Heat dissipation structure of frequency converter group or multiple frequency converter group

A technology of heat dissipation structure and frequency converter, which is applied to the circuit layout of the supporting structure, the modification of power electronics, and the conversion device of output power, etc., which can solve the problems of increased cost, increased width or thickness of the control cabinet, and elevator control cabinets. Large volume and other issues, to achieve the effect of miniaturization and thin design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

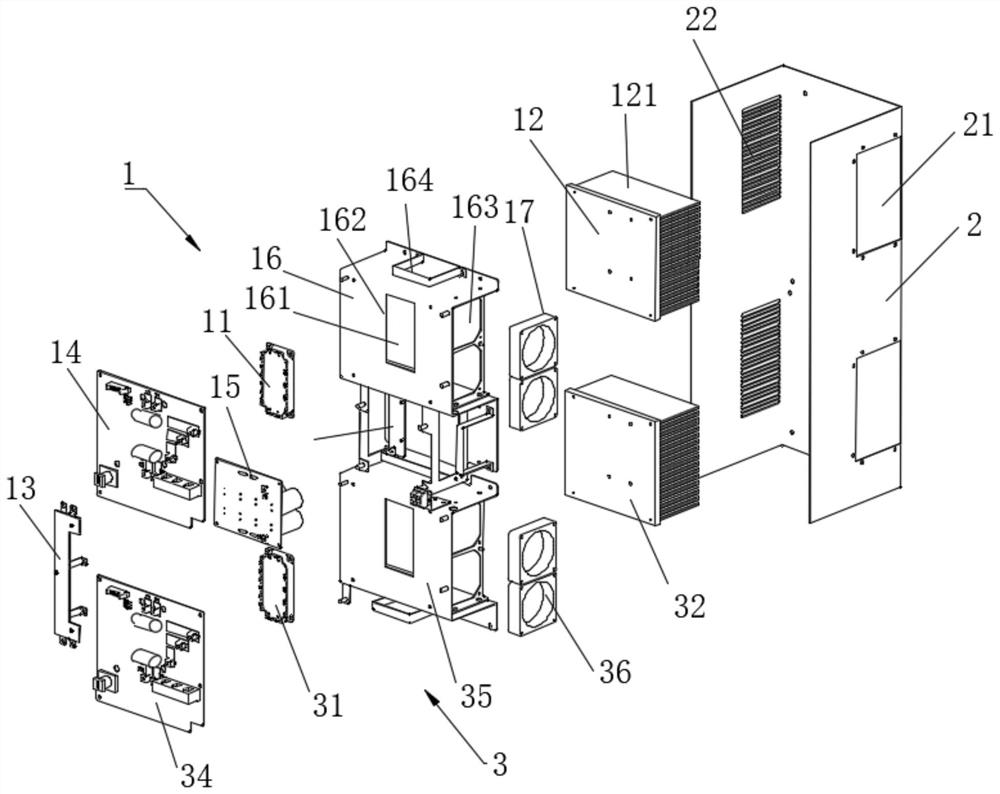

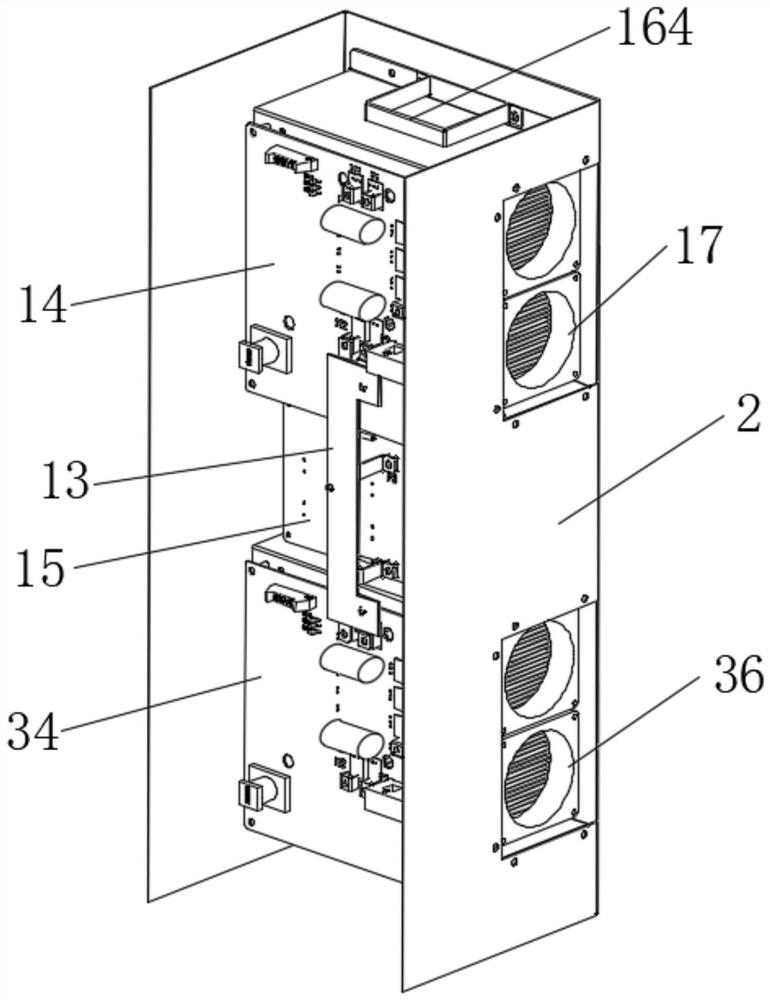

[0032] Embodiment 2, with reference to figure 2Specifically, in the solution of this embodiment, a heat dissipation structure for multiple frequency converter groups includes the control cabinet body 2 and multiple groups of frequency converter groups; each of the frequency converter groups moves from bottom to top or Vertically arranged and installed inside the control cabinet body 2 from top to bottom; the second group of frequency converters 3 also includes: heating element power modules 31, radiators 32, copper bars, drive electronic boards 34, fixed sheet metal Part 35 and heat dissipation fan 36; through the integrated design of the heat dissipation air duct and the control cabinet body 2, the heat dissipation between two or more frequency converter groups does not affect each other. It should be noted that the heat dissipation between two or more inverter groups does not affect each other, the volume of the control cabinet body 2 or the volume of the inverter group is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com