A device for polishing tree ring samples by scraping with a knife and a convex grinding wheel in stages

A technology of tree rings and polishing devices, which is applied in the direction of grinding/polishing safety devices, grinding drive devices, grinding/polishing equipment, etc., and can solve the problems of increased pressure, difficulty in centralized output of sawdust, and personal safety threats to staff and other problems to achieve the effect of reducing the slipping displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

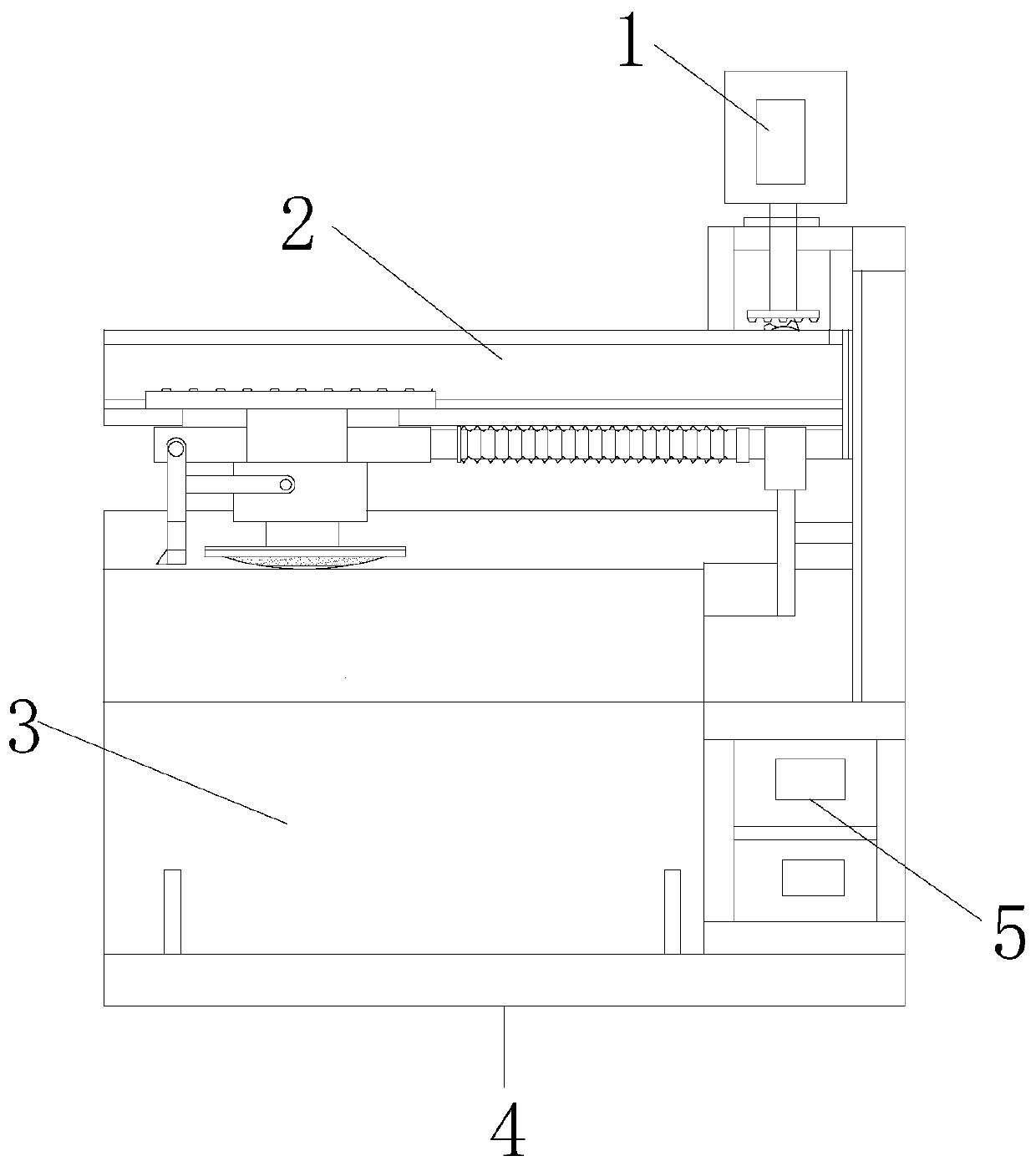

[0028] see figure 1, the present invention provides a tree ring sample polishing device that uses a knife and a convex grinding wheel to scrape and grind in stages. The unit 5 is located on the upper end surface of the base 4 and is movably connected with the base 4. The fixed base 3 is arranged on the upper surface of the base 4 and is mechanically connected with the base 4. The intelligent grinding device 2 is located on the upper side of the fixed base 3. The end face is welded together with the base 4. The bidirectional motor 1 is embedded in the intelligent smoothing device 2 and is movably connected with the intelligent smoothing device 2. The lower end face of the base 4 is provided with two parallel rubber Pads, the rubber pads parallel to each other can better reduce the vibration of the equipment during operation.

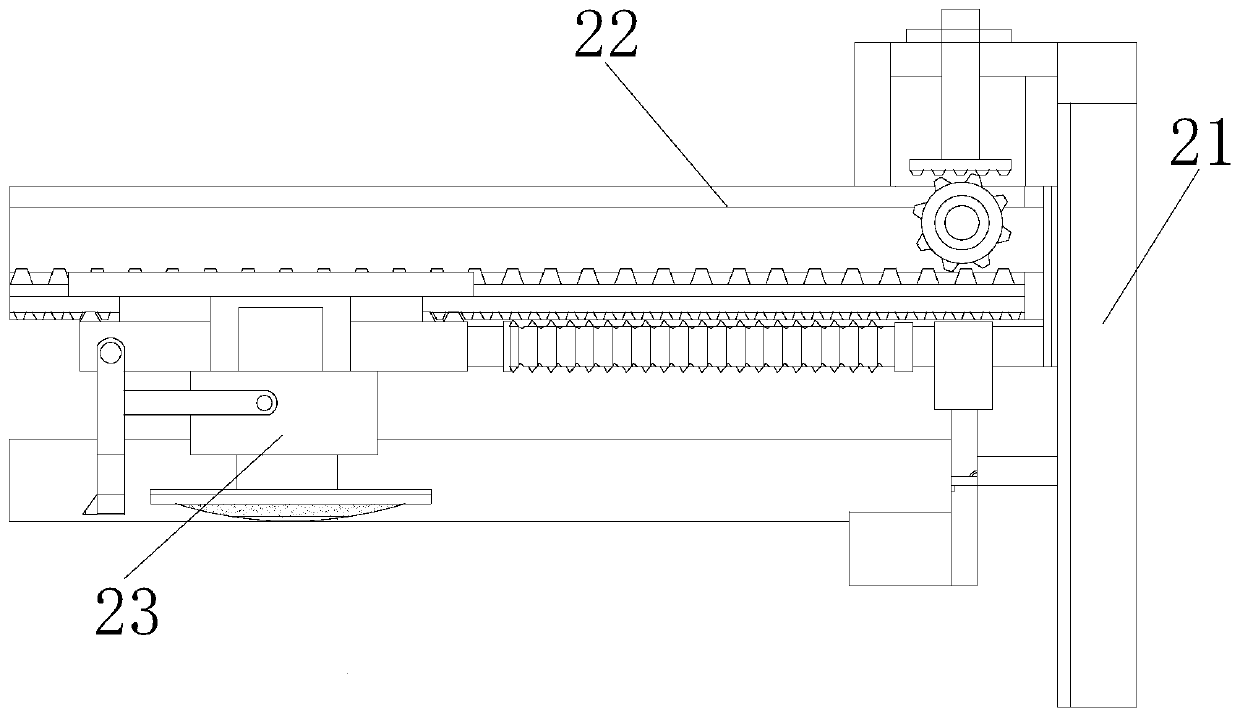

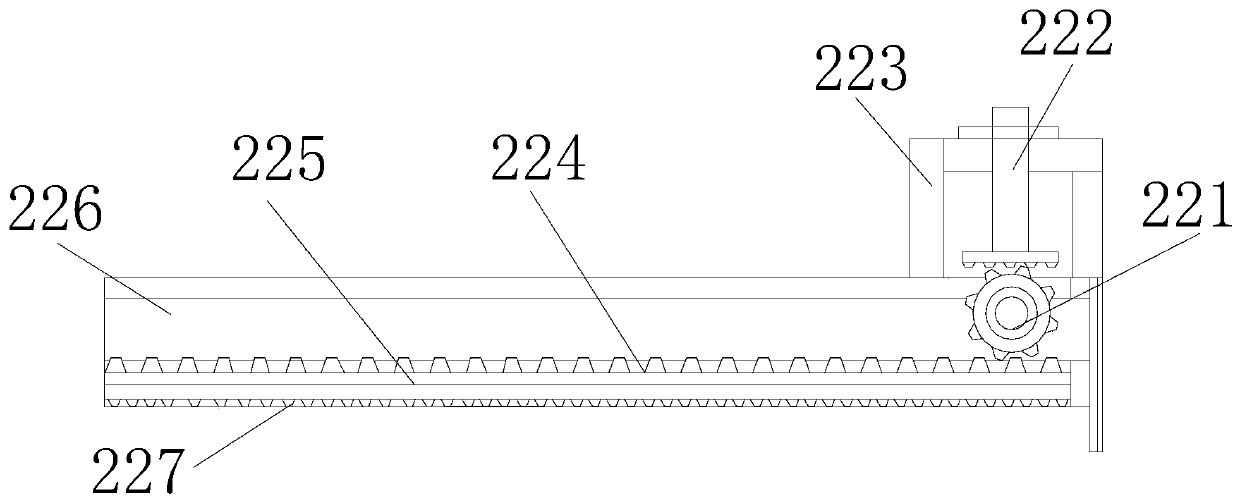

[0029] see figure 2 , the present invention provides a tree ring sample polishing device that uses a knife and a convex grinding wheel to scrape and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com