Lipstick metal tube polishing device

A polishing device and metal tube technology, which is applied to grinding drive devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of small and inconvenient grinding and polishing of metal tubes, and achieves strong practicability and improved Work efficiency, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

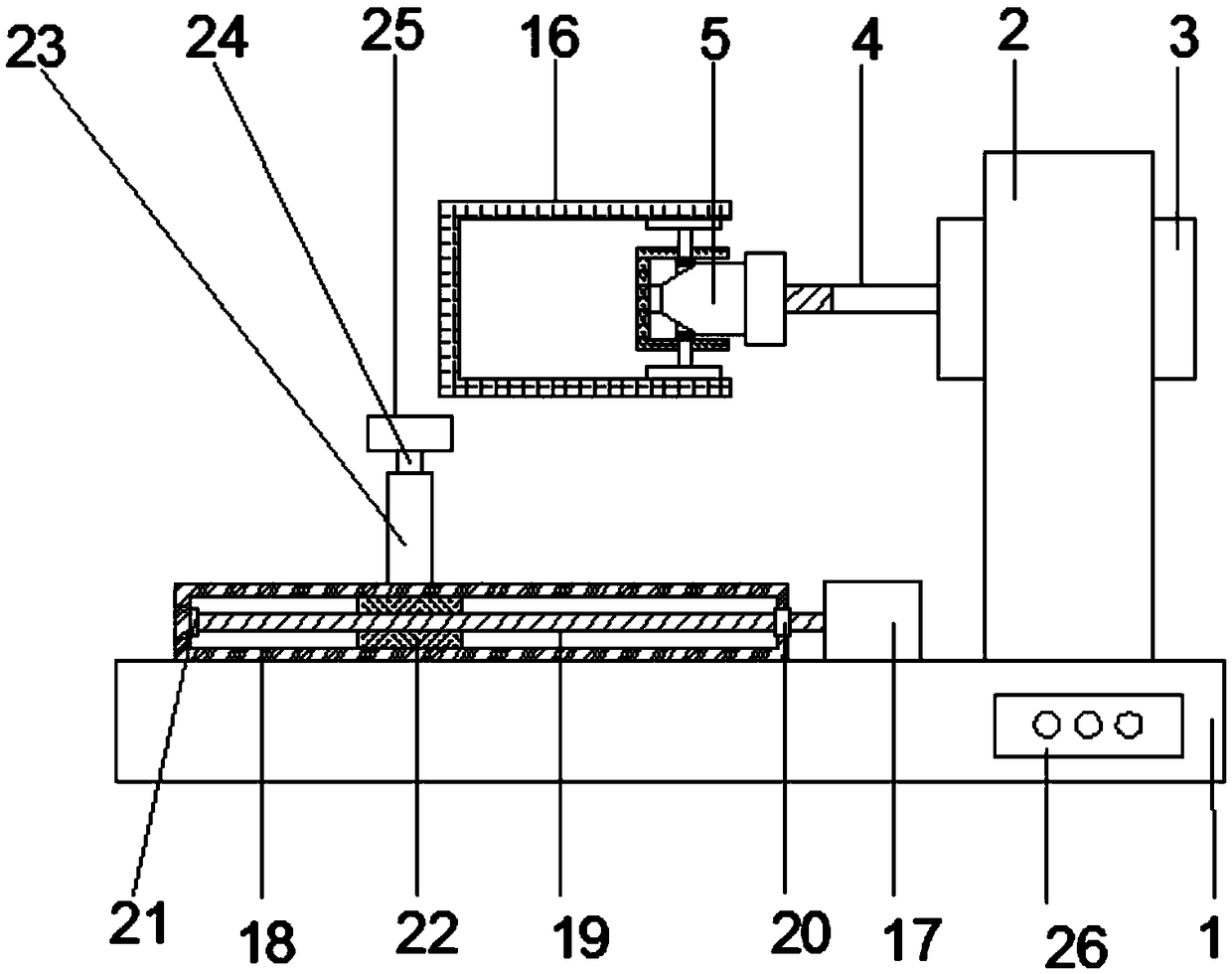

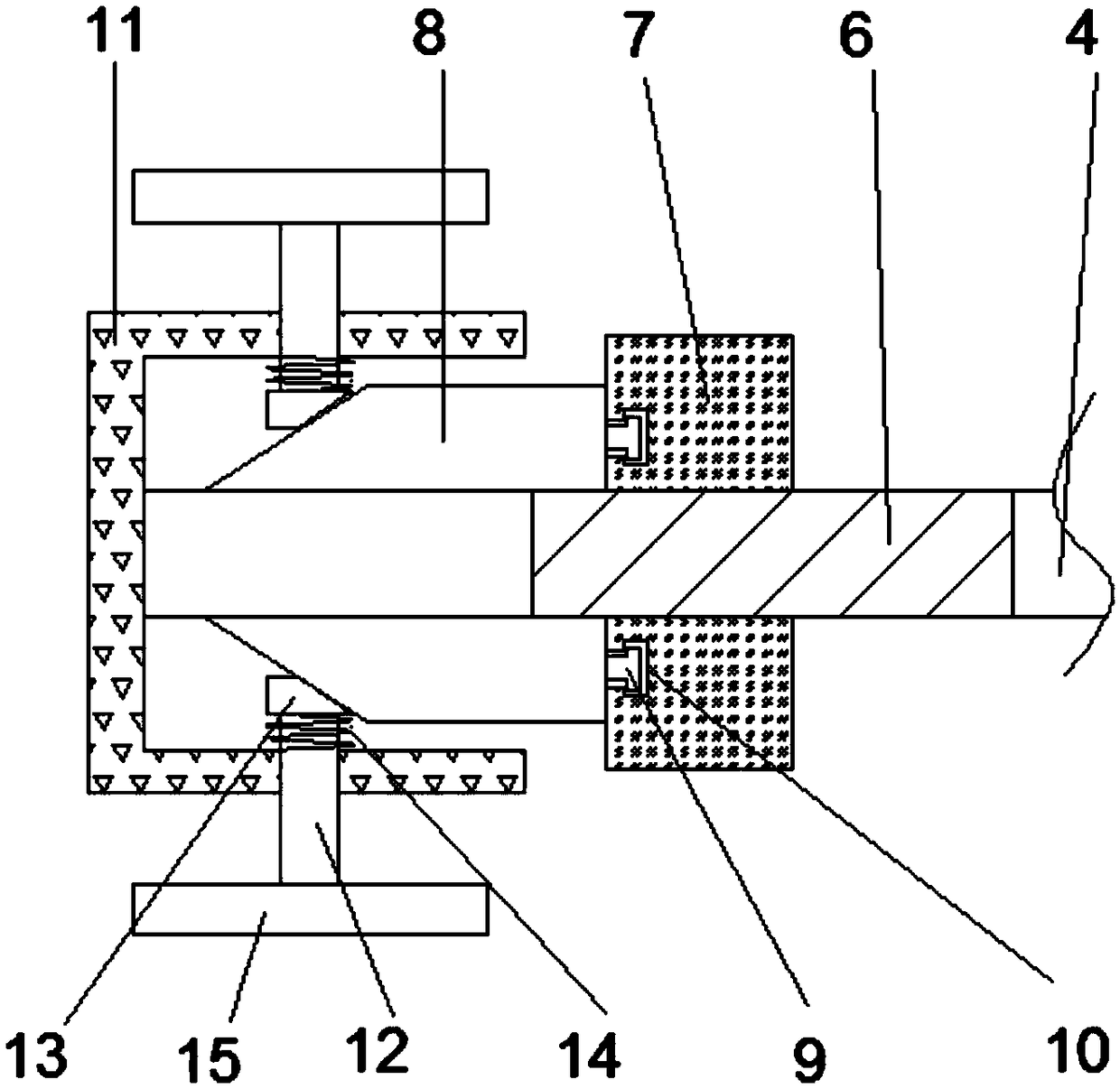

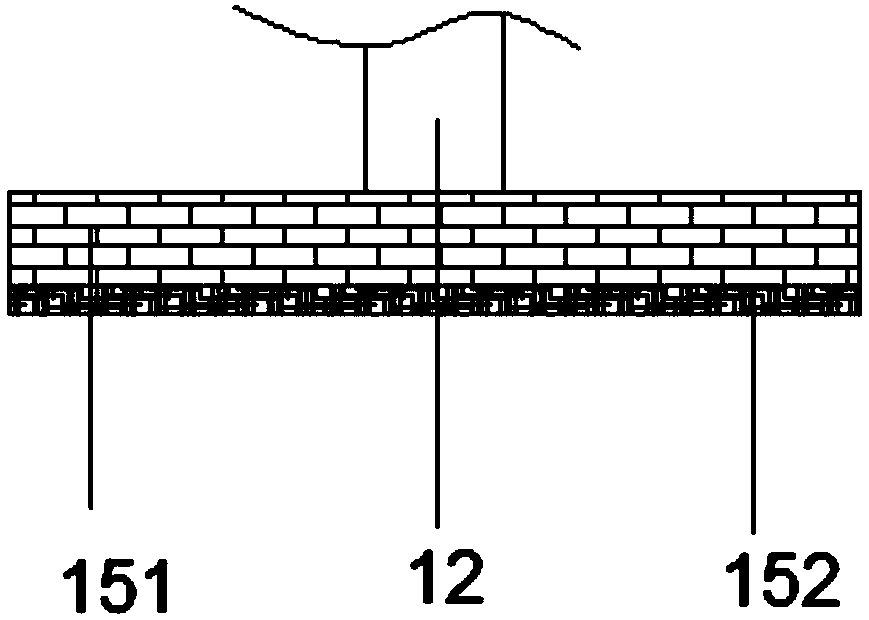

[0020] Such as Figure 1-Figure 4 As shown, a kind of lipstick metal tube polishing device that the present invention proposes comprises frame 1, first motor 3, fixed assembly 5, second motor 17, screw mandrel 19 and polishing part 25, and frame 1 upper end right side is provided with The fixed frame 2, and the upper end of the fixed frame 2 is fixedly connected to the first motor 3, the left end of the first motor 3 is provided with a rotating shaft 4, and the rotating shaft 4 is fixedly connected to the metal pipe 16 through the fixed assembly 5, and the fixed assembly 5 includes a push button 7, an inclined slide Sleeve 8, fixed sleeve 11, telescopic rod 12, inclined-plane slider 13 and fixed plate 15, push button 7 is sleeved in the outer middle part of the rotating shaft 4, and the outer middle part of the rotating shaft 4 is provided with an external thread structure 6, and the push button 7 is connected with the external thread structure 6 is correspondingly provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com