Device for reducing bearing temperature

A bearing temperature and bearing technology, which is applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., can solve problems such as lowering production stability, rising radial bearing temperature, and affecting the stable operation of air separation units, so as to reduce temperature and ensure The effect of stable operation and avoiding excessive bearing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

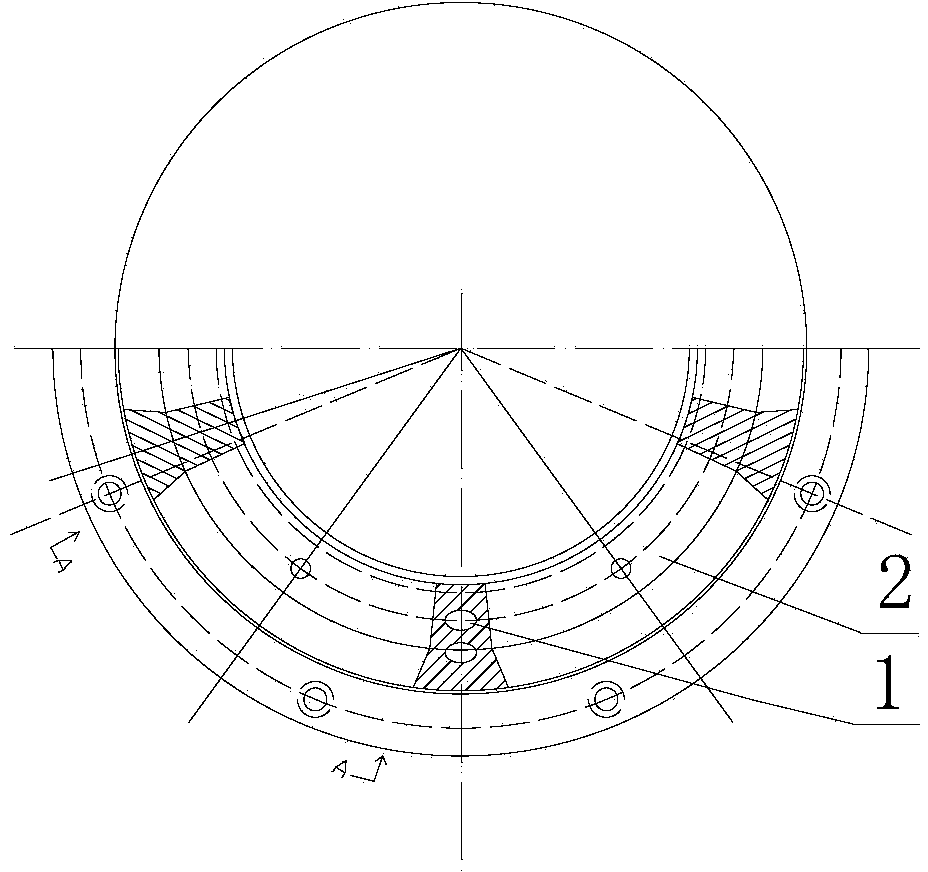

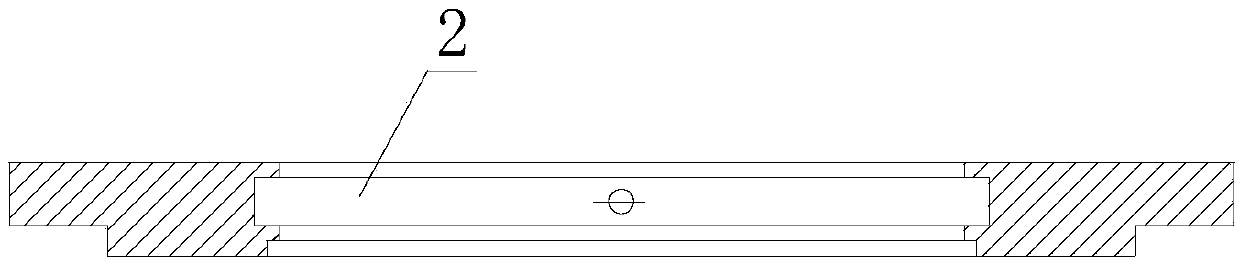

[0013] The device for reducing the bearing temperature of this embodiment has a structure such as figure 1 and figure 2 As shown, including the bearing body, there are two oil return holes 1 with a diameter of Ф6.5mm on the lower side of the body, and the oil return area is 47% of the oil inlet area. The lines are at a 45° angle. Wherein, the bearing is a fully immersed tilting pad bearing, and the oil return holes 1 are distributed on the pad fixing frame of the bearing, specifically, the oil return holes 1 are distributed in the gap between two pads 2 on the pad fixing frame.

[0014] When using, first refer to the actual object, measure the oil return hole, bearing inner diameter, shaft diameter and other related dimensional parameters one by one, use the measured dimensional parameters to calculate the oil inlet cross-sectional area and oil return cross-sectional area of the bearing, and judge by comparison Whether the high bearing temperature is caused by insufficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com