Conveying belt

A technology of conveyor belt and main conveyor belt, applied in the field of conveyor belt, can solve the problems of rolling down of sand and gravel, shaking of conveyor belt, etc., and achieve the effect of saving sand and gravel and reducing manpower for cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

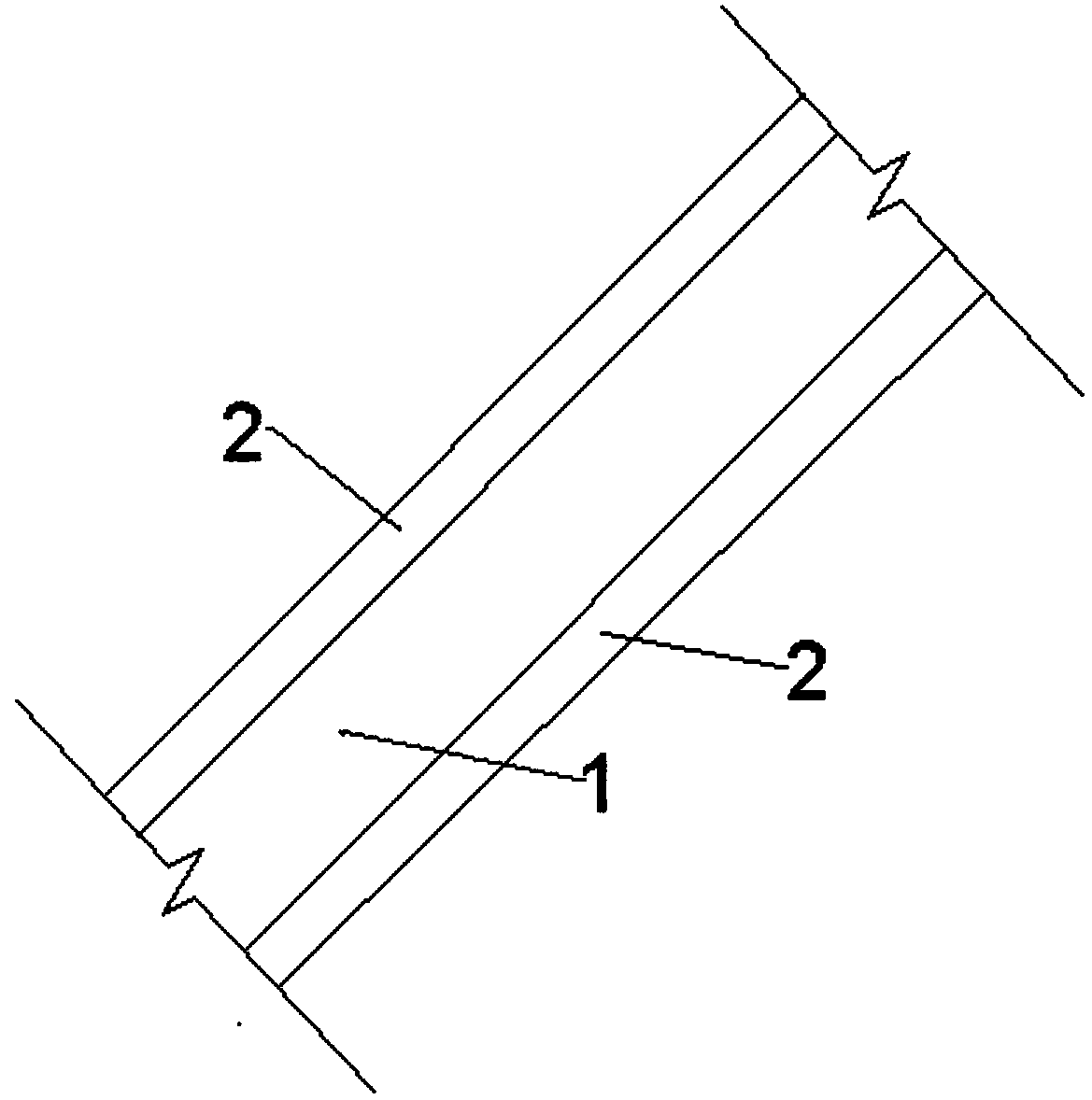

[0008] Below in conjunction with the accompanying drawings figure 1 The present invention is further explained.

[0009] Specific embodiment: When using this improved conveyor belt, since the auxiliary conveyor belt (2) lower than the height of the main conveyor belt is set on the two sides of the main conveyor belt (1), when the sand and gravel are transported on the conveyor belt, the main conveyor belt ( 1) The gravel material that accidentally rolls off from the upper part will fall on the auxiliary conveyor (2) and continue to be conveyed downwards without falling to the ground. It not only saves sand and gravel, but also reduces cleaning manpower, and does not affect the working environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com