Patents

Literature

31results about How to "Does not affect the working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricant for drawing radial tyre steel cord thread and its preparing method

InactiveCN1473915AReduce consumptionImprove adhesionBase-materialsChlorinated paraffinsFatty alcohol

The lubricant consists of polyethylene wax, paraffin chloride, triethanolamine, sodium benzoate, fatty alcohol-polyoxyethyleneether, benzotriazole, sodium soap and water in certain proportion. The preparation process includes the following steps: mixing homogeneously paraffin chloride and triethanolamine while heating to 140-150 deg.c; mixing homogeneously polyethylene wax, sodium benzoate, fattyalcohol-polyoxyethyleneether, benzotriazole, sodium soap and water while heating to 80-90 deg.c; mixing the two kinds of mixture in the foregoing steps, emulsifying, cooling and filtering to obtain ivory white liquid as the product. The lubricant ensures complete coating on the steel cord thread, increases the adhesion between the steel card thread and rubber, and has no corrosion to pipeline andapparatus and low cost.

Owner:王俊

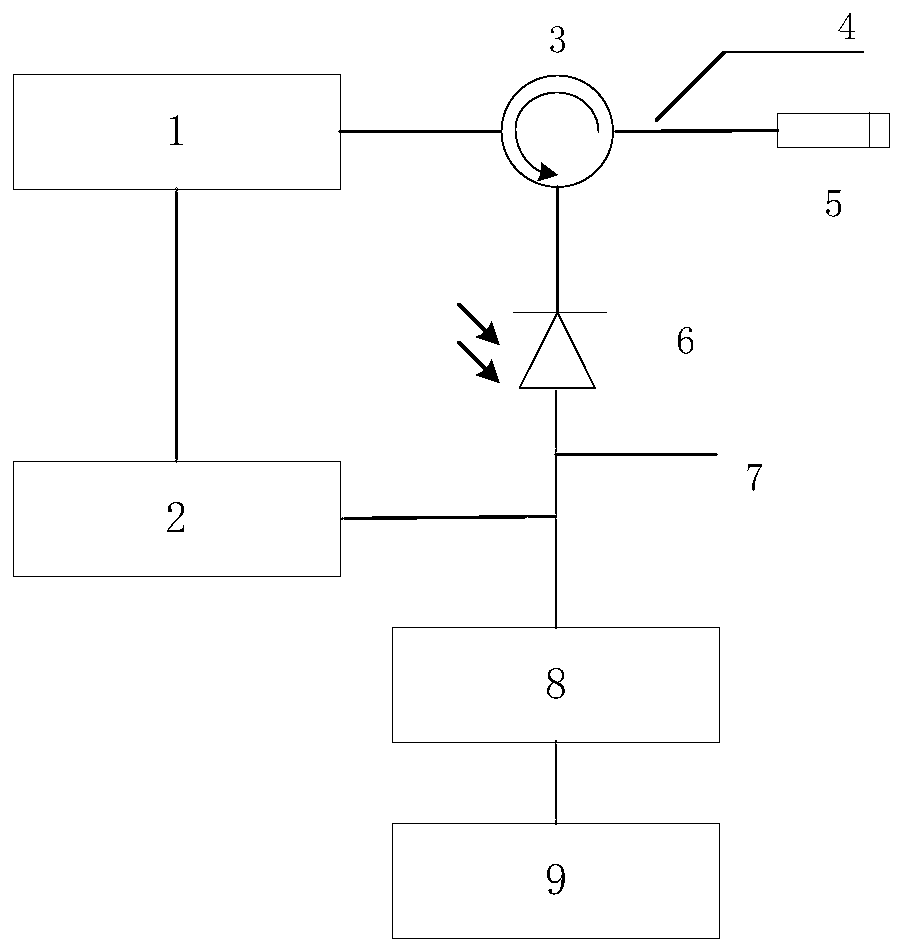

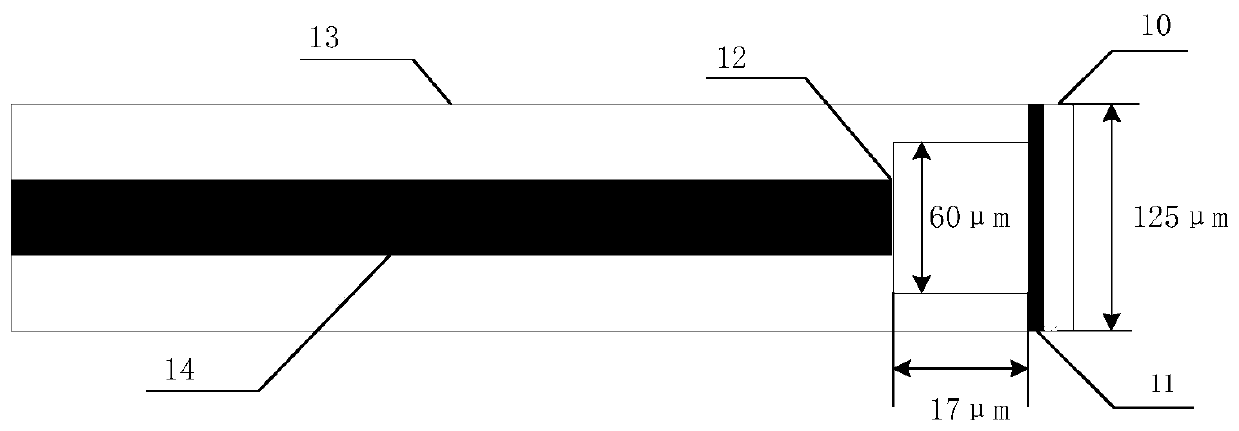

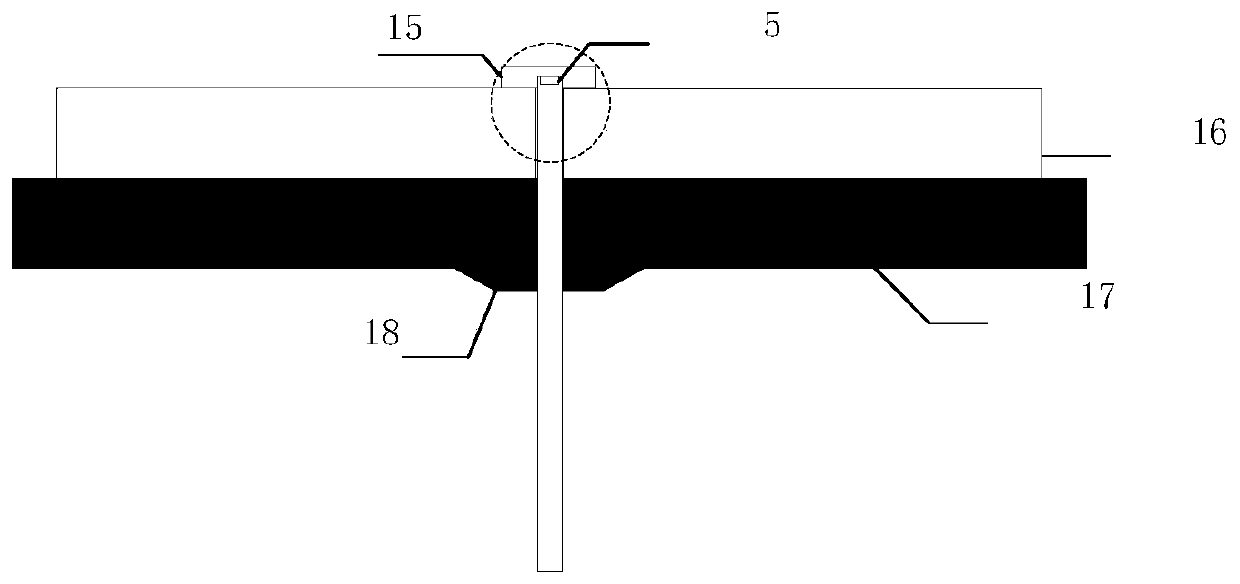

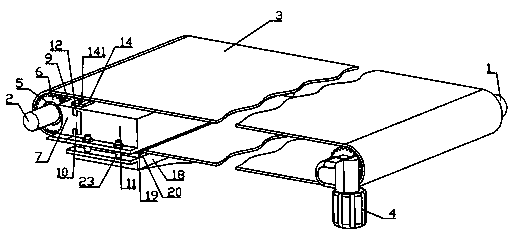

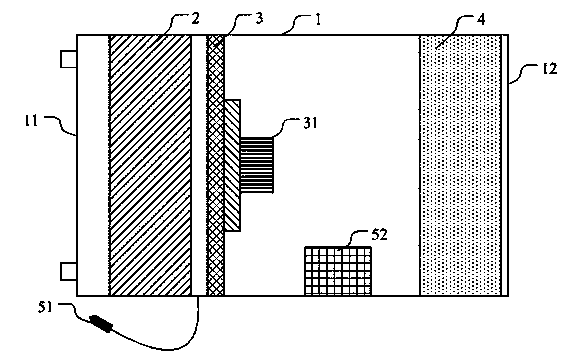

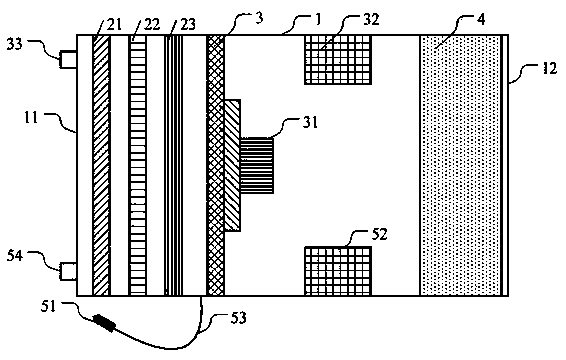

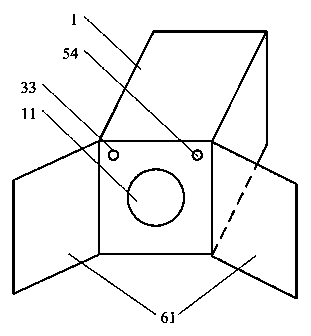

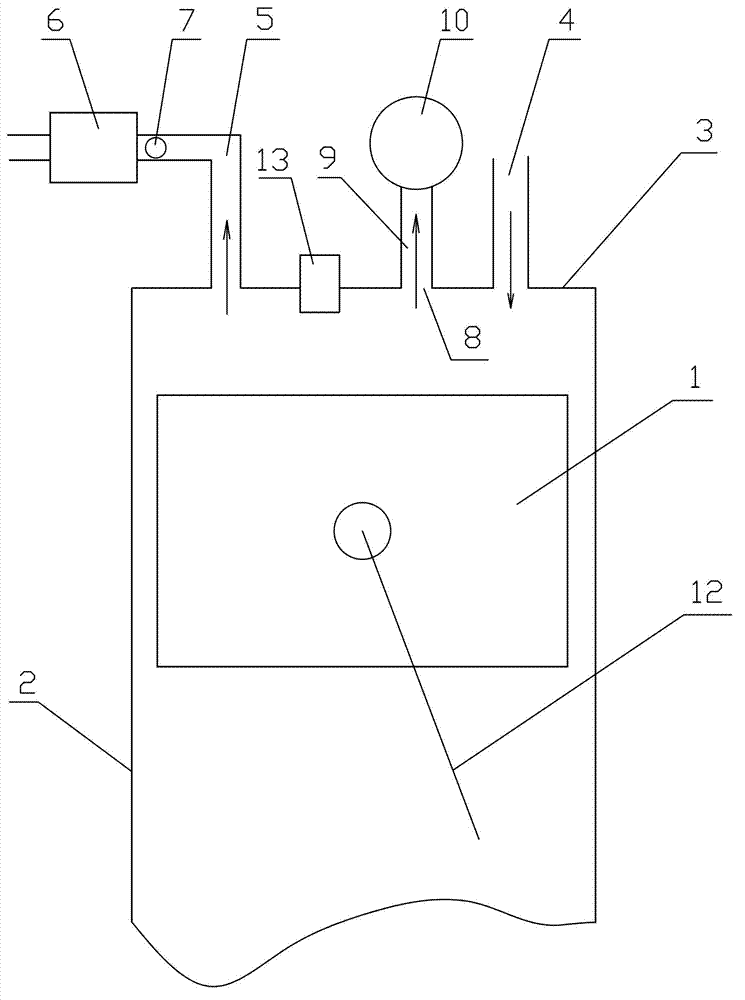

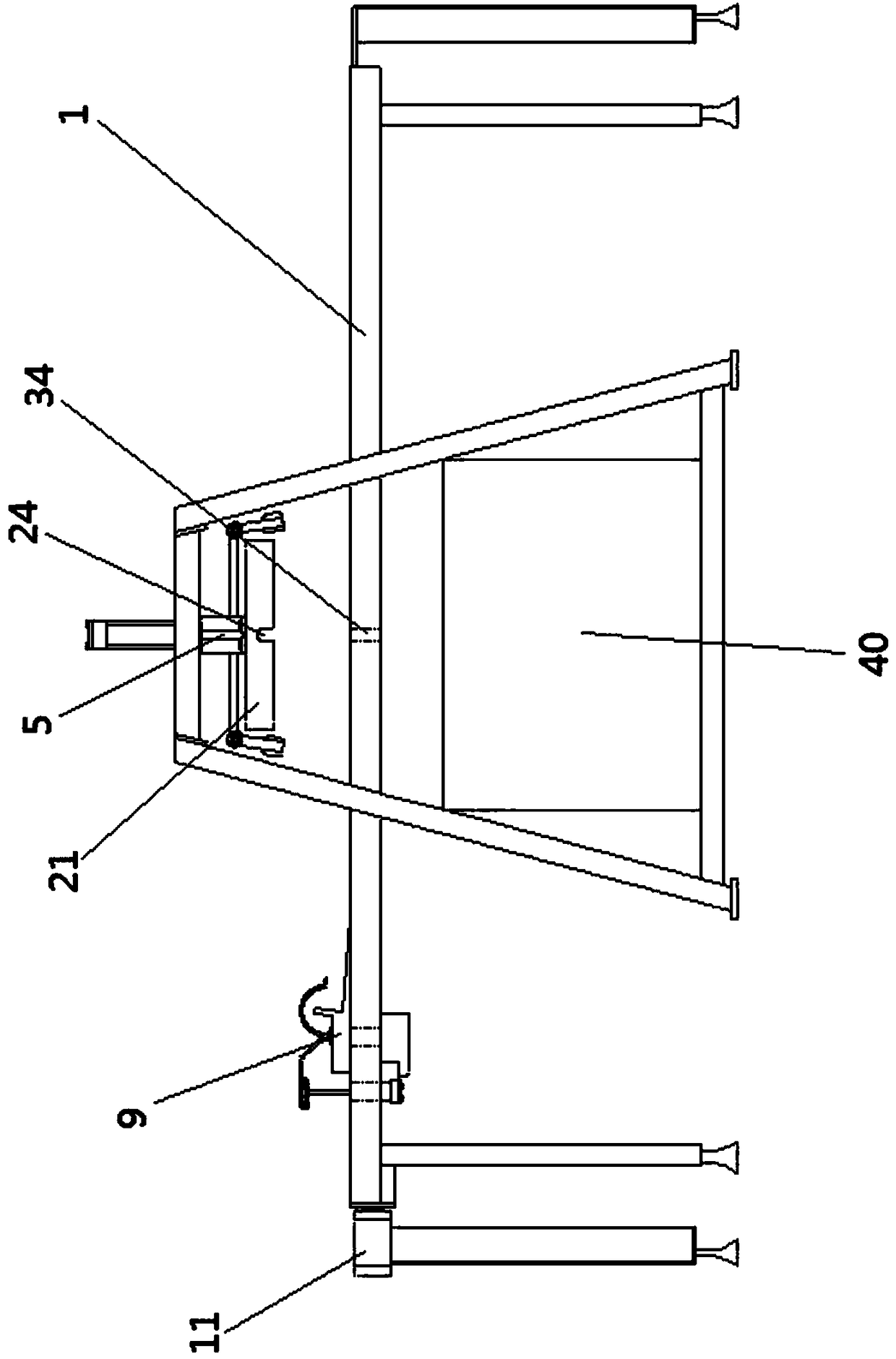

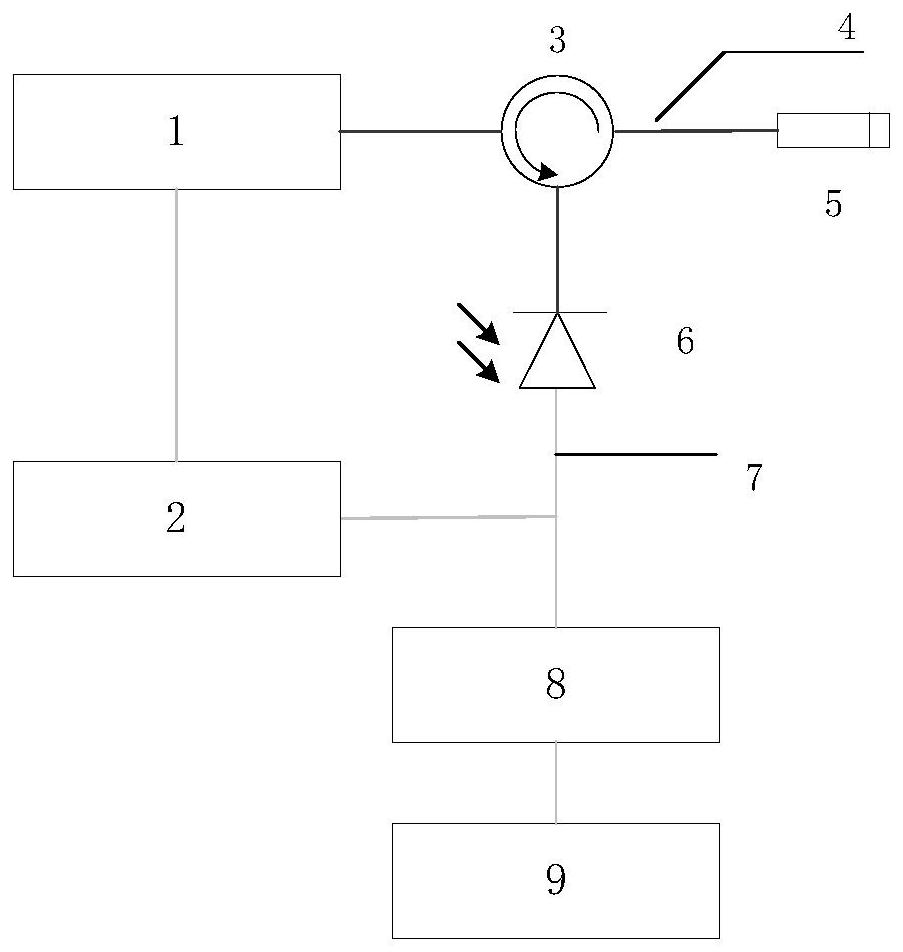

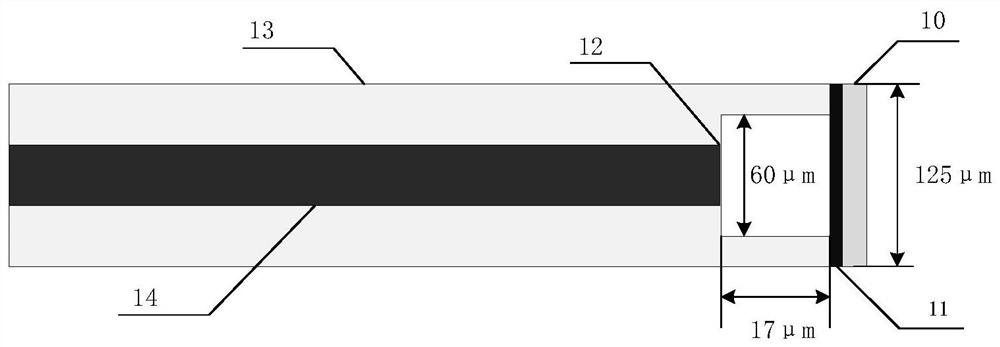

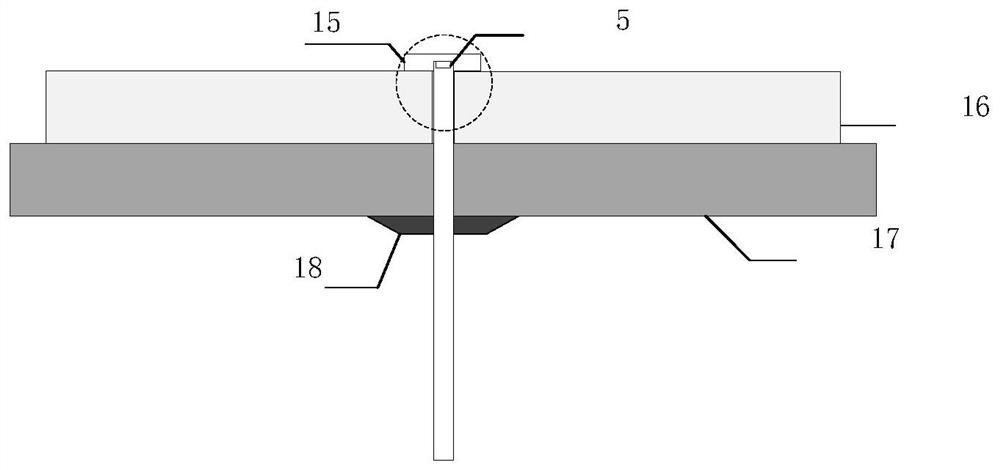

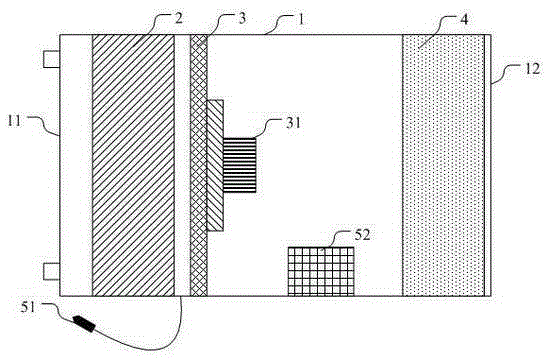

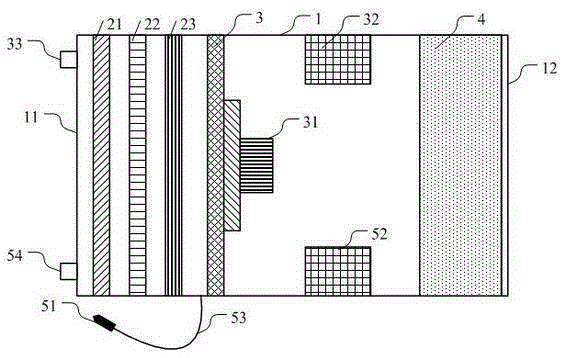

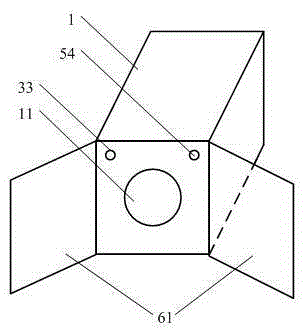

Local discharging sensor combining graphene diaphragm with micro optical fiber interference cavity and detection method based thereon

ActiveCN109799435AHigh detection sensitivityStructural parameter optimizationTesting dielectric strengthData acquisitionElectrical devices

The invention discloses a local discharging sensor combining a graphene diaphragm with a micro optical fiber interference cavity and a detection method based thereon. The local discharging sensor comprises a tunable laser device (1), a laser device wavelength control module (2), an optical fiber circulator (3), monomode optical fiber (4), the micro optical fiber interference cavity (5), a photoelectric detector (6), a signal line (7), a filter (8) and a data collection card (9). A multilayer graphene membrane is adopted, so that detection sensitivity of the sensor is improved; on the basis ofstructure optimization design of the multilayer graphene membrane, the multilayer graphene membrane is enabled to adapt to local discharging detection frequency band requirements; a polyimide coatingis adopted to prolong service life of the multilayer graphene membrane; femtosecond laser is adopted to process the micro optical fiber interference cavity inside optical fiber, and a static-state working point is stabilized on the basis of laser device wavelength control. On the basis of optimization design of a detection device mounting mode, original working environment of electrical equipmentis unaffected during mounting of the local discharging sensor.

Owner:CHONGQING UNIV

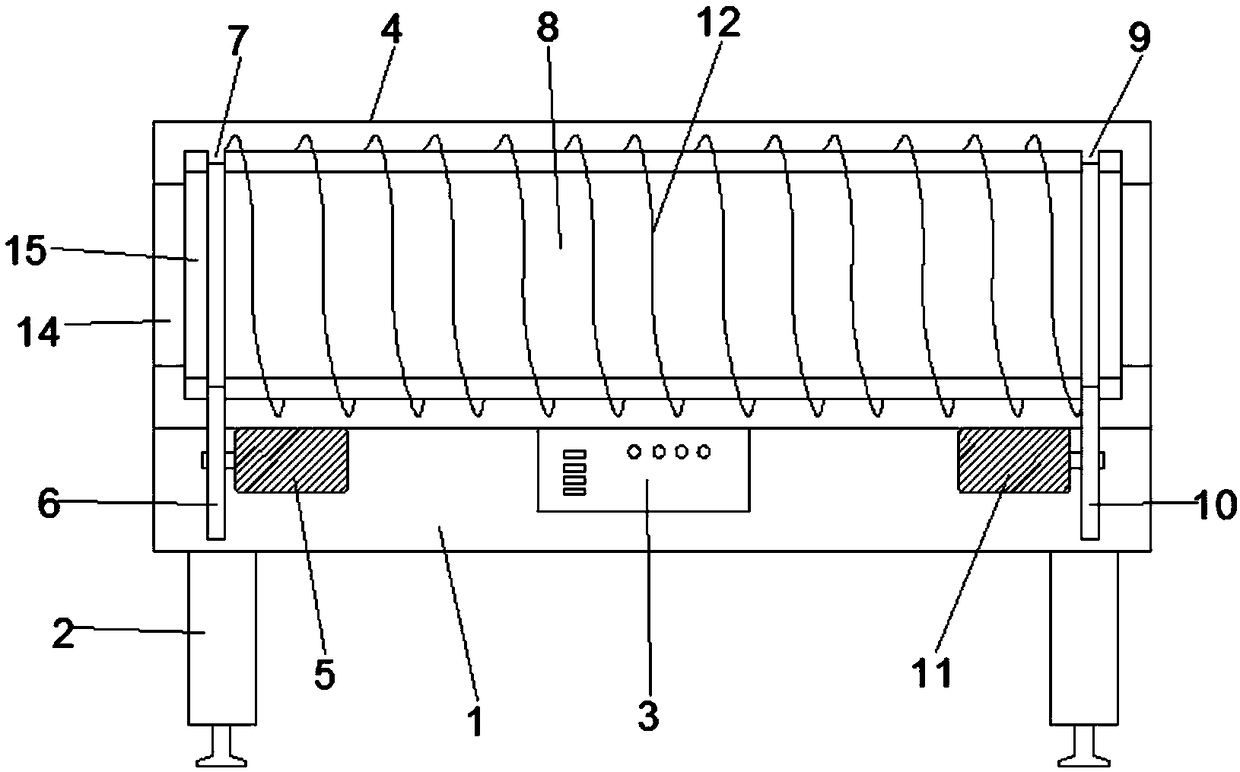

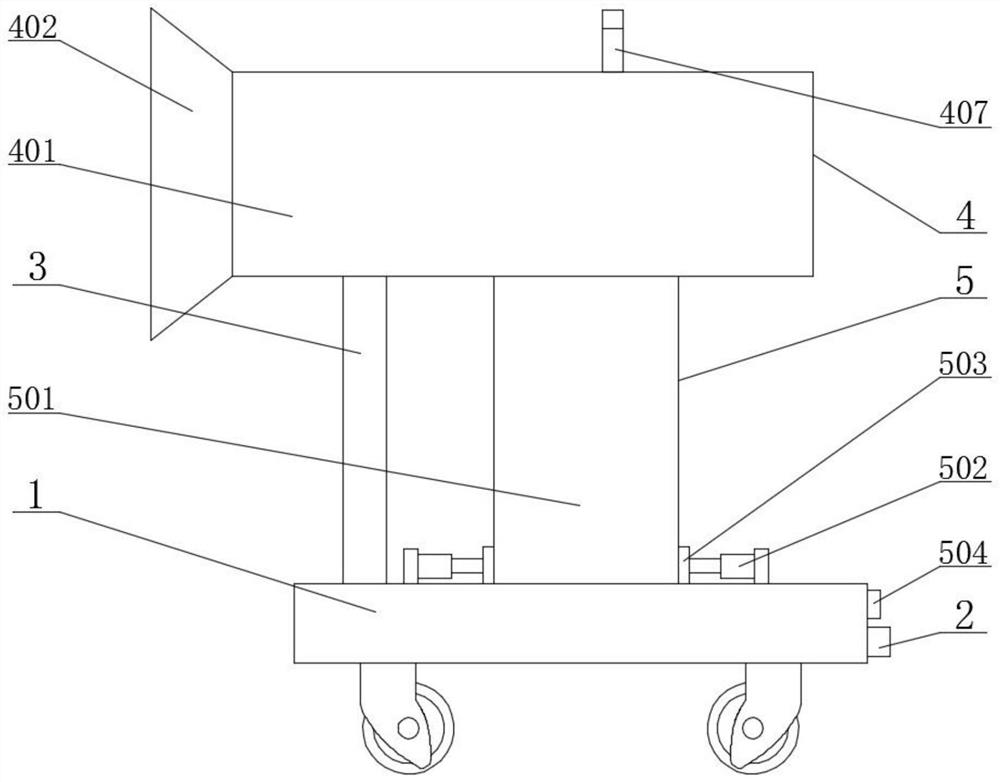

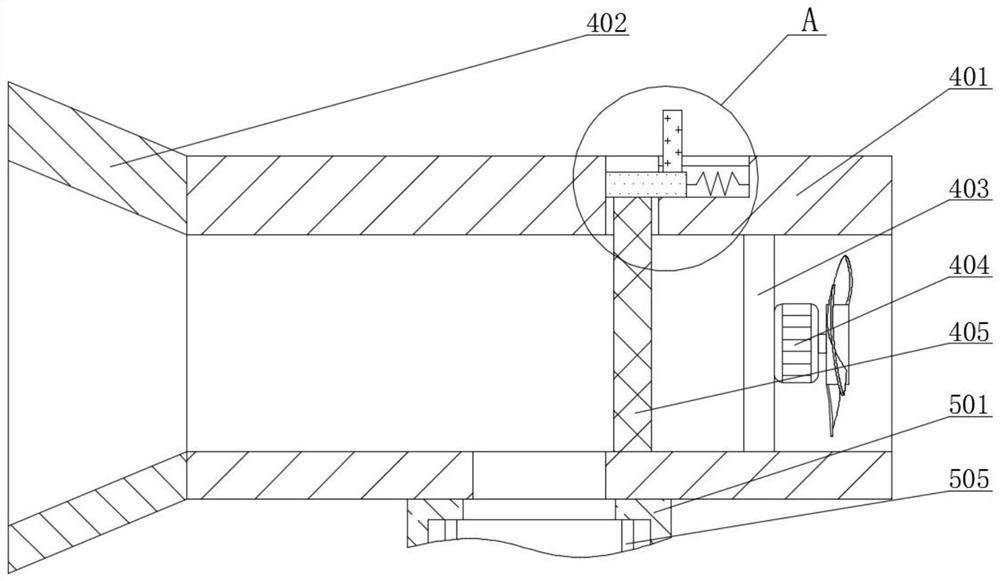

Automatic equipment cleaning device

PendingCN111591720ARealize the effect of automatic cleaningSave human resourcesCleaningGear wheelElectric machinery

The invention discloses an automatic equipment cleaning device. The automatic equipment cleaning device comprises a driving roller, a driven roller and a chain conveyor belt, wherein the power end ofthe driving roller is connected with a motor, a bearing and a gear are installed on the driven roller, the driven roller is matched with a fixing block, the fixing block is provided with a fixing through hole and a fixing screw, the fixing block is provided with a receding arc-shaped groove and a T-shaped fixing block, the T-shaped fixing block is matched with a cleaning box, the cleaning box comprises a fixing groove and buckling grooves, the buckling grooves are matched with buckling blocks, the cleaning box comprises an air drying box, a separating block and a spraying box, the air drying box comprises an air outlet, a rotating shaft, an air box, fan blades, a cam, through holes and an air inlet pipe, the input end of the air inlet pipe is connected with a hot air blower, the separatingblock comprises a cross-shaped groove, a cross-shaped sliding block, a stopping table, a spring, an ejector rod and a U-shaped brush body, the spraying box comprises spraying holes and a water inlet,the input end of the water inlet is connected with a water supply device, and the cleaning box is hinged to a water receiving box, the water receiving box and the cleaning box are provided with limiting blocks and auxiliary brush bodies, and the output end of the water receiving box is provided with a drain hole, fixing holes and fastening screws.

Owner:GUANGDONG INST OF SCI & TECH

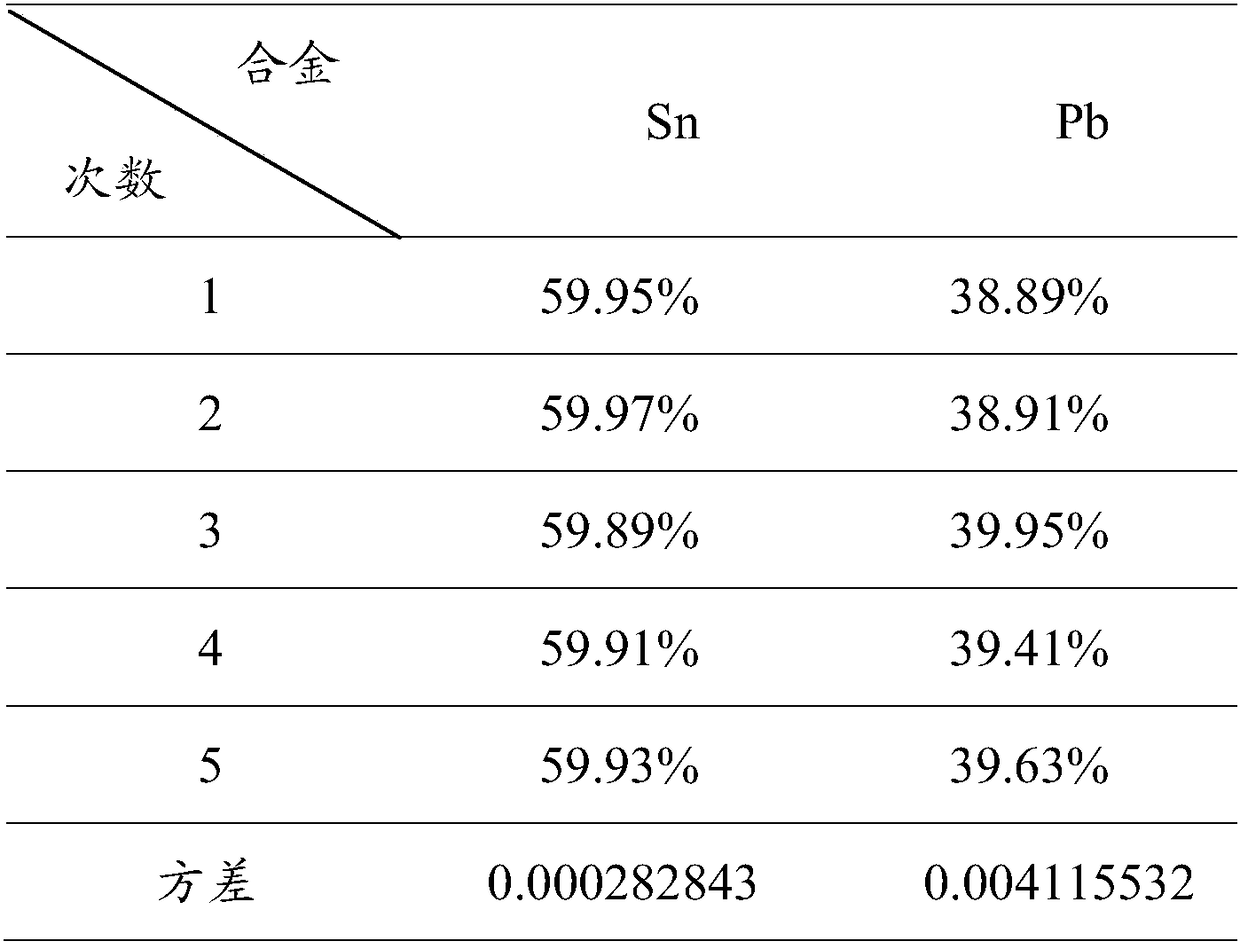

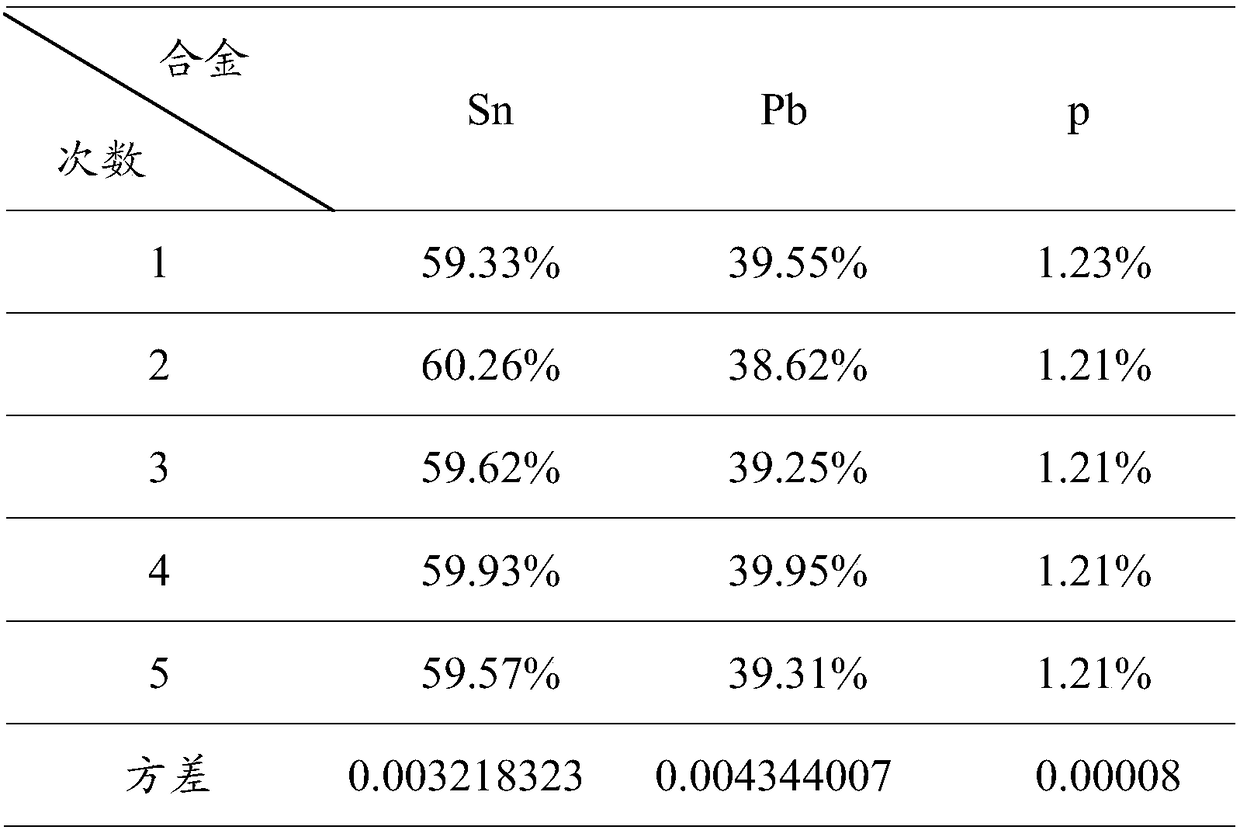

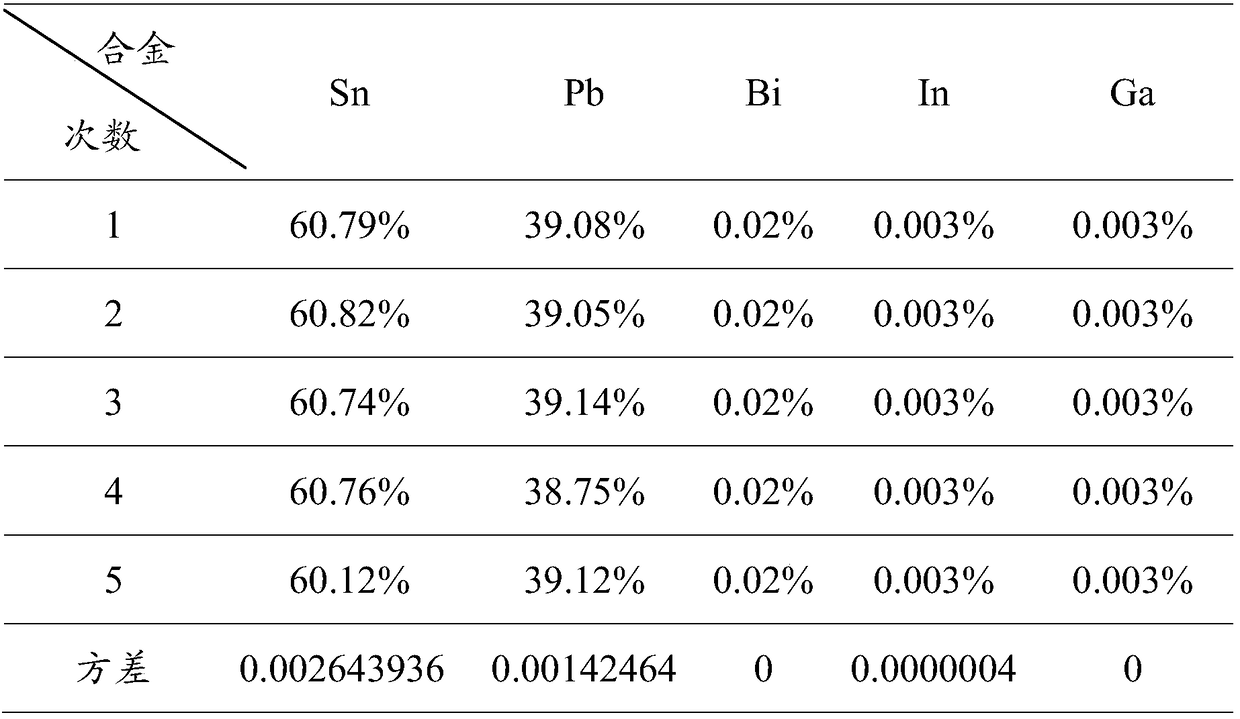

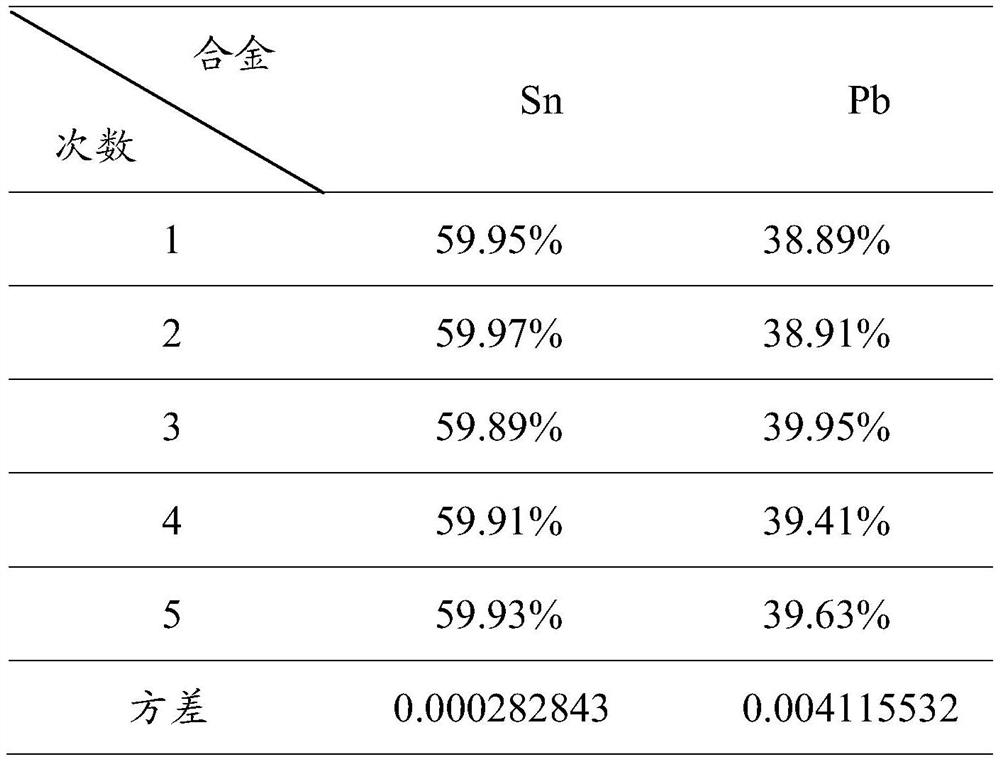

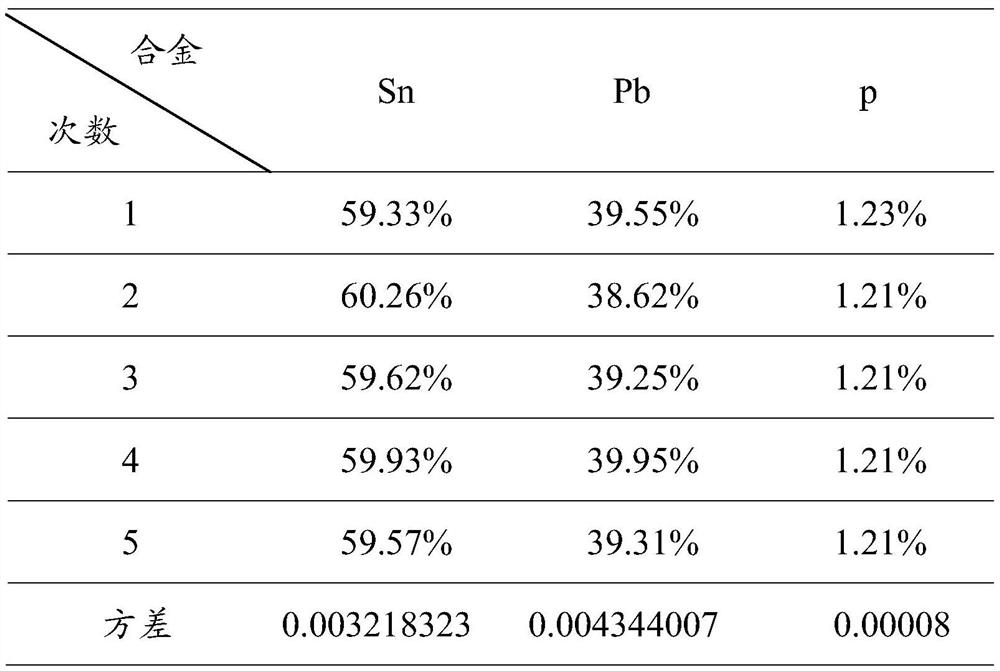

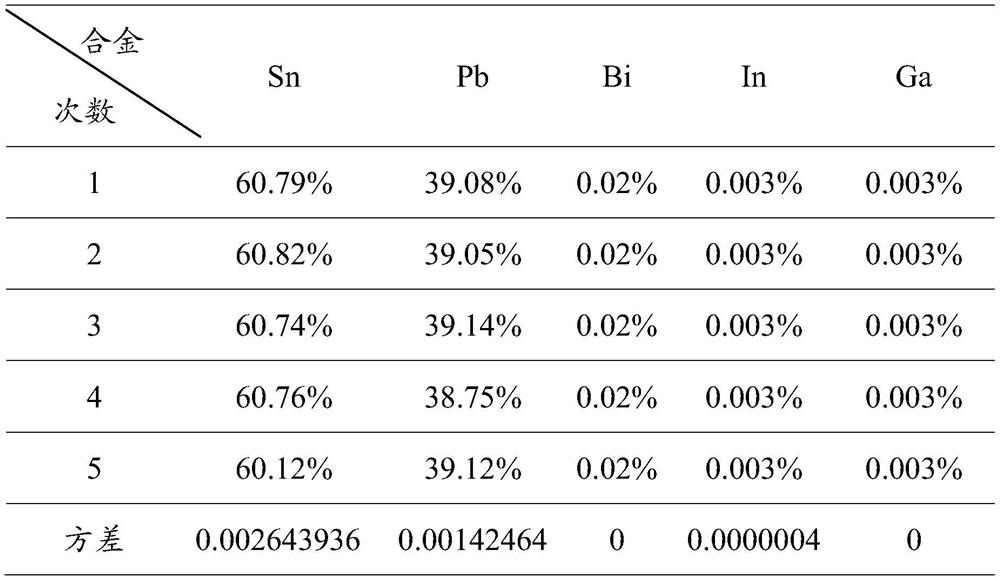

Photovoltaic welding strip alloy solder and preparation method thereof

ActiveCN108555472ALow melting pointImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaTinningEnvironmental resistance

The invention provides photovoltaic welding strip alloy solder and a preparation method thereof. The raw material of the photovoltaic welding strip alloy solder comprises tin-lead alloy, bismuth, indium, phosphorus, cerium, neodymium and germanium. According to the photovoltaic welding strip alloy solder, the bismuth, indium, neodymium, cerium, germanium, gallium, phosphorus and copper are added into the tin-lead alloy, the melting point of the photovoltaic welding strip alloy solder is effectively reduced, the oxidation resistance, welding tension, expansion rate and fluidity of the photovoltaic welding strip alloy solder are improved, and the generation of slag soil is reduced. According to the photovoltaic welding strip alloy solder, the yield of tin products is improved, the productivity of hot tinning products is improved, the wettability of tin plating solution is improved, and other physical and mechanical properties of tin plating products are not affected; and the preparationmethod is simple, the cost is low, the daily maintenance and curing of an existing equipment are not affected, the environmental protection requirements are met, and the working environment of the production site is not affected.

Owner:XIAN TELISON NEW MATERIAL

Welding device with smoke purifying function

ActiveCN103386527AReduce space occupationEasy to operateMetal working apparatusSoldering auxillary devicesEngineeringSmoke

The embodiment of the invention discloses a welding device with a smoke purifying function, comprising a columnar shell, wherein a gas inlet and a gas outlet are respectively arranged in the two end faces of the shell; a filter layer, a clapboard and a noise reduction and odor removal layer are arrayed in sequence from the end face where the gas inlet is arranged to the direction of the end face where the gas outlet is arranged; a fan is arranged on the clapboard and is used for driving gas entering the inside of the shell from the gas inlet to flow towards the gas outlet and discharging the gas out of the shell; a welding device drive module which is used for driving the welding device to work is arranged in a space which is encircled by the shell, the clapboard and the noise reduction and odor removal layer; the welding device is arranged outside the shell and is connected with the welding device drive module through a wire. By using the welding device with the smoke purifying function, the existing space which is used for the welding device is capable of containing a smoke purifier and the welding device simultaneously, the occupied space is reduced, and meanwhile, compared with the existing smoke purifier, the welding device with the smoke purifying function has the advantages that the cleaning is more thorough, the noise is small, and the working environment of operating workers is not influenced.

Owner:深圳市谷多普科技有限公司

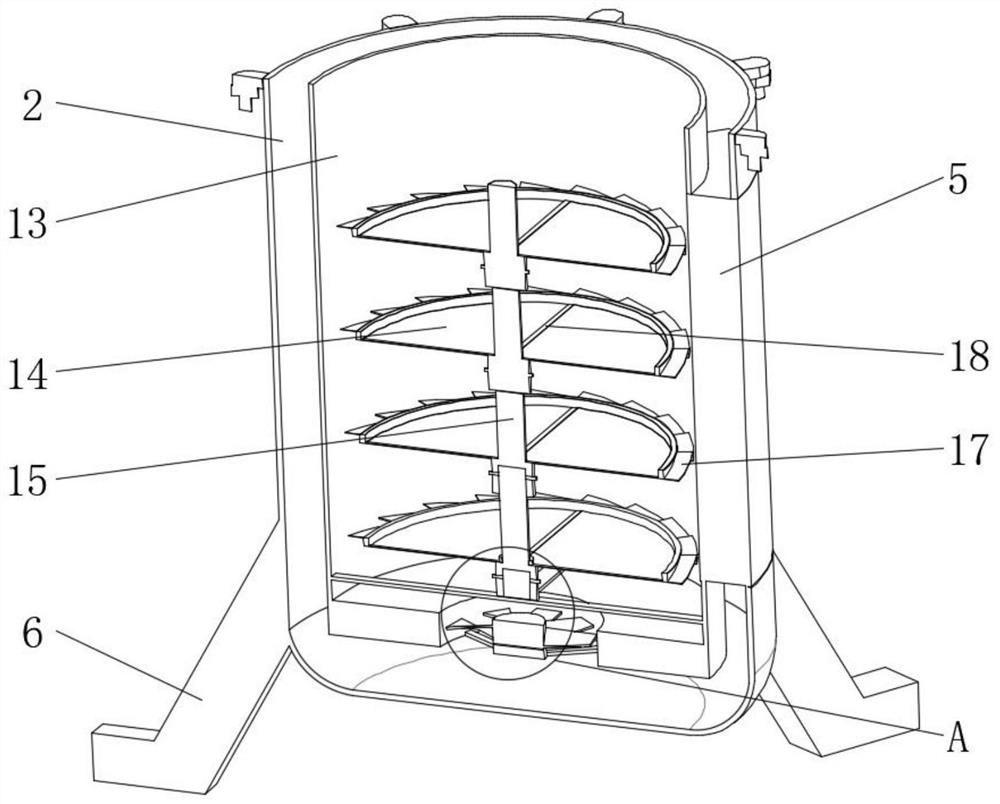

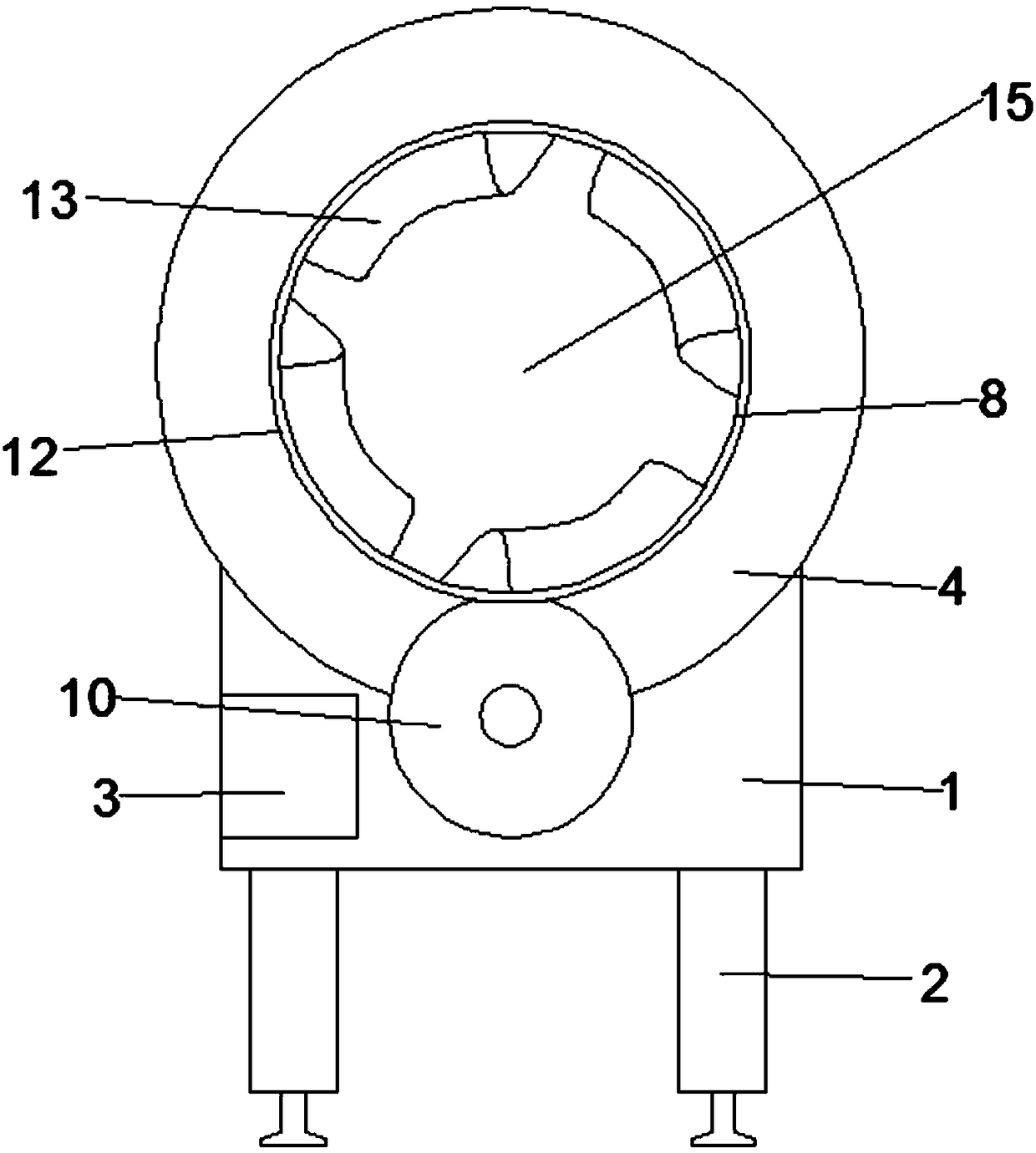

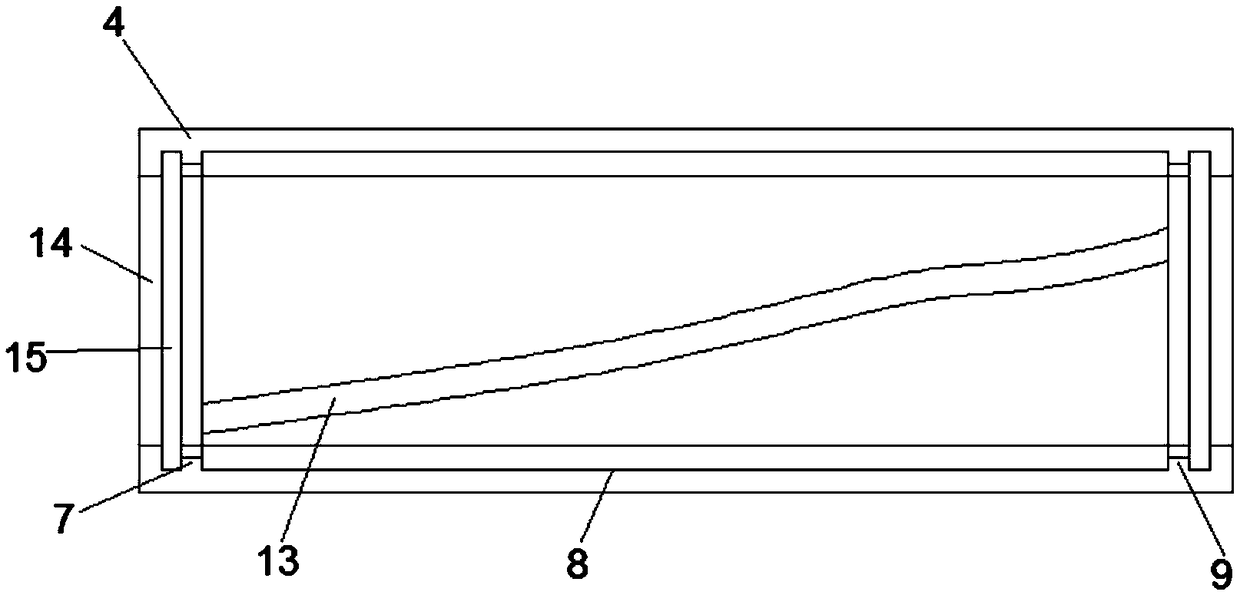

Low-noise ventilator

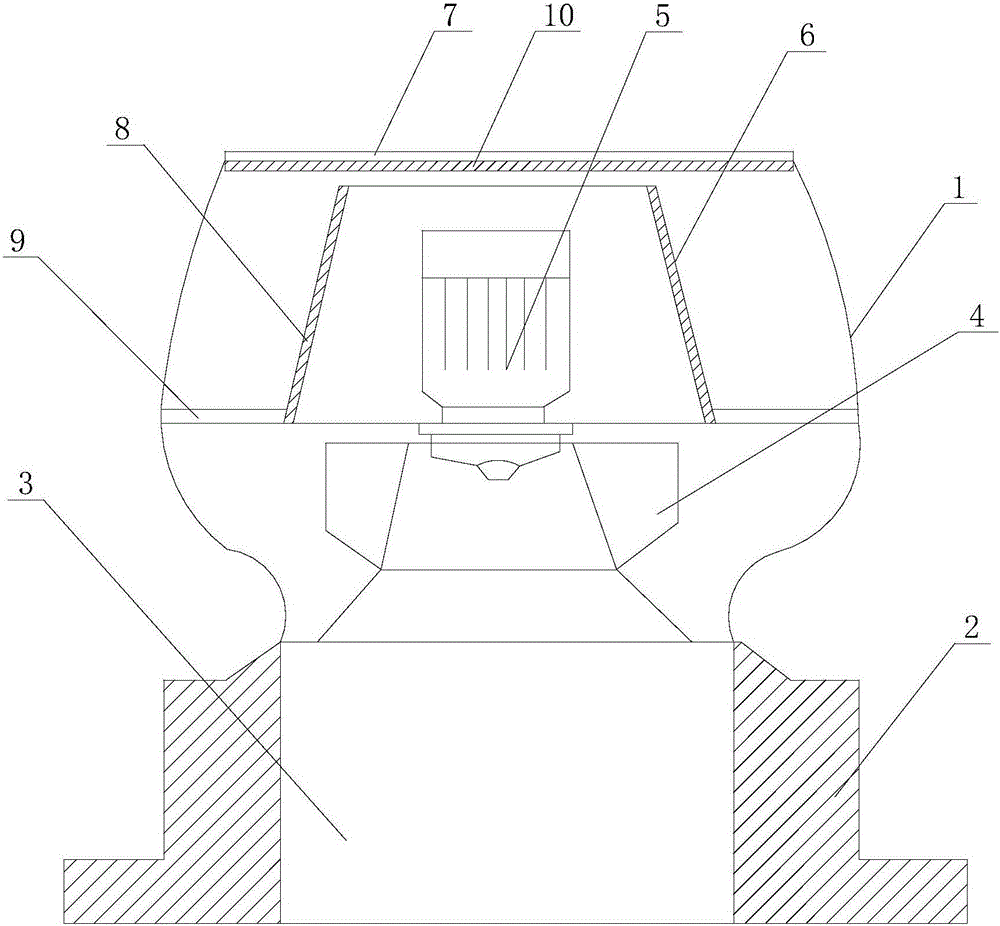

InactiveCN105715567ASimple structureReduce volumePump componentsPump installationsNoise pollutionImpeller

The invention discloses a low-noise ventilator which comprises a housing, wherein a base is mounted at the bottom end of the housing; a ventilation opening is formed in the base; an impeller and a motor are arranged in the housing; the impeller is mounted at the bottom end of the motor; a noise-reduction housing is mounted outside the motor; an air outlet is formed in the top end of the housing; and a filter screen is arranged at the air outlet. The low-noise ventilator has the following beneficial effects: the low-noise ventilator is simple in structure, small in size, convenient to maintain and convenient to operate and use; by adopting a double-layer housing structure, the low-noise ventilator can greatly reduce noise pollution, doesn't affect the working environment of workers and meanwhile is improved in stability; and an arranged heat dissipation layer can effectively prevent a motor overheating phenomenon and has high stability performance.

Owner:苏州保酚环境科技有限公司

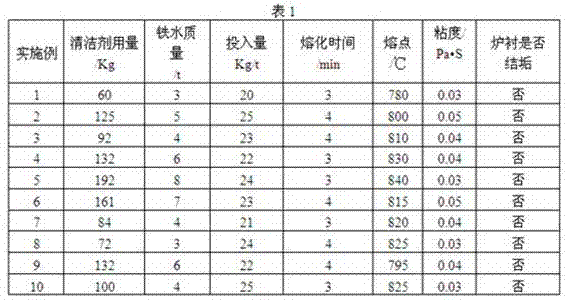

Special cleaner for molten iron ladle furnace liner and using method thereof

The invention discloses a special cleaner for a molten iron ladle furnace liner and a using method thereof. The cleaner comprises the following raw materials in percentage by weight: 35-40% of pre-melting materials, 23-27% of fluxing agents, 9-11% of calcite powder and 6-8% of soda-lime glass. The special cleaner for the molten iron ladle furnace liner can be used for removing slag of molten iron ladles; meanwhile, the special cleaner is high in melt performance, stable in slag removal effect, low-cost and easily available in preparation raw materials, free of other peculiar smells after put into a working furnace, environmentally-friendly in way and free of influence on the operation environment; the quality of the molten iron is improved; the high-quality raw materials are directly provided for subsequent processes; the subsequent melting processes are eliminated; the processing cost is reduced; the corresponding fees are reduced; the green production standard can be met.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Combustion chamber air interchanger without disturbance to three-way catalyst and oxygen sensor

InactiveCN103195554AReduce the temperatureIncrease the compression ratioInternal combustion piston enginesCombustion chamberOxygen sensor

The invention discloses a combustion chamber air interchanger without disturbance to a three-way catalyst and an oxygen sensor. The air interchanger comprises a combustion chamber composed of a piston with motion close to an upper dead center, an air cylinder, a cylinder cover and an air pumping mechanism or an air blow mechanism. An air feeding mechanism and an air exhaust mechanism are communicated with an air inlet and an air outlet of the combustion chamber through an air inlet tube and an air outlet tube. The three-way catalyst and the oxygen sensor are arranged in the air outlet tube, and the oxygen sensor is connected with a computer through a line to control the oil spray amount of an oil injector. In an exhaust stroke of a motor, the air pumping mechanism pumps residual waste air from the combustion chamber when the air exhaust mechanism closes the air outlet in advance and opens an air inlet valve, or the air blow mechanism blows away residual waste air from the combustion chamber when the air exhaust mechanism closes the air outlet in advance and the air feeding mechanism opens the air inlet in advance. According to the non-interface air interchanger, operation environments of the three-way catalyst and the oxygen sensor are not affected while the waste air is exhausted, the operation efficacy of the three-way catalyst is maintained, instructions of the oxygen sensor are not interfered, and normal operation conditions of the motor is guaranteed.

Owner:麦镇荣

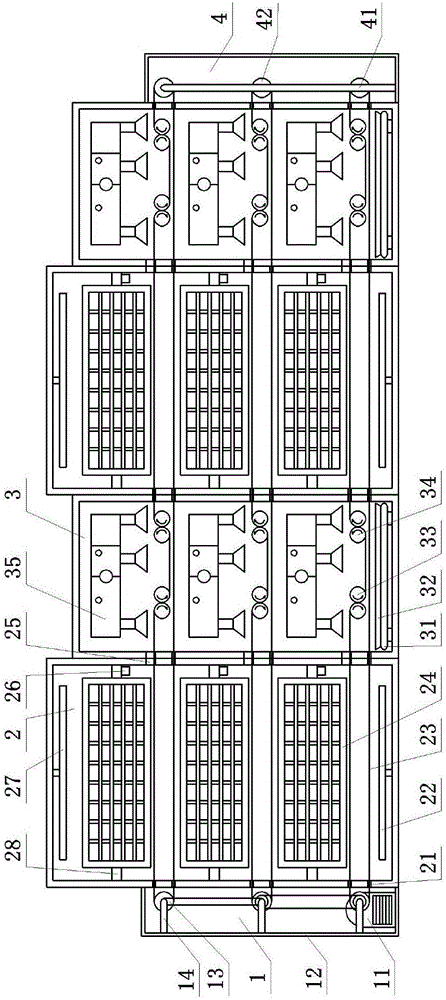

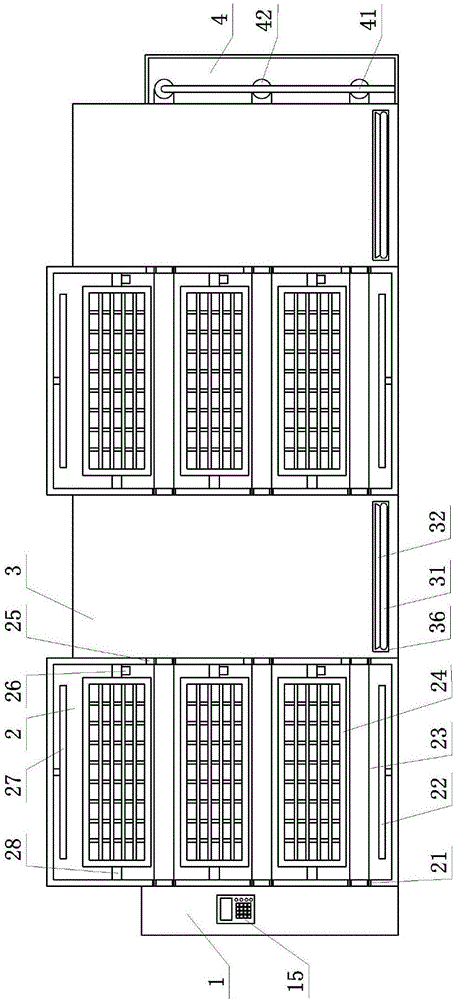

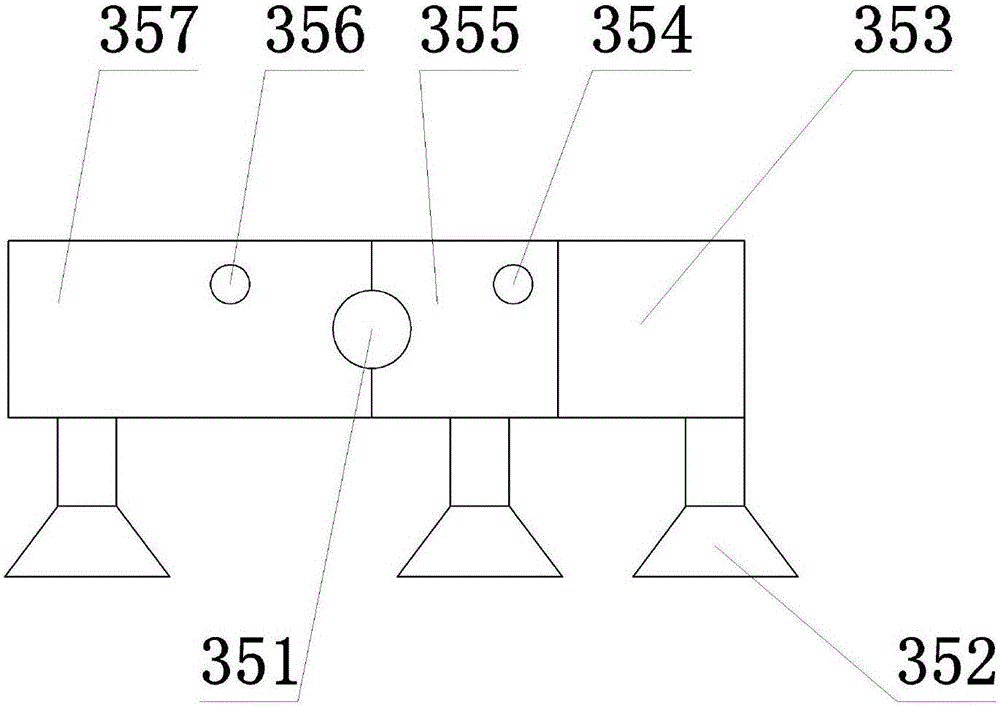

Multifunctional reciprocating type cut-to-size saw

InactiveCN108422492ANot easy to slipReduce frictionCircular sawsSawing componentsHydraulic cylinderEngineering

The invention discloses a multifunctional reciprocating type cut-to-size saw. The multifunctional reciprocating type cut-to-size saw comprises a machine main body, one side of the machine main body isprovided with three front workbenches which are arranged at equal intervals, the other side of the machine main body is provided with three rear workbenches which are arranged at equal intervals, a downwards pressing device is erected above the machine main body through a pair of cross beams, a plate fixing device is arranged across three rear workbenches, the plate fixing device comprises a transverse baffle plate on which a sliding rail is arranged, and the sliding rail is internally provided with a plurality of plate fixing device single bodies which are arranged at equal intervals; the downwards pressing device comprises a downwards pressing plate, the downwards pressing plate is connected with a hydraulic cylinder through a piston rod, the lower surface of the downwards pressing plate is provided with a first groove, a square plate sleeves the tail end of the piston rod, two ends of the square plate are connected with an inclined baffle plate through a torsion spring, and the tail end of the inclined baffle plate is provided with a silica gel piece. The multifunctional reciprocating type cut-to-size saw has the advantages that the plate protection effect is good, the waste scraps generated during plate sawing cannot drift all around and an additional workbench is flexible to disassemble and assemble.

Owner:湖州博立科技股份有限公司

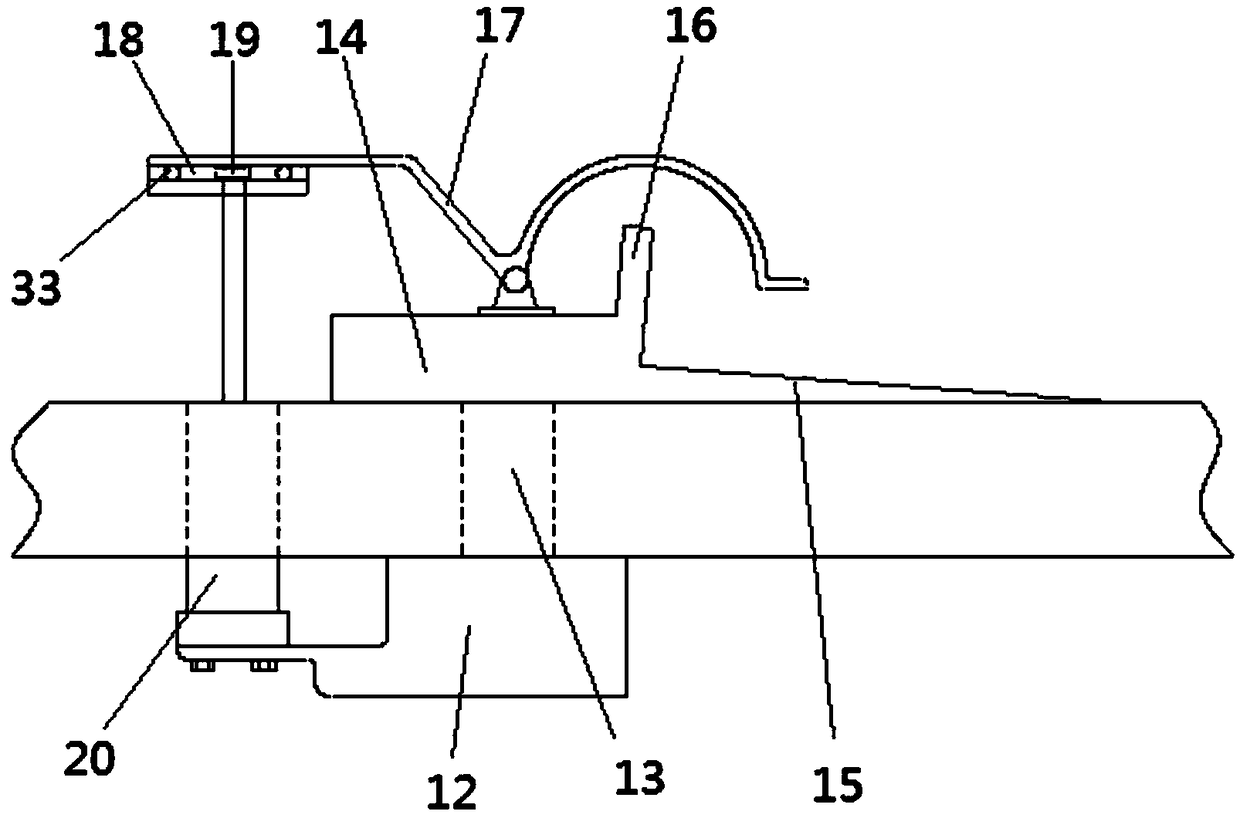

Lawn mower convenient in use

InactiveCN106717463AAvoid secondary weedingAvoid secondary cleaningLawn-mowersWorking environmentEngineering

The invention discloses a lawn mower convenient in use. The lawn mower comprises a mower body, a motor and a reference rod are arranged on the mower body, a reference size is arranged on the reference rod, a screw rotation blade is arranged at the position of the nose of the mower body, mowing control rods are arranged on two sides of the screw rotation blade, blade height adjustment blocks are arranged on two sides of the nose of the mower body, a rack and a grass collecting box are arranged at the tail of the mower body, a plurality of clamping grooves are arranged in the grass collecting box, and a first filter screen, a second filter screen and a third filter screen are respectively arranged in the clamping grooves. By the arrangement, the grass cannot be directly discharged after mowed, secondary cleaning is not needed for people, dust cannot be produced after air is discharged, working environment of users is protected, mowing efficiency is improved, labor intensity is decreased, and convenience in use is achieved.

Owner:吴晓美

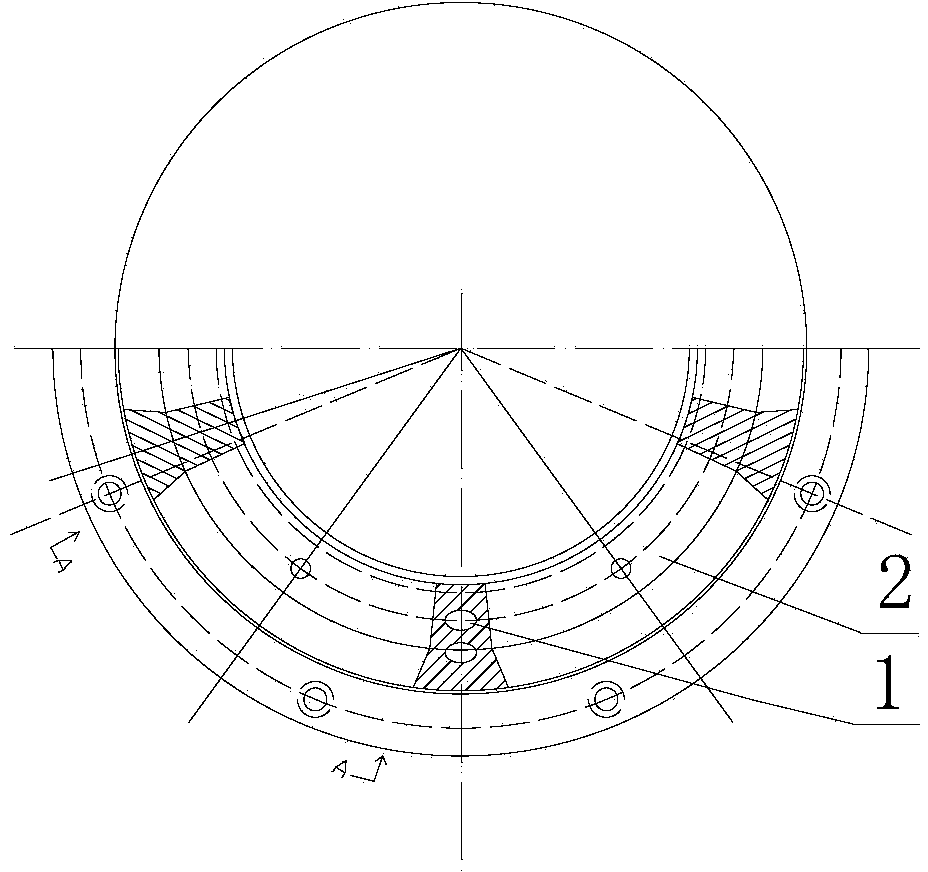

Device for reducing bearing temperature

ActiveCN103470644AReduce the temperatureDoes not affect the structureBearing coolingWorking environmentEngineering

The invention relates to a device for reducing bearing temperature, comprising a bearing body, wherein a group of oil return holes is formed in the side lower part of the bearing body, and the axial lead of the oil return holes and the center line of a bearing form an angle of 45 degrees. According to the invention, by forming the oil return holes in the bearing, the oil return quantity is increased so as to reduce the temperature of the bearing, on the premise that the integral structure, the strength and the working environment of the bearing are not affected, the problem of overhigh radial bearing temperature can be effectively controlled, the phenomenon of overhigh bearing temperature caused by insufficient oil return is avoided, the phenomenon of interlocking jump caused by overhigh bearing temperature is further avoided, and stable production is ensured.

Owner:JIANGSU LIANFENG IND EQUIP TECH CO LTD

Safety high efficient compound mildew-proof paper and preparation method thereof

InactiveCN100370077CWide variety of sourcesSimple production processNon-macromolecular organic additionPaper coatingBenzoic acidPropanoic acid

The invention discloses safe high efficiency complex type anti-fungicide paper and its manufacturing method. It is used the common kraft as base paper. One surface of the base paper is painted or spayed one layer complex type anti-fungus agent formed by o-phenyl phenyl phenol, benzoic acid, nipalgin propyl ester, and sorbic acid. The complex type anti-fungus agent layer is painted one layer complex type adhesion agent contained anti-fungus agent propionic acid, carbendazim, and vitamin E or C, and antioxidant complex type adhesion agent. The manufacturing method includes the following steps: selecting base paper; preparing and painting and spraying complex type anti-fungus; preparing and painting and spraying complex type adhesion agent. The anti-fungicide paper is no odor and peculiar smell, not influenced by environment, and no harm for people and animal. It can be applied to mould proofing of tobacco and its products, foods, forage, and so on.

Owner:唐建文 +3

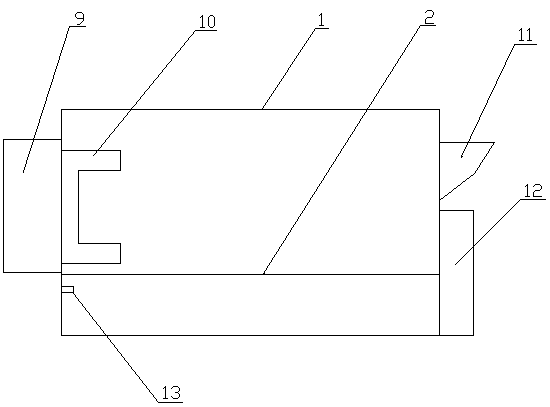

Conveying belt

InactiveCN107758203AReduce cleaning manpowerDoes not affect the working environmentConveyorsEngineeringConveyor belt

The invention discloses a conveyor belt, which comprises a main conveyor belt and an auxiliary conveyor belt. An auxiliary conveyor belt lower than the height of the main conveyor belt is installed on both sides of the main conveyor belt. When the gravel material is transported on the conveyor belt, the sand and gravel material accidentally rolled off the main conveyor belt will fall on the auxiliary conveyor belt and continue downward. Transmission, will not fall to the ground, maintain a good workplace environment, and save manpower for cleaning.

Owner:江苏通王工程科技有限公司

A kind of photovoltaic ribbon alloy solder and preparation method thereof

ActiveCN108555472BLow melting pointImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaSlag (welding)Indium

The invention provides photovoltaic welding strip alloy solder and a preparation method thereof. The raw material of the photovoltaic welding strip alloy solder comprises tin-lead alloy, bismuth, indium, phosphorus, cerium, neodymium and germanium. According to the photovoltaic welding strip alloy solder, the bismuth, indium, neodymium, cerium, germanium, gallium, phosphorus and copper are added into the tin-lead alloy, the melting point of the photovoltaic welding strip alloy solder is effectively reduced, the oxidation resistance, welding tension, expansion rate and fluidity of the photovoltaic welding strip alloy solder are improved, and the generation of slag soil is reduced. According to the photovoltaic welding strip alloy solder, the yield of tin products is improved, the productivity of hot tinning products is improved, the wettability of tin plating solution is improved, and other physical and mechanical properties of tin plating products are not affected; and the preparationmethod is simple, the cost is low, the daily maintenance and curing of an existing equipment are not affected, the environmental protection requirements are met, and the working environment of the production site is not affected.

Owner:XIAN TELISON NEW MATERIAL

Anti-oxidation tinning solution based on yttrium, bismuth and phosphorus

The invention belongs to the technical field of metal anti-oxidation protection and particularly discloses an anti-oxidation tinning solution based on yttrium, bismuth and phosphorus. The anti-oxidation tinning solution comprises the following components of yttrium, bismuth, phosphorus and tin and includes, by weight percent, 0.005%-0.02% of yttrium, 0.004%-0.05% of bismuth and 0.01%-0.05% of phosphorus with the weight of tin as the benchmark. Yttrium, bismuth and phosphorus are added into the tin solution, oxidization of the tinning solution can be effectively inhibited, the wettability of the tinning solution is improved, generation of tin slag is reduced, the tin product yield is increased, productivity of the hot tinning product is improved, and other physical and mechanical properties of the tinning product are not affected. The anti-oxidation tinning solution is low in cost, an existing production technology is not changed, daily caring and maintaining of existing equipment are not affected, the environment-friendly requirement is met, and the working environment of a production place is not affected.

Owner:XIAN TELISON NEW MATERIAL

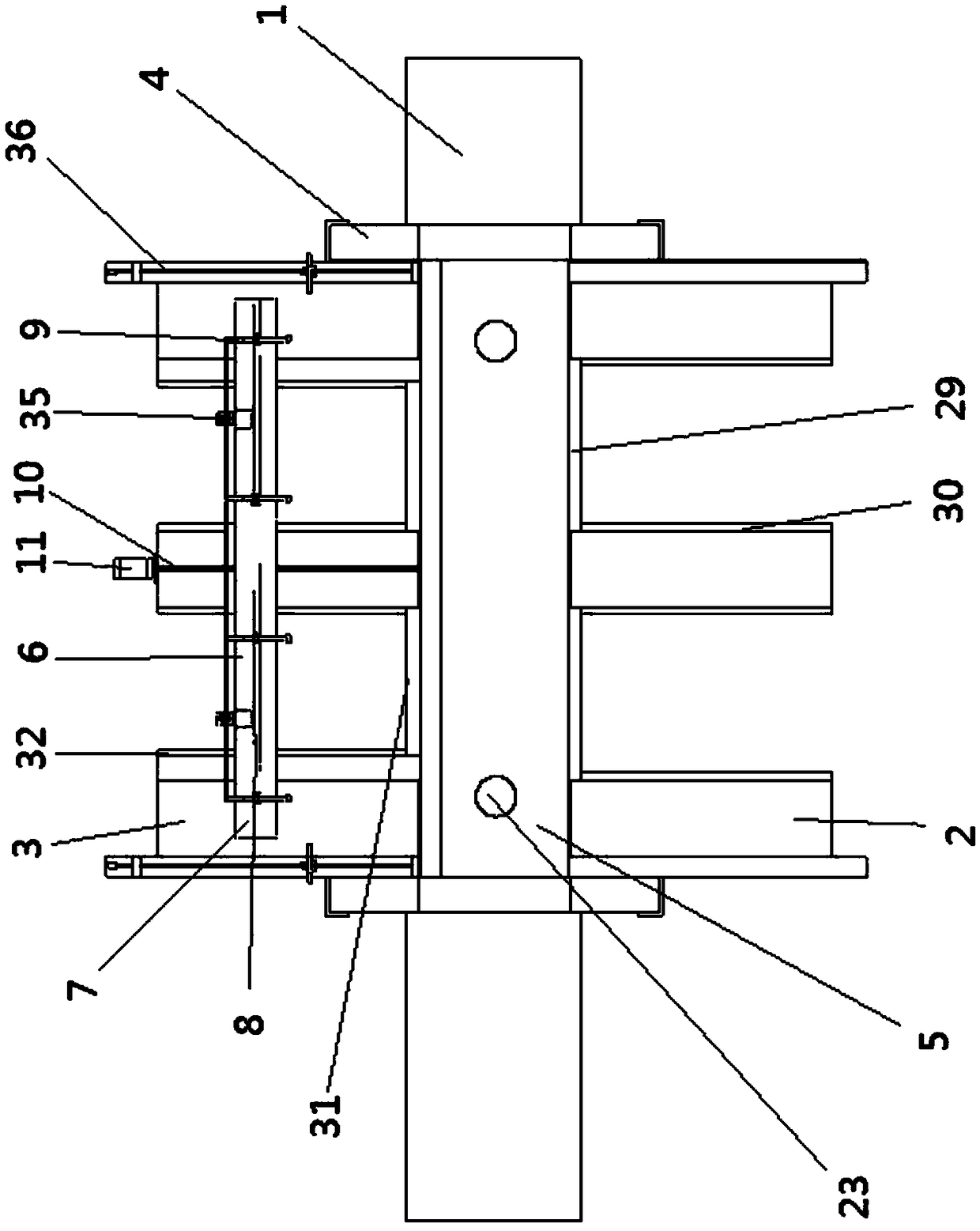

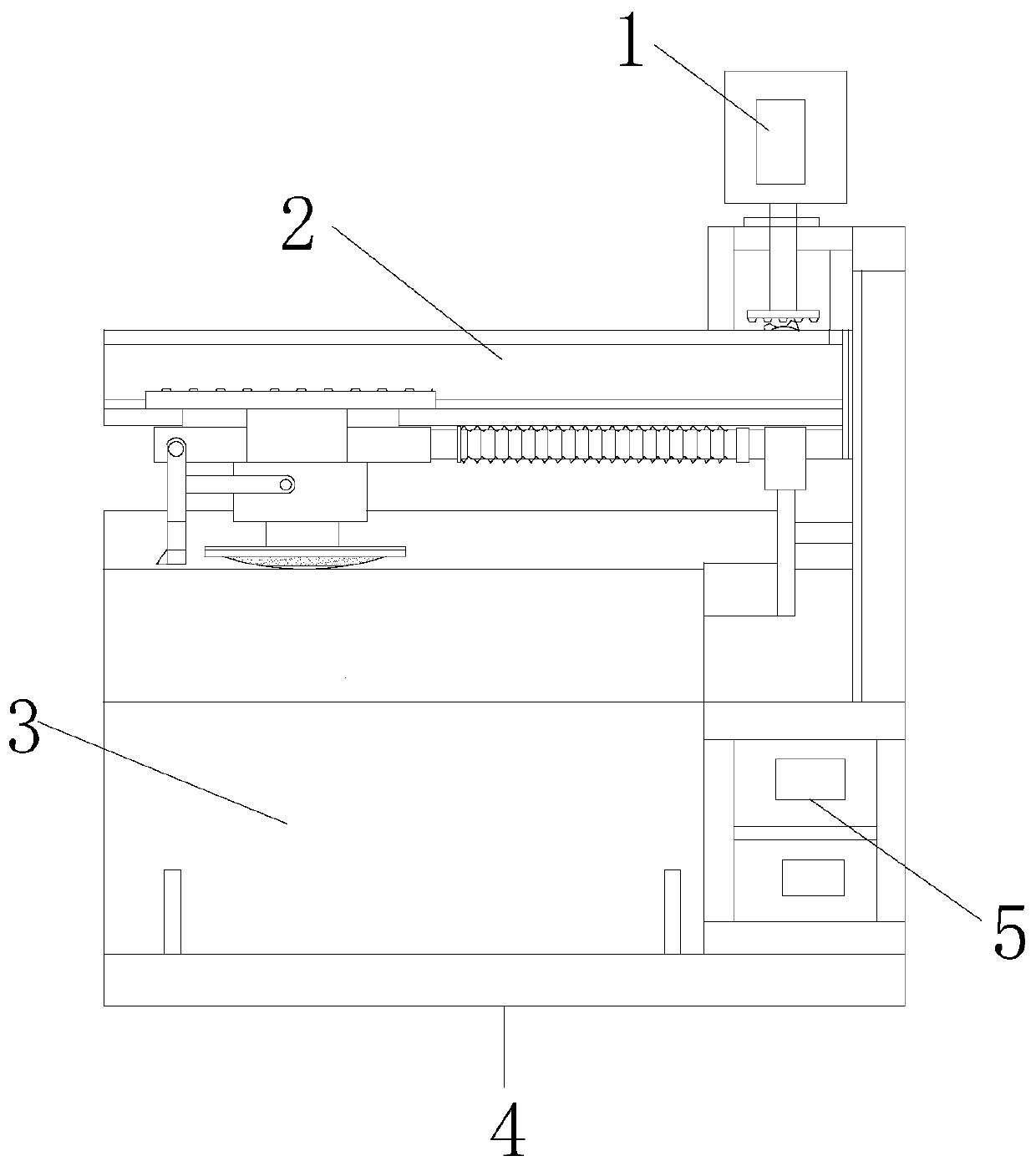

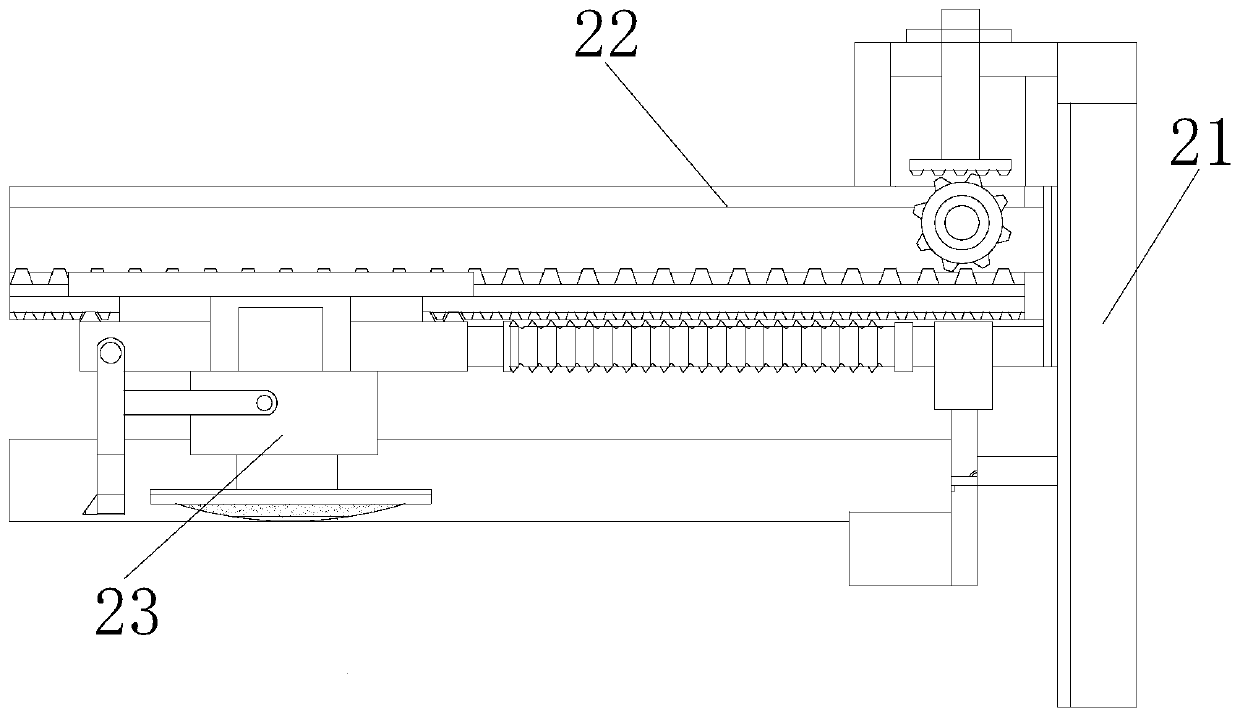

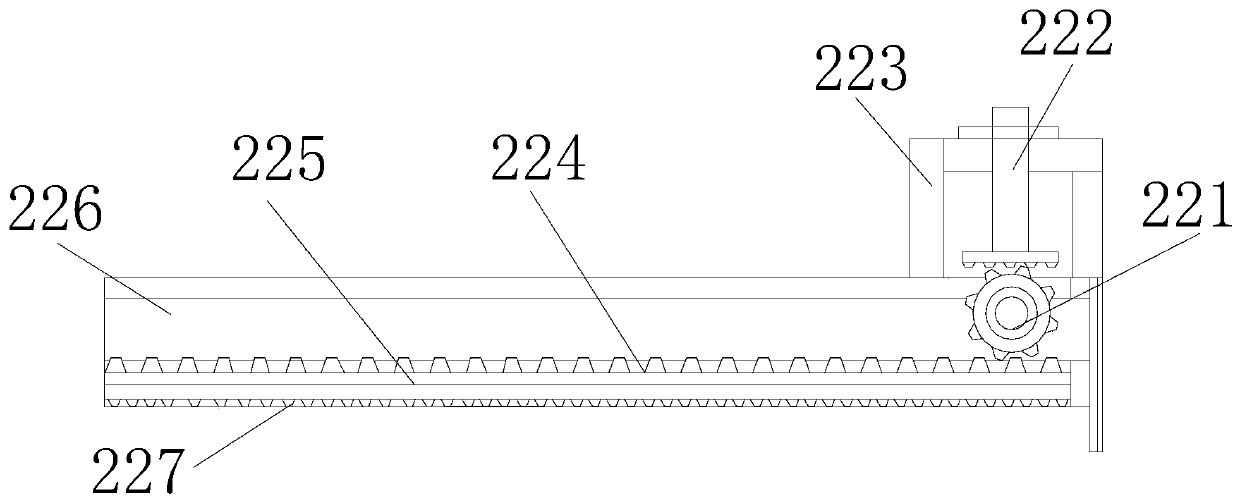

A device for polishing tree ring samples by scraping with a knife and a convex grinding wheel in stages

ActiveCN109366331BImprove polishing effectThreat to job securityPolishing machinesGrinding drivesGear driveGear wheel

The invention discloses a tree ring sample polishing device which uses a knife and a convex grinding wheel to scrape and grind in stages. Its structure includes: a bidirectional motor, an intelligent grinding device, a fixed seat, a base, and a motor unit. The motor unit is located on the upper end surface of the base. At the same time, it is movably connected with the base, so that the rotation of the gear drives the gear rack below, so that the slider on the tooth groove is forced to mesh with a stable displacement on the slider rack, instead of manual pressure displacement running-in, which can reduce the slipping displacement of the equipment At the same time, through the flatness of the scraping frame at the front end and the arc-shaped structure of the grinding wheel frame, the raised structure can be scraped off in advance during displacement, and the polished wood can be layered in an arc-shaped structure, so that it can be better The work of polishing the wood is faster, and finally, the negative pressure generated by the displacement and compression of the air bag inside the telescopic frame is pulled to attract the wood chips generated by the polishing, so as not to affect the working environment.

Owner:苏州心愿美电子商务有限公司

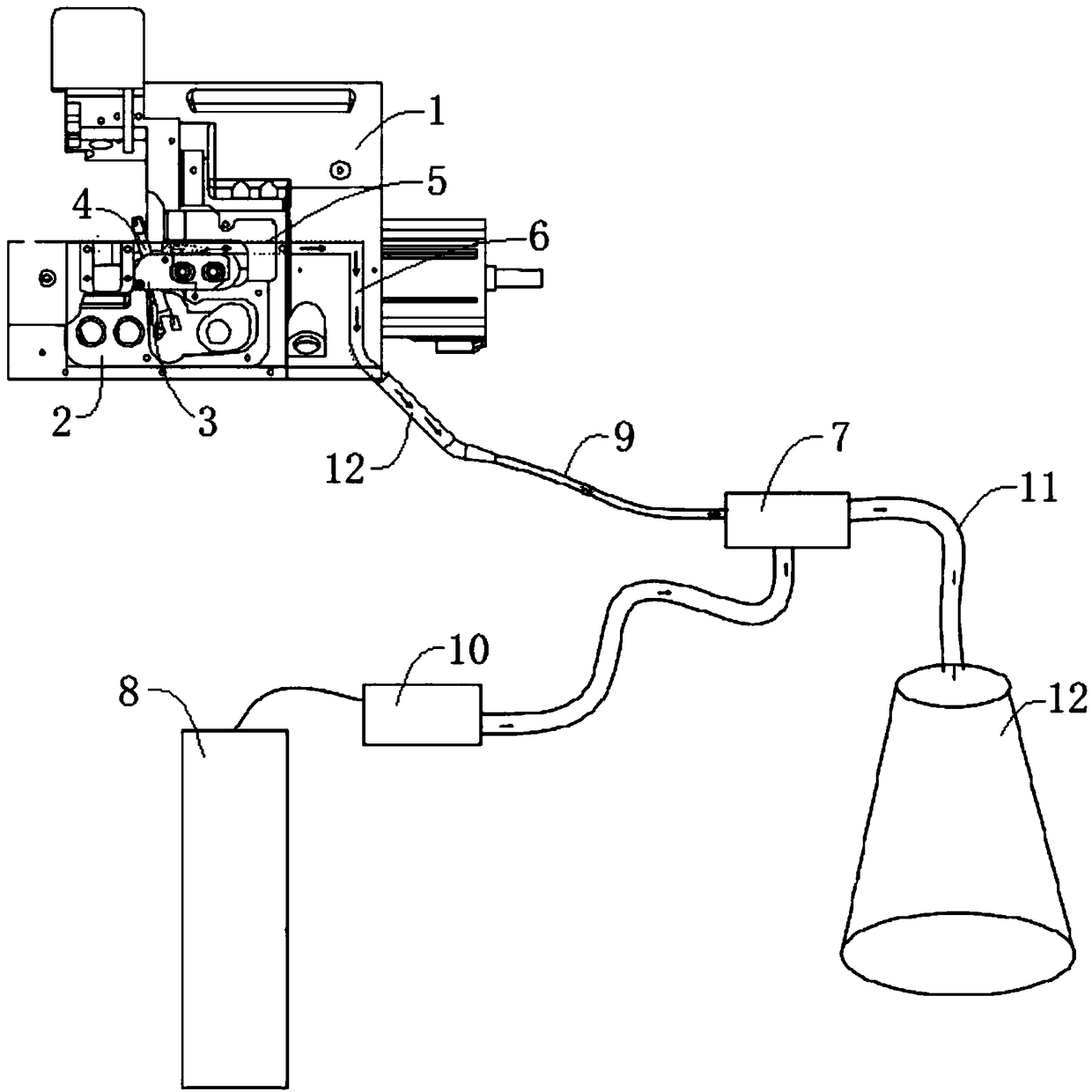

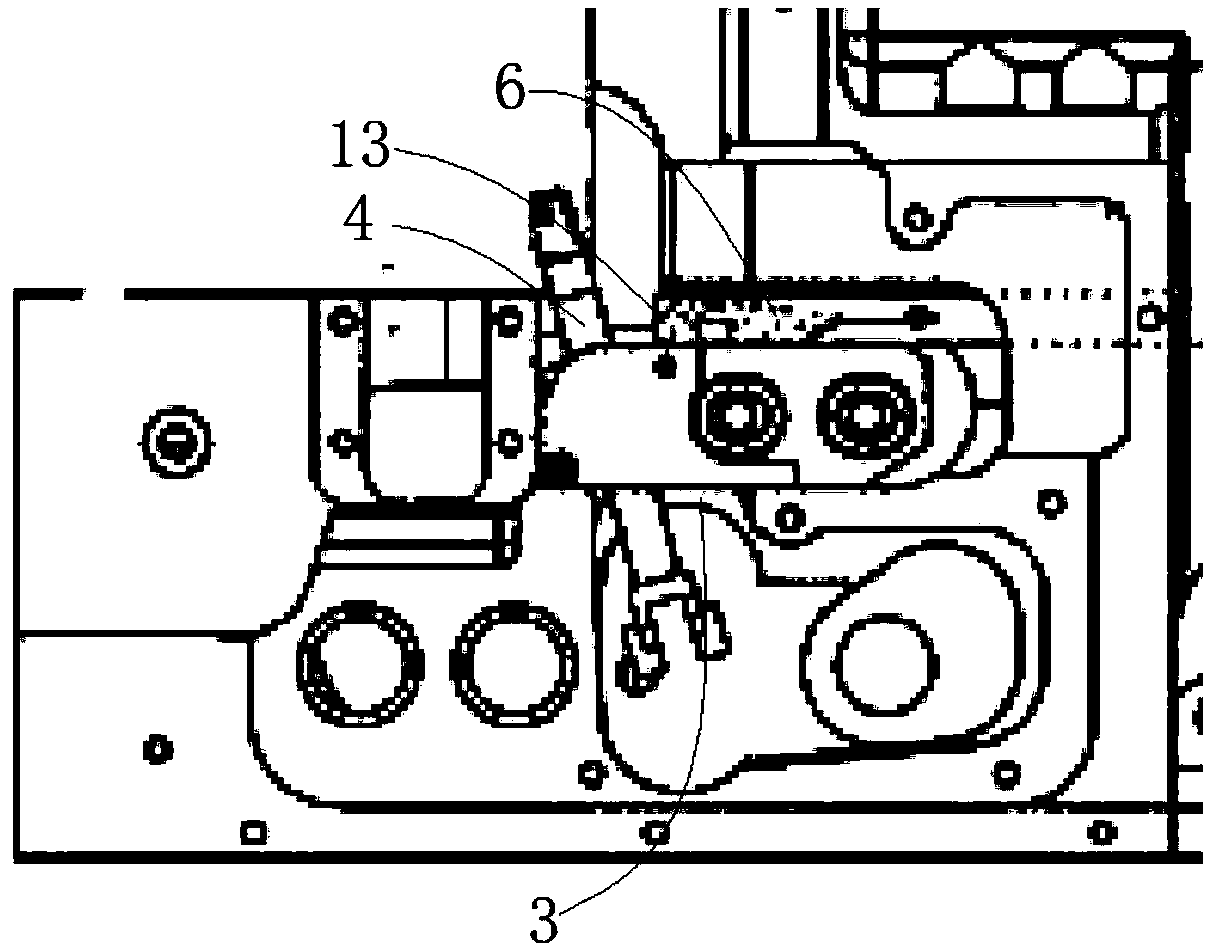

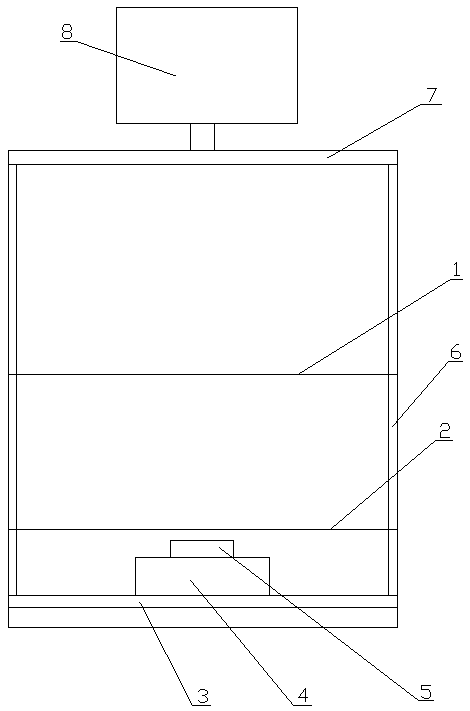

Cleaning device of dust inside sewing machine

PendingCN108866852ADoes not affect appearanceDoes not affect the working environmentSewing-machine casingsSolenoid valveWorking environment

The invention discloses a cleaning device of dust inside a sewing machine. The sewing machine comprises a sewing machine body and a protective shield plate, a concave cavity is formed close to a suture inside the sewing machine body, the concave cavity is internally provided with a rocking bar part, the protective shield plate is covered on the concave cavity, the cleaning device comprises an airdraft hole, an air draft pipe, a vacuum generator and an electric cabinet, the air draft hole is arranged from outside to inside in the right side wall direction of the sewing machine body and horizontally stretches into the concave cavity, one end of the air draft pipe passes through the air draft hole and then stretches to the rocking rod part, the other end of the air draft pipe is connected with the vacuum generator through a flexible pipe, the vacuum generator is connected with the electric cabinet through a solenoid valve, wherein a gap is arranged between an end part of one end of the air draft pipe and the rocking rod part. The cleaning device is simple and convenient to use and good in dust cleaning effect, and does not influence the appearance and work environment of the sewing machine.

Owner:上海富山精密机械科技有限公司

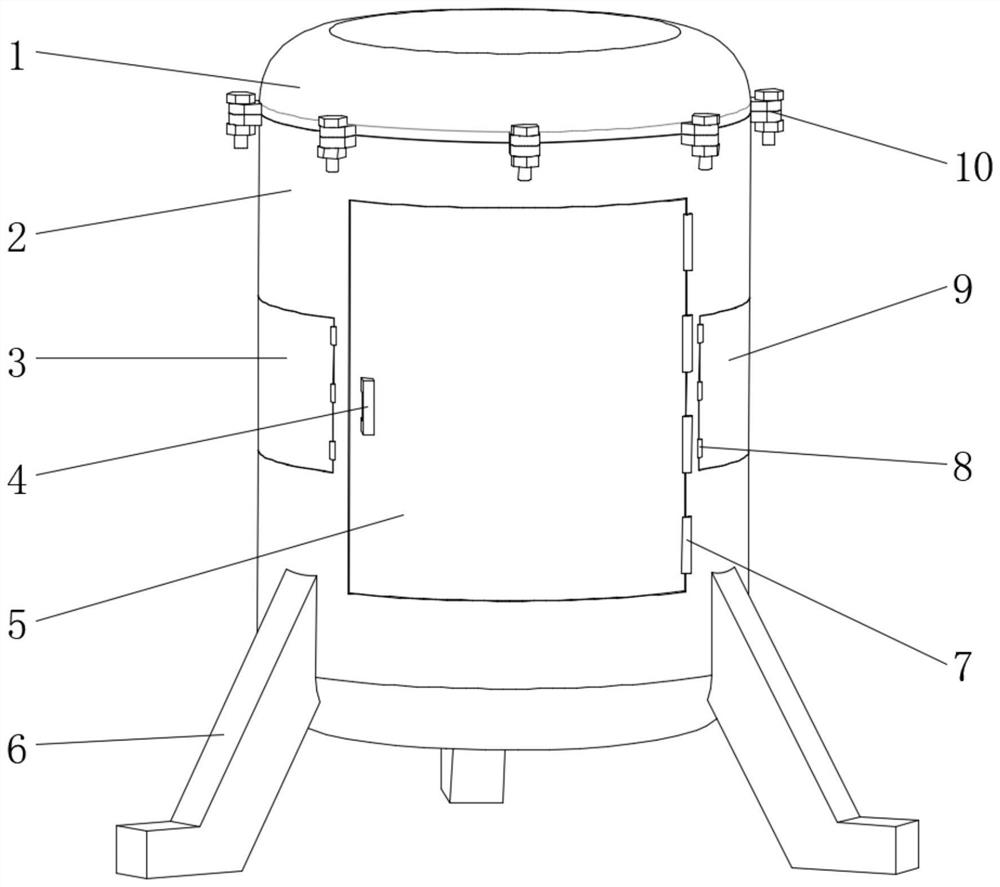

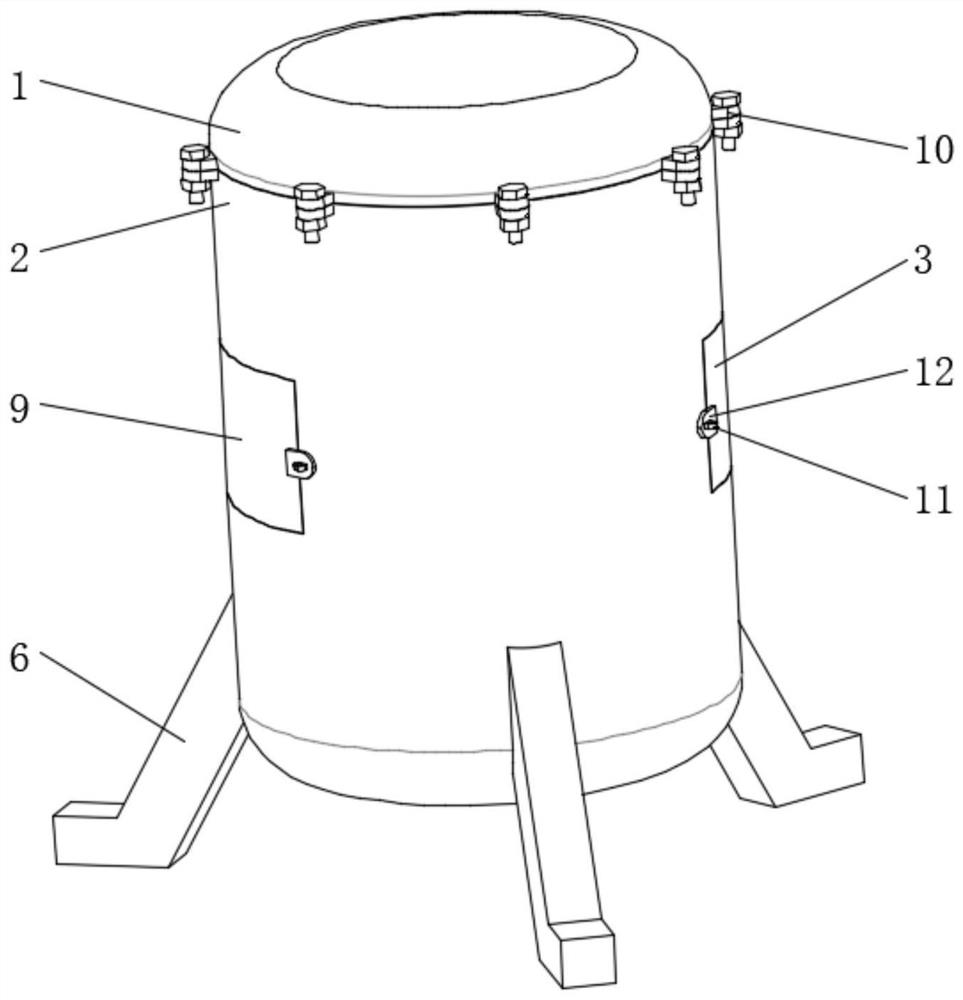

Rapid drying device for new materials

InactiveCN112344694ADry evenlyDoes not affect the working environmentDrying gas arrangementsDrying chambers/containersElectric machineryAir blower

The invention discloses a rapid drying device for a new material, and relates to the technical field of new materials. The rapid drying device comprises an outer shell and an inner shell, wherein an air blowing mechanism is arranged on the inner bottom wall of the inner shell, and a wind sensing sheet is arranged on the outer side surface of a baffle ring. According to the device, by arranging thewind sensing sheet, when fan blades and a fan motor are used for blowing air into the inner shell, due to the fact that air flow in the inner shell can influence the wind sensing sheet, the wind sensing sheet can drive the baffle ring to rotate, the new material at the top of an iron gauze can rotate on a plane while being dried, the purpose of uniformly drying the new material is achieved, by arranging the outer shell and the inner shell, when the new material is subjected to drying, hot air can be circulated through the space between the outer shell and the inner shell, the purpose of continuous high-temperature drying is achieved, the drying efficiency is improved, and when the new material is subjected to drying, no hot air is exhausted, and the purpose of not influencing the workingenvironment of workers is achieved.

Owner:赵伟

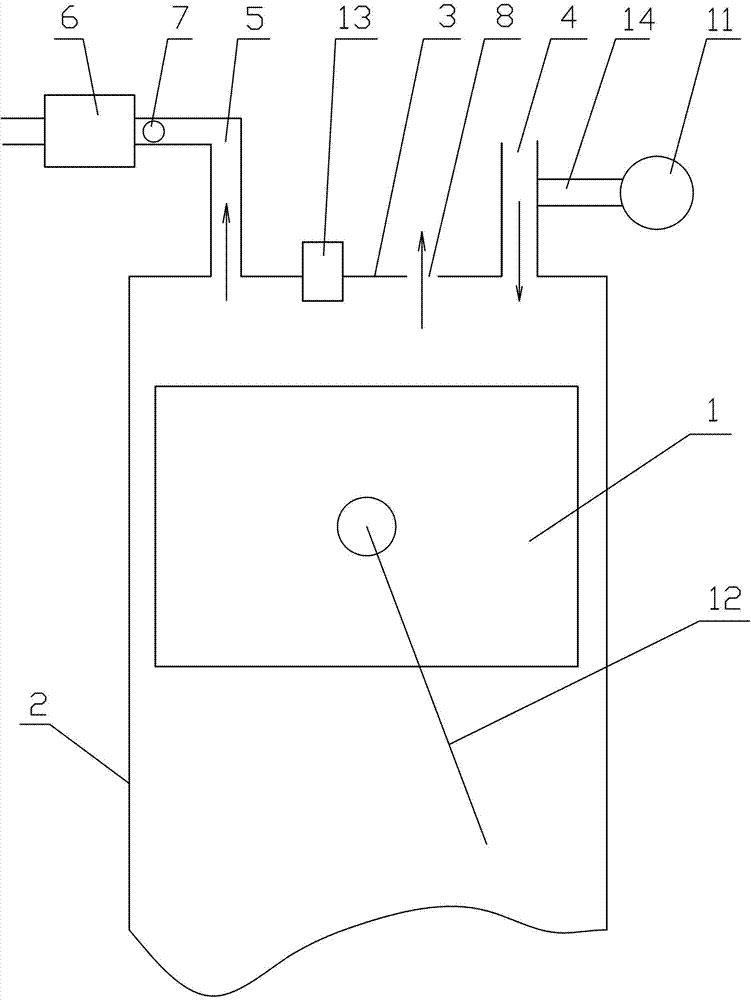

Belt-type manure cleaning device with disinfecting mechanisms and application thereof

InactiveCN106665405APrevent deviationClean up in timeConveyorsRollersWorking environmentElectric control

The invention discloses a belt-type manure cleaning device with disinfecting mechanisms and application thereof. The belt-type manure cleaning device comprises a control cabinet, a chicken raising bin, a cleaning bin and a rear cabinet, the control cabinet is arranged in front of the chicken raising bin, multiple chicken cages are longitudinally arranged in the chicken raising bin, the cleaning bin is arranged in rear of the chicken raising bin, the disinfecting mechanisms are sequentially arranged in the cleaning bin, a first belt wheel set and a second belt wheel set are horizontally arranged below the disinfecting mechanisms sequentially, conveying belts are arranged at the bottom of the cleaning bin and electrically connected with an electric control box, a chicken manure containing tank is arranged above each conveying belt, and waste discharging ports matched with the conveying belts and the chicken manure containing tank are arranged at the bottom end of the side face of the cleaning bin. The first belt wheel set and the second belt wheel set are arranged to prevent transferring belts from off tracking, the transferring belts of multiple layers are used to realize timely cleaning of chicken manure of multiple layers, the cleaning bin is arranged in rear of the chicken raising bin to timely clean the manure and the transferring belts, and the disinfecting mechanisms arranged in the cleaning bin clean the manure without having influence on growing environment of chickens and working environment of workers, so that the belt-type manure cleaning device has wide practicability in the field of breeding.

Owner:伊犁职业技术学院

A partial discharge sensor combining a graphene membrane and a micro-fiber interference cavity and a detection method based on it

ActiveCN109799435BHigh detection sensitivityStructural parameter optimizationTesting dielectric strengthPhotodetectorFemto second laser

A partial discharge sensor combined with a graphene diaphragm and a micro-fiber interference cavity and a detection method based on it, the sensor includes: a tunable laser (1), a laser wavelength control module (2), an optical fiber circulator (3), a single Mode optical fiber (4), micro-fiber interference cavity (5), photoelectric detector (6), signal line (7), filter (8), data acquisition card (9). The present invention adopts the multi-layer graphene diaphragm, improves the detection sensitivity of the sensor; Based on the optimal design of the structure of the multi-layer graphene diaphragm, it adapts to the requirements of the partial discharge detection frequency band; adopts polyimide coating to improve multi-layer The service life of the one-layer graphene diaphragm; the femtosecond laser is used to process the micro-fiber interference cavity inside the fiber, and based on the laser wavelength control, the static working point is stabilized. Based on the optimized design of the installation method of the detection device, the original working environment of the electrical equipment is not affected while the device is installed.

Owner:CHONGQING UNIV

Lubricant for drawing radial tyre steel cord thread and its preparing method

InactiveCN1215155CReduce consumptionImprove adhesionBase-materialsChlorinated paraffinsFatty alcohol

The lubricant consists of polyethylene wax, paraffin chloride, triethanolamine, sodium benzoate, fatty alcohol-polyoxyethyleneether, benzotriazole, sodium soap and water in certain proportion. The preparation process includes the following steps: mixing homogeneously paraffin chloride and triethanolamine while heating to 140-150 deg.c; mixing homogeneously polyethylene wax, sodium benzoate, fatty alcohol-polyoxyethyleneether, benzotriazole, sodium soap and water while heating to 80-90 deg.c; mixing the two kinds of mixture in the foregoing steps, emulsifying, cooling and filtering to obtain ivory white liquid as the product. The lubricant ensures complete coating on the steel cord thread, increases the adhesion between the steel card thread and rubber, and has no corrosion to pipeline and apparatus and low cost.

Owner:王俊

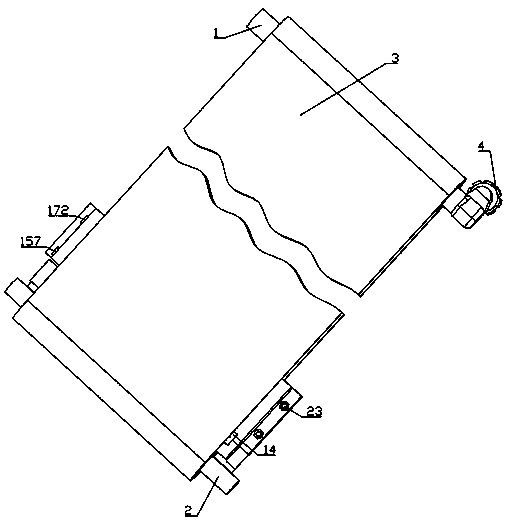

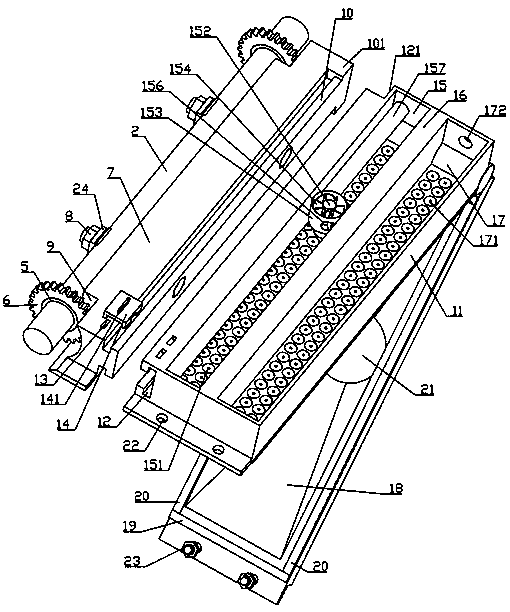

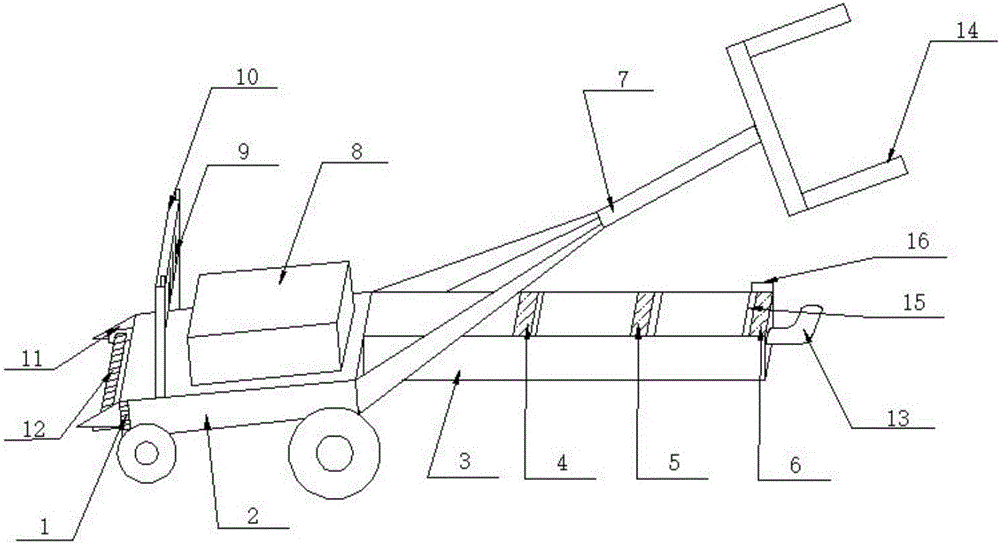

Tea leaf enzyme deactivation and segmented conveying device

InactiveCN108782815ASimple processEfficient use ofConveyorsPre-extraction tea treatmentCircular discEngineering

The invention relates to the technical field of tea leaf enzyme-deactivation and segmented conveying, in particular to a tea leaf enzyme-deactivation and segmented conveying device. The device comprises a main U-shaped box body, wherein the bottom face of the main U-shaped box body is fixedly provided with a plurality of support columns by threads, the side face of the inner wall of the main U-shaped box body is in threaded connection to one side of a main control box, the open end of the main U-shaped box body is in threaded connection with the outer wall of a main temperature-insulation barrel body, a motor I is downward vertically and fixedly connected with the main temperature-insulation barrel body and on the outer wall of the open side of the main U-shaped box body by screws, the outer wall of the output end of the motor I is sleeved by the central inner wall of a transmission round disk I, the transmission round disk I is connected to the inner wall of a rotating groove I, the rotating groove I is formed in the outer wall of one end of a main enzyme-deactivation barrel body, a rotating groove II is formed in the outer wall of the end, away from the rotating groove I, of themain enzyme-deactivation barrel body, and the inner wall of the rotating groove 2 sleeves the outer wall of a transmission disk II. The device reduces the employment cost of enterprise by high-efficiency and fast tea leaf enzyme deactivation and improves the quality uniformity of tea leaves.

Owner:ANHUI SHENGXIANG ECOLOGICAL AGRI DEV

Surface paint coating device for hot water pipe

InactiveCN108607766AEfficient and fast paintingIncrease productivityLiquid surface applicatorsCoatingsWater pipeMotor drive

The invention aims to provide a surface paint coating device for a hot water pipe. A paint coating box is included, and a paint groove is formed in the inner bottom of the paint coating box; a liftingplate is arranged in the paint groove, and a paint injecting motor is arranged on the top of the lifting plate; a paint coating brush is arranged on the top of the paint injecting motor; the tops ofthe left side and the right side of the lifting plate are connected with lifting rods; the tops of the two lifting rods are jointly connected with a connection plate, and the top of the connection plate is connected with a lifting motor; a rotating motor is arranged on the front side of the paint coating box, and the rear side of the rotating motor is connected with a clamping block; and the clamping block is located on the front side in the paint coating box and is used for clamping the hot water pipe. Firstly, the clamping block clamps the hot water pipe in the paint coating box, and then the lifting motor rises and drives the paint injecting motor to rise; the paint injecting motor drives the paint coating brush to rise and make contact with the hot water pipe, and then the rotating motor is started and rotates; the paint coating brush performs paint coating on the surface of the hot water pipe, in this way, paint coating can be efficiently and fast performed, the work environment is not affected, the production efficiency is greatly improved, and the surface paint coating device for the hot water pipe is suitable for production.

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

Special cleaning agent for ladle furnace lining and its application method

The invention discloses a special cleaner for a molten iron ladle furnace liner and a using method thereof. The cleaner comprises the following raw materials in percentage by weight: 35-40% of pre-melting materials, 23-27% of fluxing agents, 9-11% of calcite powder and 6-8% of soda-lime glass. The special cleaner for the molten iron ladle furnace liner can be used for removing slag of molten iron ladles; meanwhile, the special cleaner is high in melt performance, stable in slag removal effect, low-cost and easily available in preparation raw materials, free of other peculiar smells after put into a working furnace, environmentally-friendly in way and free of influence on the operation environment; the quality of the molten iron is improved; the high-quality raw materials are directly provided for subsequent processes; the subsequent melting processes are eliminated; the processing cost is reduced; the corresponding fees are reduced; the green production standard can be met.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

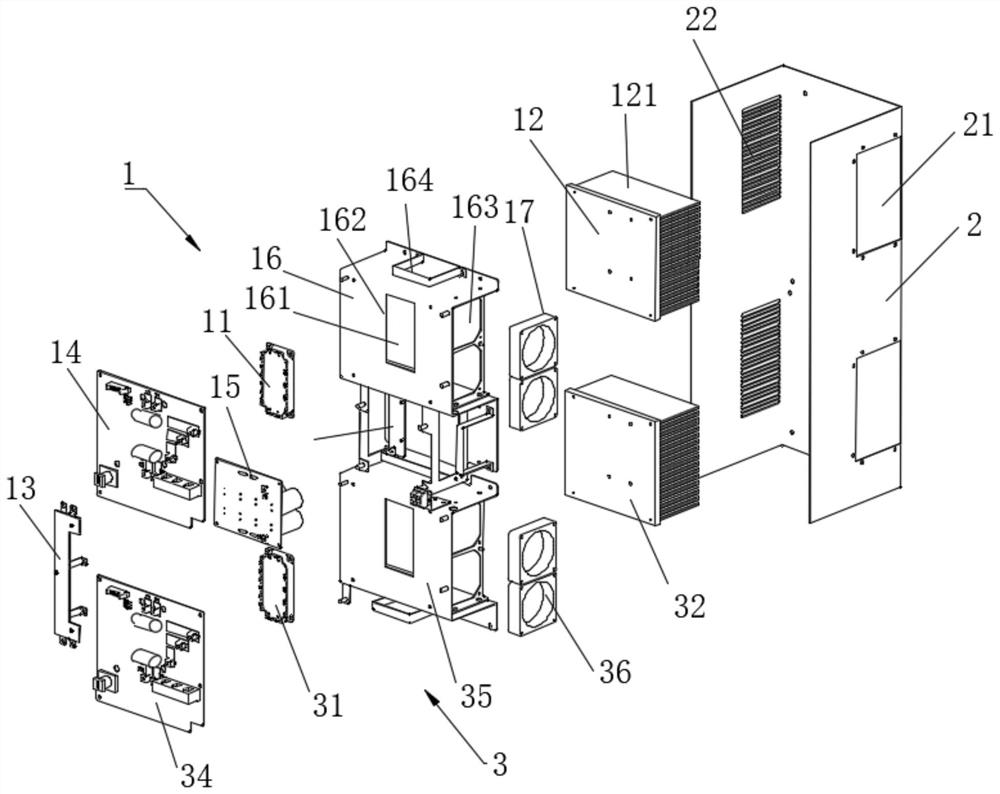

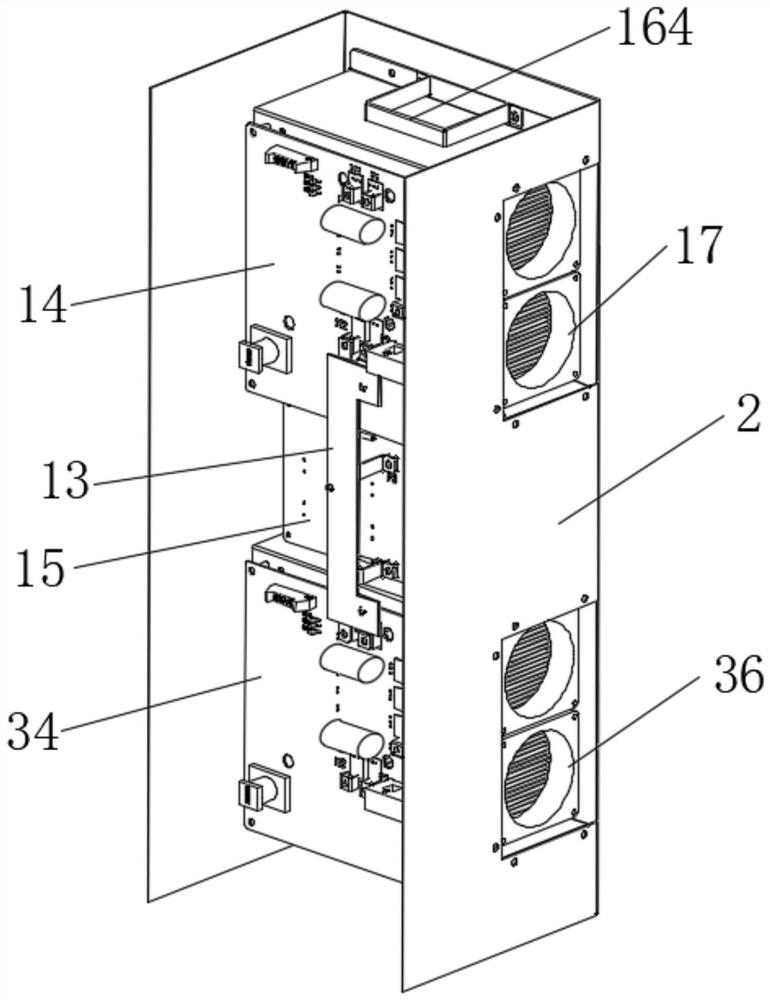

Heat dissipation structure of frequency converter group or multiple frequency converter group

PendingCN112584681AAchieve horizontal coolingMiniaturizationCircuit arrangements on support structuresCasings/cabinets/drawers detailsFrequency changerCapacitance

The invention discloses a heat dissipation structure of a frequency converter group or multiple frequency converter groups. The heat dissipation structure comprises the frequency converter groups anda control cabinet body. The frequency converter group comprises a heating element power module, a radiator, a copper bar, a driving electronic board, a bus capacitor board, a fixed sheet metal part and a cooling fan. The fixed sheet metal part is installed in the control cabinet body. The fixed sheet metal part is provided with a placing part for accommodating a radiator; a rectangular through hole is formed in the bottom of the placing part; one surface of the heating element power module penetrates through the rectangular through hole and is in surface contact with the end surface of the radiator, and the other surface of the heating element power module is electrically connected with the driving electronic board; a heat dissipation part is arranged on the side surface of the fixed sheetmetal part; the heat dissipation fan is mounted on the heat dissipation part; the control cabinet body is provided with a heat dissipation port corresponding to the heat dissipation part. Through theintegrated design of the heat dissipation air duct and the control cabinet body, the frequency converter group realizes heat dissipation in the horizontal direction; and when multiple frequency converter groups are arranged, the heat dissipation among the frequency converter groups is not influenced.

Owner:HITACHI ELEVATOR CHINA

A kind of anti-oxidation tin plating solution based on yttrium bismuth phosphorus

The invention belongs to the technical field of metal anti-oxidation protection and particularly discloses an anti-oxidation tinning solution based on yttrium, bismuth and phosphorus. The anti-oxidation tinning solution comprises the following components of yttrium, bismuth, phosphorus and tin and includes, by weight percent, 0.005%-0.02% of yttrium, 0.004%-0.05% of bismuth and 0.01%-0.05% of phosphorus with the weight of tin as the benchmark. Yttrium, bismuth and phosphorus are added into the tin solution, oxidization of the tinning solution can be effectively inhibited, the wettability of the tinning solution is improved, generation of tin slag is reduced, the tin product yield is increased, productivity of the hot tinning product is improved, and other physical and mechanical properties of the tinning product are not affected. The anti-oxidation tinning solution is low in cost, an existing production technology is not changed, daily caring and maintaining of existing equipment are not affected, the environment-friendly requirement is met, and the working environment of a production place is not affected.

Owner:XIAN TELISON NEW MATERIAL

An anti-oxidation tin plating solution based on indium gallium phosphide

ActiveCN106119755BPrevent oxidationReduce generationHot-dipping/immersion processesTinningProduction rate

The invention belongs to the technical field of metal antioxidation protection and particularly discloses an antioxidant tin plating solution containing the following components: indium, gallium, phosphorus and tin, wherein the weight percentages of indium, gallium and phosphorus are respectively 0.005-0.04%, 0.005-0.06% and 0.01-0.05% based on the weight of tin. Indium, gallium and phosphorus are added into the tin plating solution, so that the oxidation of the tin plating solution can be effectively inhibited, the generated tin residues can be reduced, and the effects of increasing the yield of tin products and the production rate of hot tinning products and the like are remarkable; meanwhile, the wettability of the tin plating solution is slightly improved, the melting points of the tin plating products are slightly reduced, and other physical and mechanical properties of the tin plating products are not affected; and the antioxidant tin plating solution is low in cost and meets the environment-friendly requirement, the existing production process is not changed, and the daily maintenance of the existing equipment and the working environment of a production place are not affected.

Owner:XIAN TELISON NEW MATERIAL

A welding device with fume purification function

ActiveCN103386527BReduce occupancyReduce workloadMetal working apparatusSoldering auxillary devicesWorking environmentEngineering

Owner:深圳市谷多普科技有限公司

Glass dust collecting device for glass production

InactiveCN112845382ADoes not affect the working environmentEasy to useCleaning using gasesInternal fittingsWorking environmentEngineering

The invention relates to the field of glass production, in particular to a glass dust collecting device for glass production. The glass dust collecting device comprises a base, a dust suction device and an alarm device, wherein a supporting plate is fixedly connected to the left side of the top end surface of the base, a controller is fixedly connected to the bottom of the right end surface of the base, an air box is fixedly connected with the supporting plate, a dust collecting cover is fixedly connected to the left end surface of the air box, a supporting rod is fixedly connected to the right end of the inner side of the air box, and a fan is fixedly connected to the right end surface of the supporting rod. According to the glass dust collecting device, the air box, the dust collecting cover, the fan and a filter screen are arranged, when the glass dust collecting device is used, the fan is controlled to rotate through the controller, the fan rotates to pull dust generated in the glass production process, the dust enters the air box through the dust collecting cover, is accumulated at the filter screen and falls into a collecting box, so that the dust generated in the glass production process can be pulled and collected during use, the dust cannot float in a workshop, the working environment is not influenced, and the health of a worker cannot be harmed.

Owner:衡阳市衡锋玻璃有限公司

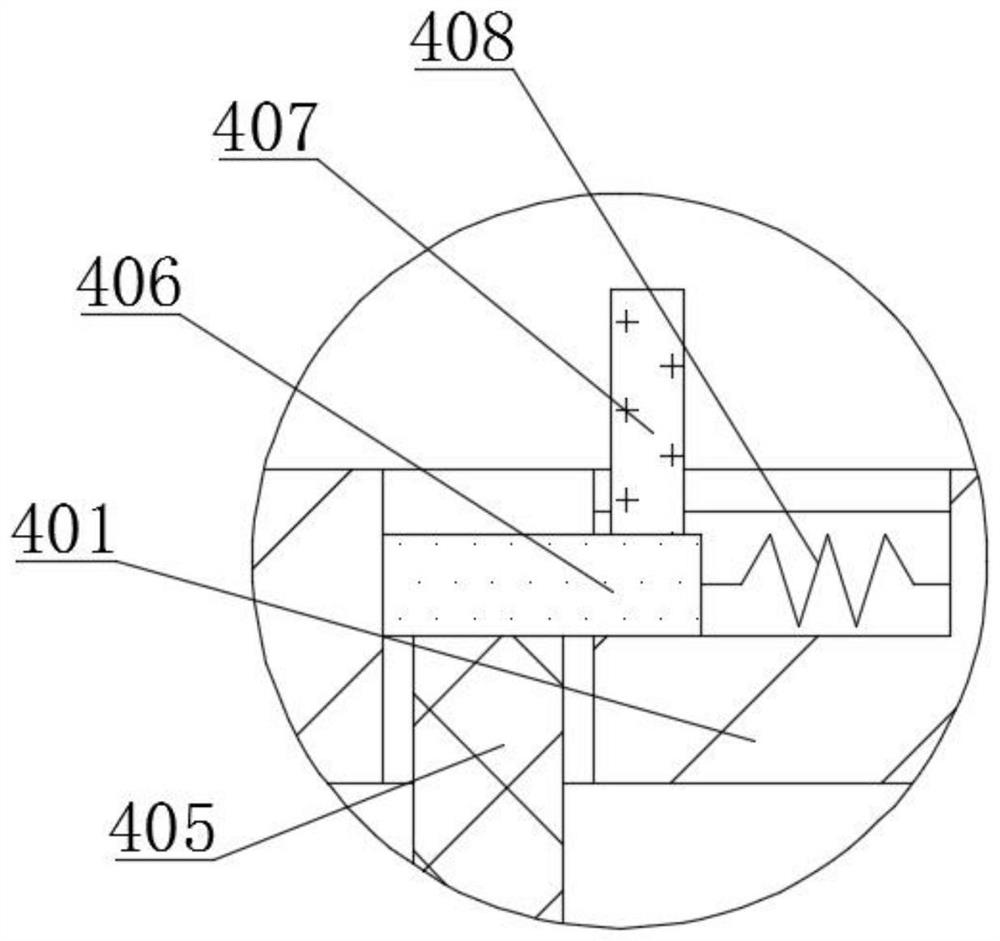

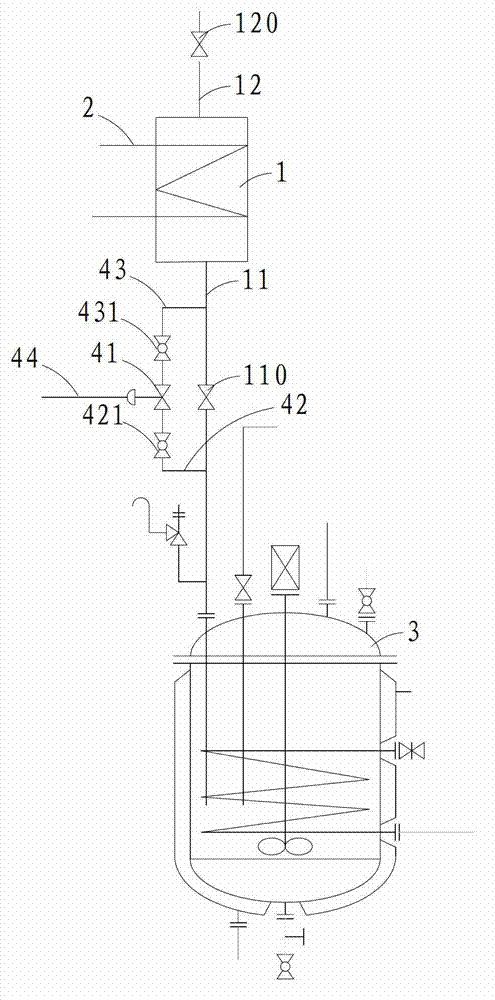

Condensed reflux device of epoxy reactor

InactiveCN103111249AAvoid dangerReduce the risk factorSteam/vapor condensersChemical/physical/physico-chemical stationary reactorsEpoxyReflux

The invention discloses a condensed reflux device of an epoxy reactor. The device comprises a barrel-shaped reflux container, wherein a condensation pipe is assembled on the reflux container, one end of the reflux container is connected with a reflux pipe which extends into the reactor from the top of the epoxy reactor, and the other end of the reflux container is connected with a blow-down pipe. The device has the beneficial effects that volatile formic acid gas is condensed into liquid in the reflux container so as to reflow into the reactor again, so that formic acid in a reaction system cannot be reduced, the working environment cannot be influenced, and risks generated by the formic acid gas can also be avoided; moreover, the production efficiency and benefit are improved through using a condenser; and in addition, the working environment is purified, the danger coefficients of workshops are decreased, and environmental pollution is reduced.

Owner:ANHUI TIANYI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com