Polishing equipment for interior of glass sleeve

A glass sleeve and equipment technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of not being able to deal with dust, powder affecting the working environment, and affecting the work process, so as to improve the polishing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

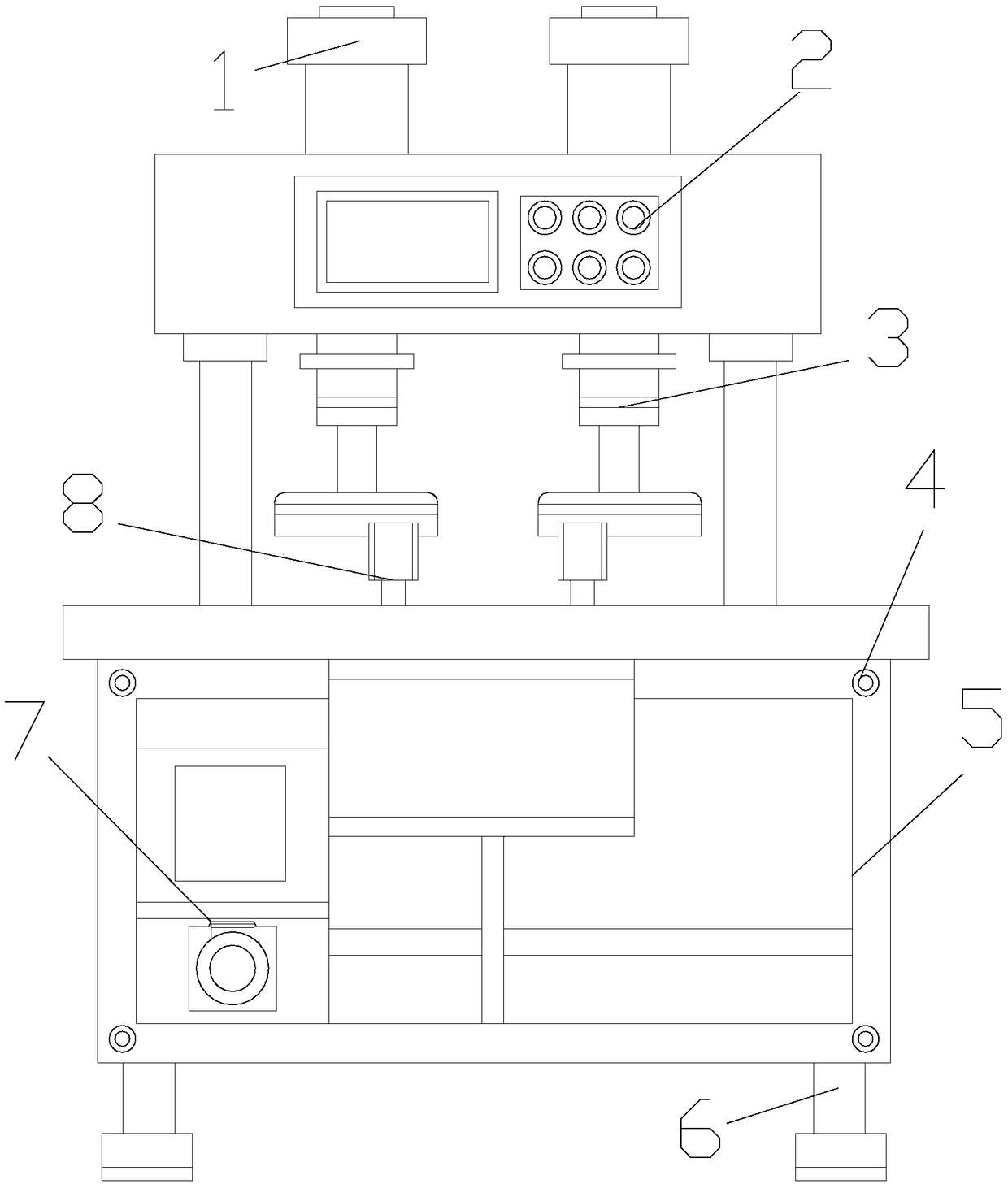

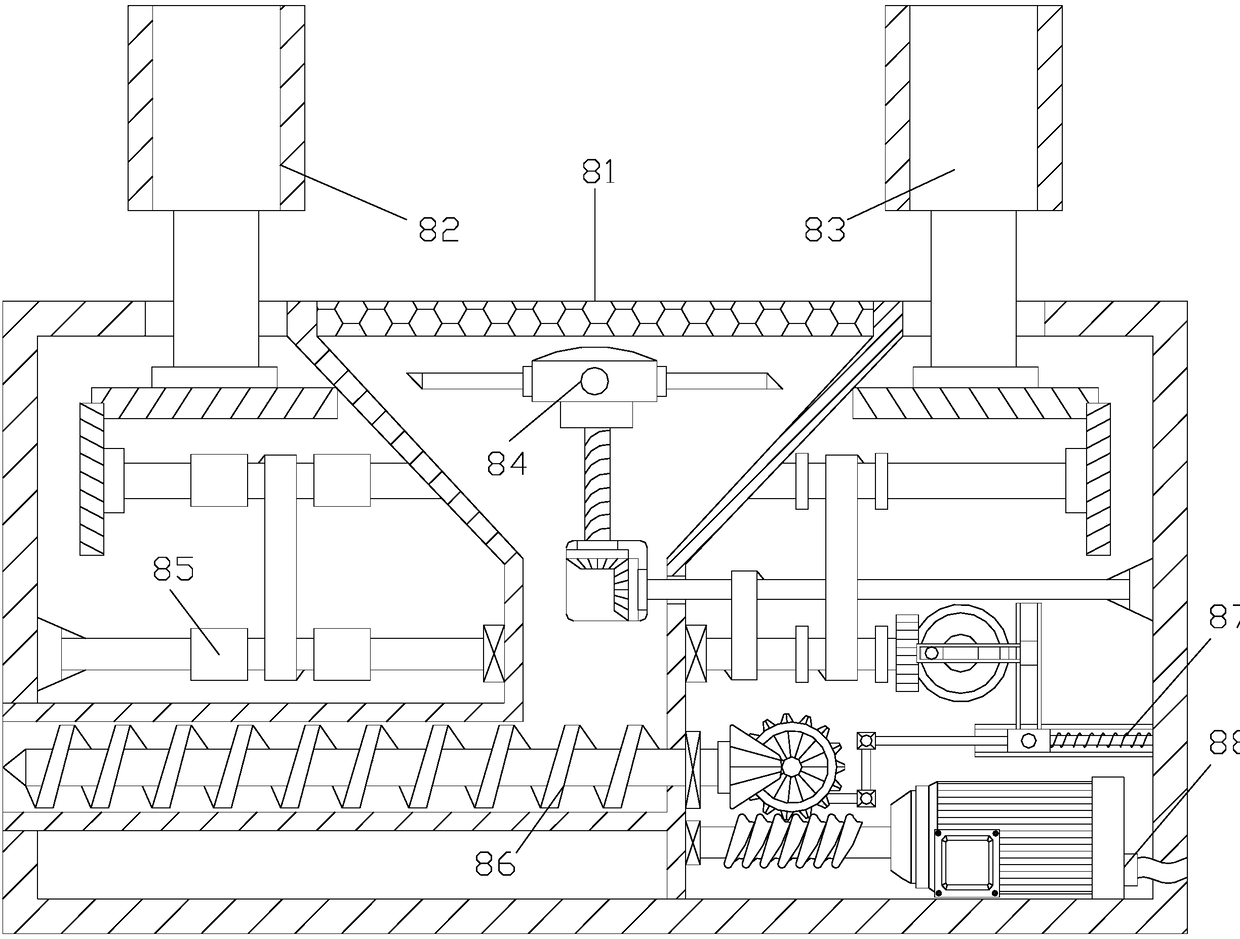

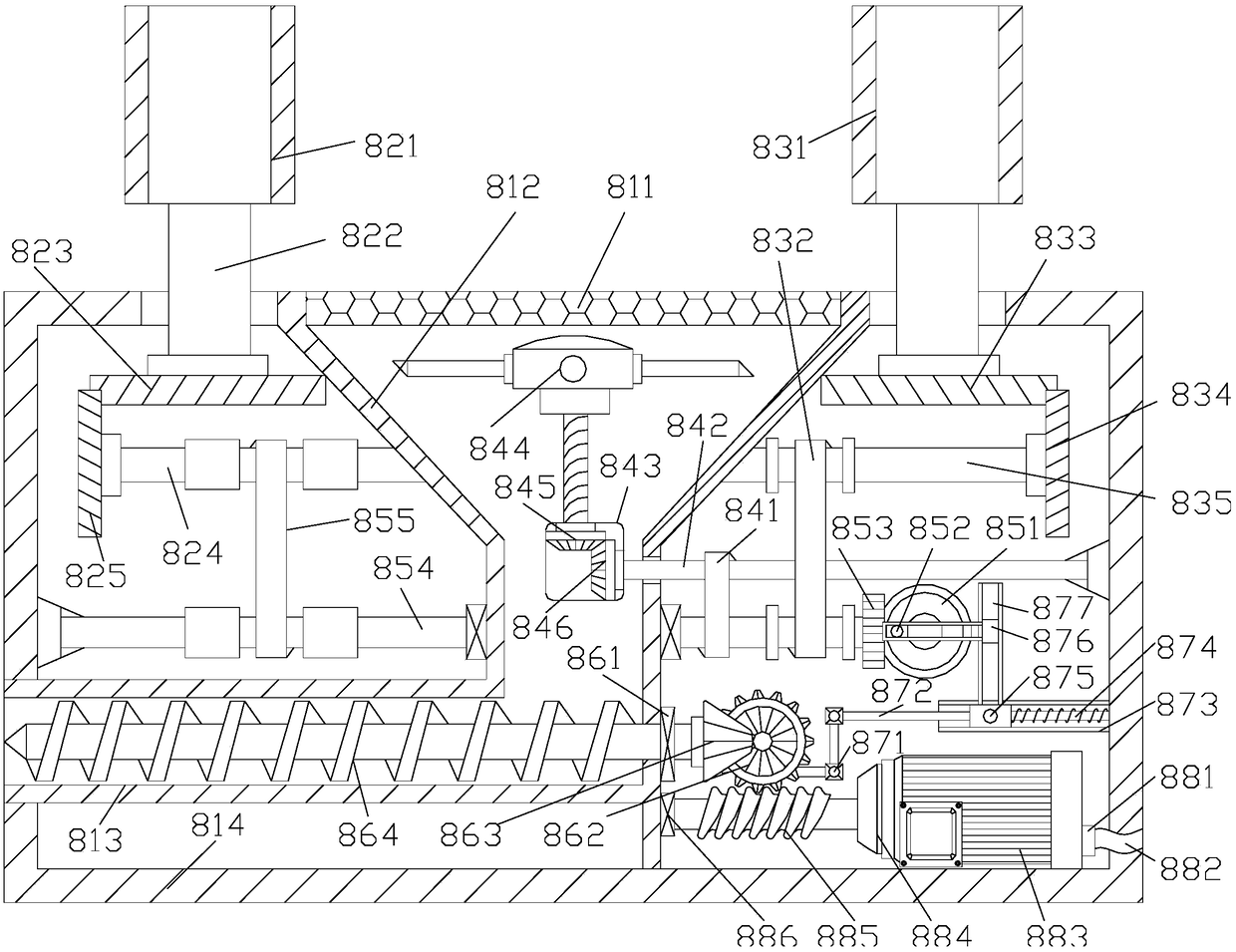

[0023] see Figure 1-Figure 4, the present invention provides glass sleeve internal polishing equipment, the structure of which includes a hydraulic cylinder 1, a controller 2, a telescopic polishing disc 3, a locking bolt 4, a polishing body 5, a fixed tripod 6, a dust storage box 7, and a dust treatment device 8 , the end of the water level of the hydraulic cylinder 1 is inlaid with the head end of the telescopic polishing disc 3, a dust treatment device 8 is provided directly below the telescopic polishing disc 3, and the controller 2 is installed on the head end of the front surface of the polishing machine body 5 The end of the front surface of the polishing body 5 is provided with four locking bolts 4, which are screwed together, and the top corners of the end of the polishing body 5 are provided with four fixed legs 6, which are welded together by electric welding. The dust storage box 7 is installed on the left side of the polishing machine body 5 in an embedded manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com