Polishing brush for photovoltaic module

A photovoltaic module and polishing brush technology, which is applied to grinding/polishing equipment, surface polishing machine tools, brushes, etc., can solve the problems of affecting the appearance and use effect, and the uneven surface of photovoltaic modules, and achieve fast and convenient polishing work. Simple, practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

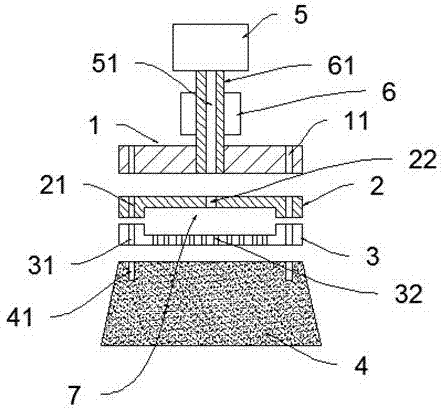

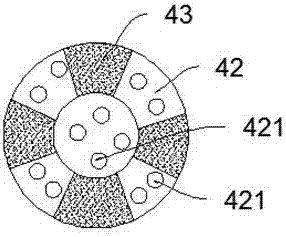

[0021] as attached Figure 1~2 As shown, a polishing brush for photovoltaic modules includes a water tank 5, a rotating shaft 61, a fixed layer 1, an upper concave layer 2, a lower concave layer 3 and a polishing layer 4; the water tank 5, the rotating shaft 61, the fixed layer 1, and the upper concave surface Layer 2, lower concave surface layer 3 and polishing layer 4 are arranged on the coaxial center line in order from top to bottom; the rotating shaft 61 is longitudinally provided between the water tank 5 and the fixed layer 1, and the water tank 5 and the The rotating shaft 61 between the fixed layers 1 is provided with a drive motor 6; the rotating shaft 61 is provided with a liquid inlet pipe 51 coaxially arranged with the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com