Patents

Literature

41results about How to "Convenient polishing work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

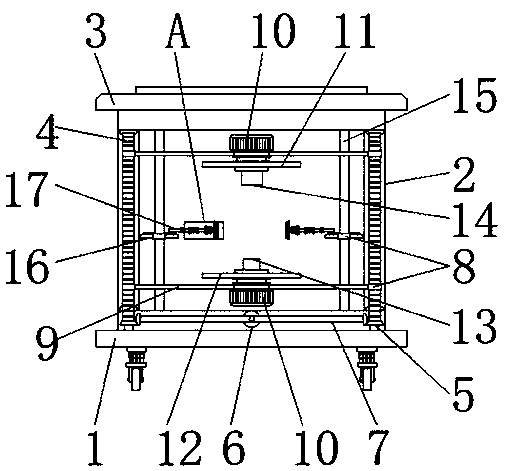

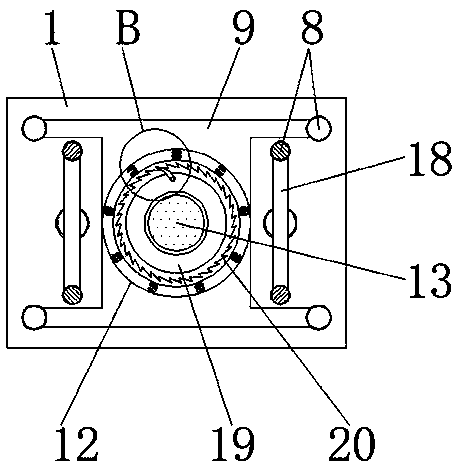

Bearing outer ring polishing machine

InactiveCN107263296AImprove efficiencyImprove yield rateGrinding carriagesPolishing machinesMotor shaftMotor drive

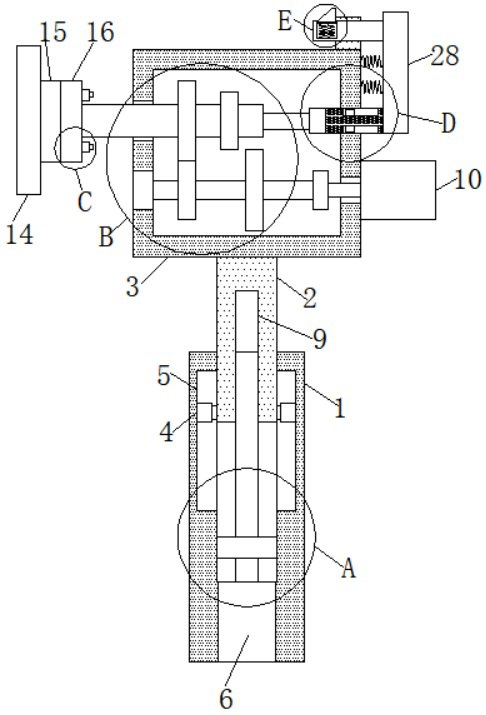

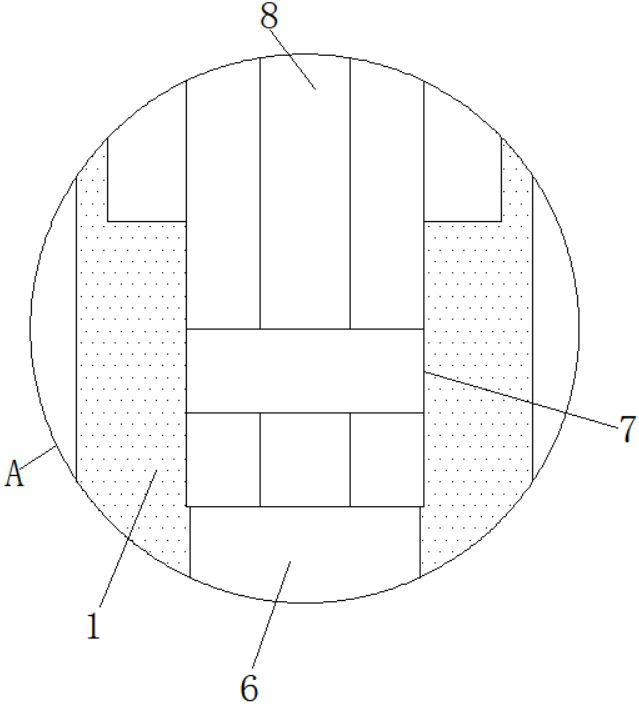

The invention discloses a bearing outer ring polishing machine, which includes a workbench, a support frame is fixedly connected to the bottom of the workbench, a first motor is fixedly connected to the bottom of the inner cavity of the support frame, and a rotating shaft of the first motor Through the top of the workbench and extending to the outside of the workbench, the rotating shaft of the first motor is fixedly connected with a first electric telescopic rod, and the bottom of the first electric telescopic rod is threaded with a limit plate. The present invention facilitates the first motor to drive the outer ring of the bearing to rotate through the cooperation of the first motor, the first electric telescopic rod, the limit plate, the groove, the second electric telescopic rod and the anti-skid pad. The bearing, the support rod, the driven gear and the third electric telescopic rod are used together to sweep the outer ring of the bearing off the limit plate after the polishing of the outer ring of the bearing is completed. This device improves the efficiency of polishing and improves the quality of the product. rate, reducing the production cost of the enterprise.

Owner:HUNAN MEIBEIDA TECH CO LTD

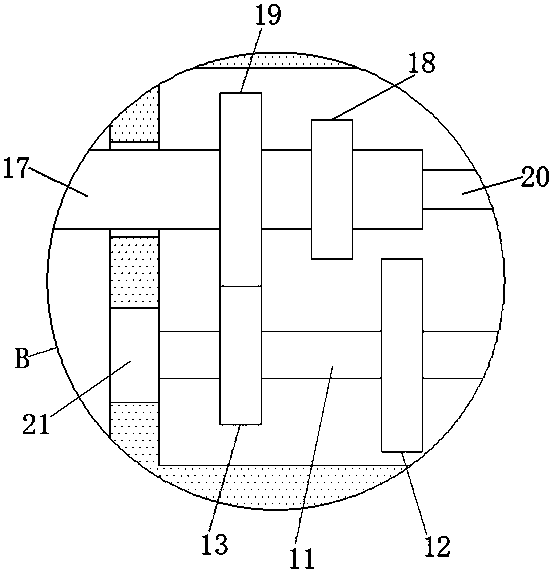

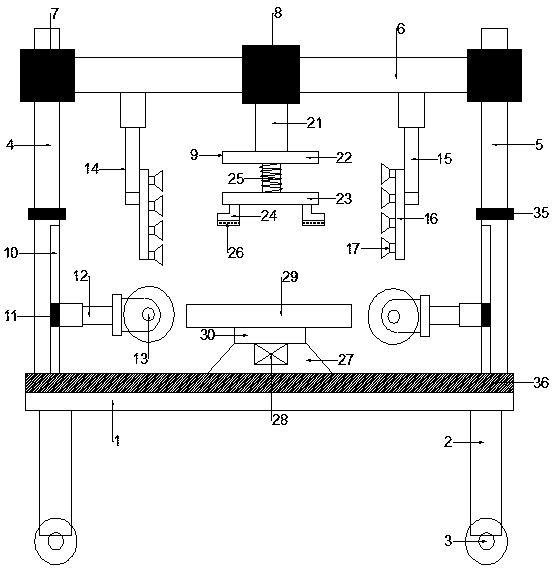

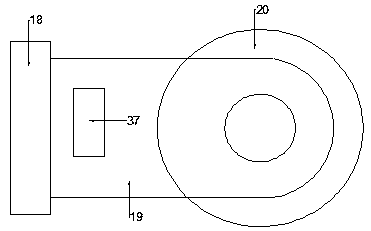

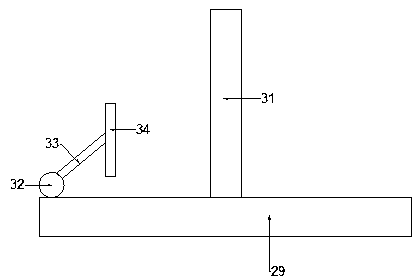

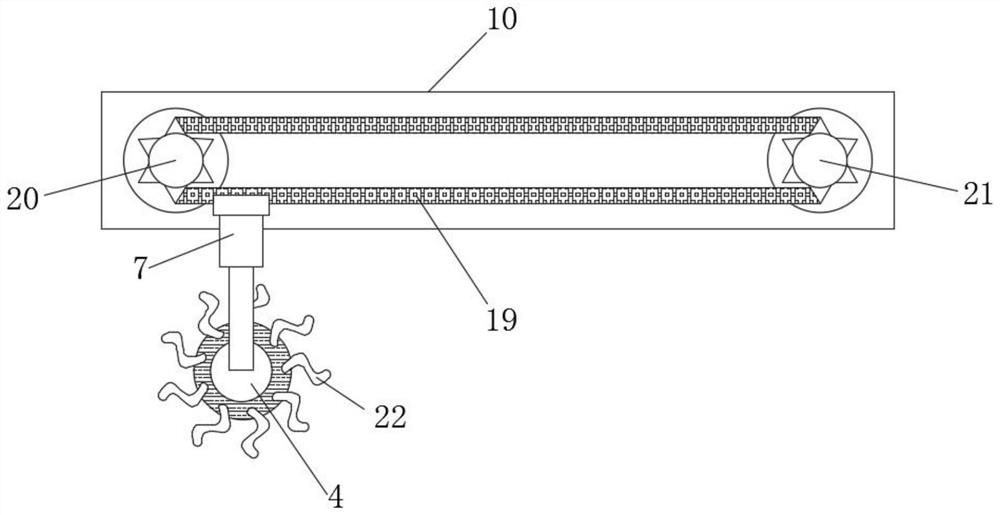

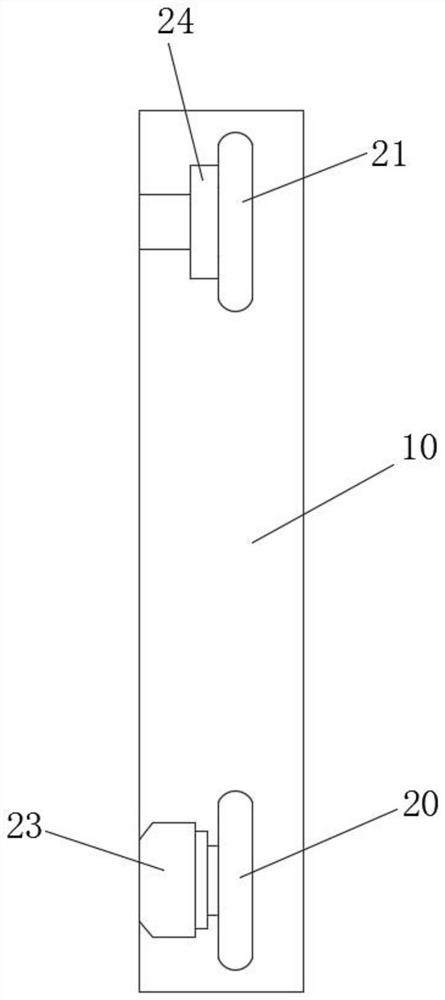

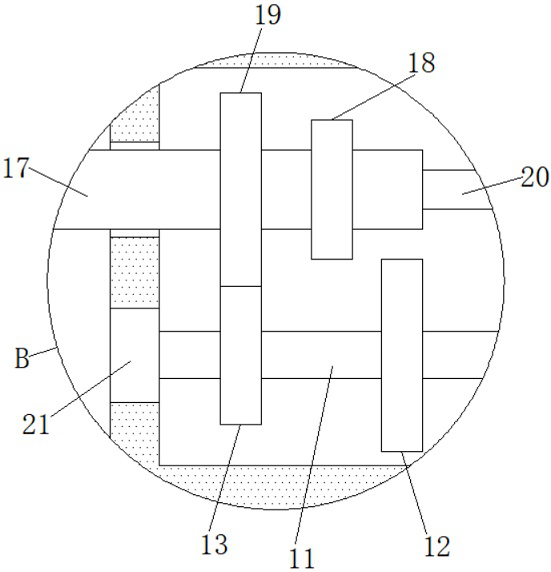

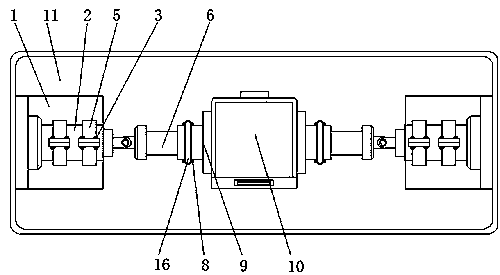

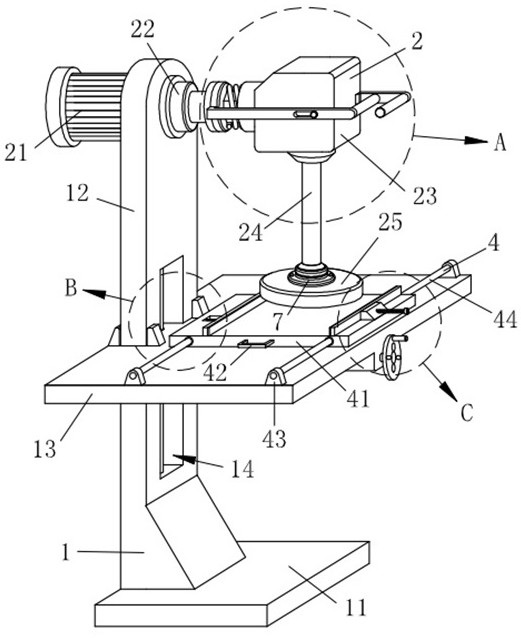

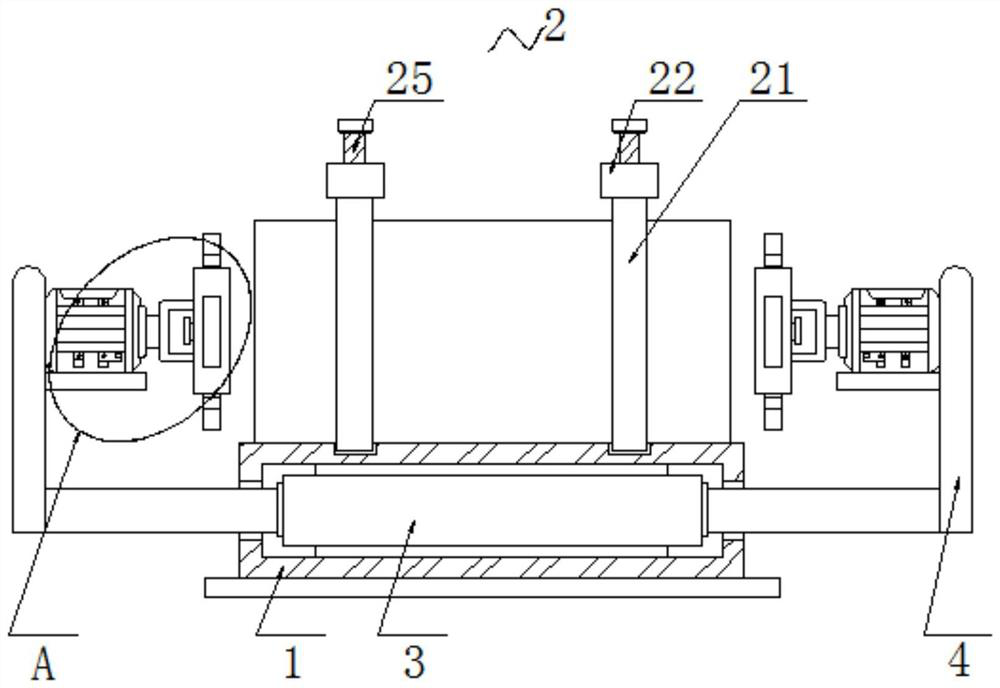

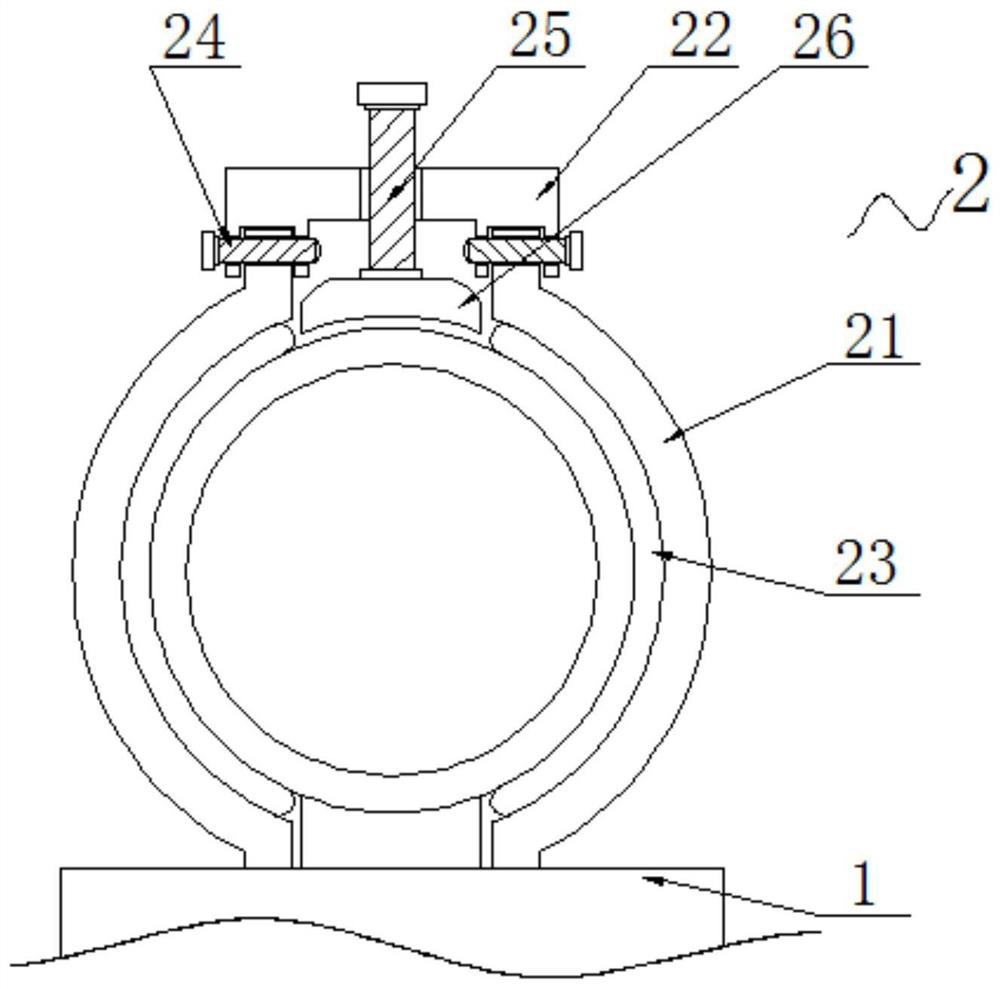

Polishing device for tubular mechanical processing which provides convenience for multi-angle work

ActiveCN109227345AReduce safety incidentsConvenient for fixed workGrinding carriagesPolishing machinesWire rodEngineering

The invention discloses a polishing device for tubular mechanical processing which provides convenience for multi-angle work. The device comprises a base and a lower rising plate, the upper portion ofthe base is connected with a top plate through a support rod, a first wire rod penetrates through the inside of the support rod, the lower bottom of the first wire rod is connected to a first motor through a steering gear set and a conveyor belt, push rods are connected by a compression spring, the top ends of the push rods are provided with third motors, mounting blocks are connected to the topends of the third motors, the mounting blocks and a steel wire brush head are connected by a fixing head, and thread grooves are formed in the upper and lower sides of the steel wire brush head. The polishing device for the tubular mechanical processing which provides convenience for the multi-angle work can perform polishing and grinding work on a large area above tubular parts during single time, and the entire device needs fewer people assist in the work during polishing processing.

Owner:盐城意权汽配制造有限公司

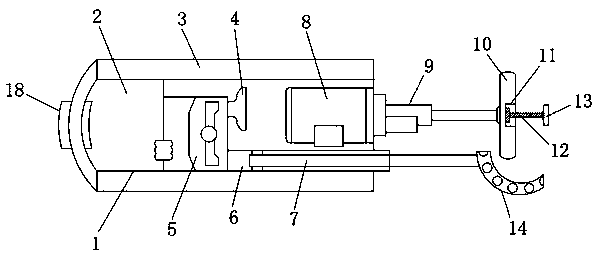

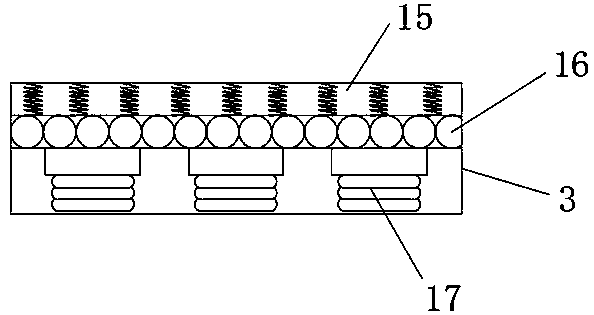

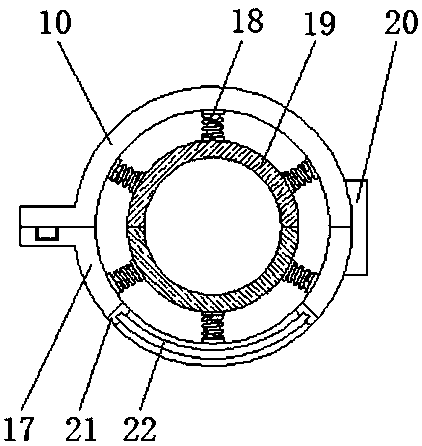

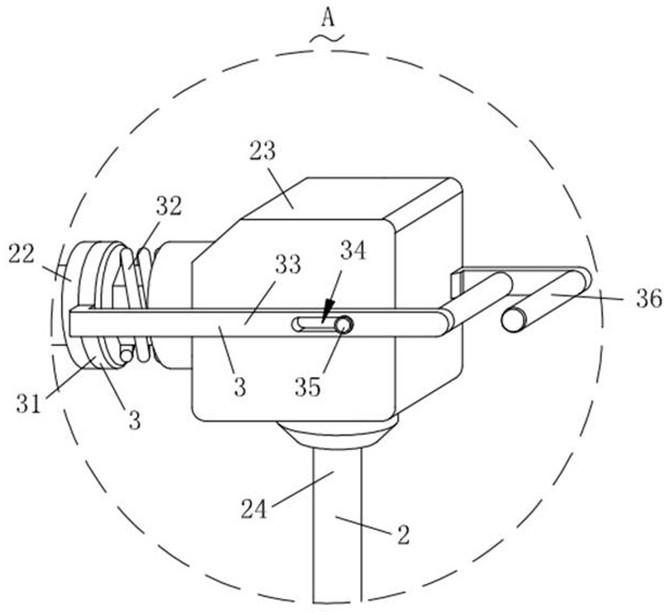

Lipstick metal tube polishing device

InactiveCN108942598AImprove work efficiencyConvenient polishing workPolishing machinesGrinding drivesFixed frameEngineering

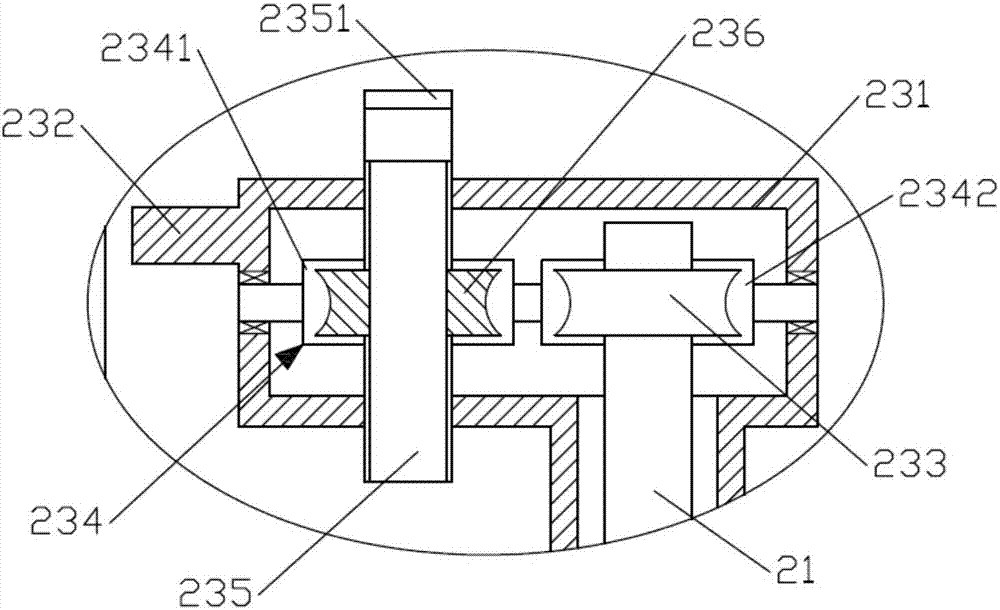

The invention discloses a lipstick metal tube polishing device. The lipstick metal tube polishing device comprises a rack, a first motor, a fixed assembly, a second motor, a lead screw and a grindingpart, wherein the right side of the upper end of the rack is equipped with a fixed frame; the upper end part of the fixed frame is fixedly connected with the first motor; the left end of the first motor is equipped with a rotary shaft; the rotary shaft is fixedly connected with a metal tube through the fixed assembly; the fixed assembly comprises a pushing button, an inclined-surface slide sleeve,a fixed sleeve, a telescopic pole, an inclined-surface slide block and a fixed plate; the pushing button sleeves the middle part of the outer side of the rotary shaft; and the middle part of the outer side of the rotary shaft is equipped with an outer threaded structure. According to the lipstick metal tube polishing device disclosed by the invention, the pushing button rotates, so that the inclined-surface slide sleeve slides leftwards, and therefore, the inclined-surface slide sleeve is pushed to move to the outer side; and the inclined-surface slide block pushes the fixed plate through thetelescopic pole, so that the inner side wall of the metal tube is blocked, follow-up polishing work is convenient, and polishing of the outer side of the metal tube is not affected, and therefore, working efficiency of the lipstick metal tube polishing device is improved.

Owner:ANHUI YIXUAN METAL SCI & TECH CO LTD

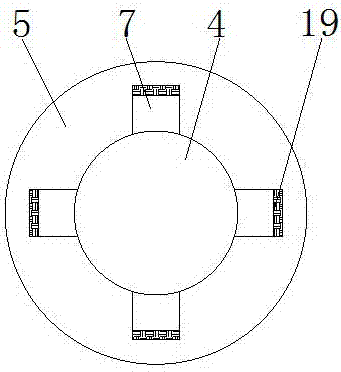

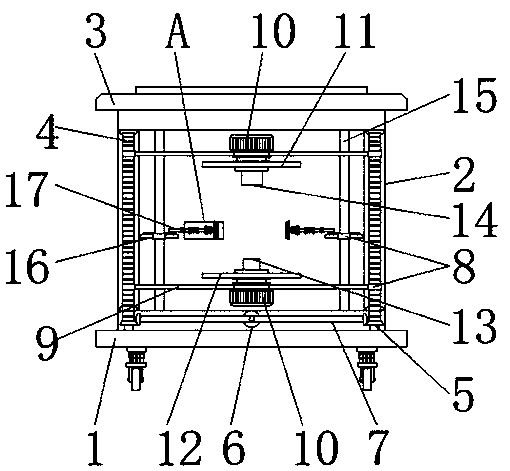

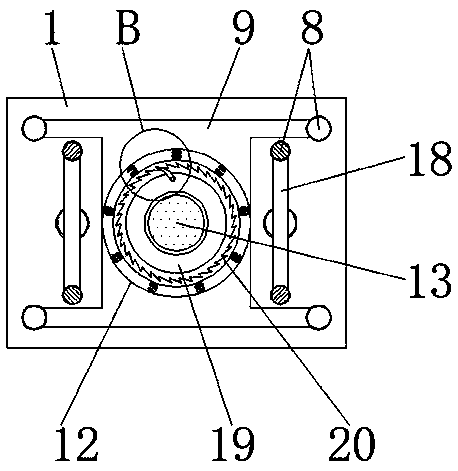

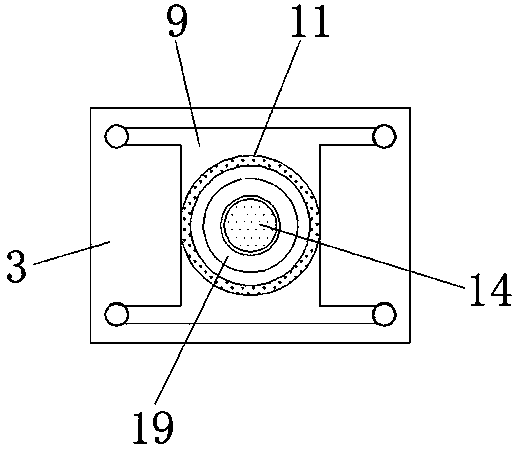

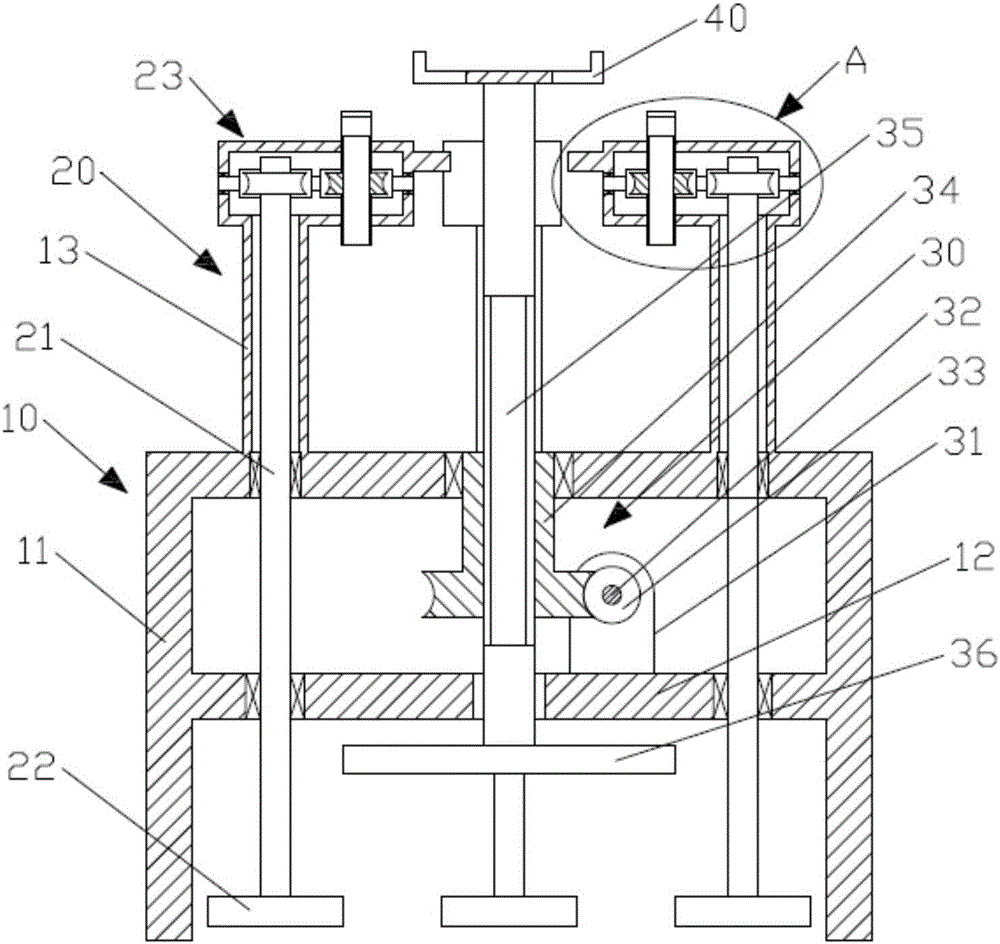

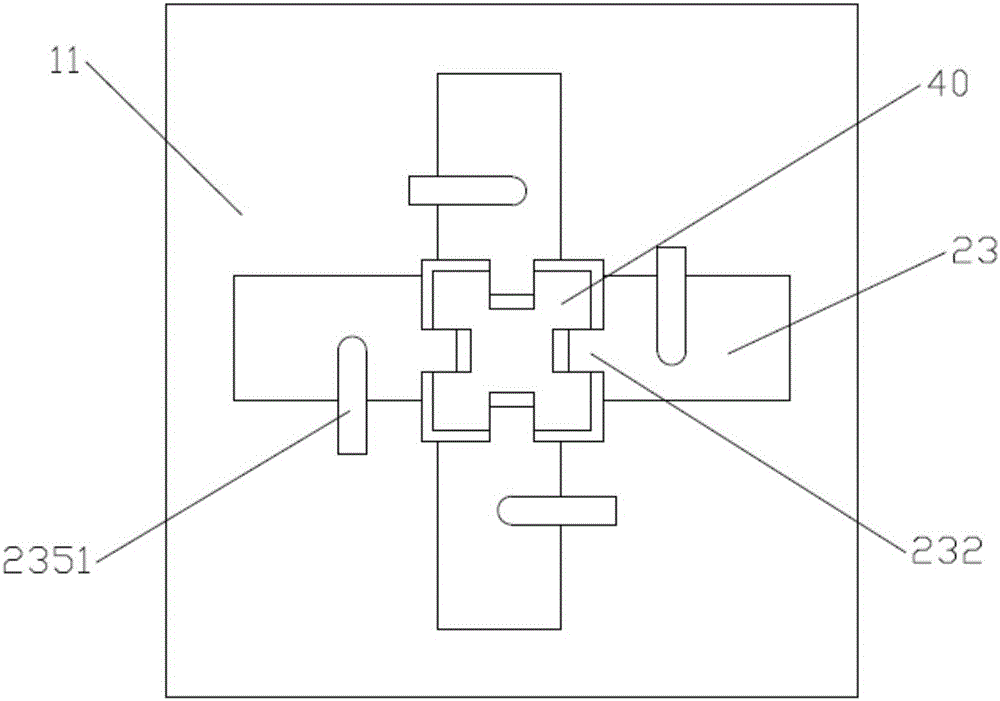

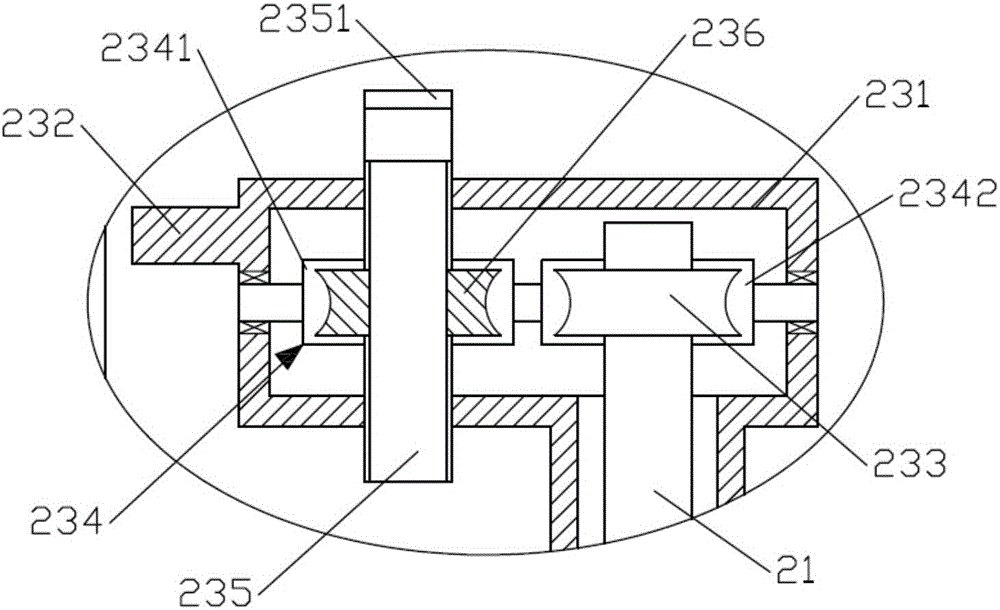

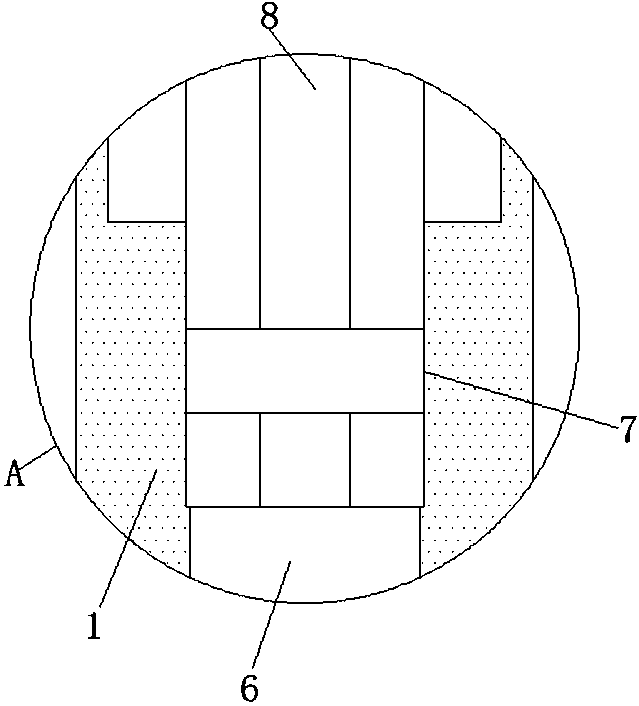

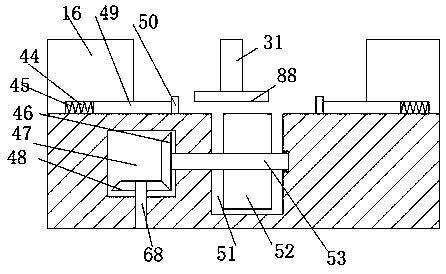

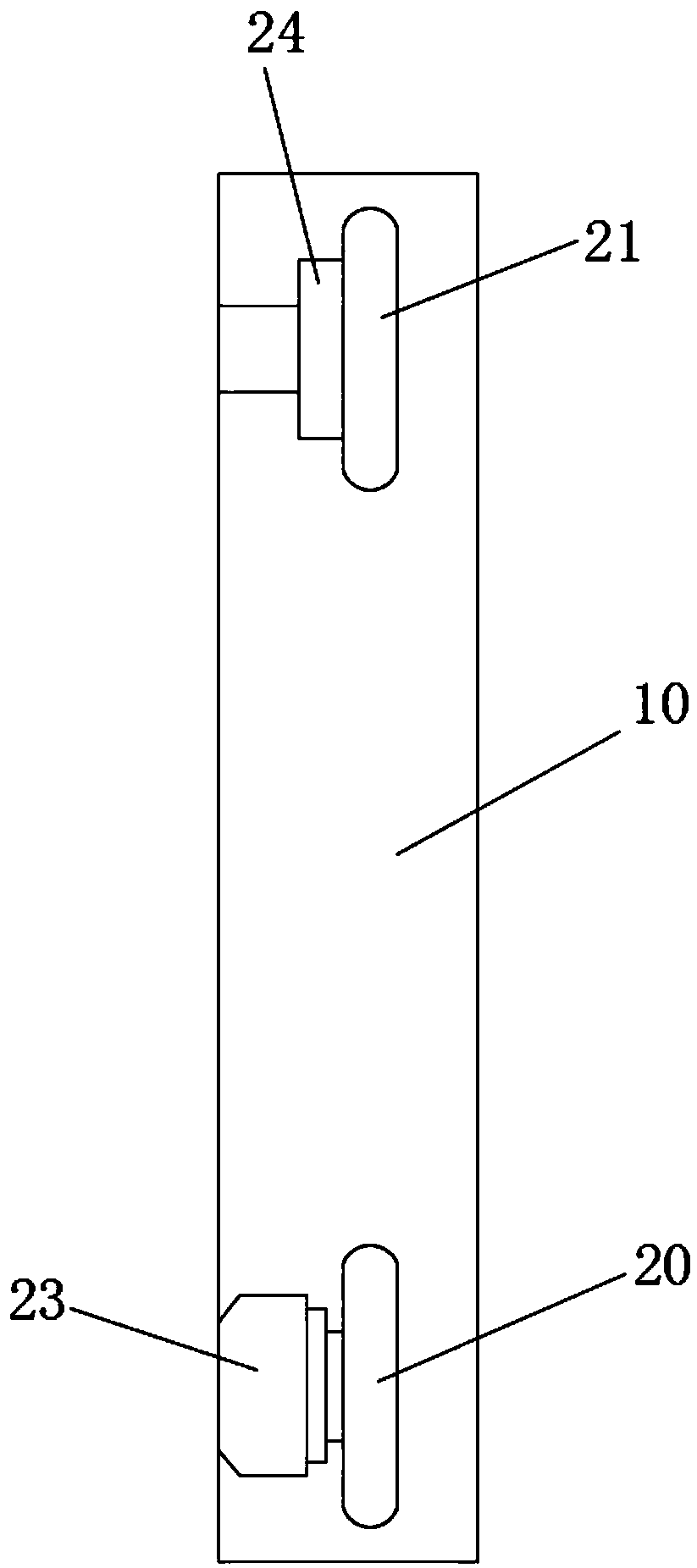

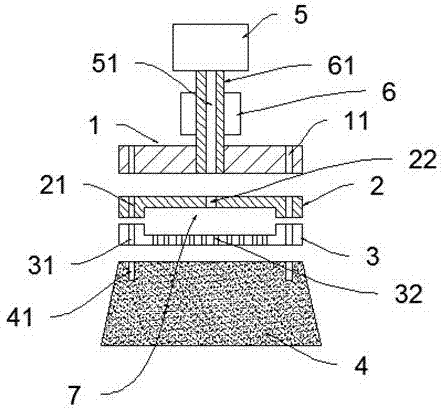

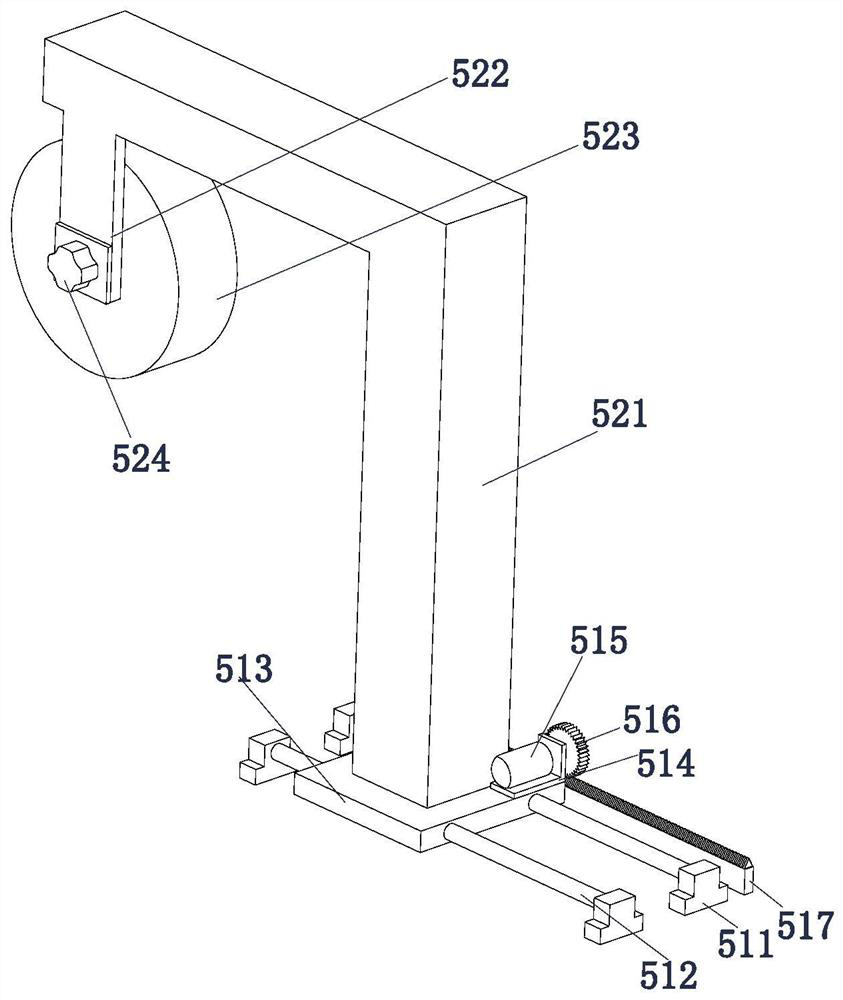

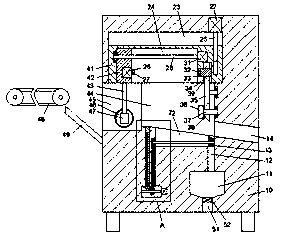

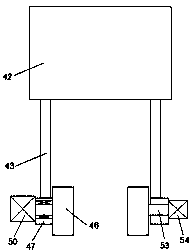

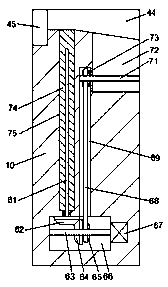

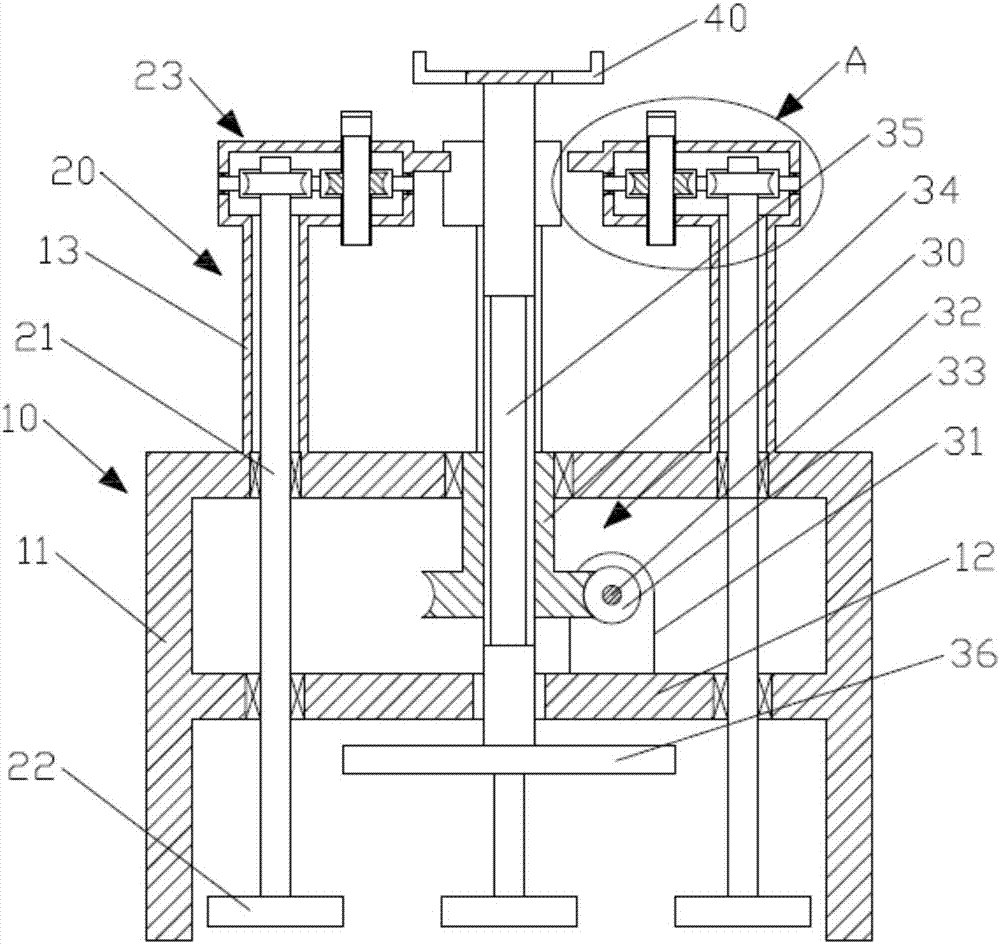

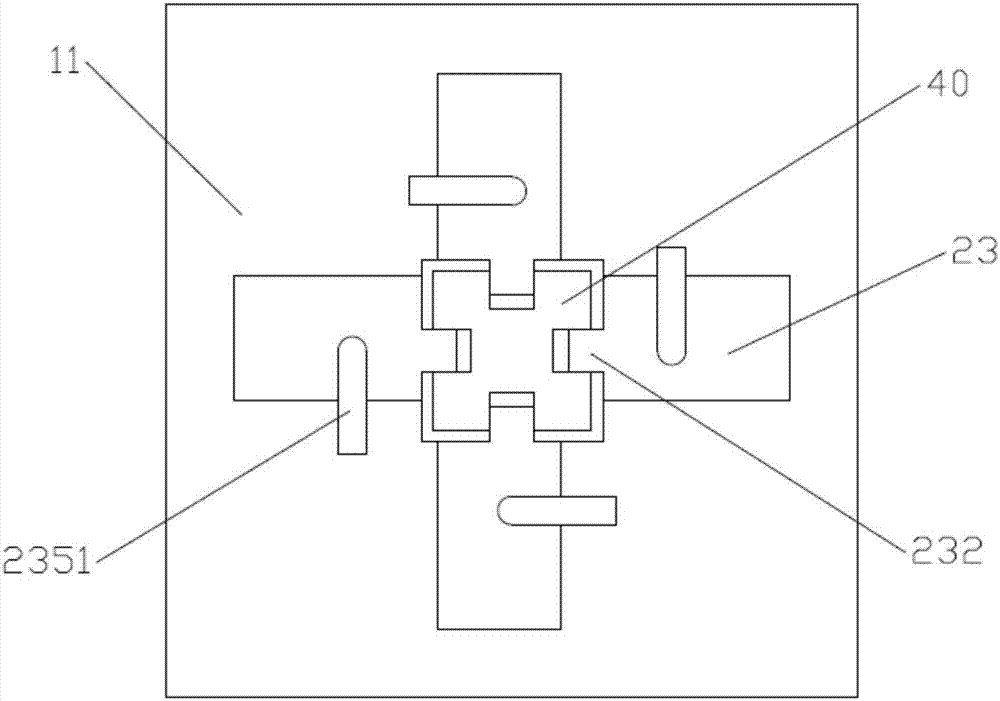

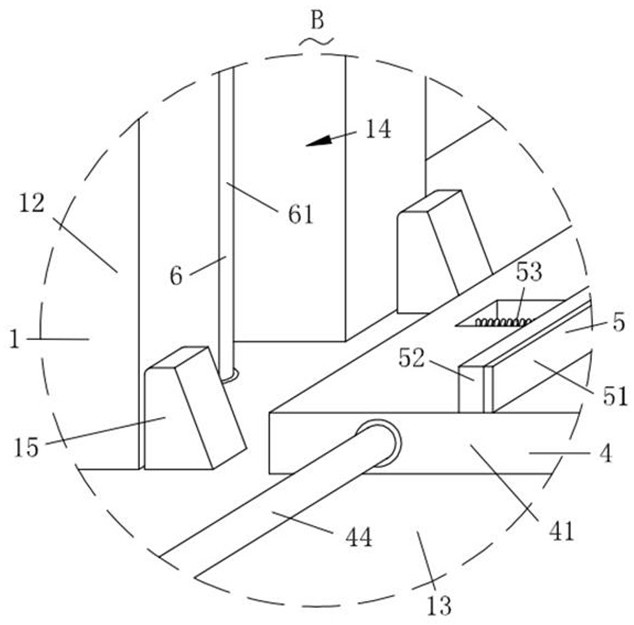

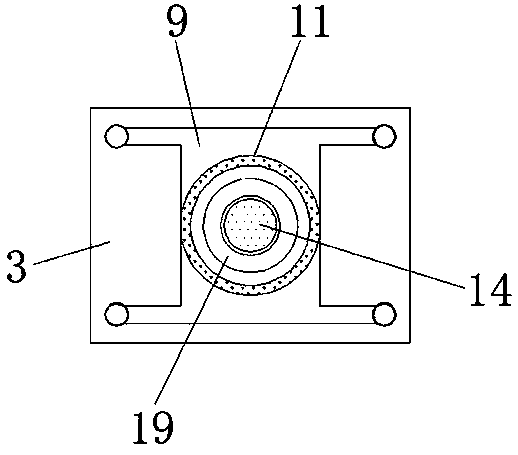

SMT laser template polishing clamp

The invention discloses an SMT laser template polishing clamp. The SMT laser template polishing clamp comprises a rack, clamping devices and a template lifting device. A vacant cavity is formed in the rack. A fixing plate is transversely arranged in the rack. Four hollow columns are vertically fixed to the upper end face of the rack. Through holes in the hollow columns communicate with the vacant cavity in the rack. The template lifting device is vertically arranged in the center position of the rack. The number of the clamping devices is the same as the number of the hollow columns. The clamping devices are fixed to the hollow columns. A template containing box is fixed to the upper portion of a first threaded rod of the template lifting device, and a center gear is fixed to the lower portion of the first threaded rod of the template lifting device. Transmission shafts of the clamping devices are vertically inserted in the hollow columns. The middle portions of the transmission shafts are pivoted to the upper side wall of the rack, and transmission gears are fixed to the upper portion and the lower portion of the fixing plate. The SMT laser template polishing clamp has the beneficial effects that by means of the template lifting device and the clamping devices, a template can be suspended above the rack, and the subsequent polishing work is greatly facilitated.

Owner:中山市创隆电子有限公司

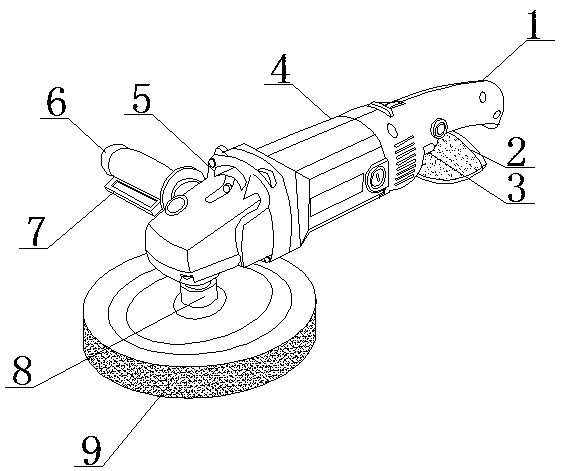

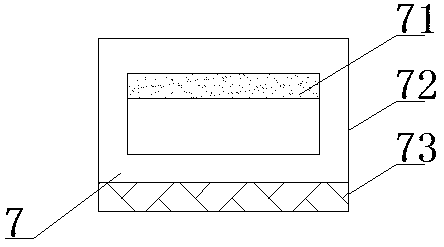

Handheld metal surface treatment device with multi-rotating speed adjusting mechanism

ActiveCN110561243AAchieve scaleControl lengthGrinding drivesPortable grinding machinesMechanical engineeringThreaded rod

The invention discloses a handheld metal surface treatment device with a multi-rotating speed adjusting mechanism. The handheld metal surface treatment device comprises an installation pipe, wherein an installation box is fixedly installed at one end, far away from the installation pipe, of a movable rod, and a manual speed adjusting device is installed in the installation box. The handheld metalsurface treatment device has the advantages that a telescopic device is installed between the installation pipe and the movable rod, and a first motor is used for driving a first threaded rod and a threaded groove on the movable rod to be matched with each other, so that the telescoping of the movable rod is realized, the length of a holding rod is further controlled, and convenience is provided for polishing work; amd the manual speed regulating device is installed in the installation box, and a first gear and a third gear are engaged or a second gear and a fourth gear are engaged through sliding a linkage rod, so that different rotating speeds are realized by different transmission ratios, the operation is convenient, and the polishing quality is improved.

Owner:重庆华智天下科技有限公司

Gear manufacturing equipment with illuminating function

InactiveCN109352469AEffective control of rotationControl rotationGrinding machinesGrinding work supportsEngineeringAtmospheric pressure

The invention discloses gear manufacturing equipment with an illuminating function. The gear manufacturing equipment with the illuminating function comprises a manufacturing equipment body, a manufacturing cavity is formed in the manufacturing equipment body, and a clamping assembly is installed in the manufacturing cavity; the clamping assembly comprises pushing sliding rods which are slidably installed on the left side wall and the right side wall of the manufacturing cavity in a bilateral symmetry mode, first sliding cavities are formed in the portions, on the outer sides of the pushing sliding rods, of the interior of the manufacturing equipment body in a bilateral symmetry mode, and first piston blocks fixedly connected with the pushing sliding rods are slidably installed in the firstsliding cavities; and first air pressure cavities are formed in the outer side walls of the first sliding cavities in a communicating mode, the left first air pressure cavity and the right first airpressure cavity are in power connection with a first air pressure cylinder, and the first air pressure cylinder is fixedly installed in the manufacturing equipment body. According to the gear manufacturing equipment, a gear can be quickly and conveniently clamped between abutting plates on the left side and the right side, the clamped gear can be effectively controlled to rotate, then polishing work can be conveniently conducted on the gear, the working steps are simple and convenient to operate, and the high usage and popularization value is achieved.

Owner:NINGBO ZHUXING MACHINERY DESIGN

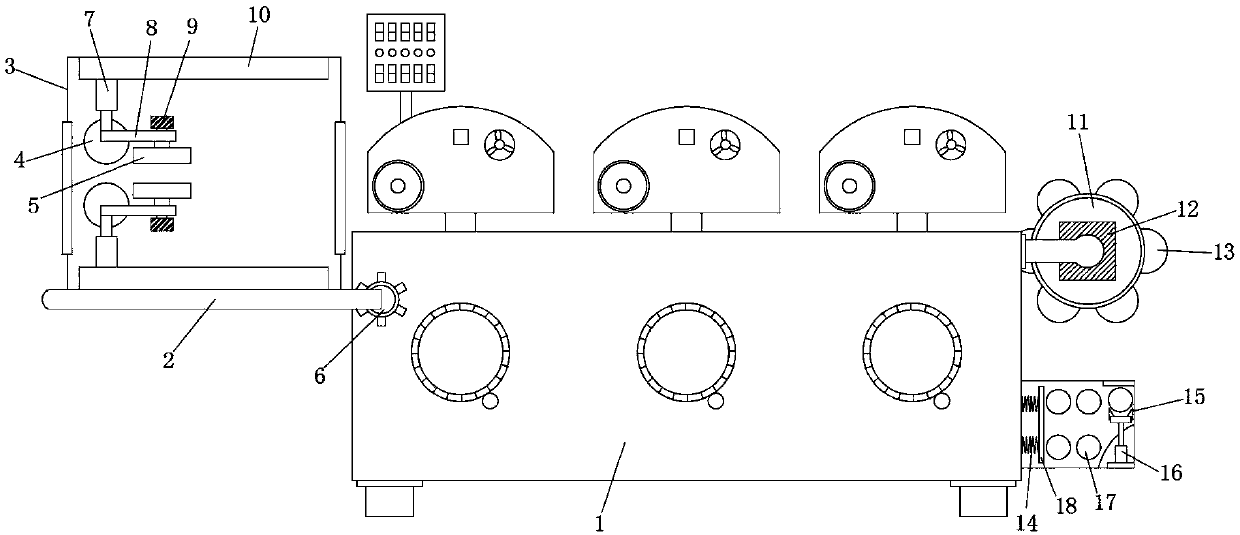

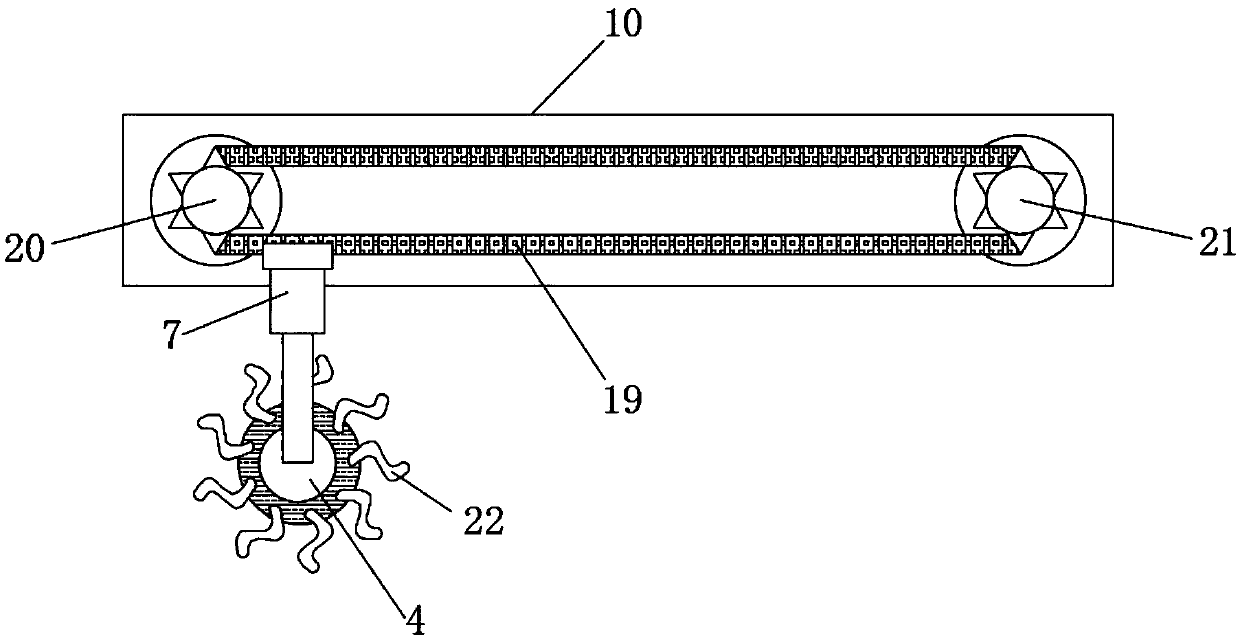

Polishing and grinding device for pearl processing

The invention discloses a polishing and grinding device for pearl processing. The device comprises a bottom plate, an upper shell, a lower shell, a screw rod, a support frame, a fixed frame and a workbench, wherein the lower shell is arranged in the middle of the upper end of the bottom plate; a first filter screen is arranged at the upper part of the inner side of the lower shell; a sliding slopeis arranged at the lower end in the lower shell; the workbench is arranged at the upper end of the lower shell; a working plate is arranged in the middle of the upper end of the workbench; through holes are formed in the middle of the working plate and the middle of the workbench; a pressing plate is arranged at the upper end of the working plate; a pearl cavity is formed between the pressing plate and the workbench and corresponds to the through holes; and the upper shell is arranged at the workbench. The polishing and grinding device for pearl processing is reasonable in structural design;an air blowing mechanism and a dryer are arranged, drying of pearls is facilitated, the air drying process is reduced, and time is saved; and a gear, a rack, the screw rod and a sliding rod are arranged, a polishing motor assembly can be moved in a front-back direction and the left-right direction, polishing work can be conveniently conducted, and the using requirement can be better met.

Owner:SUZHOU CHINA PEARL & GEM CITY CO LTD

Tile polishing device

InactiveCN111251168AConvenient polishing workAvoid damageGrinding carriagesPolishing machinesElectric machineGear wheel

The invention discloses a tile polishing device which comprises a device body. Connecting frames are symmetrically and fixedly connected to the front side and the rear side of the upper end face of the device body. A groove opened upwards is formed in the left side of the device body. An upper device body is fixedly installed at the upper ends of the connecting frames. A first moving cavity is formed in the device body. A through hole is formed in the portion, between the front connecting frame and the rear connecting frame, of the lower end face of the first moving cavity. A first motor is fixedly installed on the left end face of the first moving cavity. The first motor is in power connection with a first transmission shaft. A second bevel gear is fixedly connected to the first transmission shaft. A transmission device is arranged in the first moving cavity. A first rotating shaft is connected to the connecting frames in a rotating manner. A second roller is fixedly installed on thefirst rotating shaft. The groove is provided with a worm connected with the front end face and the rear end face in a rotating manner.

Owner:LISHUI LIANDU MINGBAO AUTOMATION TECH CO LTD

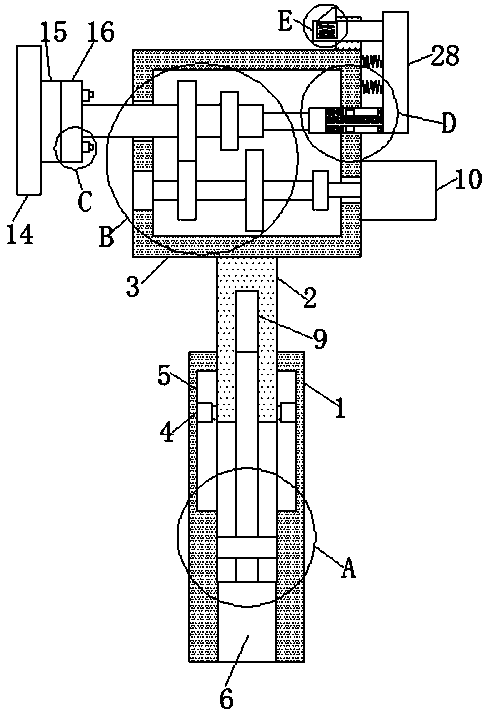

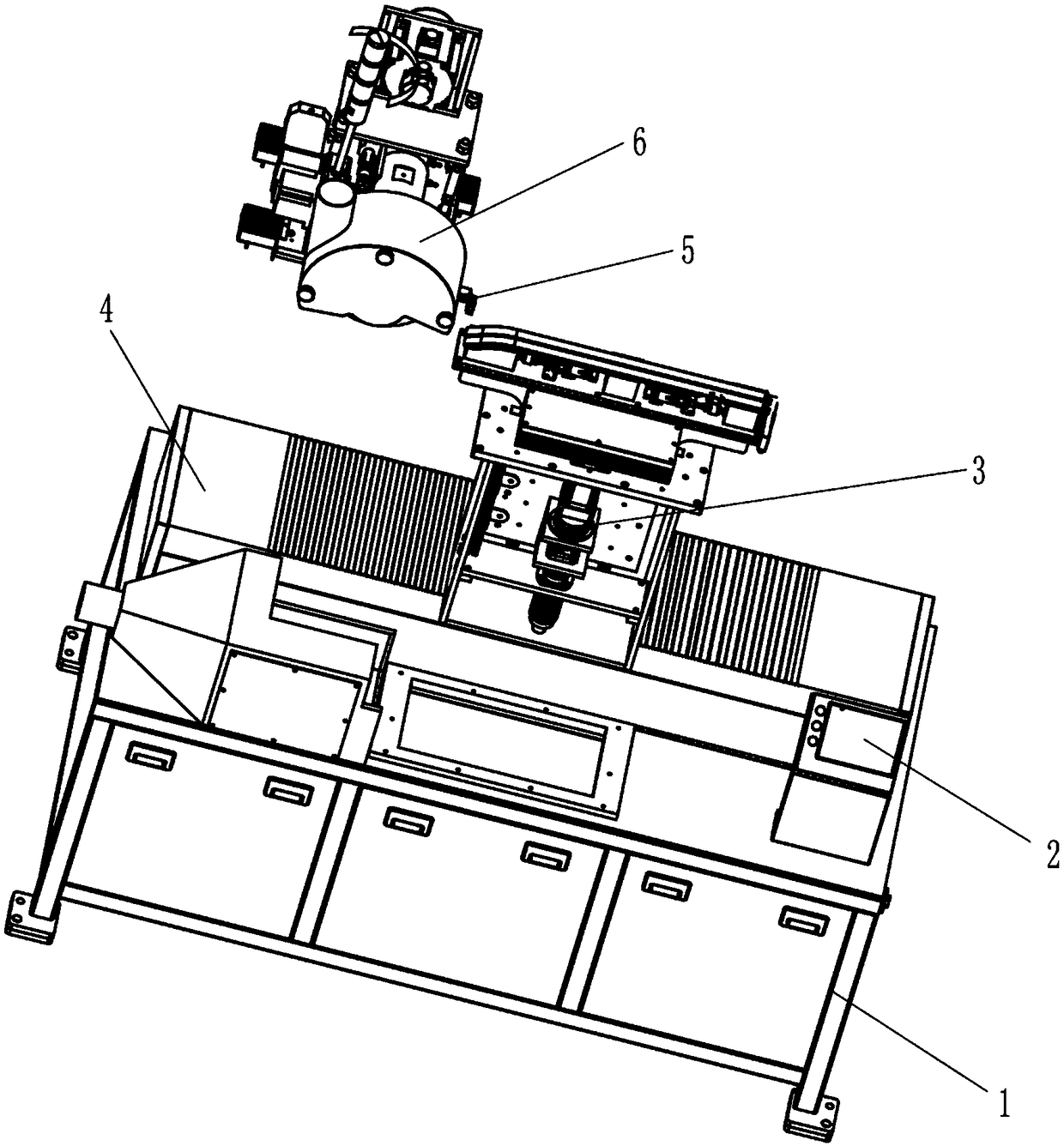

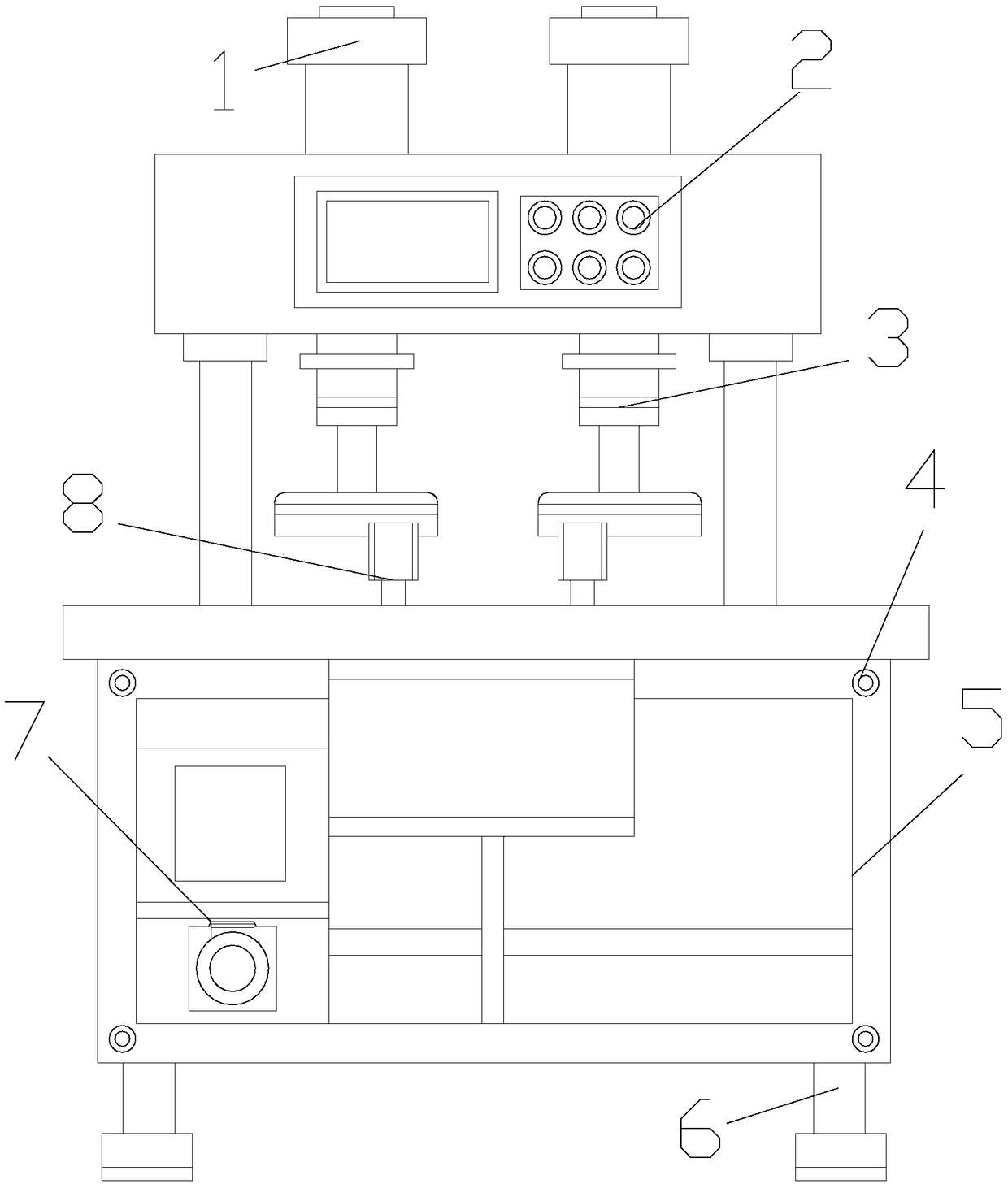

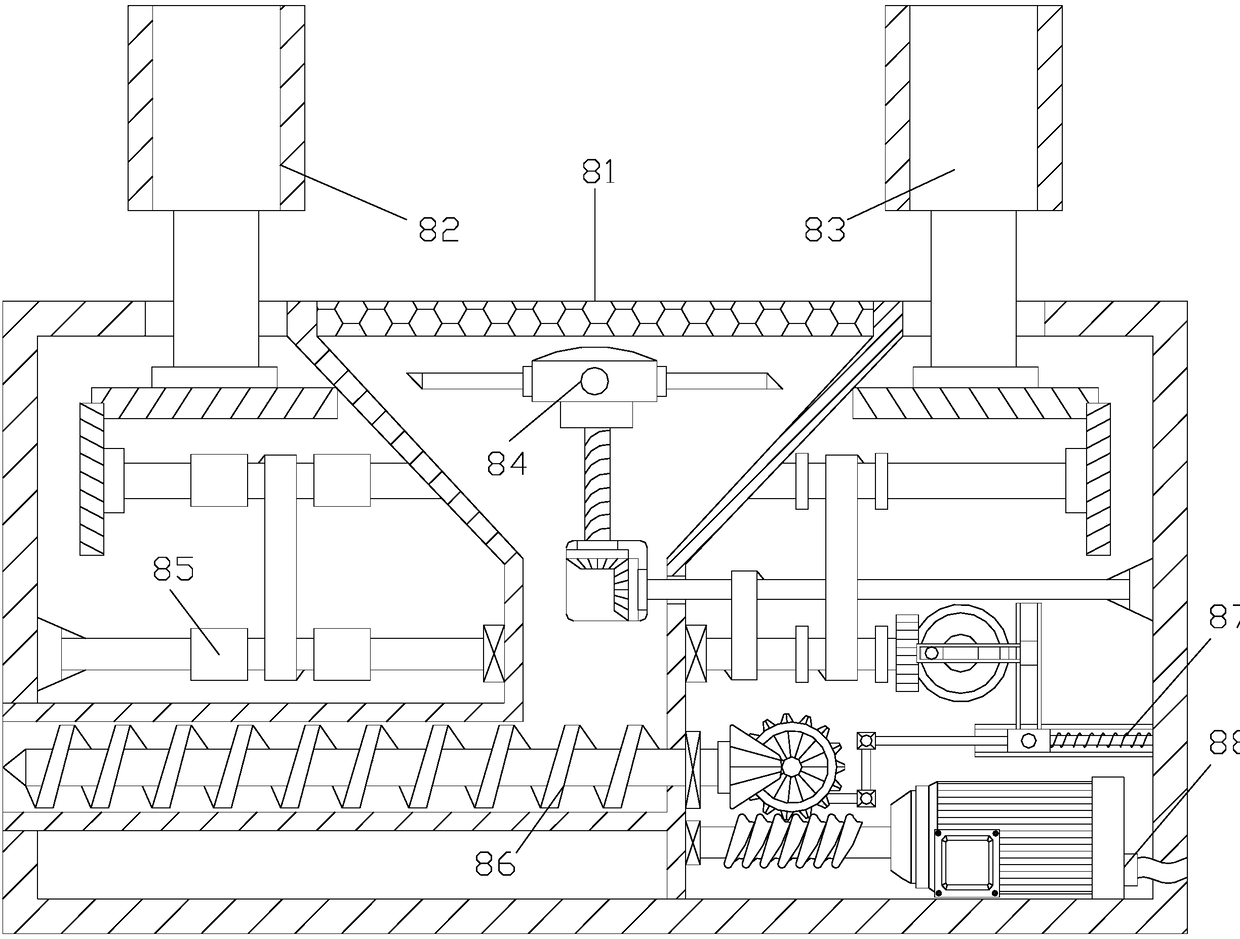

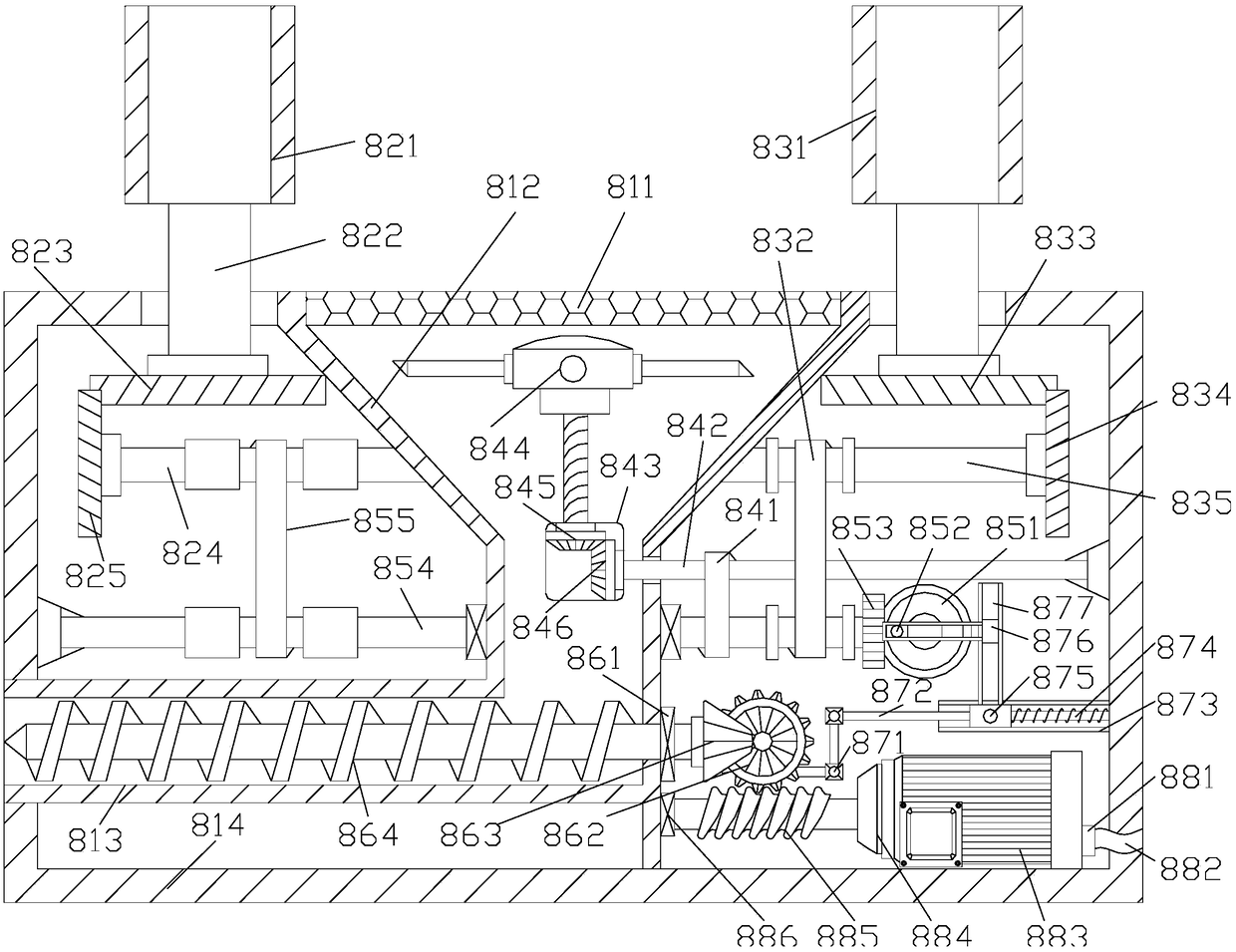

Automatic-contour-tracking polishing device

PendingCN109434664AConvenient polishing workHigh polishing precisionPolishing machinesGrinding drivesReciprocating motionEngineering

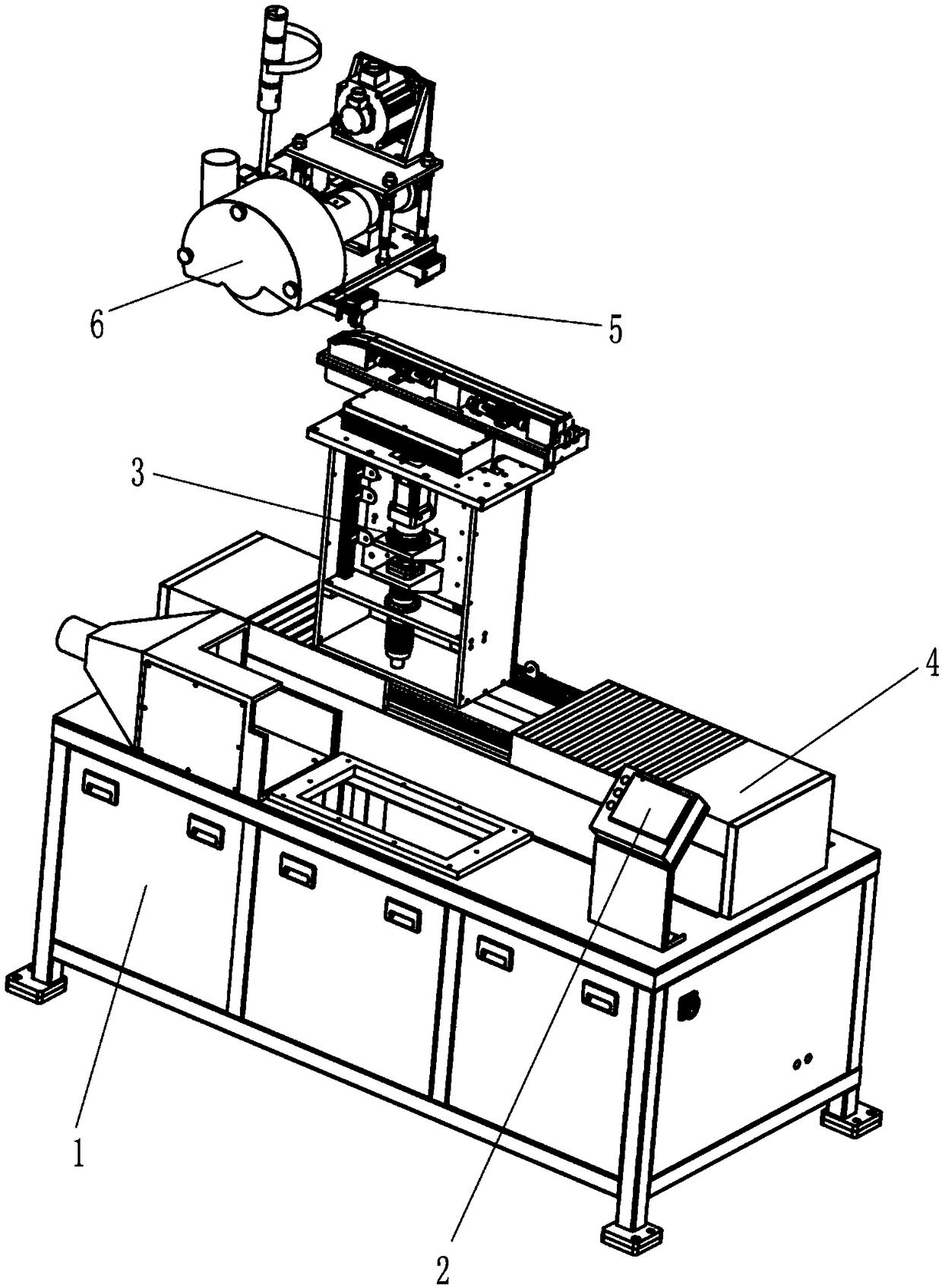

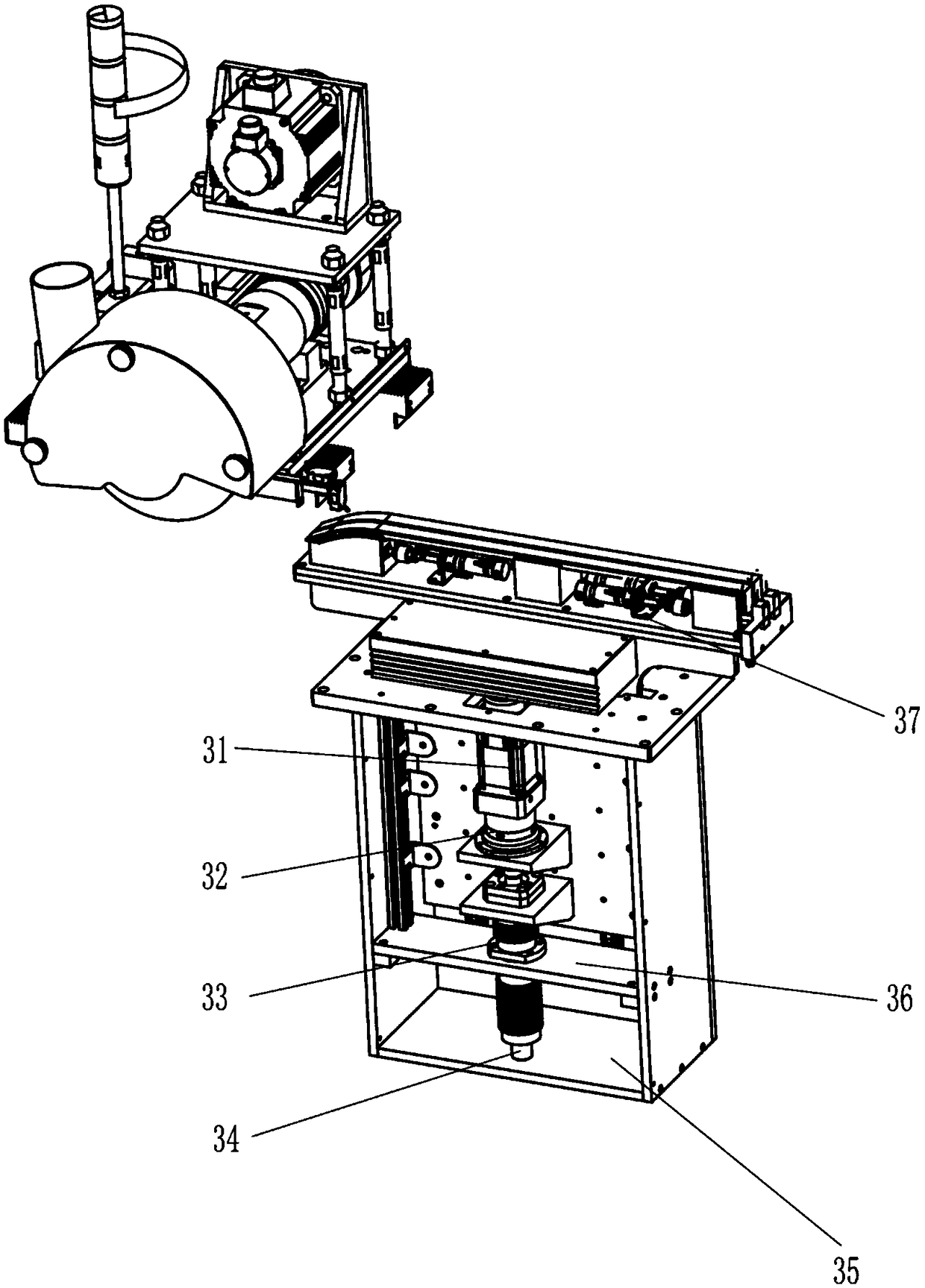

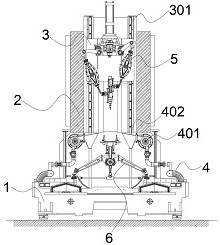

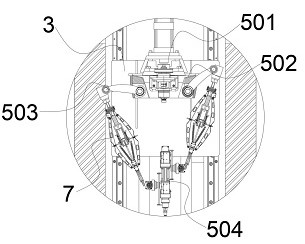

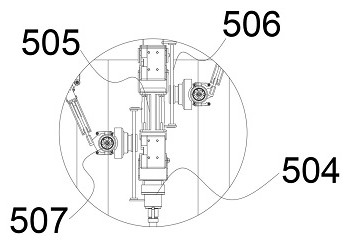

The invention relates to a polishing device, in particular to the automatic-contour-tracking polishing device. The device aims to solve the technical problem that the automatic-contour-tracking polishing device is provided so that the size deviation can be automatically corrected, and the good polishing contact with the surface of a product to be polished is guaranteed. In order to solve the technical problem, the invention provides the automatic-contour-tracking polishing device. The device comprises a rack, a control touch screen, an up-down moving mechanism, a reciprocating motion mechanismand the like, wherein a polishing mechanism can do reciprocating motion along the motion trail of the reciprocating motion mechanism, the bottom of the up-down moving mechanism is arranged on the rack, and the moving end of the up-down moving mechanism is used for clamping a workpiece to be machined. According to the device, the state that the workpiece is always in friendly contact with an output end of the polishing mechanism can be ensured, so that the effects that the polishing mechanism can automatically track the contour of the workpiece and the polishing precision is high are achieved.

Owner:ZHONGSHAN DAYA HARDWARE

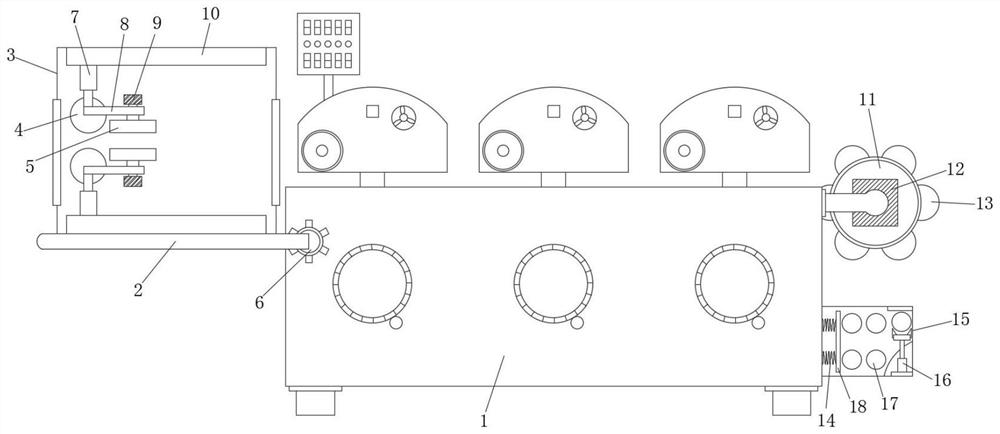

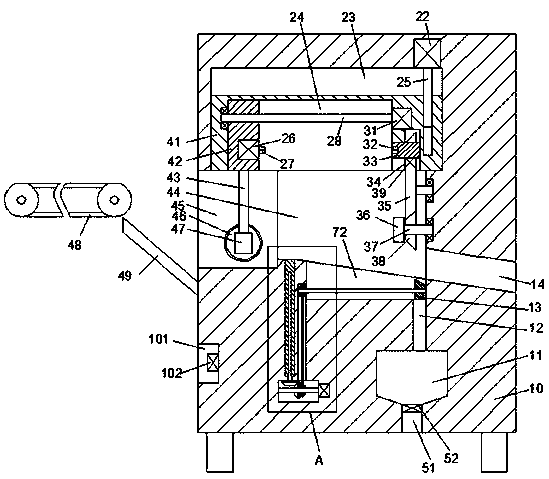

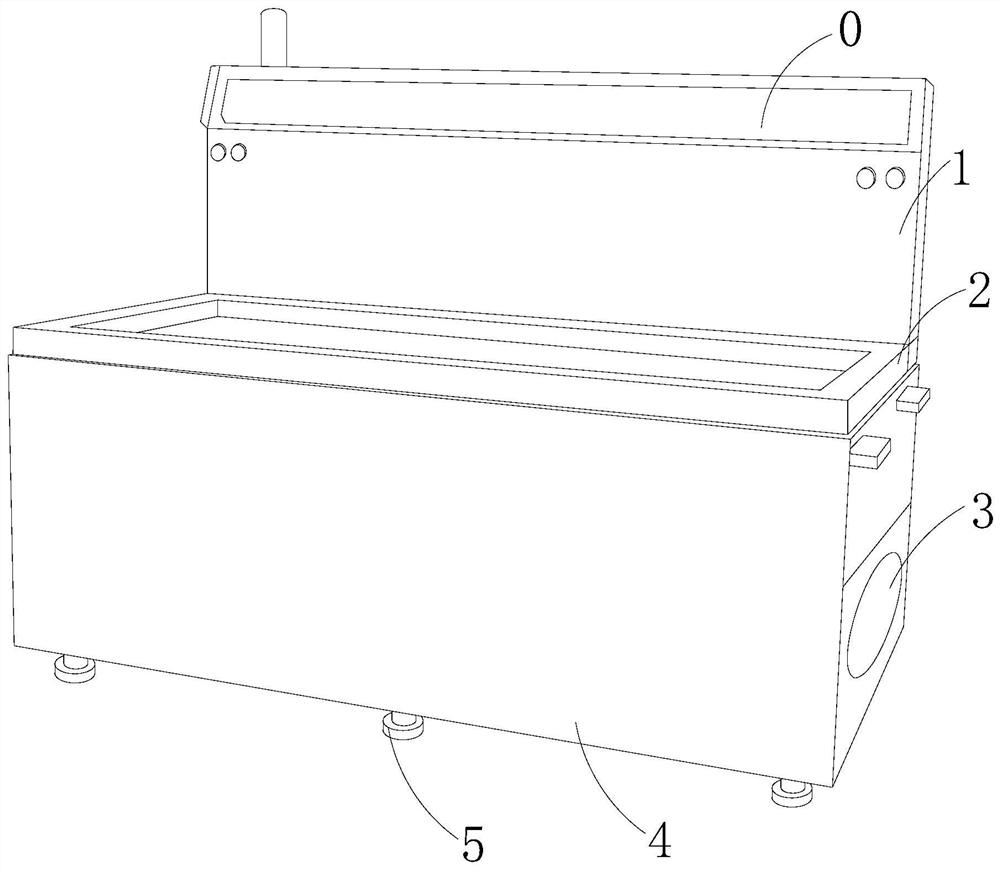

Full-automatic special adhesive tape coating machine

ActiveCN109604116AEfficient preprocessingEasy to cleanLiquid surface applicatorsPolishing machinesEngineeringMechanical engineering

The invention discloses a full-automatic special adhesive tape coating machine. The full-automatic special adhesive tape coating machine comprises an adhesive tape coating machine main body, wherein abearing plate is arranged at one side of the adhesive tape coating machine main body; a clamping bolt is welded at one end of the bearing plate; the bearing plate is clamped with the adhesive tape coating machine main body through the clamping bolt; a box body is mounted at the upper part of the bearing plate; sliding devices are embedded into two sides in the box body; a pneumatic rod is arranged at the bottom of each sliding device; and a rotary roller is mounted at one side of the bottom of each pneumatic rod. According to the full-automatic special adhesive tape coating machine, the pneumatic rods and a polishing plate are arranged and are used for effectively pre-treating a base material; the distance between a sponge brush and the polishing plate, and the base material is convenientto adjust through the pneumatic rods; the surface of the base material is effectively polished through the polishing plate; a servo motor and a chain are arranged so that the pneumatic rods effectively move in the box body and the cleaning and polishing work is carried out better; a rotary table and an electric air cylinder are arranged, so that the working efficiency of the adhesive tape coatingmachine is effectively improved; a winding roller is prevented from being repeatedly replaced and the working time is saved; and the full-automatic special adhesive tape coating machine is suitable for being widely popularized and applied.

Owner:安徽长正升科技有限公司

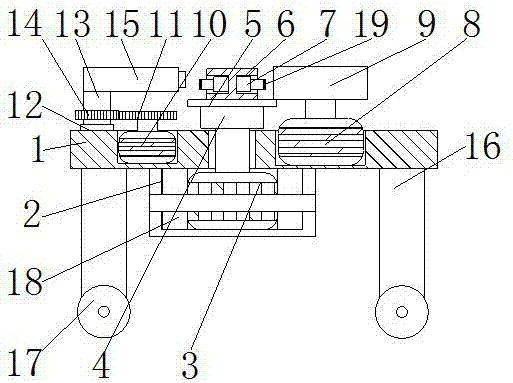

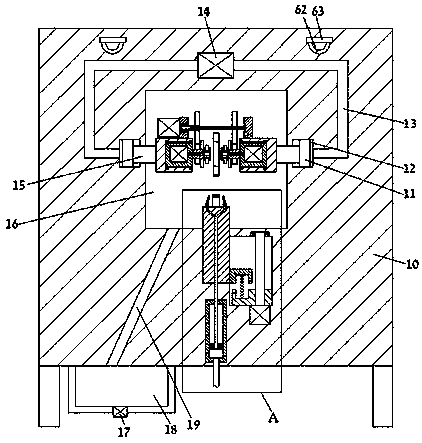

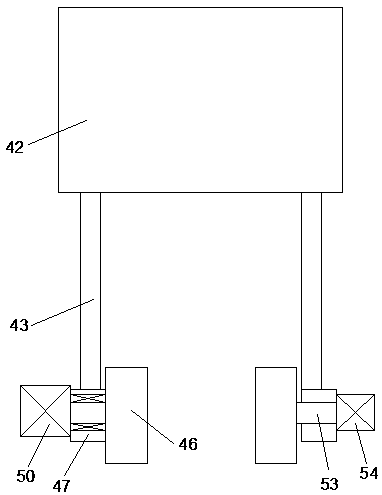

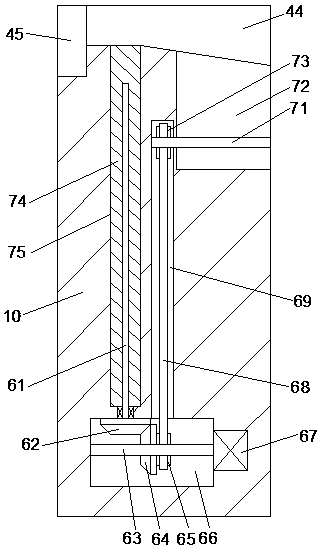

Bearing polishing device

PendingCN109794840AEasy to moveConvenient polishing workPolishing machinesGrinding machinesEngineering

The invention discloses a bearing polishing device, which comprises a base. Supporting legs are arranged on the two sides of the bottom of the base correspondingly, and universal wheels are arranged at the bottoms of the supporting legs correspondingly; a left supporting column and a right supporting column are arranged on the two sides of the upper part of the base correspondingly and fixedly welded to the base; a cross beam is arranged above the base, and the two ends of the cross beam are provided with lifting cylinders correspondingly; the cross beam is slidably connected with the left supporting column and the right supporting column through the lifting cylinders, and a sliding cylinder is arranged in the middle of the cross beam; a fixing device is arranged at the bottom of the sliding cylinder and slidably connected with the cross beam through the sliding cylinder; sliding grooves are formed in the inner sides of the left supporting column and the right supporting column correspondingly and internally provided with sliding blocks; and the other ends of the sliding blocks are provided with first electric telescopic rods, and the other ends of the first electric telescopic rods are connected with a polishing device body. The novel bearing fixing device is arranged to be adjustable, bearings with different sizes can be polished, and the polishing efficiency is effectively improved.

Owner:KUNMING UNIV OF SCI & TECH

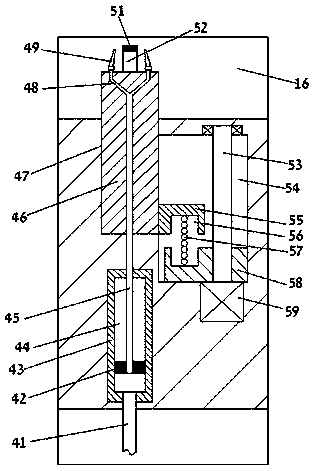

Polishing equipment for interior of glass sleeve

ActiveCN108942621AImprove polishing effectConvenient polishing workPolishing machinesGrinding/polishing safety devicesEngineeringPower transmission

The invention discloses polishing equipment for the interior of a glass sleeve. The polishing equipment structurally comprises a hydraulic cylinder, a controller, a telescopic polishing disc, a locking bolt, a polishing machine body, a fixing foot stand, a dust storage box, a dust processing device, a dust filtering mechanism, a first sleeve interior polishing mechanism, a second sleeve interior polishing mechanism, a fan suction mechanism, a power transmission mechanism, a dust conveying mechanism, a vertical pushing mechanism and a power motor mechanism. According to the polishing equipment,the dust processing device is adopted, and two cylindrical polishing wheels are arranged, so that the polishing work of the glass sleeve is facilitated, the polishing effect is improved, moreover, the glass sleeve can be polished and machined, and meanwhile, glass powder generated after polishing is sucked into the dust storage box to be stored and recovered, therefore, the random drift of the powder can be effectively reduced, and the working environment and the health of workers can be prevented from being influenced.

Owner:江苏卓燃高新科技有限公司

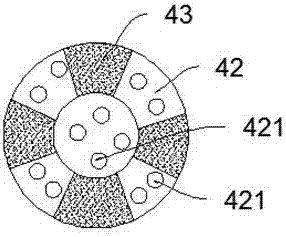

Polishing brush for photovoltaic module

A polishing brush for a photovoltaic module comprises a water channel, a rotating shaft, a fixing layer, an upper concave surface layer, a lower concave surface layer and a polishing layer which are co-axially arranged from top to bottom, wherein the rotating shaft is longitudinally arranged between the water channel and the fixing layer; a driving motor is arranged on the rotating shaft between the water channel and the fixing layer; and a liquid-in pipe coaxial with the rotating shaft is arranged on the rotating shaft. The polishing brush has the following beneficial effects: (1) the polishing brush is simple in structure and high in practicability, and the water channel can provide a polishing solution for a groove area, so that inconvenience caused by manually adding the polishing solution in the groove area is avoided; and (2) under the action of the driving motor, the polishing layer achieves the function of quick rotation, so that the polishing work is quick and convenient and saves both time and labor.

Owner:安徽中柜智能科技有限公司

A fully automatic special tape coating machine

ActiveCN109604116BEfficient preprocessingEasy to cleanLiquid surface applicatorsPolishing machinesAdhesive beltPolishing

The invention discloses a full-automatic special tape coating machine, which comprises a main body of the tape coating machine, a load-bearing plate is arranged on one side of the main body of the tape coater, a clamping bolt is welded at one end of the load-bearing plate, and the load-bearing plate passes through The clamping bolt is clamped with the main body of the tape coating machine. The upper part of the load-bearing plate is equipped with a box. Both sides of the inside of the box are inlaid with sliding devices. The bottom of the sliding device is provided with an air pressure rod. Installed with turning rollers. The present invention pretreats the base material effectively by setting the air pressure rod and the polishing plate, the air pressure rod is convenient to adjust the distance between the sponge brush and the polishing plate The motor and chain can effectively make the air pressure rod move inside the box to better clean and polish. By setting the turntable and electric cylinder, the working efficiency of the tape coating machine can be effectively improved, and repeated replacement of the winding roller can be avoided, saving money. Working hours are suitable for being widely promoted and used.

Owner:安徽长正升科技有限公司

Polishing device for sheet metal parts

PendingCN110385631AEasy to adjust the lengthConvenient polishing workPolishing machinesGrinding drivesEngineeringSmall hole

The invention discloses a polishing device for sheet metal parts. The polishing device comprises a handle, wherein a motor is clamped at one end inside the handle, an electric cylinder is installed atone end of the handle, a motor output shaft is connected with the electric cylinder in a clamped mode, one end of the electric cylinder is connected with a polishing disk in a clamped mode, and a groove is inlaid in the polishing disk. According to the polishing device, through the arrangement of the electric cylinder, an air pressure rod and a small-hole polishing disk, people can conveniently polish a sheet metal small part, and a through hole and small hole of the sheet metal part, the device is small and flexible, and the convenience in use of the polishing device is effectively improved;through the arrangement of a small suction fan, a connecting pipeline, a sleeving connecting pipe and an arc dust suction pipe, chippings, dust and the like generated by polishing work are effectively sucked, and the human body is prevented from sucking in the chippings, the dust and the like; and through the arrangement of a spring layer, an elastic ball layer and an air cushion damper, the vibration during working of the device is effectively reduced, the inconvenient operation of hands due to vibration is avoided, and the device is suitable for being widely popularized and used.

Owner:合肥高科科技股份有限公司

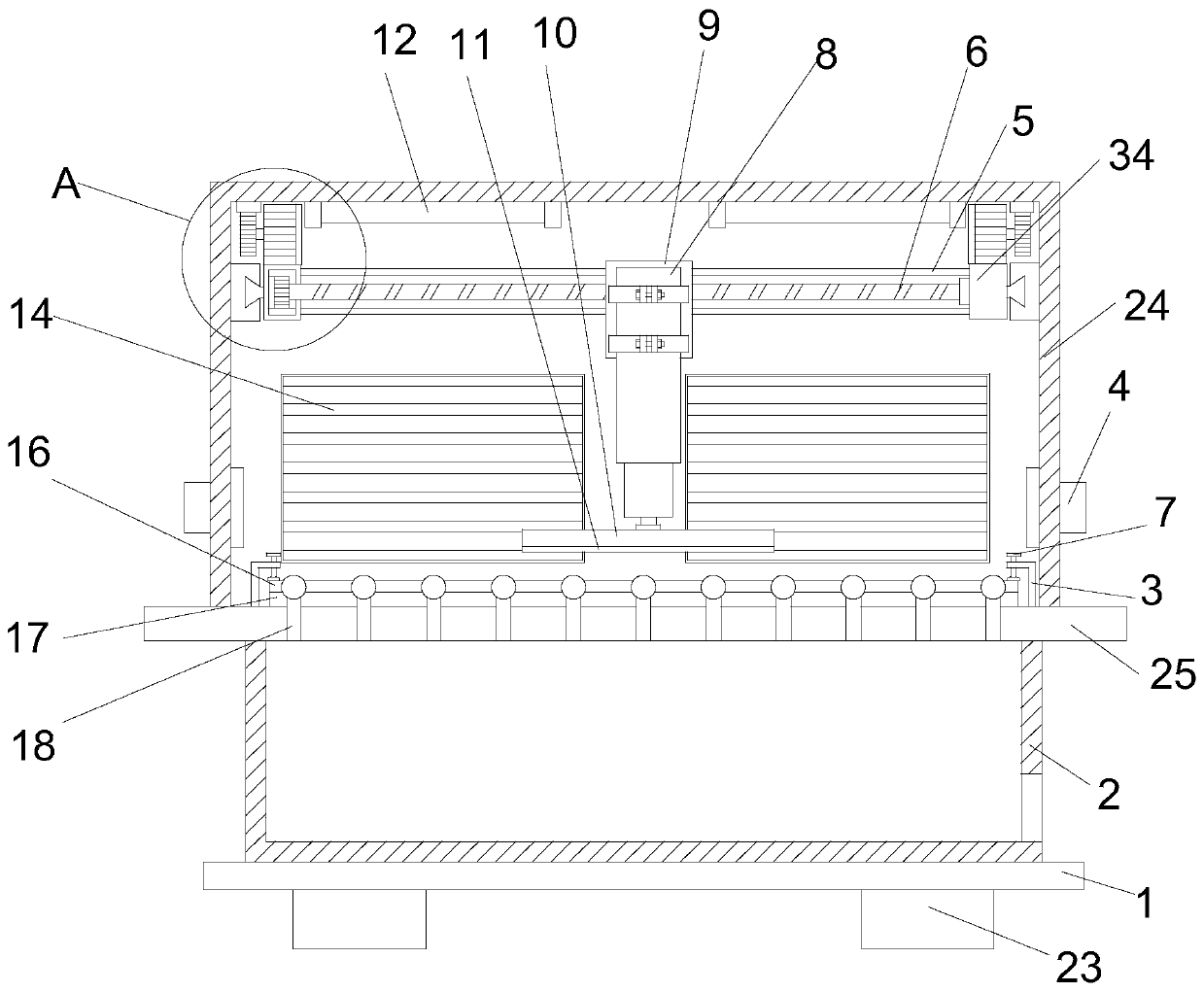

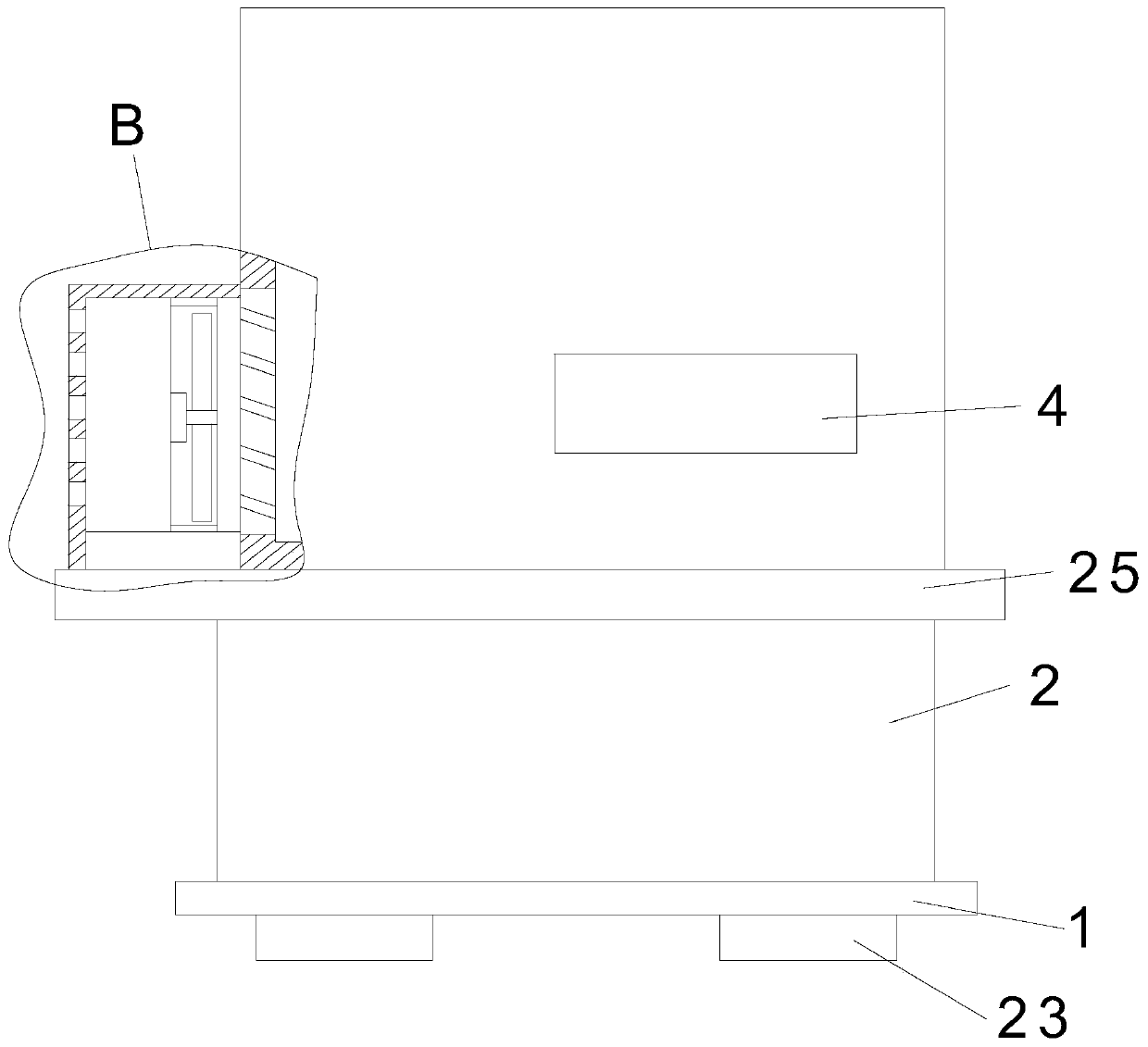

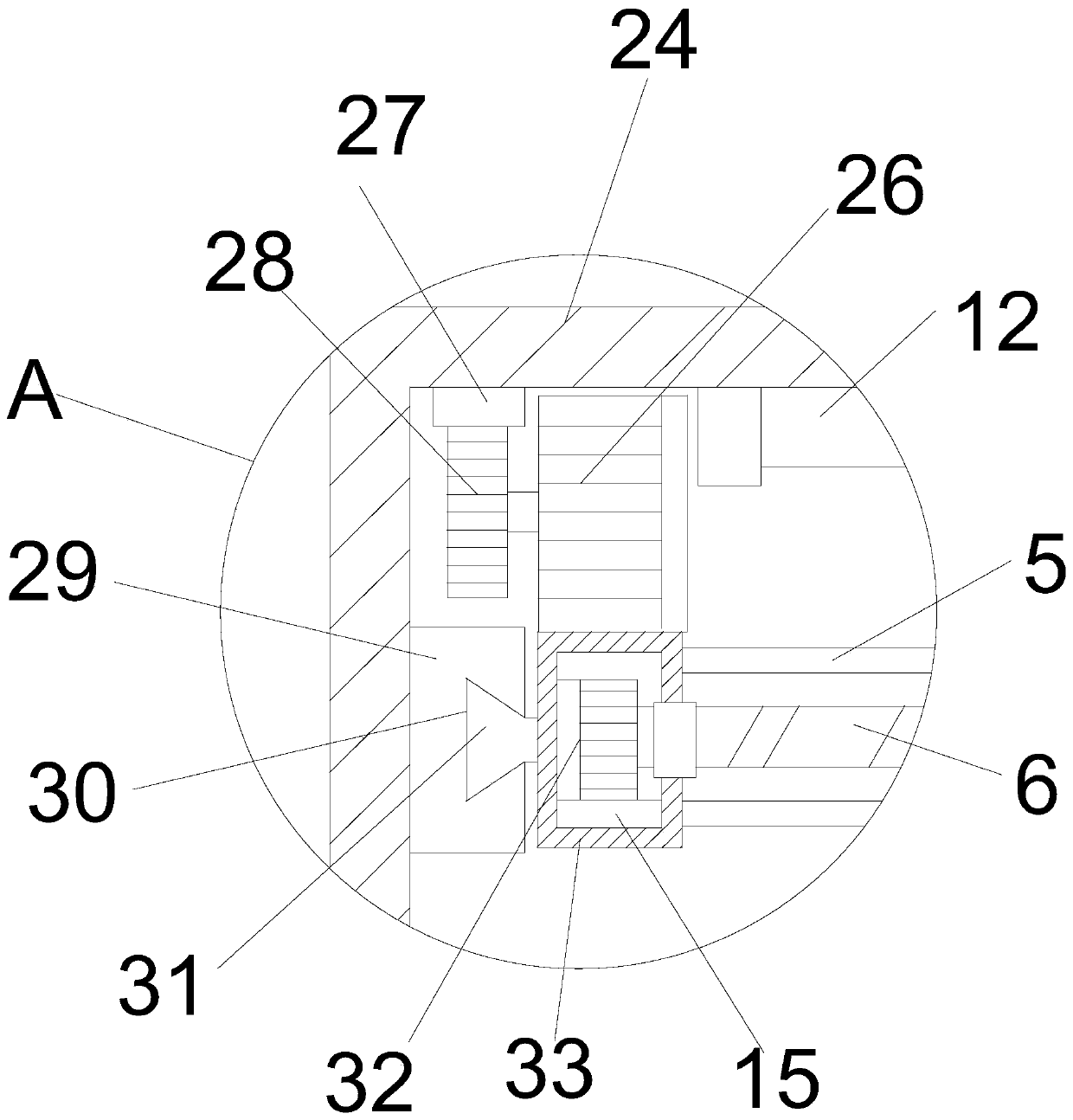

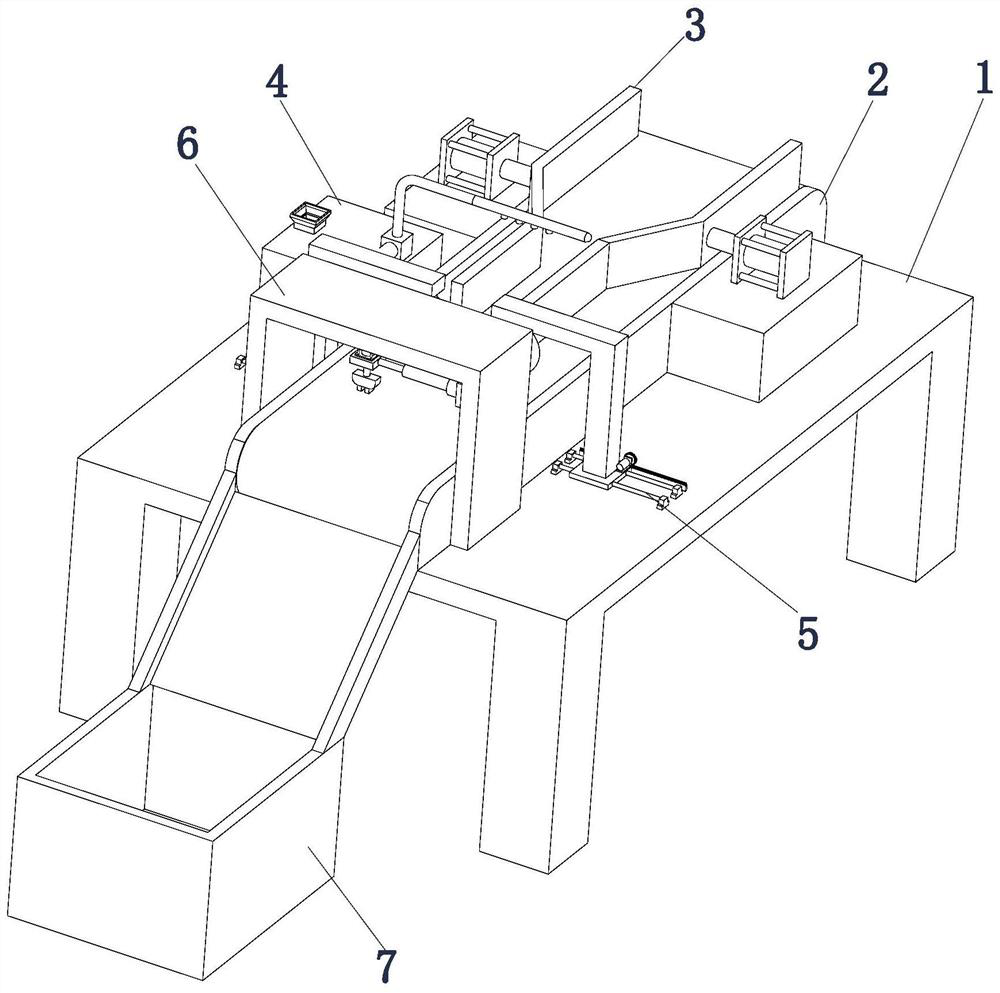

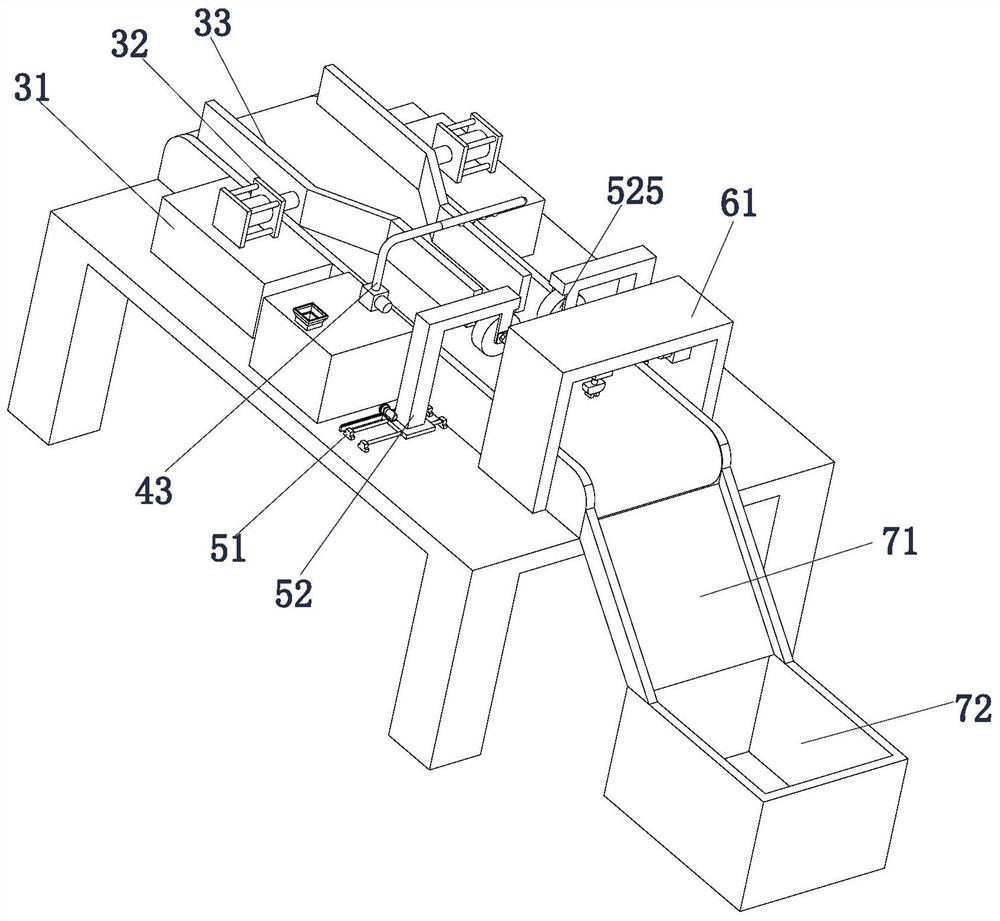

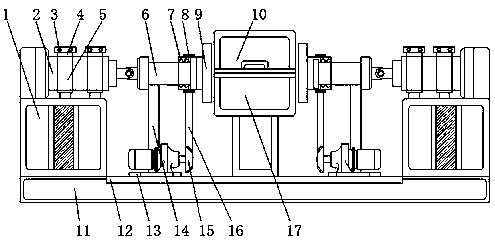

Bearing polishing device

InactiveCN112192426APrecise polishingFast polishingPolishing machinesGrinding feedersPolishingEngineering

The invention discloses a bearing polishing device, and relates to the field of bearing processing. The bearing polishing device comprises a bearing table, a conveying table, two groups of limiting mechanisms, a lubricating and cooling mechanism, two groups of polishing mechanisms, a wiping mechanism and a discharging mechanism, wherein the conveying table is fixedly arranged on the bearing table,and the two groups of limiting mechanisms are respectively arranged on two sides of the conveying table; the lubricating and cooling mechanism is arranged on the bearing table and arranged on one side of the limiting mechanisms, and the two groups of polishing mechanisms are arranged on the two sides of the bearing table correspondingly; the wiping mechanism is fixedly arranged on one side of thepolishing mechanisms; and the discharging mechanism is arranged at the tail end of the conveying table. According to the bearing polishing device, a bearing is polished through the interaction between polishing rollers. Compared with the traditional mode that the bearing is rotated and makes contact with a fixedly-placed abrasive belt to be polished, the bearing polishing device is more accuratein polishing operation and higher in polishing speed.

Owner:高跃

Automobile data recorder lens polishing device

InactiveCN109877673AProtect healthImprove polishing efficiencyOptical surface grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention discloses an automobile data recorder lens polishing device. The device comprises a supporting mechanism, wherein a dust sucking mechanism is fixedly connected to the bottom of the supporting mechanism, and a clamping mechanism is fixedly connected to the bottom of the supporting mechanism and located above the dust sucking mechanism. According to the device, through the cooperationamong first electric telescopic rods, a top plate, a first motor and a polished plate, a lens can be polished; through the cooperation among a dust suction box, a back plate, shielding plates, a box door, a handle, a separation plate, a fixing block, a dust suction fan, an isolation net and dust suction holes, chippings generated during polishing can be adsorbed, so that the chippings do not driftaround, so that the health of workers can be better guaranteed; and through the cooperation of clamping plates, a second motor, rubber pads, a second electric telescopic rod, a mounting block, a driving belt disc, a belt and a driven belt disc, not only the lenses with different sizes can be clamped, but also the to-be-polished surfaces can be automatically replaced.

Owner:杨雪

A hand-held metal surface treatment device with a multi-speed adjustment mechanism

ActiveCN110561243BAchieve scaleControl lengthGrinding drivesPortable grinding machinesGear wheelPolishing

Owner:重庆华智天下科技有限公司

Preparation equipment for stainless steel boards

InactiveCN109465731ASimple structureEasy to operateGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention discloses preparation equipment for stainless steel boards. The preparation equipment comprises an outer frame; a containing cavity is formed in the left end face of the outer frame; a firm clamping device is arranged inside the containing cavity; a first slide cavity is arranged in the top wall of the interior of the containing cavity in a rightwards extending mode; a slide frame isinstalled in the first slide cavity in a sliding fit mode; a first screw rod is installed in the top end face of the slide frame in a threaded fit mode; a first electric roller is installed at the tail end of the top of the first screw rod in a power fit mode; the first electric roller is fixedly arranged in the top wall of the interior of the first slide cavity; a second slide cavity is arrangedin the bottom end face of the slide frame in a left-and-right extending mode; a slide body is installed inside the second slide cavity in a sliding fit mode; a second screw rod is installed inside the slide body in a threaded fit mode; and the extending tail end of the left side of the second screw rod and the left side wall of the second slide cavity are connected in a rotary fit mode.

Owner:惠安康奥建材有限公司

Mold polishing machine shell with functions of protecting hands and facilitating holding

ActiveCN108687624AImprove protectionNo damage problemPolishing machinesPortable grinding machinesEngineeringControl switch

The invention discloses a mold polishing machine shell with functions of protecting hands and facilitating holding. The mold polishing machine shell comprises a control switch installed at the lower end of a rear end block. A protective plate is arranged on the position, on the rear end block, of the lower portion of the control switch. The protective plate composed of a welding block, a soft block and a hard block can protect fingers of a user quite well, and the problems that during polishing, due to angle adjusting, the fingers are in friction with a mold and consequently the fingers are injured, and due to the fact that the soft block is in friction with the mold, polishing is troublesome are solved. Through a fixed holding rod composed of a sponge block, a ring block and a connectingblock, operation can be more convenient during angle adjusting for polishing, the connecting block of the fixed holding rod is connected to a holding column, when the angle is adjusted for polishing,the hands can hold the fixed holding rod to control moving, and in this way, operation by the user is more convenient.

Owner:瑞安市凯宇环保设备有限公司

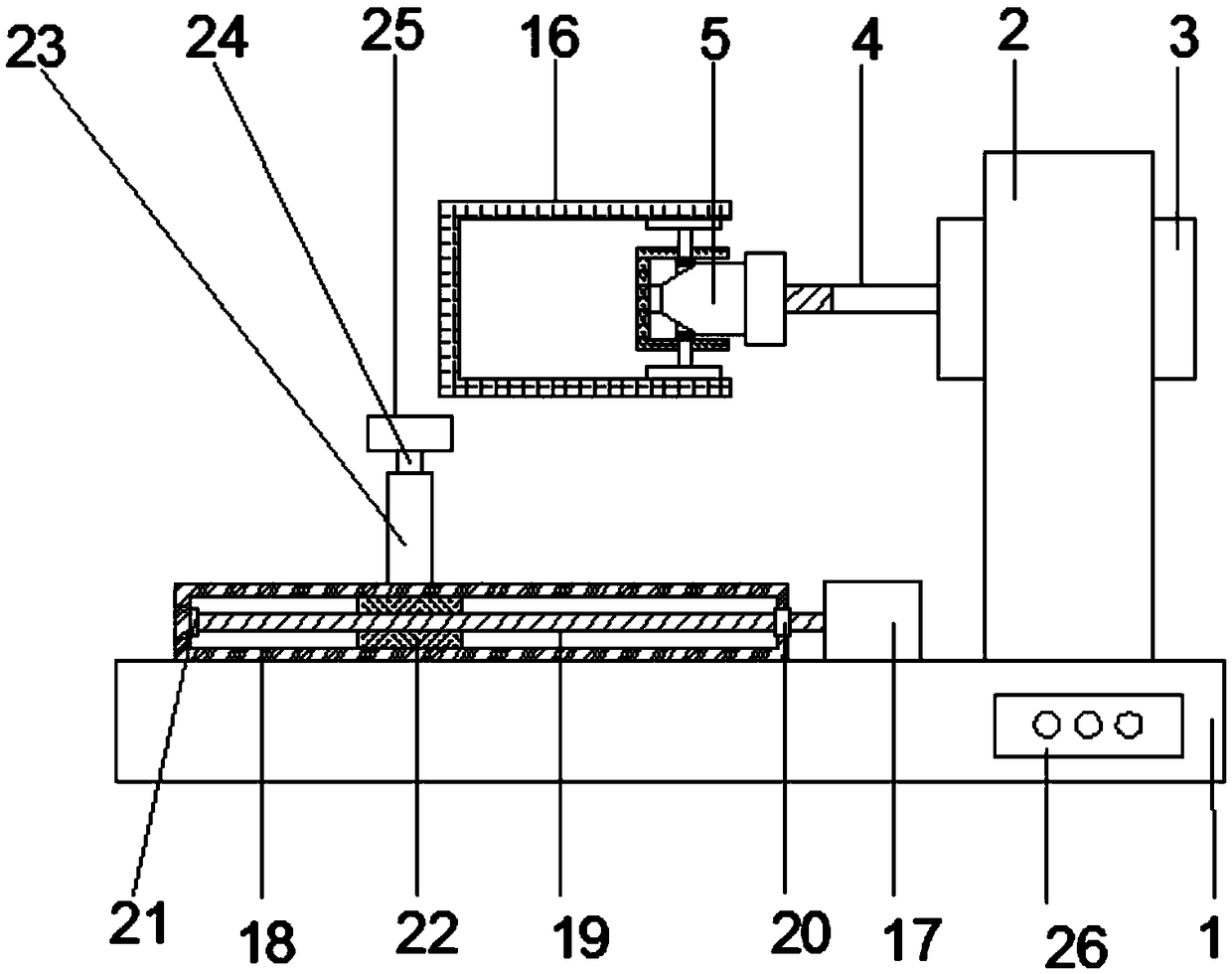

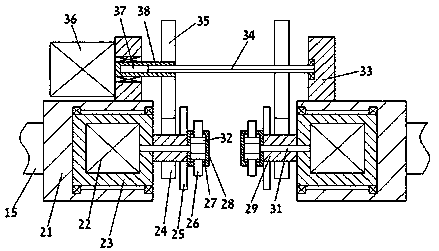

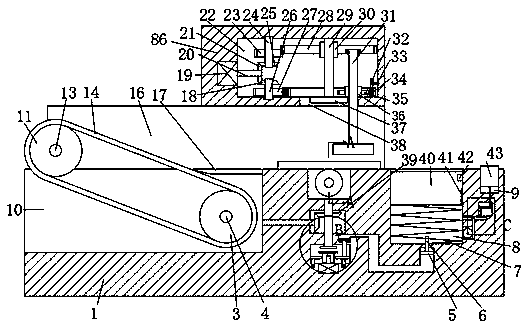

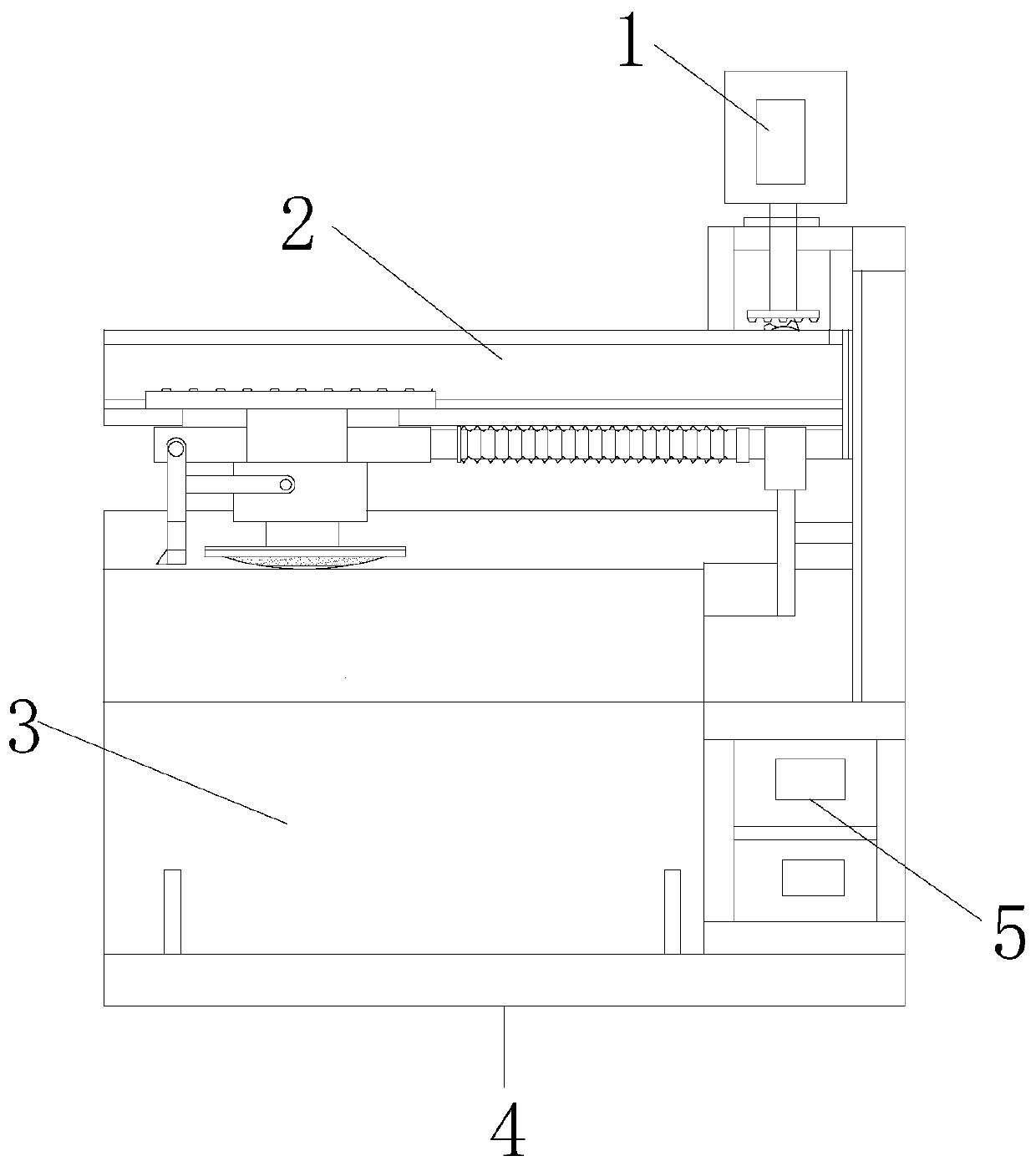

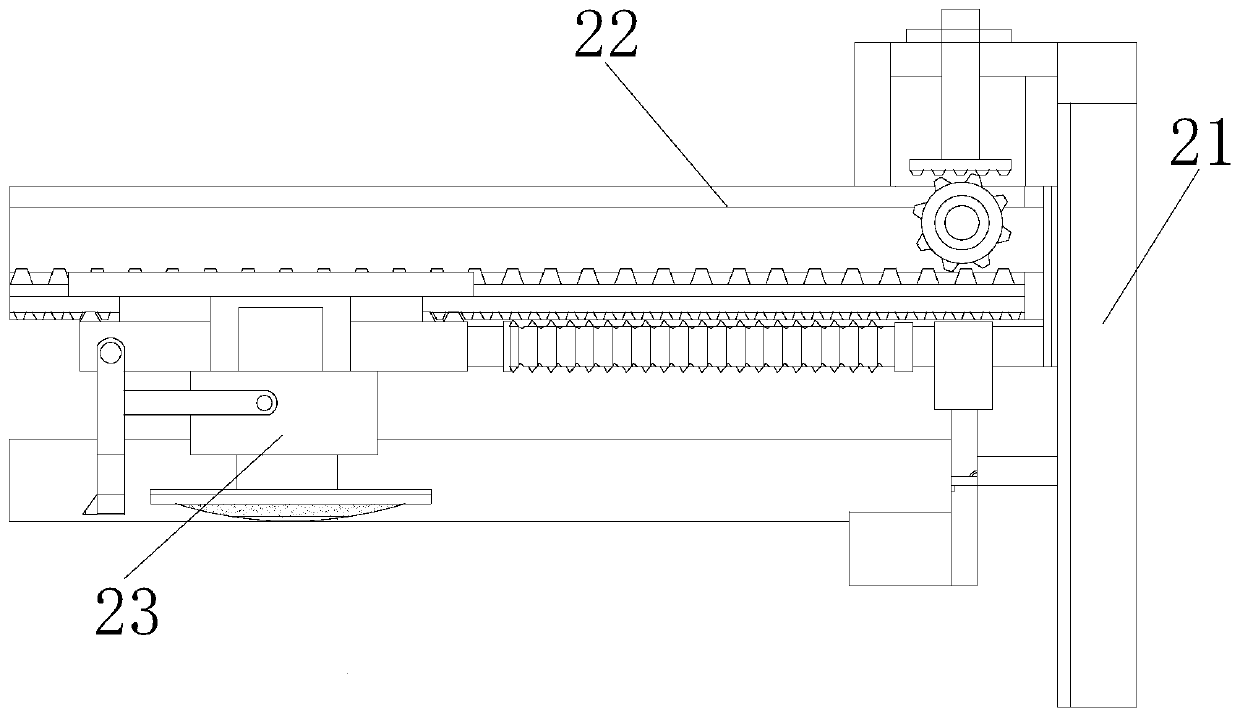

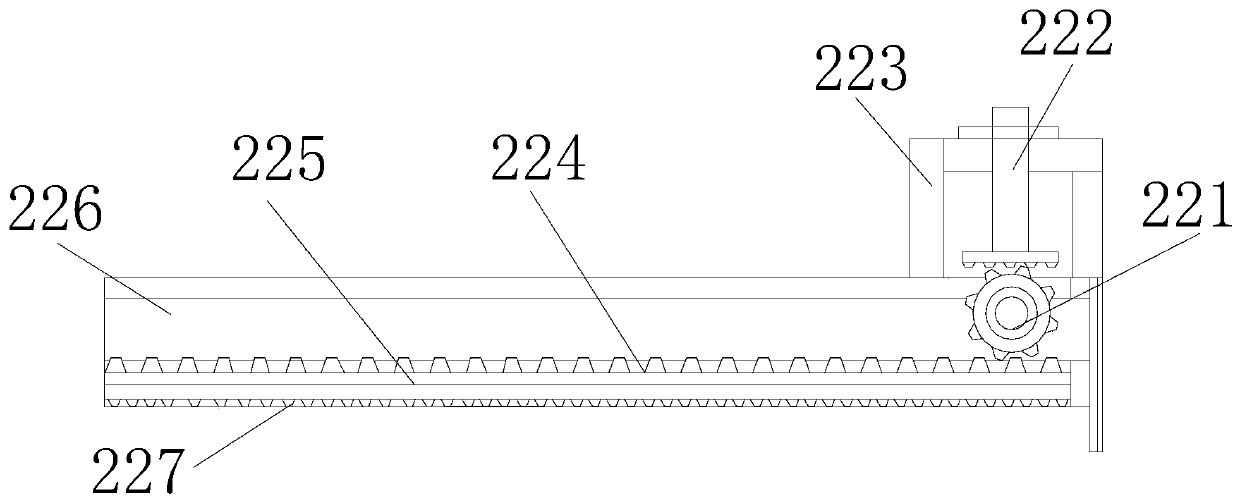

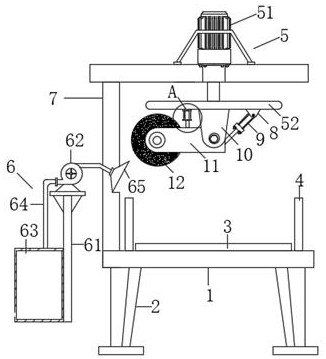

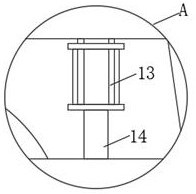

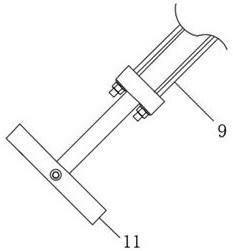

A device for polishing tree ring samples by scraping with a knife and a convex grinding wheel in stages

ActiveCN109366331BImprove polishing effectThreat to job securityPolishing machinesGrinding drivesGear driveGear wheel

The invention discloses a tree ring sample polishing device which uses a knife and a convex grinding wheel to scrape and grind in stages. Its structure includes: a bidirectional motor, an intelligent grinding device, a fixed seat, a base, and a motor unit. The motor unit is located on the upper end surface of the base. At the same time, it is movably connected with the base, so that the rotation of the gear drives the gear rack below, so that the slider on the tooth groove is forced to mesh with a stable displacement on the slider rack, instead of manual pressure displacement running-in, which can reduce the slipping displacement of the equipment At the same time, through the flatness of the scraping frame at the front end and the arc-shaped structure of the grinding wheel frame, the raised structure can be scraped off in advance during displacement, and the polished wood can be layered in an arc-shaped structure, so that it can be better The work of polishing the wood is faster, and finally, the negative pressure generated by the displacement and compression of the air bag inside the telescopic frame is pulled to attract the wood chips generated by the polishing, so as not to affect the working environment.

Owner:苏州心愿美电子商务有限公司

Polishing disc swing polishing machine used for leather padding

InactiveCN111775027APrevent splashEasy to useGrinding carriagesPolishing machinesPolishingWaste material

The invention discloses a polishing disc swing polishing machine used for leather padding. The polishing disc swing polishing machine comprises a base. A worktable is fixedly installed on the upper surface of the base. Material blocking plates are fixedly installed on one side of the upper surface of the base through fixing screws, and supporting rods are fixedly installed on the other side of theupper surface of the base. A dust sucking mechanism is fixedly installed on the outer wall of the side, close to the supporting rods, of the base, and a top plate is fixedly installed at the top endsof the supporting rods. A swing mechanism is arranged on the upper surface of the top plate, and a fixing seat is fixedly installed in the center of the lower surface of the swing mechanism. A connecting rod is rotationally connected in the fixing seat through a rotating shaft, and a first sliding groove is formed in one side of the connecting rod. The polishing disc swing polishing machine has the beneficial effects that the swing polishing machine can be used for extremely conveniently completing the swing work during polishing, the use performance is high, the machining convenience is high, the machining diversity is achieved, the limitation is small, meanwhile, very good dust sucking work is achieved, waste material recycling work can be extremely conveniently completed, waste of materials is reduced, and the production cost is reduced. The structure is simple, the layout is reasonable, and the manufacturing and maintaining cost is low.

Owner:杨光

Automobile part polishing machine

InactiveCN109277931AAct as a fixed supportPlay a protective effectGrinding carriagesPolishing machinesPulp and paper industryX-machine

The invention discloses an automobile part polishing machine. The automobile part polishing machine comprises a fixing support, an upper cover and a gear, wherein an air pressure rod is installed on the surface of the inner wall of the fixing support, a supporting frame is fixed outside the air pressure rod, and a soft cushion is connected to the surface of the inner wall of the supporting frame;a bolt is installed above the interior of the supporting frame, a connecting rod is arranged on the right side of the air pressure rod, a polishing disc is installed outside the right end of the connecting rod, and a ball is arranged inside the polishing disc; and a tooth block is fixed on the outer surface of the polishing disc, and a spring is arranged inside the upper cover, the upper cover islocated above the right side of the polishing disc, and the top end of the spring is connected with a clamping block. Compared with an existing common automobile part polishing machine, the automobilepart polishing machine can polish a front face and a back face of a workpiece at the same time, so that the polishing time of the polishing machine is shortened, the working efficiency of the polishing machine is improved, waste materials generated in a polishing working process of the polishing machine can be collected, and waste of the raw materials is avoided.

Owner:广州蓝海自动化设备科技有限公司

A smt laser template polishing fixture

The invention discloses an SMT laser template polishing clamp. The SMT laser template polishing clamp comprises a rack, clamping devices and a template lifting device. A vacant cavity is formed in the rack. A fixing plate is transversely arranged in the rack. Four hollow columns are vertically fixed to the upper end face of the rack. Through holes in the hollow columns communicate with the vacant cavity in the rack. The template lifting device is vertically arranged in the center position of the rack. The number of the clamping devices is the same as the number of the hollow columns. The clamping devices are fixed to the hollow columns. A template containing box is fixed to the upper portion of a first threaded rod of the template lifting device, and a center gear is fixed to the lower portion of the first threaded rod of the template lifting device. Transmission shafts of the clamping devices are vertically inserted in the hollow columns. The middle portions of the transmission shafts are pivoted to the upper side wall of the rack, and transmission gears are fixed to the upper portion and the lower portion of the fixing plate. The SMT laser template polishing clamp has the beneficial effects that by means of the template lifting device and the clamping devices, a template can be suspended above the rack, and the subsequent polishing work is greatly facilitated.

Owner:中山市创隆电子有限公司

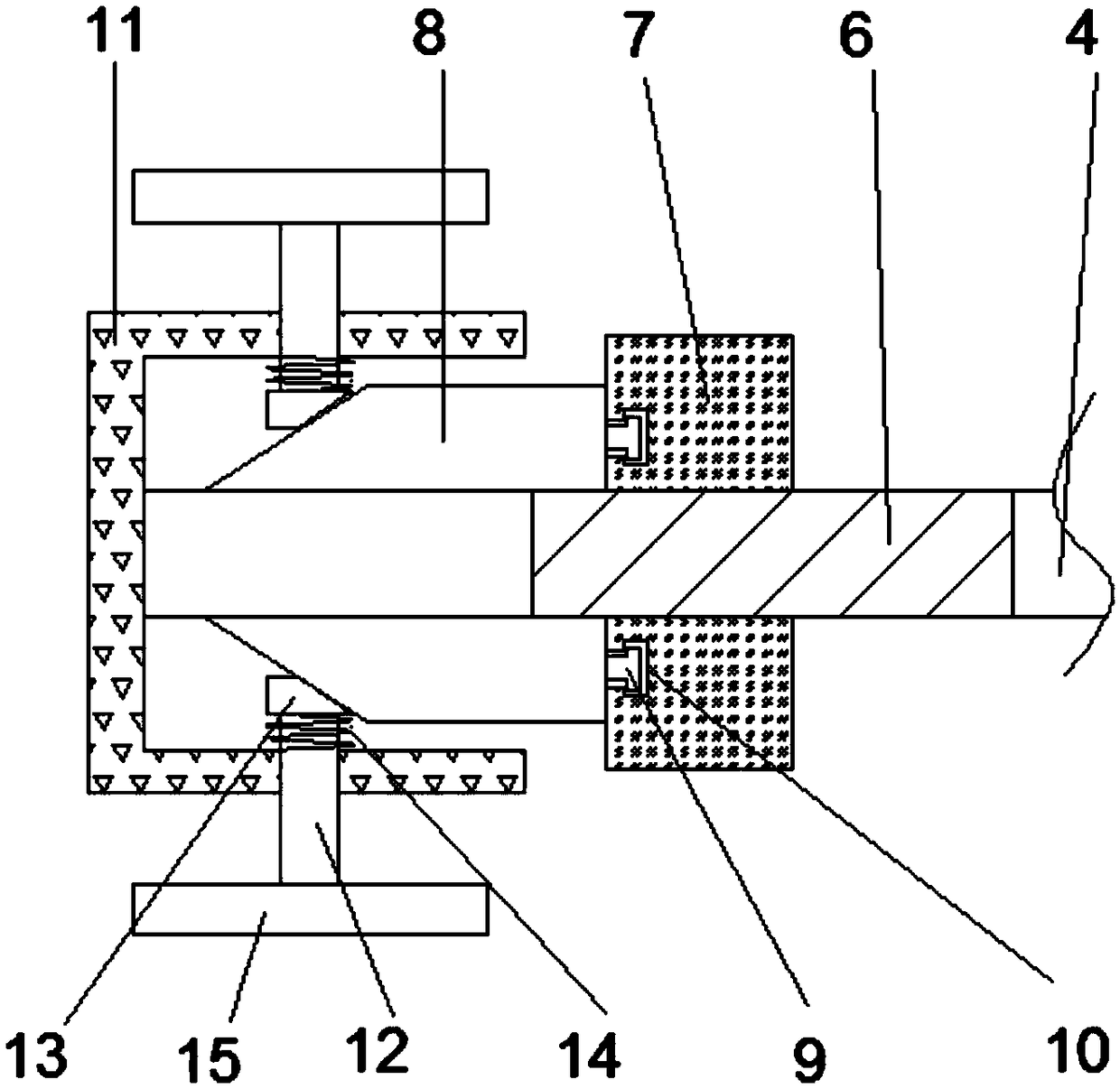

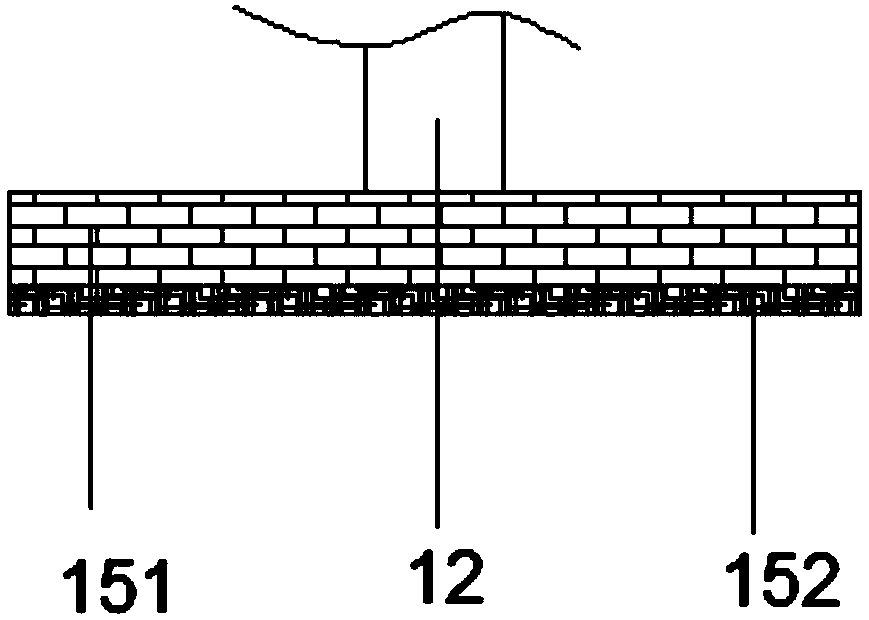

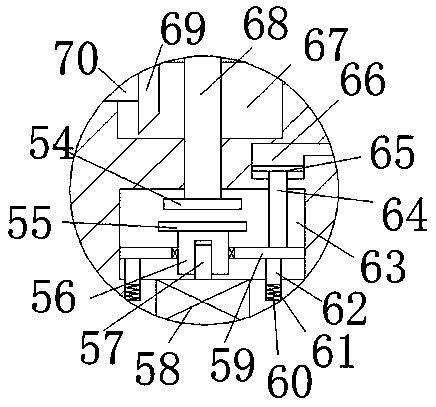

Two-dimensional ultrasonic vibration polishing device for optical curved surface machining

ActiveCN113997130AEasy to processAchieve precision machining effectGrinding carriagesOptical surface grinding machinesPolishingStructural engineering

The invention discloses a two-dimensional ultrasonic vibration polishing device for optical curved surface machining. The two-dimensional ultrasonic vibration polishing device comprises a machining base; an upper connecting main frame which is vertically fixed on the upper end surface of the processing base; a deviation adjusting clamping assembly which is arranged in the middle of the upper end face of the machining base, wherein the deviation adjusting clamping assembly is used for positioning and clamping a machined workpiece and can adjust the track of the machined workpiece at the same time; fixed guide rails which are vertically and symmetrically erected on the two sides of the upper connecting main frame; a bearing seat which is arranged on the fixed guide rail in a relatively sliding and limiting manner, and is vertically driven to slide by a transmission chain plate arranged in the upper connecting main frame; a curved surface adjusting and polishing assembly which is arranged in the middle of the bearing base and located over the deviation adjusting and clamping assembly. and drainage wheel sets which are symmetrically erected on the two sides of the upper end face of the machining base in a relatively rotating mode; a dust collection cover is fixed to one end of each drainage wheel set, and the other end of each drainage wheel set communicates with an outer drainage pipe.

Owner:CHANGCHUN UNIV OF TECH

A polishing machine capable of changing the polishing angle

ActiveCN113290476BEasy to placeConvenient polishing workGrinding wheel securing apparatusGrinding carriagesPolishingEngineering

The invention relates to the technical field of polishing machines, in particular to a polishing machine capable of changing the polishing angle, including a supporting mechanism, on which a polishing mechanism is installed, and a control mechanism is connected to the polishing mechanism, and the supporting mechanism An adjustment mechanism is installed inside, a placement mechanism is installed on the support mechanism, a clamping mechanism is installed on the placement mechanism, a locking mechanism is installed on the polishing mechanism, and a fastening mechanism is installed inside the locking mechanism; Under the action of the supporting mechanism and the polishing mechanism, it is convenient to polish the parts. At the same time, under the action of the regulating mechanism, it is convenient to adjust the angle of the polishing mechanism, and it is convenient to polish different parts. In the adjusting mechanism, the placing mechanism and the clamping mechanism It is convenient to install and place parts under the action of the machine.

Owner:徐州恒辉热力有限公司

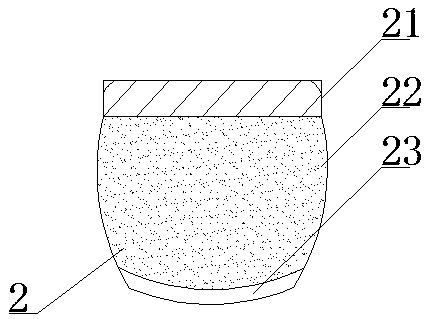

Novel shower gel and shampoo matrix polishing equipment

InactiveCN109434658ASimple structureEasy to operatePolishing machinesGrinding work supportsShower gelEngineering

The invention discloses novel shower gel and shampoo matrix polishing equipment. The equipment comprises a main frame body, a limiting cavity is formed in the end surface of the left side of the mainframe body, a clamping device is arranged in the limiting cavity, a first sliding cavity is formed in the inner top wall of the limiting cavity in a rightward extending mode, a sliding seat is installed in the first sliding cavity in a sliding fit mode, a first spiral rod is installed in the end surface of the top of the sliding seat in a threaded fit mode, a first motor is installed at the tail end of the top of the first spiral rod in a power fit mode, the first motor is fixedly arranged in the inner top wall of the first sliding cavity, a second sliding cavity is formed in the end surface of the bottom of the sliding seat in a left-and-right extending mode, a sliding block is installed in the second sliding cavity in a sliding fit mode, a second spiral rod is installed in the sliding block in a threaded fit mode, and the extending tail end of the left side of the second spiral rod is connected with the left side wall of the second sliding cavity in a rotating fit mode.

Owner:泉州市君健智能家居设备有限公司

A polishing device for tubular machining that facilitates multi-angle work

ActiveCN109227345BReduce safety incidentsConvenient for fixed workGrinding carriagesPolishing machinesWire rodGear wheel

The invention discloses a polishing device for tubular mechanical processing which provides convenience for multi-angle work. The device comprises a base and a lower rising plate, the upper portion ofthe base is connected with a top plate through a support rod, a first wire rod penetrates through the inside of the support rod, the lower bottom of the first wire rod is connected to a first motor through a steering gear set and a conveyor belt, push rods are connected by a compression spring, the top ends of the push rods are provided with third motors, mounting blocks are connected to the topends of the third motors, the mounting blocks and a steel wire brush head are connected by a fixing head, and thread grooves are formed in the upper and lower sides of the steel wire brush head. The polishing device for the tubular mechanical processing which provides convenience for the multi-angle work can perform polishing and grinding work on a large area above tubular parts during single time, and the entire device needs fewer people assist in the work during polishing processing.

Owner:盐城意权汽配制造有限公司

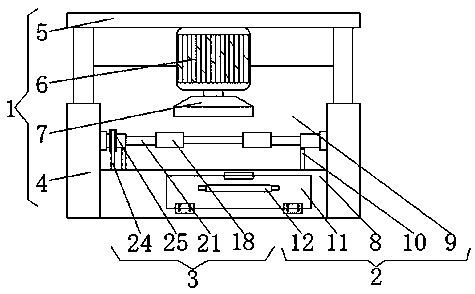

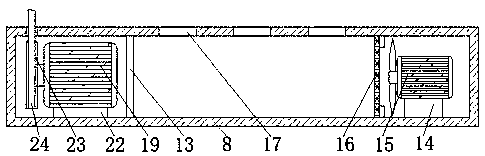

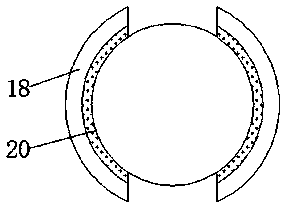

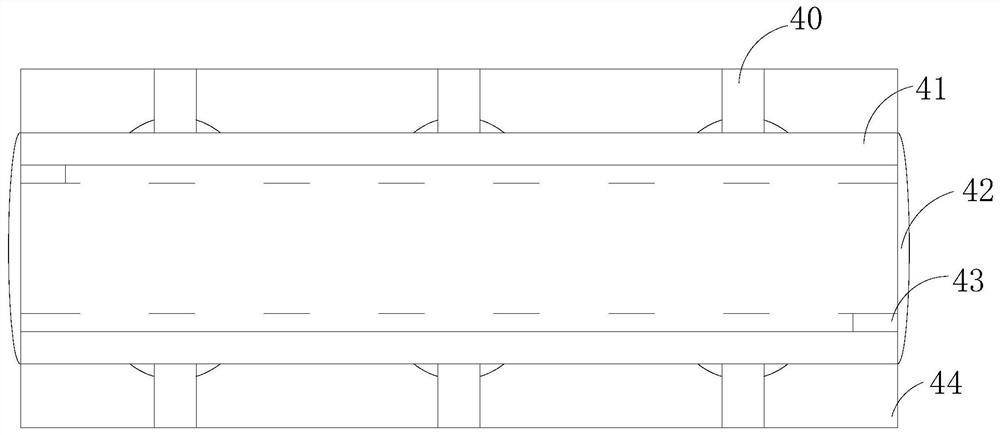

A Stainless Steel Tube Polishing Equipment with Convertible Inner Shaft

ActiveCN110977662BConvenient polishing workEdge grinding machinesGrinding drivesPolishingEngineering

The invention discloses stainless steel pipe polishing equipment with a convertible inner shaft. The structure comprises a control adjusting frame, a wire arranging plate, a dust suction frame, a through hole, a polishing box and supporting column feet. The adjusting frame is electrically connected to an upper portion of a surface of the wire arranging plate. displacement distances of a reverse abutting ring, a pushing head and a pressing piece can be adjusted through an outer diameter of a thrown circular pipe so that a diameter adjusting strip can be controlled to cover an outer portion of the circular pipe, and the whole outer surface of the circular pipe can be machined. A triangular unfolding strip can be ejected out when a triangular pipe is machined so that a nail pressing bent frame applies a force to the triangular unfolding strip to make the triangular unfolding strip be tightly attached to an outer surface of the triangular pipe, the equipment can be adjusted according to ashape of the machined stainless steel pipe, and the polishing equipment can adapt to more shapes of the stainless steel pipes.

Owner:重庆巨源不锈钢制品有限公司

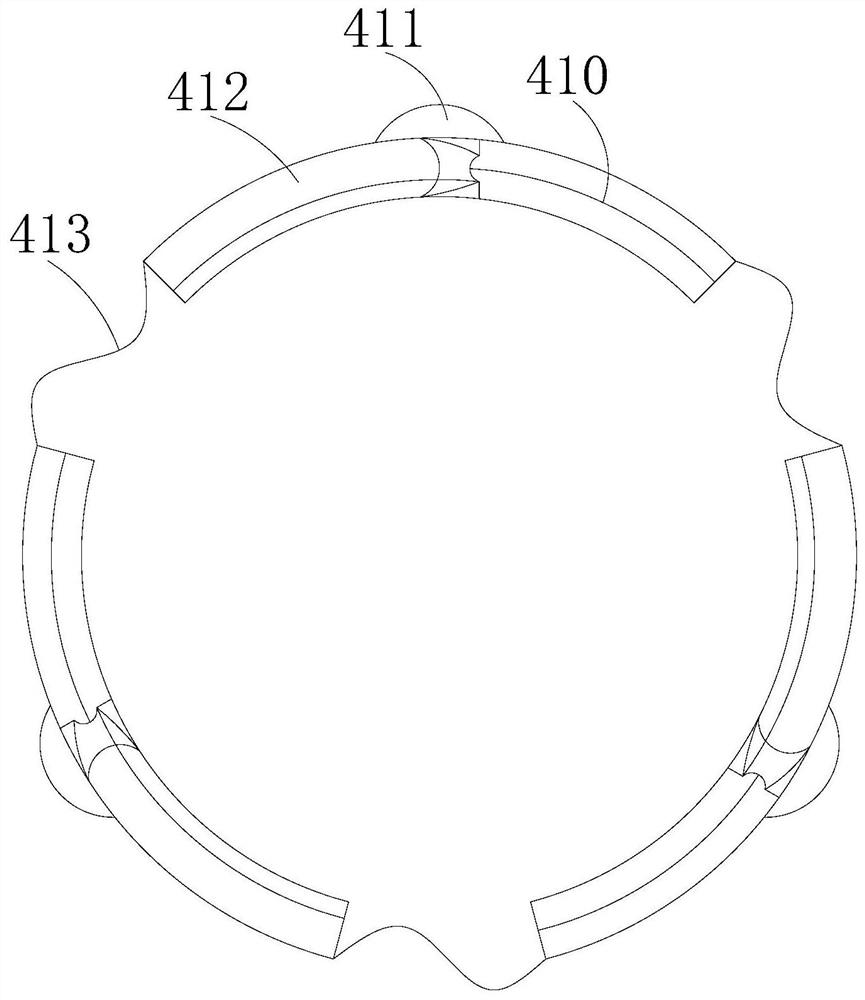

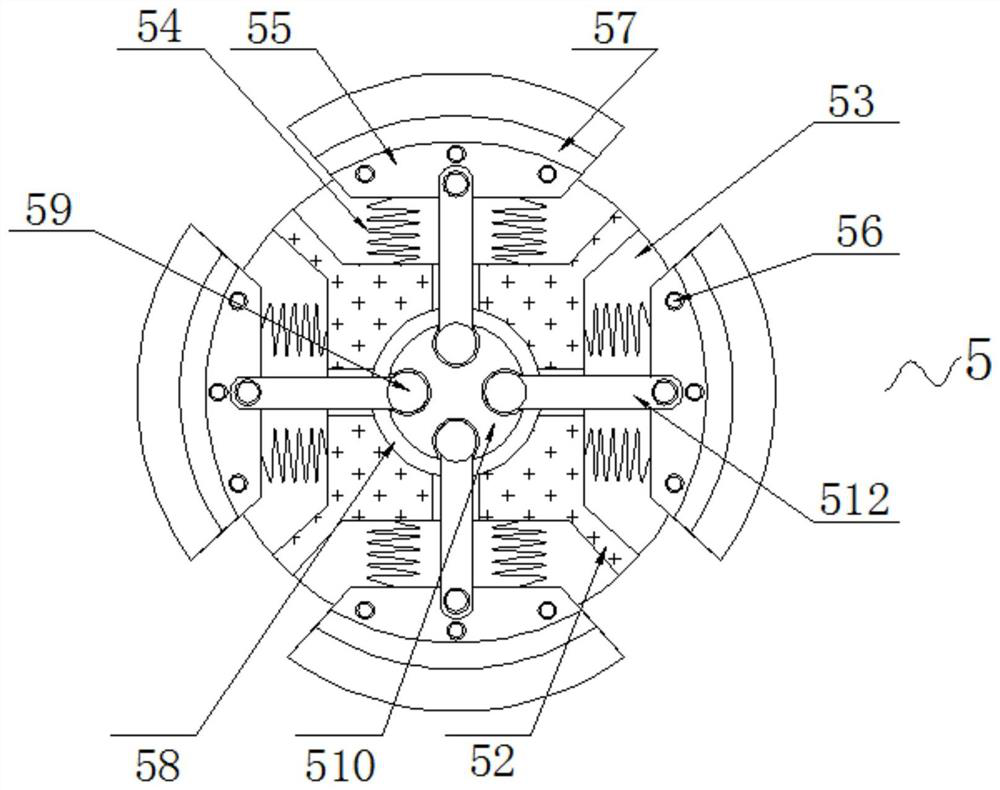

A polishing wheel expansion assembly for a lathe

ActiveCN112276774BMeet the grinding needs of different diametersReduce economic costsGrinding carriagesPolishing machinesHydraulic cylinderPolishing

Owner:襄阳鹏图机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com