Interface mortar with ardealite-based hydraulicity composite cementing material as cementing material

A composite cementitious material and interface mortar technology, applied in the field of building materials, can solve problems such as serious harm to the atmosphere, soil and groundwater, unfavorable people, harmonious development of the environment and society, loss of land resources, etc., to improve durability, flow Good performance, uniform slurry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062]Example 1, an interface mortar using phosphogypsum-based hydraulic composite cementitious material as a cementitious material, according to phosphogypsum 100, slag powder 100, fly ash 25, metakaolin 15, copper tailings slag powder 15, red mud 2 , 42.5 grade ordinary Portland cement 15, aluminate cement 8, quartz sand 200, quartz powder 120, twill stone powder 40, calcium-based bentonite 10, polycarboxylate superplasticizer 0.50, cellulose ether 0.2, latex powder 10 Formulated with a weight ratio. When in use, add water and stir evenly according to 20% of the total weight of the material. The performance test results are shown in Table 1.

Embodiment 2

[0063] Example 2, a kind of interface mortar using phosphogypsum-based hydraulic composite cementitious material as cementing material, according to phosphogypsum 100, slag powder 150, fly ash 20, metakaolin 35, copper tailings slag powder 30, red mud 6 , 52.5 grade ordinary Portland cement 35, aluminate cement 5, quartz sand 800, quartz powder 60, twill stone powder 90, calcium-based bentonite 20, polycarboxylate water reducer 2.0, cellulose ether 0.1, latex powder 15 Formulated with a weight ratio. When in use, add water to 21% of the total weight of the material and stir evenly. The performance test results are shown in Table 1.

Embodiment 3

[0064] Example 3, a kind of interface mortar using phosphogypsum-based hydraulic composite cementitious material as cementing material, according to phosphogypsum 100, slag powder 50, fly ash 60, metakaolin 45, copper tailings slag powder 50, red mud 18 , 42.5 grade ordinary Portland cement 5, aluminate cement 10, quartz sand 400, quartz powder 150, twill stone grain powder 60, calcium-based bentonite 5, polycarboxylate superplasticizer 1.5, cellulose ether 0.4, latex The weight ratio of powder 5 is formulated. When in use, add water to 25% of the total weight of the material and stir evenly. The performance test results are shown in Table 1.

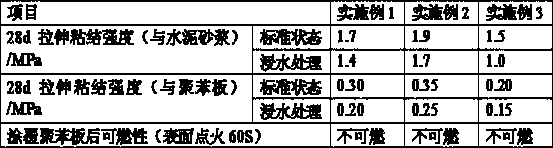

[0065] Table 1 Example performance test results

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com