A fully automatic special tape coating machine

A kind of coating machine, fully automatic technology, applied in the direction of surface coating liquid device, coating, surface polishing machine tool, etc., can solve the problem of lack of substrate cleaning and polishing functions, poor substrate pretreatment, and work efficiency Low-level problems, to achieve the effect of improving fully automatic performance, convenient automatic replacement, and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

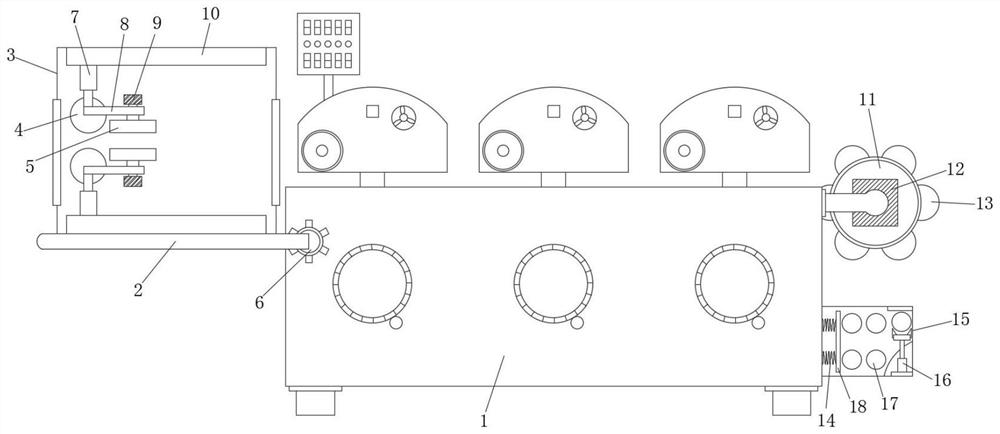

[0025] Such as figure 1 As shown, a fully automatic special tape coating machine includes a main body 1 of the tape coating machine, a load-bearing plate 2 is provided on one side of the main body 1 of the tape coating machine, and a clamping bolt 6 is welded at one end of the load-bearing plate 2, and the load-bearing plate 2 passes through the card The bolt 6 is clamped with the main body 1 of the tape coating machine, and the upper part of the load-bearing plate 2 is installed with the box body 3. The sliding device 10 is inlaid on both sides of the box body 3. The bottom of the sliding device 10 is equipped with an air pressure rod 7, and the bottom side of the air pressure rod 7 is The rotating roller 4 is installed, and the other side of the bottom of the air pressure rod 7 is welded with a connecting column 8, the bottom end of the connecting column 8 is equipped with a polishing plate 5, the upper end of the connecting column 8 is provided with a motor one 9, and the ou...

Embodiment 2

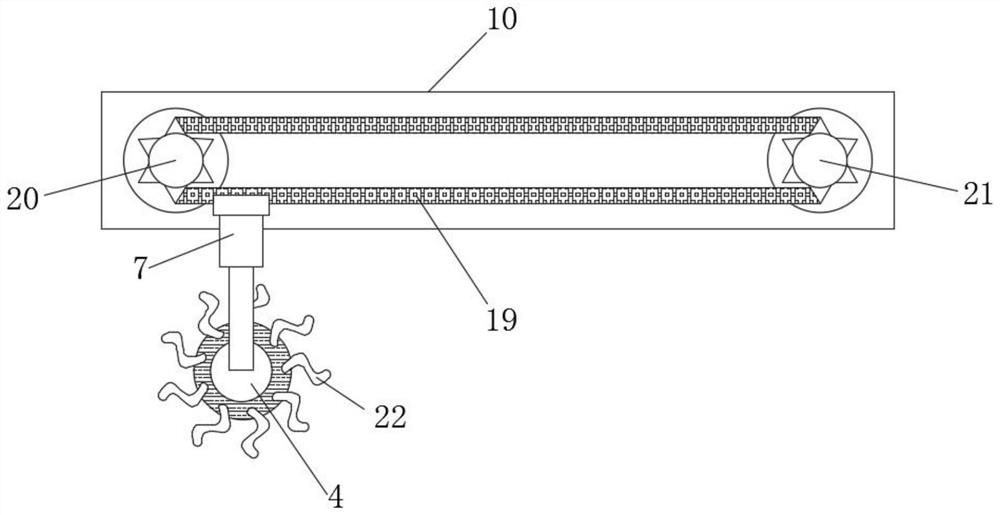

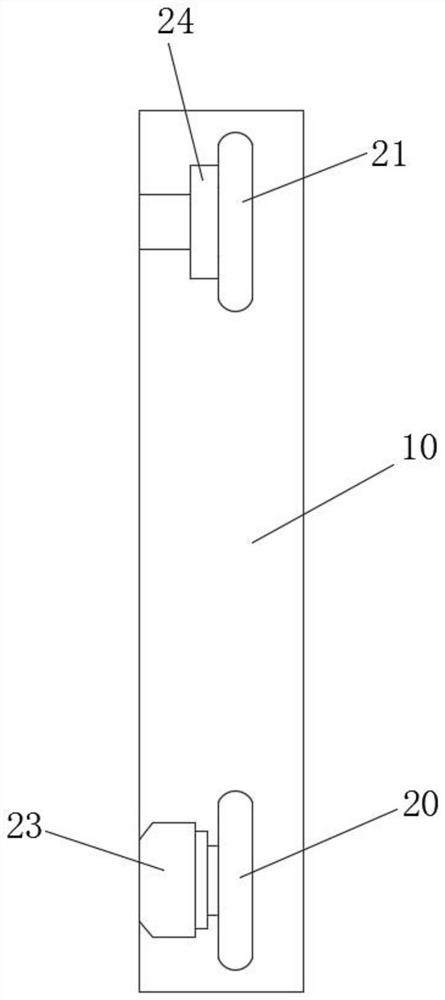

[0028] Such as Figure 1-3 As shown, one end of the sliding device 10 is provided with a gear one 20, and the other end of the sliding device 10 is provided with a gear two 21, the gear one 20 is externally meshed with the chain 19, the gear one 20 is meshed with the gear two 21 through the chain 19, and the chain One end of the bottom of 19 is welded with an air pressure rod 7, and the outside of the rotating roller 4 is bonded with a sponge brush 22, and one side of the gear one 20 is provided with a servo motor 23, and the output shaft of the servo motor 23 is connected with the gear one 20, and the gear one 20 is connected to the The sliding device 10 is connected, and a bearing 24 is installed on one side of the gear two 21, and the second gear 21 is connected with the sliding device 10 through the bearing 24.

[0029] In this embodiment, by setting the servo motor 23 and the chain 19, the air pressure rod 7 can be effectively moved inside the box body, and the cleaning a...

Embodiment 3

[0031] Such as figure 1 with Figure 4 As shown, a turntable 11 is installed at one end of the main body 1 of the adhesive tape coating machine, and a motor 2 12 is arranged on one side of the turntable 11. The side ring is provided with a hydraulic cylinder 25, and one end of the hydraulic cylinder 25 is fixedly connected to the motor 3 26, the output shaft of the motor 3 26 is connected to the slot 27, and the side of the slot 27 is connected to the winding roller 13. One end of the bottom of the main body 1 is equipped with a storage box 15, and the storage box 15 is located directly below the turntable 11. A spring 14 is installed on one side of the inner wall of the storage box 15, and one end of the spring 14 is welded with a push plate 18. The storage box 15 is provided with a storage box. Roller two 17, winding roller two 17 are positioned at push plate 18 one sides, and electric cylinder 16 is installed at one end of storage box 15 bottoms.

[0032] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com