Glass dust collecting device for glass production

A technology of dust collection and dust collection device, which is applied to cleaning methods and utensils, cleaning methods using gas flow, internal accessories, etc., can solve problems such as environmental pollution, inconvenient use, and inability to collect dust, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

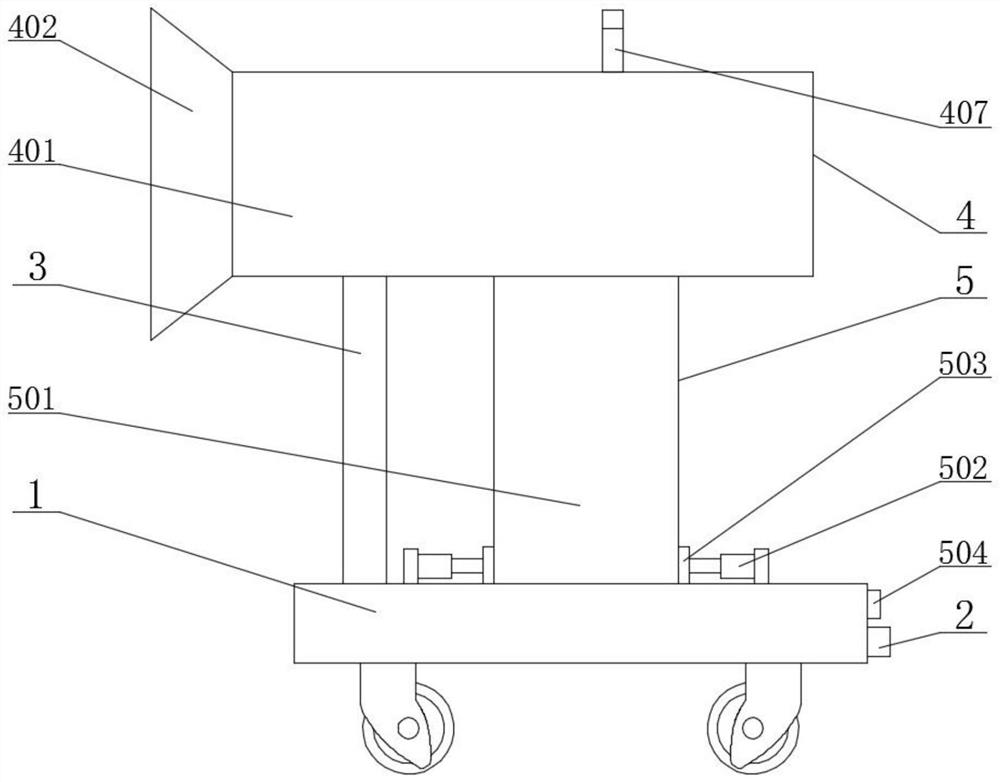

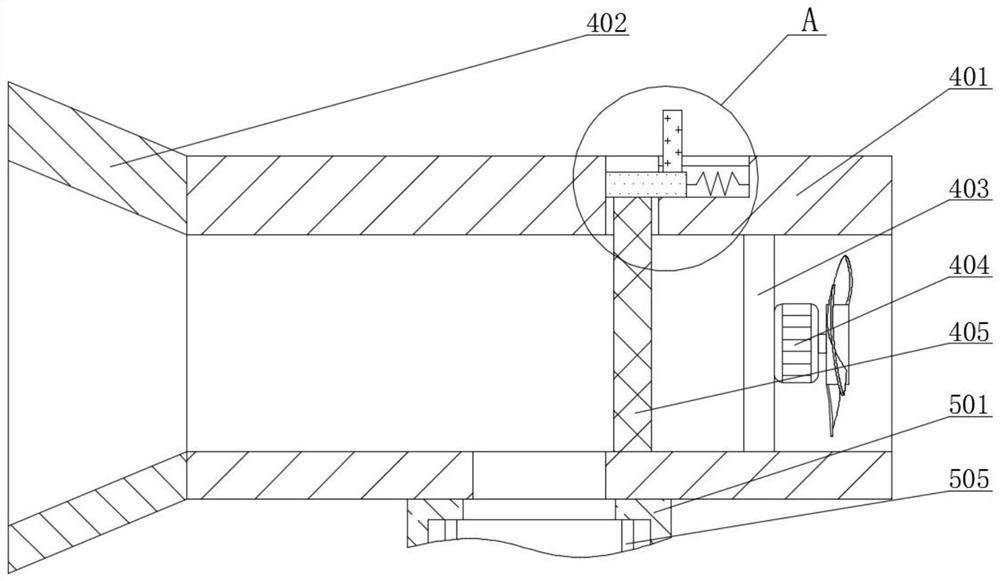

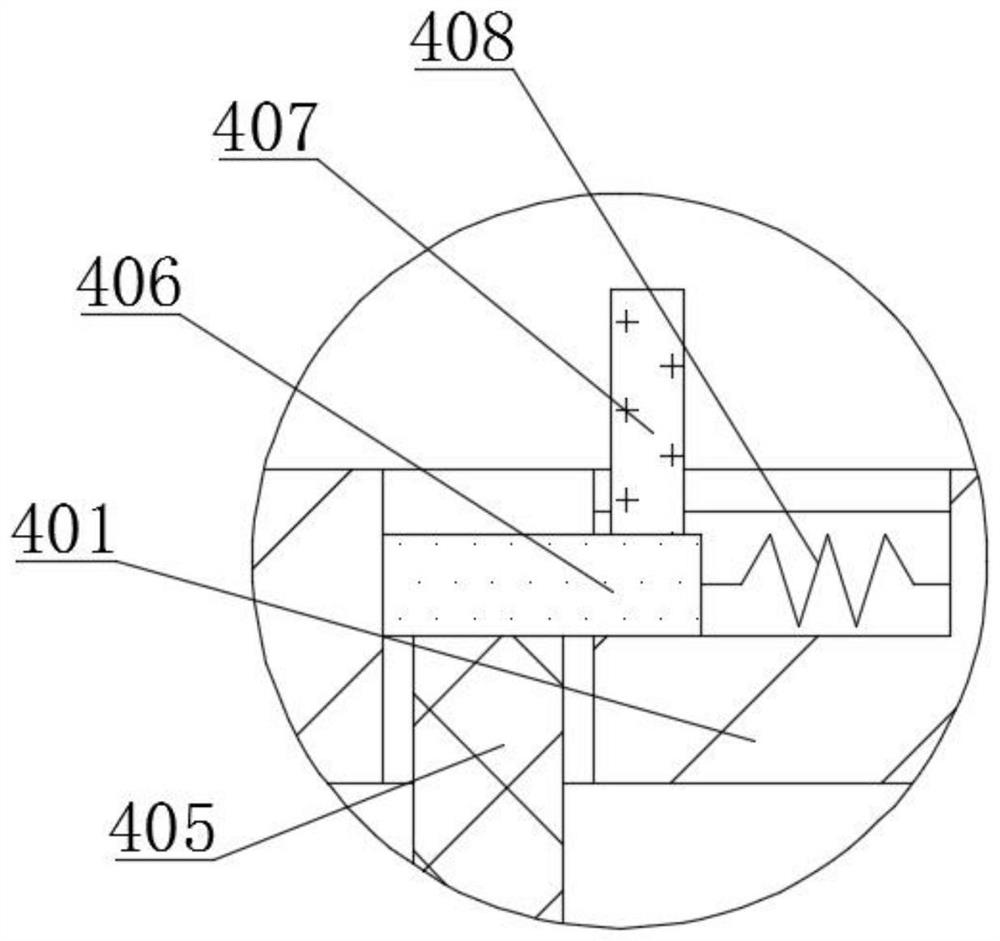

[0020] see Figure 1-5 , the present invention provides a technical solution:

[0021] A glass dust collection device for glass production, comprising a base 1, a dust suction device 4 and an alarm device 5, a support plate 3 is fixedly connected to the left side of the top surface of the base 1, a controller 2 is fixedly connected to the bottom of the right end surface of the base 1, and a dust suction device The device 4 includes a bellows 401, the bellows 401 is fixedly connected with the support plate 3, the left end of the bellows 401 is fixedly connected with a dust collecting cover 402, the inner right end of the bellows 401 is fixedly connected with a support rod 403, and the right end of the support rod 403 is fixedly connected with a fan 404, supporting The left side of the rod 403 is provided with a filter 405, the filter 405 is slidingly connected with the bellows 401, the filter 405 runs through the bellows 401, the top surface of the filter 405 is slidingly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com