Concrete repair agent and application thereof

A technology of concrete repair agent and emulsifier, which is applied in the field of building materials, can solve the problems of cracking and low strength, poor permeability, poor later strength, etc., and achieves the effects of improving bonding fastness, improving early strength and increasing compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

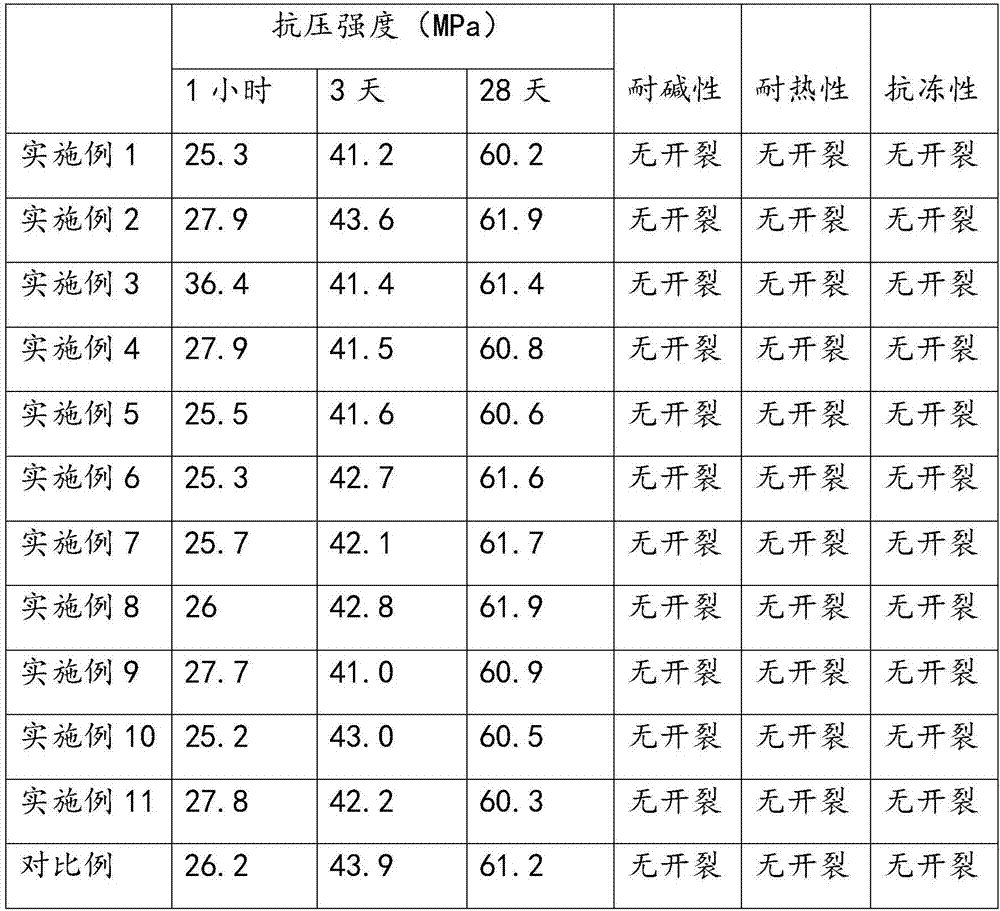

Examples

Embodiment 1

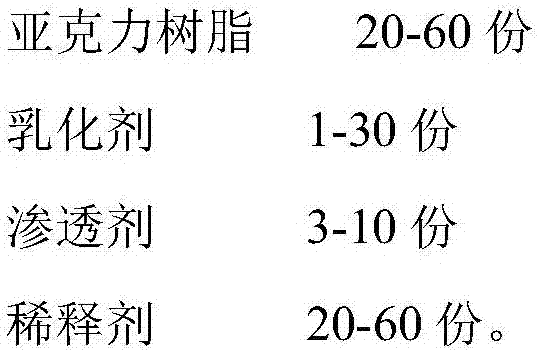

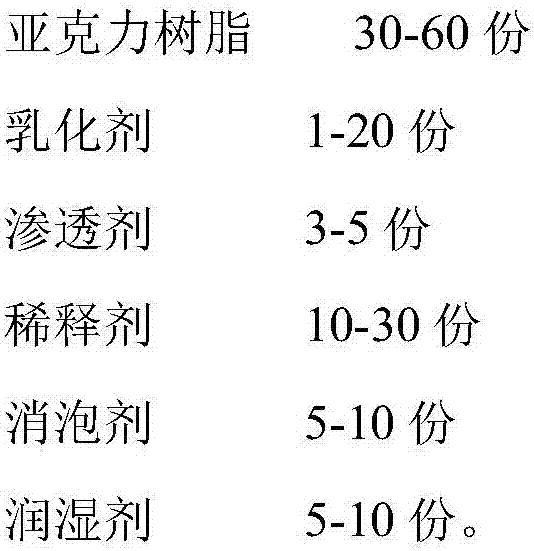

[0033] A concrete repair agent, mainly including acrylic resin, emulsifier, penetrant and diluent, wherein the emulsifier can use alkylphenol polyoxyethylene ether, dibenzyl biphenyl polyoxyethylene ether or styrylphenol formaldehyde resin One of the polyoxyethylene ethers can also be used in combination. The penetrating agent adopts fatty alcohol polyoxyethylene ether, the diluent adopts water and organic solvent, and the organic solvent adopts butyl acetate; in this embodiment, the emulsifier Alkylphenol polyoxyethylene ether is used.

[0034] Take a clean container, dissolve 20 parts of acrylic resin in 10 parts of butyl acetate, add 10 parts of water and 1 part of emulsifier after it is completely dissolved, stir at high speed to form an emulsified suspension; then pour 3 parts of penetrant into Until it is stirred evenly, the preparation of the concrete repair agent is completed.

Embodiment 2

[0036] A concrete repair agent, mainly including acrylic resin, emulsifier, penetrant and diluent, wherein the emulsifier can use alkylphenol polyoxyethylene ether, dibenzyl biphenyl polyoxyethylene ether or styrylphenol formaldehyde resin One of the polyoxyethylene ethers can also be used in combination. The penetrating agent adopts fatty alcohol polyoxyethylene ether, the diluent adopts water and organic solvent, and the organic solvent adopts butyl acetate; in this embodiment, the emulsifier Styrylphenol formaldehyde resin polyoxyethylene ether is used.

[0037] Take a clean container, dissolve 60 parts of acrylic resin in 30 parts of butyl acetate, add 30 parts of water and 30 parts of emulsifier after it is completely dissolved, and stir at high speed to form an emulsified suspension; then pour 10 parts of penetrant into Until it is stirred evenly, the preparation of the concrete repair agent is completed.

Embodiment 3

[0039] A concrete repair agent, mainly including acrylic resin, emulsifier, penetrant and diluent, wherein the emulsifier can use alkylphenol polyoxyethylene ether, dibenzyl biphenyl polyoxyethylene ether or styrylphenol formaldehyde resin One of the polyoxyethylene ethers can also be used in combination. The penetrating agent adopts fatty alcohol polyoxyethylene ether, the diluent adopts water and organic solvent, and the organic solvent adopts butyl acetate; in this embodiment, the emulsifier Dibenzyl biphenyl polyoxyethylene ether is used.

[0040] Take a clean container, dissolve 40 parts of acrylic resin in 20 parts of butyl acetate, add 20 parts of water and 16 parts of emulsifier to it after complete dissolution, stir at high speed to form an emulsified suspension; then pour 6 parts of penetrant into Until it is stirred evenly, the preparation of the concrete repair agent is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com