Combustion chamber air interchanger without disturbance to three-way catalyst and oxygen sensor

A three-way catalytic converter and oxygen sensor technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as oxygen sensor sending out wrong instructions, fuel injection volume and duration errors, and engines not working properly, etc. Achieve the effects of improving fuel efficiency, reducing cylinder temperature, and reducing the probability of deflagration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

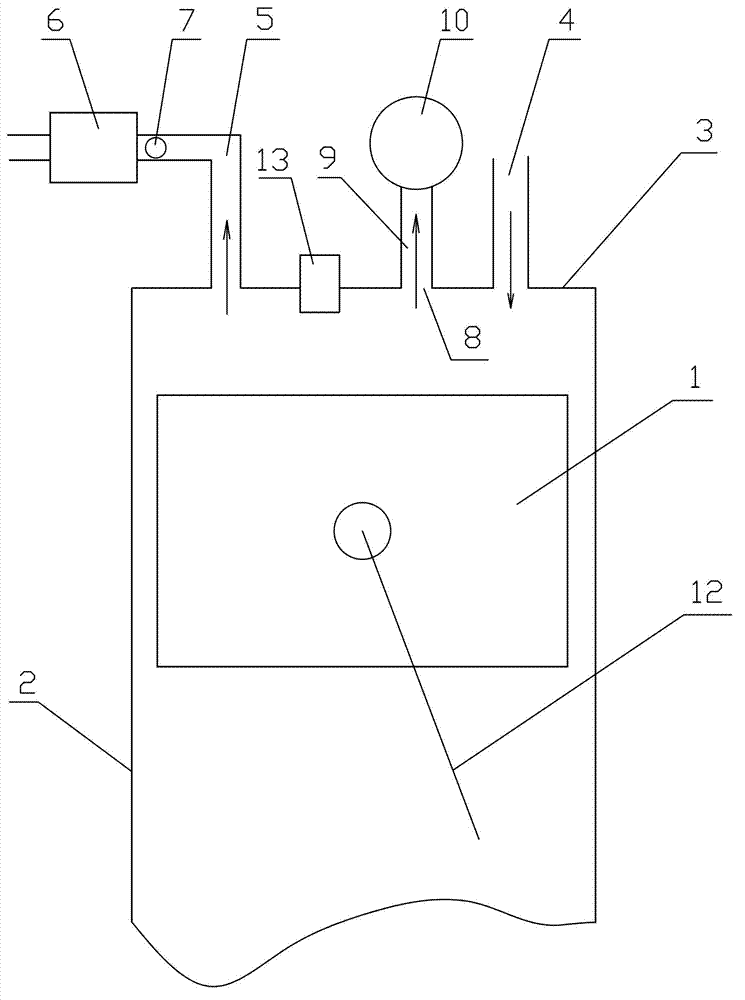

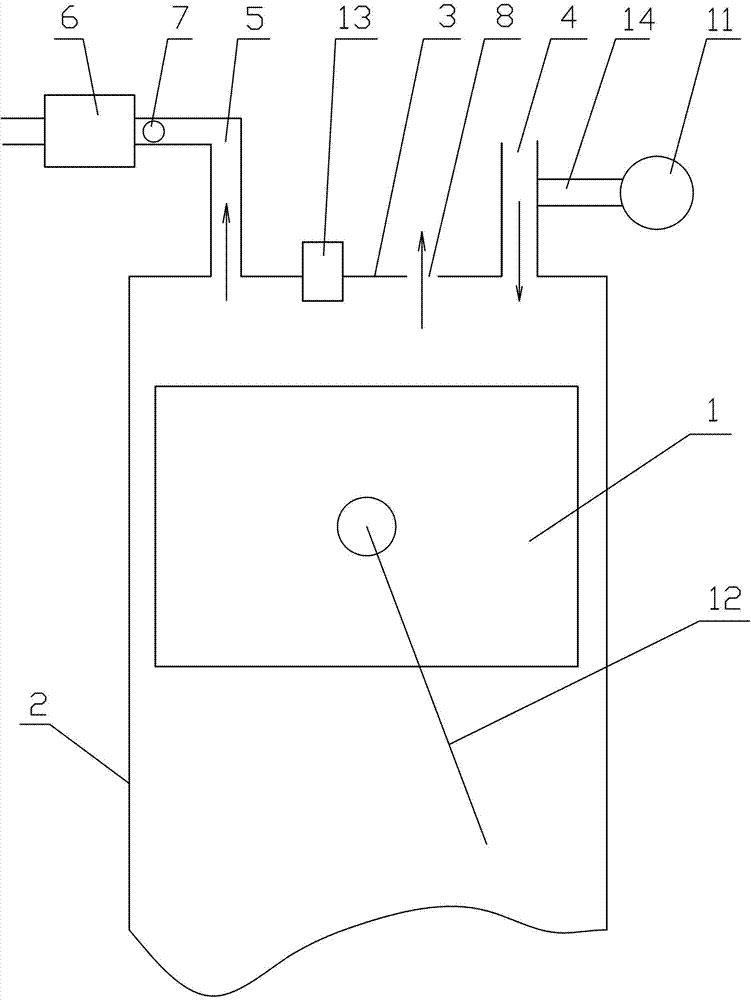

[0027] The combustion chamber ventilation device without interfering with the operation of the three-way catalytic converter and the oxygen sensor of the present invention relates to a gasoline internal combustion engine, and the engine is a one-cylinder engine or a multi-cylinder engine, such as figure 1 , figure 2 Shown is the single cylinder structure of the engine and its supporting components.

[0028] The upper opening of the cylinder block 2 of the single-cylinder engine is sealed by the cylinder head 3, and the fuel injector 13 of the fuel injection device is arranged in the center of the cylinder head 3, and the air inlet and the exhaust port of the cylinder block 2 are opened on the cylinder head 3; The lower port of the cylinder block 2 is connected to the crankcase, and the crankcase is provided with a crank connecting rod mechanism 12; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com