Patents

Literature

71results about How to "Easy to grind and polish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

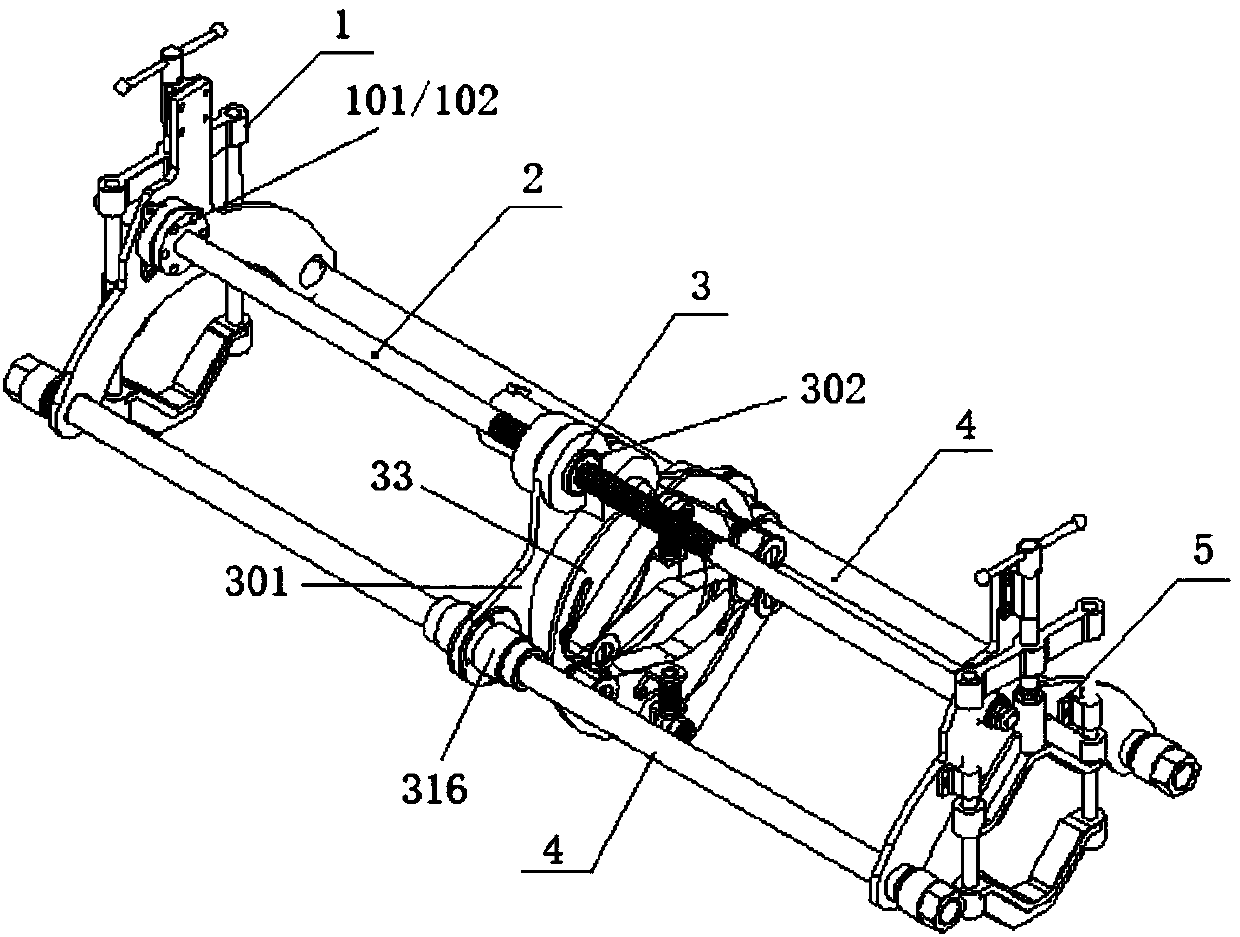

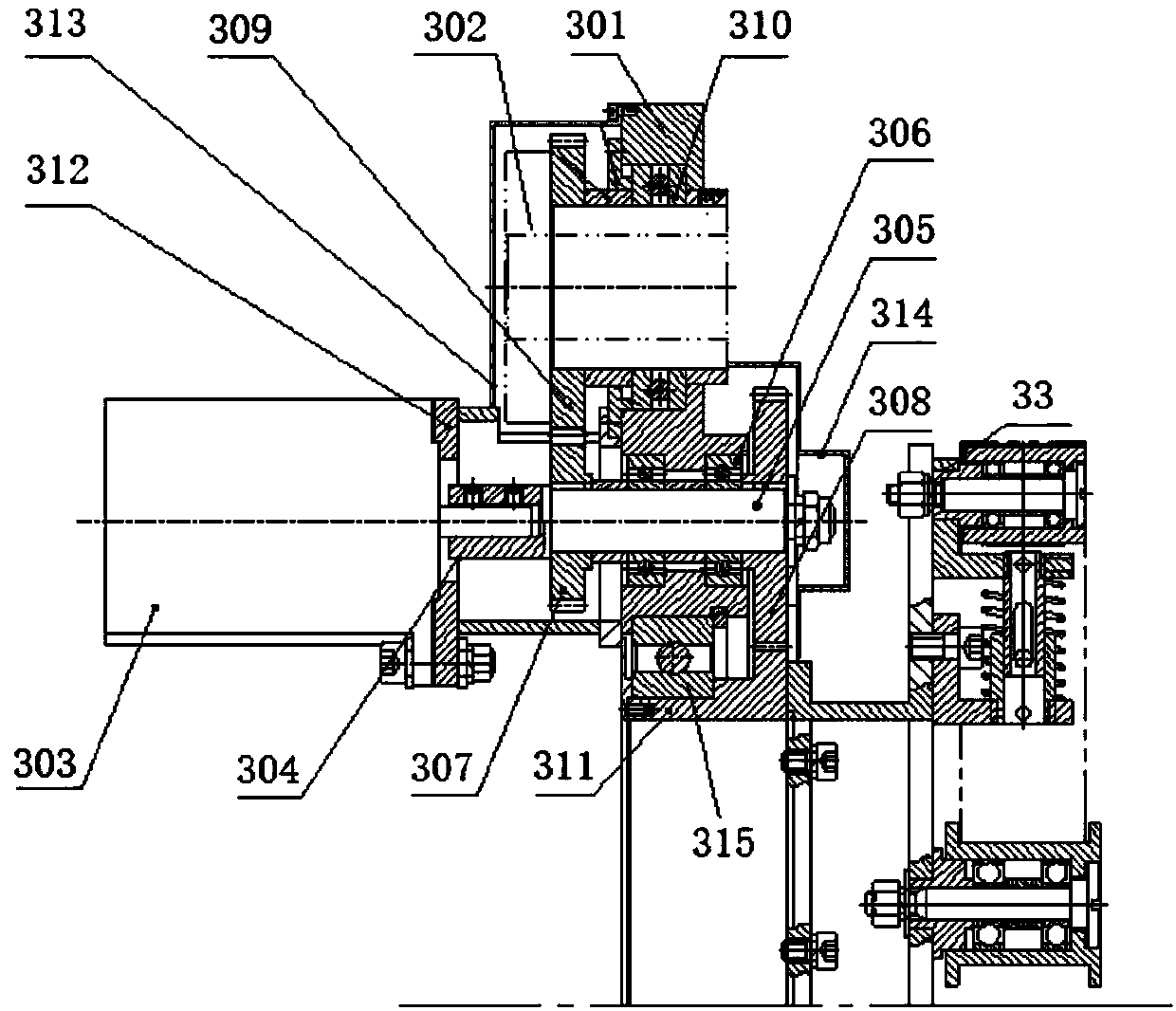

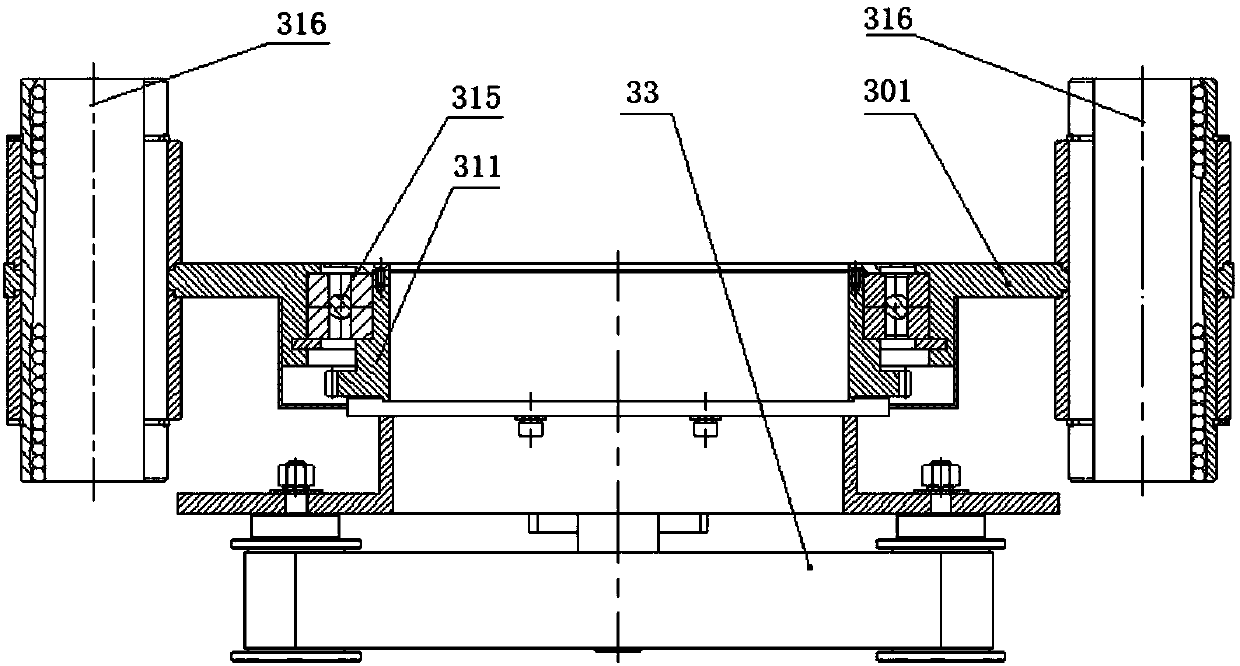

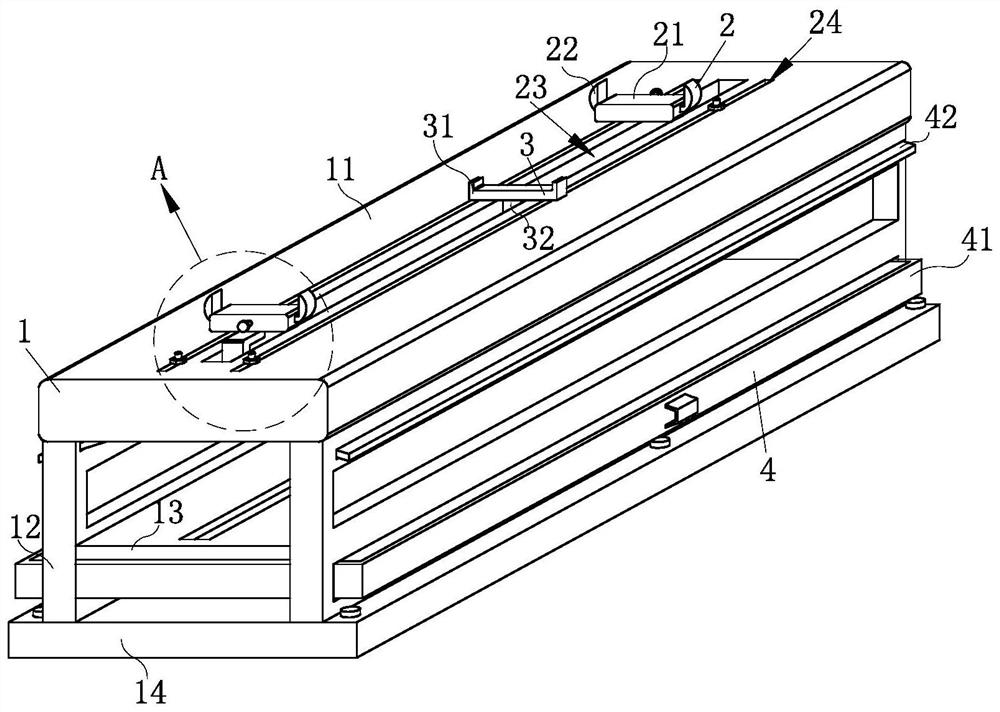

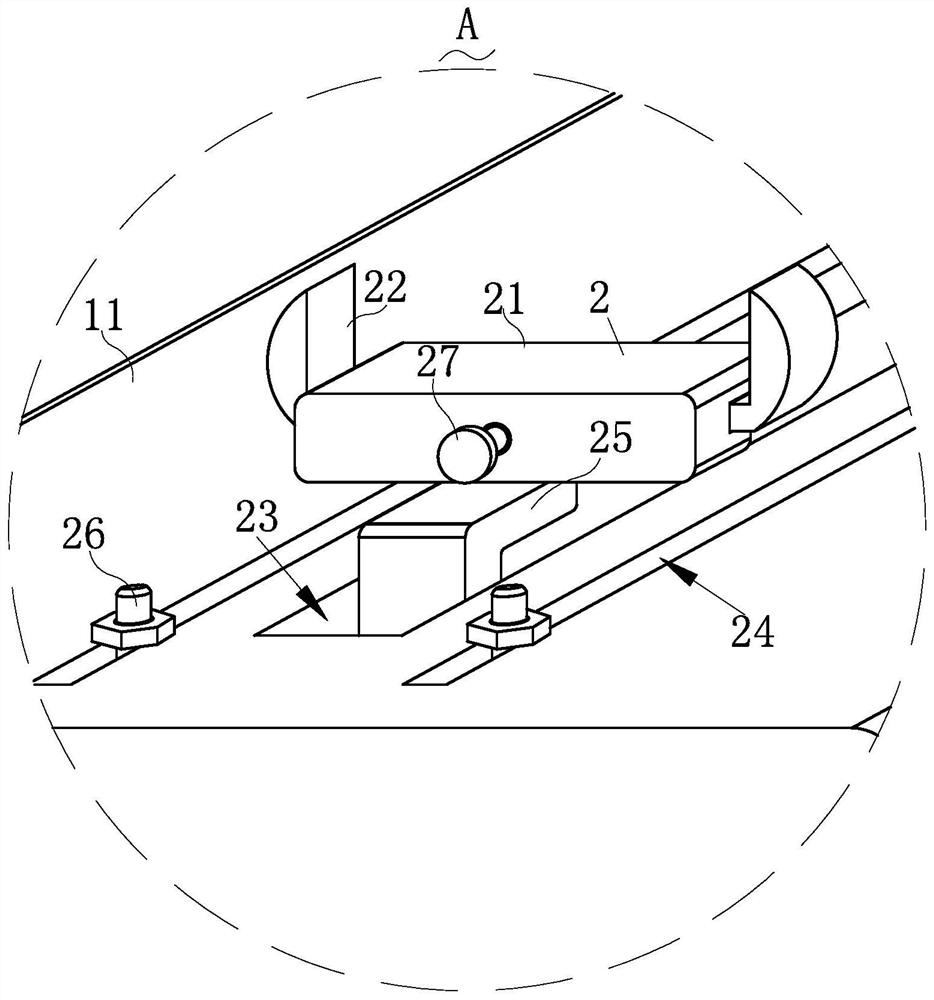

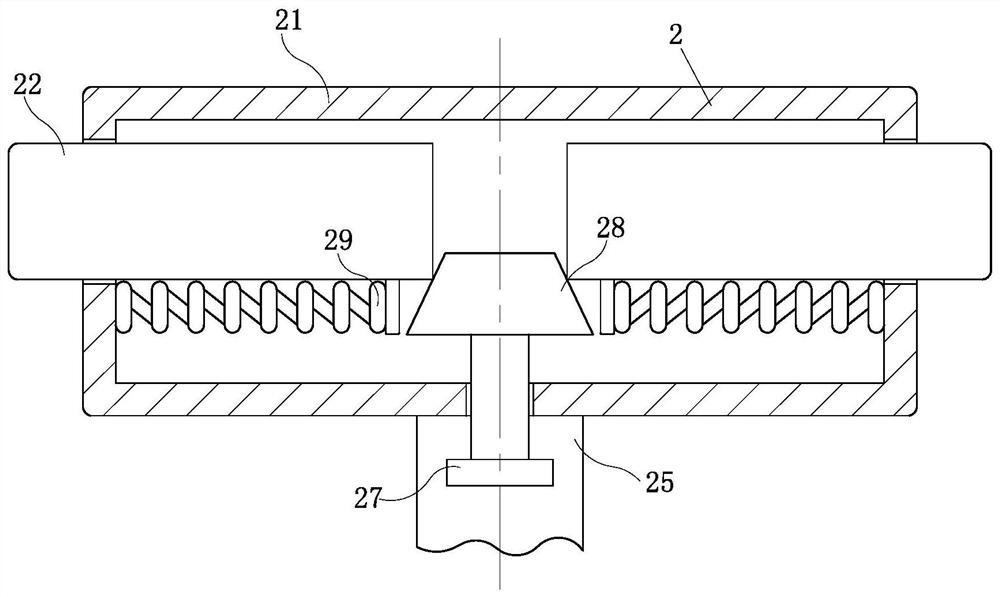

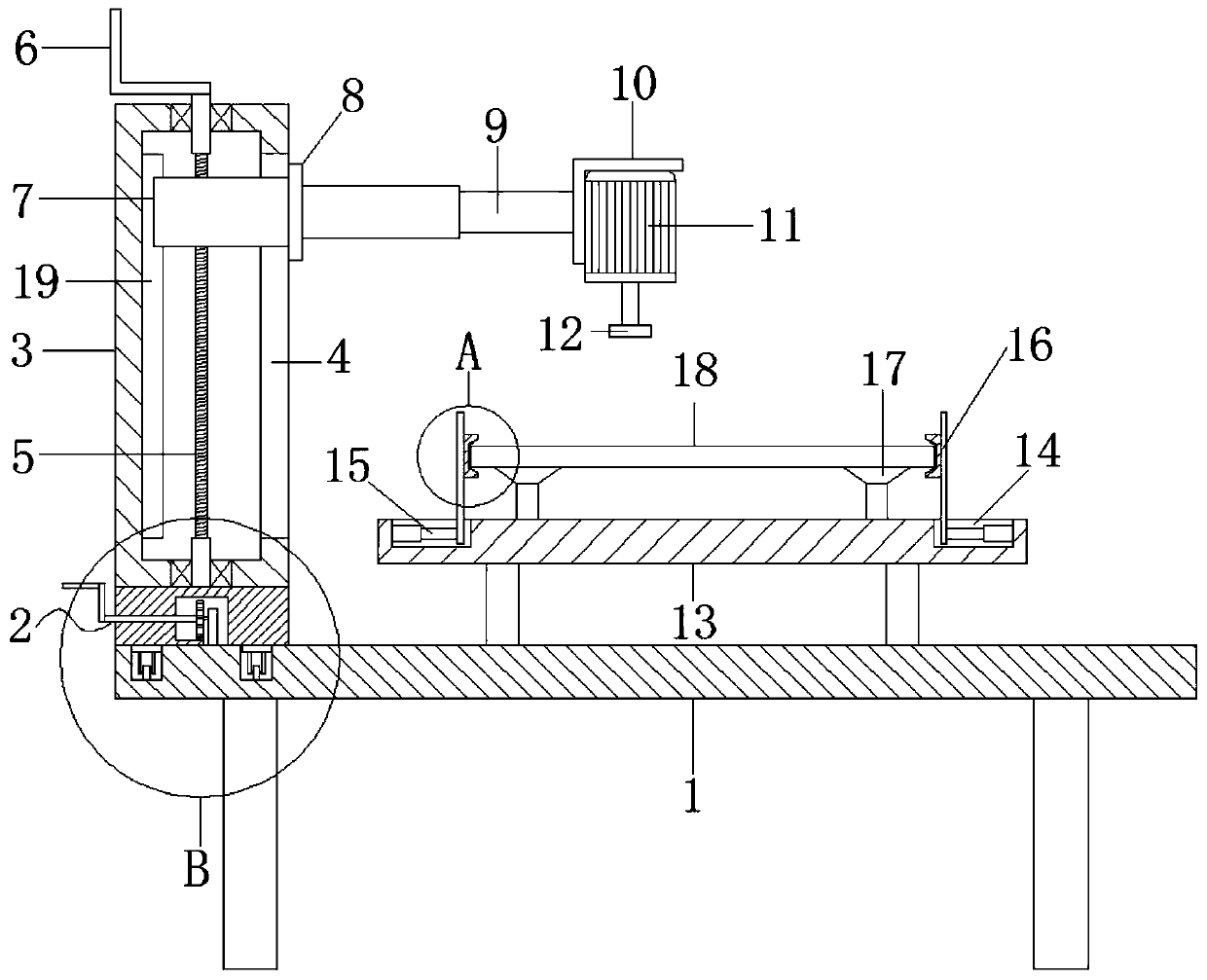

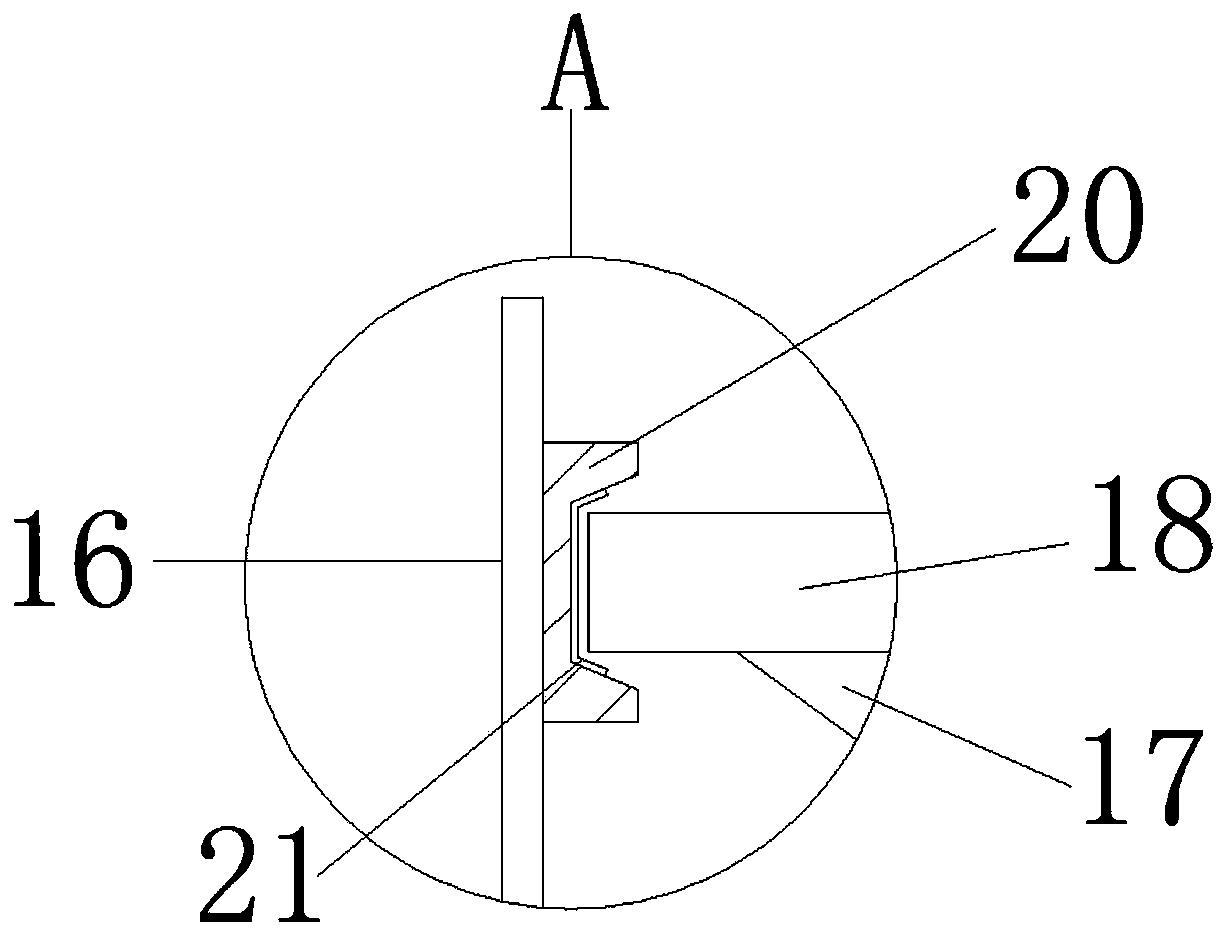

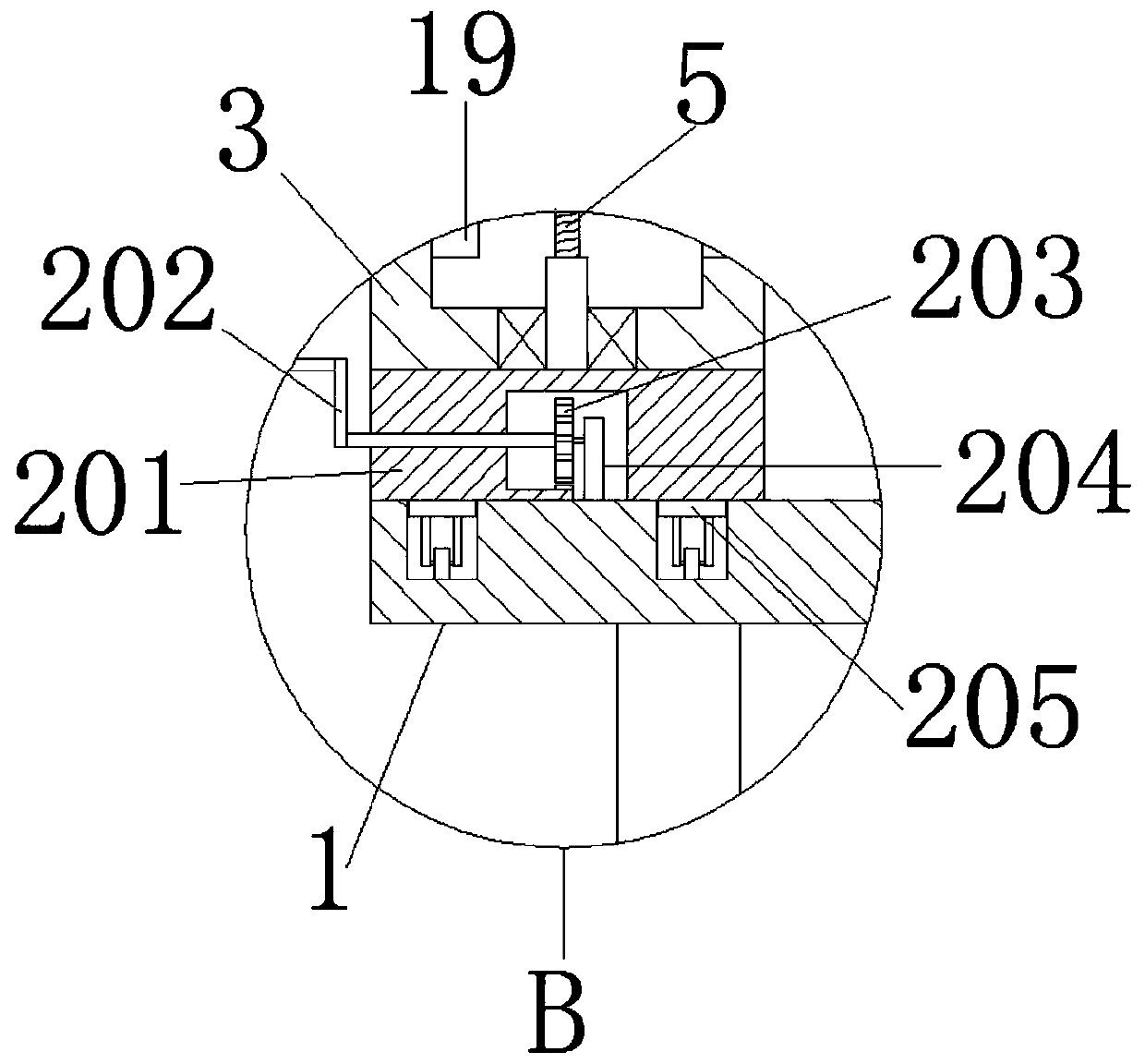

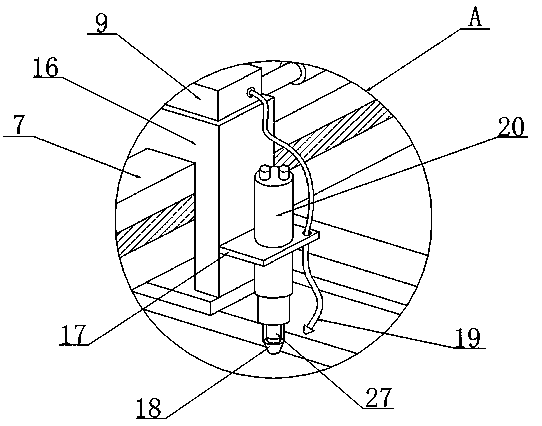

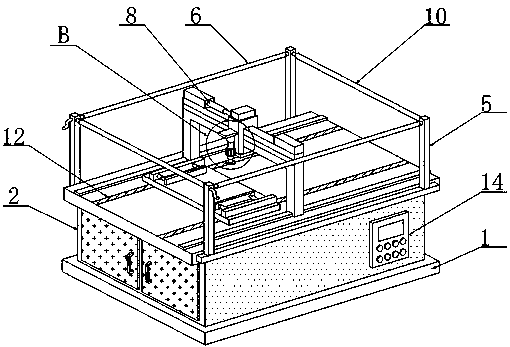

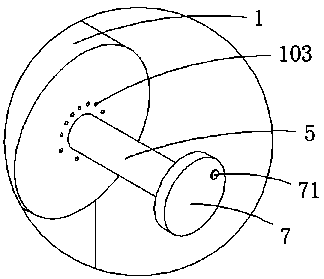

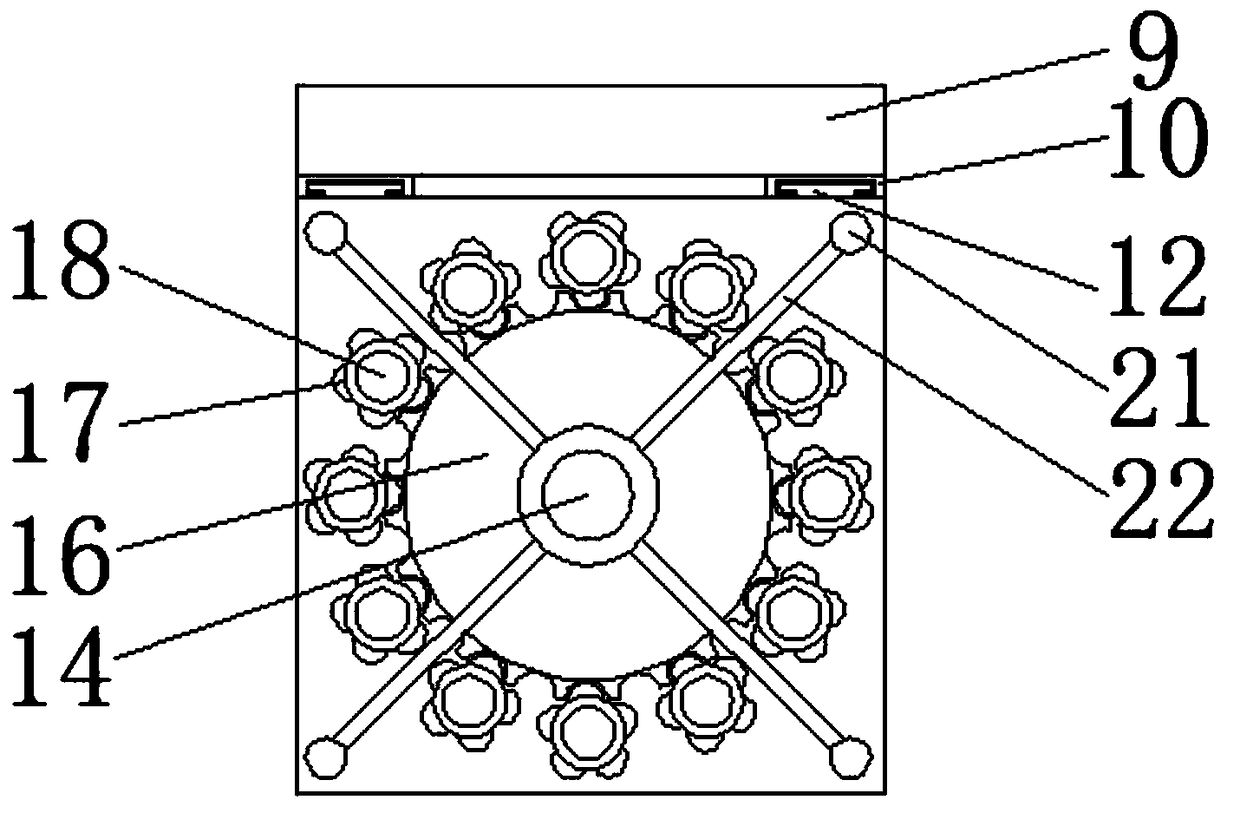

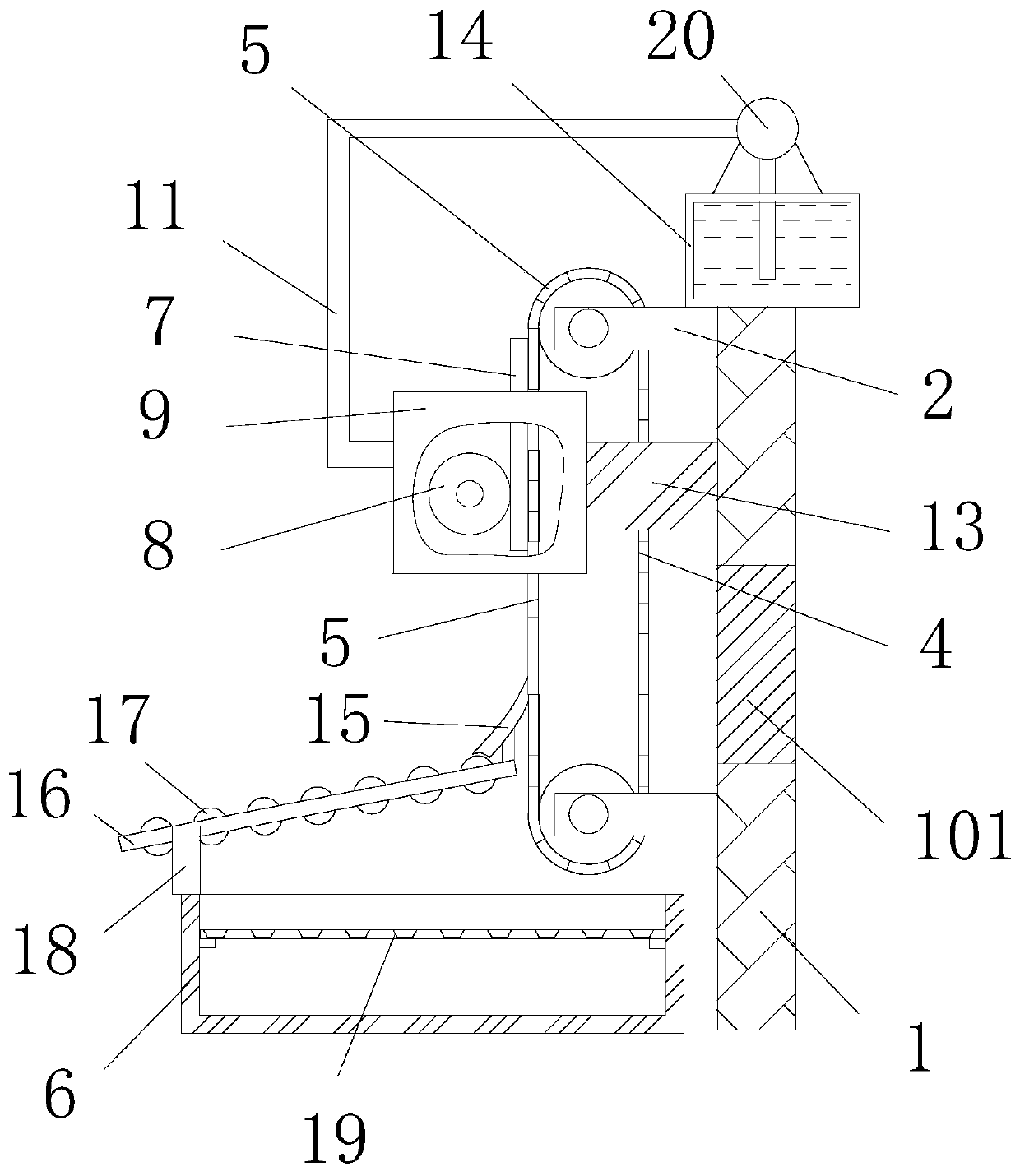

Automatic cable insulation layer polishing machine

PendingCN107745309AEasy to grind and polishQuick changeGrinding drivesBelt grinding machinesInsulation layerReciprocating motion

The invention discloses an automatic cable insulation layer polishing machine which comprises a first clamping device, a driving lead screw, a polishing device, reciprocating motion guide rods and a second clamping device; the first clamping device and the second clamping device clamp the two ends of a to-be-polished cable correspondingly; the driving lead screw and the reciprocating motion guiderods are mutually parallel and are fixedly connected between the first clamping device and the second clamping device; a polishing driving nut and polishing guide cylinders are arranged on the polishing device; the polishing driving nut is assembled with the driving lead screw; the polishing guide cylinders are assembled with the reciprocating motion guide rods; a polishing head carrying out rotary polishing around the outer wall of a cable insulation layer is arranged on the polishing device; and a motor driving the polishing driving nut and the polishing head to rotate is arranged on the polishing device. Rapid centering clamping on the cable and automatic reciprocating polishing on the cable insulation layer can be realized, the polishing efficiency and quality of the cable insulation layer are improved, safe operation of construction personnel is guaranteed, and the application scope of automatic polishing on the cable insulation layer is extended.

Owner:CHANGLAN CABLE ACCESSORIES

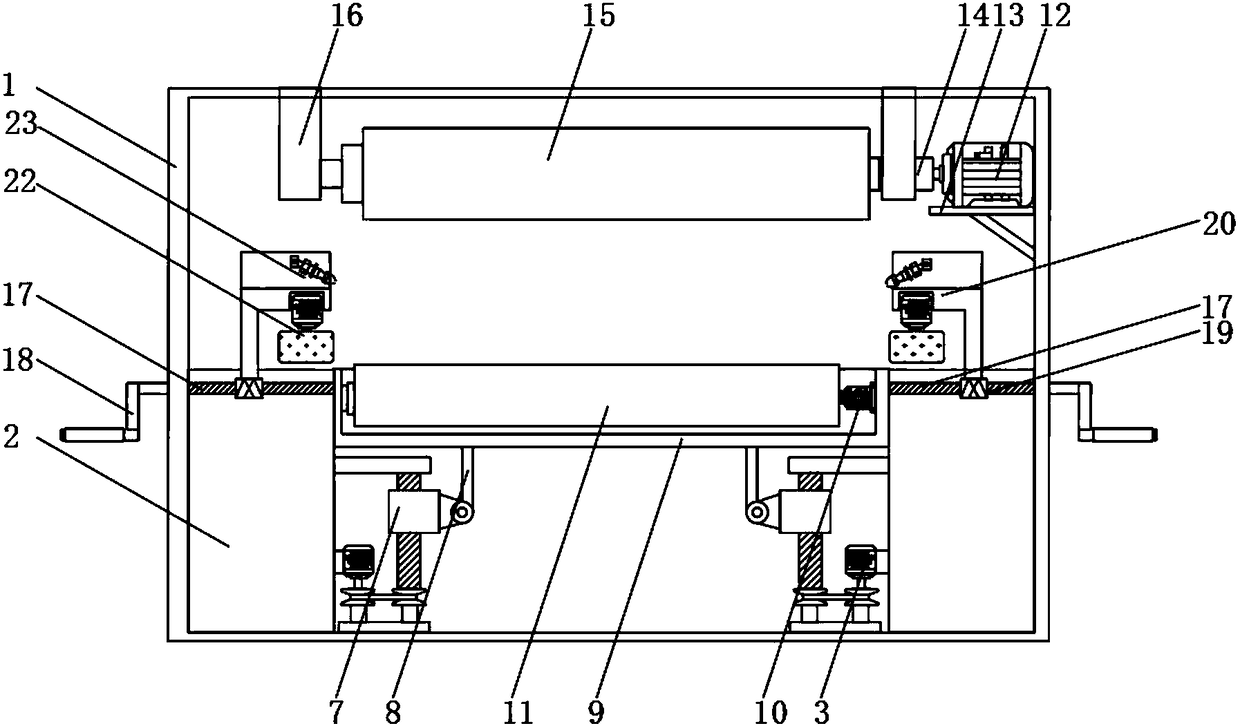

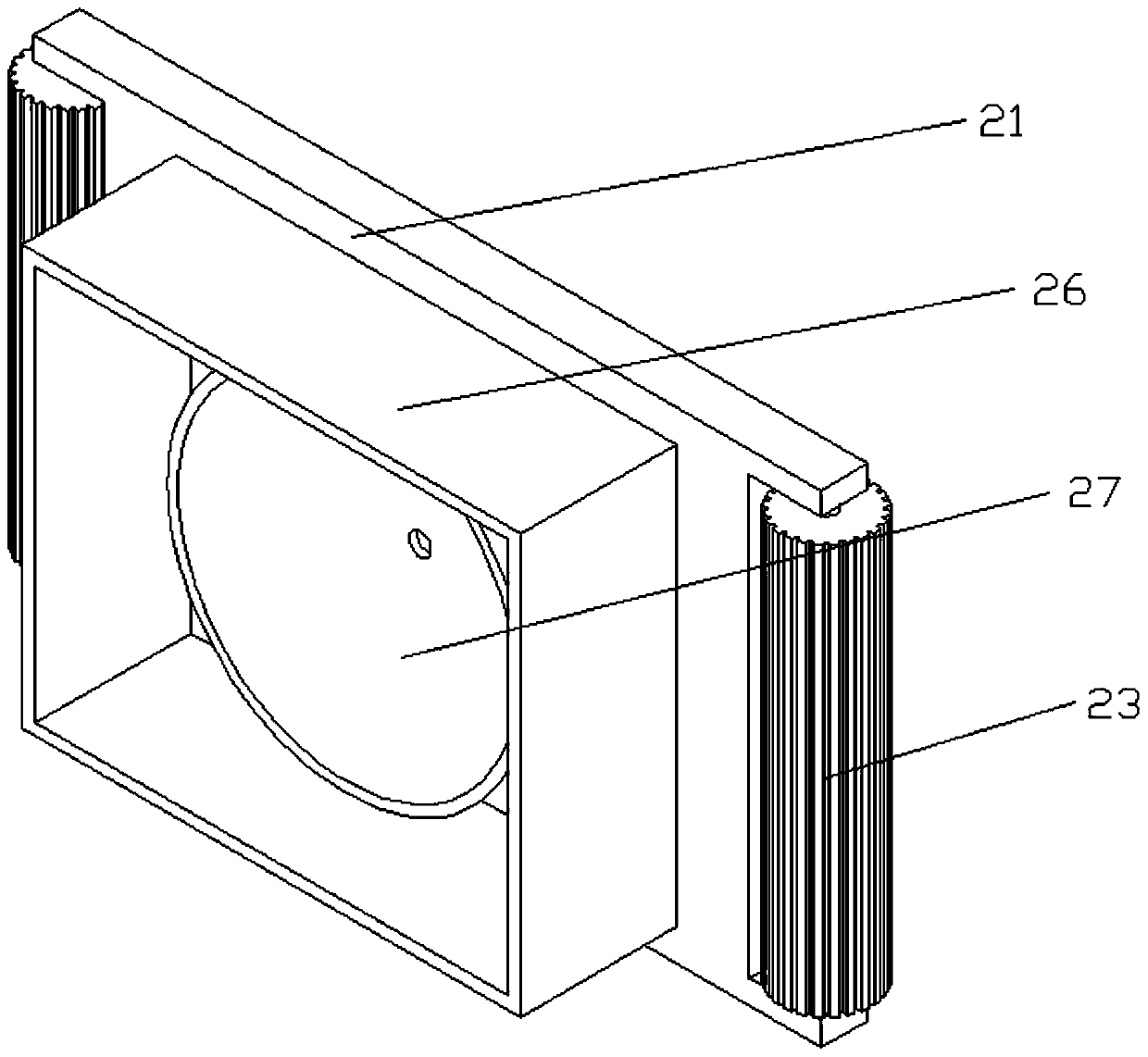

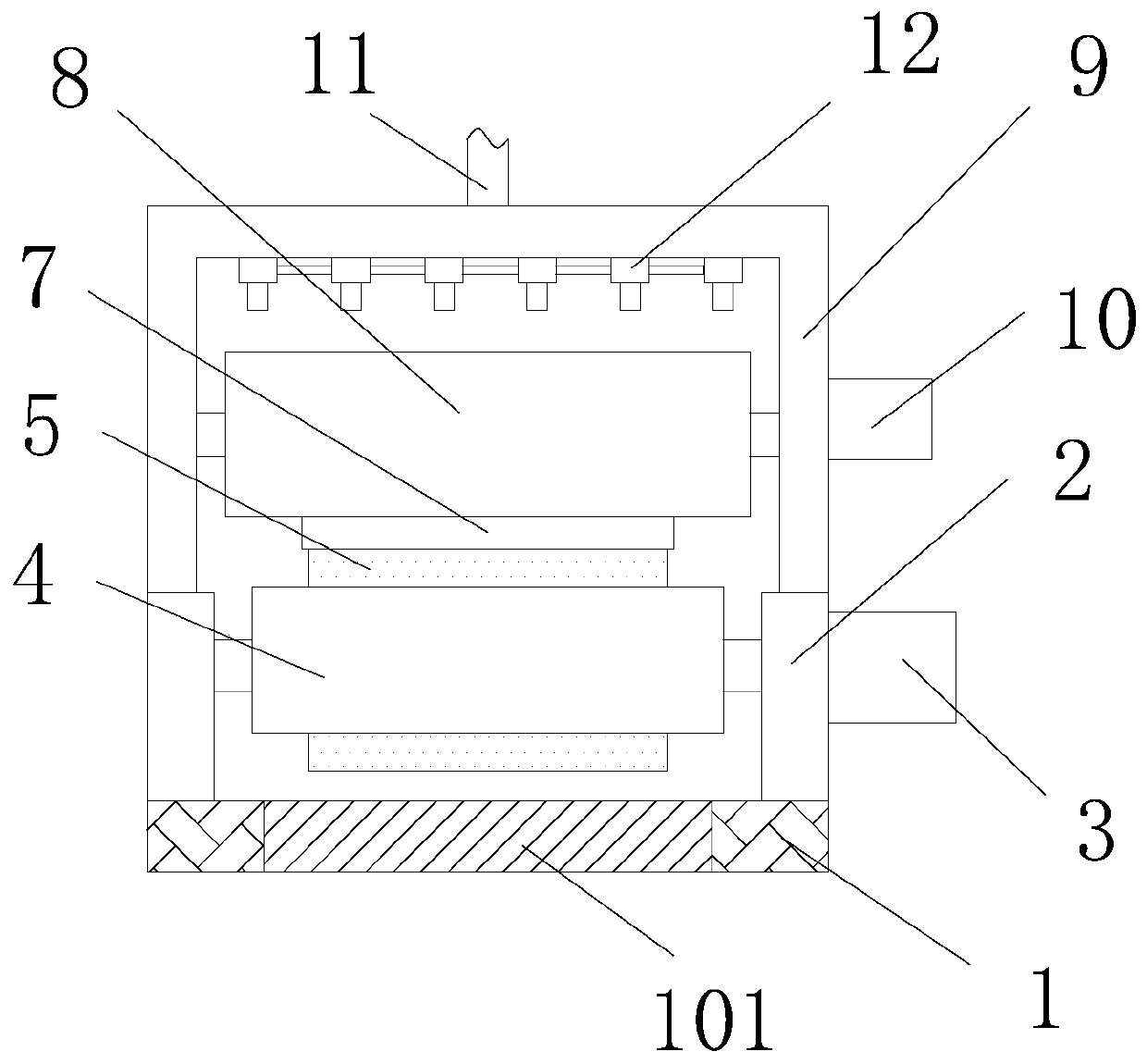

Grinding and polishing device for bamboo wood processing

InactiveCN108453600AEasy to processTo achieve the purpose of grinding and polishingEdge grinding machinesPlane surface grinding machinesArchitectural engineeringThreaded rod

The invention discloses a grinding and polishing device for bamboo wood processing and relates to the technical field of bamboo wood processing. The grinding and polishing device comprises an outer frame. Support tables are fixedly connected to the two sides of the bottom of the inner wall of the outer frame. Rotating motors are fixedly connected to the bottoms of the sides, opposite to each other, of the support tables. A first belt wheel is connected to each rotating motor in a rotary manner through an output shaft. A second belt wheel is connected to each first belt wheel in a rotary manner. A first threaded rod is mounted at the top of each second belt wheel. A moving block is connected to the outer wall of each first threaded rod in a sliding manner. A support pillar rod is fixedly connected to the outer side of each moving block. A workbench is fixedly connected to the tops of the support pillar rods. By means of the grinding and polishing device for bamboo wood processing, the purpose that grinding and polishing are conducted on bamboo wood plates and side edges of the bamboo wood plates is achieved; by means of the workbench with the height being adjusted freely, the bamboowood plates of different thicknesses can be processed more conveniently, and work efficiency is improved; and by means of a disinfection mechanism, the bamboo wood plates obtained after grinding andpolishing can be disinfected and prevented from being damaged by worms.

Owner:安吉县怡成竹木工艺品厂

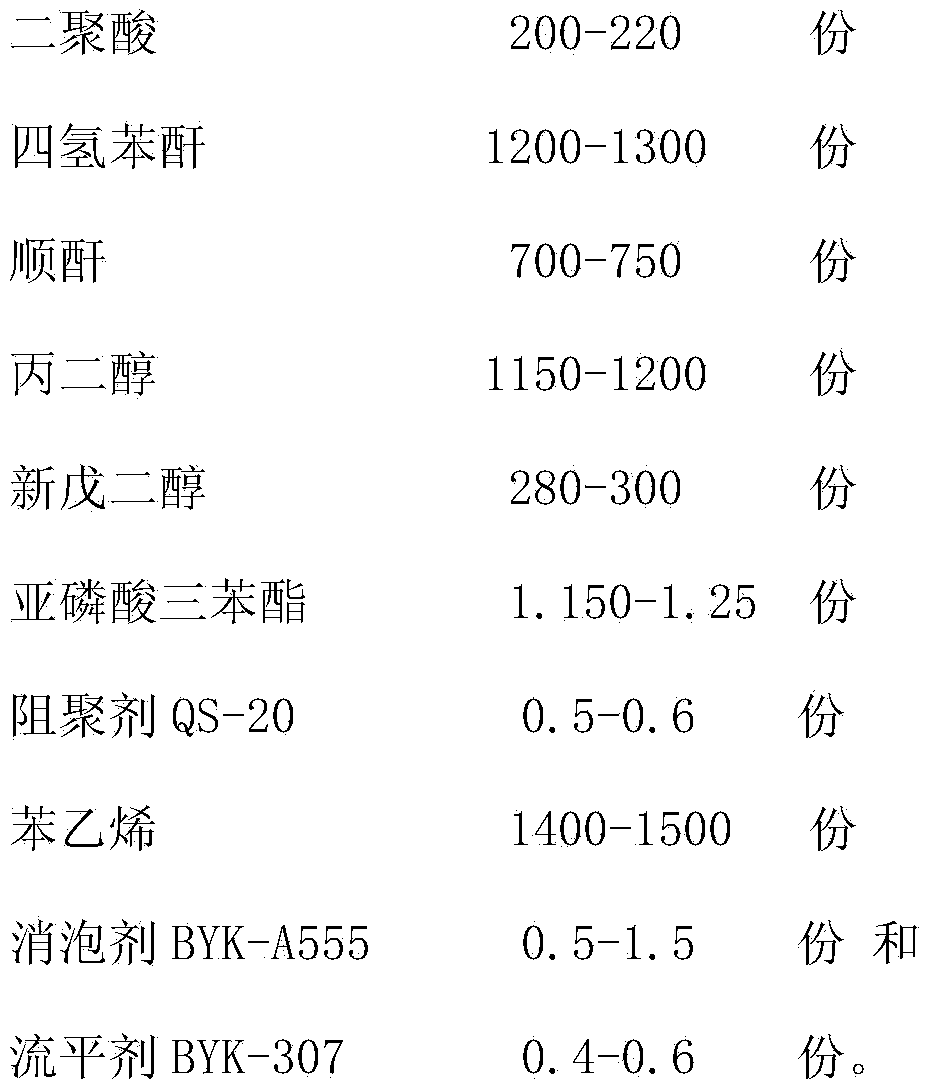

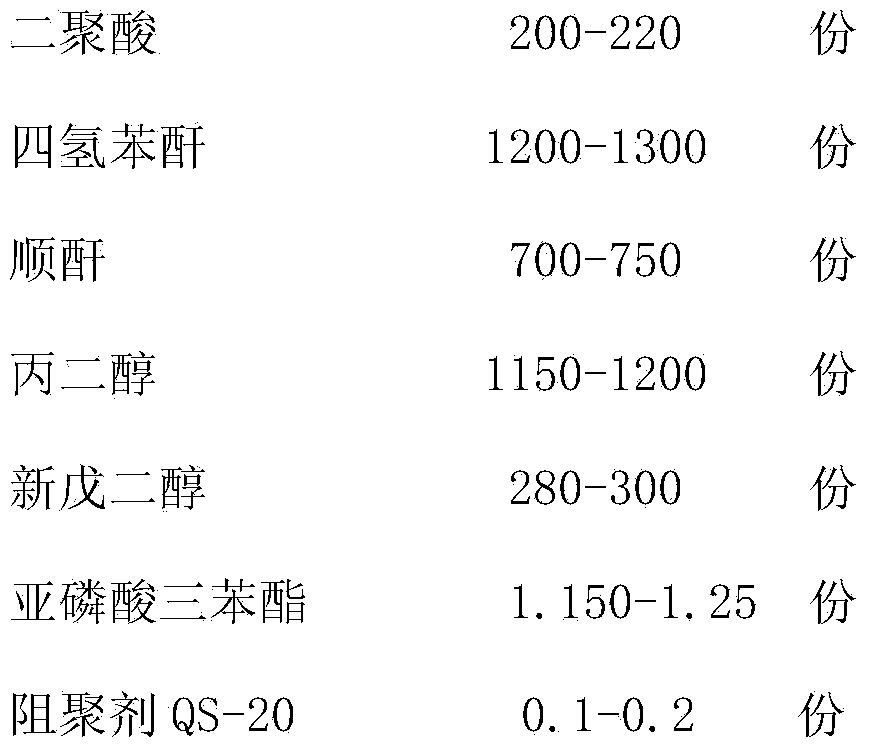

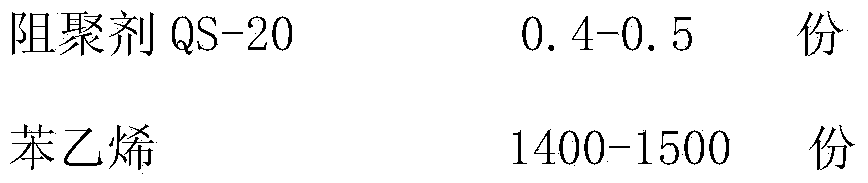

Air-dried unsaturated polyester resin and production method thereof

The invention discloses an air-dried unsaturated polyester resin and a production method thereof. The air-dried unsaturated polyester resin comprises the following raw materials by weight: 200-220 parts of dimer acid; 1200-1300 parts of tetrahydrophthalic anhydride; 700-750 parts of maleic anhydride; 1150-1200 parts of propylene glycol; 280-300 parts of neopentyl glycol; 1.150-1.25 parts of triphenyl phosphite; 0.5-0.6 part of a polymerization inhibitor QS-20; 1400-1500 parts of styrene; 0.5-1.5 parts of an antifoaming agent BYK-A555 and 0.4-0.6 part of a leveling agent BYK-307. The invention also discloses the production method of the resin.

Owner:ZHANGZHOU YABANG CHEM

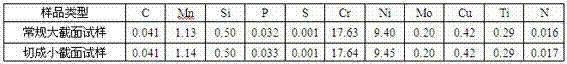

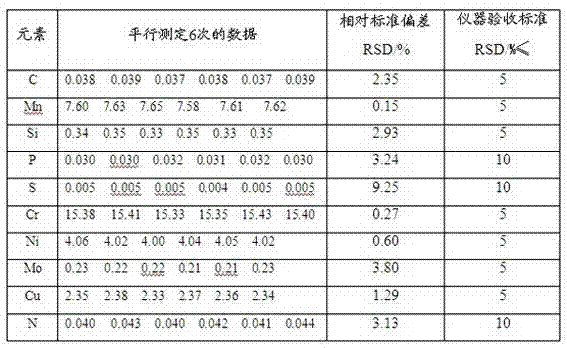

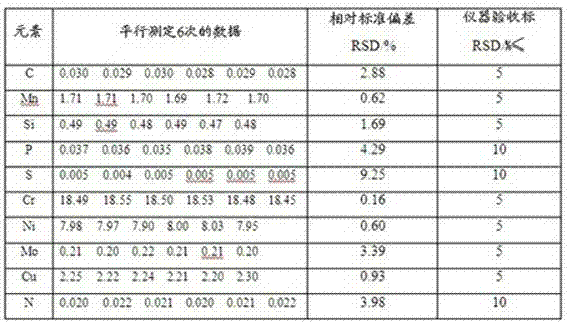

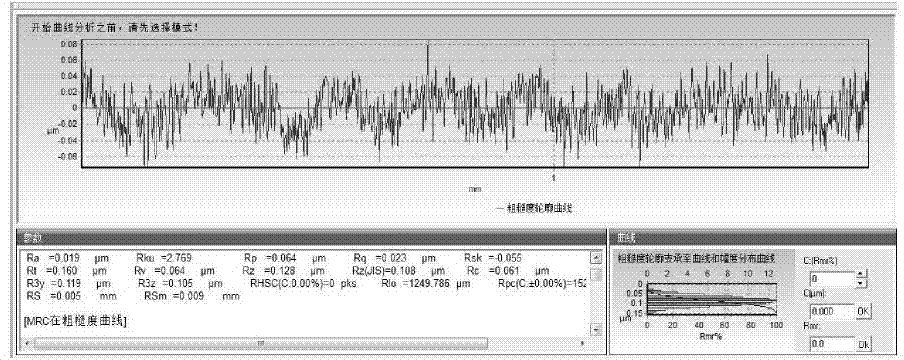

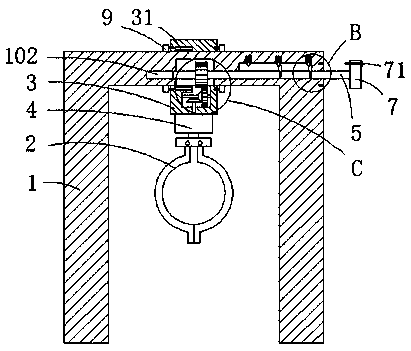

Method for analyzing small-section metal sample through direct reading spectrometry

InactiveCN102359957ASolve the air leakage of the spark tableEasy to operatePreparing sample for investigationAnalysis by electrical excitationDirect readingIron production

The present invention relates to a method for analyzing a small-section metal sample through direct reading spectrometry, and belongs to the technical field of metallurgy analysis and detection. The method comprises the following three steps: inlaying, grinding and analyzing. With adopting inlaying for the small-section metal sample, the section of the inlayed sample is large, the thickness is high, such that the problems of inconvenience during the small-section metal sample grinding, air leakage of the spark table during analyzing, and the like are solved. According to the present invention, the small fixture is not required; the method has advantages of simple operation, rapidness and precision, and is suitable for popularization in iron and steel production and test.

Owner:YONGXING SPECIAL STAINLESS STEEL

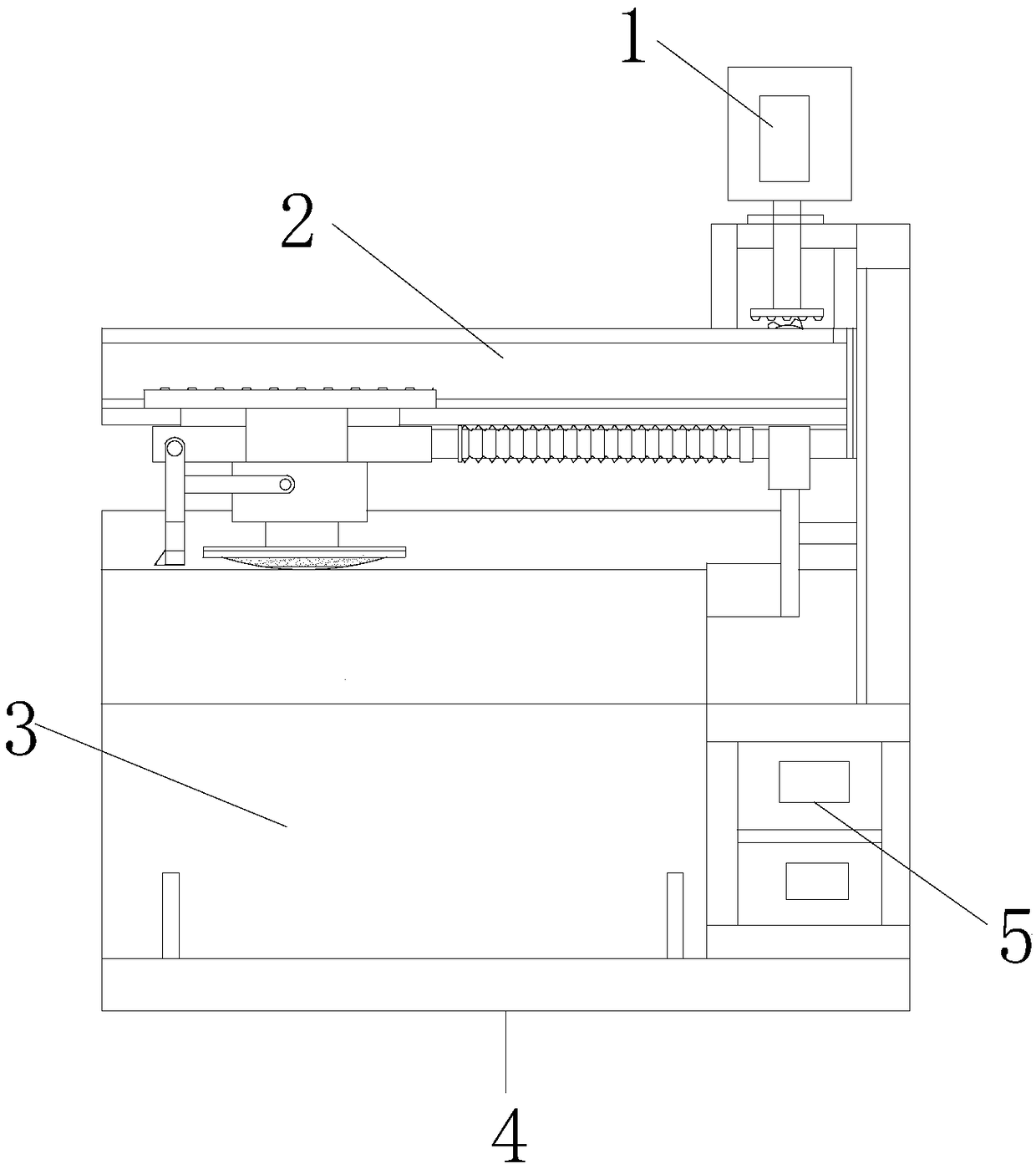

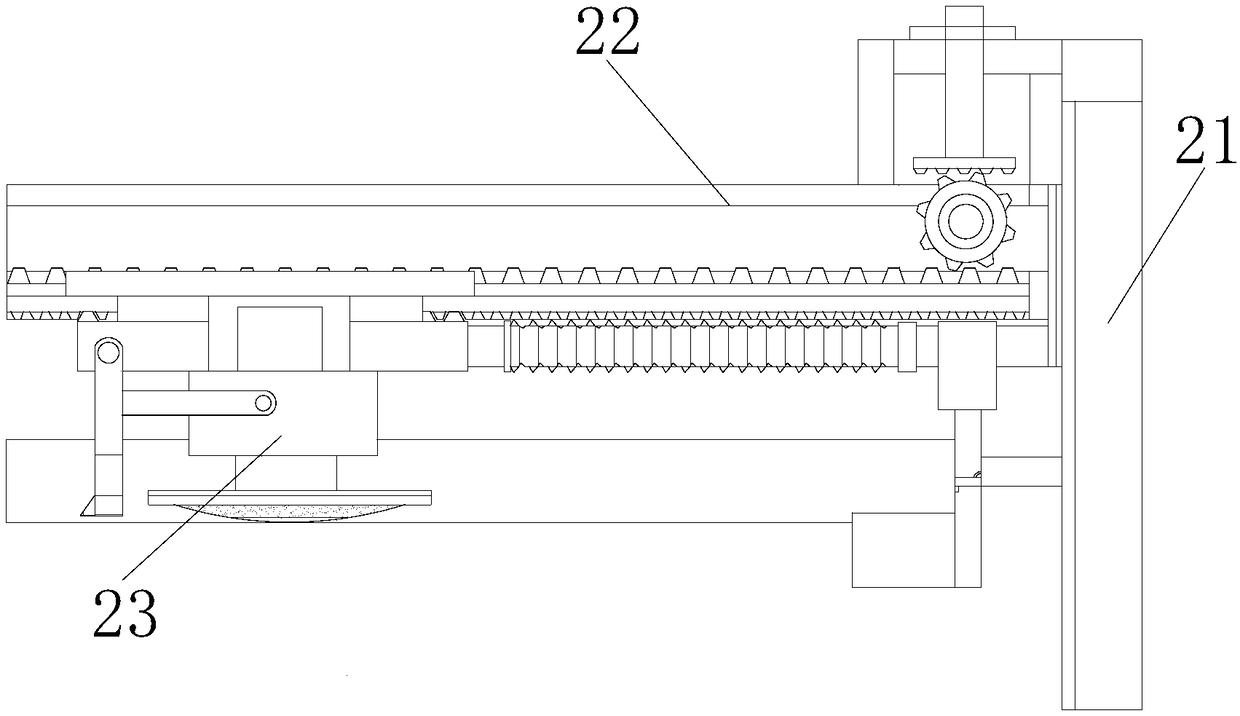

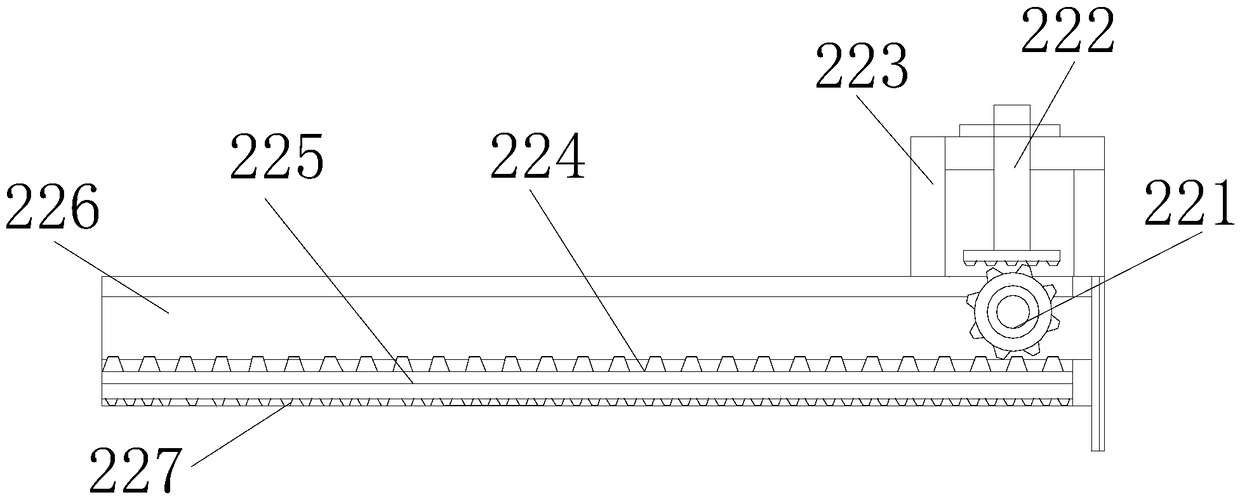

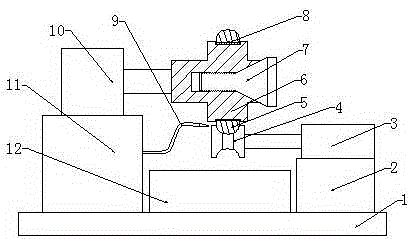

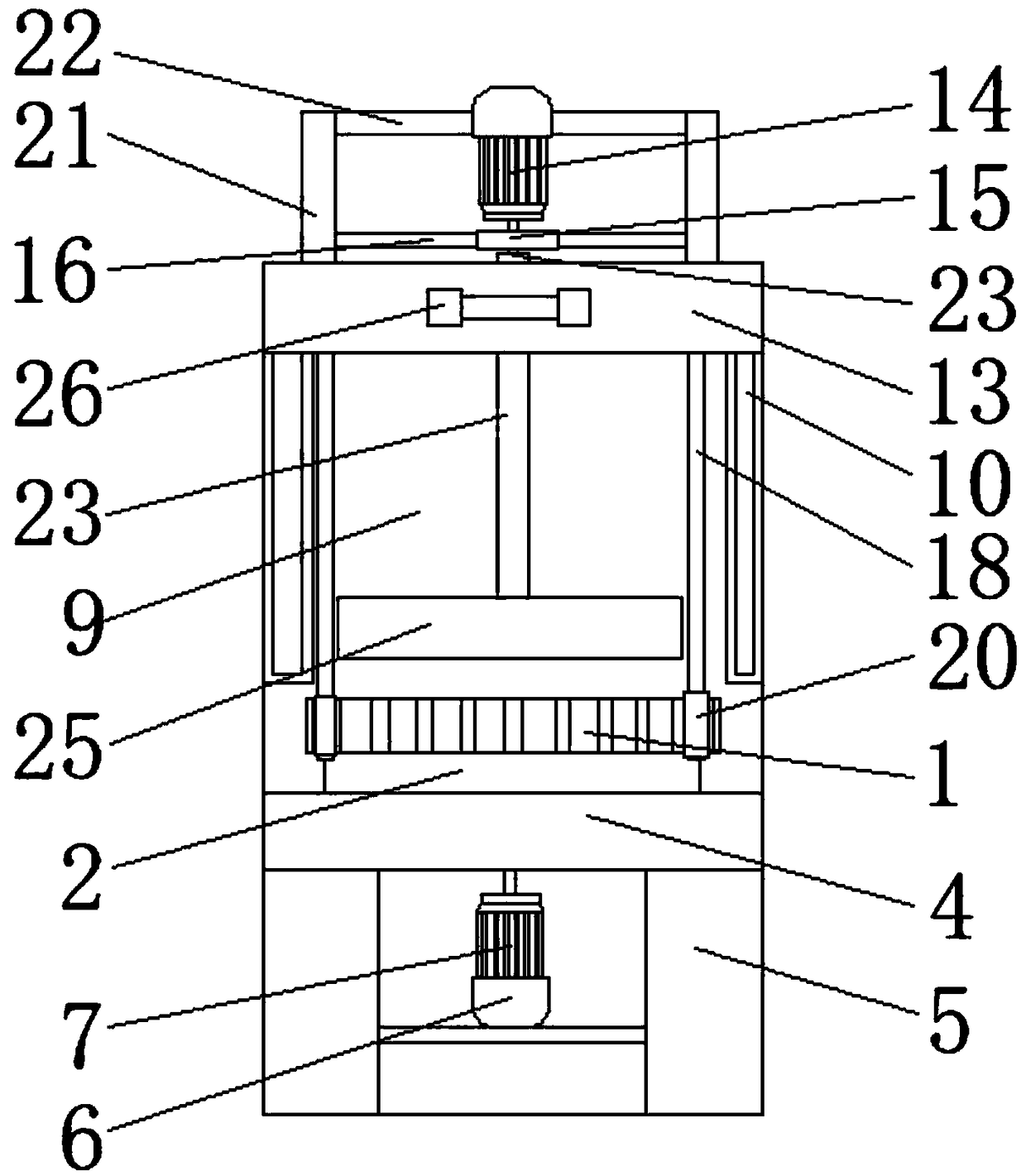

Tree annual ring sample polishing device by using cutters and convex surface type grinding wheel phased scraping

ActiveCN109366331AQuick polish jobIn case of reduced slip displacementPolishing machinesGrinding drivesGear wheelWorking environment

The invention discloses a tree annual ring sample polishing device by using cutters and convex surface type grinding wheel phased scraping. The device is structurally comprises a bi-directional motor,an intelligent flat grinding device, a fixing base, a bottom base and a motor set, wherein the motor set is located on the upper side end face of the bottom base and is movably connected with the bottom base at the same time, thus driving a gear frame in the lower part through the rotation of the gear is achieved, so that a sliding block on tooth grooves are stressed to be meshed on the sliding frame to realize stable displacement, manual pressing dynamic displacement running-in is replaced, and the slippage displacement of the equipment can be reduced; meanwhile, through the flattening of ascraping frame at the front end and the arc-shaped structure of a grinding wheel frame, the structures of bulges can be scraped in advance during displacement, and wood is polished in a layering modewith a arc-shaped structure, so that polishing work can be better and more quickly carried out on the wood, and finally, the negative pressure generated through compression caused by pulling an air bag inside a telescopic frame when displacement is carried out is used for attracting sawdust generated by the polishing, and the working environment is not influenced.

Owner:苏州心愿美电子商务有限公司

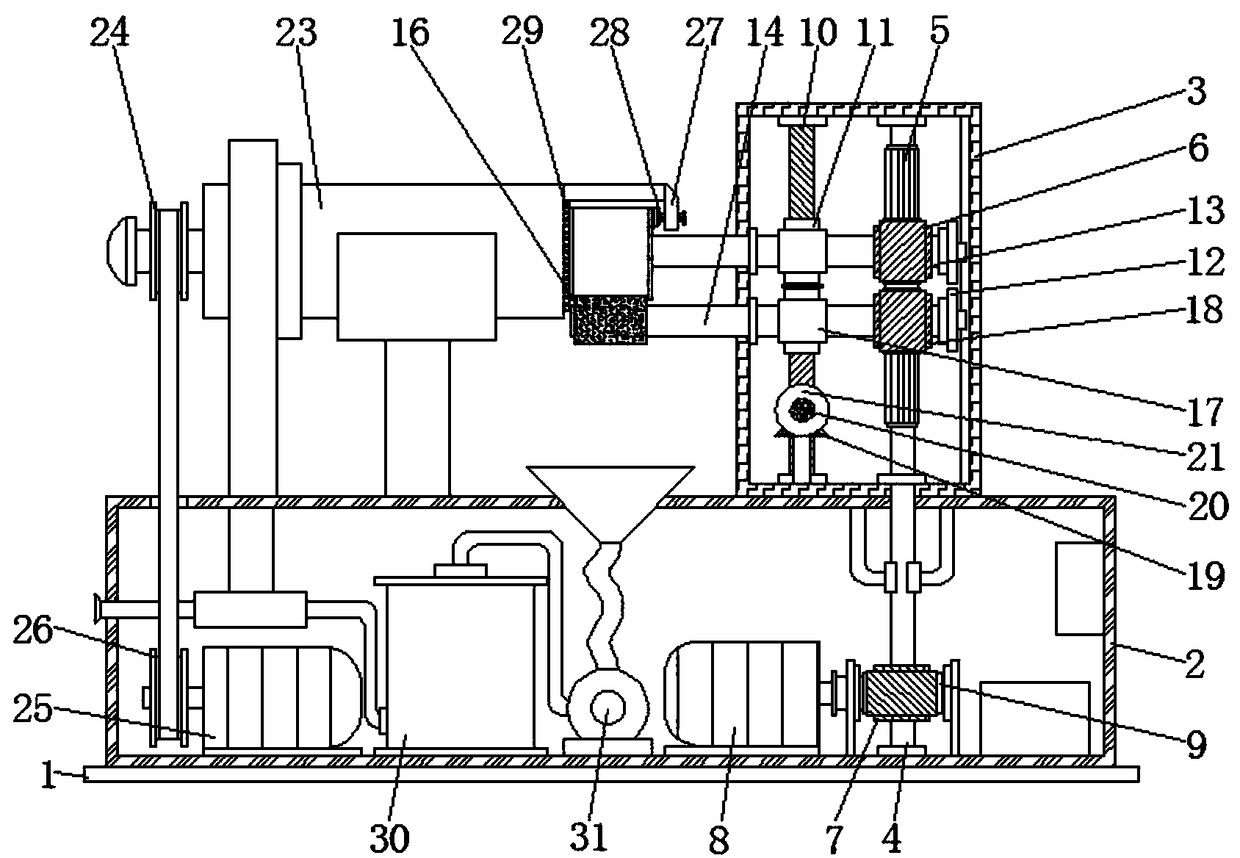

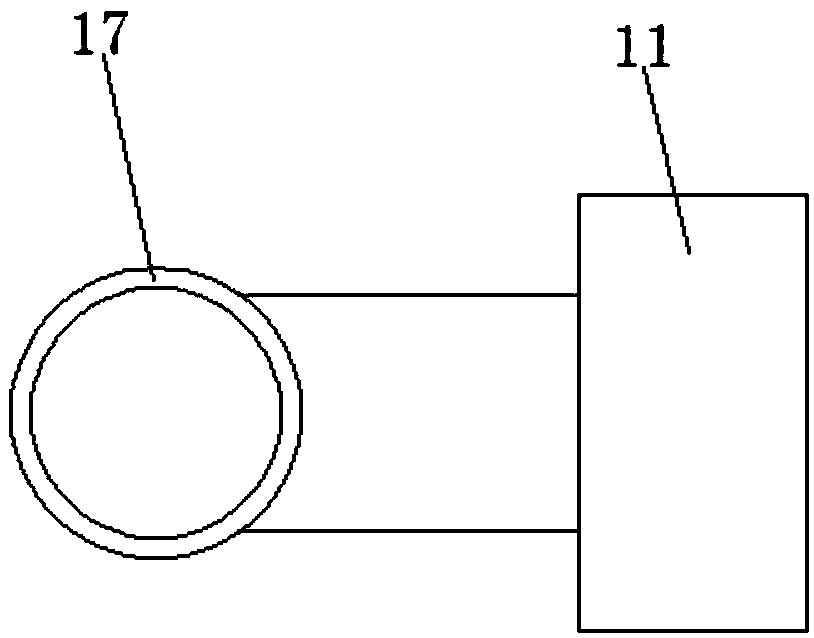

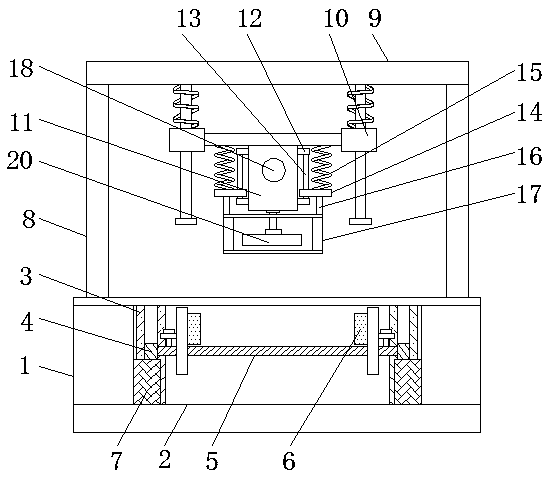

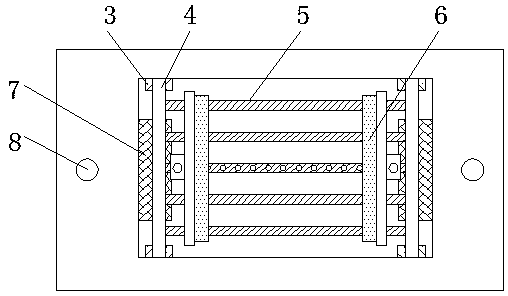

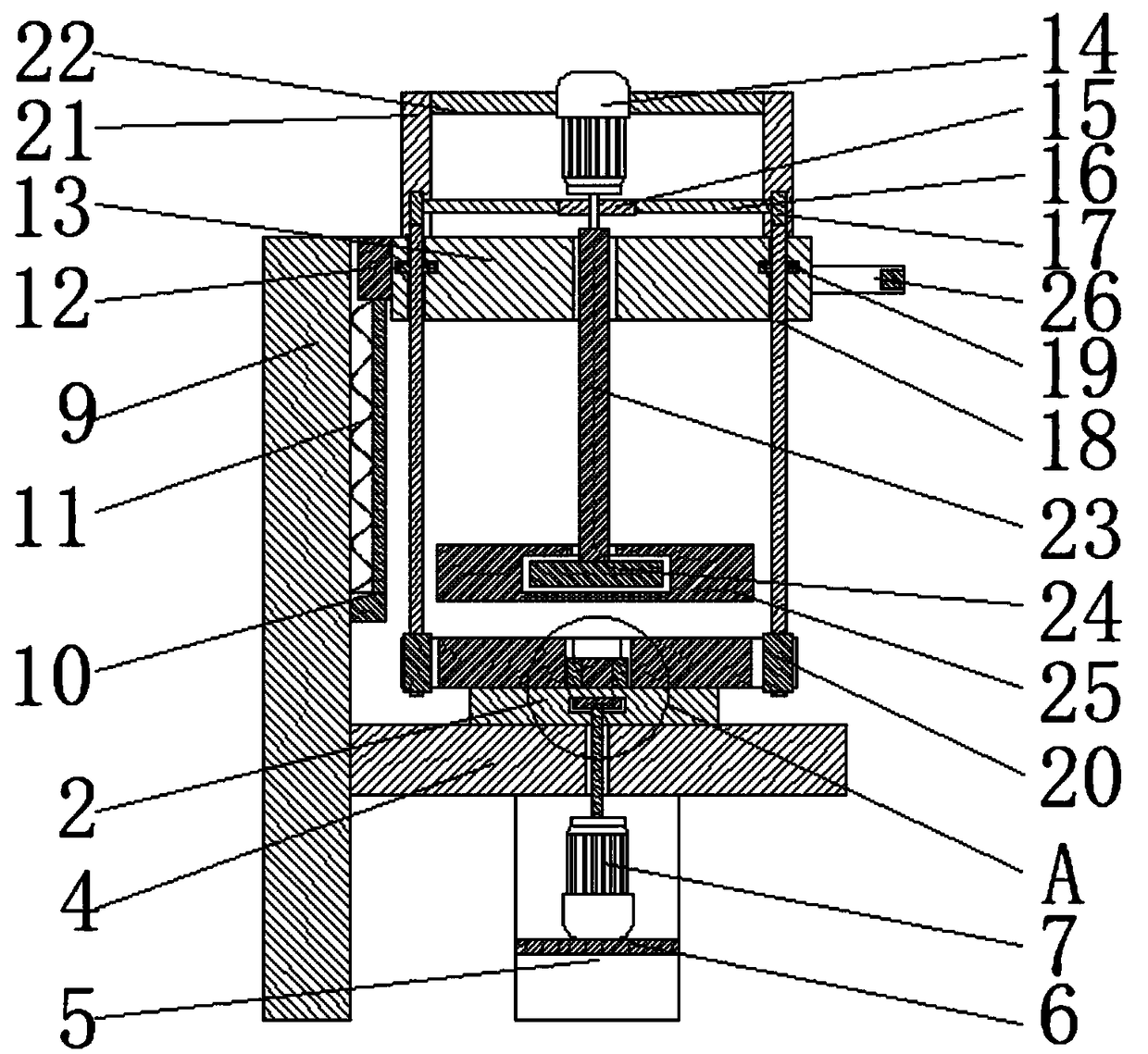

Internal combustion machine bearing bush machining device and machining method thereof

ActiveCN108356648AEasy dischargeImprove grinding and polishing effectRevolution surface grinding machinesGrinding work supportsCombustionEngineering

The invention discloses an internal combustion machine bearing bush machining device, and relates to the technical field of internal combustion machine bearing bush production equipment. The device comprises a bottom plate, the top of the bottom plate is fixedly connected with a box body, one side of the top of the box body is fixedly connected with a transmission box, the bottom of the inner wallof the box body is rotatably connected with a rotating shaft through a bearing pedestal, the top end of the rotating shaft sequentially penetrates the box body and the transmission box and extends into the transmission box, and the rotating shaft extends into the outer surface inside the transmission box and is rotatably connected with the top of the inner wall of the transmission box through a bearing. According to the internal combustion machine bearing bush machining device and the machining method thereof, the grinding and polishing effect is greatly improved, the grinding and polishing efficiency is well improved, a person does not need to waste a large amount of time for grinding and polishing a bearing bush, work burdens of the person are well reduced, work efficiency of the personis improved, the inner surface and the outer surface of the bearing bush can be rapidly and efficiently ground and polished at the same time, and grinding machining of the bearing bush by the personis greatly facilitated.

Owner:湖北安达精密工业有限公司

Abrasive and grinding tool for conveniently grinding and polishing metal plate

The invention relates to the field of grinding and polishing equipment, and discloses an abrasive and grinding tool for conveniently grinding and polishing a metal plate. The abrasive and grinding tool comprises a base; the middle of the top end of the base is provided with a rectangular groove, and eight limiting plates are fixedly installed on the inner wall of the rectangular groove and dividedinto four small groups; the four small groups are divided into two large groups and symmetrically distributed on the inner walls of the two sides of the rectangular groove, and a limiting rod is movably connected between limiting plates of each small group in a sleeved mode. According to the abrasive and grinding tool for conveniently grinding and polishing the metal plate, through the action ofelastic force of springs, when the abrasive and grinding tool grinds and polishes the metal plate, a protection cover is always located below a grinding sheet, splashed scrap iron is isolated by the protection cover, thus, the scrap iron enters the rectangular groove of the base through gaps in limiting shaft brackets to be collected, accordingly, the situation that operators and products are prone to being scratched due to scrap iron splashing, and consequentially, abrasive and grinding tool using is influenced is avoided.

Owner:FORTURE TOOLS CO LTD

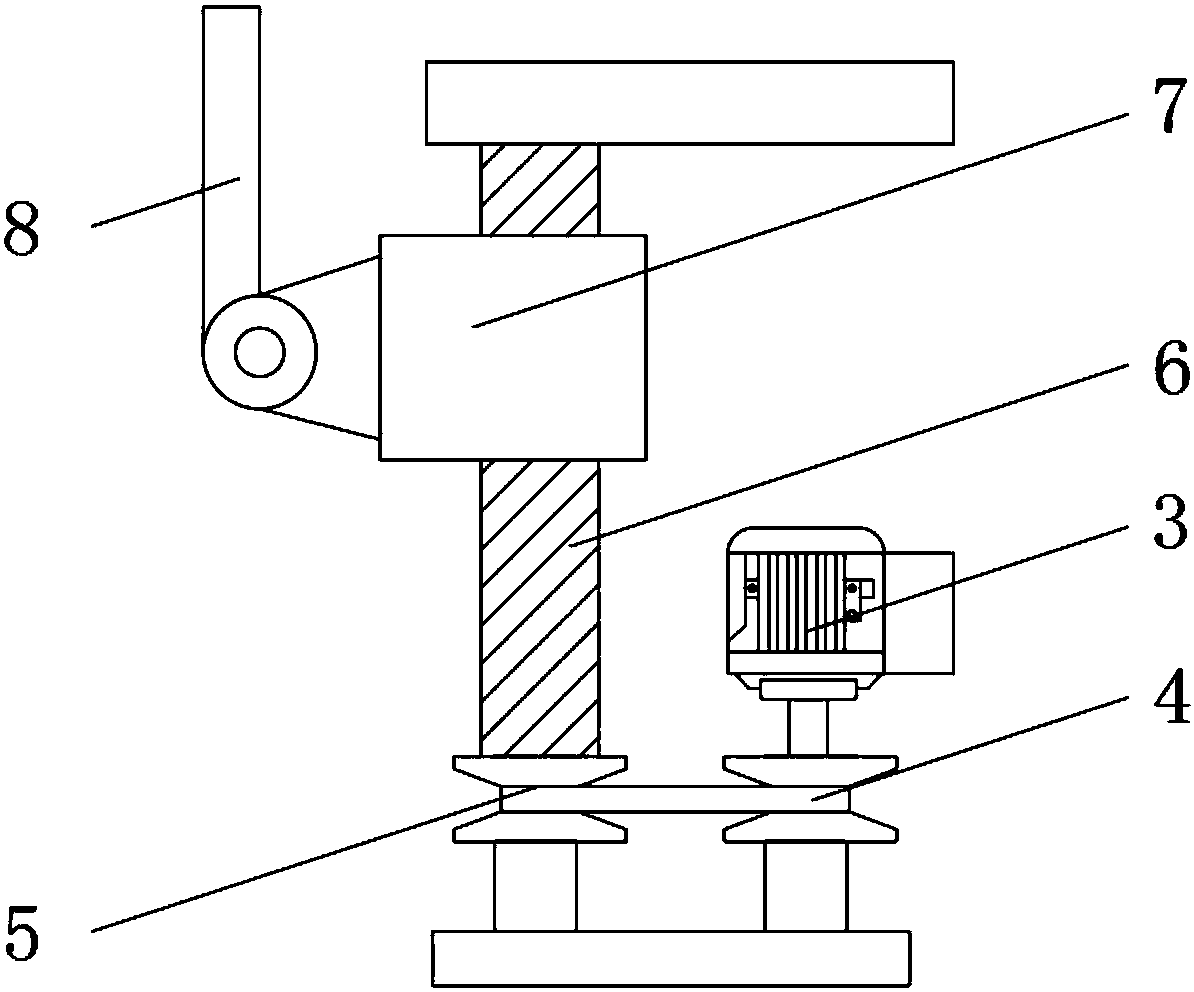

Size-controllable flywheel polishing device

ActiveCN109093503ARealize location movementEasy to polishPolishing machinesGrinding work supportsFreewheelGear wheel

The invention discloses a size-controllable flywheel polishing device in the technical field of flywheels. The size-controllable flywheel polishing device comprises a base and is characterized in thata rotary shaft is vertically arranged on the left side of the inner cavity of the base in a penetrating manner, a first bevel gear sleeves the circumferential outer wall of the bottom of the rotary shaft, a motor is fixedly mounted on the right side of the inner cavity of the base, a second bevel gear meshing with the first bevel gear sleeves the output end of the motor, an inner hole clamping chuck is arranged at the top of the rotary shaft, two first bearing blocks are arranged on the rear side of the top of the base, and a first screw is arranged between the two first bearing blocks in a penetrating manner. The size-controllable flywheel polishing device has the advantages that the device is suitable for being used for polishing flywheel faces of different types; the device uses a polishing plate, so that frequent abrasive paper replacing is avoided, and time and labor are saved; by the inner hole clamping chuck, flywheel inner hole clamping can be achieved, and simpleness and convenience are achieved; by the rotation of second manual rotary wheel, the ascending and descending of a polishing block can be achieved, and the polishing of the flywheel faces is benefited.

Owner:浙江盛诚机械科技有限公司

Consumer electronic panel machining process based on sapphire technology

InactiveCN106163178AImprove thermal stressHigh product strengthCasings/cabinets/drawers detailsL&D processSurface finishing

The invention discloses a consumer electronic panel machining process based on a sapphire technology. A consumer electronic panel is machined using a cutting process, a tree process and a surface treatment process. Consumer electronic panels comprise mobile phone panels and tablet computer panels. The machining process comprises the following steps: cutting sapphire after quality inspection into a block, finishing blank allowance of 0.15-0.2mm according to the single-side size of a consumer electronic panel, and rounding the edges of the block corresponding to the four corners of the panel, wherein the fillet dimension is 4.5-8R; and then, cutting the block into a piece through linear cutting equipment. In view of the defects of the existing large-screen sapphire panel, such as high processing difficult, low efficiency and poor yield, a novel machining process is provided, which can be used to machine a 2.5D consumer electronic panel with a wear-resistant and scratch-resistant arc edge contour.

Owner:成都市思卡利科技有限公司

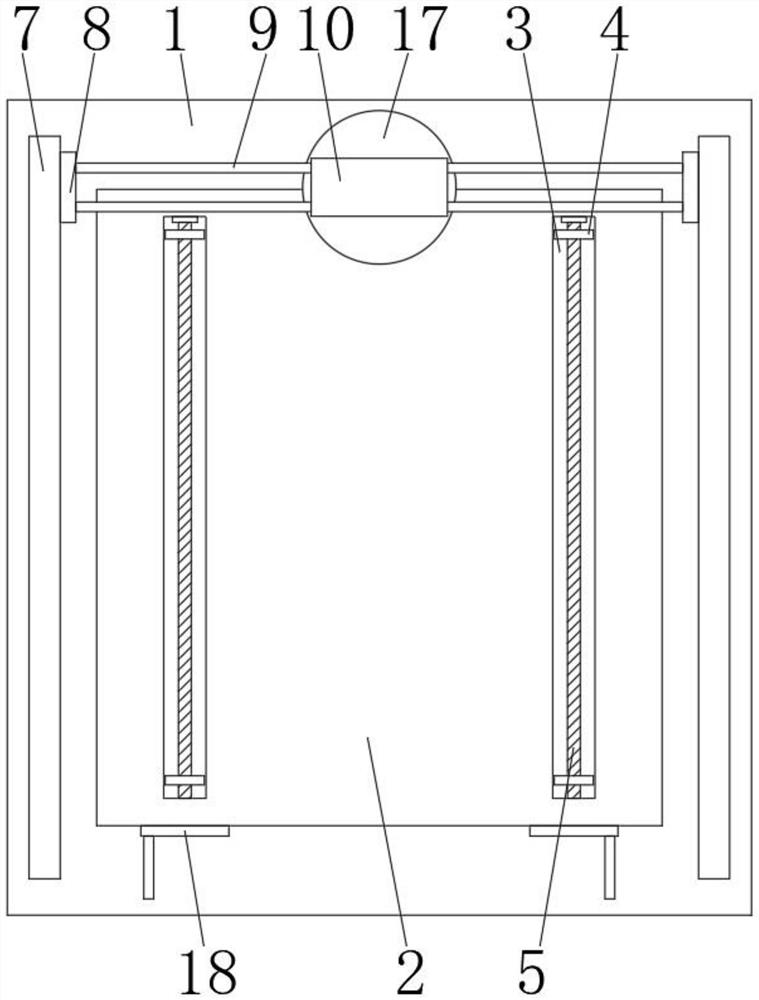

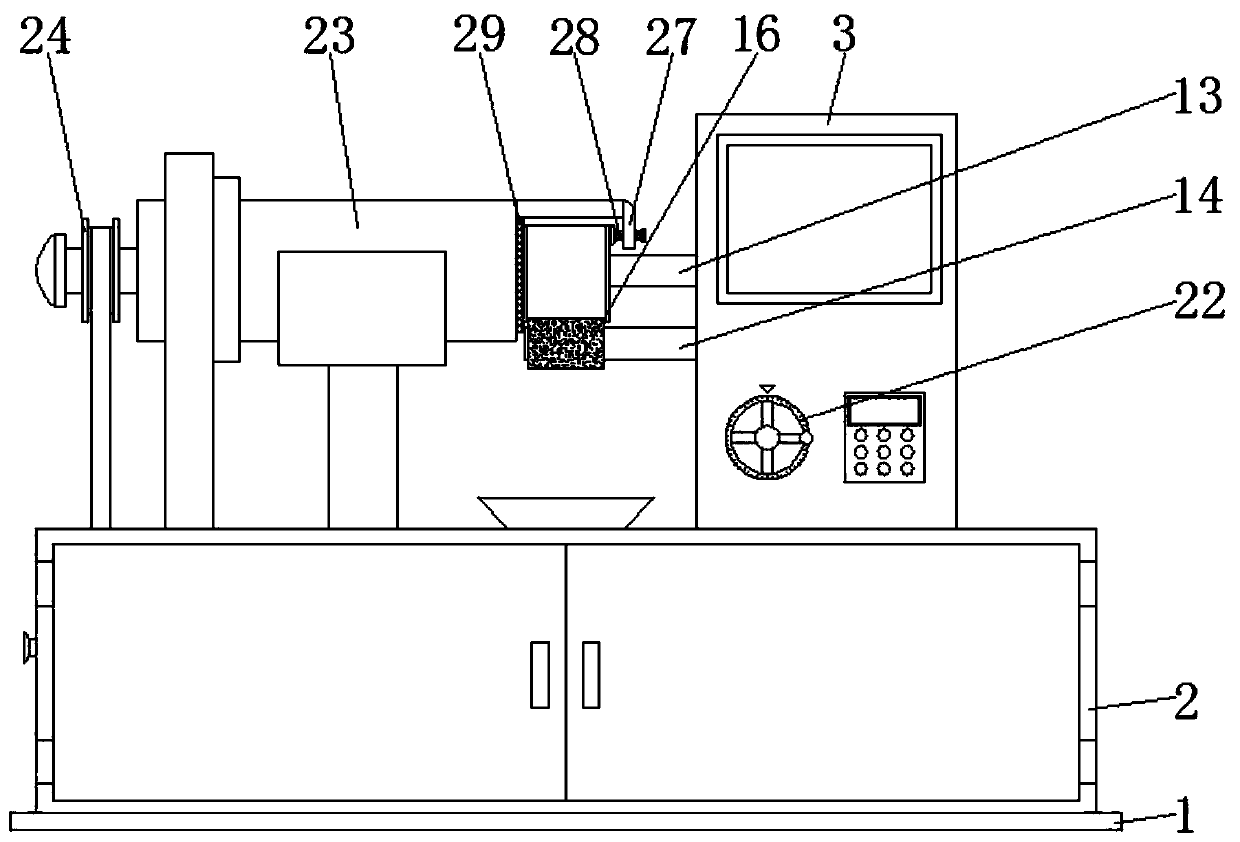

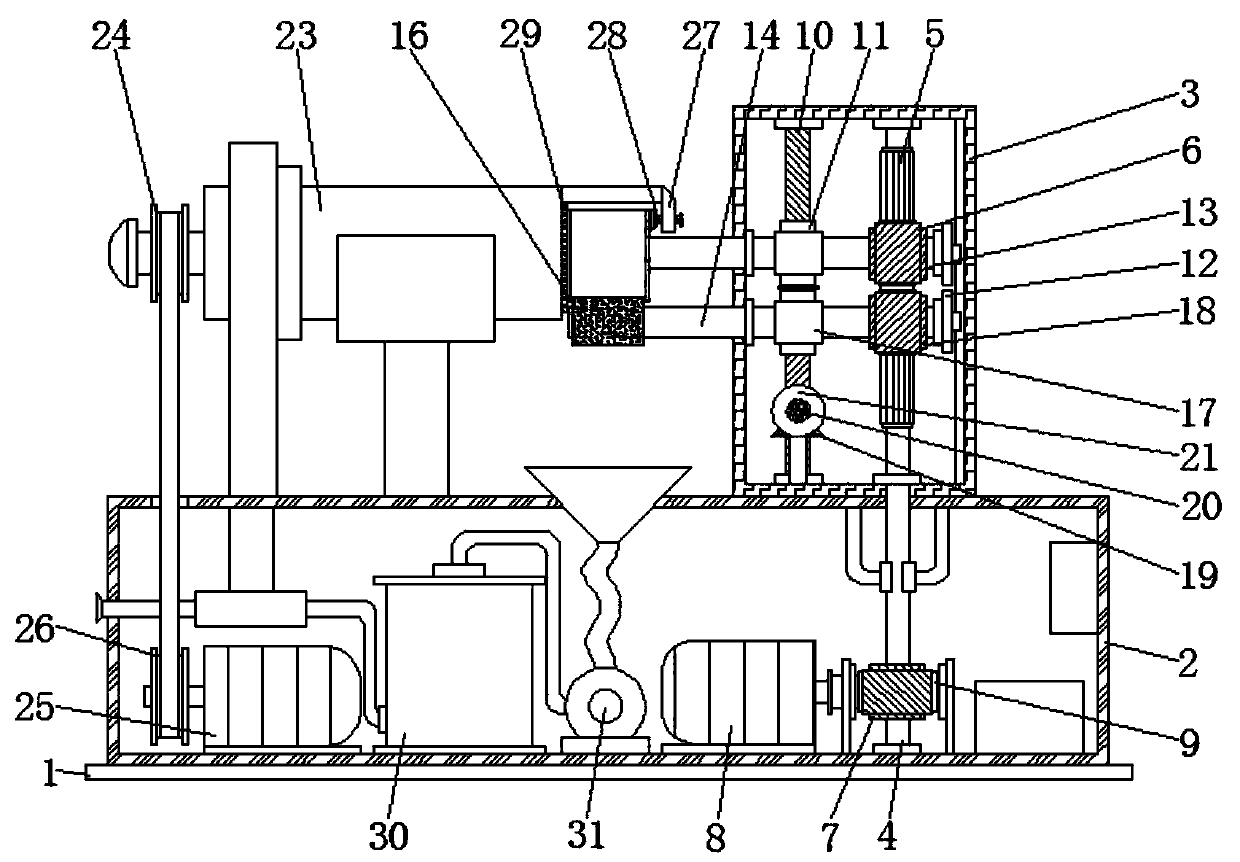

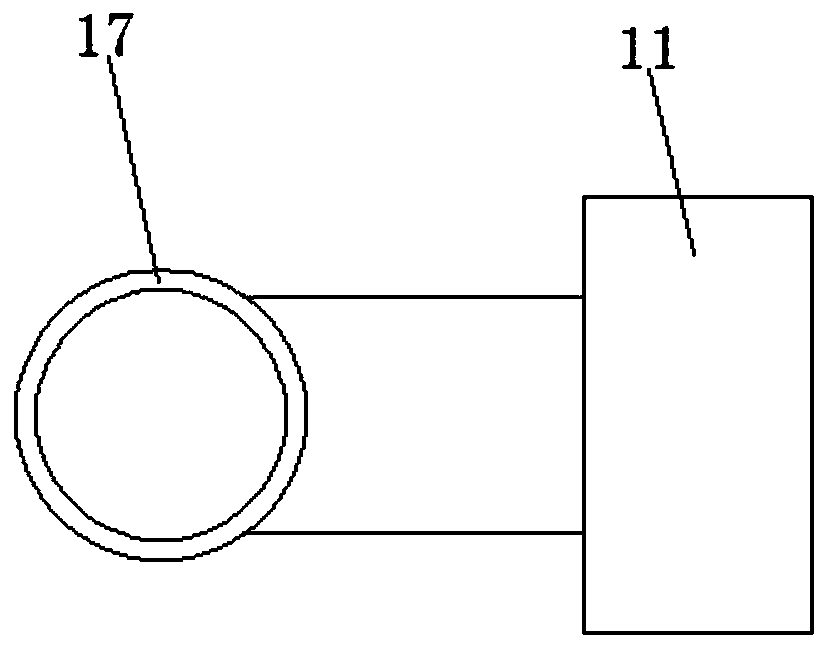

Quartz stone polishing machine

ActiveCN109773645AEasy to grind and polishAvoid affecting work efficiencyPolishing machinesGrinding drivesEngineeringMechanical engineering

The invention relates to a polisher, in particular to a quartz stone polishing machine. According to the technical scheme, the quartz stone polishing machine can polish quartz stones instead of manuallabor, so that it is avoided that the working efficiency is reduced because a worker aches in hands, and the quartz stone polishing machine can further spray cooling fluid onto the quartz stones. According to the technical scheme, the quartz stone polishing machine comprises a base, a frame body, first bearing blocks and the like, wherein the frame body is fixedly connected with the top of the base, a water inlet is formed in the left side of the bottom of the frame body, and the first bearing blocks are fixedly connected with the upper part of the left side and the upper part of the right side of each of the front side face and the rear side face of the frame body respectively in an inlaid manner. According to the quartz stone polishing machine, by starting up a first driving motor, a conveyer belt can rotate forwards, a polishing wheel can move upwards and downwards at the same time, then a servo motor is started up to make the polishing wheel rotate, one quartz stone is placed ontothe conveyer belt and moves rightwards, the polishing wheel carries out polishing on the quartz stone, it is not needed that a worker holds a polisher by hands to polish the quartz stone, labor is saved, and furthermore, it is avoided that the working efficiency is reduced because the worker aches in hands.

Owner:佛山市南海区卓迪机械有限公司

Polishing device for mechanical accessory processing

InactiveCN111468997AMobile real timeEasy to grind and polishRevolution surface grinding machinesGrinding drivesElectric machineryEngineering

The invention belongs to the technical field of machining, and in particular relates to a polishing device for mechanical accessory processing. The polishing device comprises a cabinet. A driving motor is fastened to the cabinet through a bolt, an output shaft of the driving motor is rotatably connected to a polishing wheel, a housing is arranged outside the polishing wheel, the housing is weldedand fixed to the cabinet, a thrusting plate is arranged on the side, far away from the cabinet, of the housing, the thrusting plate is slidably connected to the housing, a servo motor is fixedly arranged on one side of the housing, and an output shaft of the servo motor penetrates the housing. A tubular product is placed between clamping plates. When a hydraulic air cylinder works, the hydraulic air cylinder stretches to push the clamping plates to be close to each other till a rotary wheel is attached to the tubular product. When the servo motor works, an output shaft of the servo motor drives a screw to rotate, so that a sliding seat drives the thrusting plate to move synchronously through a screw, and therefore, it is convenient for people to move the tubular product in real time through the servo motor when polishing the tubular product.

Owner:JIAXING UNIV

Machining fixing device for special-shaped steel pipe

ActiveCN111906652AAchieve fixationAchieve dilation fixationGrinding carriagesPolishing machinesSteel tubeManufacturing engineering

The invention relates to the technical field of special-shaped steel pipe machining, in particular to a machining fixing device for a special-shaped steel pipe. The device comprises a supporting mechanism, two clamping mechanisms, a material lifting mechanism and a dust receiving mechanism. When a steel pipe of a semi-circular structure is machined, the inner wall of the steel pipe of the semi-circular structure is fixed through the two clamping mechanisms with the side walls of the arc-shaped structures, meanwhile, steel pipes of different types and of semi-circular structures are expanded and fixed, and the surface of the steel pipe of the semi-circular structure can be comprehensively ground and polished. The surface of the supporting mechanism is slidably connected with the material lifting mechanism located between the two clamping mechanisms, the two clamping mechanisms are loosened when the ground semicircular steel pipe is cut, the material lifting mechanism is adjusted to abutagainst the bottom of the semicircular steel pipe, and saw clamping is avoided; and the dust receiving mechanism used for storing sundries falling when the semicircular steel pipe is cut is installedat the bottom of the supporting mechanism, when the steel pipe is cut, chippings fall into the dust receiving mechanism, and cleaning is convenient.

Owner:中汇钢管制造有限公司

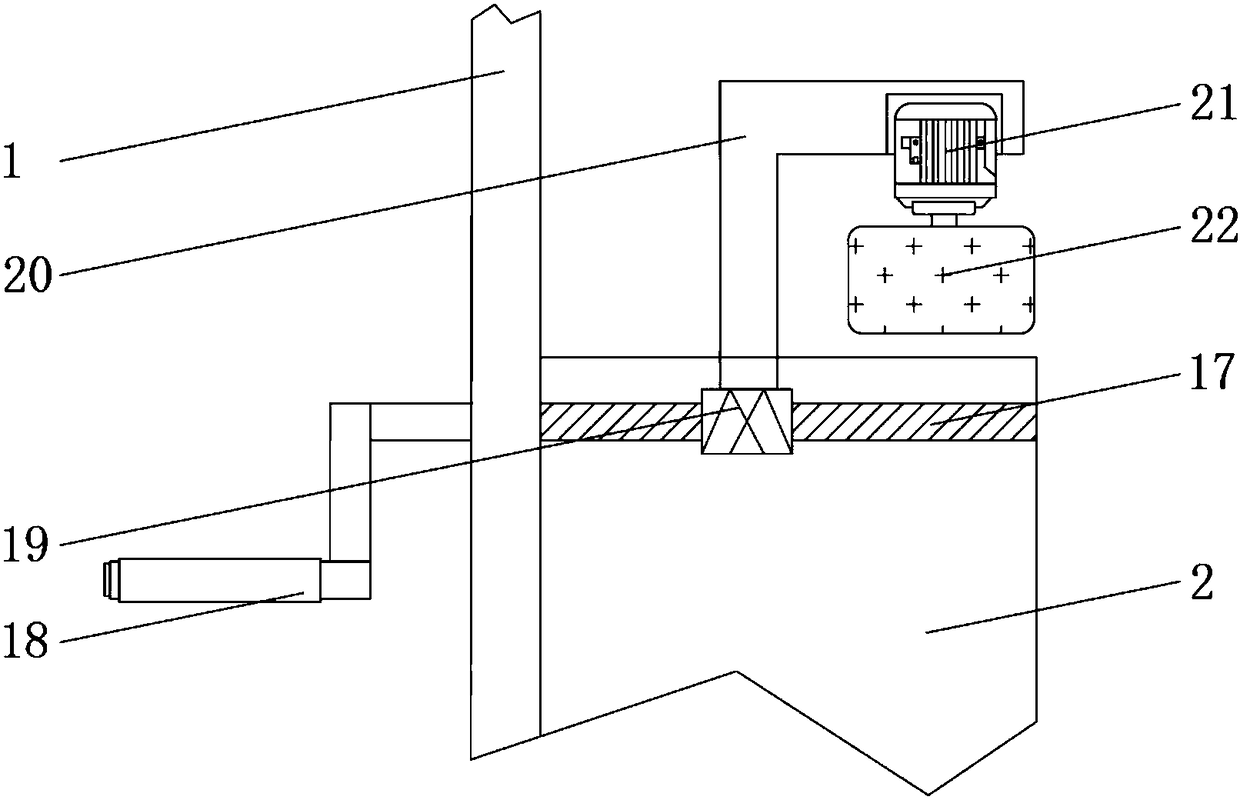

Vacuum glass repairing device used for polishing

PendingCN110561210AEasy to fixEasy to polishGrinding drivesGrinding work supportsHydraulic cylinderArchitectural engineering

The invention discloses a vacuum glass repairing device used for polishing in the technical field of vacuum glass repairing. The vacuum glass repairing device comprises a bottom plate. The left side of the top of the bottom plate is connected with a sliding device in a sliding manner. A transmission box is connected to the top of a rotary disc. An opening is formed in the right side wall of the transmission box, and a screw rod is vertically arranged in an inner cavity of the transmission box. The top of the screw rod penetrates the top of the transmission box and is connected with a crank. The outer side wall of the circumference of the screw rod is in screw joint with a screw rod nut. The right side of the screw rod nut is fixedly connected with a connecting plate, and the right side ofthe connecting plate is fixedly connected with a first hydraulic cylinder. The telescopic end of the right side of the first hydraulic cylinder is provided with a motor through a motor base, and the power output end of the bottom of the motor is provided with a grinding wheel. A worktable is arranged on the right side of the top of the bottom plate. By means of the vacuum glass repairing device, the polishing face of vacuum glass can be flat, the polishing efficiency is high, the labor force of workers is saved, and the vacuum glass repairing device can be widely applied conveniently.

Owner:JIANGSU JINGTAI GLASS CO LTD

Rapid polishing and grinding equipment for circular semiconductor materials

InactiveCN112428100AEasy to grind and polishImprove work efficiencyGrinding carriagesGrinding drivesRatchetSemiconductor materials

The invention relates to the technical field of semiconductor materials, and discloses rapid polishing and grinding equipment for circular semiconductor materials. The equipment comprises a fixing frame; a workbench is movably connected with the upper portion of the fixing frame; and a rotating wheel is movably connected with the upper portion of the workbench. Four clamping jaws can fixedly clampand release the circular materials through the cooperation of an ejecting rod, pushing plates, a push rod, a hinge rod, a toothed plate, a positioning gear, and a transmission gear; when the push rodcontinues to descend, the materials can be pressed on the workbench through an arc-shaped pressing block, so that grinding and polishing are facilitated; the polishing and grinding process and the feeding process can be conducted at the same time through the action of the upper set of push plates, the lower set of push plates and the push rod; and through the cooperation of an electromagnetic push block, a moving rod and a clamping block, a ratchet wheel can drive the ejecting rod or the whole rotating wheel to rotate together, so that the switching of the upper set of clamping jaws and the lower set of clamping jaws is facilitated, the repeated feeding time in the polishing and grinding process is saved, the working efficiency is improved, and the practicability of the equipment is further improved.

Owner:广州创春商贸有限公司

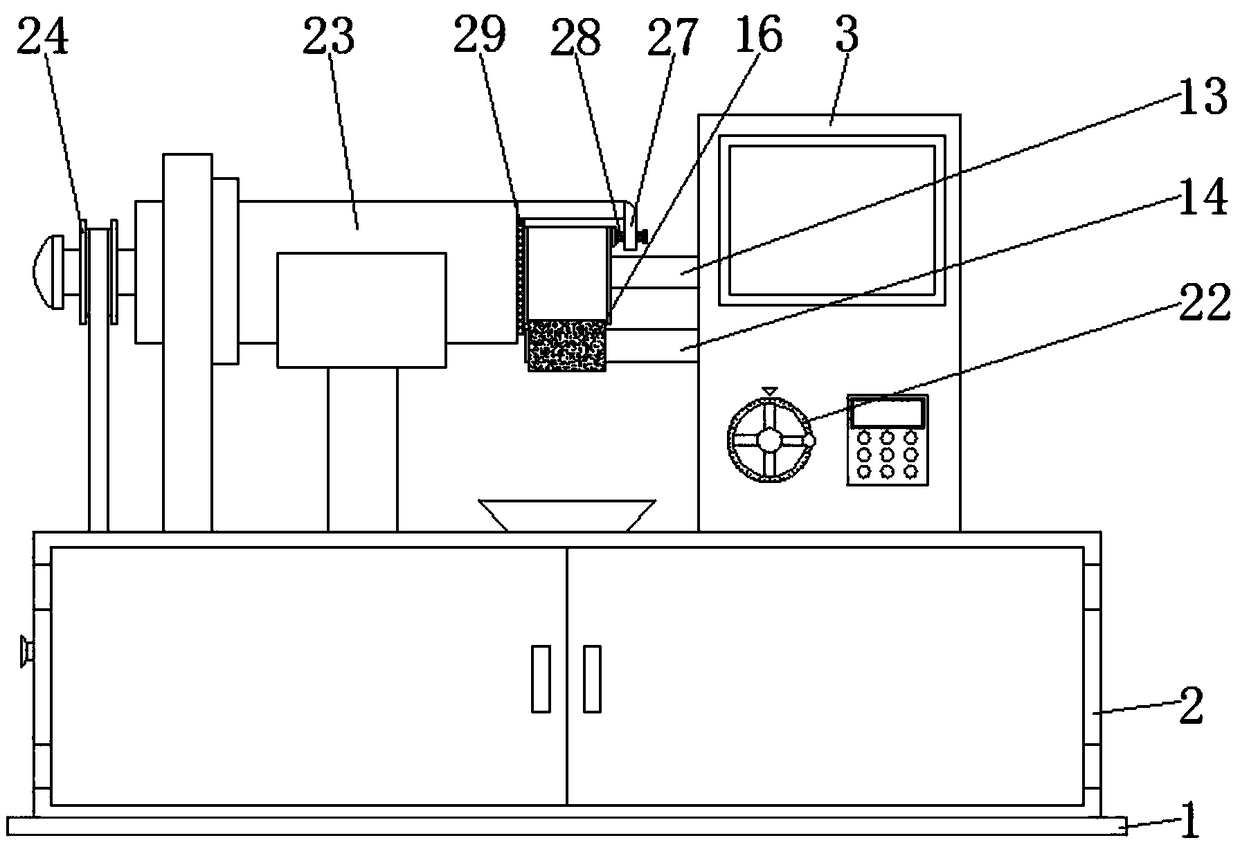

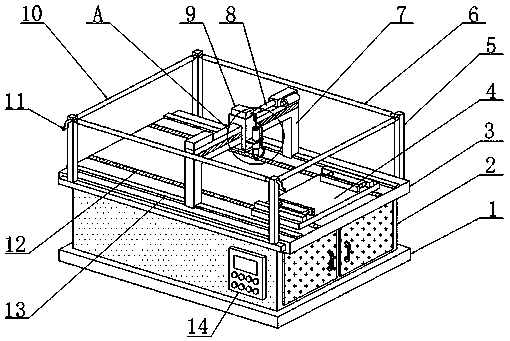

Novel numerical control machine tool with protection function

InactiveCN108857448AEasy to lockEasy to handleOther manufacturing equipments/toolsSputteringNumerical control

The invention discloses a novel numerical control machine tool with a protection function. The novel numerical control machine tool with the protection function comprises a base, wherein the upper endof the base is provided with a machine box; a control box is arranged in the position, near one side surface of the machine box, of the upper end of the base; a work table is arranged at the upper end of the machine box. The locking device is used for positioning a workpiece; in addition, a storage groove in the locking device is used for conveniently collecting waste chips; through a pressure sensor and an air blowing hole, waste chips generated during punching can be blown into the storage grooves; the punching high temperature generated during the punching in the punching position can alsobe reduced; through a polishing wheel, burrs on the hole opening are ground and polished; the hole opening attractive degree is improved; the damage to workers due to burrs in the punching position of the workpiece is also avoided; meanwhile, a laminar flow hood is installed, so that waste chips generated when the numerical control machine tool works can be conveniently prevented from influencingthe work environment through the sputtering in any directions; the workers can also be protected; the collision injury to workers due to waste chip sputtering is prevented.

Owner:台山市向友五金制品有限公司

Shell surface polishing equipment for appliance processing

InactiveCN110883671AInsert to ensureImprove cleanlinessPolishing machinesGrinding drivesGear wheelElectric machinery

The invention relates to the field of appliance processing, in particular to shell surface polishing equipment for appliance processing. The shell surface polishing equipment for appliance processingcomprises a connecting frame. A connecting groove is fixedly formed in the connecting frame, the inner side of the connecting groove is connected to a connecting gear through a connecting shaft, a first motor is mounted on the upper side of the connecting shaft at the left end, the first motor is mounted on the upper side of the connecting groove, an outer gear is engaged to the inner side of theconnecting gear, the outer gear is connected to a mounting seat through a connecting ring, a first insertion slot is formed in the upper side of the mounting seat, a second insertion slot is formed inthe lower side of the mounting seat, a first connecting hood is inserted onto the lower end of the second insertion slot, a discharge pipe is arranged on the lower side of the first connecting hood,a storage cavity is formed in the lower side of the discharge pipe, an exhaust column is arranged on the outer side of the storage cavity, an exhaust pump is mounted on the exhaust column located in the connecting frame, and movable polishing equipment is arranged on the top of the connecting frame. The shell surface polishing equipment for appliance processing can guarantee the surrounding working environment effectively, so that the environment and health of surrounding staff can be protected.

Owner:宁夏天地经纬电力设备工程有限公司

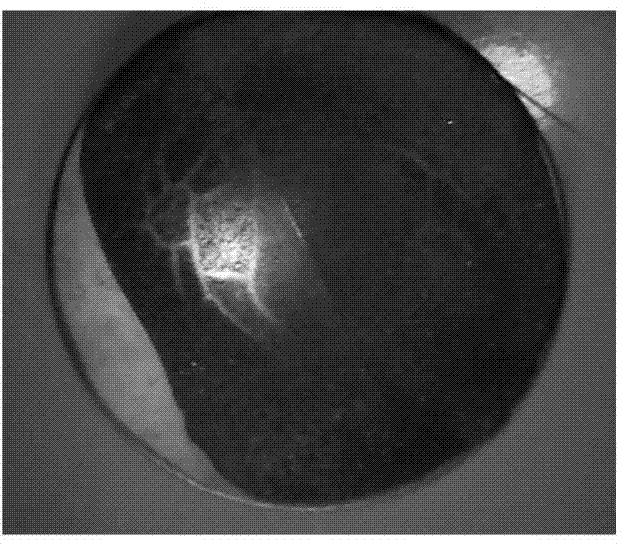

Special polishing liquid for diamond compact and preparation method of special polishing liquid

ActiveCN104497886AImprove efficiencyLow costPolishing compositions with abrasivesKeroseneMachining process

The invention discloses special polishing liquid for a diamond compact and a preparation method of the special polishing liquid, and belongs to the field of precise and ultra-precise polishing. The special polishing liquid is developed to solve the problem that common polishing liquid cannot meet ultra-precise mirror finishing of ultrahard materials including the diamond compact and the like. The polishing liquid is prepared from the following materials according to certain volume ratios: 5% of a brightening agent, 5% of diamond micro powder, 10% of Vaseline, 20% of mixed fat and 60% of kerosene; and a diamond compact workpiece processed by the polishing liquid is uniform in surface quality, does not have polishing defects and can achieve a mirror polishing effect. Meanwhile, the polishing liquid can also achieve effects of cooling, lubricating, adsorbing and cleaning during processing, can also be used for mirror polishing processing of similar ultrahard materials, and is simple to operate, high in efficiency, low in cost and pollution-free.

Owner:中恒华创(山东)技术服务有限公司

Profile cutting device

InactiveCN107718107AEasy to grind and polishSave powerMetal working apparatusStress concentrationEngineering

A profile cutting device provided by the present invention includes a mounting base and a lifting shaft rotatably arranged on the mounting base. A cutting mechanism is provided on the top of the lifting shaft, and the cutting mechanism includes a first blade mounting frame and a lifting shaft set The second blade mounting frame, the first blade mounting frame and the second blade mounting frame are provided with a plurality of cutting blades, and the cutting blades are arranged in the first blade mounting frame and the second blade mounting frame through a telescopic mechanism , different processing forms can be adjusted between the first blade mounting frame and the second blade mounting frame. When the profile needs to be cut from the outside, only the cutting blade in the second blade mounting frame is required to cut the profile. When cutting outward from the inside of the profile, the first blade mounting frame and the second blade mounting frame extend outward after entering into the profile, and cut the profile from the inside to the outside. Multiple cutting blades can increase the contact area between the blade and the profile to avoid stress concentration.

Owner:扬州丽合华工程建设有限公司

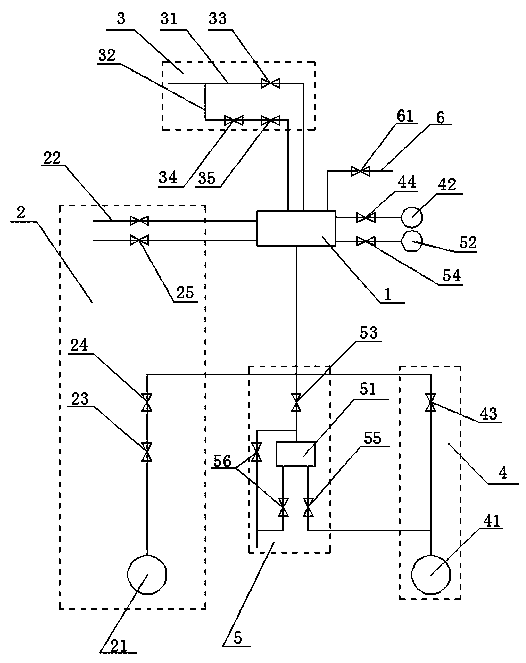

vacuum equipment

ActiveCN104832398BGuaranteed accuracyAvoid damagePump testingPositive displacement pump componentsSystems designProcess engineering

The vacuum equipment of the present invention belongs to the technical field of vacuum equipment; the technical problem to be solved is to provide vacuum equipment, improve the structural design of the vacuum system through work practice, add filter valves, reduce the impact of gas internal residues on high-pressure vacuum pumps, and add The low vacuum gauge and high vacuum gauge accurately measure the inside of the system to control the accuracy of the equipment. At the same time, the multi-valve series connection method is used to ensure the stability of the intake air, and the appropriate sealing method is selected to improve the sealing performance of the vacuum system, thereby reducing the air leakage of the system. efficiency and improve equipment safety performance; the technical solution adopted is: vacuum equipment, including vacuum chamber, process system, vacuum breaking system, low vacuum system and high vacuum system, and each system is connected with the vacuum chamber to realize low vacuum , high vacuum, process air intake and vacuum breaking; the invention can be widely used in the technical field of vacuum equipment.

Owner:CHANGZHI CITY HUAJIE GUANG TECH CO LTD

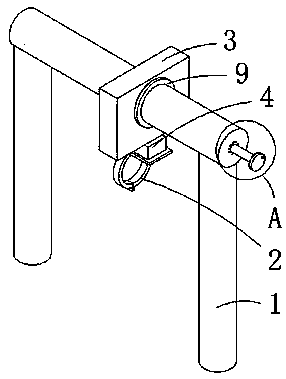

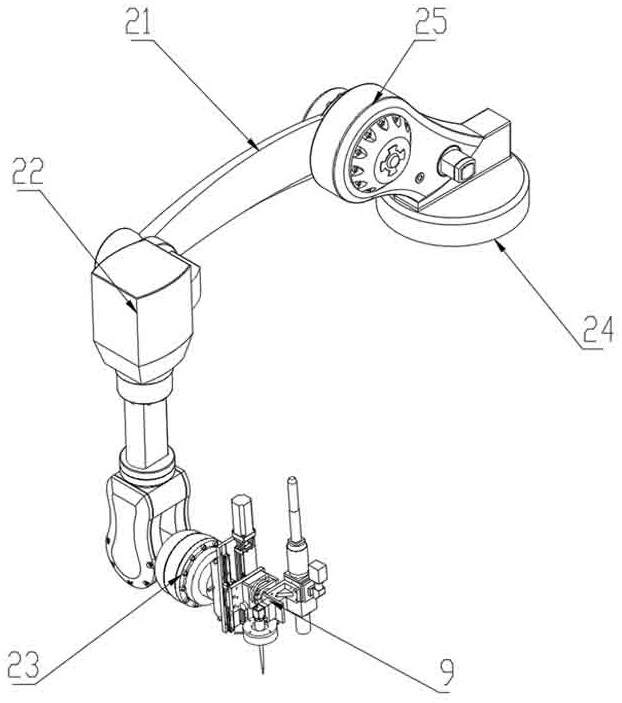

Precision-polishing gripper steering device for sand core die production

The invention discloses a precision-polishing gripper steering device for sand core die production. The precision-polishing gripper steering device for sand core die production comprises a U-shaped support rod, a gripper and a rotating plate, wherein a circular through hole is formed in the rotating plate; the rotating plate sleeves a top rod of the U-shaped support rod through the circular through hole; an annular plate for limiting the rotating plate from moving is fixedly connected onto the top rod of the U-shaped support rod; a connecting block is rotatably connected to the lower surface of the rotating plate; the upper end surface of the gripper is fixedly connected to the lower surface of the connecting block; a holding groove is formed in the lower surface of the top rod of the U-shaped support rod; a rotating rod is rotatably connected onto the side wall of the holding groove; and a groove for the rotating rod to move left and right is formed in the side wall of the holding groove. According to the precision-polishing gripper steering device for sand core die production provided by the invention, the direction of a precision-polishing gripper can be effectively adjusted, objects on the gripper can be conveniently ground and polished, the position of the precision-polishing gripper can be adjusted, the objects on the precision-polishing gripper can be conveniently pickedand replaced, and convenience is brought for working personnel.

Owner:ANHUI QUANCHAI TIANHE MACHINERY

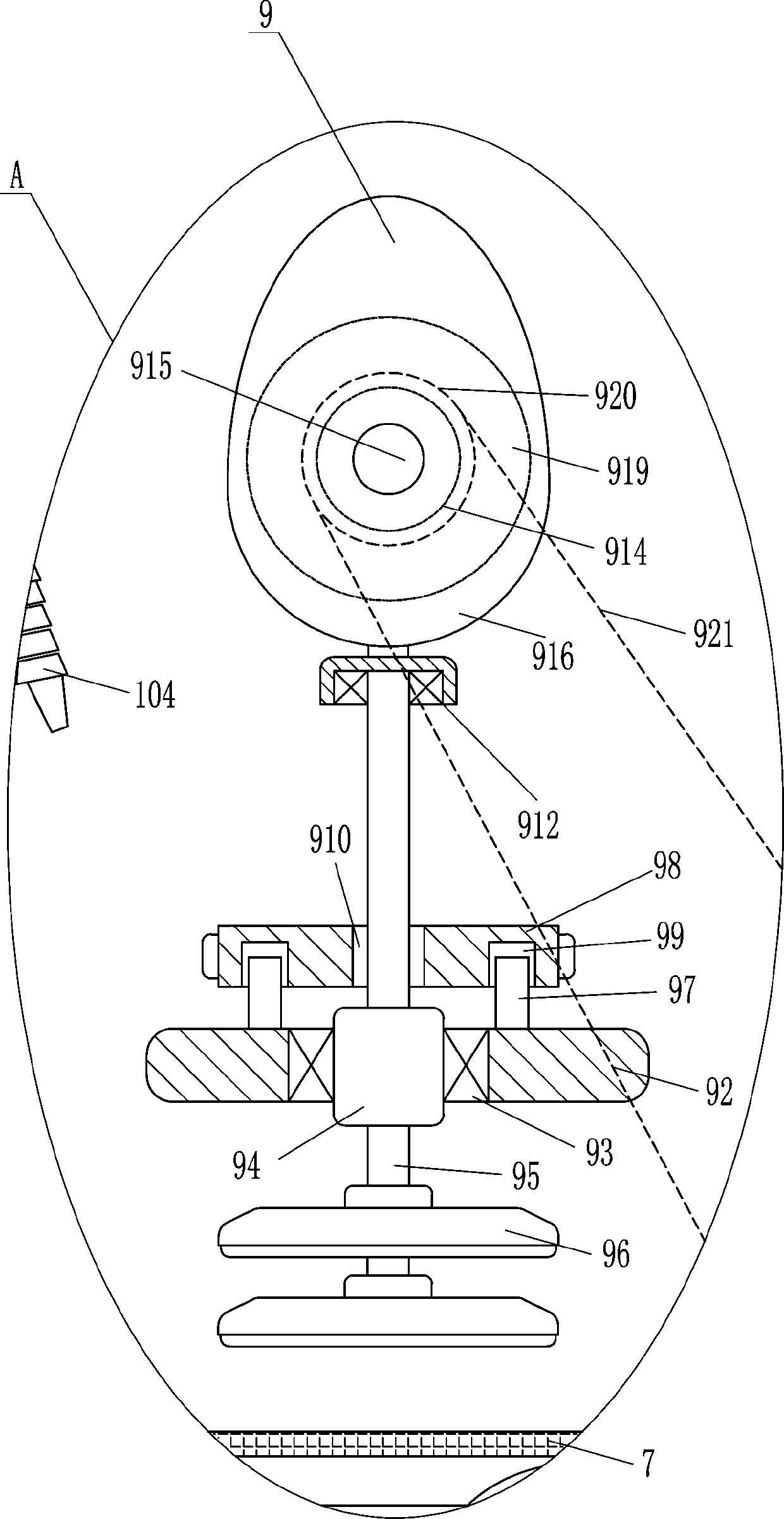

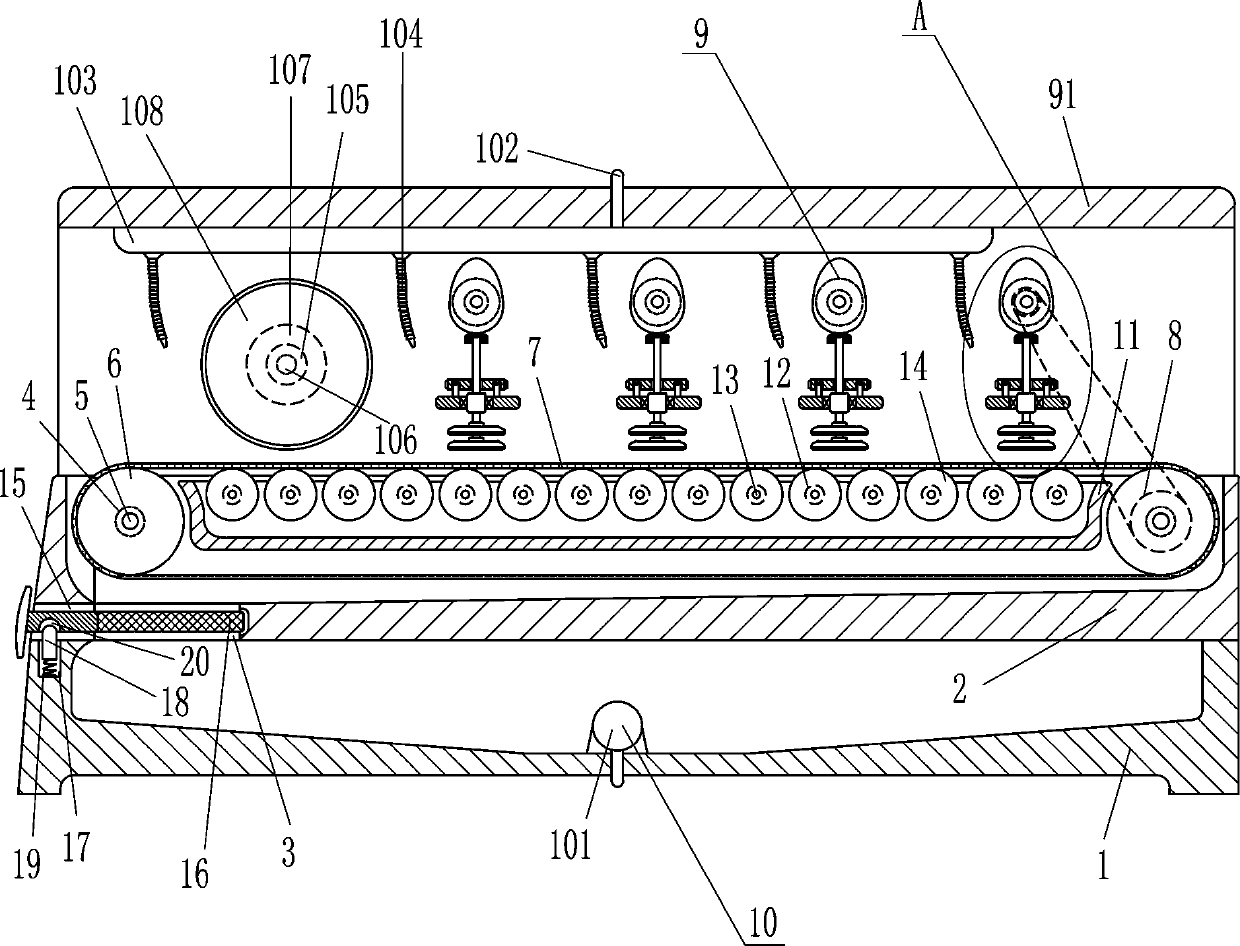

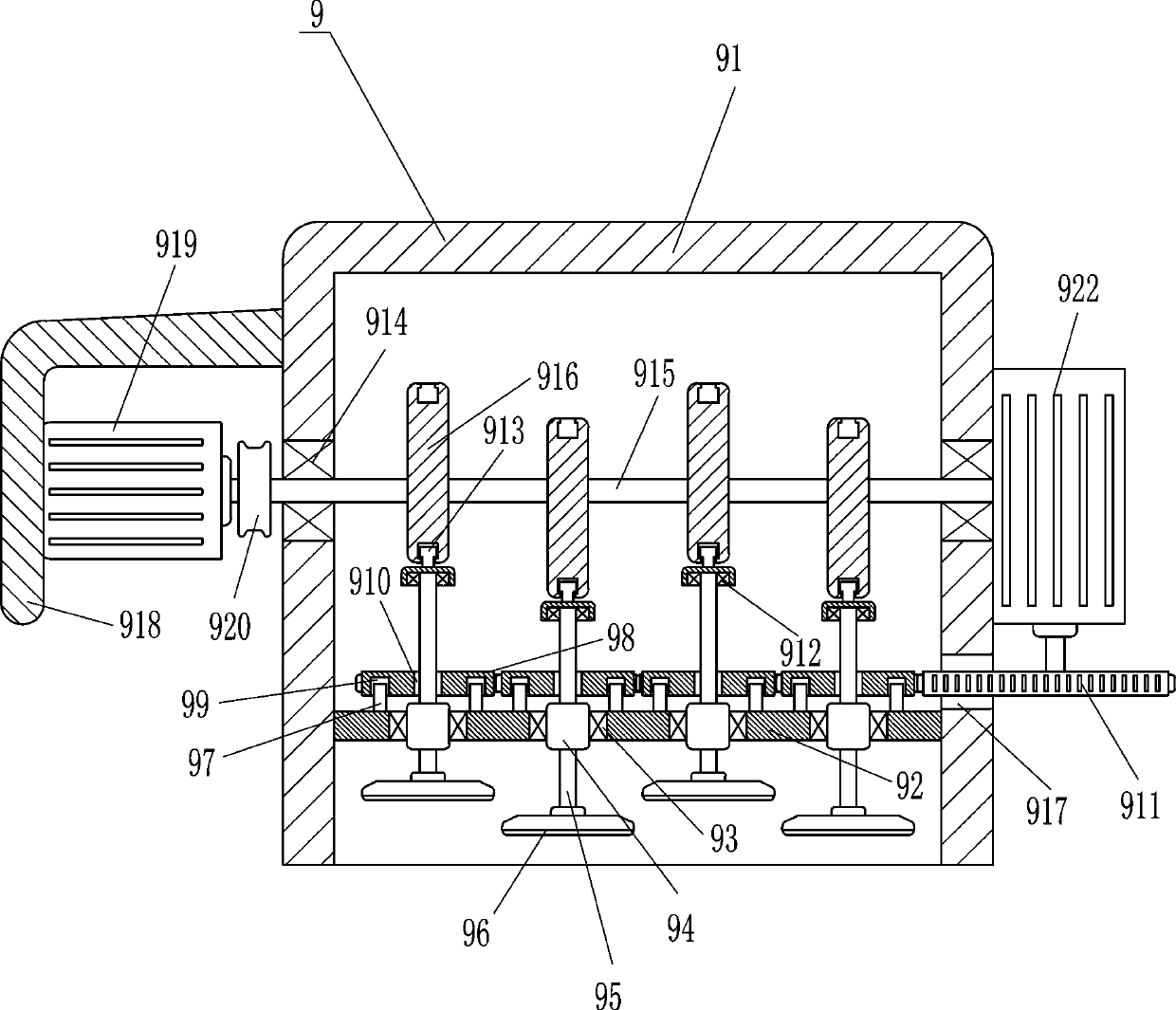

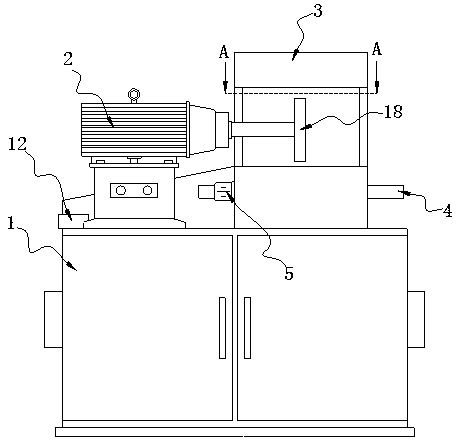

Double-motor water mill device for jade bracelet

InactiveCN105252356AGrinding and polishing evenlyEasy to grind and polishRevolution surface grinding machinesGrinding drivesVertical planeEngineering

The invention discloses a double-motor water mill device for a jade bracelet, and belongs to the field of ornament processing. The double-motor water mill device comprises a base and motors. A water tank, a water collecting trough and a tool kit are fixed onto the base. The first motor is fixed to the top of the water tank, and a clamp is fixed to the output shaft of the first motor. The second motor is fixed to the top of the tool kit, and a grinding wheel is fixed to the output shaft of the second motor and located below the clamp. The first motor and the second motor are opposite in rotating direction, and the axis of the first motor and the axis of the second motor are located in the same vertical plane. A water spraying pipe is connected to the water tank, and a nozzle of the water spraying pipe is aligned with the wheel surface of the grinding wheel; the water collecting trough is located below the grinding wheel. According to the scheme, the clamp, the grinding wheel and the motors are integrated on one device, the two motors are used for automatically grinding and polishing the jade bracelet, and people do not need to hold the jade bracelet by hand for grinding. The structure is compact, the occupied space is small, the labor intensity is relieved, and the processing efficiency is improved.

Owner:CHONGQING CHANGSHOU YIMEI ACCESSORIES PROCESSING MILL

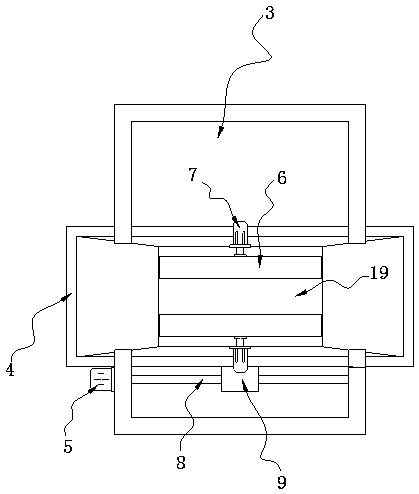

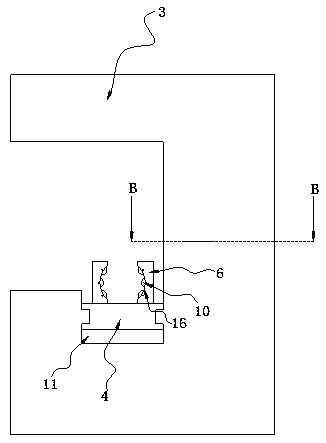

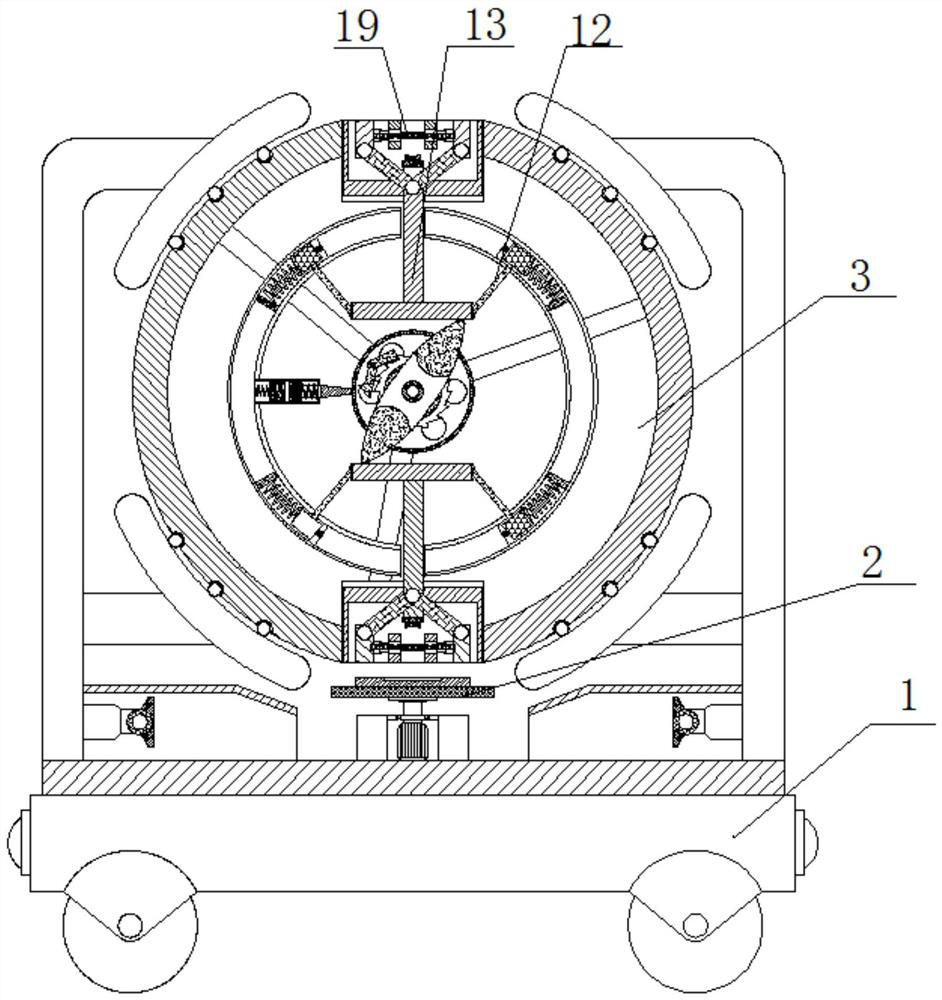

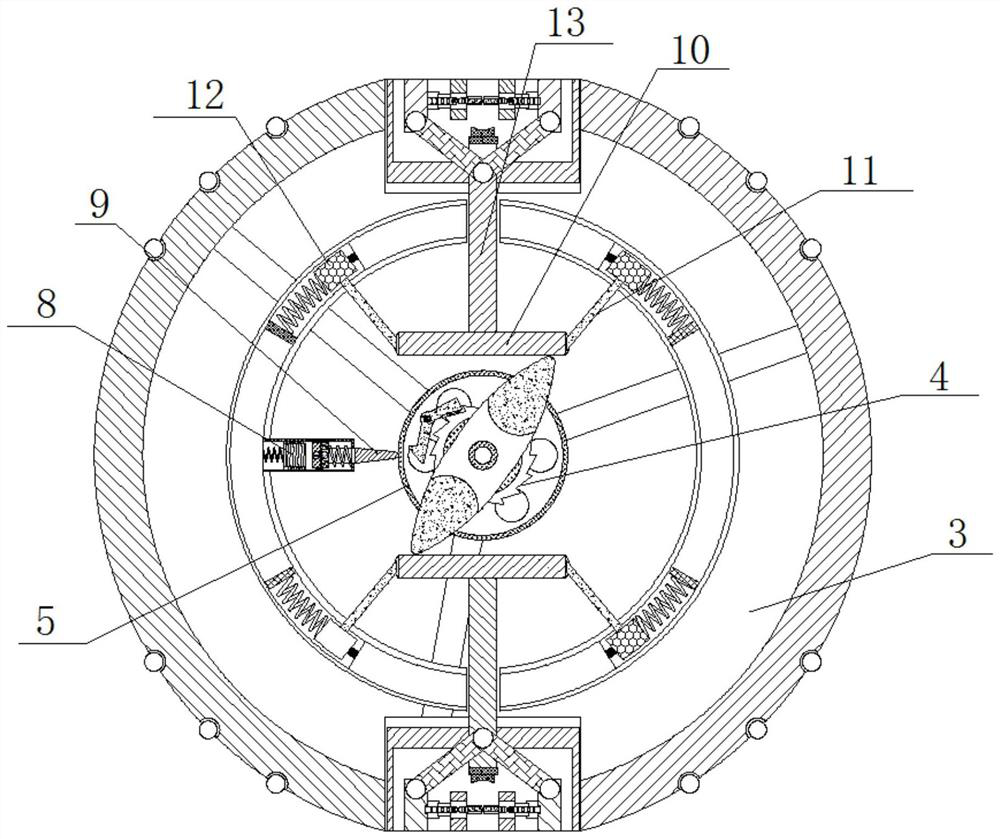

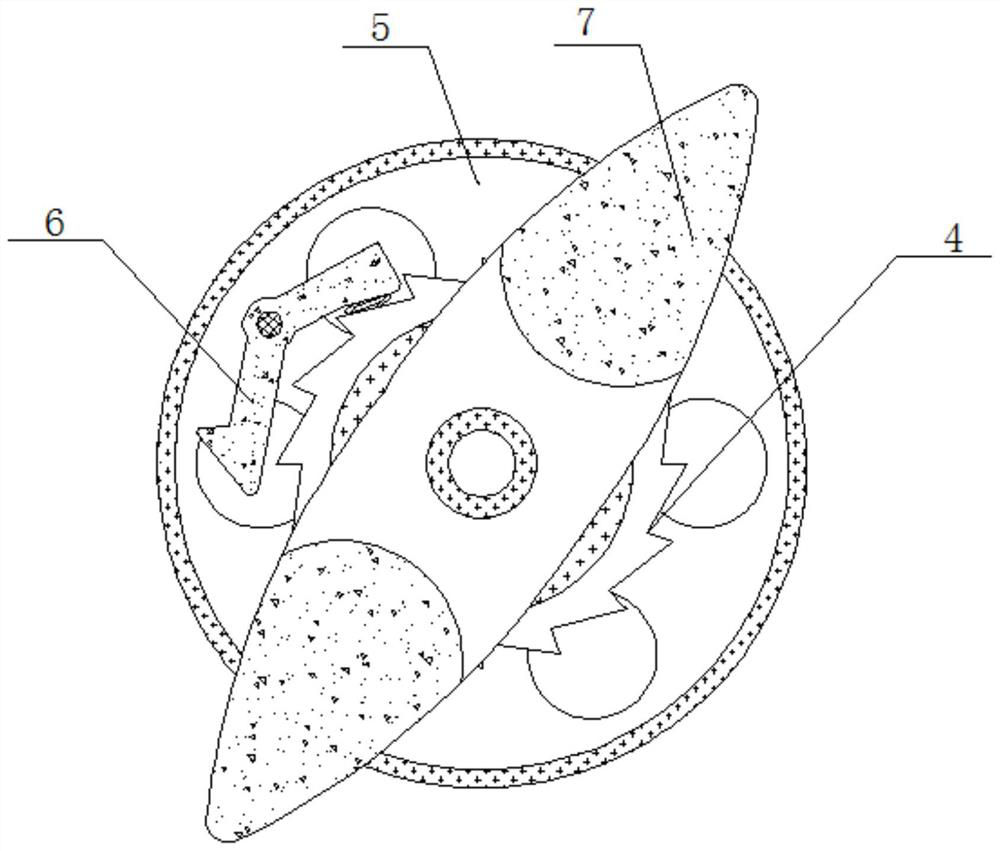

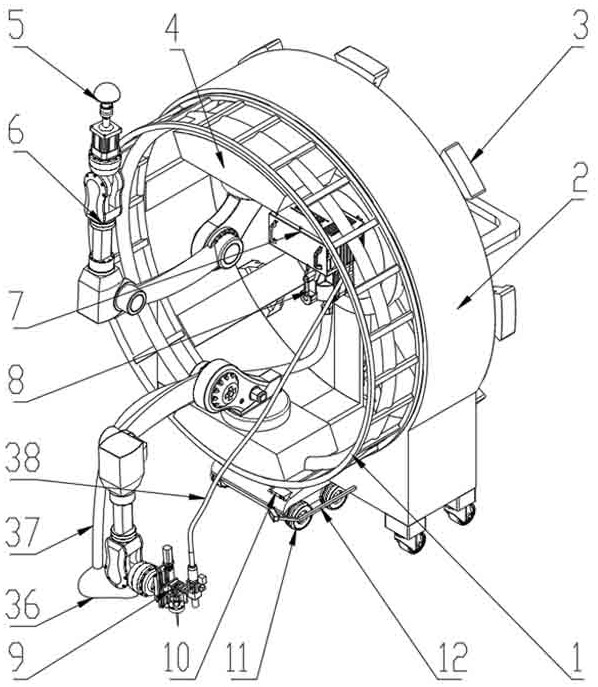

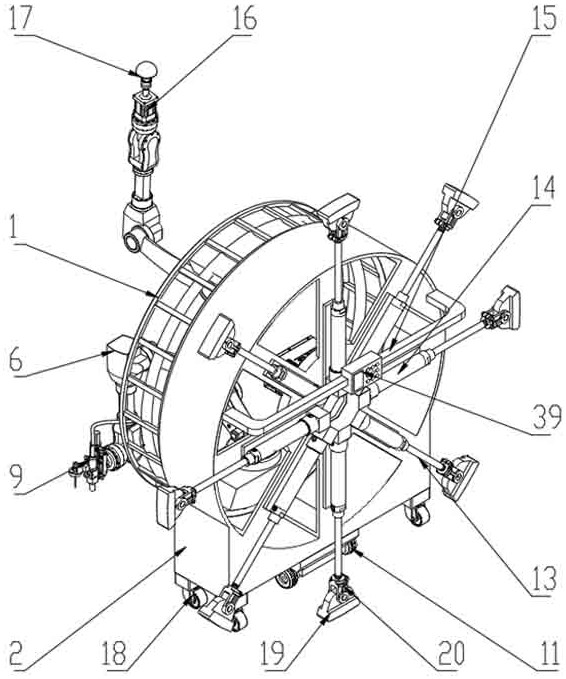

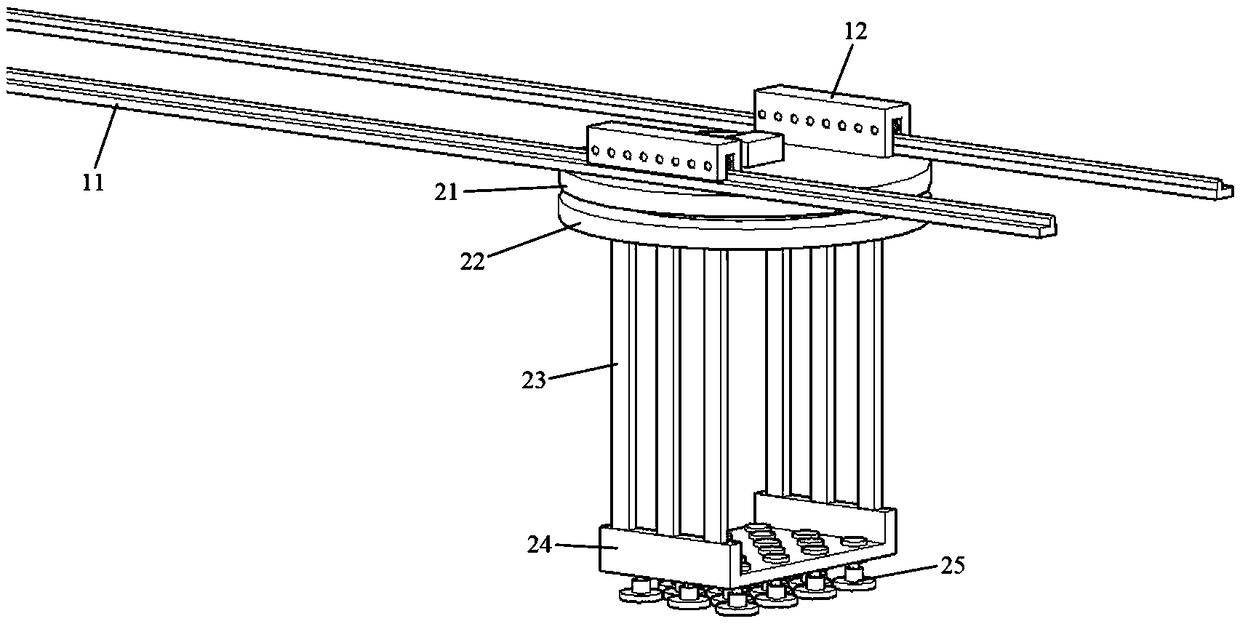

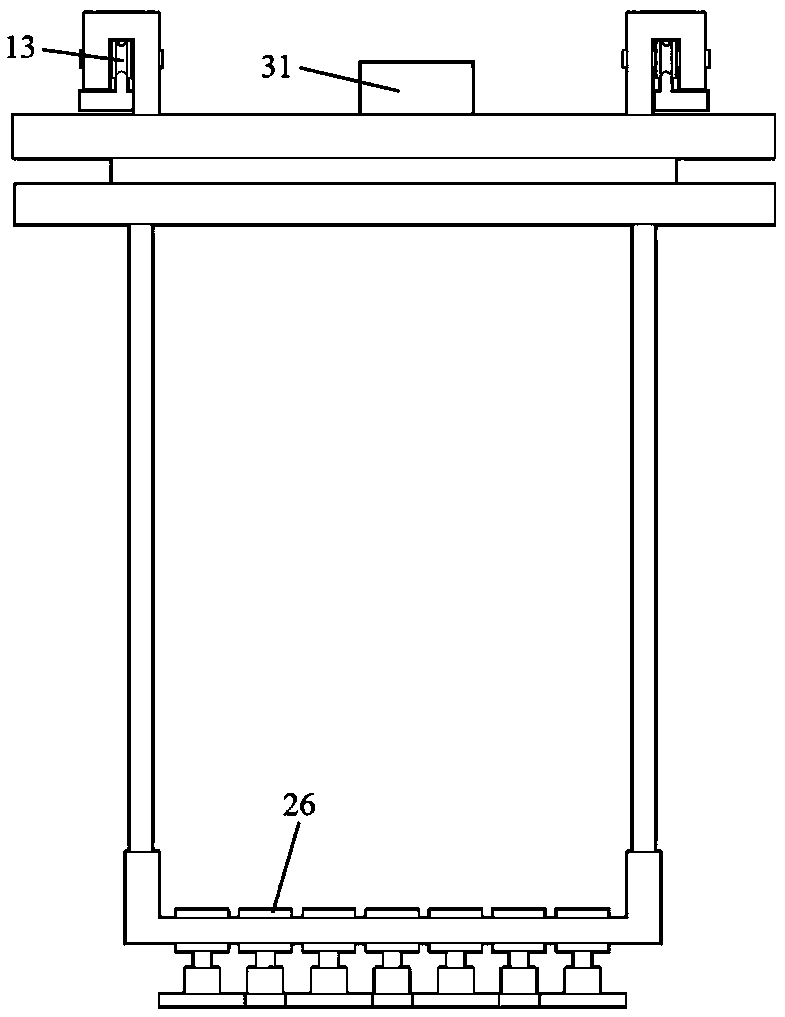

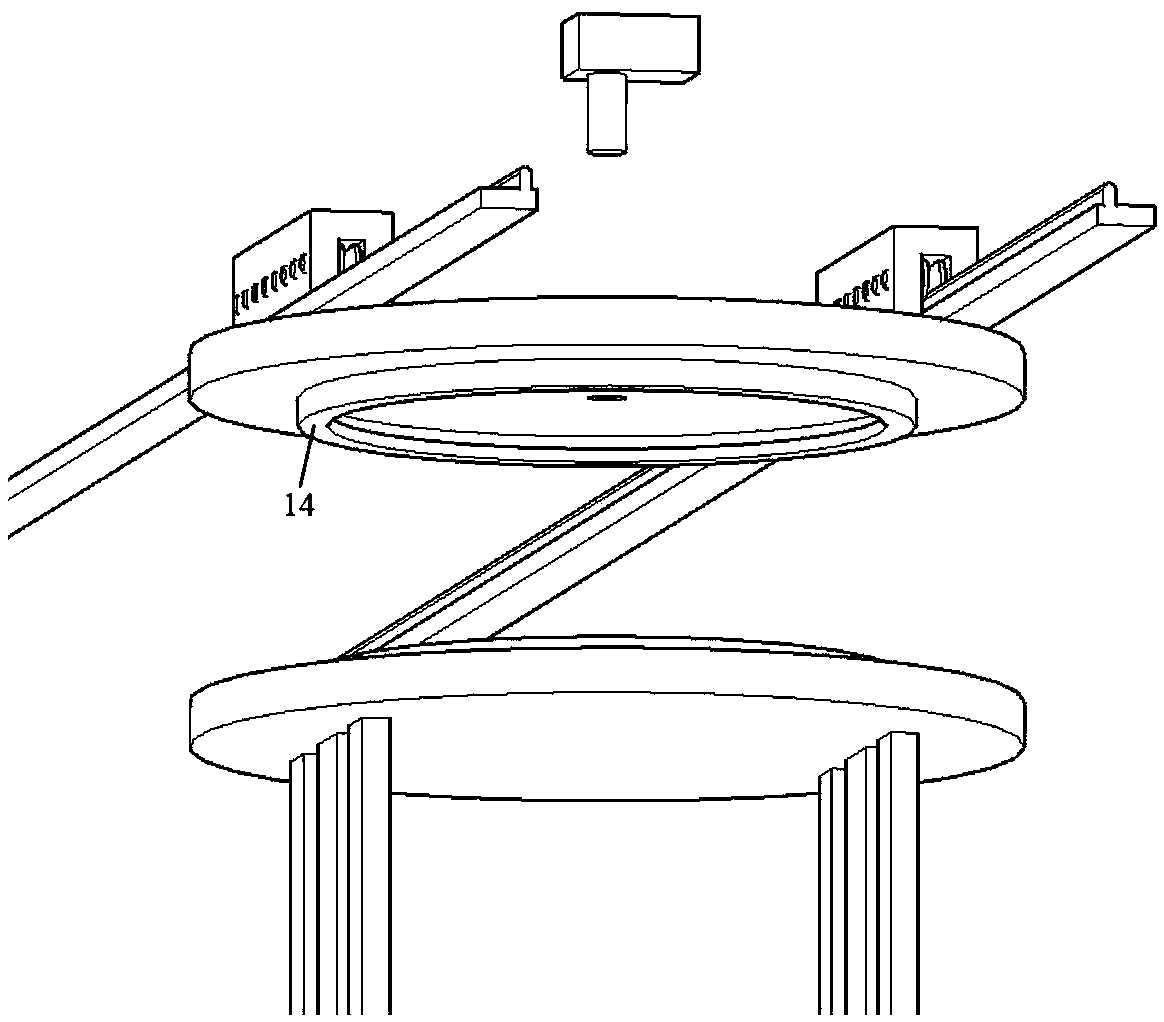

Automatic welding moving trolley for offshore wind power tower drum production

ActiveCN114012440AEasy to moveWalking smoothlyOther manufacturing equipments/toolsWind energy generationStructural engineeringOffshore wind power

The invention provides an automatic welding moving trolley for offshore wind power tower drum production, and belongs to the technical field of tower drum welding. The moving trolley is used for solving the problems that a large amount of manual operation is needed, the welding efficiency is low and the like when wind power tower drums are welded. The moving trolley comprises a mounting rack, an annular rail is arranged on the front side of the mounting rack, two symmetrical moving locomotives are arranged on the inner side of the annular rail, mechanical arm assemblies are arranged on the moving locomotives, and a grinding assembly and a welding head assembly are arranged on the two mechanical arm assemblies correspondingly; a rotating disc is rotationally arranged in the mounting rack; fixing connecting rods are arranged between the rotating disc and the two moving locomotives, a welding machine and a fan are arranged on the rotating disc, the welding machine is connected with a welding head assembly through a wire conduit, a walking motor vehicle is fixed to the lower side of the mounting rack, and a plurality of adjusting supporting assemblies which are evenly distributed in the circumferential direction are arranged on the rear side of the mounting rack; The trolley is convenient to move and stable in walking, can synchronously carry out circumferential welding and grinding and polishing, and has the functions of dust collection and welding detection.

Owner:中国水电四局(阳江)海工装备有限公司

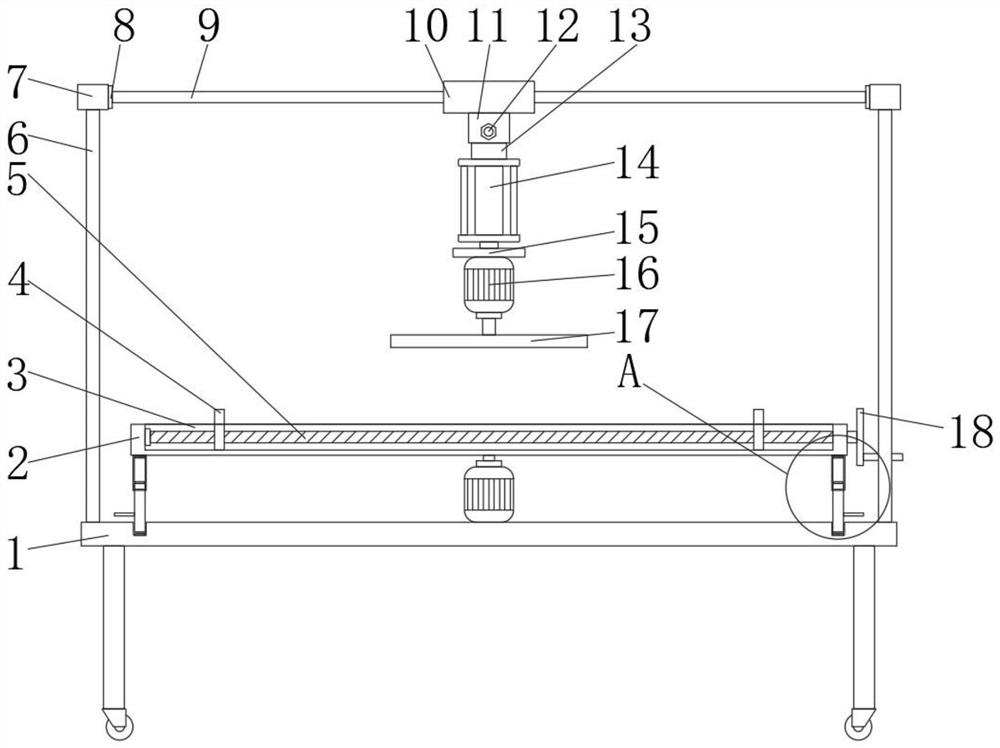

Wooden furniture grinding and polishing device convenient to adjust

InactiveCN112706024AMeet the needs of edge grindingAvoid manual manipulationEdge grinding machinesGrinding drivesPolishingEngineering

The invention discloses a wooden furniture grinding and polishing device convenient to adjust, and relates to the technical field of furniture machining.The wooden furniture grinding and polishing device convenient to adjust comprises a bottom plate, wherein a carrying plate is rotationally connected to the top surface of the bottom plate through an arranged rotary locating mechanism, a clamping mechanism is arranged on the carrying plate, and a grinding mechanism is further arranged on the bottom plate. According to the invention, the grinding mechanism of the device is used for grinding the wooden furniture clamped by the clamping mechanism on the carrying plate, the angle of the grinding mechanism of the device can be adjusted, then the edge and corner angle grinding requirement of grinding personnel for the furniture is met, and the situation that the grinding machine is manually operated, and the same angle and strength are kept for a long time is avoided; and a rotating mechanism is used for rotating, locating and fixing the carrying plate to be matched with the grinding mechanism to grind different edges and corners, and therefore certain convenience is brought to grinding and polishing of furniture users.

Owner:FUYANG WEIYE FURNITURE

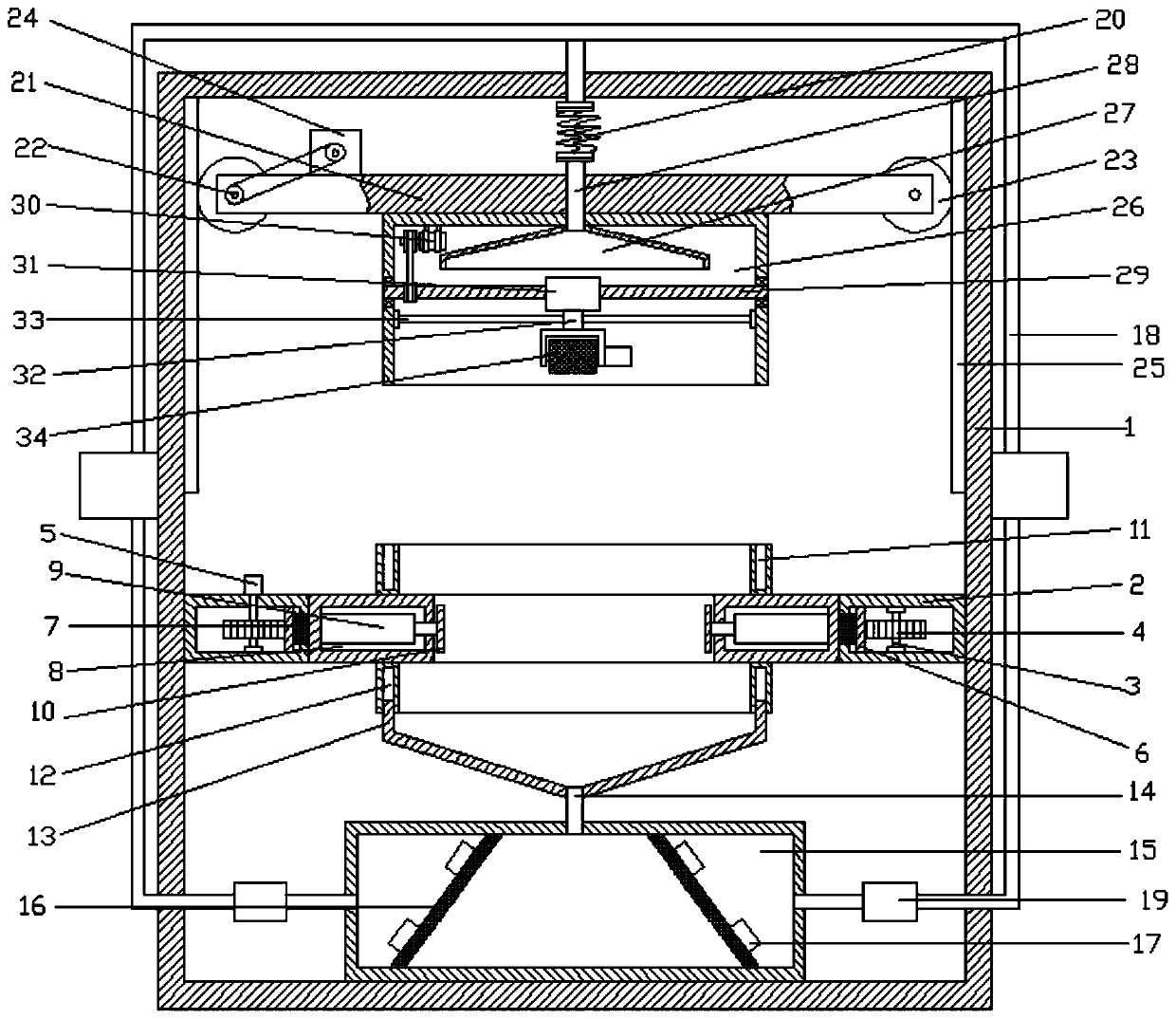

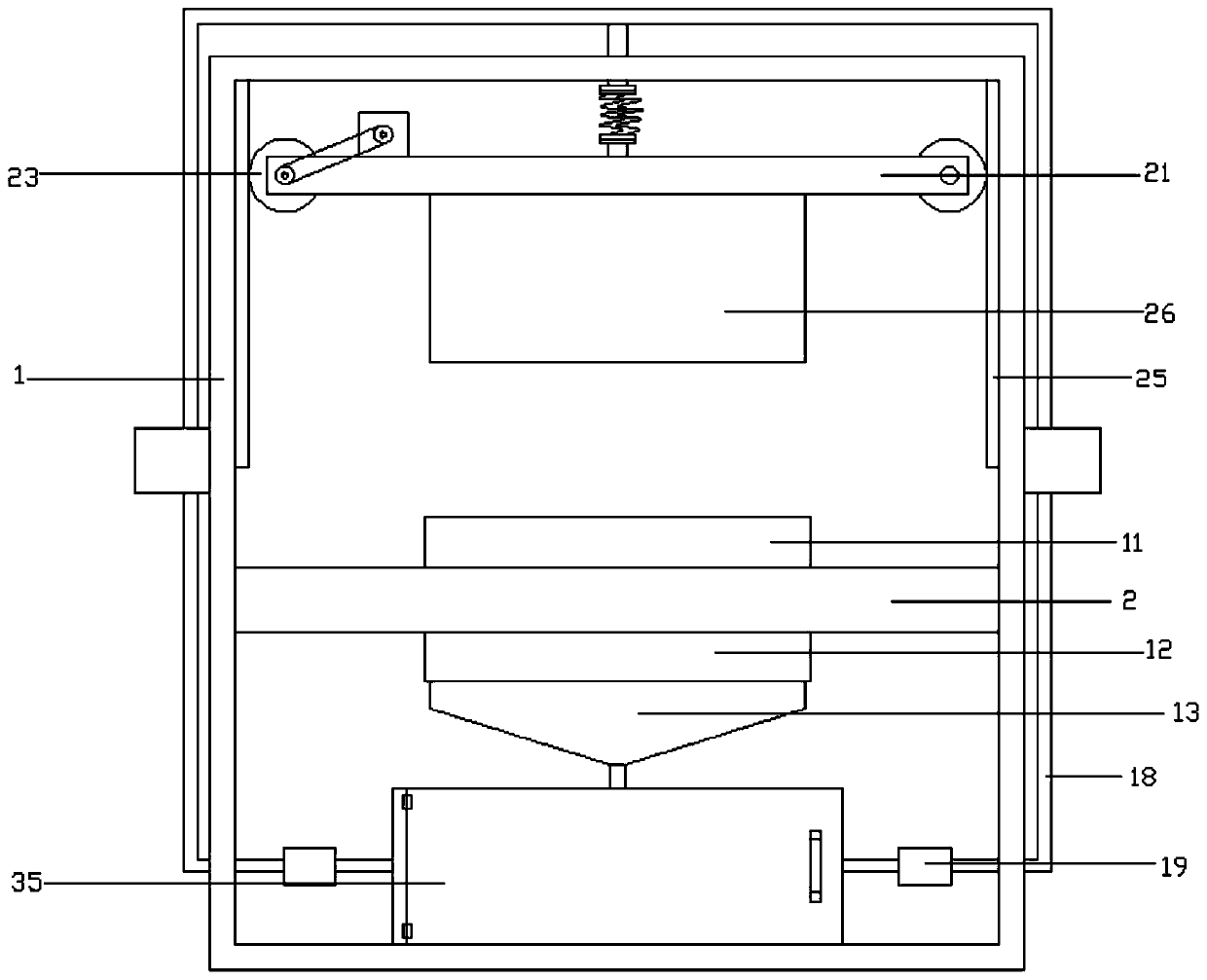

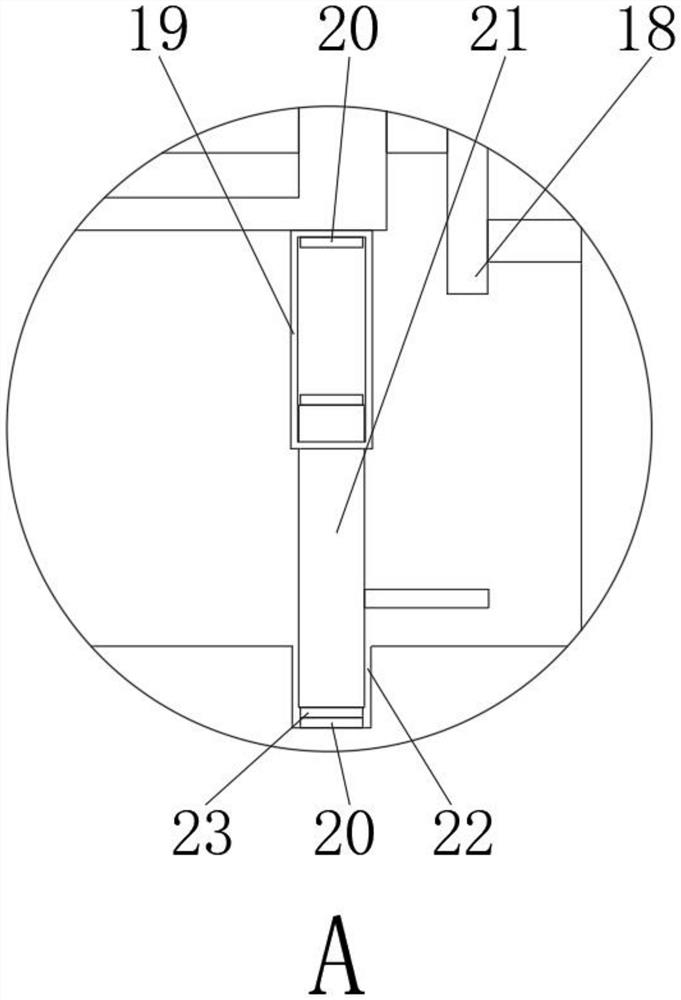

Lifting type flat stone grinding, polishing and polishing device

ActiveCN108838783AEasy to grind and polishLow costGrinding carriagesPolishing machinesEngineeringInverted u

The invention provides a lifting type flat stone grinding, polishing and polishing device. The lifting type flat stone grinding, polishing and polishing device comprises guide rails and moving blocks;the moving blocks are mounted on the guide rails, and the two guide rails are parallel to each other and are fixed; the front cross section of each moving block is inverted U-shaped; a pulley is arranged in each moving block and each moving block is erected on the corresponding guide rail; the end part of each moving block is fixed to the upper surface of an upper wheel disc; a lower wheel disc is rotatably fixed to the lower part of the upper wheel disc; connecting rods are vertically fixed to the lower part of the lower wheel disc; the lower ends of the connecting rods are fixed to a fixedblock; the front cross section of the fixed block is U-shaped; and the connecting rods are fixed to the upper end of the fixed block. According to the lifting type flat stone grinding, polishing and polishing device, the completion of grinding and polishing can be greatly facilitated at one time with lower cost through the structural design of the upper wheel disc, the lower wheel disc and the moving blocks; and a set of the upper wheel disc and the lower wheel disc is arranged and less peripheral equipment is arranged, so that the lifting type flat stone grinding, polishing and polishing device is more beneficial to grinding and polishing a small batch of flat stone plates with small sizes.

Owner:广西百色四通石业有限公司

Grinding and polishing device for automobile gears

The invention discloses a grinding and polishing device for automobile gears. The grinding and polishing device comprises a gear body, a rotary plate is movably connected to the bottom of the gear body, and a fixing column is fixedly connected to the upper surface of the rotary plate. A fixed plate is movably connected to the bottom of the rotary plate, and supporting columns are fixedly connectedto the bottom of the fixed plate, a supporting plate is fixedly connected to the side faces of the supporting columns, a first motor is fixedly connected to the upper surface of the supporting plate,and a long strip is fixedly connected to the side face of an output shaft of the first motor. The gear body can be rotated to facilitate the grinding and polishing effect by arranging the rotary plate, the fixing column, the fixed plate, the supporting columns, the first motor and the long strip, and the gears can be conveniently polished and buffed by arranging sliding rails, a spring, a slidingrod, a moving plate, a second motor, a belt pulley, a transmission wheel, a round wheel, a connecting rod, a connecting rod, discs, sand columns, a transmission rod and a sand tray.

Owner:嘉兴正野新材料有限公司

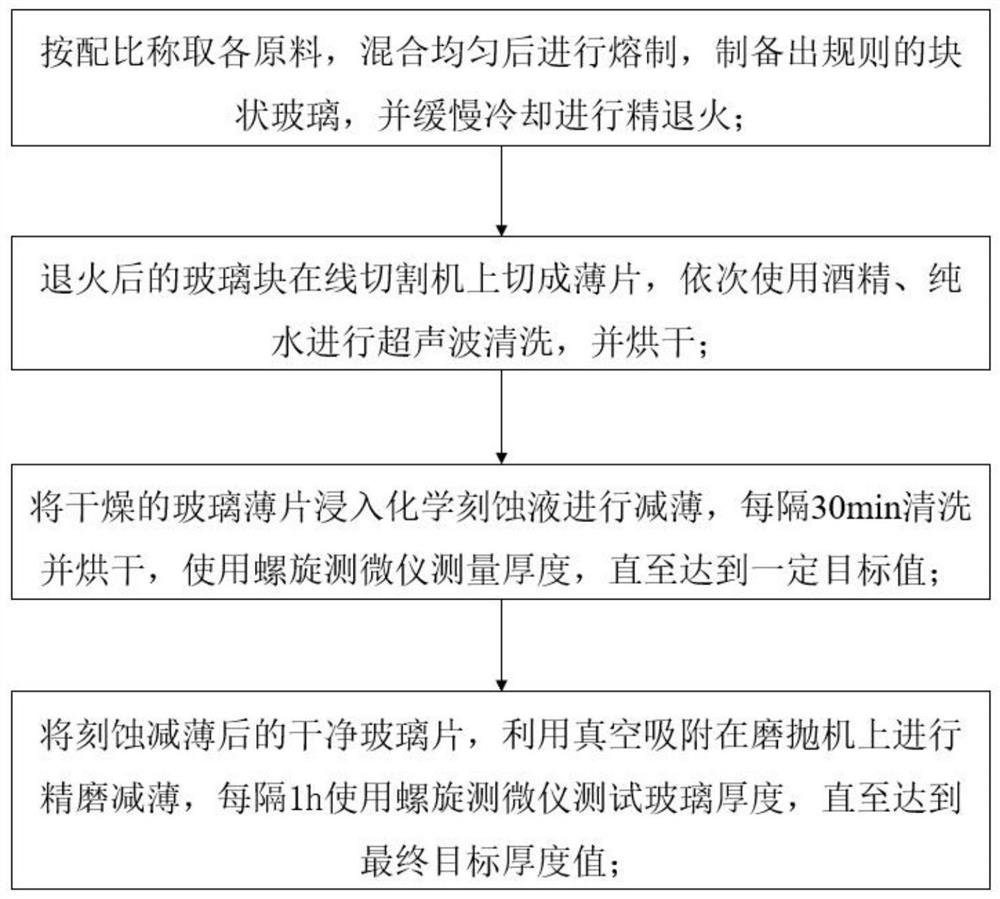

Alkali-free substrate glass and thinning method thereof

PendingCN113880429AReduce thicknessBendableLapping machinesWork carriersHydrofluoric acidAcetic acid

Alkali-free substrate glass comprises the components in percentage by mass: 58.9% to 62.5% of SiO2, 14.2% to 18.4% of Al2O3, 4.3% to 13.7% of B2O3, 1.4% to 1.9% of MgO, 4.1% to 7.6% of CaO, 1.0% to 2.1% of SrO, 0 to 8.3% of BaO and 0.1% to 0.2% of SnO2. The thinning method comprises the following steps: immersing the alkali-free substrate glass into a chemical etching solution composed of hydrofluoric acid, a glacial acetic acid surfactant and the balance being water, thinning the alkali-free substrate glass to 0.4 mm-0. 5mm, taking out the alkali-free substrate glass, and carrying out ultrasonic cleaning and drying; and placing the alkali-free substrate glass on a grinding disc of a grinding and polishing machine, and carrying out mechanical polishing, thinning the alkali-free substrate glass to 0.3 mm-0.35 mm, and thus obtaining the flexible substrate glass. The alkali-free substrate glass is reasonable in composition, the specific modulus value of the prepared alkali-free glass is moderate, the glass has good flexibility, the thinning method is convenient to operate, the alkali-free substrate glass with the thickness of 0.7 mm is thinned by combining two modes of chemical etching thinning and mechanical polishing thinning, and the flexible substrate glass with smooth surface and bendable performance is obtained.

Owner:IRICO DISPLAY DEVICES

A kind of internal combustion engine bearing bush processing equipment and processing method thereof

ActiveCN108356648BImprove grinding and polishing effectImprove grinding and polishing efficiencyRevolution surface grinding machinesGrinding work supportsRotational axisEngineering

The invention discloses an internal combustion machine bearing bush machining device, and relates to the technical field of internal combustion machine bearing bush production equipment. The device comprises a bottom plate, the top of the bottom plate is fixedly connected with a box body, one side of the top of the box body is fixedly connected with a transmission box, the bottom of the inner wallof the box body is rotatably connected with a rotating shaft through a bearing pedestal, the top end of the rotating shaft sequentially penetrates the box body and the transmission box and extends into the transmission box, and the rotating shaft extends into the outer surface inside the transmission box and is rotatably connected with the top of the inner wall of the transmission box through a bearing. According to the internal combustion machine bearing bush machining device and the machining method thereof, the grinding and polishing effect is greatly improved, the grinding and polishing efficiency is well improved, a person does not need to waste a large amount of time for grinding and polishing a bearing bush, work burdens of the person are well reduced, work efficiency of the personis improved, the inner surface and the outer surface of the bearing bush can be rapidly and efficiently ground and polished at the same time, and grinding machining of the bearing bush by the personis greatly facilitated.

Owner:湖北安达精密工业有限公司

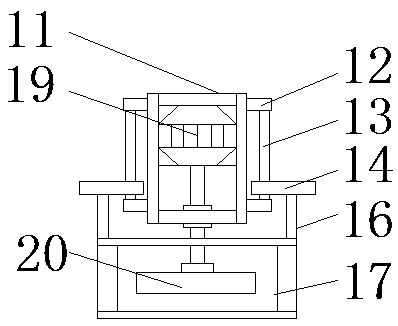

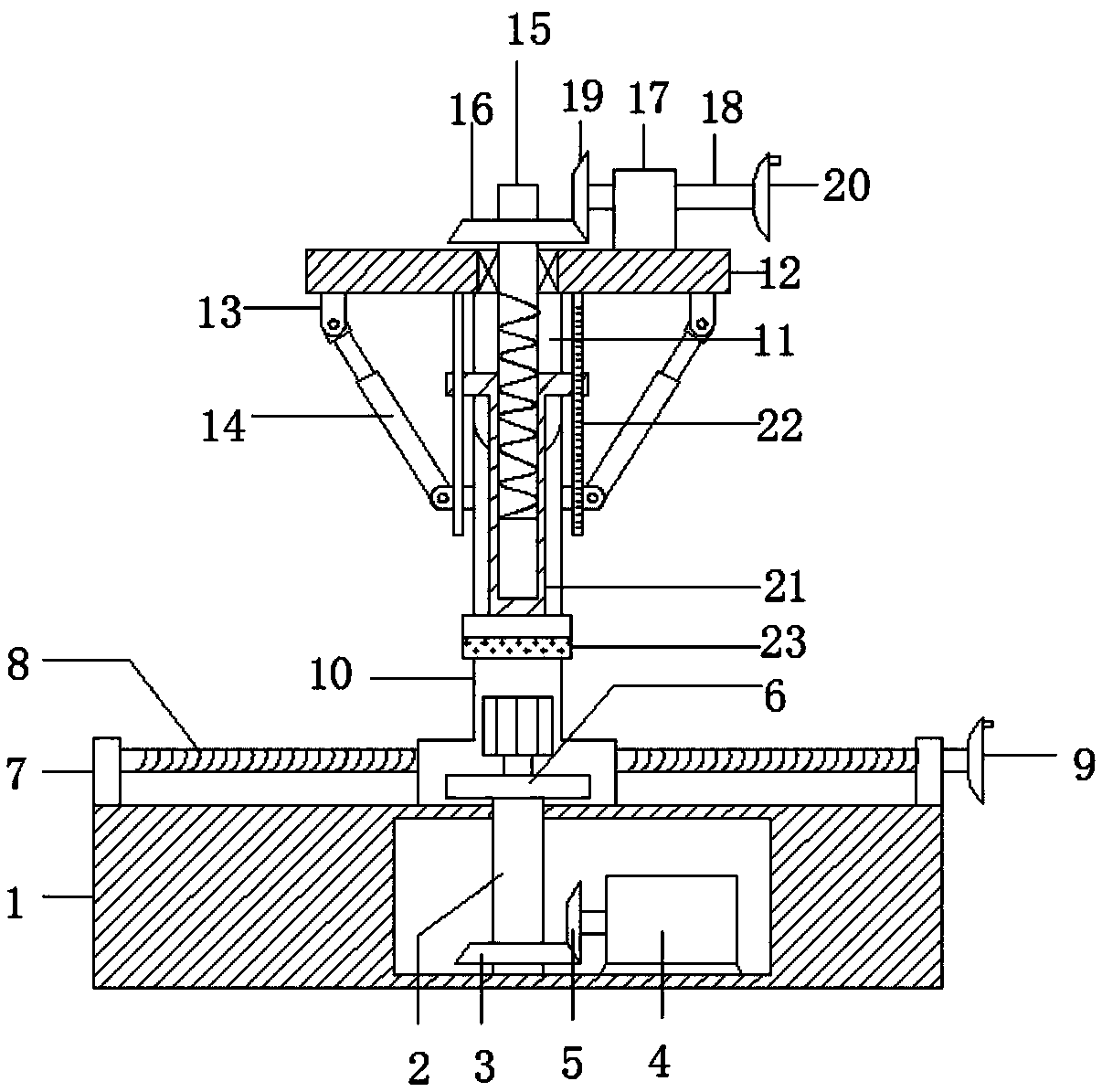

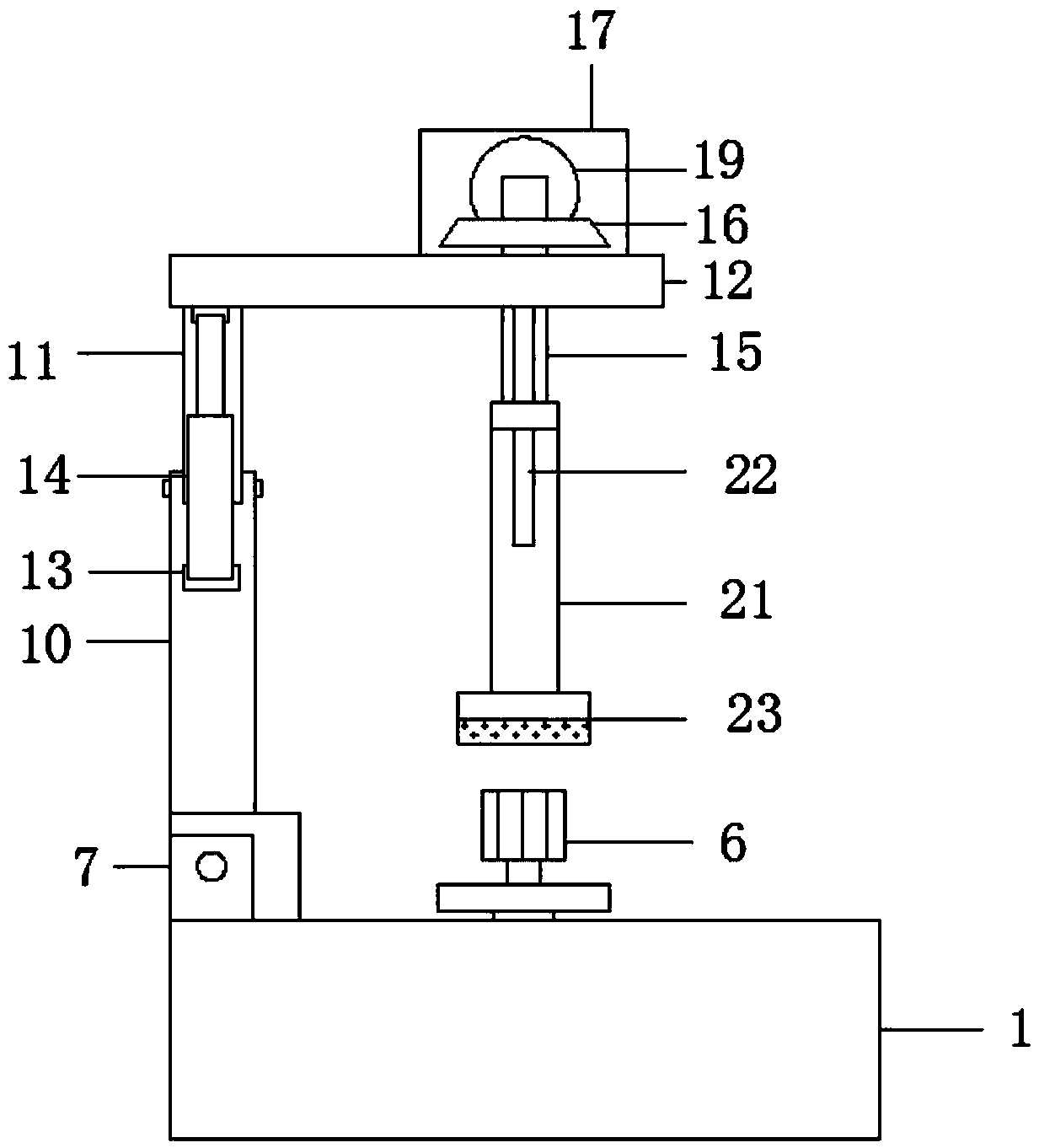

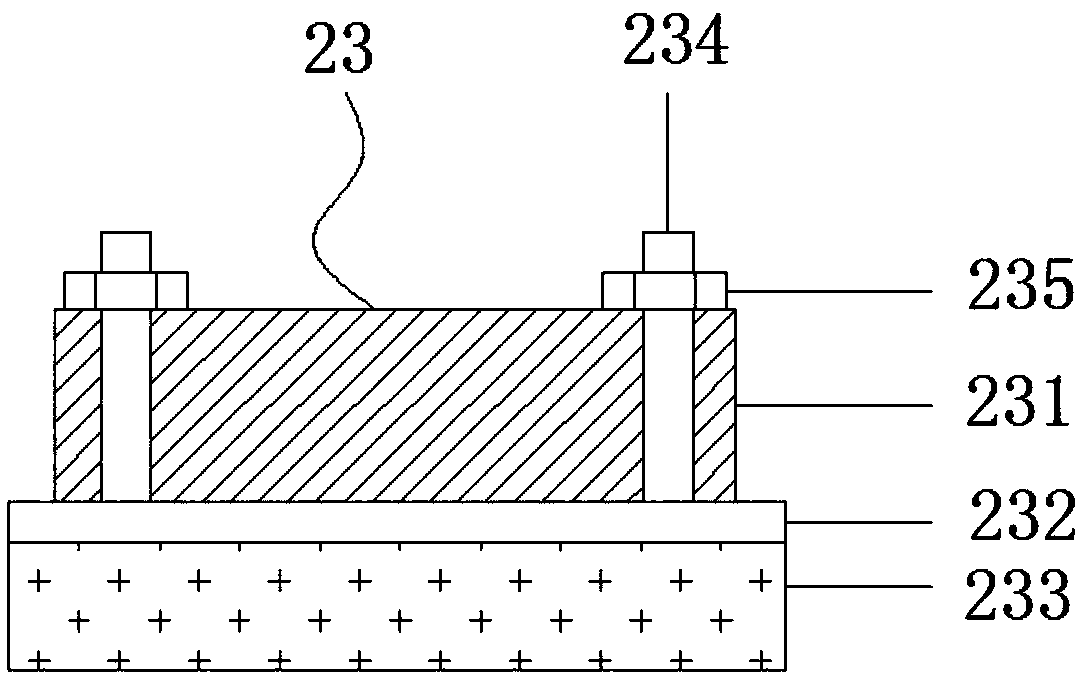

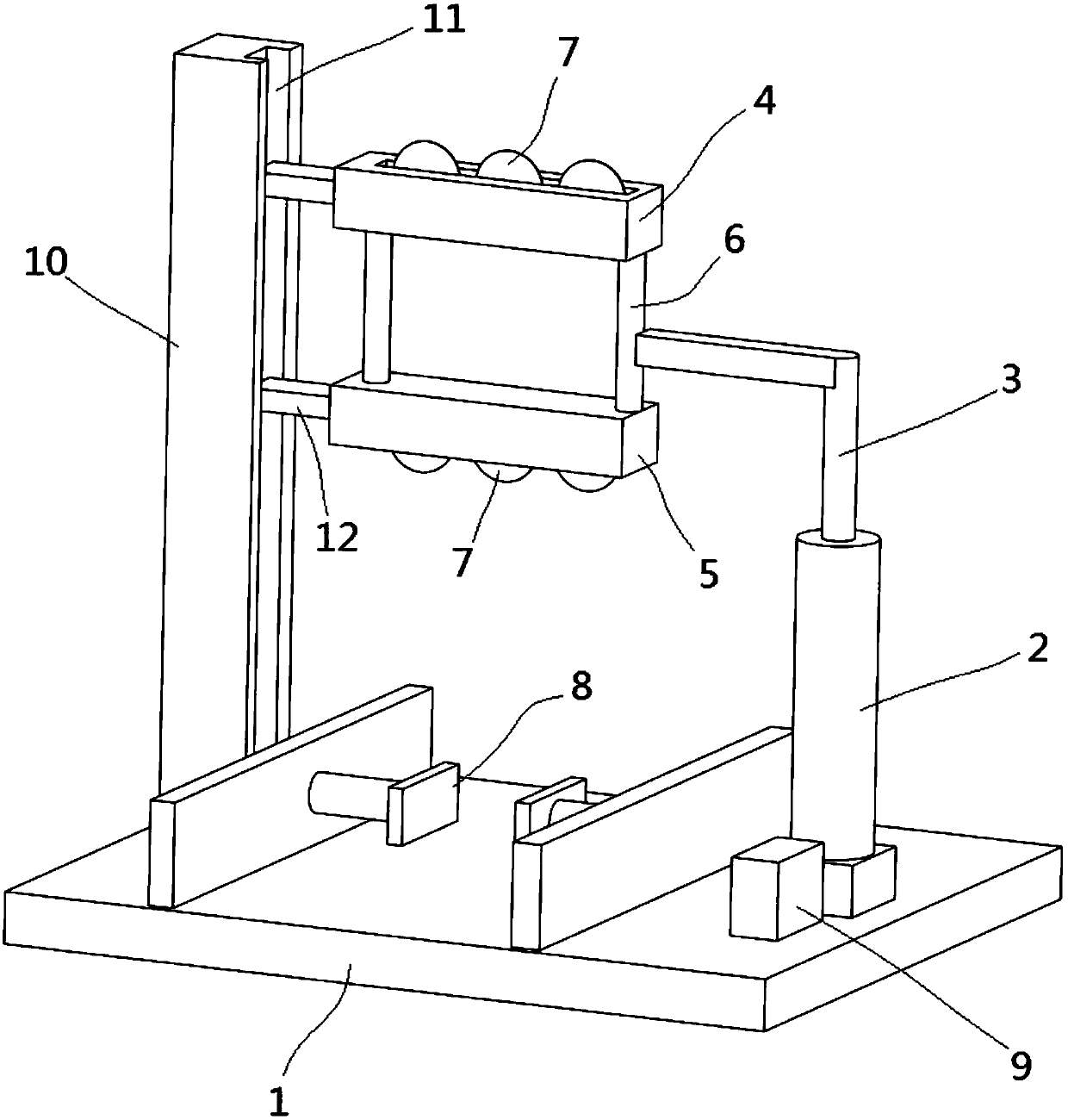

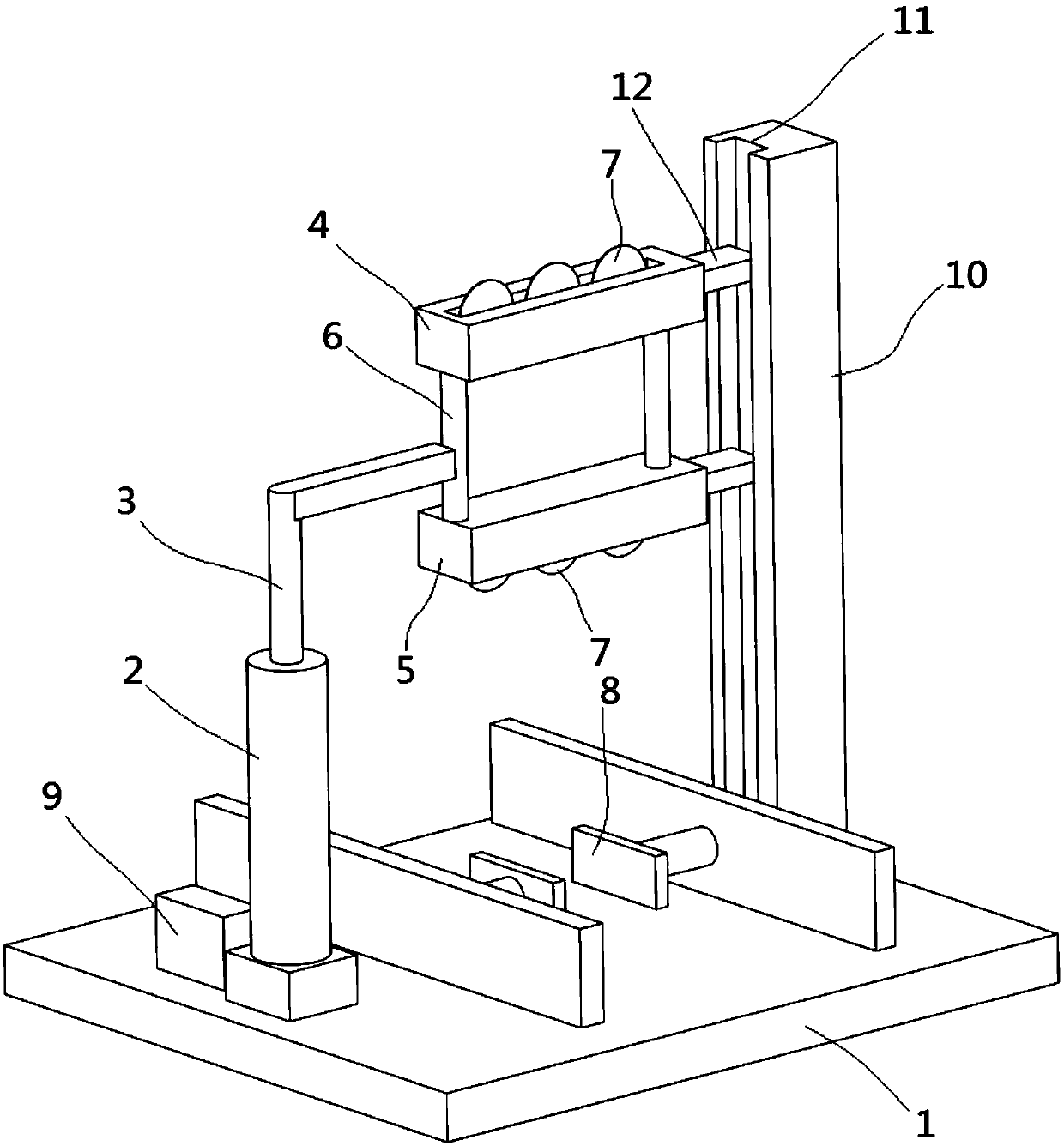

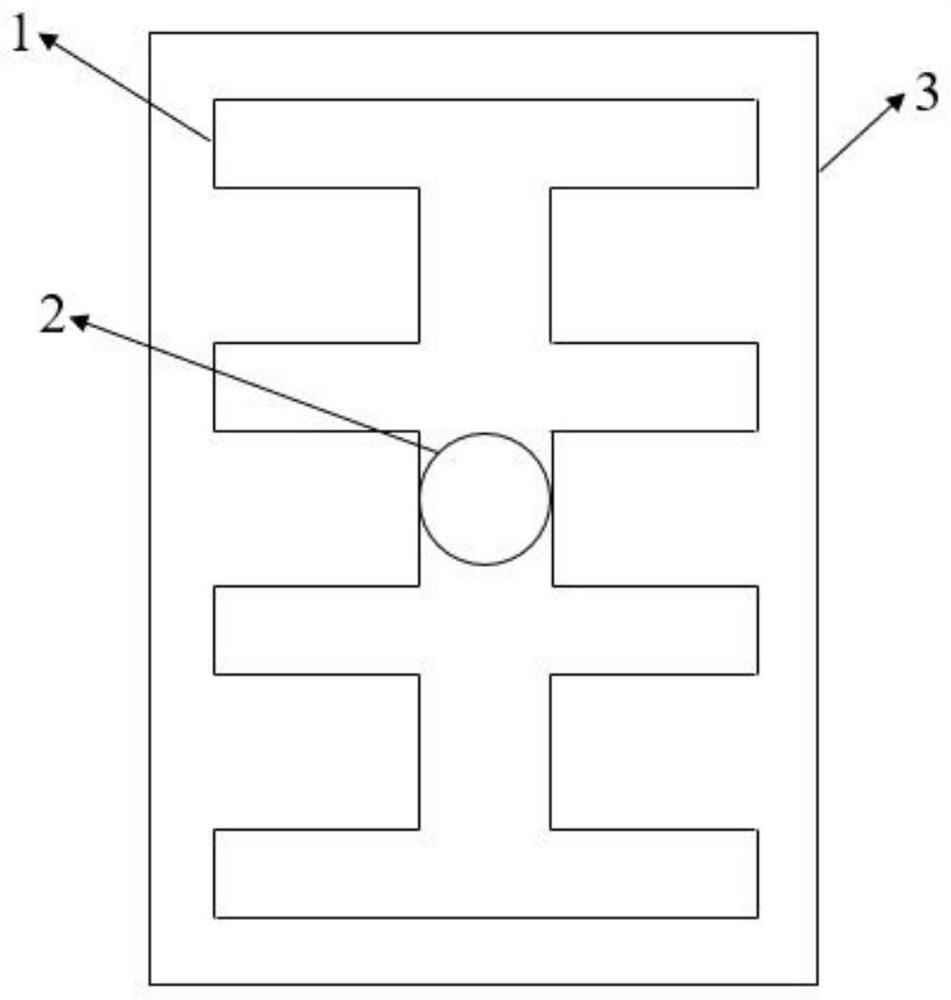

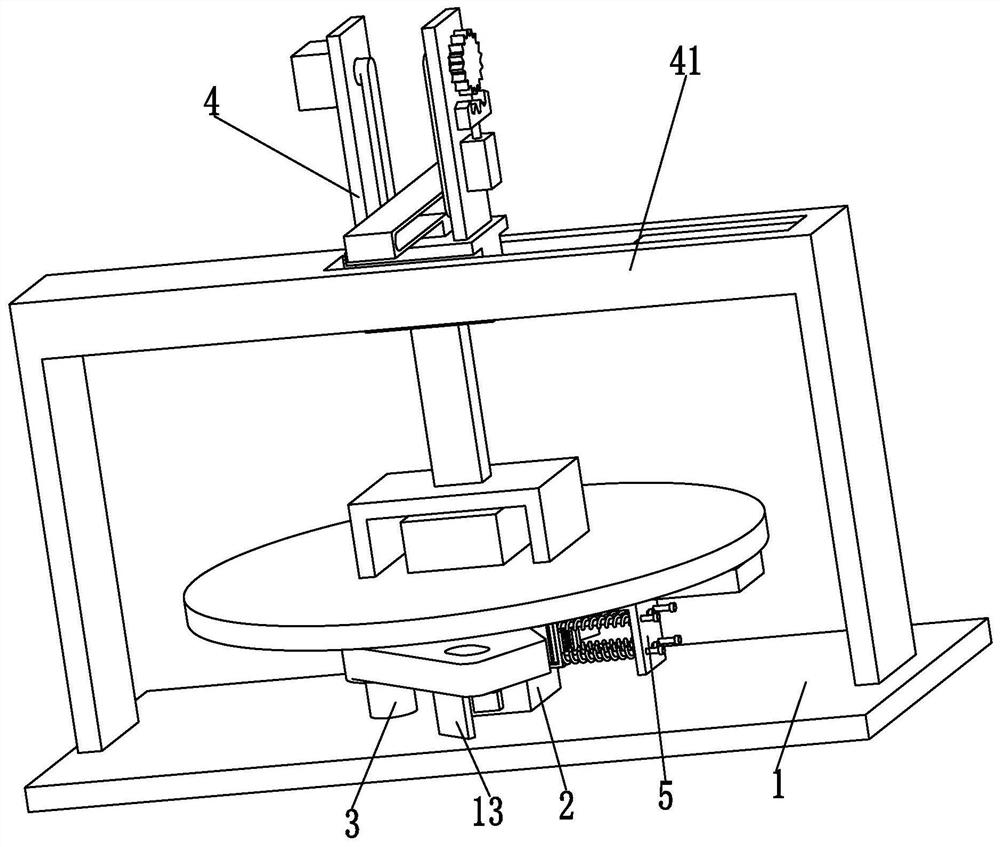

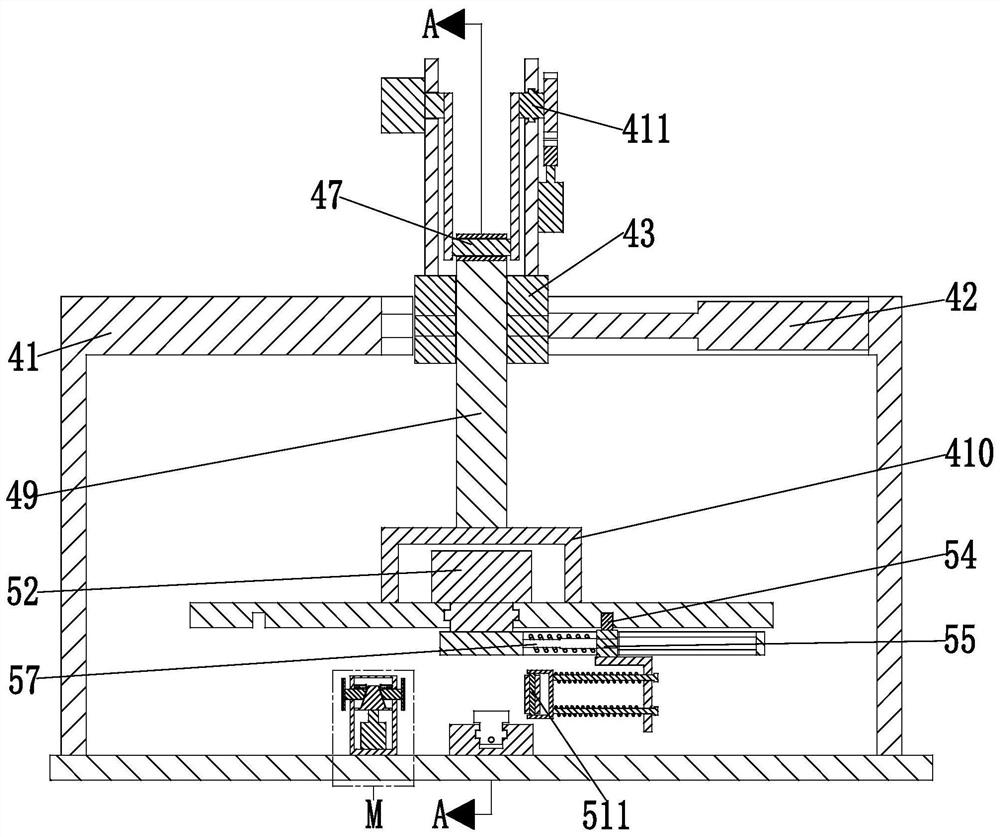

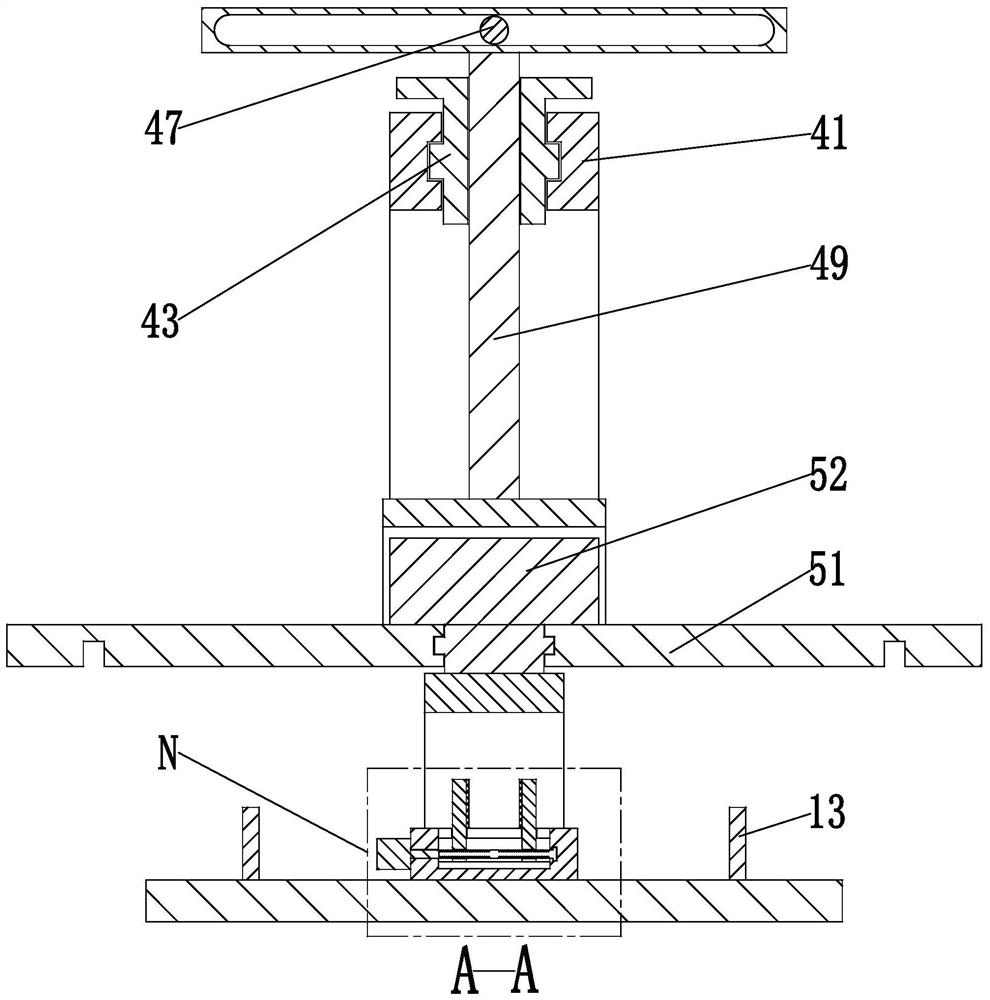

Manufacturing, forming and machining equipment for truck seat framework assembly accessories

ActiveCN113414690AReduce sanding qualityImprove sanding qualityCleaning using toolsGrinding machinesEngineeringTruck

The invention relates to manufacturing, forming and machining equipment for truck seat framework assembly accessories. The manufacturing, forming and machining equipment comprises a bottom plate, a clamping device, a positioning device, a lifting device and a grinding device. The lifting device is mounted on the bottom plate. The grinding device is mounted on the lifting device. The positioning device is mounted on the left side of the bottom plate. The clamping device is mounted in the middle of the bottom plate. The manufacturing, forming and machining equipment can solve the following problems when an existing triangular disc is ground and polished after being produced and formed: firstly, when a traditional triangular disc is ground after being formed, the triangular disc needs to be manually positioned and then ground, due to the fact that positioning of the triangular disc is unstable, the circumstance that the triangular disc moves during manual grinding is caused, and the grinding quality of the triangular disc is reduced; and secondly, when an existing manual grinding tool is used for grinding the outer edge of the triangular disc, the manual grinding efficiency is low, and the production quality and efficiency of the triangular disc are affected.

Owner:JIANGSU SHUANGJU AUTOMOBILE PARTS

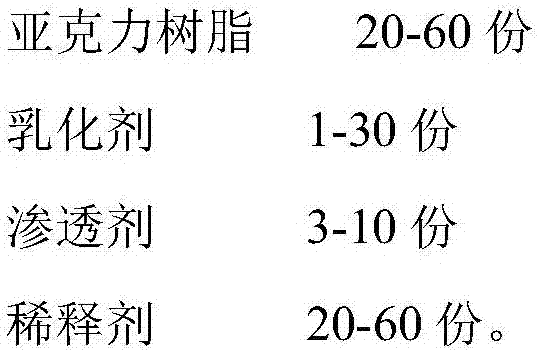

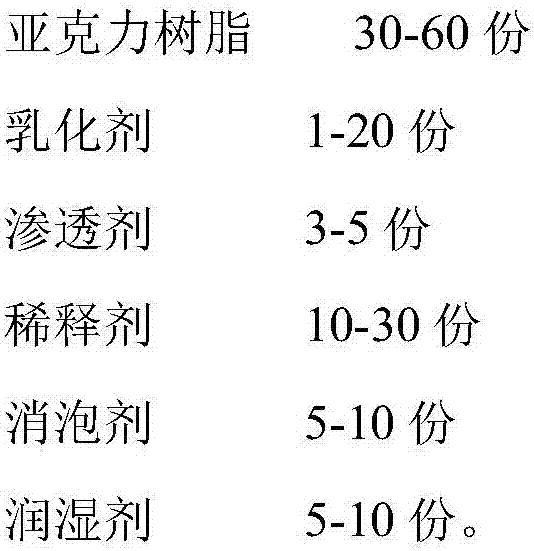

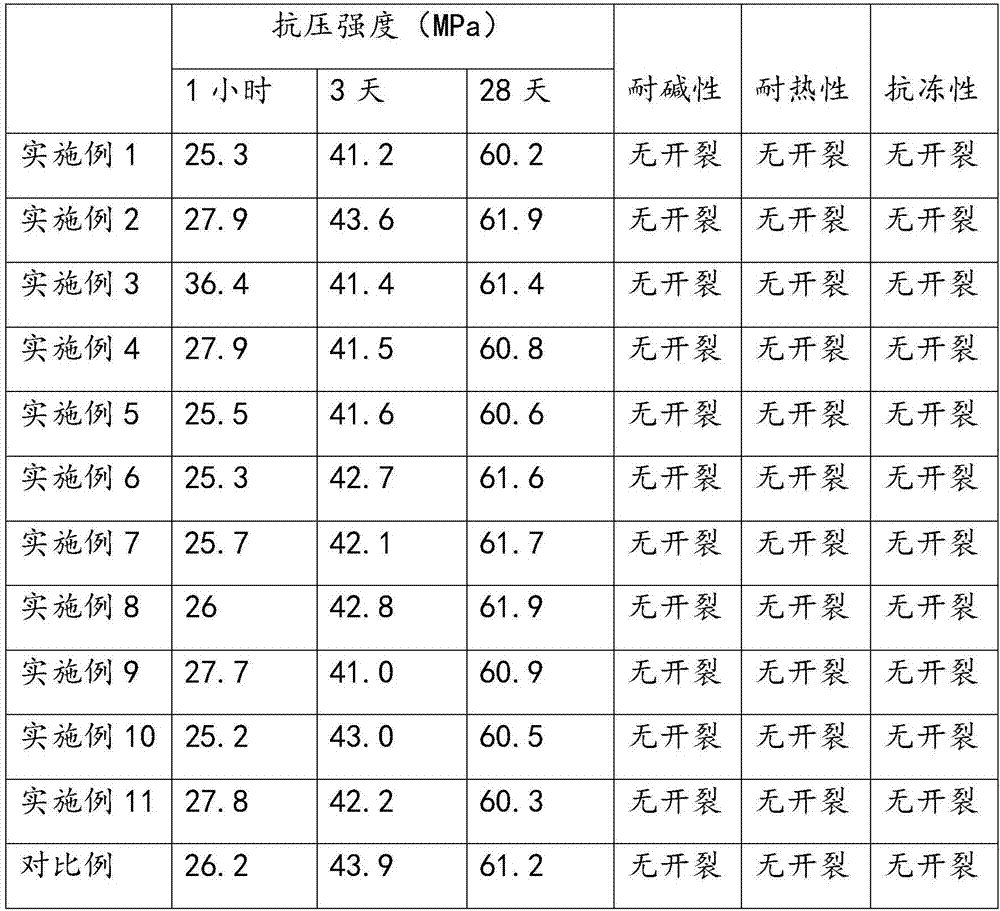

Concrete repair agent and application thereof

The invention relates to a concrete repair agent. The concrete repair agent is prepared from, by weight, acrylic-based resin, an emulsifying agent, a penetrating agent and a diluting agent. The concrete repair agent is commonly known as a concrete solder and is a waterborne environment-friendly agent, and the concrete repair agent is capable of having cross-linking reaction with dust generated ina cement and concrete grinding process to enable re-setting and hardening, and defects of holes, cracks and the like of concrete repaired. By application of the concrete repair agent to new and old concrete combination faces, adhesion firmness of the new and old concrete combination faces can be remarkably improved, and concrete bulging, layering and shedding can be prevented. In addition, the concrete repair agent is simple in operation, early strength of concrete can be quickly improved, an integral construction period is shortened, and concrete compactness is improved to make it easy for grinding and polishing.

Owner:苏州金润新材料科技有限公司

Steel plate surface polishing device for steel structure building

InactiveCN109848823ASimple structureInnovative designPolishing machinesGrinding drivesWater storage tankMaterials science

The invention discloses a steel plate surface polishing device for a steel structure building. The steel plate surface polishing device comprises a fixing plate, a discharging hole, supporting legs, afirst motor, a conveying belt, magnet blocks, a storage shell, a steel plate, a grinding roller, a fixed frame, a second motor, a water pipe, nozzles, a supporting plate, a water storage tank, a material pouring plate, a connecting frame, rollers, a connecting plate and a metal scrap filter screen. A steel plate surface polishing device for the steel structure building is simple in structure, novel in design and capable of realizing automatic conveying of the polished steel plate, and meanwhile, the stable fixation of the conveyed steel plate is guaranteed, the polishing roller conveniently polish and polish the steel plate surface to be polished, the grinding and polishing efficiency of the steel plate is improved, the grinding roller and the surface of the polished steel plate can be washed in the grinding process, and the surfaces of the grinding roller and the steel plate are guaranteed to be clean; and in addition, the steel plate surface polishing device conveniently blanks theground steel plate, is convenient to use by workers, facilitates washing and filtering of washed waste liquid, and is convenient to process by the workers, and suitable for popularization and use.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com