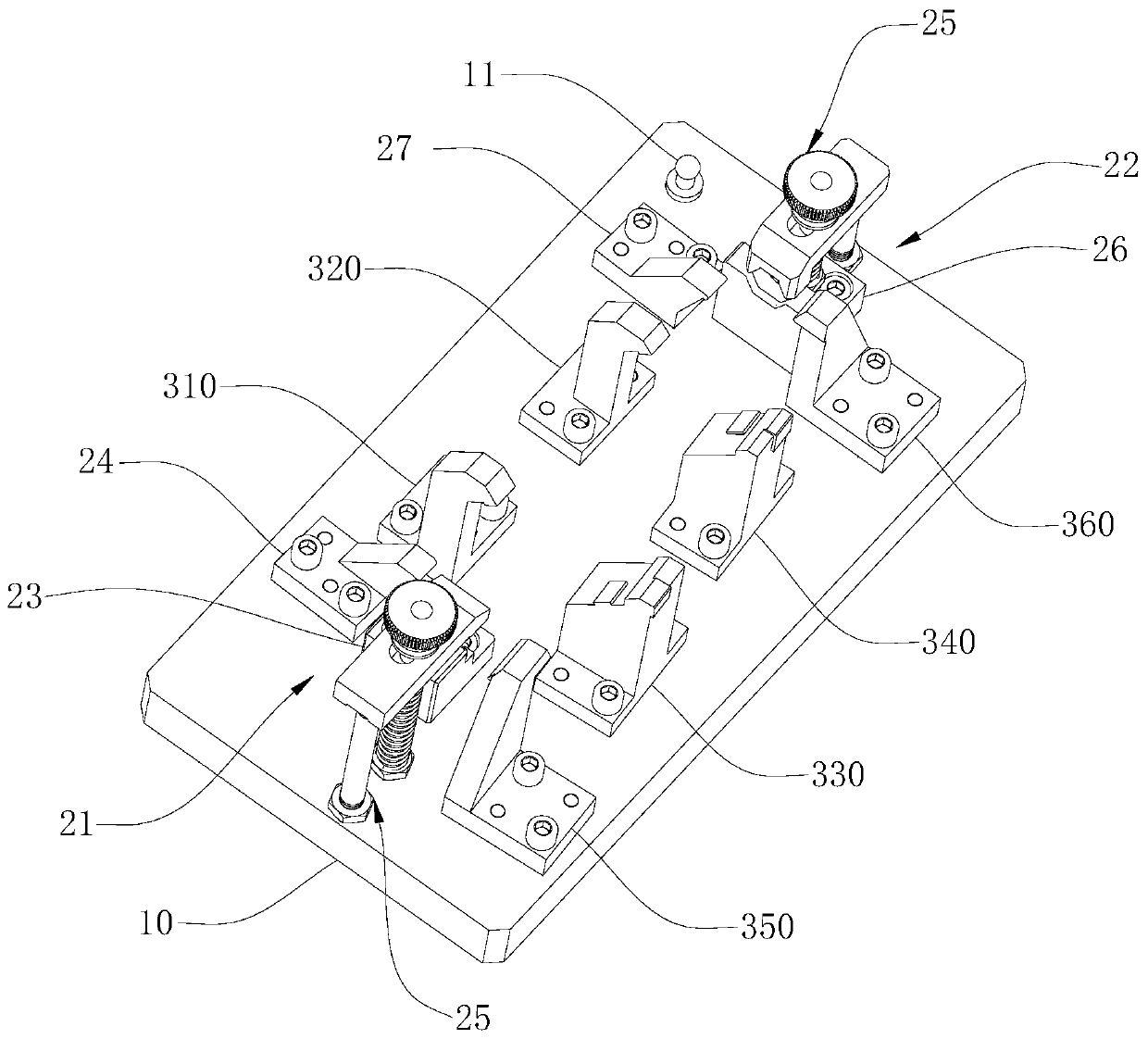

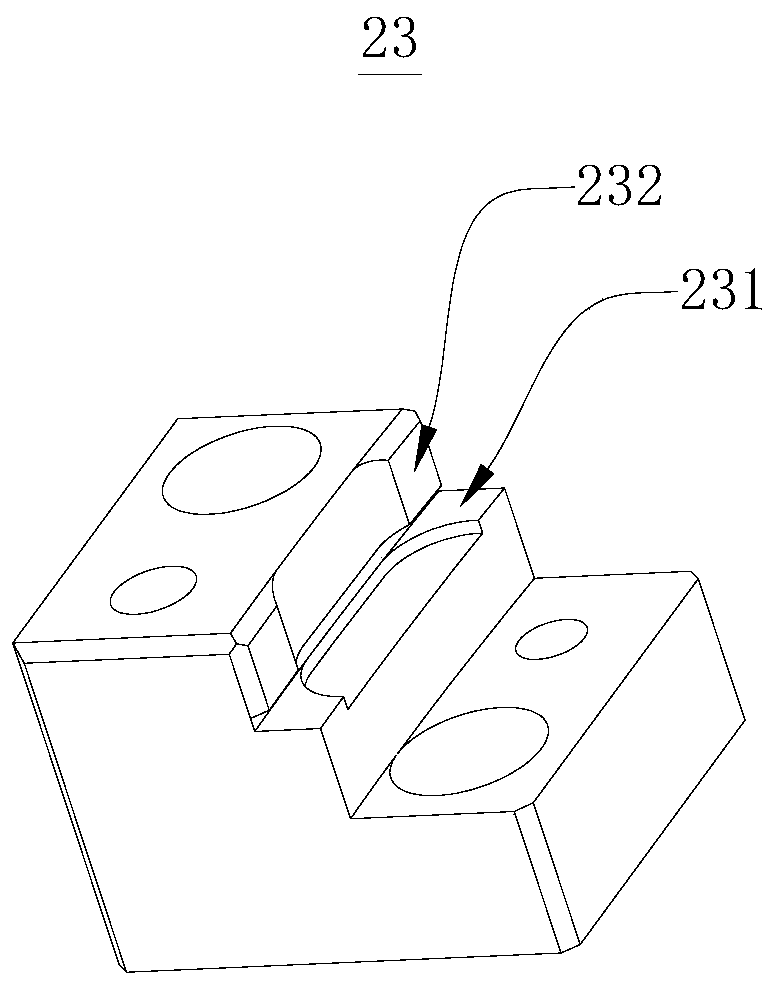

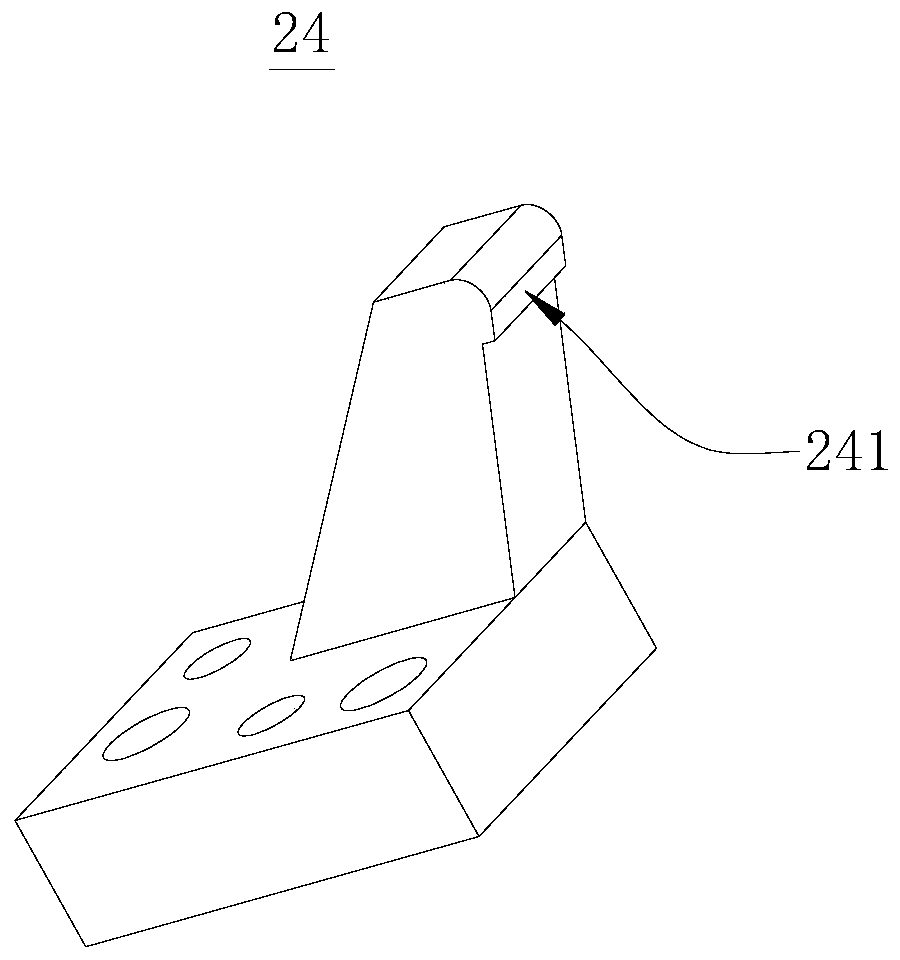

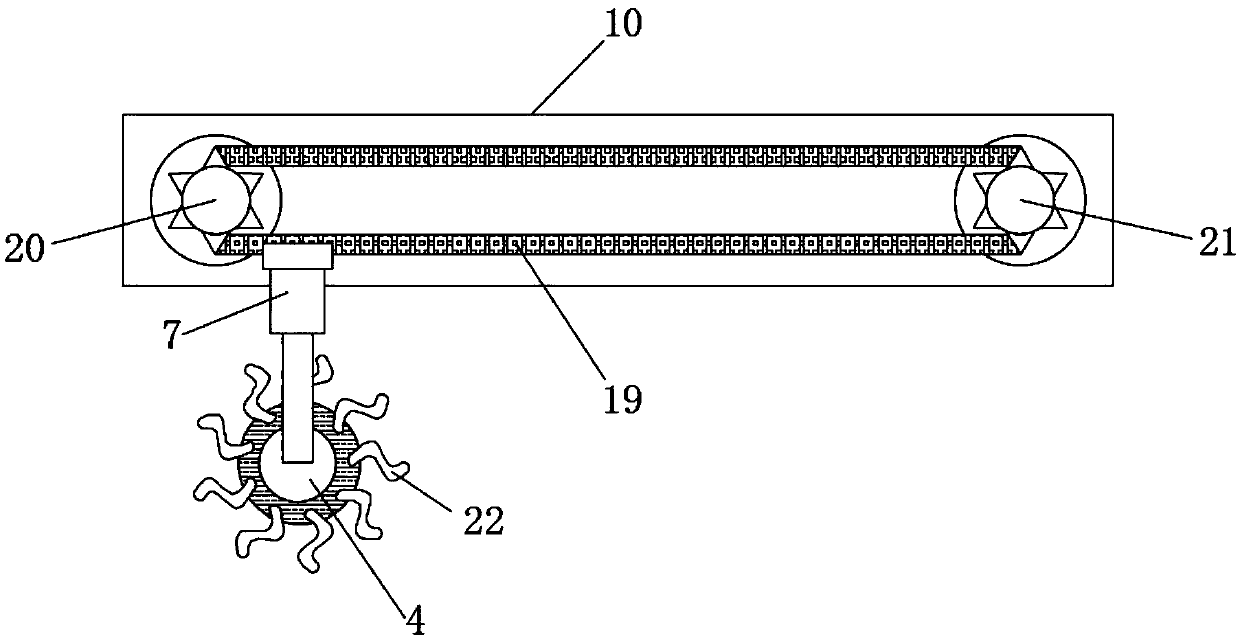

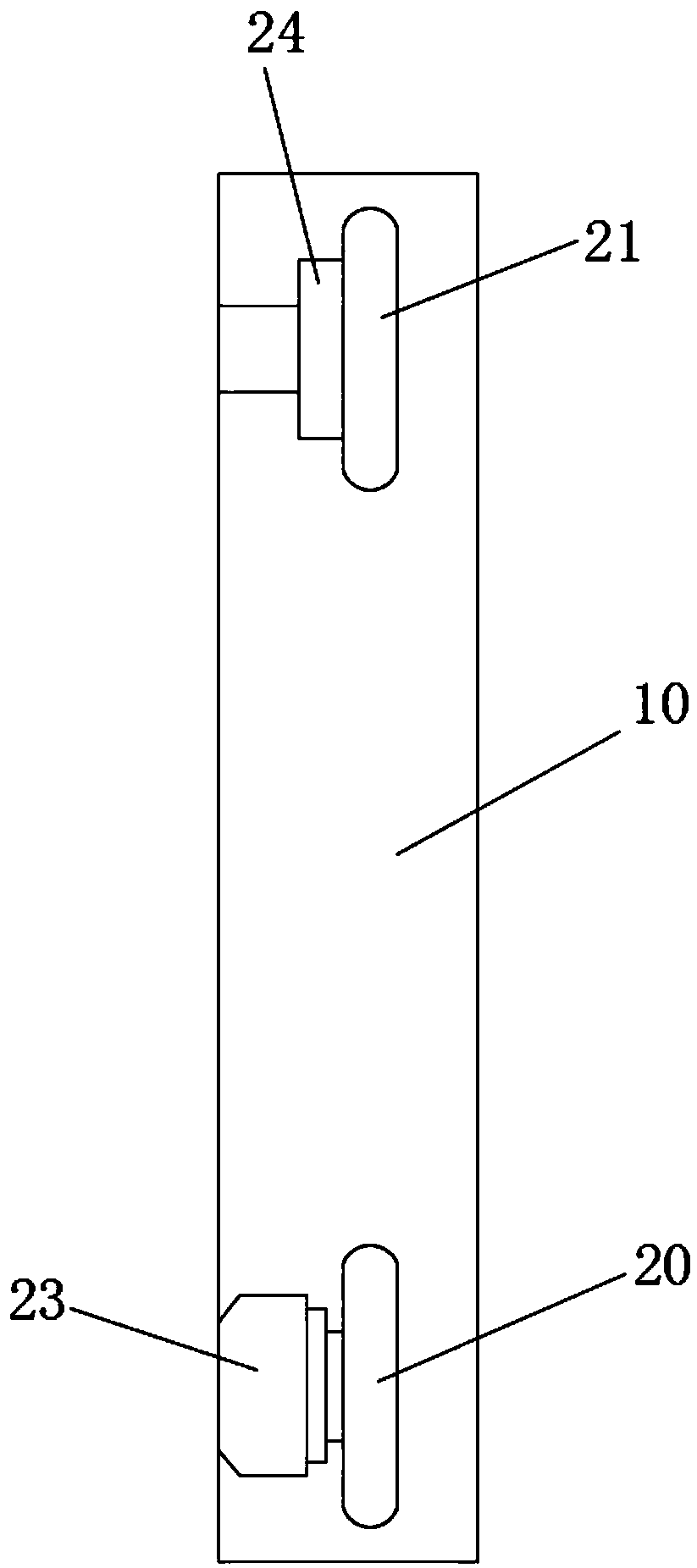

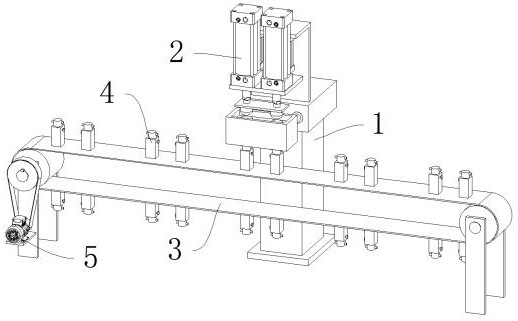

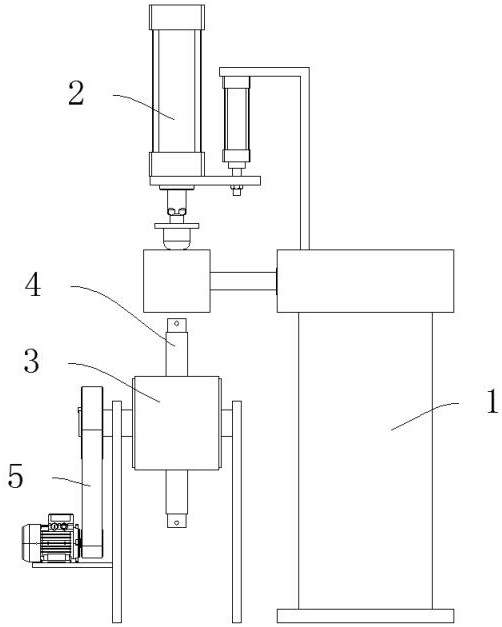

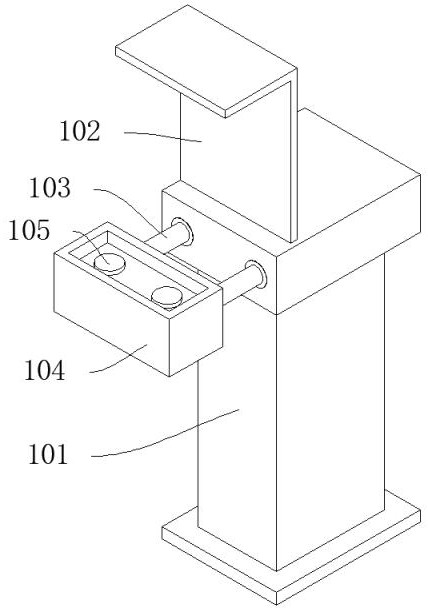

Milling machine fixing tool for intelligent carbon contact strip milling and using method of tool

ActiveCN111054957AConvenient for milling workReduce labor burdenWork clamping meansFeeding apparatusStrip millSlide plate

The invention discloses a milling machine fixing tool for intelligent carbon contact strip milling. The tool comprises a bottom plate and a carbon contact strip, and two ends of the carbon contact strip are respectively inserted into corresponding limit cylinders; a pair of rectangular block-shaped third bases are arranged at the center of the top surface of a first slide plate, a third telescopiccylinder with output facing upward is installed at the top surface of each third base, and the telescopic cylinder end part of each third telescopic cylinder is clamped with two sides of the middle of the carbon contact strip through a clamping mechanism; the other side of the top surface of the bottom plate is vertically provided with a rectangular long plate-shaped vertical plate, and a liftingmechanism is arranged at the inner end surface of the vertical plate; and a rectangular long plate-shaped horizontal plate is horizontally arranged directly above the bottom plate, a driving mechanism is arranged on one side of the bottom surface of the horizontal plate, and the other end of the bottom surface of the horizontal plate is fixedly connected with the top surface of the vertical plate. The invention also discloses a using method of the milling machine fixing tool for the intelligent carbon contact strip milling. By designing a complete set of tool structure, the tool can meet theprocessing requirements of a carbon contact strip airway, is convenient for disassembly and assembly, and can adapt to different heights of structures.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

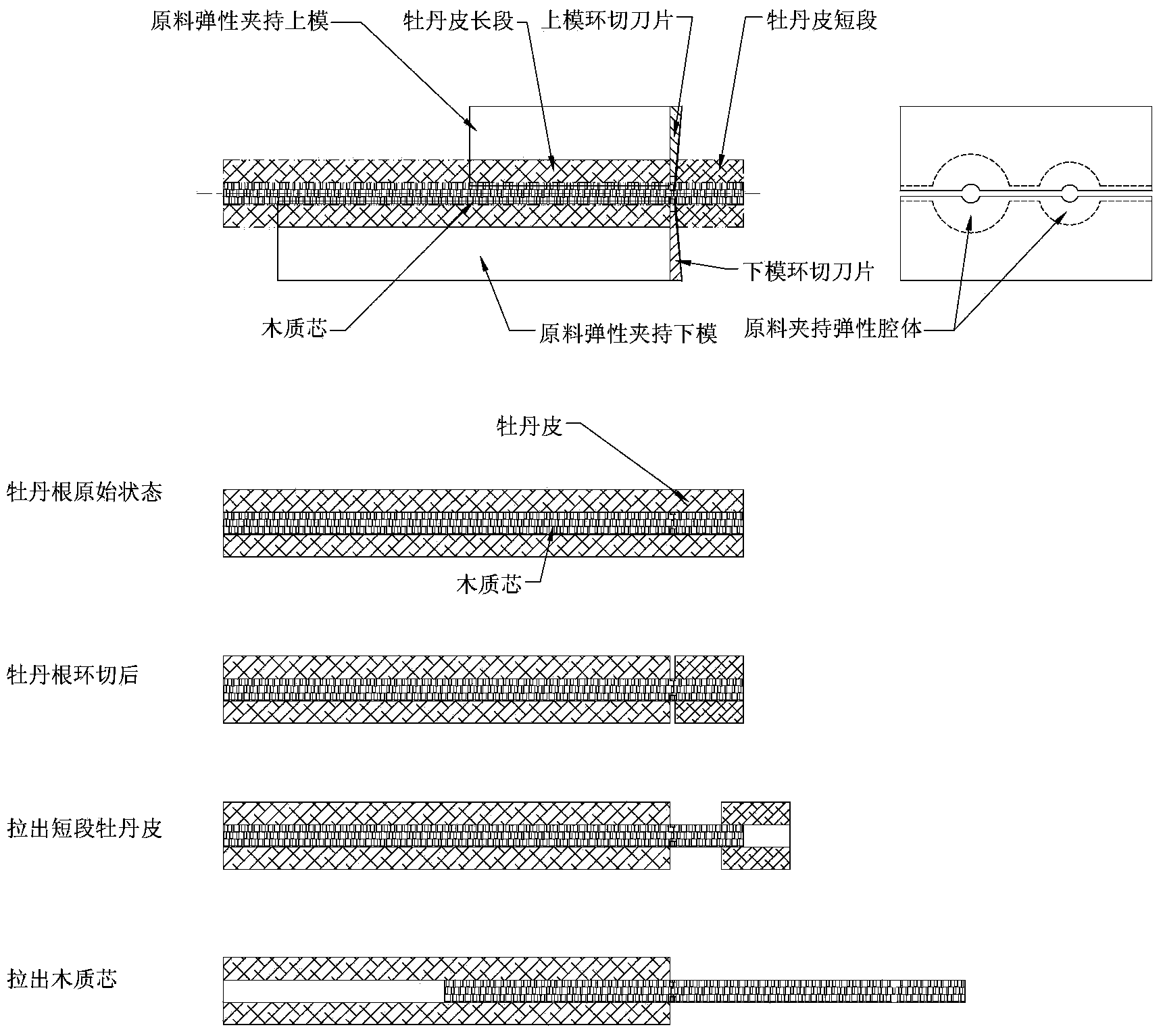

Method for peeling moutan bark

InactiveCN103405519AComplete disengagementAvoid breakingPlant ingredientsMechanical engineeringRhizome

The invention aims to provide a method for peeling moutan bark. According to the method for peeling the moutan bark, by properly and stably clamping and positioning moutan rootstalks and circularly cutting the moutan rootstalks at end part positions of an upper die and a lower die, the moutan bark is cut off, a wooden core is not cut off and is clamped by a flexible material, then a cut short end is pulled outwards to be separated from a body, and the wooden core is clamped again to be separated from the moutan bark at the long end, so as to realize the complete separation of the moutan bark, so that a finished product of the moutan bark is prevented from being fractured or crushed, and the appearance of the product is better; meanwhile, a raw material clamping die used in the method is produced by lining an elastic material to the inner cavity made of the elastic or a rigid material, so that not only a shell of the raw material clamping die can be protected, but also the raw material clamping die can be suitable for the raw materials with different thicknesses in a certain range, the repeated exchanging of the die is avoided, and the labor time is saved.

Owner:铜陵禾田中药饮片股份有限公司 +2

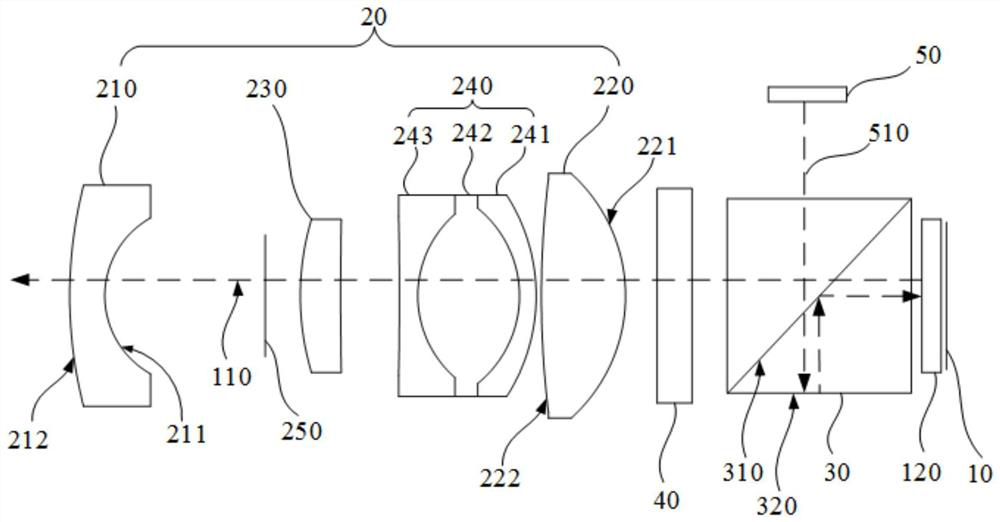

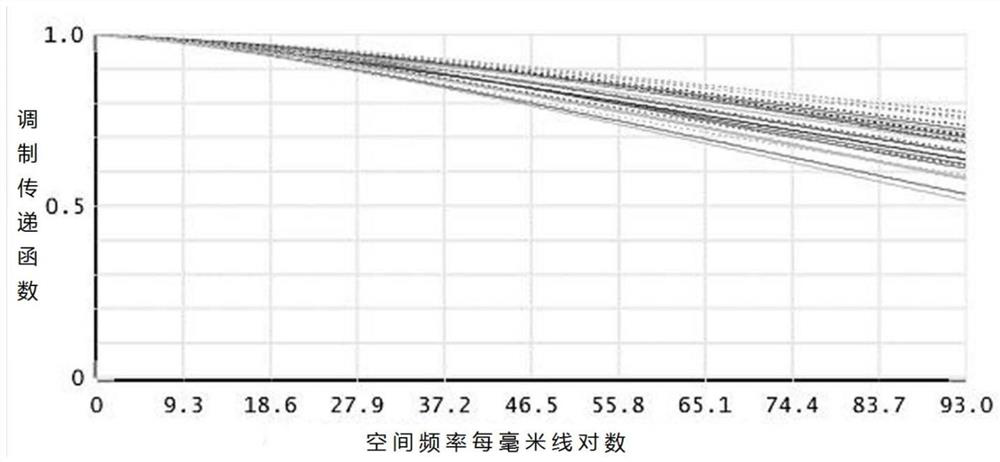

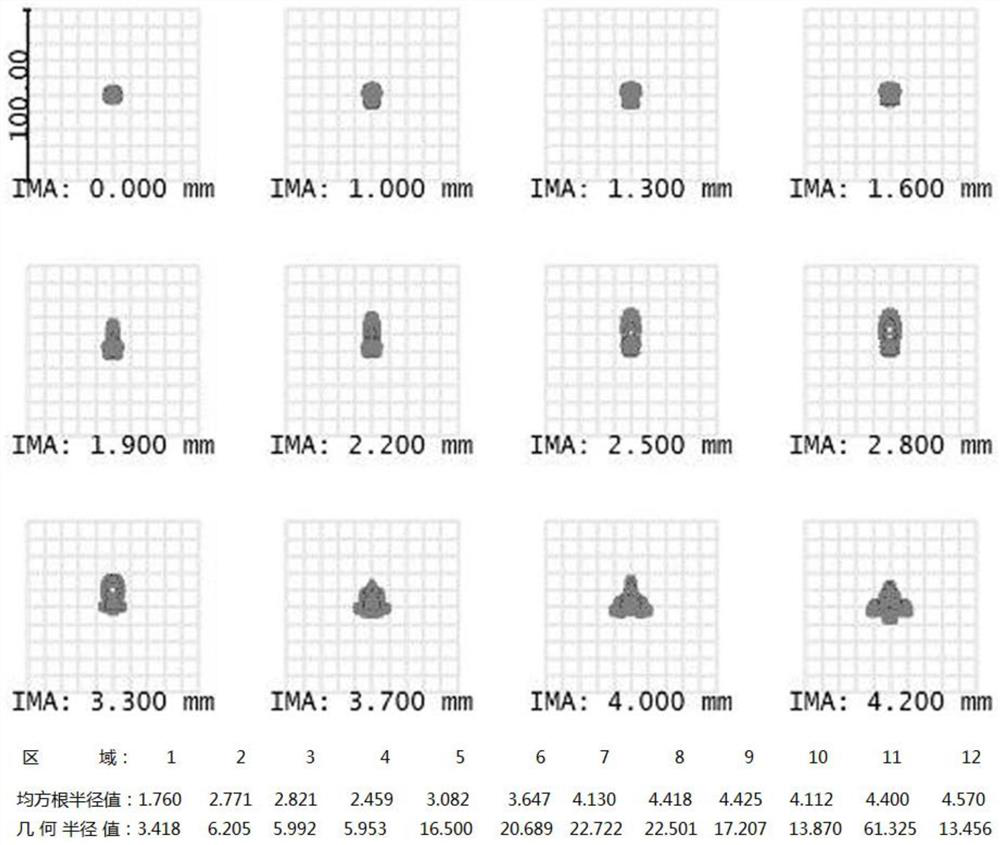

Projection lens and projection equipment

PendingCN112255767AReduce aberrationAvoid repeated lens changesProjectorsOptical elementsPhysicsGalvanometer

The invention discloses a projection lens and projection equipment, the projection lens is provided with a light incoming end for receiving projection light and a light outgoing end for emitting the projection light, the projection lens comprises a first lens, a second lens, a third lens and a cemented lens, and the first lens is arranged at the light outgoing end; a galvanometer is arranged at the light incoming end, the second lens and the third lens are sequentially arranged in a light path from the galvanometer to the first lens, the first lens is a negative lens, and the second lens and the third lens are positive lenses; and the cemented lens is arranged in a light path between the second lens and the third lens. According to the technical scheme, repeated replacement of the lens canbe avoided, and use is more flexible and convenient.

Owner:GOERTEK OPTICAL TECH CO LTD

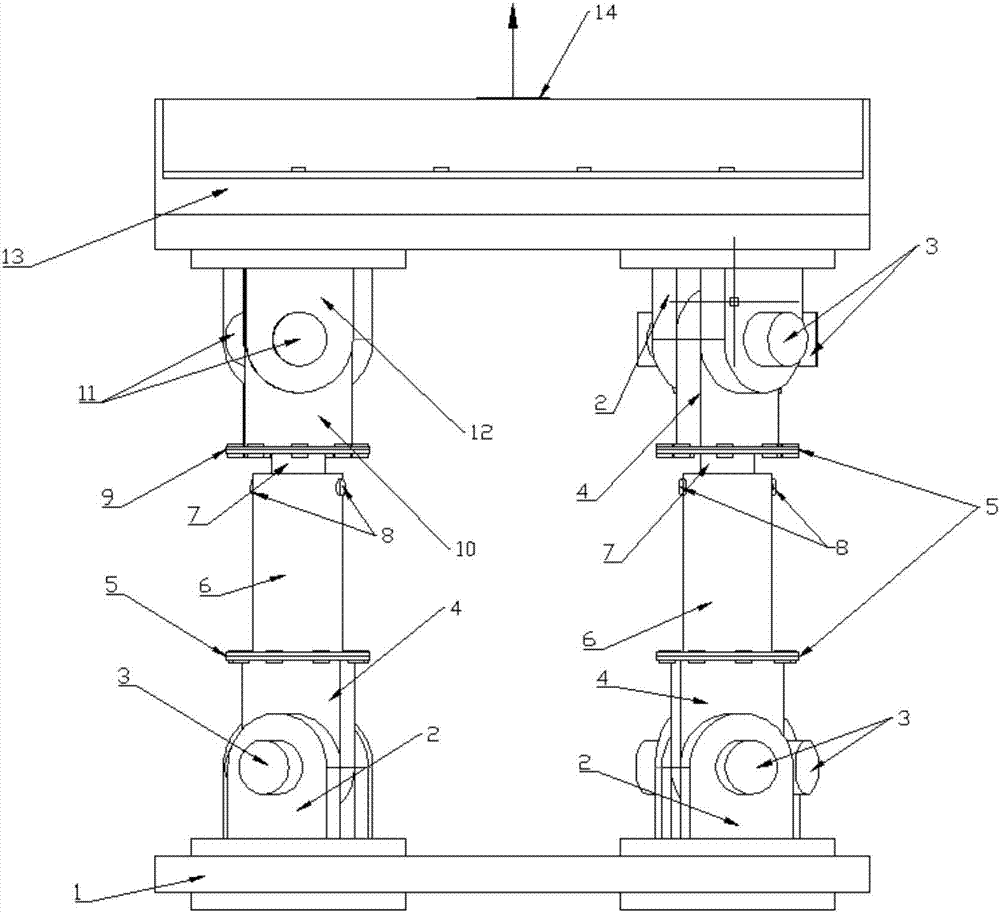

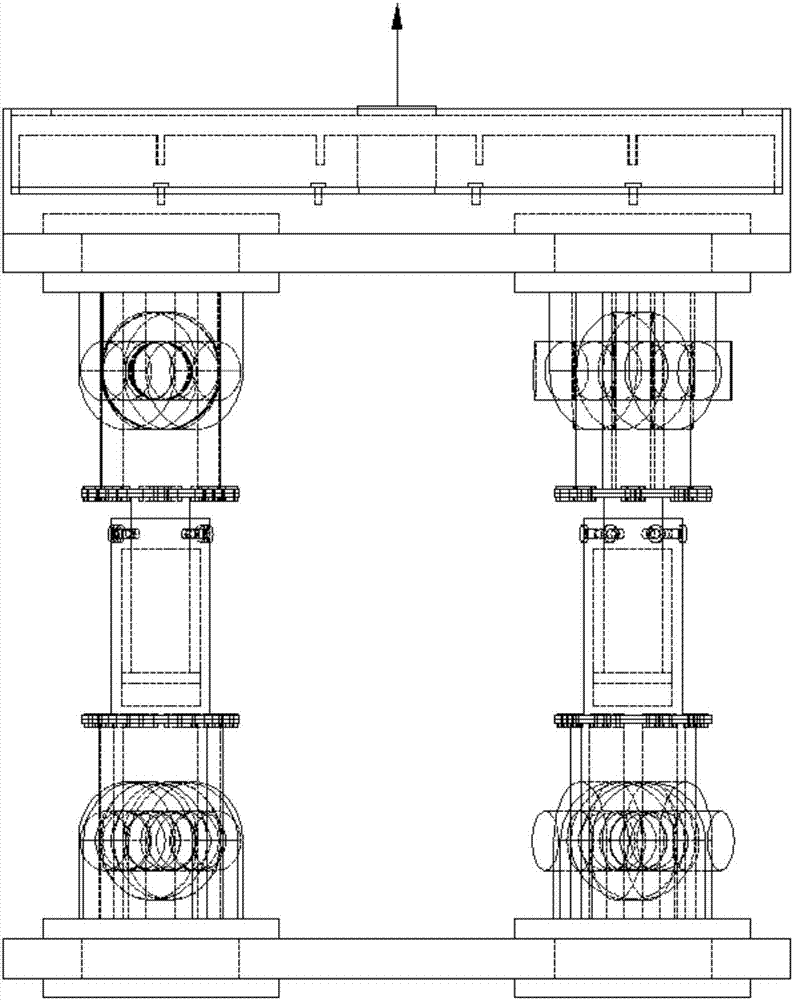

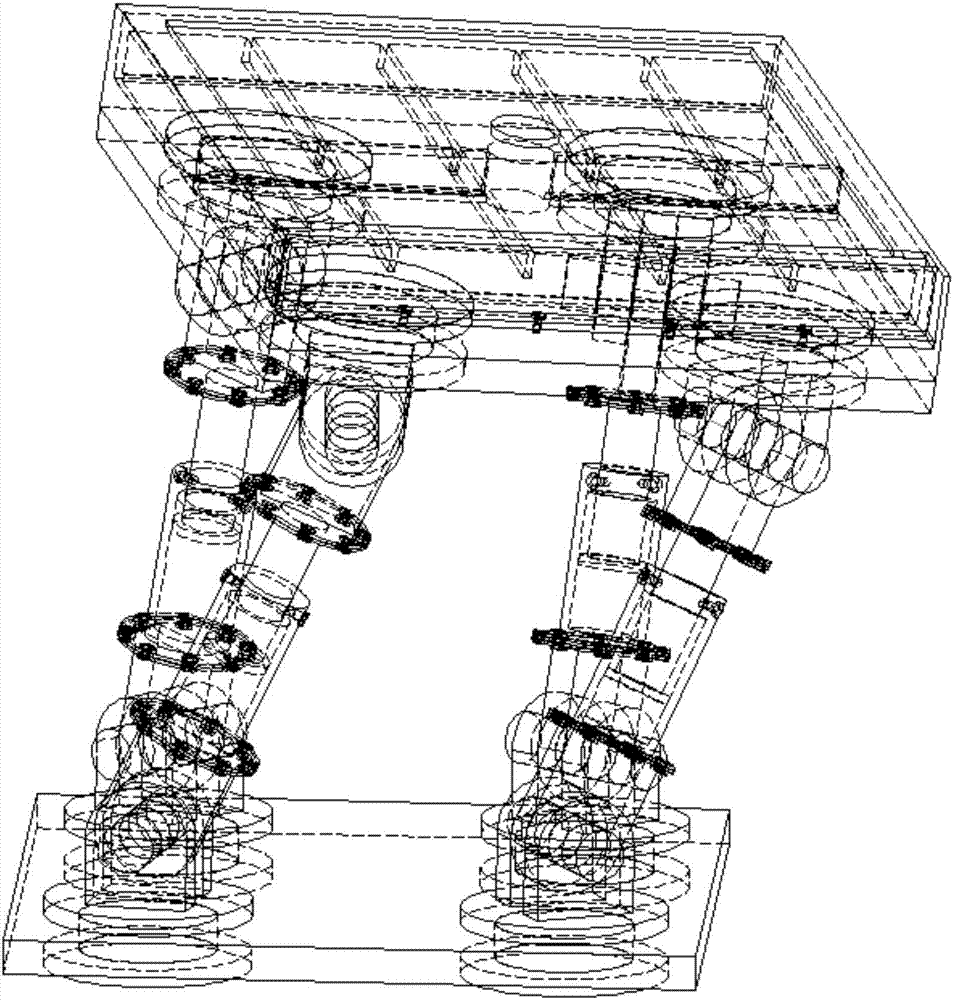

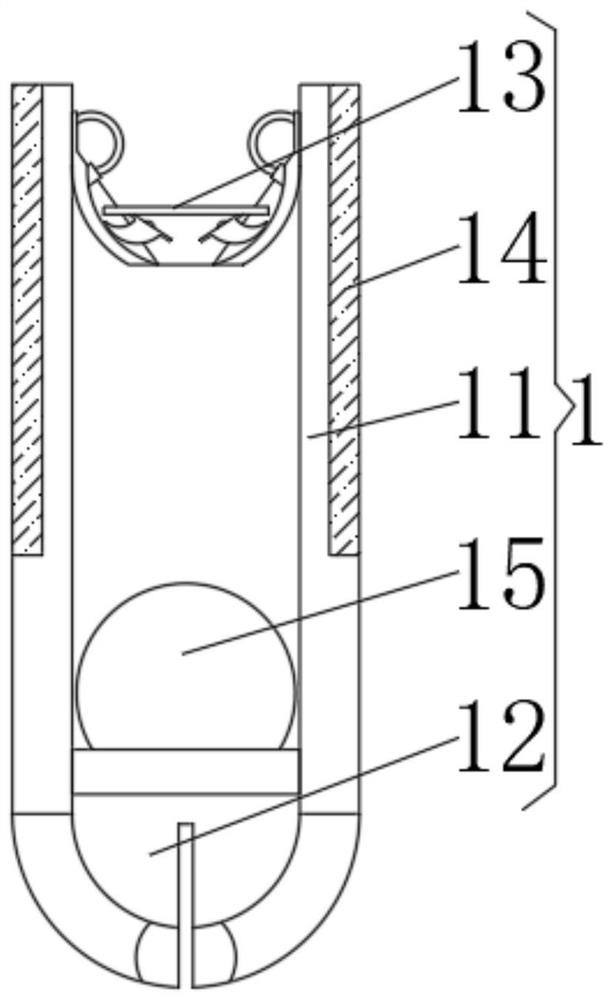

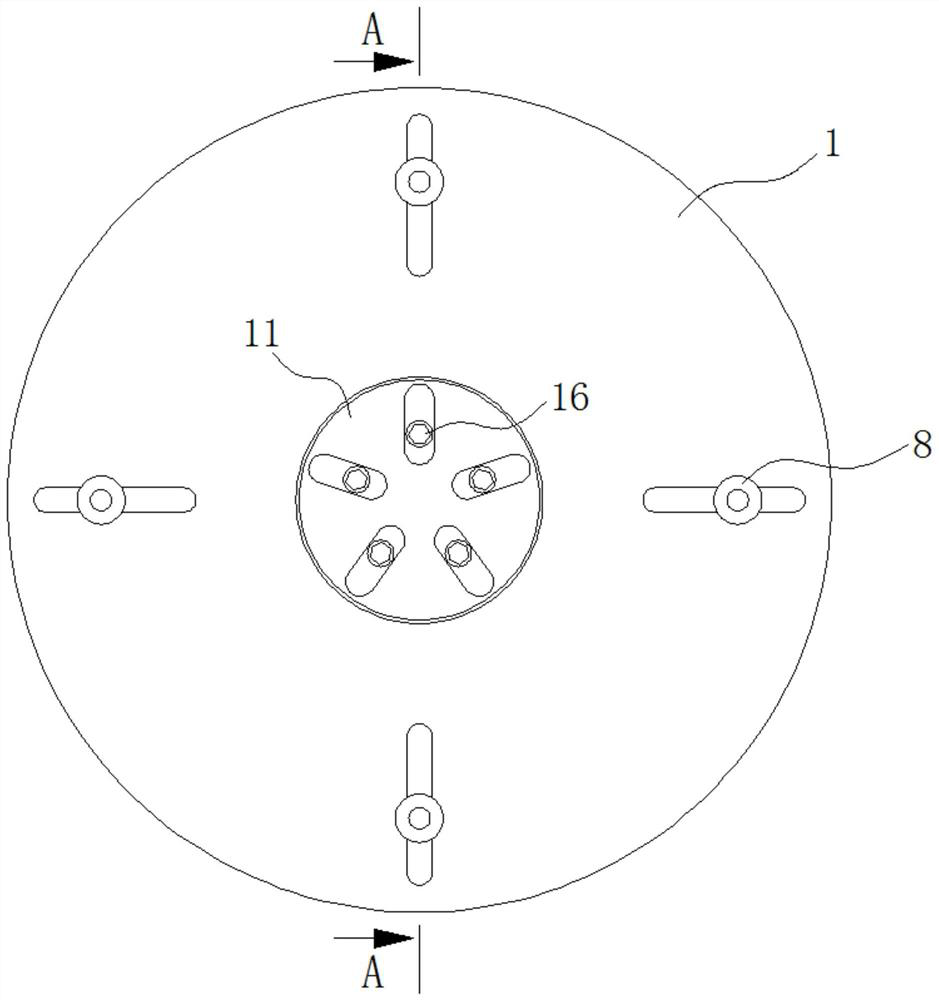

Mooring hole local structure strength testing mechanism

The invention belongs to the field of mooring hole structure strength and in particular relates to a mooring hole local structure strength testing mechanism. The mooring hole local structure strength testing mechanism is composed of a support, a lower double-lug rotary wheel, a lower bolt, a lower single lug, a lower flange disc, a sleeve, an adjusting rod, an ejector pin, an upper flange disc, an upper single lug, an upper bolt, an upper double-lug rotary wheel, a clamp and a plate frame with a mooring hole, wherein the support is a fixed support; four round holes with the same size are formed in four corners of the support; the lower double-lug rotary wheel is in a combined structure of a double-lug structure and an I-shaped wheel and rotates in the support; and the lower double-lug rotary wheel is connected with the lower single lug through the lower bolt and rotates around the lower bolt. According to the mooring hole local structure strength testing mechanism, the I-shaped wheel is matched with a single lug and double lugs and the adjusting rod rotates in the sleeve to adjust the direction; and the adjusting rod is fixed at a certain position in the sleeve through the ejector pin and does not move up and down or rotate, so that a clamping component panel is adjusted and is fixed at any angle. A test piece can be loaded at any angle and a condition that a buttress is repeatedly replaced in a test is avoided.

Owner:HARBIN ENG UNIV

Transmission line protective device

ActiveCN104407424AEasy to fixGuaranteed disengagementOverhead installationOptical fibre/cable installationEngineeringDisconnector

The invention discloses a transmission line protective device. The transmission line protective device comprises a steel strand clamping plate, a disconnector pedestal, a positioning suspending hammer component hung at the lower end of the steel strand clamping plate, and an electric pole connecting mechanism arranged on the disconnector pedestal, wherein the disconnector pedestal comprises a hollow barrel and a universal rotating mechanism arranged inside the hollow barrel; the upper end of the hollow barrel is in contact with the lower surface of the steel strand clamping plate; part of the universal rotating mechanism is connected with a central barrel, and the other part of the universal rotating mechanism is connected with the positioning suspending hammer component; the positioning suspending hammer component can be kept vertical when the central barrel is inclined randomly. With application of the transmission line protective device disclosed by the invention, when the electric pole is toppled in any direction, the steel strand and the cable can be detached from the electric pole, so as to protect the steel strand and the cable from snap; the transmission line protective device has the advantages of convenient installation, good waterproofness and long service life.

Owner:四川欣和嘉盛信息技术有限公司

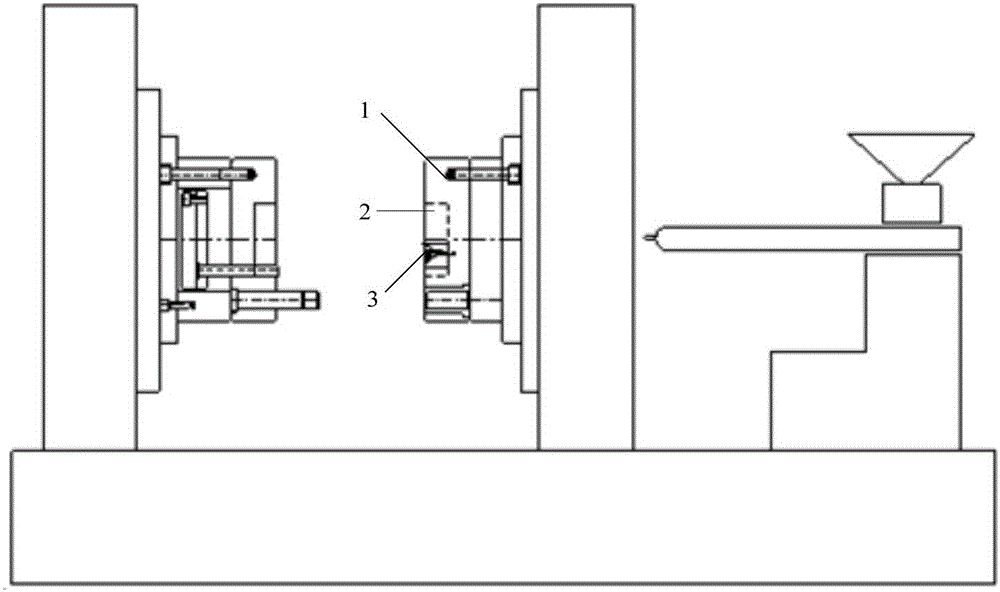

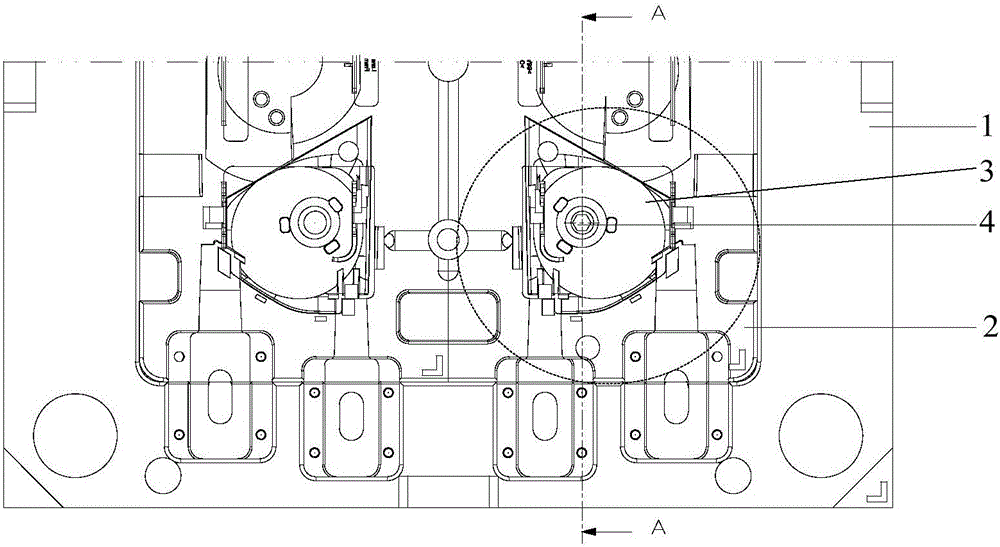

Mold with mold insert replaceable from front

The invention discloses a mold with a mold insert replaceable from the front. The mold comprises a mold plate, a mold cavity, the mold insert and a threaded fastener, wherein the mold plate is provided with a mold cavity groove; the mold cavity is embedded in the mold cavity groove and provided with a mold insert groove; the mold insert is embedded in the mold insert groove and provided with a mold insert fixing hole; the mold insert fixing hole penetrates the mold insert; a mold plate fixing hole is formed in the mold plate at a position corresponding to the mold insert fixing hole; the inner surfaces of the mold insert fixing hole and the mold plate fixing hole are both provided with internal threads; and the threaded fastener is in threaded connection with the mold insert fixing hole and the mold plate fixing hole successively and fixes the mold insert and the mold cavity onto the mold plate. In the mold, the threaded fastener can penetrates the mold insert from the front of the mold insert; when the mold insert is to be replaced, the mold insert can be taken out from the front; the mold insert fixing hole is provided with the internal thread which is used as an acting point, so the mold insert can be taken out from the front by using a tool like a drawing device; so the replacing time of the mold insert is shortened and production efficiency is improved.

Owner:威海海创模塑科技有限公司

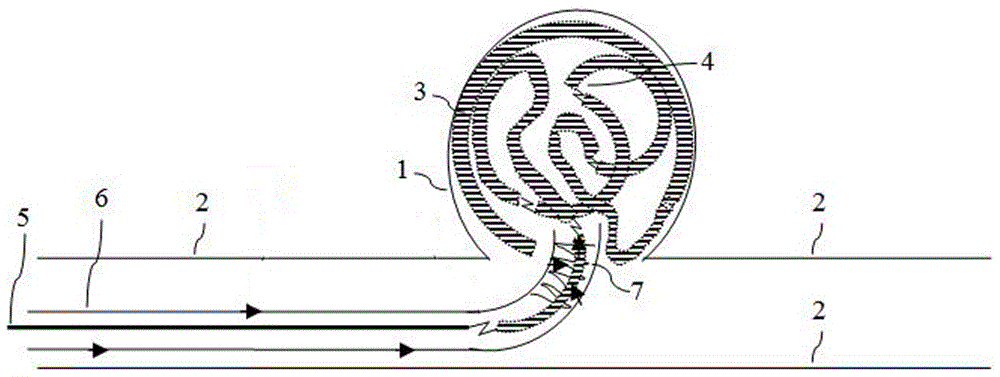

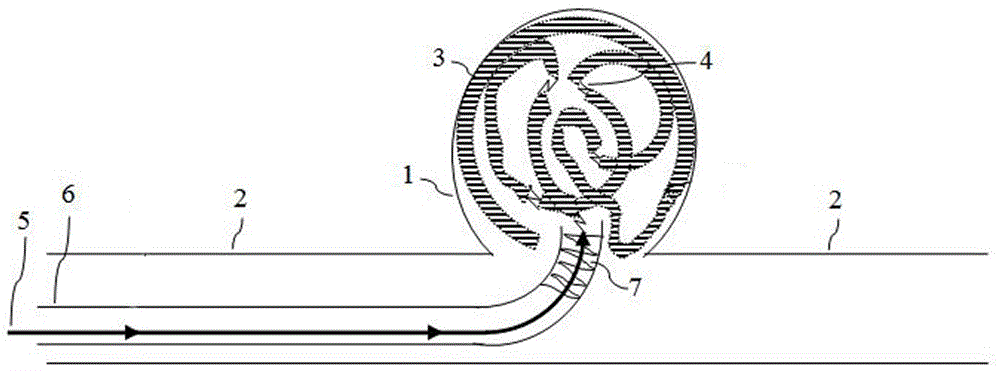

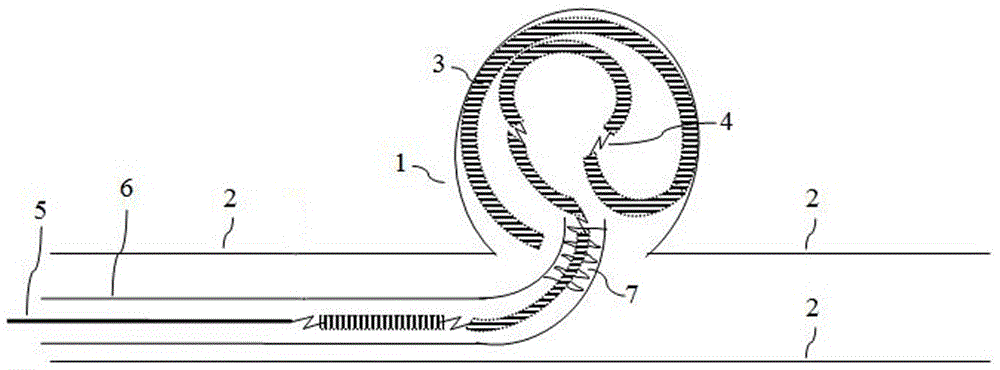

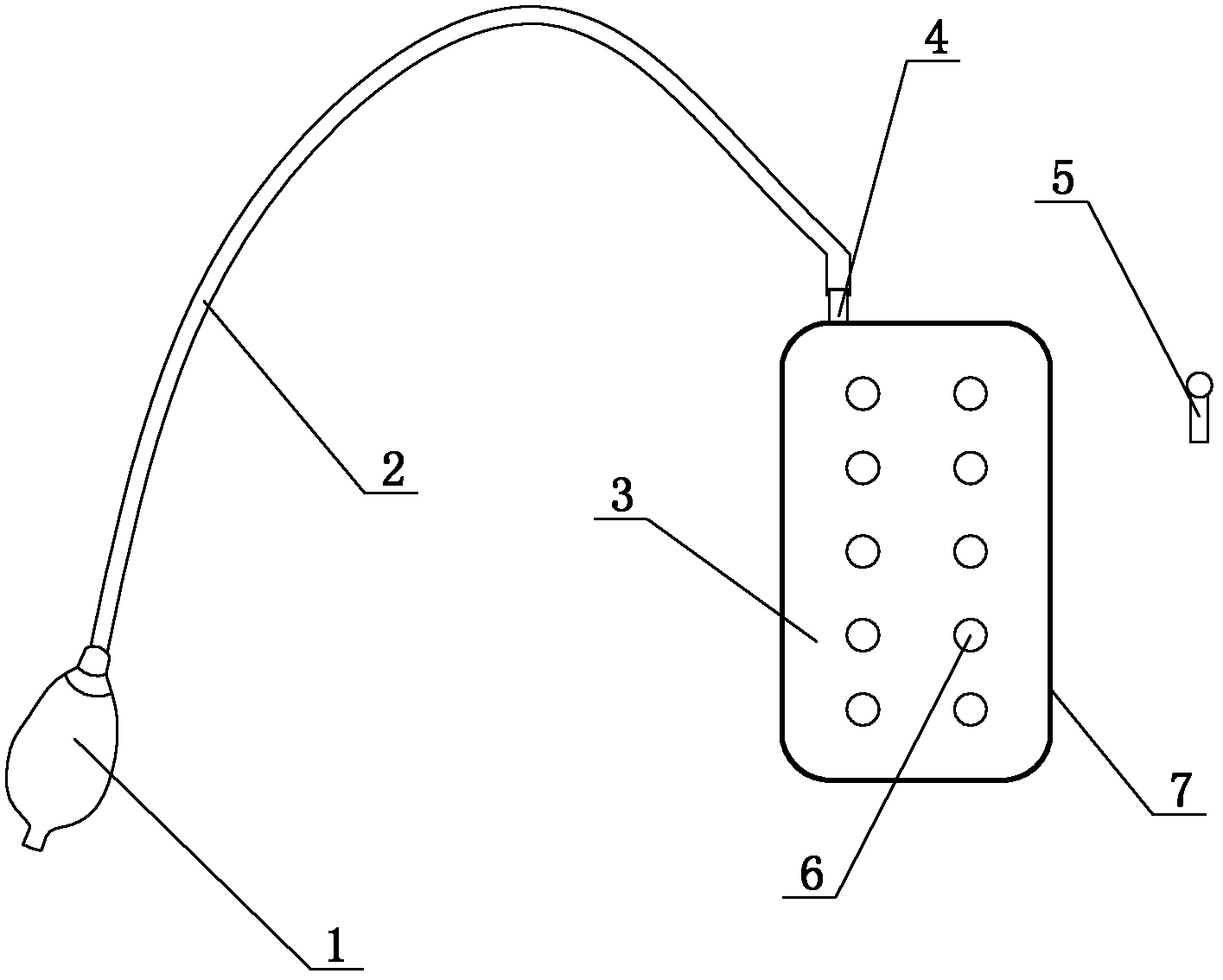

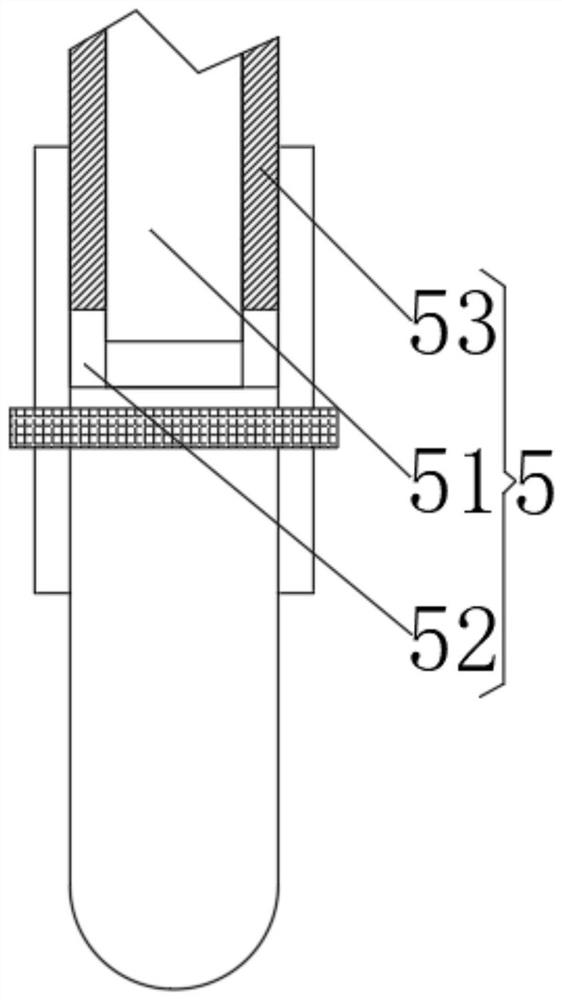

Multi-point electrolytic detachment system and method for detaching embolism materials

The invention discloses a multi-point electrolytic detachment system and method for detaching embolism materials. The system comprises a spring ring and a spring ring conveying system. The spring ring comprises a plurality of end-to-end small spring rings and detachment points for connecting the small spring rings. The spring ring conveying system comprises a conveying guide wire and a micro catheter. The conveying guide wire is arranged inside the micro catheter. The front end of the conveying guide wire is connected with the tail end of the spring ring through the last detachment point, an electrified wire is arranged at the front end of the micro catheter, a micro wire is arranged on the wall of the micro catheter, and the micro wire is connected with the electrified wire. Different detachment points are arranged on the spring ring, detachment is performed at nearby detachment points after arterial aneurysm embolism is satisfied, an existing multi-spring-ring implanting method is replaced, the operation time is shortened, and the operation cost of a patient is lowered.

Owner:上海微密医疗科技有限公司

Measurement device and measurement method of exhaust area of single-guide vane

PendingCN110702058AEasy detectionQuick detectionGas-turbine engine testingJet-propulsion engine testingMeasurement deviceStructural engineering

The invention discloses a measurement device and measurement method of an exhaust area of a single-guide vane, and belongs to the technical field of aeroengine detection. A single guide vane exhaust area measurement device comprises a base, a fixed device and a simulation device which are arranged on the base; the fixed device comprises a first positioning module and a second positioning module arranged at two ends of the base; the simulation module comprises a first backside blade simulation block and a second backside blade simulation block arranged at one side of the base, and a first basinside blade simulation block, a second basin side blade simulation block, a large edge plate simulation block and a small edge plate simulation block which are arranged at the other side of the base.An exhaust area value of single to-be-measured blade can be obtained through measurement, the blades of which the total exhaust area value is in accordance with the requirement of a design drawing canbe selected from the blades through screening and matching the blades, thereby effectively reducing the assembly and measurement times of the guide blades and finally realizing one-time assembly.

Owner:AECC AERO SCI & TECH CO LTD

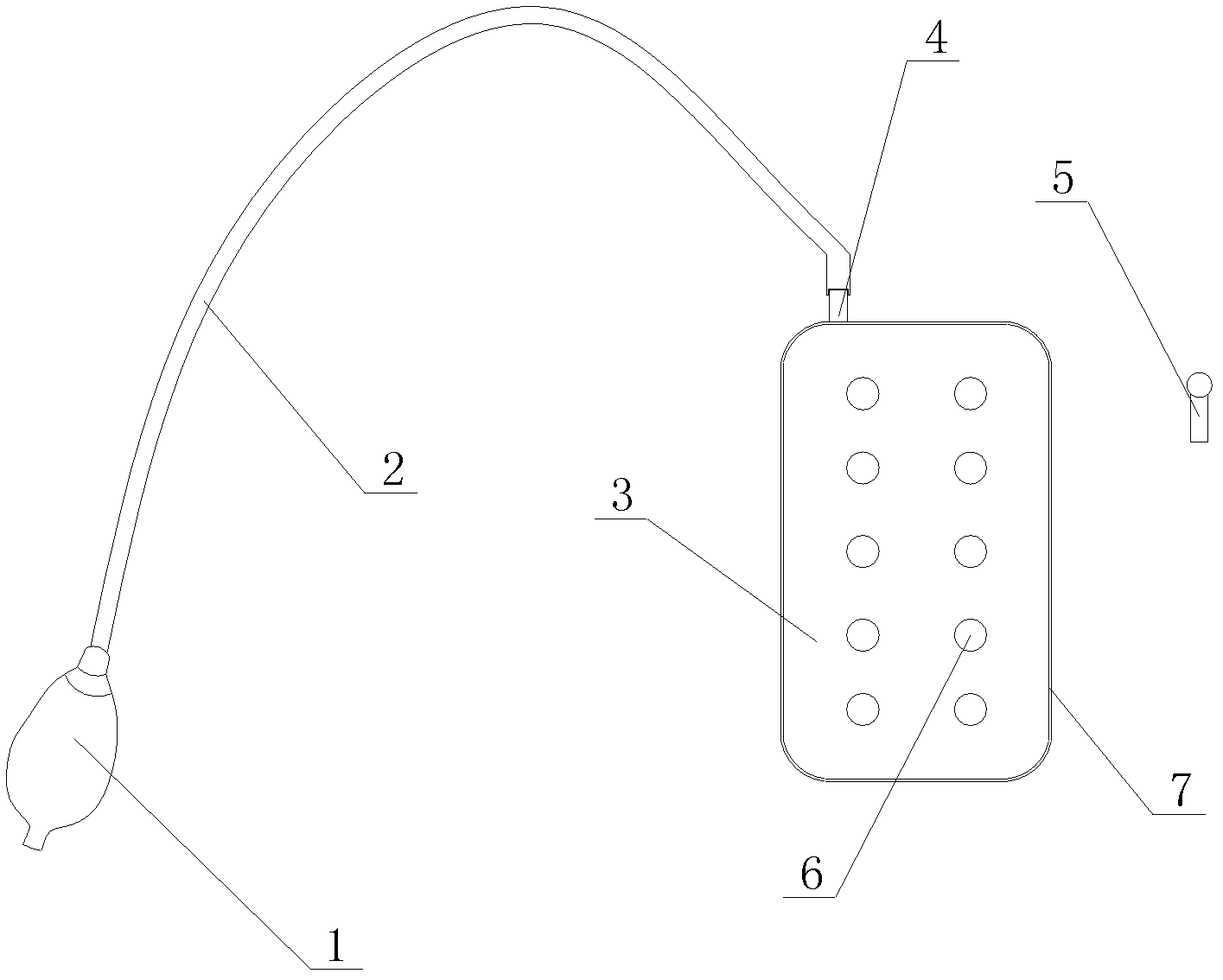

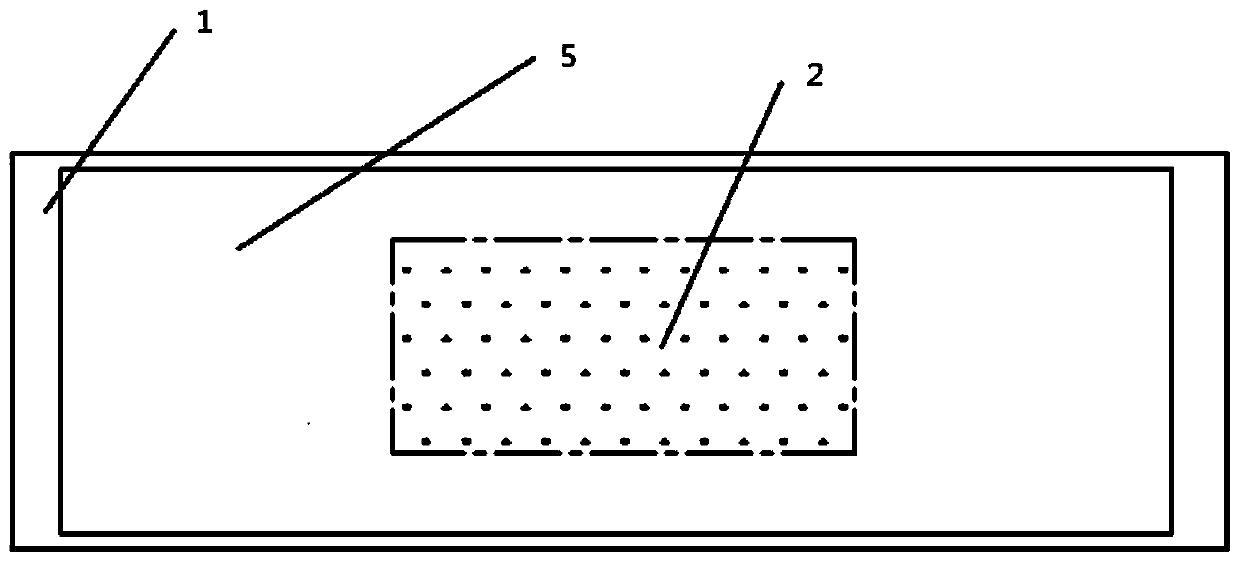

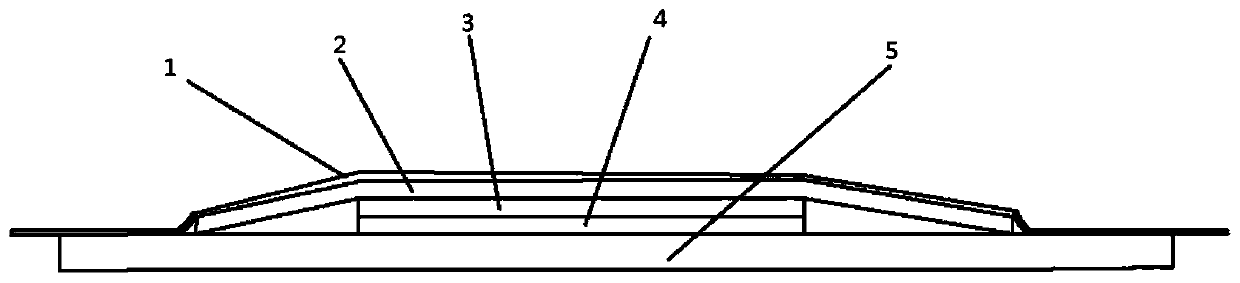

Inflatable gypsum liner device

The invention discloses an inflatable gypsum liner device, which is characterized by comprising an air storage device. An inflating opening is arranged on the air storage device; a switch device is arranged on the inflating opening; the inflating opening is communicated with an inflating device via an air inlet tube; furthermore, the air storage device is an air storage sac made of a medical polyvinyl chloride material; and the air inlet tube is also made of a medical polyvinyl chloride material. The inflating device is an inflating ball sac made of silicon. The switch device is an air inlet tube plug. The inflatable gypsum liner device effectively prevents gypsum pressure sore, avoids that gypsum is replaced repeatedly, reduces economic load of a patient, further avoids the problem that fracture re-displacement is caused clinically due to the fact that the gypsum is not replaced in time, and protects the patient.

Owner:马胜忠 +1

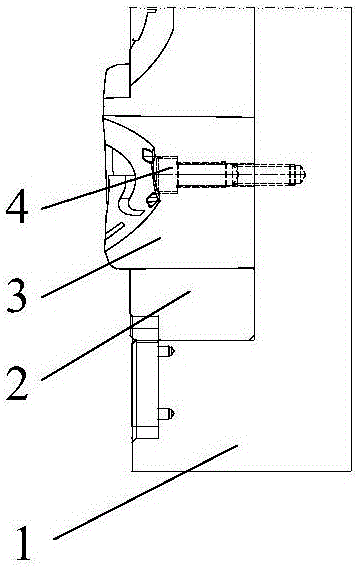

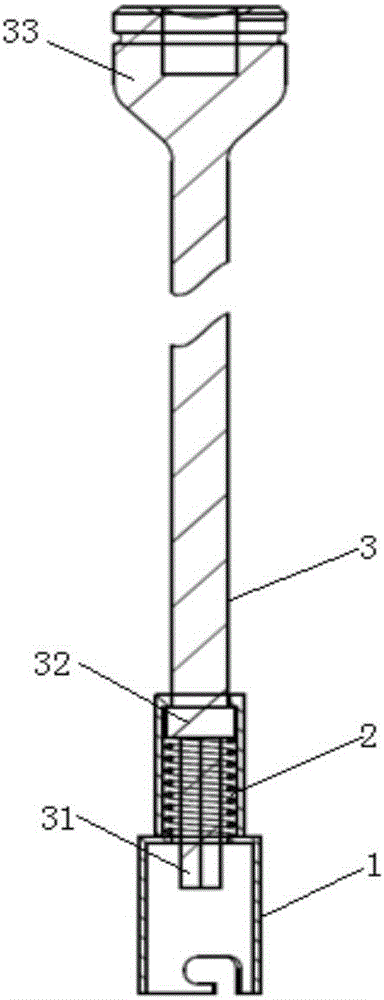

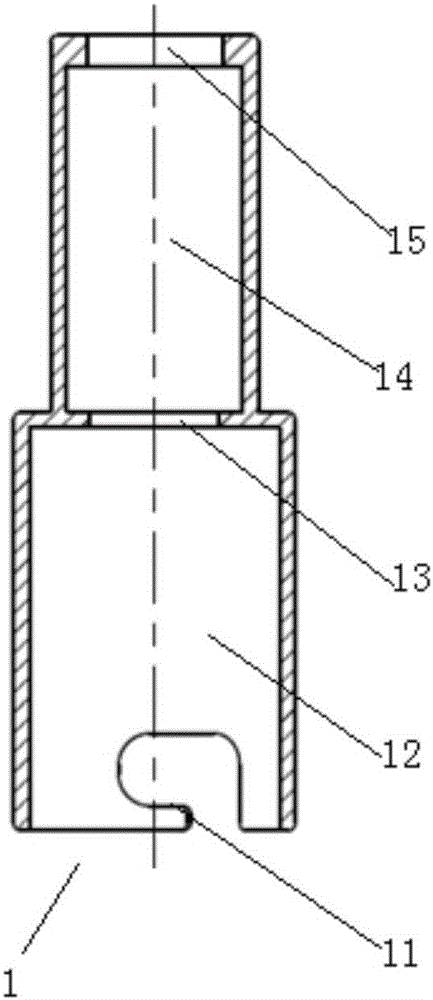

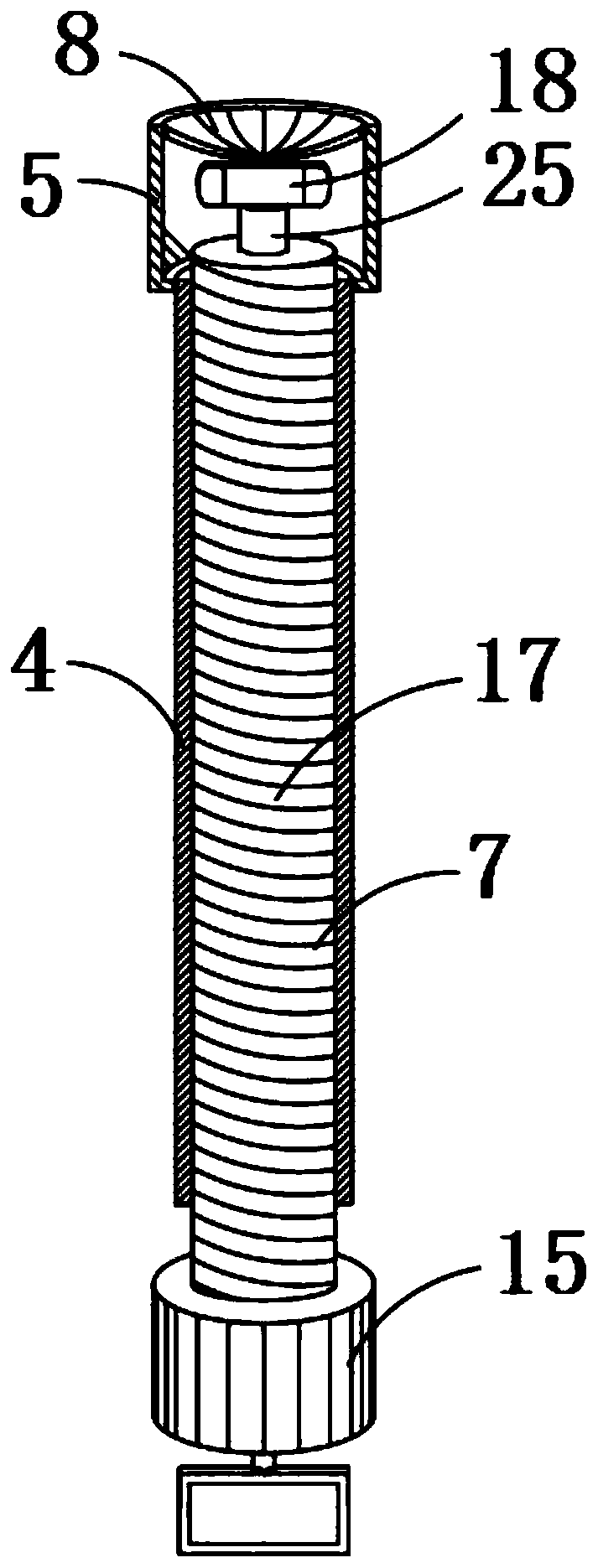

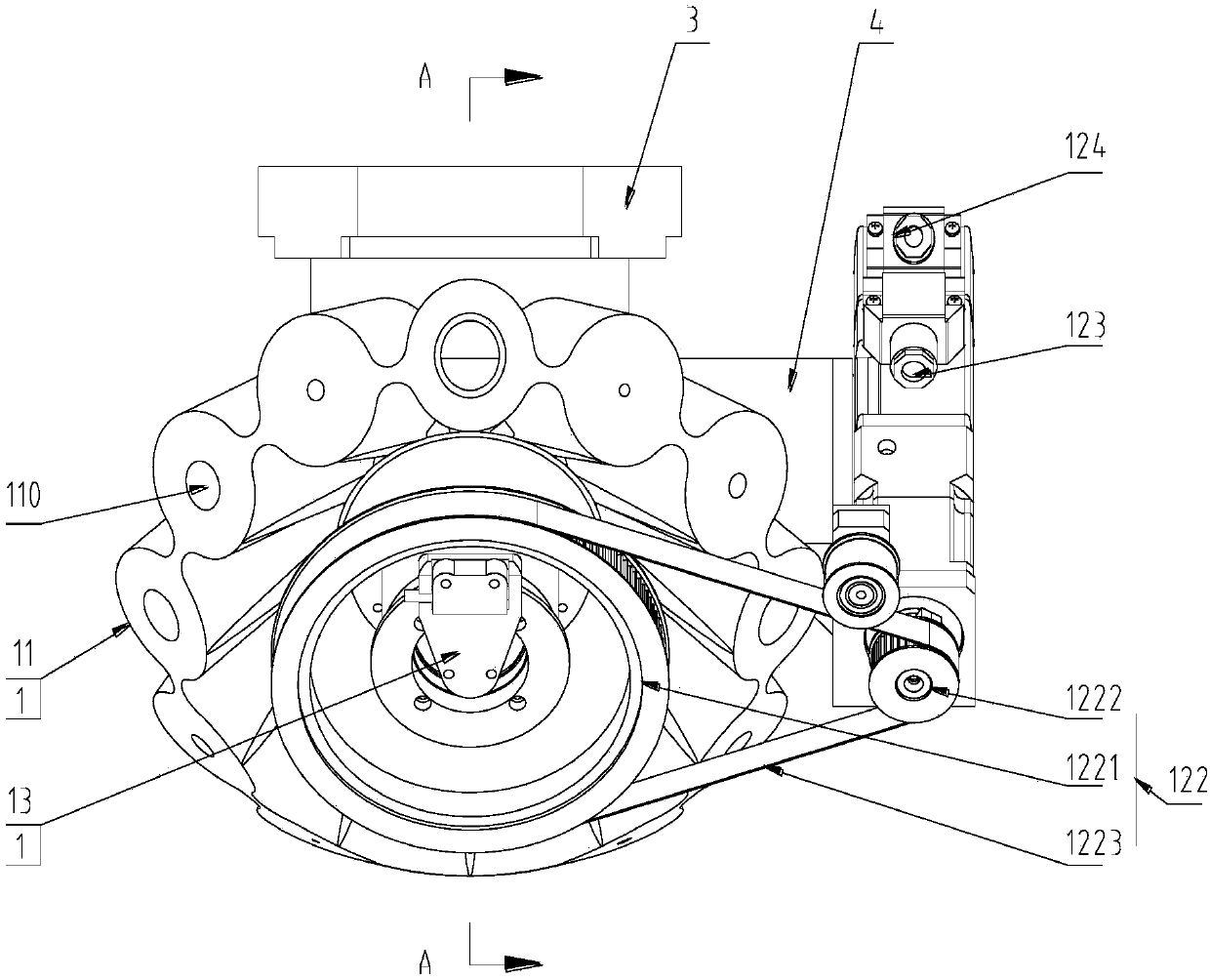

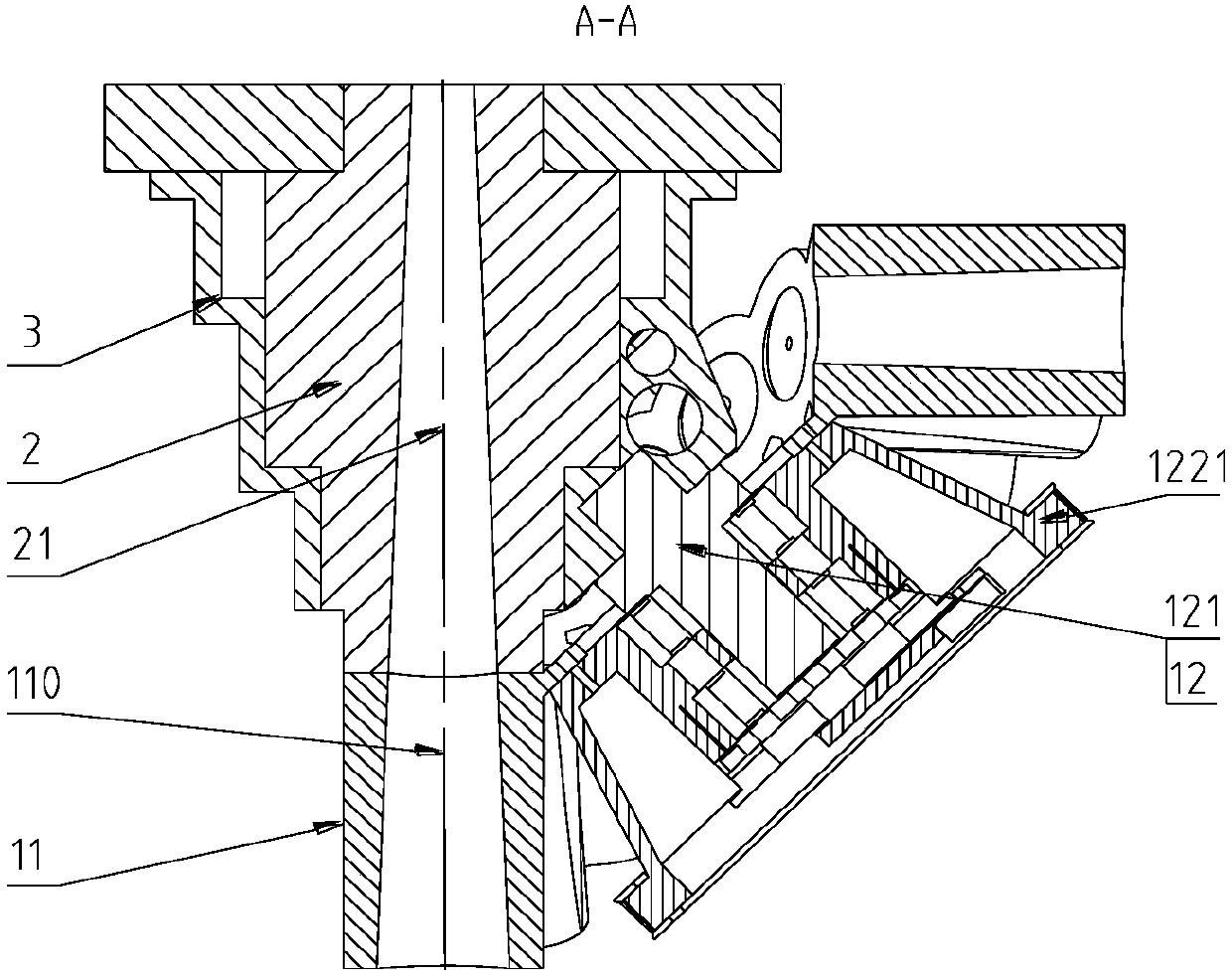

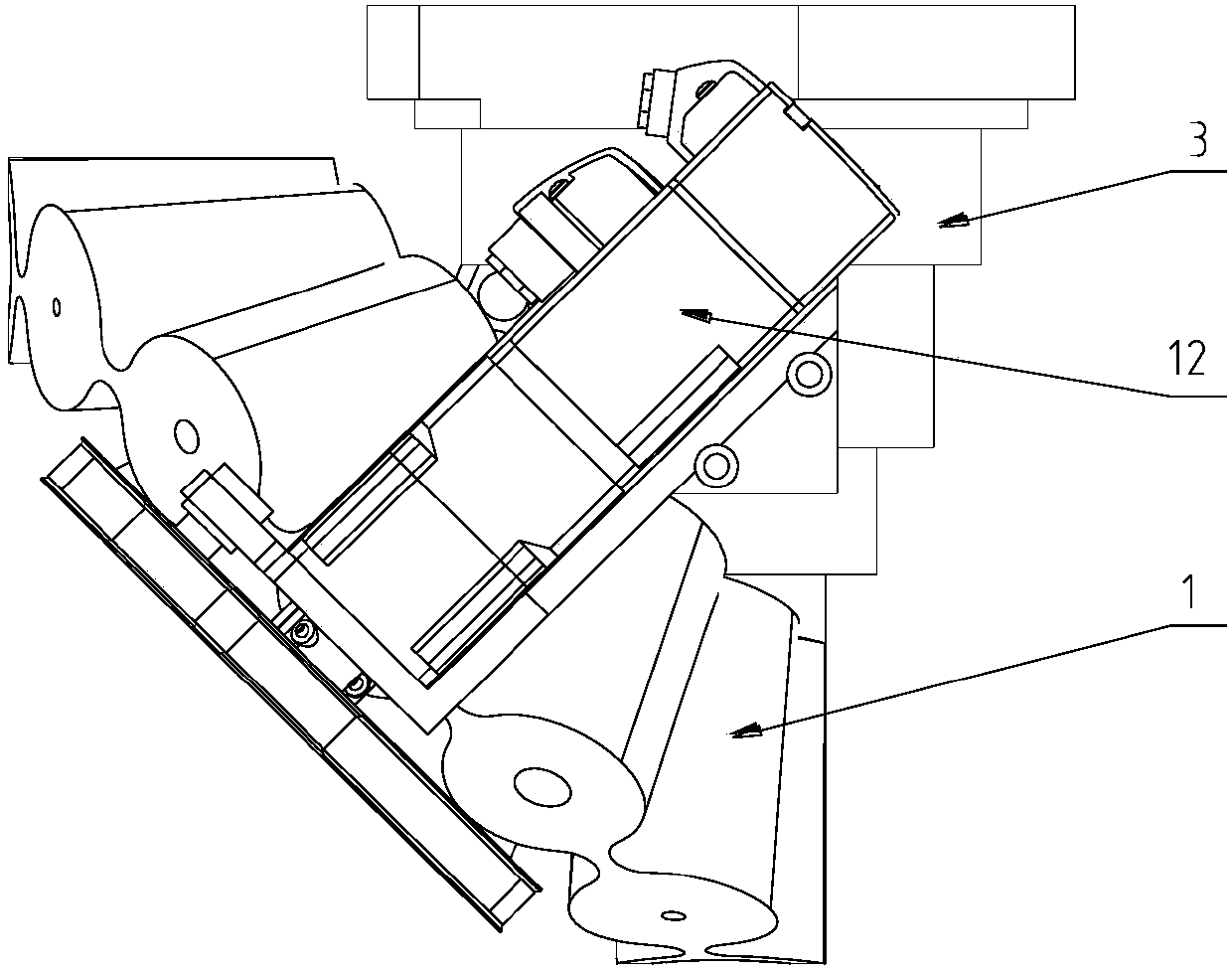

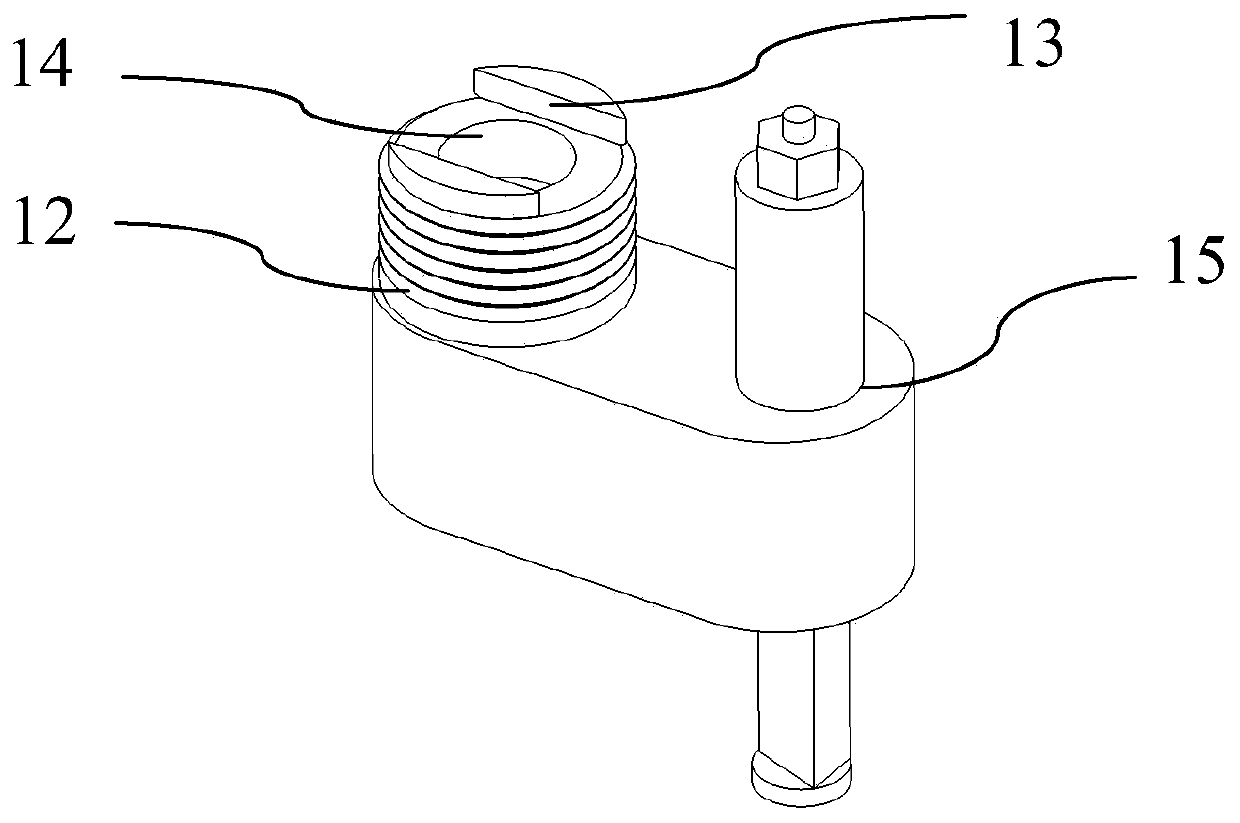

Assembly tooling and assembly method of piston cooling nozzle assembly

ActiveCN106335027ASmall form factorSave assembly spaceMetal-working hand toolsEngineeringOpen structure

The invention relates to an assembly tooling of a piston cooling nozzle assembly. The assembly tooling comprises a connecting rod, wherein the upper end part of the connecting rod is a torque connector; the lower end part of the connecting rod is a hexagonal prism; a hollow sleeve of which the lower end face is of an open structure is arranged on the hexagonal prism in a sleeving manner; a baffle plate is arranged inside the hollow sleeve; central holes are formed in an upper end panel of the hollow sleeve and the baffle plate; a connecting rod pressing block used for preventing the hexagonal prism from falling off the hollow sleeve is arranged at the upper end part of the hexagonal prism; a buffer reset spring which is positioned inside the hollow sleeve is limited between the connecting rod pressing block and the baffle plate; the baffle plate of the hollow sleeve and the side wall below the baffle plate define an accommodating space of the piston cooling nozzle assembly; a limiting bayonet used for limiting up-and-down motion of an oil injection tube of the piston cooling nozzle assembly is formed in the side wall of the accommodating space; and the opening of the limiting bayonet is in the lower end face of the hollow sleeve. The invention further relates to an assembly method of the piston cooling nozzle assembly. According to the assembly tooling, the problems that a conventional tooling cannot achieve one-time assembly and the size of the tooling is relatively large are solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Algae-bacterium gel dressing and preparation method thereof

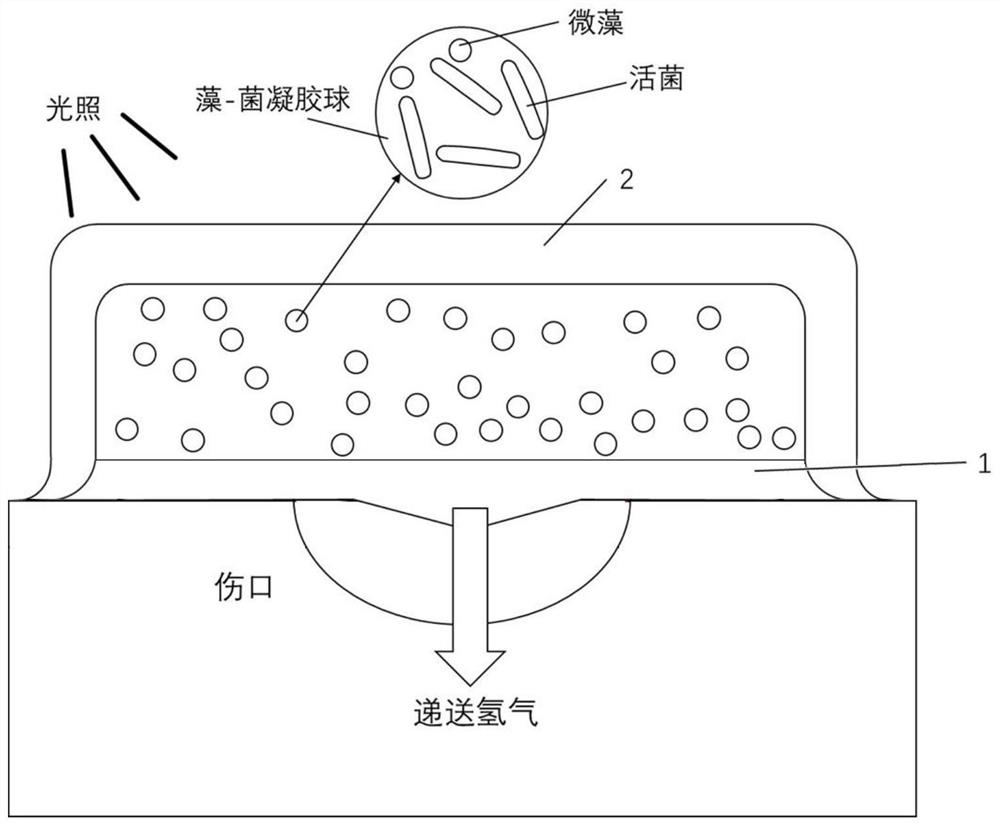

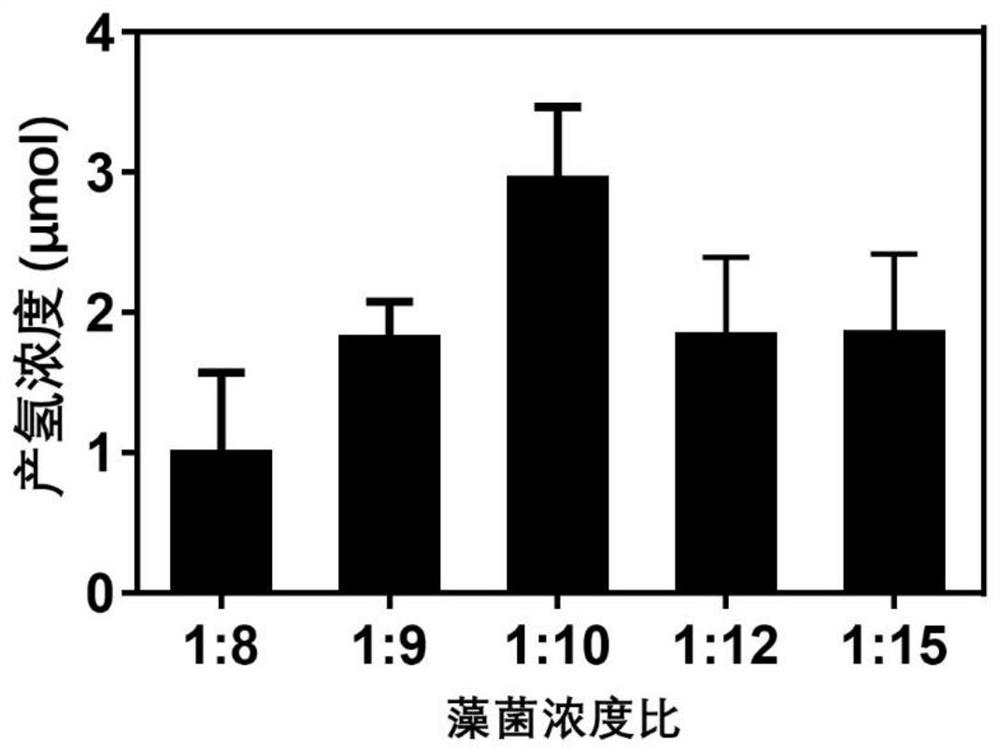

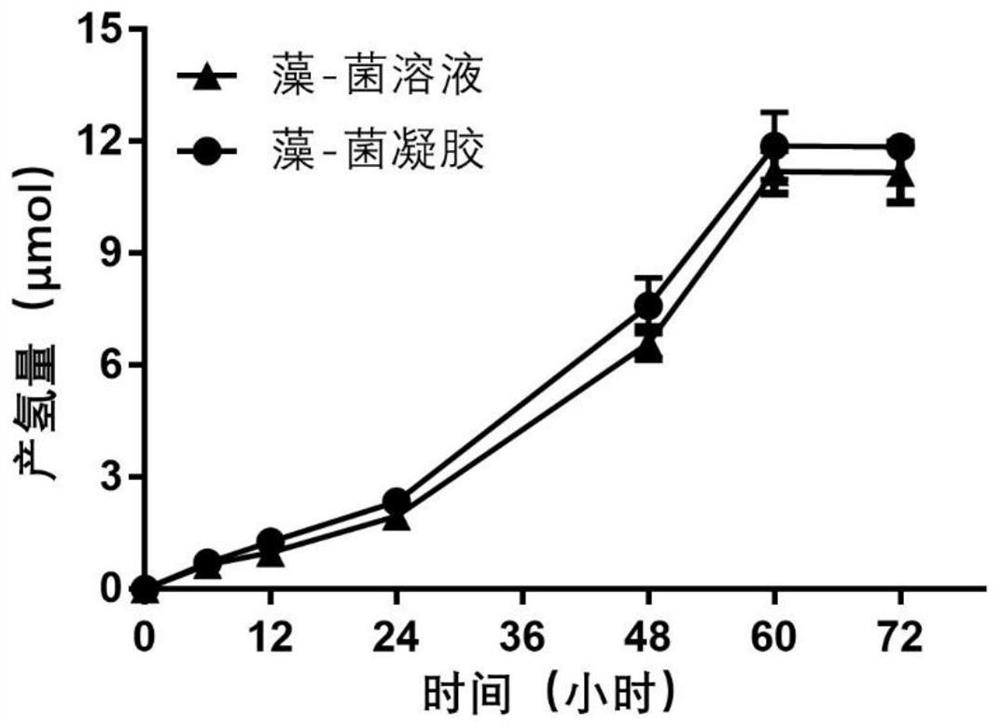

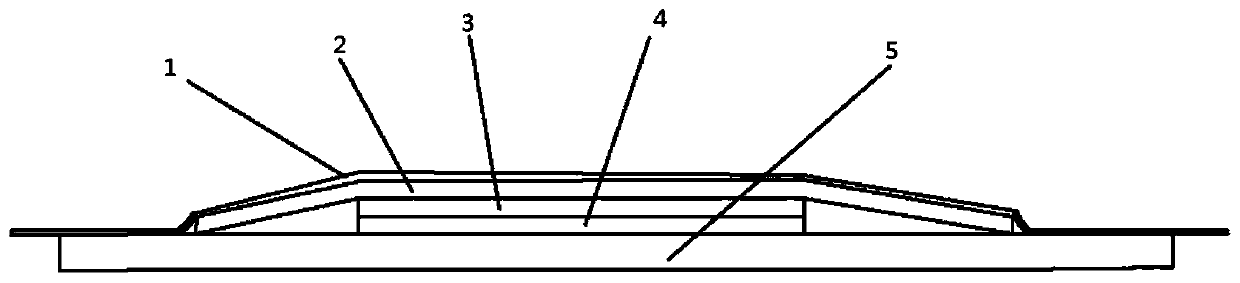

ActiveCN113440640AAvoid contactReduce oxidative damageAbsorbent padsBandagesBiotechnologyDiabetes mellitus

The invention discloses a simultaneous algae-bacterium gel dressing. The simultaneous algae-bacterium gel dressing comprises an airtight and transparent backing layer and gel arranged in the backing layer, and the gel is gel particles containing microalgae and live aerobic bacteria. According to the dressing, gel is used as a carrier, oxygen consumption of aerobic bacteria is used for accelerating system hypoxia, and hydrogenase activated by microalgae can release hydrogen through photosynthesis, so that chronic wound inflammation is improved, and healing is promoted. A filler of the dressing contains active microalgae and / or aerobic bacteria capable of delivering high-concentration dissolved oxygen to tissues at the same time, the dressing backing layer is a transparent and airtight film, and after the dressing is attached to a wound surface, hydrogen generated by the microalgae can efficiently permeate the tissues and improve oxidative damage and chronic inflammation of the wound surface, so that the dressing has the effects of promoting various wounds, especially, the chronic wounds, and more particularly the chronic wound of diabetes mellitus, to be repaired. The dressing adopts a local hydrogen supply technology and is convenient to carry.

Owner:NANJING UNIV

Medical dressing set with pressure

The invention relates to the field of medical auxiliary articles, in particular to a medical dressing set with pressure. The medical dressing set with pressure comprises a medical dressing with pressure and a separately prepared Chinese medicine bag. The medical dressing mainly consists of four layers from top to bottom, wherein the first layer is an absorption pad which does not stick to a woundand is compounded of medical water-absorbable fibers and a PE dialysis membrane; the second layer is a medical gauze cotton pad consisting of medical absorbent gauze and medical absorbent cotton; thethird layer is medical silica gel, and air-permeable artificial latex silica gel is selected as the medical silica gel; the fourth layer is medical high-elasticity waterproof adhesive tape and consists of a low-sensitivity medical pressure-sensitive adhesive and a cotton back lining, and elastic yarn is embedded in the cotton back lining. The Chinese medicine bag comprises talcum powder, lotus root node powder, mussel adhesive proteins and a coating material. The provided medical dressing set with pressure can avoid and reduce the problems of inflammation, ecchymosis, leakage, subcutaneous hematoma and the like, greatly reduce the infection probability of patients, and improve the comfort level of the patients.

Owner:GUANGZHOU EIGHTH PEOPLES HOSPITAL

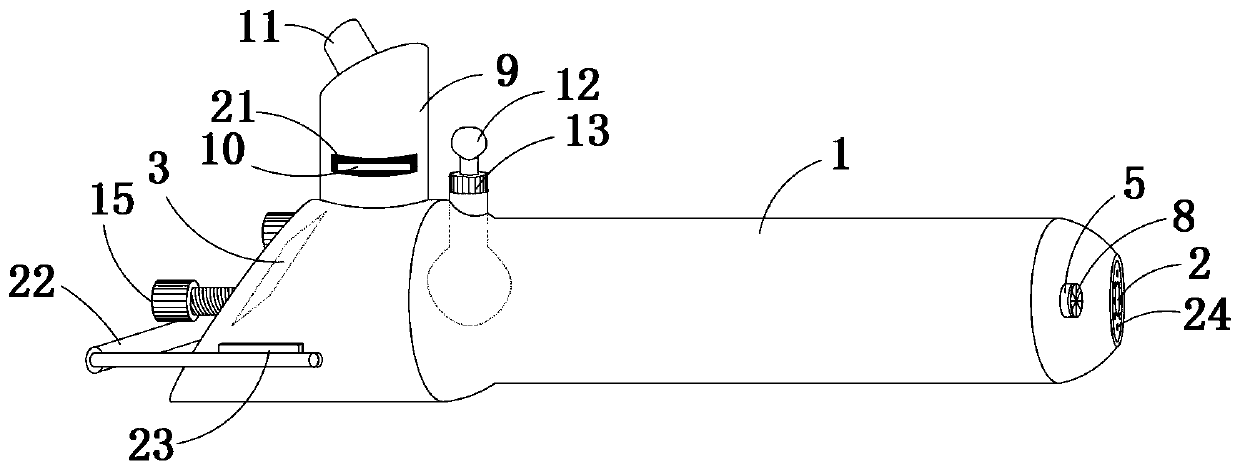

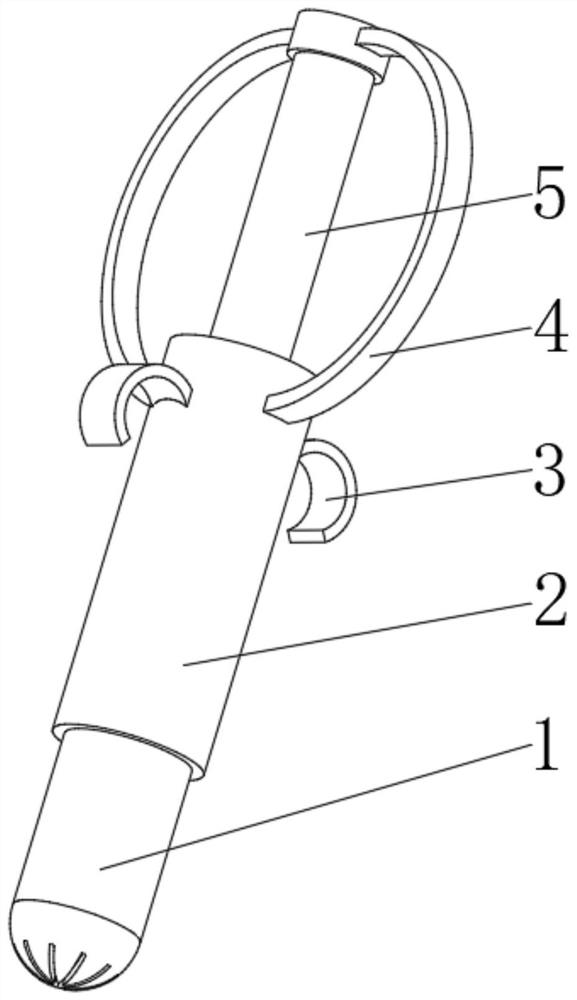

Gynecological cervical cancer screening instrument

InactiveCN110575127AGuaranteed tightnessEasy to useSurgeryMaterial analysis by optical meansMicroscopeEngineering

The invention belongs to the field of gynecology, and especially relates to a gynecological cervical cancer screening instrument, which includes a shell. The shell is cylindrical; one end of the shellis in a bullet shape, and the other end of the shell is in a thickened cylinder shape; a groove is formed in the bullet-shaped end of the shell; a camera is fixedly mounted in the groove; containingcylinder sealingly sleeve cylinders; the two cylinders are provided with a first sampling mechanism and a second sampling mechanism respectively; the ends, away from the cylinders, of the two containing cylinders are provided with sealing mechanisms; a strip-shaped groove is horizontally formed in the arc-shaped side wall of a cylindrical block; a microscope is fixedly installed in a circular opening; and a glass pipette is fixedly sleeved with a rotating block. The cervical cancer screening instrument can enter the vagina to screen cervical cancer. The cervical cancer is judged through threemethods of direct observation, living tissue examination and TCT screening, and therefore the screening effect is guaranteed. In addition, operation is convenient, and sampling is accurate.

Owner:闫丽萍

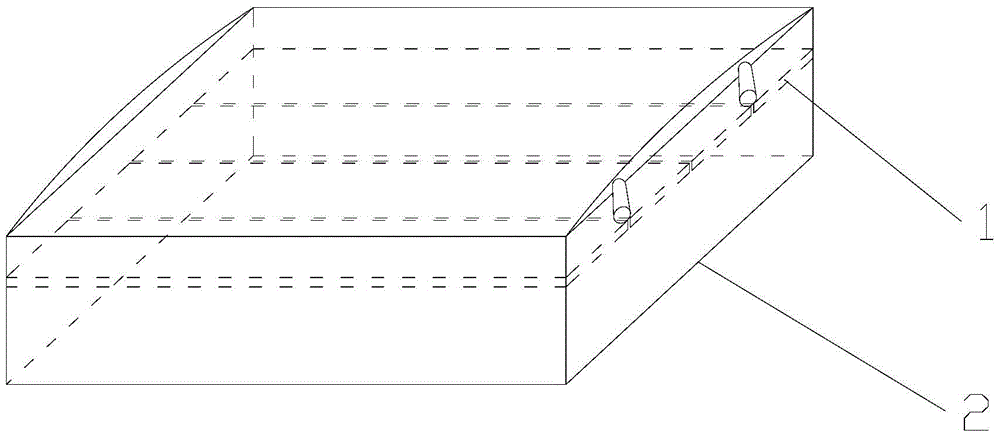

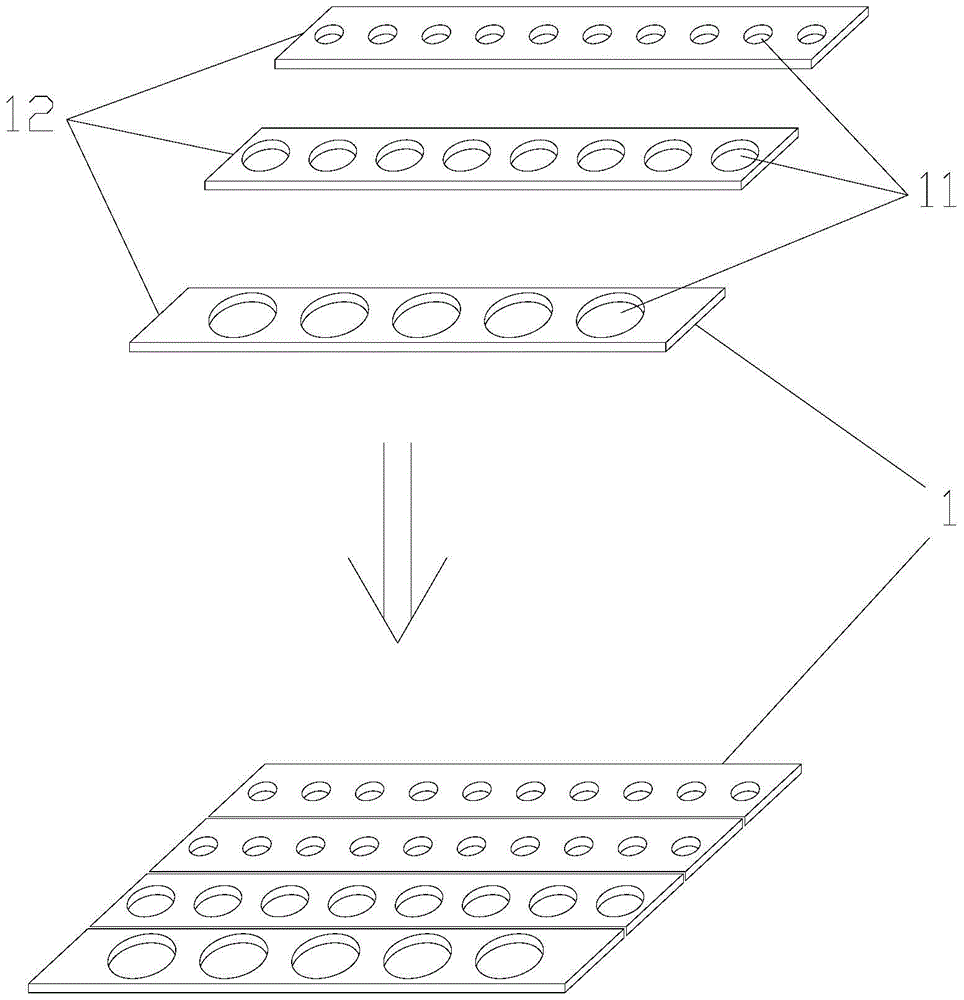

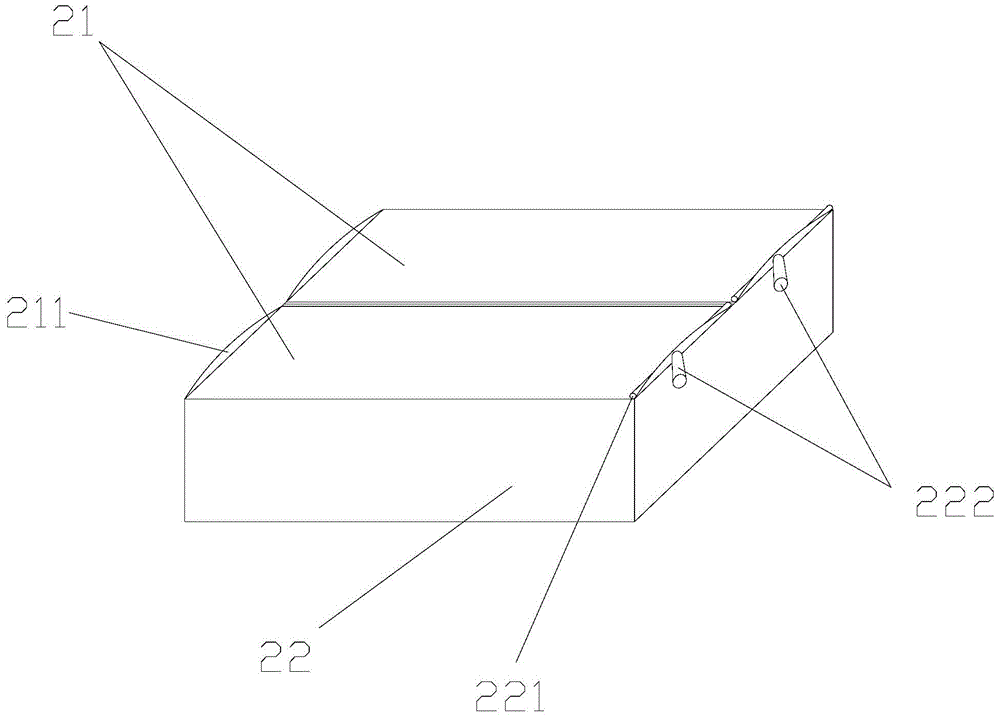

A removable sample tube storage box

Owner:SHANGHAI USEN BIOLOGICAL TECH CO LTD

Self-checking method, device and host of internal integrated circuit host

ActiveCN103530215BAvoid repeated replacementError detection/correctionNetwork packetIntegrated circuit

The invention discloses a self-inspection method and device of an inter integrated circuit host and the host, and belongs to the technical field of communication. The method comprises the steps that the I2C host detects whether an I2C bus is busy; when the I2C bus is busy, data packets transmitted on the I2C bus are received, and whether a link of the I2C host is normal is detected according to the data packets. According to the method, when the I2C bus is busy, the data packets transmitted on the I2C bus are received, whether the link of the I2C host is normal is detected according to the data packets, and therefore it is not necessary to wait to conduct self-inspection of the I2C host when the I2C bus is free, self-inspection can be conducted in real time, and the problem that when the I2C host waits for self-inspection, the I2C host controlling the I2C bus at present breaks down and cannot be replaced by a spare I2C host, and therefore the I2C host controlling the I2C bus is changed repeatedly is solved.

Owner:XFUSION DIGITAL TECH CO LTD

Fixation protection apparatus for acidity meter electrode rods

InactiveCN107677701AAchieve fixationReduce workloadBranching pipesMaterial electrochemical variablesSolenoid valveThreaded pipe

A fixed protection device for the electrode rod of the acidity meter, including a three-way pipe, the two ends of the main pipe of the three-way pipe are provided with bent pipes, the bent pipe is provided with a fixed section connection, and a fixed plate is provided in the opening of the branch pipe of the three-way pipe , the fixed plate is pierced with a protective sheath layer, and the electrode rod of the acidity meter extends into the tee pipe through the protective sheath layer; the fixed section of the tee pipe at both ends of the main pipe is provided with a flange plate, and the tee pipe passes through the flange The plate is fixed on the material tube. The two ends of the main pipe of the three-way pipe are provided with electromagnetic valves. A trachea is also arranged on the three-way pipe, and the air pipe communicates with the three-way pipe and the outside world. The branch pipe of the three-way pipe is also fixed with a threaded pipe, the threaded pipe is provided with internal threads, the electrode rod of the acidity meter is provided with external threads, and the part of the electrode rod of the acidity meter located outside the three-way pipe is connected with the threaded pipe through threads. By adopting the above structure, the electrode rod of the acidity meter can be effectively protected, the damage and replacement of components can be reduced, and the operating rate can be improved while saving costs.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Radiotherapy equipment and beam limiting device thereof

PendingCN110404181AEasy to operateAvoid repeated collimator replacementX-ray/gamma-ray/particle-irradiation therapyRadiation fieldCollimator

The application discloses a beam limiting device. The beam limiting device comprises a rotation collimator, wherein the rotation collimator comprises a truncated cone-shaped housing, a driving devicefor driving the truncated cone-shaped housing to rotate, an angle detecting device for detecting the angle of the truncated cone-shaped housing and a control device, wherein the truncated cone-shapedhousing is provided with a central cavity, and a plurality of rotation collimating holes which are different in hole diameters and are in parallel to a generatrix are formed in the side surface of thetruncated cone-shaped housing in a radial direction; and the control device is connected with the driving device and the angle detecting device, and is used for receiving a signal transmitted by theangle detecting device, and controlling the driving device to start or stop according to the received signal. Through the adoption of the beam limiting device disclosed by the invention, the collimator is applied, the driving device is jointly controlled by the angle detecting device and the control device to automatically rotate or stop, and the truncated cone-shaped housing automatically rotatesor stops along with the driving device to complete the replacement of a radiation field, so that repeatedly replacing the collimator is avoided, and the radiation field of the collimator provided bythe application can be conveniently, quickly and automatically replaced. The application also discloses radiotherapy equipment.

Owner:RADIATION THERAPY MEDICAL SCI & TECH CO LTD

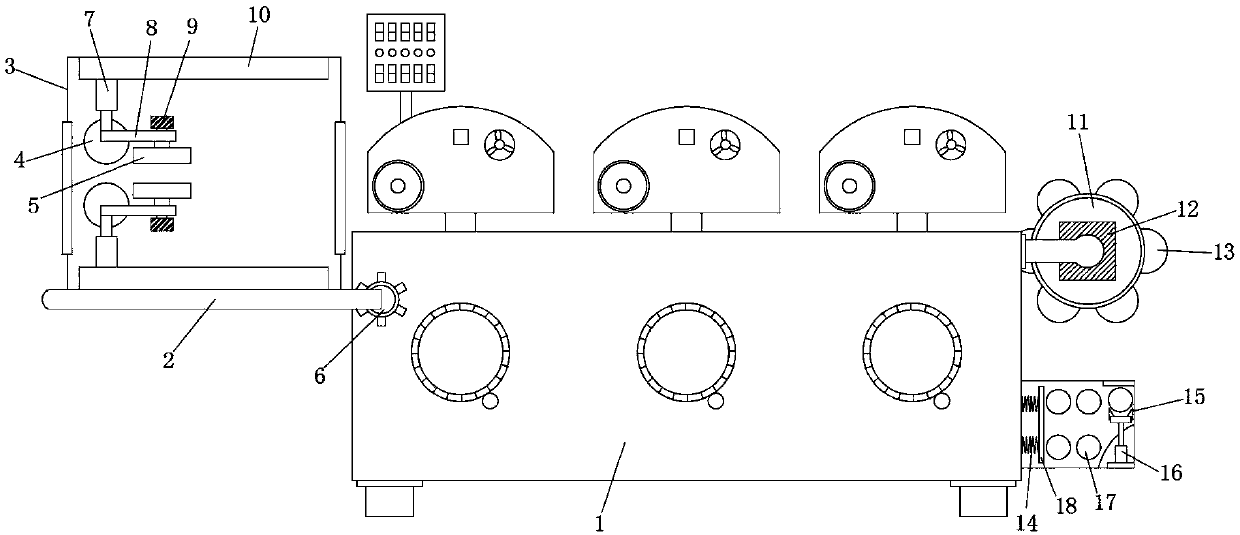

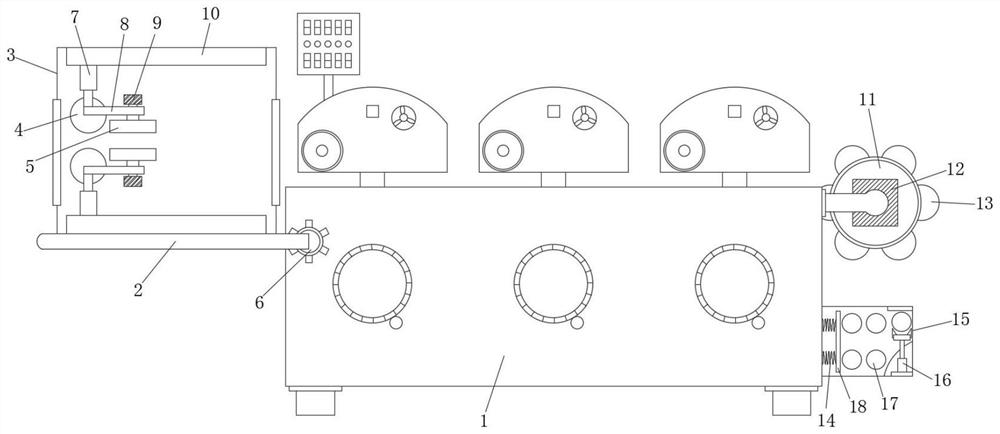

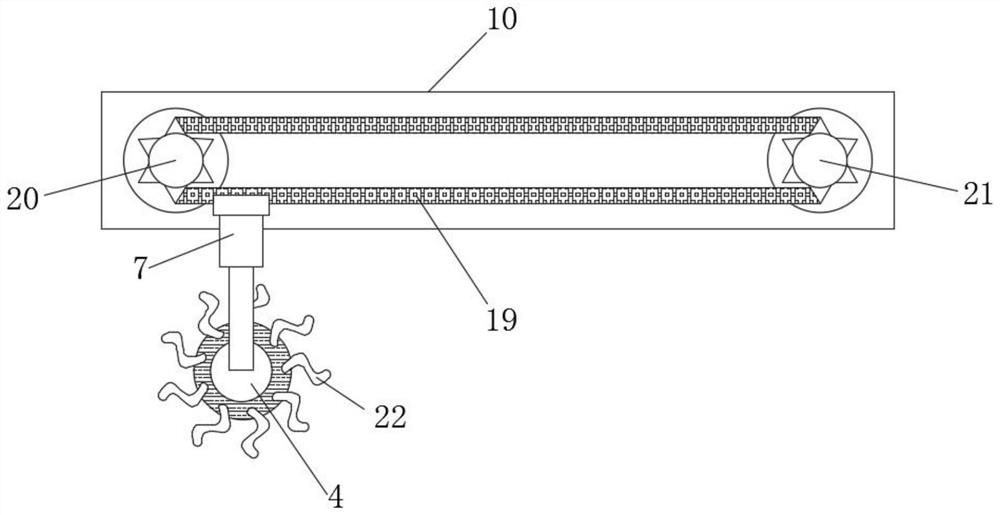

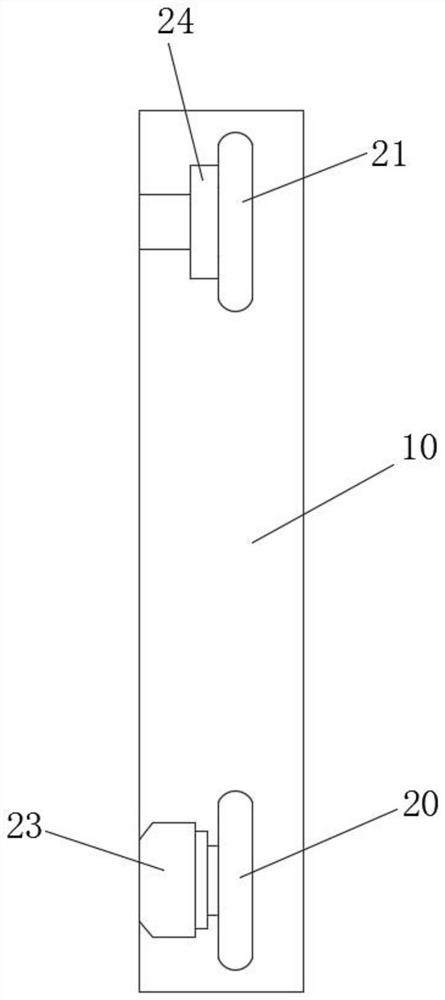

Full-automatic special adhesive tape coating machine

ActiveCN109604116AEfficient preprocessingEasy to cleanLiquid surface applicatorsPolishing machinesEngineeringMechanical engineering

The invention discloses a full-automatic special adhesive tape coating machine. The full-automatic special adhesive tape coating machine comprises an adhesive tape coating machine main body, wherein abearing plate is arranged at one side of the adhesive tape coating machine main body; a clamping bolt is welded at one end of the bearing plate; the bearing plate is clamped with the adhesive tape coating machine main body through the clamping bolt; a box body is mounted at the upper part of the bearing plate; sliding devices are embedded into two sides in the box body; a pneumatic rod is arranged at the bottom of each sliding device; and a rotary roller is mounted at one side of the bottom of each pneumatic rod. According to the full-automatic special adhesive tape coating machine, the pneumatic rods and a polishing plate are arranged and are used for effectively pre-treating a base material; the distance between a sponge brush and the polishing plate, and the base material is convenientto adjust through the pneumatic rods; the surface of the base material is effectively polished through the polishing plate; a servo motor and a chain are arranged so that the pneumatic rods effectively move in the box body and the cleaning and polishing work is carried out better; a rotary table and an electric air cylinder are arranged, so that the working efficiency of the adhesive tape coatingmachine is effectively improved; a winding roller is prevented from being repeatedly replaced and the working time is saved; and the full-automatic special adhesive tape coating machine is suitable for being widely popularized and applied.

Owner:安徽长正升科技有限公司

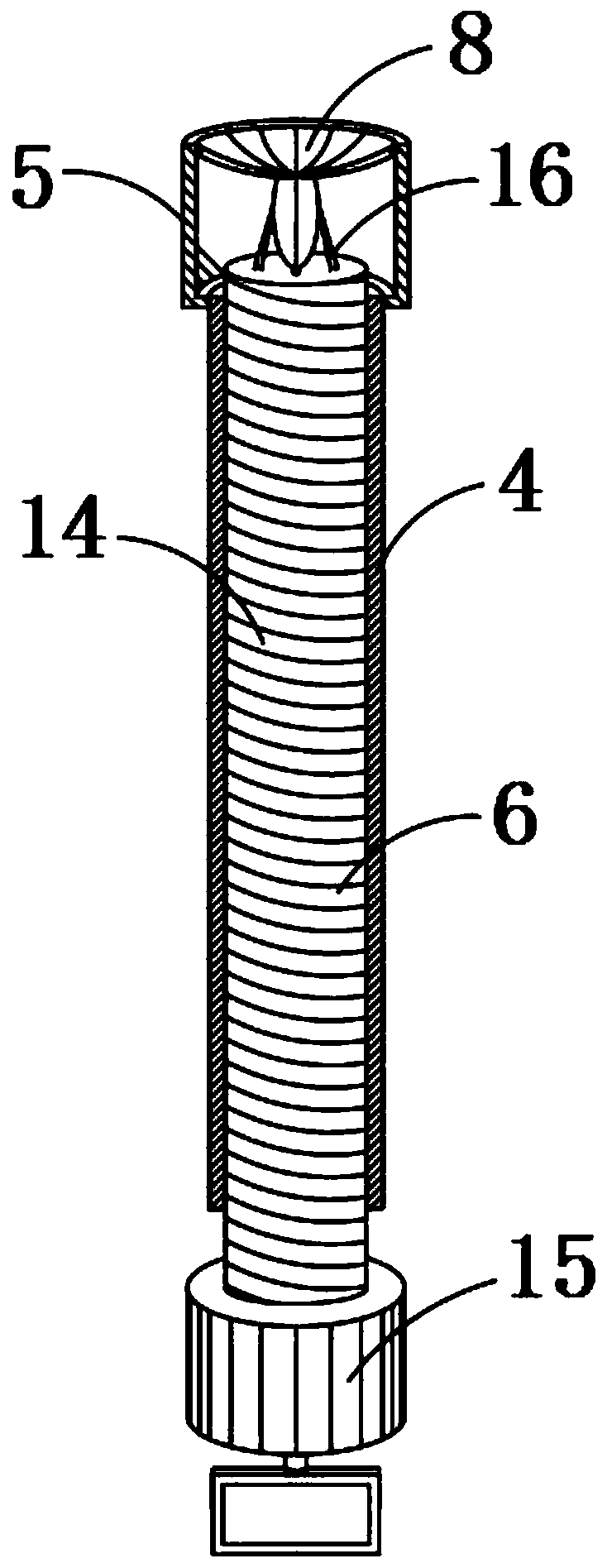

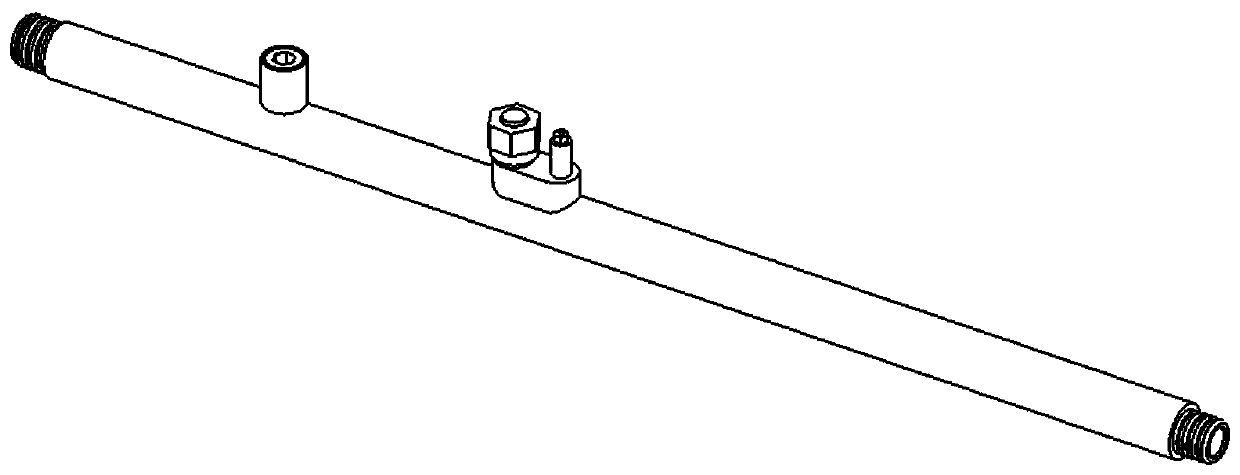

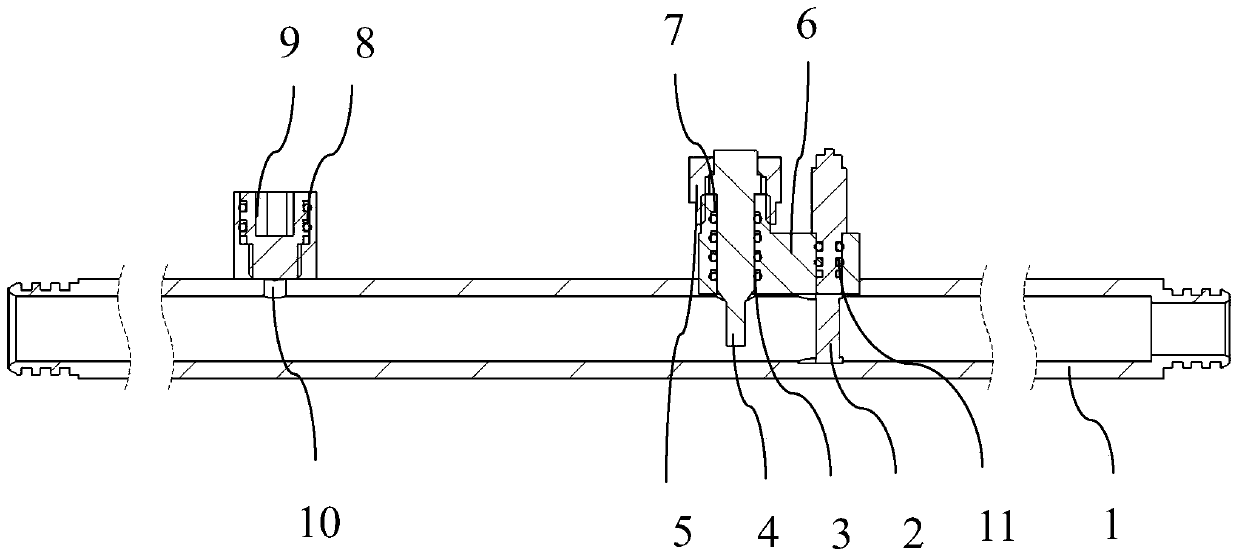

Underground multiphase flow vortex shedding flowmeter

InactiveCN110987092AImprove installation efficiencyRealize repeated replacementVolume/mass flow by dynamic fluid flow effectEngineeringMechanics

The invention discloses an underground multiphase flow vortex shedding flowmeter. The vortex shedding flowmeter comprises a vortex shedding flowmeter pipeline (1), a temperature sensor, a first O-shaped ring set, a vortex shedding probe, a clamping sleeve type pipe nut, an installation body, a second O-shaped ring set, a pressure sensor and a third O-shaped ring set. The vortex shedding probe andthe installation body are fixed through the clamping sleeve type pipe nut. The flow meter is provided with the temperature sensor and the pressure sensor, so that measurement of water, polymers and gas can be realized, injection pressure control is completed through monitoring of the temperature sensor and the pressure sensor, so that measured fluid is guaranteed to be in a fluid state capable ofbeing detected by the vortex street probe and then multi-phase flow fluid flow measurement is achieved. While the detachability of the vortex street probe is realized, problems that when a traditionalvortex street flowmeter is used in an underground rechargeable intelligent water distributor, materials are wasted, the design efficiency is low, the vortex shedding probe cannot be replaced in the later period, installation and maintenance are improper, and the failure rate is high are solved.

Owner:NORTHEAST GASOLINEEUM UNIV

A fully automatic special tape coating machine

ActiveCN109604116BEfficient preprocessingEasy to cleanLiquid surface applicatorsPolishing machinesAdhesive beltPolishing

The invention discloses a full-automatic special tape coating machine, which comprises a main body of the tape coating machine, a load-bearing plate is arranged on one side of the main body of the tape coater, a clamping bolt is welded at one end of the load-bearing plate, and the load-bearing plate passes through The clamping bolt is clamped with the main body of the tape coating machine. The upper part of the load-bearing plate is equipped with a box. Both sides of the inside of the box are inlaid with sliding devices. The bottom of the sliding device is provided with an air pressure rod. Installed with turning rollers. The present invention pretreats the base material effectively by setting the air pressure rod and the polishing plate, the air pressure rod is convenient to adjust the distance between the sponge brush and the polishing plate The motor and chain can effectively make the air pressure rod move inside the box to better clean and polish. By setting the turntable and electric cylinder, the working efficiency of the tape coating machine can be effectively improved, and repeated replacement of the winding roller can be avoided, saving money. Working hours are suitable for being widely promoted and used.

Owner:安徽长正升科技有限公司

Printing equipment capable of conveniently machining PE bottle caps of different sizes

InactiveCN111959113AEasy to adjust the widthEasy to replaceRotary pressesBottle capIndustrial engineering

The invention discloses printing equipment capable of conveniently machining PE bottle caps of different sizes. The printing equipment comprises a table device used for supporting printing. A transferprinting device used for ascending and descending to achieve printing is mounted on the front portion of the table device. A conveying device used for conveying PE bottle caps is arranged below the transfer printing device. Multiple locating devices used for fixing PE bottle caps are evenly distributed on the upper portion of the conveying device. A drive device used for providing power is mounted on the front portion of the conveying device. Through the arrangement of rotating of the locating devices, the clamping width can be adjusted conveniently so as to be suitable for machining PE bottle caps of different sizes; through the arrangement of the transfer printing device, transfer printing plates can be conveniently replaced to convert printing forms; and through the arrangement that PEbottle caps of different sizes are clamped by the locating devices, repeated replacement of clamps is avoided, and time and labor are saved.

Owner:衡阳中豪科技有限公司

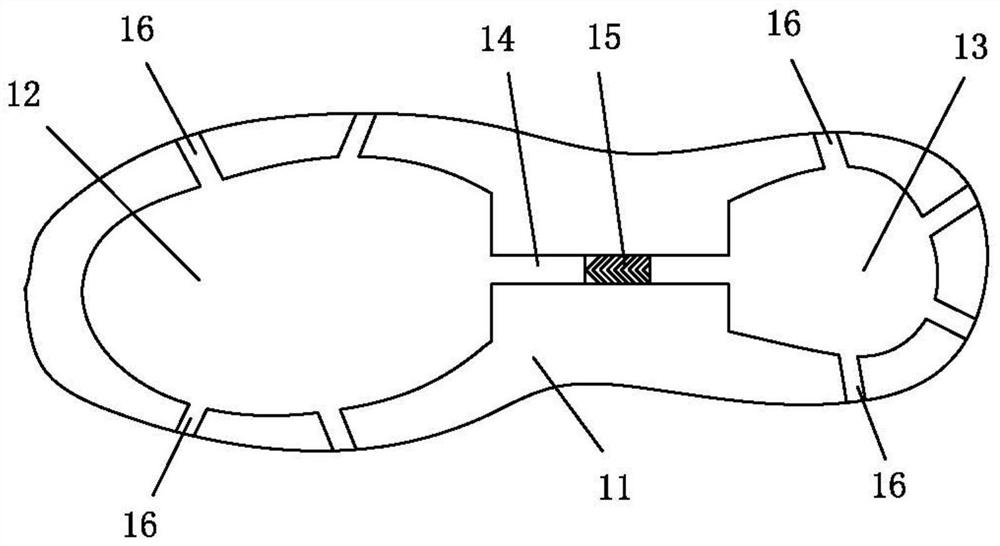

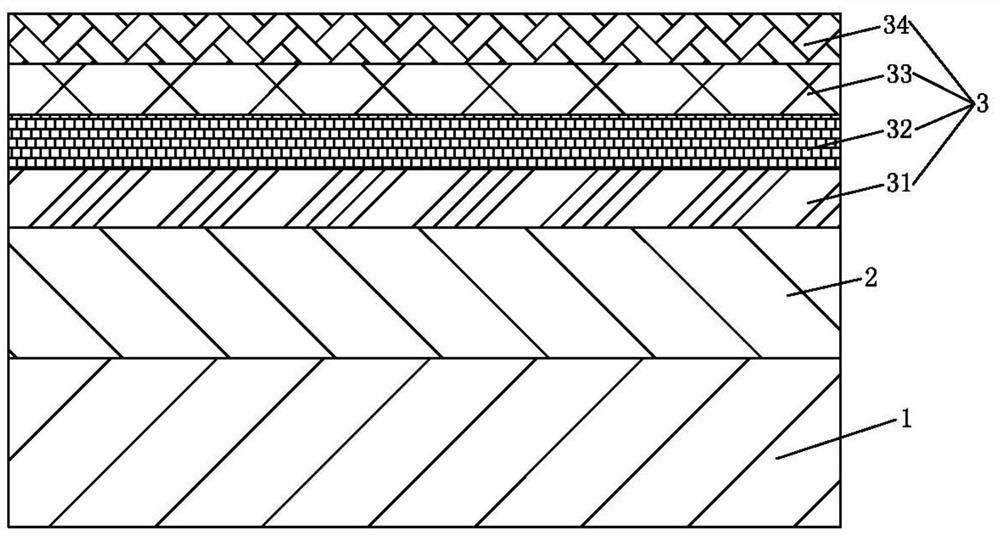

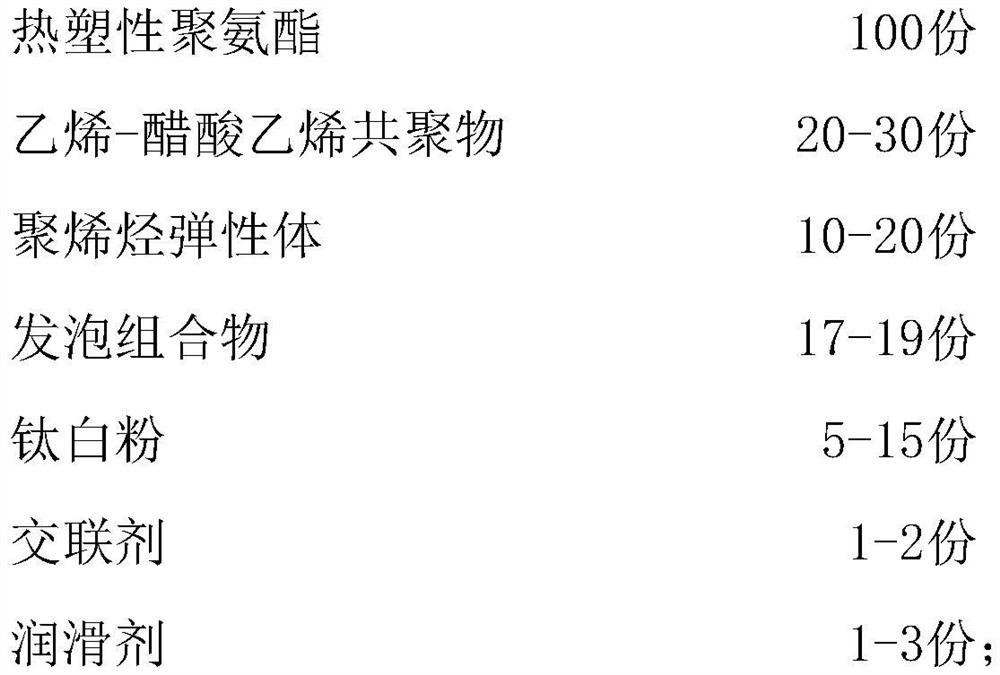

Shock-absorption sneaker sole

PendingCN111820538AImprove shock absorptionComfortable to useSolesSynthetic resin layered productsEngineeringMechanical engineering

The invention relates to the technical field of soles, in particular to a shock-absorption sneaker sole. The shock-absorption sneaker sole comprises a lower sole assembly, an insole body and an insolebody which are sequentially compounded from bottom to top. The lower sole assembly comprises a lower sole body and an air bag assembly. The lower sole body is provided with a containing groove used for containing the air bag assembly. The air bag assembly comprises a front air bag corresponding to the front sole of a human body, a rear air bag corresponding to the heel of the human body and a communicating pipe communicating the front air bag with the rear air bag. A plurality of ventilation pipes communicated with outside air are arranged on the periphery of the front air bag and the periphery of the rear air bag, and a one-way valve used for controlling air in the rear air bag to move towards the front air bag is arranged in the communication pipe. The front air bag and the rear air bagare arranged at the positions corresponding to the front sole and the heel of the human body respectively, the main buffering parts of the whole foot are damped and protected, the buffering and damping effects are better, and use is more comfortable.

Owner:广东康诚新材料科技股份有限公司

Chemical medicine sampling equipment

InactiveCN112649244AReduce reaction progressSlow reaction rateWithdrawing sample devicesControl theoryMechanical engineering

The invention discloses chemical medicine sampling equipment. The equipment comprises a sampling mechanism; a positioning cylinder is in threaded connection with the top of the outer surface of the sampling mechanism; limiting ring hooks are fixedly connected to the top of the outer surface of the positioning cylinder; an auxiliary arc rod is movably connected to the top of the outer surface of the positioning cylinder and located between the limiting ring hooks; a pressing rod is movably connected to the end, away from the positioning cylinder, of the auxiliary arc rod and comprises an inner rod; a sleeve rod is movably connected to the outer surface of the inner rod; a contraction ring sleeve is arranged in the middle of the sleeve rod; the outer surface of the sleeve rod is movably connected with the positioning cylinder; and the outer surface of the contraction ring sleeve is movably connected with the positioning cylinder. The invention belongs to the technical field of chemical machinery. Internal air is removed, an internal vacuum environment is realized, the internal air is prevented from entering a chemical reagent during sampling, the reaction progress and rate of chemicals are reduced, the reaction time of operators is prolonged, and personnel and equipment are protected.

Owner:盐城子业家具有限公司

A clamping and tightening device for an automobile tire assembly mechanical arm

ActiveCN110465962BImprove practicalityAvoid repeated replacementGripping headsWheel mounting apparatusCircular discRobotic arm

The invention provides a clamping and screwing device for an automobile tire assembling mechanical arm, and relates to the technical field of automobile assembling robots. The clamping and screwing device comprises a disk; a first gear is rotationally connected with the inner part of the disk through a ball; a first bevel gear is fixedly mounted at the front end of the first gear; a second bevel gear is engaged with the periphery of the first bevel gear; and a first threaded rod is fixedly mounted at one end, far from the center of the disk, of the second bevel gear. The clamping and screwingdevice can be adjusted to be applied to tires with different sizes at different mounting positions, so that the repeated replacement of the clamping and screwing deice is avoided, the clamping and screwing device is more convenient and quick, the practicability of the mechanical arm is improved, a tire is enabled to rotate per se, the energy consumption is reduced, the clamping and screwing deviceis simple in structure, and the manufacturing cost and difficulty of the mechanical arm are reduced.

Owner:SHAOXING NIKER AUTOMOBILE ACCESSARY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com