Patents

Literature

31results about How to "Anti-sagging" patented technology

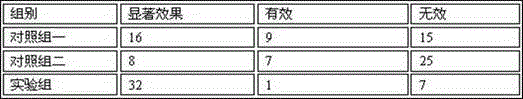

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

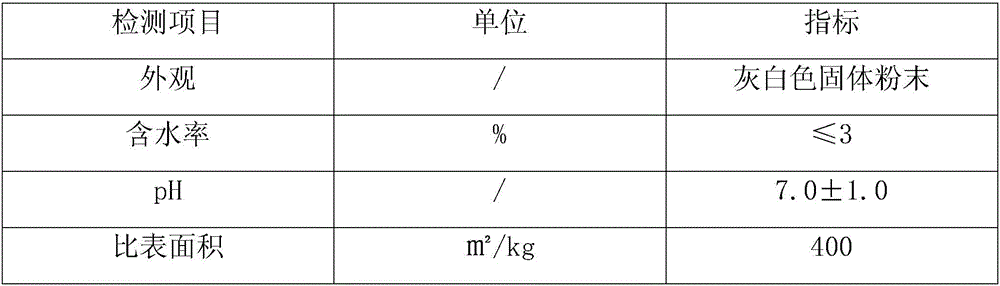

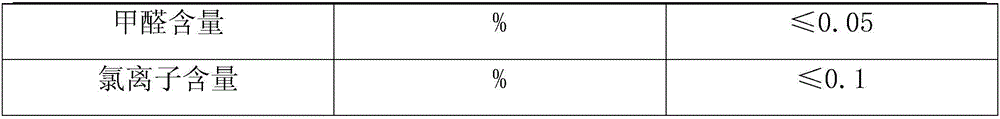

Efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as preparation method and application method thereof

The invention discloses an efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as a preparation method and an application method thereof. The composition comprises the following components in percentage by weight (100% in total): 1%-5% of a plasticizer, 15%-30% of a thickening agent, 30%-50% of a retarder, 10%-25% of an anti-cracking agent, 1-5% of a water-retaining agent, 5%-10% of an enhancer, and 1%-5% of a binding agent. By utilizing the composition, the workability, water-retaining property, adhesive property and cracking resistance of coating mortar can be remarkably improved, the cracking, hollowing and falling of the mortar are avoided, and various performance indexes such as the strength and permeability resistance of the mortar can be improved; and furthermore, cement can be saved, and the disadvantages of easiness in ash blasting, high shrinkage, low strength and the like of the cement mixed mortar are overcome.

Owner:四川巨星新型材料有限公司

Mechanical spraying plastering mortar

The invention provides a mechanical spraying plastering mortar and an additive. The mechanical spraying plastering mortar comprises: by weight, cement 10%-18%, fly ash 5%-10%, sand 75%-80%, and additive 0.5%. The additive comprises, by weight, cellulose ether 0.02%, montmorillonite powder 0.01%, starch ether 0.01%, water reducing agent 0.05%, air-entraining agent 0.0035%, and wood fibre 0.1%. The product optimizes the mix ratio of the plastering mortar, and mixes a certain ratio of additive, so that the plastering mortar has sag resistance, good lubricity, water-retaining property and fluidity, and strong binding power, and the performance requirements of mechanical pumping and spraying construction of the plastering mortar is realized. And thus, labor intensity is reduced, construction efficiency is enhanced, and the construction efficiency is more than two times of that of manual plastering. The wall plastering using mechanical spraying construction has high pressure and is uniform, avoids empty drum and crack of the plaster layer, and improves the engineering quality of the additive.

Owner:浙江正昶新型材料股份有限公司

Novel sculpture mortar

The invention discloses a novel sculpture mortar. The novel sculpture mortar comprises the following components: 40-50% of 32.5R ordinary Portland cement, 45%-55% of 40-80 mesh sand ( quartz sands), 1-2% of 50-70 mesh light-weight aggregates, 0.01-0.1% of cellulose ether, 0.02-0.2% of dispersible latex powder, 0.2-0.4% of a water-reducing agent, 2-3% of silica powder, 0.3-0.4% of lignin fiber and 0-0.04% of polyropylene fiber. The component composition is to fulfill the following purposes: the operation is simple; no other materials are required for adding and the sculpture mortar can be directly utilized; the novel sculpture mortar facilitates the construction and has excellent workability; the sag resistance of the novel sculpture mortar enables the thickness of the troweling at one time to be more than 5 cm; a more stereoscopic and richer sculptural effect can be created; the construction efficiency is improved; cracks are rarely found on the sculpture and the simulation effect is improved; the structure is compact; the matching is reasonable and the service life can be prolonged; industrialized production is realized, so that the quality is stable and guaranteed.

Owner:SUZHOU TASHI LANDSCAPE ENG TECH CO LTD

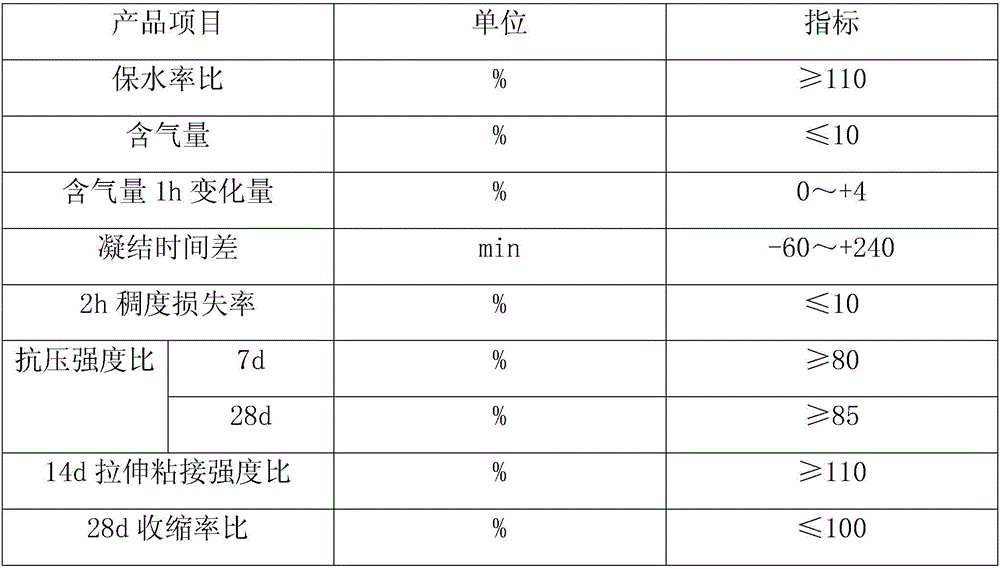

Solvent-free epoxy coating material and preparation method thereof

ActiveCN106554705ALow viscosityImprove compactnessFireproof paintsAnti-corrosive paintsSolvent freeAliphatic amine

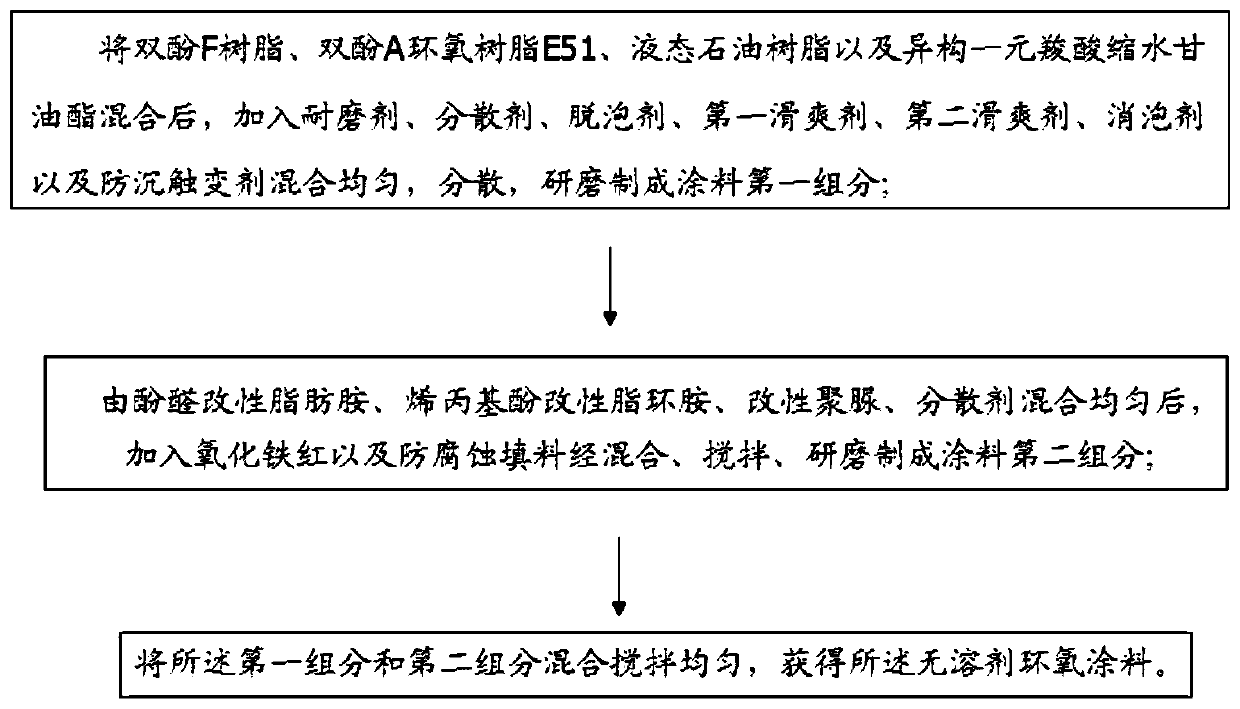

The invention provides a solvent-free epoxy coating material and a preparation method thereof. The solvent-free epoxy coating material comprises a first component and a second component, wherein the first component comprises the following components in parts by weight: 1 part of bisphenol F resin, 0.8-1.0 part of bisphenol A epoxy resin E51, 0.1-0.2 part of liquid petroleum resin, 0.15-0.3 part of isomerous monocarboxylic acid glycidyl ester, 0.2-0.7 part of an anti-wear agent, 0.1-0.3 part of a dispersant, 0.02-0.1 part of an air-release agent, 0.01-0.1 part of a first slip agent, 0.05-0.1 part of a second slip agent, 0.05-0.1 part of a defoaming agent and 0.01-0.02 part of an anti-settling thixotropic agent; and the second component comprises the following components in parts by weight: 1 part of phenolic aldehyde modified aliphatic amine, 0. 8-1.2 parts of allylphenol modified alicyclic amine, 0.015-0.03 part of modified polyurea, 0.01-0.03 part of a dispersant, 0.1-0.3 part of iron oxide red and 0.15-0.35 part of anti-corrosion packing. A coating formed by the solvent-free epoxy coating material has an excellent thin-coating property, the one-step film-forming thickness of the solvent-free epoxy coating material can be equal to or less than 100 mu m, and the coating has high apparent quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

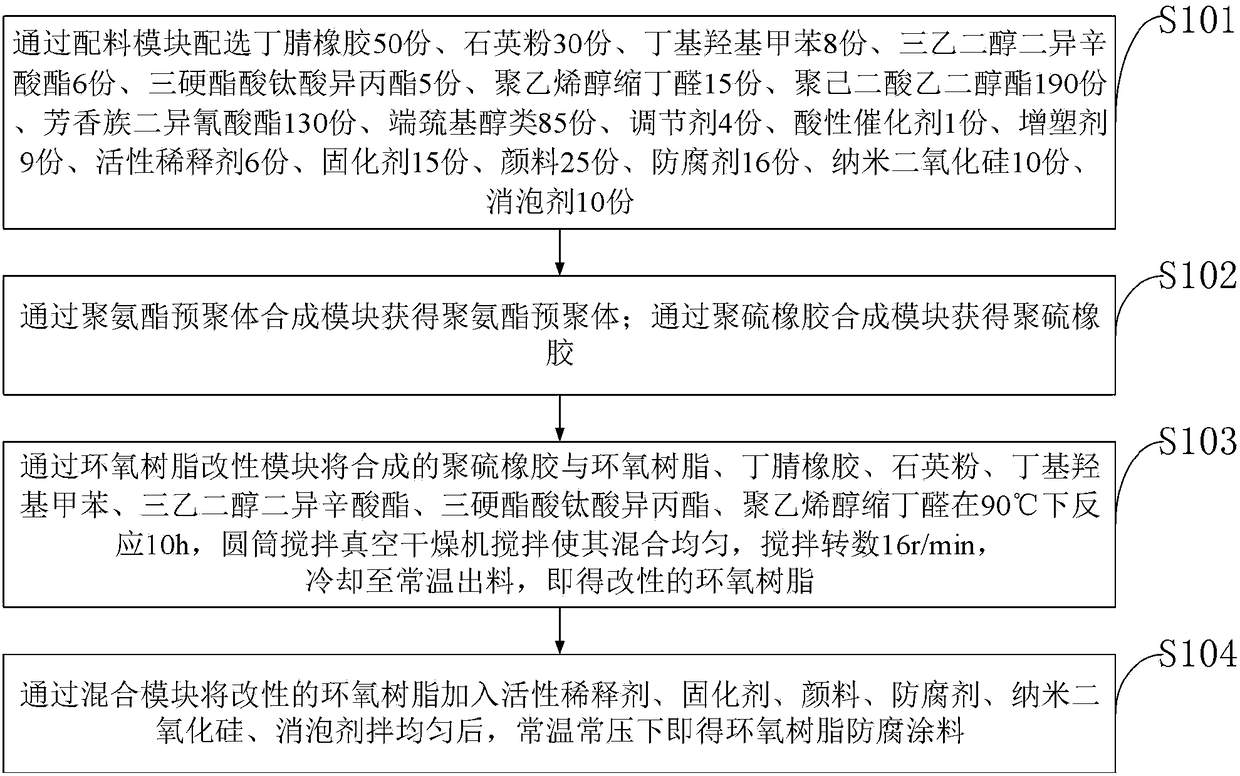

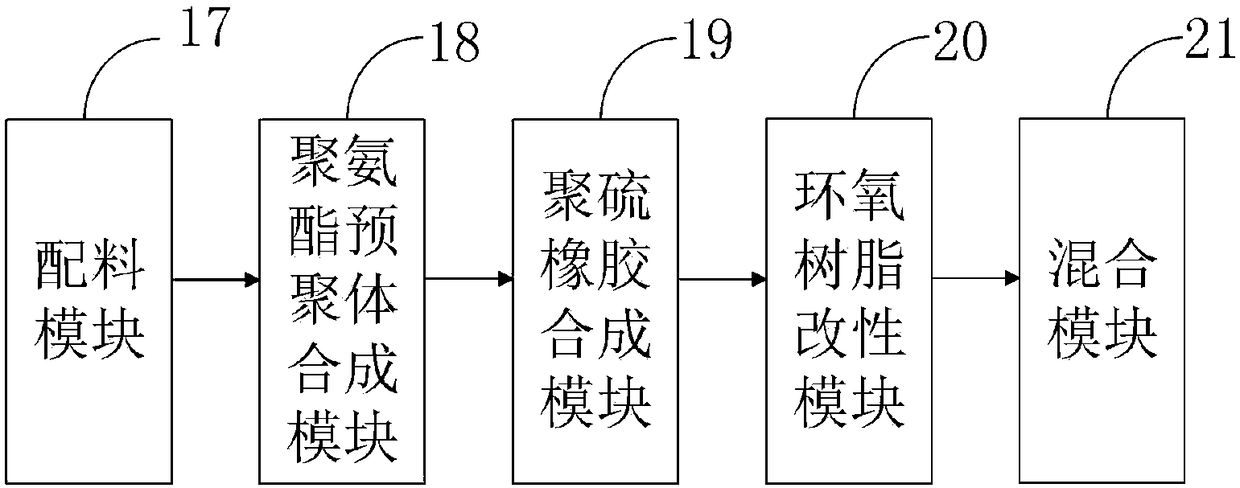

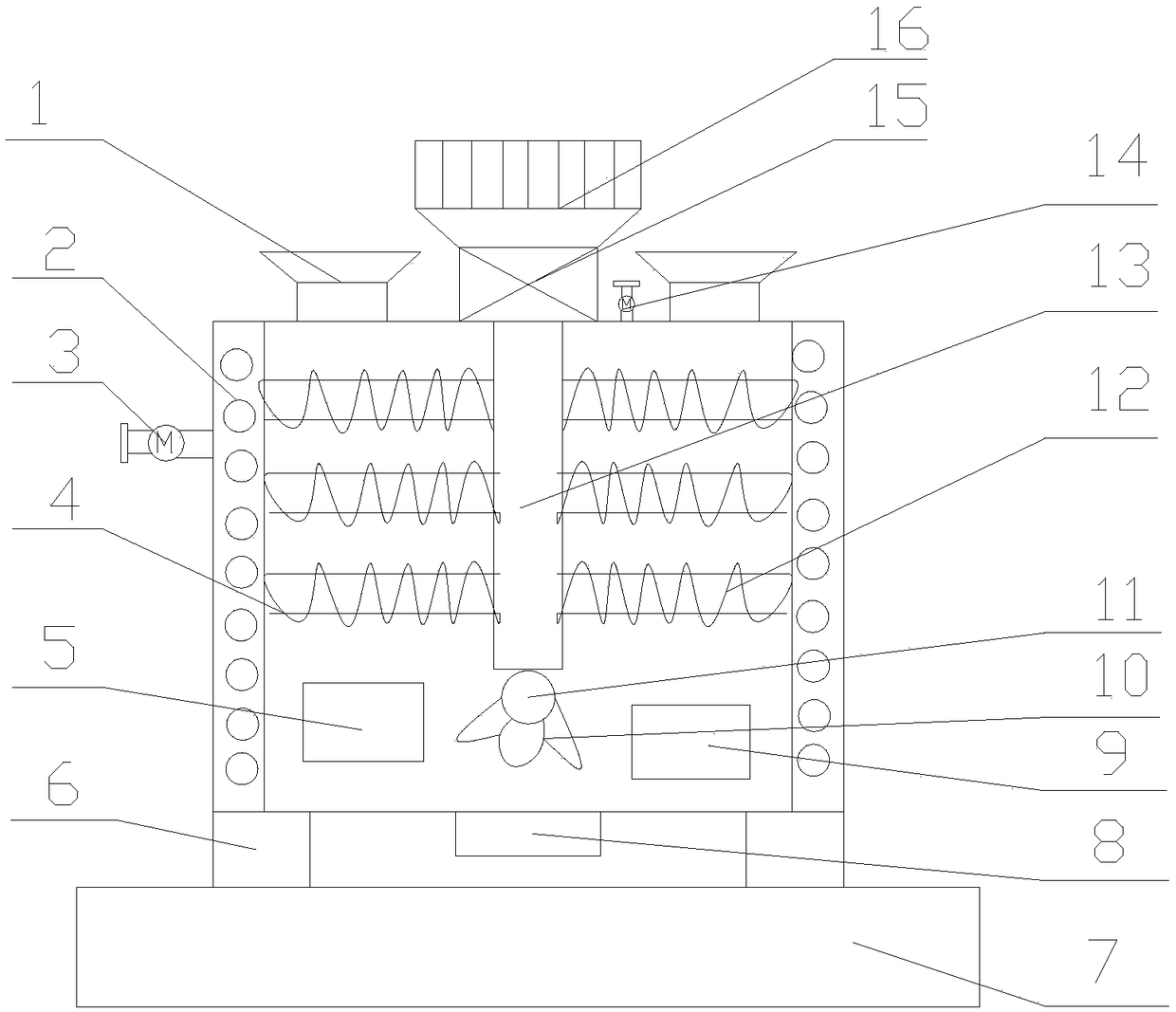

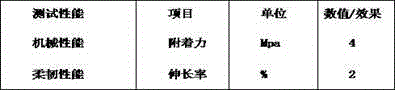

Polysulfide rubber modified epoxy resin anti-corrosion and anti-sewage coating, and preparation method and system thereof

InactiveCN108559382AHigh strengthGood suspensionAntifouling/underwater paintsChemical industryPolymer sciencePolysulfide rubber

The invention belongs to the technical field of coating preparation, discloses a polysulfide rubber modified epoxy resin anti-corrosion and anti-sewage coating, a preparation method and a system thereof. The preparation system includes a dosing module, a polyurethane prepolymer synthesis module, a polysulfide rubber synthesis module, an epoxy resin modification module and a mixing module. According to the invention, the epoxy resin modification module obtains the high-performance epoxy resin, which has excellent ageing resistance and corrosion resistance and long service life; meanwhile, nanosilicon dioxide is added to increase the strength of the coating; Additionally, preservative is added, so that the corrosion resistance of the coating in the oxidizing acidic environment and the alkaline environment is obviously improved, and the coating is suitable for the corrosion prevention coating of equipment in severe corrosive environments, such as pipelines and concrete in environments such as acid-base tanks, waste water tanks, sewage treatment and the like.

Owner:HAINAN UNIVERSITY

Special impermeable modified epoxy coating for denitrating device and preparation method thereof

InactiveCN104610848AImprove adhesionGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceFirming agent

The invention discloses a special impermeable modified epoxy coating for a denitrating device and a preparation method thereof. The impermeable modified epoxy coating comprises a component A and a component B in a weight ratio of (6: 1)-(5: 1); the component A comprises the following substances: epoxy resin, an inert flaky material, a plasticizer, precipitated barium sulfate, an auxiliary agent, an anti-sagging agent, pigment, a filler and a modifying additive; the component B comprises the following substances: a curing agent, a solvent, an accelerant and a toughening agent. The special modified epoxy coating for the denitrating device, provided by the invention, is high in bonding power, is unlikely to fall off, is good in impermeability and good in chemical agent resistance; the overall protective capability of the coating is improved; the service life of the denitrating device is prolonged; the preparation method has the advantages of simple operation, low cost and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Powerful ceramic tile adhesive

InactiveCN110028269AImprove waterproof performanceGood construction performanceAdhesiveCarvacryl acetate

The invention discloses a powerful ceramic tile adhesive. The powerful ceramic tile adhesive comprises the following components as raw materials in parts by weight: 4-6 parts of hydroxypropyl methylcellulose, 1-3 parts of sodium fatty alcohol ether sulfate, 7-9 parts of polyacrylamide, 40-45 parts of heavy calcium powder and 0-13 parts of latex powder, wherein the latex powder is one or a mixtureof at least two of an ethylene and vinyl acetate copolymer, a vinyl acetate and vinyl versatate copolymer and an acrylic copolymer. The powerful ceramic tile adhesive has the effects of active suspension, high viscosity, water retention, precipitation resistance, sagging resistance and easy construction and can effectively prevent the unstable problems such as hollowing, shedding and cracking during ceramic tile paving.

Owner:郭保军

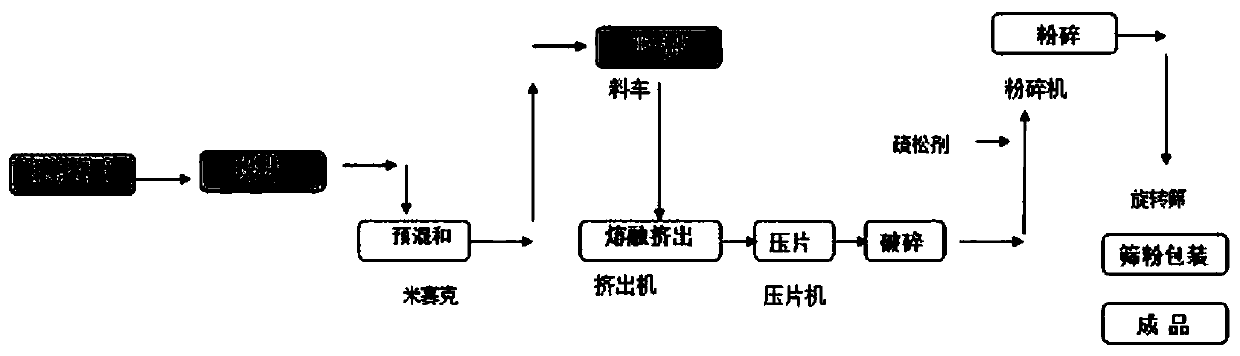

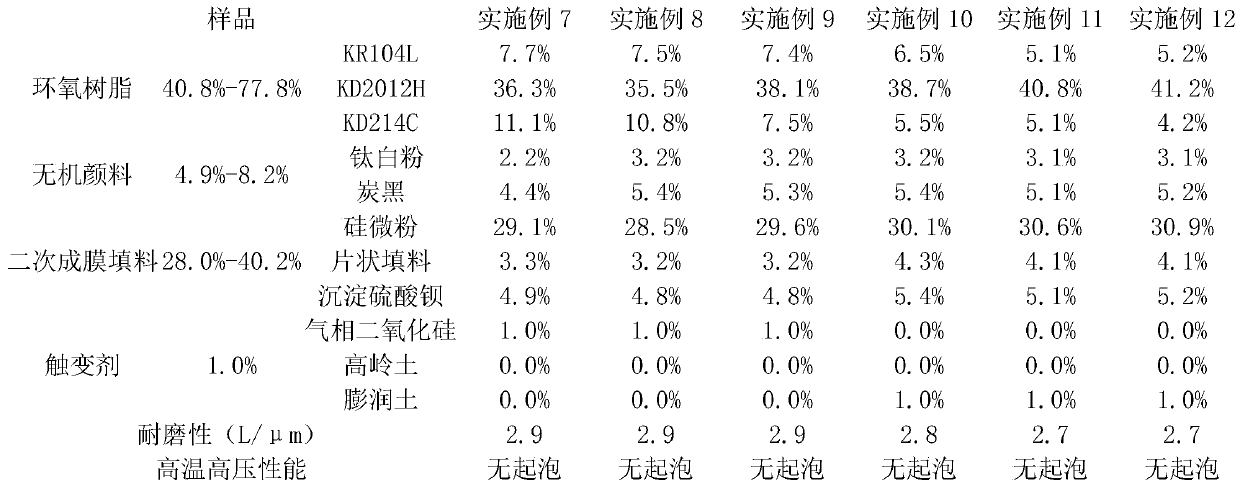

Oil drill pipe intercoat powder coating without using phenolic primer for bottoming

InactiveCN110283514AEffective tougheningIncrease crosslink densityAnti-corrosive paintsPowdery paintsEpoxyHeat resistance

The invention discloses an oil drill pipe intercoat powder coating without using a phenolic primer for bottoming. Raw materials include epoxy resin KR104L, epoxy resin KD2012H, epoxy resin KD2012H, inorganic pigments titanium dioxide and carbon black, a secondary film-forming filler and a thixotropic agent. The secondary film-forming filler includes a flaky filler. The invention also discloses a preparation method of an oil drill pipe intercoat powder coating without using a phenolic primer for bottoming. The powder coating obtained by the invention has good chemical resistance and heat resistance.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

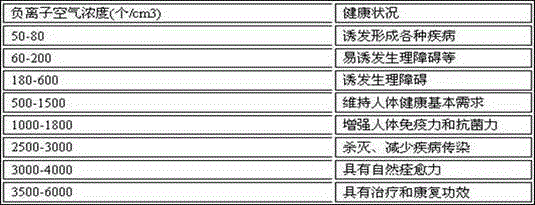

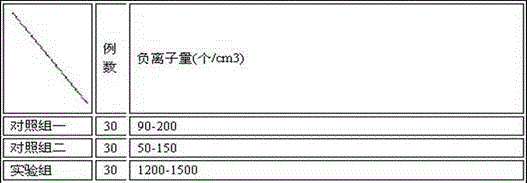

Flame-retardant environment-friendly water-based glass paint and preparation method thereof

InactiveCN106752624AOrientationControl level controlFireproof paintsAnti-corrosive paintsWater basedEpoxy

The invention belongs to the technical field of building decoration materials and in particular relates to flame-retardant environment-friendly water-based glass paint and a preparation method thereof. The flame-retardant environment-friendly water-based glass paint is prepared from the following materials in parts by weight: 9-21 parts of epoxy resin, 12-25 parts of polyurethane emulsion, 18-24 parts of acrylic acid modified epoxy resin, 11-27 parts of glycol ether, 8-19 parts of aluminum oxide, 10-17 parts of quartz sand, 27-33 parts of methyl methacrylate, 10-17 parts of methanal lytic enzyme crystals, 20-27 parts of methylpentanol, 17-30 parts of sericite, 9-19 parts of a plasticizer, 1-3 parts of sodium alkyl benzene sulfonate, 3-5 parts of polyethylene wax, 3-5 parts of microcrystalline wax, 1-4 parts of calcium stearate, 2-4 parts of high alcohol, 1-5 parts of nanometer silicon and 6-8 parts of waterborne glazing oil. The flame-retardant environment-friendly water-based glass paint provided by the invention has excellent wear-resistant property and scratch-resistant property, can release negative oxygen ions and purify indoor pollutants such as formaldehyde and is good in fireproof property.

Owner:江苏环宇纺织科技有限公司

Multifunctional thickener for waterborne paint

Provided is a multifunctional thickener for waterborne paint. The multifunctional thickener for the waterborne paint is prepared through the steps that 620-640 parts by weight of propylene glycol is added into a vessel, 18-22 parts by weight of pure water is added into the vessel, and stirring is conducted for 8 min to 15 min under the stirring condition of 400 revolutions / minute to 600 revolutions / minute; 11-15 parts by weight of wetting dispersant is added into the vessel, and stirring is conducted for 12 min to 18 min under the stirring condition of 400 revolutions / minute to 600 revolutions / minute; 340-360 parts by weight of xanthan gum is added into the vessel, and stirring is conducted for 25 min to 35 min under the stirring condition of 800 revolutions / minute to 1,000 revolutions / minute. The multifunctional thickener for the waterborne paint can achieve the anti-settling, anti-layering and anti-sagging effects in the production and use processes of the waterborne paint and can achieve thickening in paint with different pH values.

Owner:徐文学

Environment-friendly and anticorrosive graphene coating material for bridge metal member, and preparation method of environment-friendly and anticorrosive graphene coating material

InactiveCN106519970AImprove corrosion resistanceGood physical and mechanical propertiesAnti-corrosive paintsEpoxyPliability

The invention discloses an environment-friendly and anticorrosive graphene coating material for a bridge metal member, and a preparation method of the environment-friendly and anticorrosive graphene coating material. The coating material is prepared from a component A and a component B; the component A is prepared from epoxy polysiloxane resin, 3-aminopropyl trimethoxy silane, graphene, ultrafine rutile titanium dioxide, fumed silica, a dispersant, a defoamer, a flatting agent, a thickener and a film formation agent; the component B is prepared from triethoxy ethyl silane, triethoxy propyl silane and anacardol; finally the environment-friendly and anticorrosive graphene coating material is prepared according to a ratio of the component A to the component B. The preparation method of the environment-friendly and anticorrosive graphene coating material for a bridge metal member comprises the following process steps: step 1: performing a production process of the component A; step 2: performing a production process of the component B; step 3: making a finished product of the environment-friendly and anticorrosive graphene coating material. The coating material is used for protecting the bridge metal member, has low surface tension, aging resistance, water resistance, flexibility, saline water resistance and corrosion resistance, and can be widely applied to bridge metal member protection.

Owner:北京公联洁达公路养护工程有限公司 +1

Formula and construction process of exterior wall thermal insulation putty-free plastering mortar

The invention relates to the field of building materials, particularly to a formula and a construction process of exterior wall thermal insulation putty-free plastering mortar. The exterior wall thermal insulation putty-free plastering mortar comprises bottom-layer plastering mortar and surface-layer plastering mortar, wherein the bottom-layer plastering mortar comprises the following components:30-50 parts of white cement, 5-11 parts of ash calcium, 50-65 parts of white marble machine-made sand, 0.2-0.5 part of hydroxypropyl methyl cellulose, 0.1-0.3 part of wood fiber, 0.1-0.2 part of polypropylene fiber and 0.5-1.5 part of latex powder, and the surface-layer plastering mortar comprises the following components: 40-60 parts of white cement, 5-10 parts of ash calcium, 35-45 parts of white marble machine-made sand, 0.2-0.5 part of hydroxypropyl methyl cellulose, 0.1-0.3 part of wood fiber, 0.1-0.2 part of polypropylene fiber, 0.5-1.5 parts of latex powder and 0.05-0.1 part of cellulose ether. According to the exterior wall thermal insulation putty-free plastering mortar prepared by the formula, materials, procedures and time of a putty layer are saved, and the cost can be better saved.

Owner:赵开磊

A kind of solvent-free epoxy coating and preparation method thereof

ActiveCN106554705BLow viscosityImprove compactnessFireproof paintsAnti-corrosive paintsPolymer scienceSolvent free

The invention provides a solvent-free epoxy coating material and a preparation method thereof. The solvent-free epoxy coating material comprises a first component and a second component, wherein the first component comprises the following components in parts by weight: 1 part of bisphenol F resin, 0.8-1.0 part of bisphenol A epoxy resin E51, 0.1-0.2 part of liquid petroleum resin, 0.15-0.3 part of isomerous monocarboxylic acid glycidyl ester, 0.2-0.7 part of an anti-wear agent, 0.1-0.3 part of a dispersant, 0.02-0.1 part of an air-release agent, 0.01-0.1 part of a first slip agent, 0.05-0.1 part of a second slip agent, 0.05-0.1 part of a defoaming agent and 0.01-0.02 part of an anti-settling thixotropic agent; and the second component comprises the following components in parts by weight: 1 part of phenolic aldehyde modified aliphatic amine, 0. 8-1.2 parts of allylphenol modified alicyclic amine, 0.015-0.03 part of modified polyurea, 0.01-0.03 part of a dispersant, 0.1-0.3 part of iron oxide red and 0.15-0.35 part of anti-corrosion packing. A coating formed by the solvent-free epoxy coating material has an excellent thin-coating property, the one-step film-forming thickness of the solvent-free epoxy coating material can be equal to or less than 100 mu m, and the coating has high apparent quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Energy-saving environmental-protection thickener for mortar preblending and dry-mixing

The invention relates to a building material, particularly a necessary admixture for mortar preblending and dry mixing. The energy-saving environmental-protection thickener for mortar preblending and dry-mixing is prepared from the following materials in percentage by weight: 30-40% of bentonite tailings, 10-15% of zeolite powder, 10-15% of fly ash, 10-15% of ore slag micropowder, 3-8% of calciumhydroxide powder, 3-8% of gypsum powder, 1-5% of starch ether, 2-5% of lignosulphonate and 2-4% of polycarboxylate multipolymer. The thickener is prepared by the following steps: electronically weighing the materials according to the preset proportion, and evenly and mechanically stirring by using a zero-gravity double-shaft mixing machine. The product has the advantages of favorable sagging resistance, moisture retention, workability, plastic reduction and seepage resistance.

Owner:ANJI ZHONGRUI BENTONITE CHEM

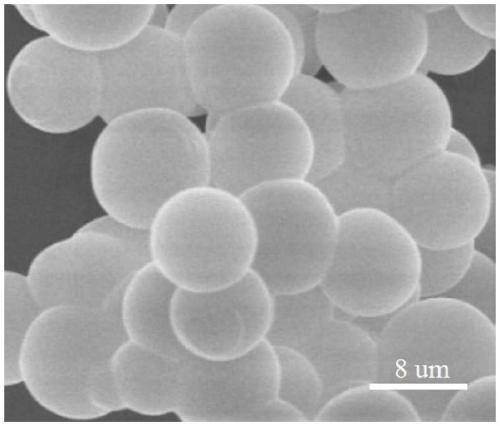

Preparation method of silica gel flatting agent used for paint

The invention discloses a preparation method of a silica gel flatting agent used for paint. The preparation method comprises following steps: 1, a gel is prepared; 2, spherical silica sol shrinkage moulding is carried out; 3, acid immersing and water washing are carried out; 4, ammonia immersing and drying are carried out; 5, high temperature activation is carried out; and 6, grinding sieving arecarried out. The silica gel micro powder flatting agent is white or milk white powder, is nontoxic, is odourless, contains no volatile substance, is large in pore volume, is narrow in pore diameter distribution range, is high in transparency; the average particle size ranges from 6 to 10 <mu>m; the pore volume is 1.95mL / g; the refractive index is 1.4 to 1.5; the oil suction value is 300g / 100g; thesilica gel flatting agent can be widely used in finishing paint, woodenware paint, furniture paint, and solvent type color paint, and possesses controlled rheological performance, bright light shielding performance, sagging resistance, settlement resistance, and improved corrosion resistance.

Owner:青岛硕远硅胶科技有限公司

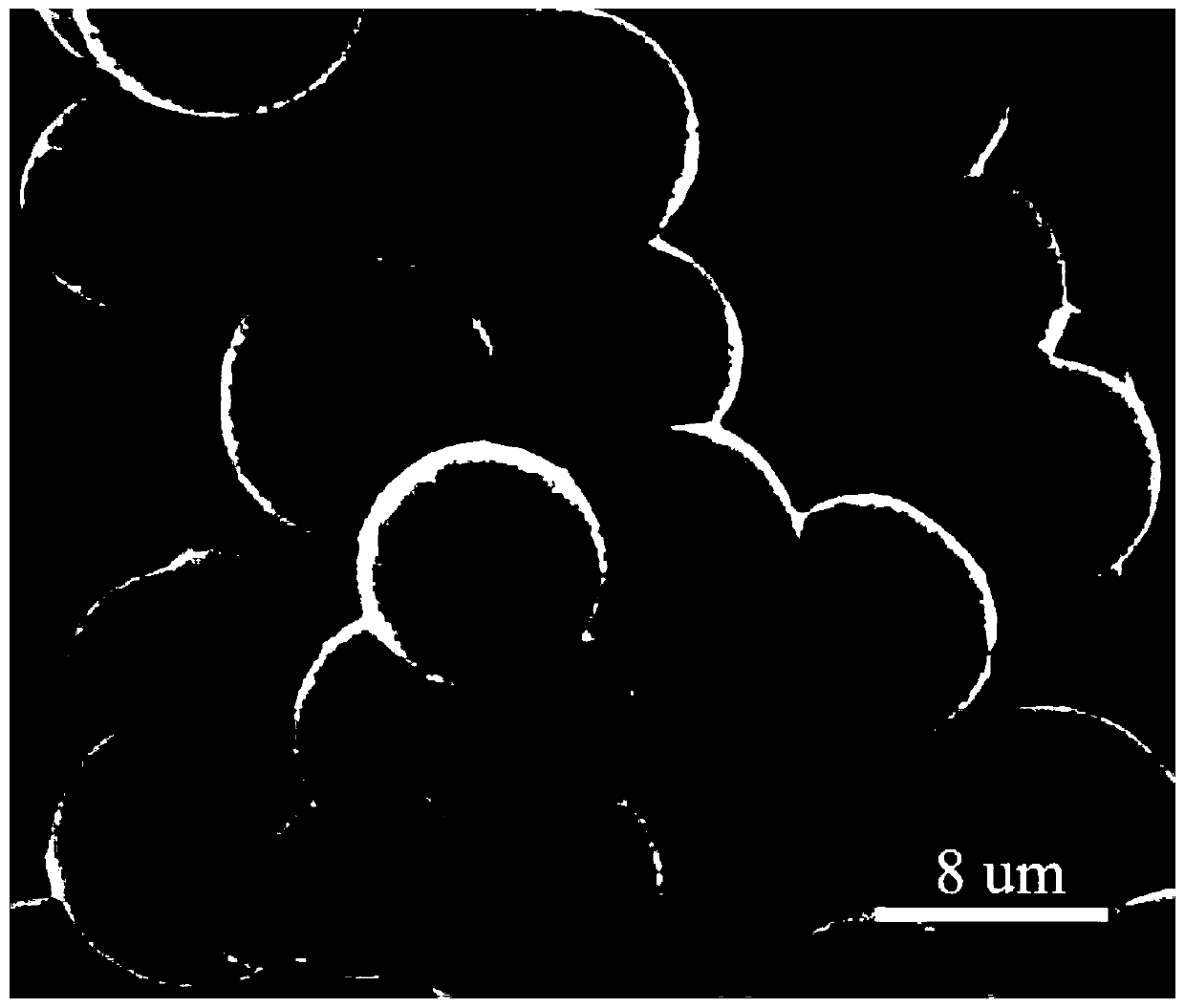

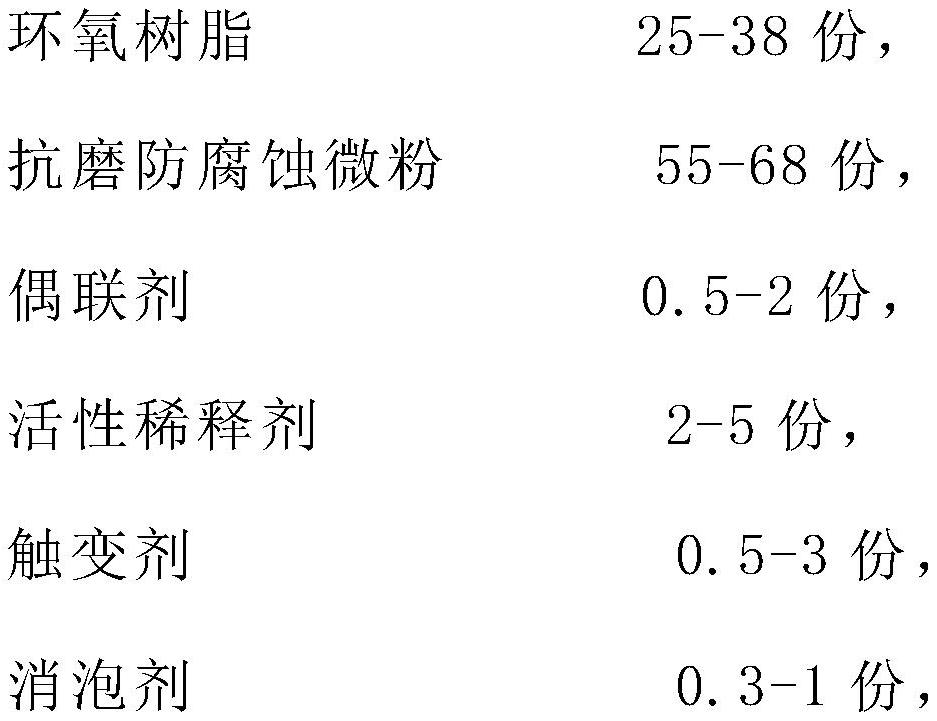

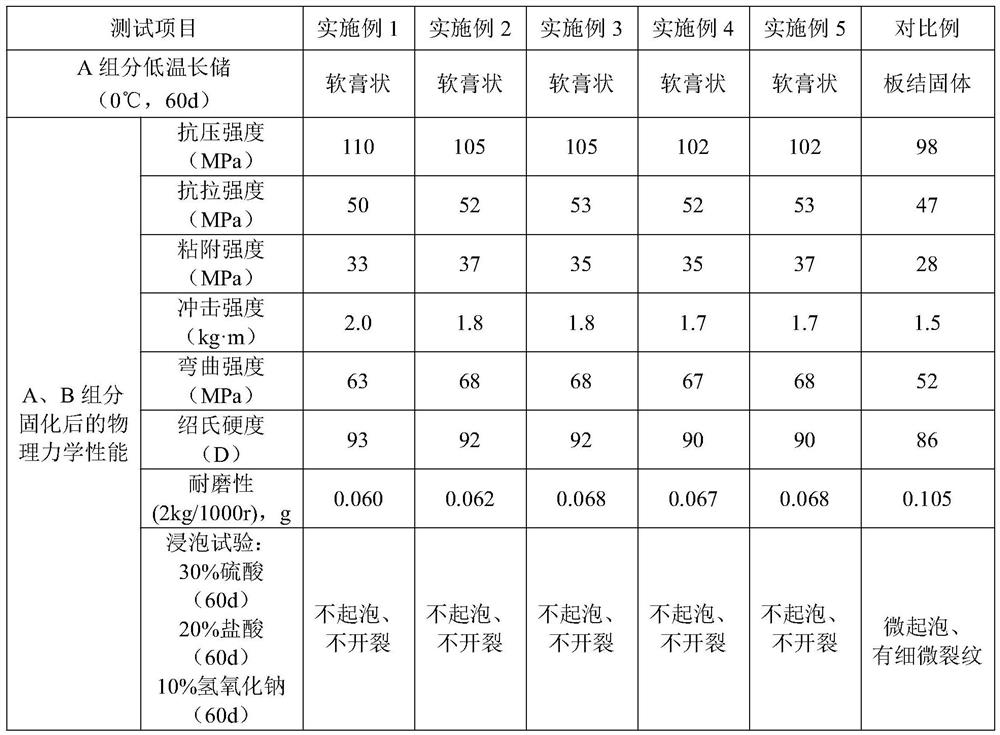

Composite coating layer material

InactiveCN113278345AGood flexibilityLow viscosityAnti-corrosive paintsEpoxy resin coatingsFirming agentOrganosolv

The invention discloses a composite coating layer material, which comprises a component A and a component B, wherein the component A is composed of epoxy resin, anti-wear and anti-corrosion micro powder, a coupling agent, a reactive diluent, a thixotropic agent and a defoaming agent, and the component B consists of the following components: a curing agent, a curing accelerator and an adhesion promoter. According to the invention, the composite coating layer material has the advantages of high flexibility, mechanical strength, bonding strength, corrosion resistance, wear resistance, weather resistance, long storage stability, low viscosity, no warping, no shedding, no cracking, and long service life; the composite coating layer material does not contain volatile organic solvents, and the cured coating has no pinholes, does not shrink, is hard, and is relatively safe to the environment and constructors; the preparation process is simple, construction operation is easy and convenient, construction can be conducted at the normal temperature, curing can be conducted at the normal temperature, shape suitability is high, the thickness of the coating is controllable, machining can be achieved, and the coating can be applied to various base materials; and the raw materials are easily available and low in cost.

Owner:ENVIRONMENTAL GASKET COMPANY

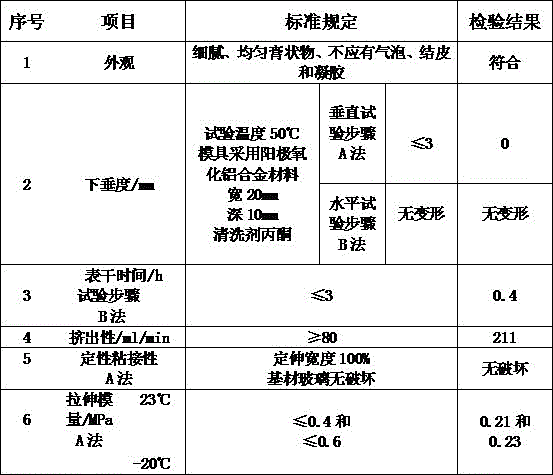

A kind of acid silicone sealant and preparation method thereof

ActiveCN104059596BAvoid the disadvantages of being easy to crystallize and not easy to useChange the cross-linked structureNon-macromolecular adhesive additivesMacromolecular adhesive additivesVacuum pumpingCross-link

The invention discloses an acidic silicone sealant and a preparation method, the preparation method comprises the following steps: 1)preparing the raw materials; 2)adding 200-220 parts of glue 107, 2-6 parts of thixotropic agent in a glue cylinder, vacuum-pumping and stirring for 3-5 minutes; 3)sucking 10-20 parts of cross-linking agent in the glue cylinder after opening a material pumping valve, then closing the material pumping valve; stirring; 4)sucking partial gas phase white carbon black in the glue cylinder by using a membrane pump, stirring; 5)repeatedly operating for 1-4 times on the residual gas phase white carbon black according to step 4); 6)fully mixing 120-130 parts of 330 silicone oil and 0.09-0.15 parts of tin acetate to obtain a mixture; 7)sucking the mixture in the step 2) in the glue cylinder after stirring, then stirring again; keeping degree of vacuum as -0.09--0.1MPa during the stirring process; and 8)filling nitrogen and emptying after stirring in the step 7) to obtain the acidic silicone sealant. The acidic silicone sealant has the advantages of good cementability, strong sealing, difficult skinning and no sagging.

Owner:扬州晨化新材料股份有限公司

Guar gum-added internal wall heat-insulating putty

The invention discloses a guar gum-added internal wall heat-insulating putty which is prepared from the following raw materials: cement, hollow glass bead, tetraethyl orthosilicate, absolute ethyl alcohol, 1mol / L hydrochloric acid, 8-10 parts of template F127 sand, guar gum, shellac resin, nano-zinc oxide, paper pulp powder, nanometer aluminum hydroxide, lauryl sodium sulfate, stannous octoate, sodium dihydrogen phosphate and a defined amount of deionized water. The putty powder prepared according to the invention has the advantages of high thickening property, high adhesive property, high strength, cracking resistance, drooping resistance, strong waterproof property, and the like, is excellent in heat insulation and simple in preparation process, is low in cost, is excellent in decorative effect for the internal wall and is worthy of popularization.

Owner:高绍彬

A paint remover containing attapulgite and its preparation method

ActiveCN105985676BNo pollution in the processHave a thickening effectChemical paints/ink removersBENZYL ALCOHOL/WATERMethanol

The invention mainly provides a paint remover comprising attapulgite, and a preparation method thereof. According to the invention, benzyl alcohol is adopted as a main component, and is mixed with water, attapulgite, starch, a surfactant and thickening agents. The paint remover comprises 20-35% of benzyl alcohol, 20-30% of water, 1-3% of the surfacant, 35-45% of attapulgite, 3-5% of starch, 2-3.5% of carboxypropylmethyl cellulose, and 2-3.5% of carboxymethyl cellulose. The paint remover is a non-fluid viscous paste-like material. The pH of the peelable paste-like material is neutral. The paint remover does not contain volatile organic compound, and does not pollute the environment. The paint remover can be used for removing surface paint of buildings, home appliances and industrial coatings.

Owner:上海昌韶环境科技有限公司

A thermal insulation mortar for building exterior walls with good rheology

Owner:温州市工大节能材料科技有限公司

Wall decoration coating as well as preparation method and application thereof

The invention discloses a wall decoration coating, which is prepared from the following ingredients in parts by mass: 30 to 65 parts of a filling agent, 10 to 35 parts of superfine slag powder, 0.2 to 3 parts of magnesium aluminum silicate, 0.02 to 0.8 part of poly high-energy latex powder, 10 to 35 parts of white cement, 0.05 to 0.5 part of a water reducing agent, 0.1 to 1.5 parts of a water retaining agent, 0.1 to 1.5 parts of waterproof powder and 0.05 to 1 part of an anti-alkali agent. The wall decoration coating has the excellent properties of no yellowing and discoloration, environmental protection, permanent alkali resistance, water resistance, mildew resistance, difficult shedding and the like, and the product has the advantages of low comprehensive cost and long service life; and the coating has the advantages of no caking, uniformity, no barrier in blade coating during construction, no crack in early dry crack resistance, manual polishing, no bubbling, cracking and powder falling phenomena within 48 hours, and environmental protection indexes exceeding national standards. The invention also discloses a preparation method and application of the wall decoration coating, the preparation is simple, the construction is simple and convenient, the comprehensive cost is low, and the wall decoration coating can replace putty wall surfaces and latex paint.

Owner:何志刚

Ceramic tile adhesive

The invention relates to a ceramic tile adhesive. The ceramic tile adhesive is prepared from the following raw materials in parts by weight: 40-45 parts of cement, 40-45 parts of silica sand, 15-20 parts of heavy calcium powder, 3-5 parts of re-dispersible latex powder, and 2-5 parts of an additive; the cement is silicate cement; as for the silica sand, the fineness is 200 meshes or below, the mudcontent is smaller than 0.5% by weight, and the water content is smaller than 0.5% by weight; as for the heavy calcium powder, the fineness is 200 meshes or below, and the water content is smaller than 0.5% by weight; and the additive is a mixture of cellulose ether, lignocellulose and starch ether. The ceramic tile adhesive has the advantages that various organic polymers are added, the bondingstrength is high, the hardening speed is high, and the service life of various ceramic tiles is greatly prolonged; and the ceramic tile adhesive is convenient to construct, and can be used only by adding the right amount of fresh water to be stirred, and the pasted ceramic tiles can be directly pasted without being soaked in water.

Owner:REAL ESTATE CONSTR ANGANG GROUP

Inner wall putty powder

InactiveCN106752247AImprove general performanceAnti-saggingFilling pastesCelluloseUltraviolet lights

The invention discloses an inner wall putty powder. The inner wall putty powder is prepared from ground calcium carbonate powder, talc powder, diatom powder, montmorillonite, polyanionic cellulose PAC, NSJF-6A gelatine powder, 821 gelatine powder, dispersing agent LBD-1, organosilicon solid defoamer, preservative BJ-75, polypropylene anti-crack and anti-seepage, ultraviolet light absorber C-20, solid sodium alginate preservative and lavender. The inner wall putty powder has the advantages of being high in universality and viscosity, sag-resistant, environmentally friendly and the like; moreover, by the addition of diatom powder and traditional Chinese medicine component lavender, the inner wall putty powder has the effects of air purification, sterilization and disinfection; the inner wall putty powder can emit fresh and elegant fragrance, has a health care effect, and is suitable for dwelling.

Owner:芜湖普乐士新型建筑材料配套有限公司

a sculpture mortar

The invention discloses a novel sculpture mortar. The novel sculpture mortar comprises the following components: 40-50% of 32.5R ordinary Portland cement, 45%-55% of 40-80 mesh sand ( quartz sands), 1-2% of 50-70 mesh light-weight aggregates, 0.01-0.1% of cellulose ether, 0.02-0.2% of dispersible latex powder, 0.2-0.4% of a water-reducing agent, 2-3% of silica powder, 0.3-0.4% of lignin fiber and 0-0.04% of polyropylene fiber. The component composition is to fulfill the following purposes: the operation is simple; no other materials are required for adding and the sculpture mortar can be directly utilized; the novel sculpture mortar facilitates the construction and has excellent workability; the sag resistance of the novel sculpture mortar enables the thickness of the troweling at one time to be more than 5 cm; a more stereoscopic and richer sculptural effect can be created; the construction efficiency is improved; cracks are rarely found on the sculpture and the simulation effect is improved; the structure is compact; the matching is reasonable and the service life can be prolonged; industrialized production is realized, so that the quality is stable and guaranteed.

Owner:SUZHOU TASHI LANDSCAPE ENG TECH CO LTD

High-rheological-property heat insulated mortar for outer wall of building

The invention provides a high-rheological-property heat insulated mortar for an outer wall of a building and a manufacturing method thereof. The high-rheological-property heat insulated mortar for theouter wall of the building comprises the following components in parts by weight: 200-240 parts of cement, 10-15 parts of ultrafine phosphorus slag powder, 5-10 parts of quick lime, 100-120 parts ofsand, 50-120 parts of modified expanded lightweight aggregate, 20-25 parts of a rheological agent, 5-10 parts of hydroxy propyl cellulose, 2-6 parts of a polycarboxylic acid high-performance water reducing agent, and 70-90 parts of water. According to the preparation method, the lightweight aggregate is subjected to ball milling through a modified ball mill agent, and the surface is modified, so that the lightweight aggregate is uniform in granule size; the surface wettability is improved; the aggregate with uniform surface wettability can be uniformly distributed in the mortar.

Owner:温州市工大节能材料科技有限公司

A machine-sprayed plaster

The invention provides a mechanical spraying plastering mortar and an additive. The mechanical spraying plastering mortar comprises: by weight, cement 10%-18%, fly ash 5%-10%, sand 75%-80%, and additive 0.5%. The additive comprises, by weight, cellulose ether 0.02%, montmorillonite powder 0.01%, starch ether 0.01%, water reducing agent 0.05%, air-entraining agent 0.0035%, and wood fibre 0.1%. The product optimizes the mix ratio of the plastering mortar, and mixes a certain ratio of additive, so that the plastering mortar has sag resistance, good lubricity, water-retaining property and fluidity, and strong binding power, and the performance requirements of mechanical pumping and spraying construction of the plastering mortar is realized. And thus, labor intensity is reduced, construction efficiency is enhanced, and the construction efficiency is more than two times of that of manual plastering. The wall plastering using mechanical spraying construction has high pressure and is uniform, avoids empty drum and crack of the plaster layer, and improves the engineering quality of the additive.

Owner:浙江正昶新型材料股份有限公司

Emulsion paint containing attapulgite and preparation method for emulsion paint containing attapulgite

ActiveCN102618128BThixotropic thickening effect is obviousPrevent subsidenceEmulsion paintsCelluloseDefoaming Agents

The invention discloses emulsion paint containing attapulgite and a preparation method for the emulsion paint containing attapulgite. The method mainly comprises the following steps of: sequentially adding water, cellulose, a dispersing agent SN-5040, a mildew preventive, an aid AMP-95, alcohol ester-12, poly ethylene-100 (PE-100), a defoaming agent JR-321, propylene glycol, 1,000-mesh triple superphosphate, talcpowder, titanium dioxide, the attapulgite, an aid BYK022, an emulsion SD-818, a thickening agent RM2020 and a thickening agent AR-235 which serve as raw materials in a weight ratio, mixing and dispersing to obtain the emulsion paint. According to the emulsion paint, the used attapulgite has an obvious thixotropic thickening effect, prevents pigments from settling, can improve the synaeresis phenomenon of paint films, and has the effects of sagging prevention and splashing resistance; the uniformity of the surfaces of the paint films is improved; and a thickening effect of the attapulgite is different from that of the cellulose, namely the attapulgite has a certain antibacterial property and a certain mildew-resistant property, and improves the tinctorial power of the pigments and the covering capacity of coatings.

Owner:安徽省明美矿物化工有限公司

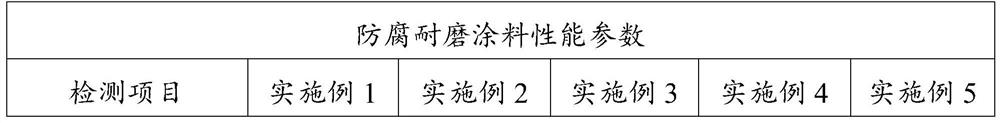

Method for preparing anti-corrosion and wear-resistant coating by using secondary aluminum ash as raw material

The invention provides a method for preparing an anti-corrosion and wear-resistant coating by utilizing secondary aluminum ash, and particularly relates to the technical field of treatment by utilizing the secondary aluminum ash, the method comprises the following steps: firstly, adding the secondary aluminum ash into water to prepare a mixed solution; filtering the mixed solution to obtain filter residues, and washing and drying the filter residues to obtain secondary aluminum ash pretreatment powder; adding the secondary aluminum ash pretreatment powder and silicon carbide into a planetary ball mill for ball milling to obtain mixed fine powder; then putting the mixed fine powder, high chlorinated polyethylene resin, an organic solvent and deionized water into a stirring kettle to be mixed and stirred to prepare pug; and adding the anti-corrosion pigment and the auxiliary agent into the stirring kettle, stirring until the mixture is viscous, and adding the inorganic flame retardant to obtain the anti-corrosion and wear-resistant coating. According to the invention, efficient recycling of the secondary aluminum ash is realized, the production cost is relatively low, the production process is simple, and the prepared anti-corrosion and wear-resistant coating has excellent performance.

Owner:江苏东台超凡创新新材料科技有限公司

A special coating for modified epoxy denitrification device and its preparation method

ActiveCN103992719BImprove adhesionGood chemical resistanceAnti-corrosive paintsPolyamide coatingsPolymer scienceFirming agent

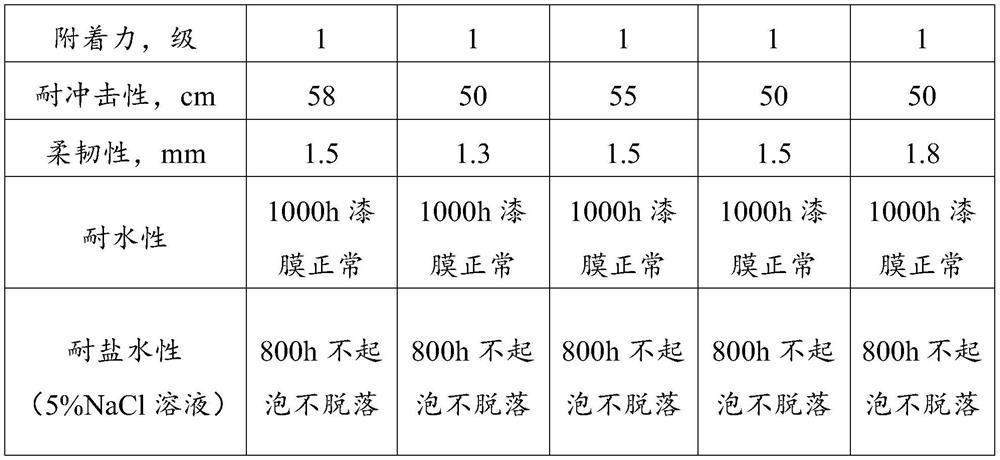

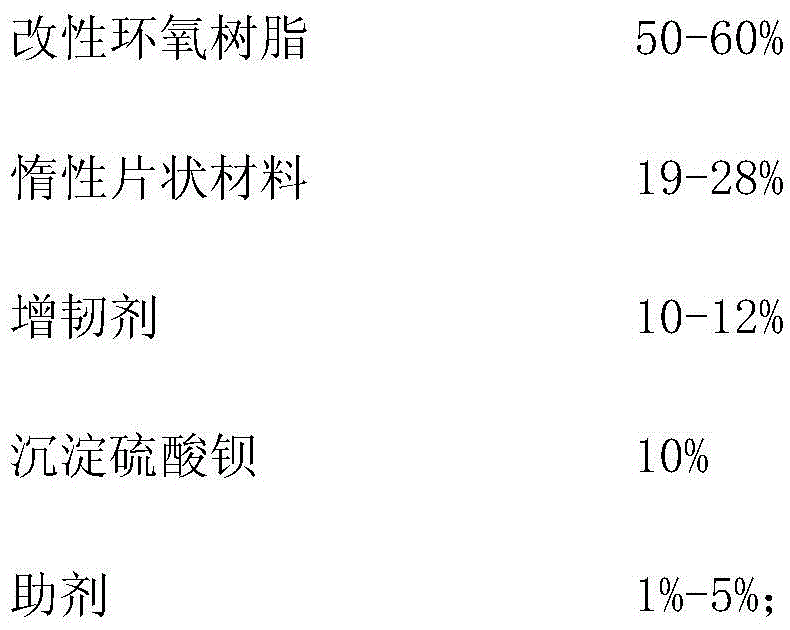

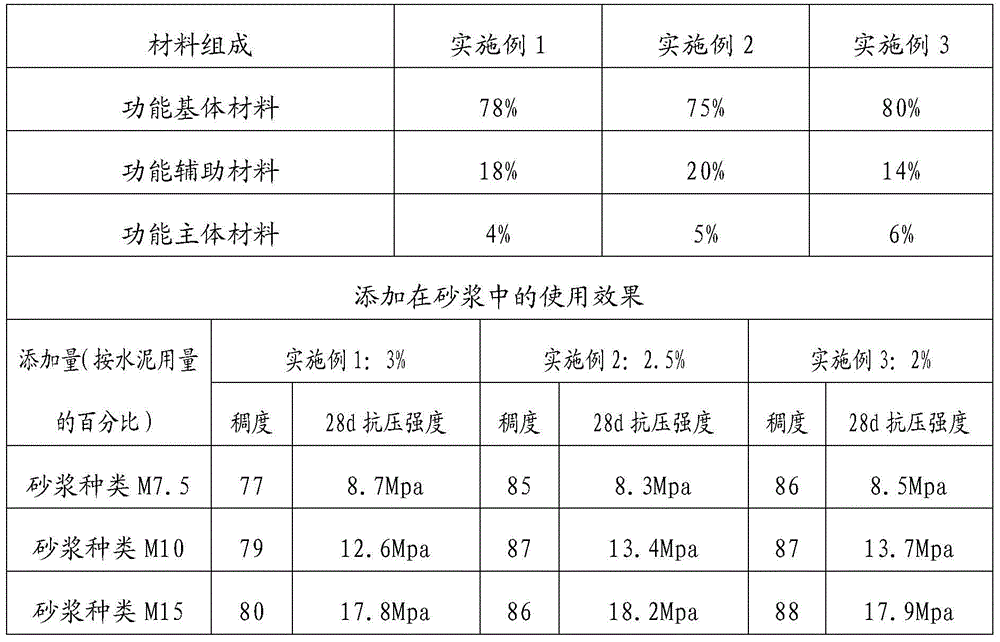

The invention discloses a special coating for a modified epoxy denitration device, and a preparation method thereof. The coating comprises a component A and a component B, the component A comprises modified epoxy resin, an inert sheet material, a flexibilizer, precipitated barium sulfate and an assistant, and the component B comprises a curing agent and a solvent. The preparation method comprises the following steps: adding the epoxy resin, the flexibilizer and the assistant in the component into a dispersion cylinder, stirring, adding precipitated barium sulfate, adding the inert sheet material, filtering to obtain the component A of the coating, dissolving the curing agent by using the solvent in the component B, filtering to obtain the component B of the coating, weighing the prepared component A and the component B according to a mass ratio, uniformly mixing, and curing to obtain the special coating for a modified epoxy denitration device. The special coating for a modified epoxy denitration device has the advantages of strong adhesion, unlikely shedding, good impermeability, chemical reagent resistance, improvement of the whole protection capability of the coating, and prolongation of the service life of the denitration device, and the method has the advantages of simple operation, low cost and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

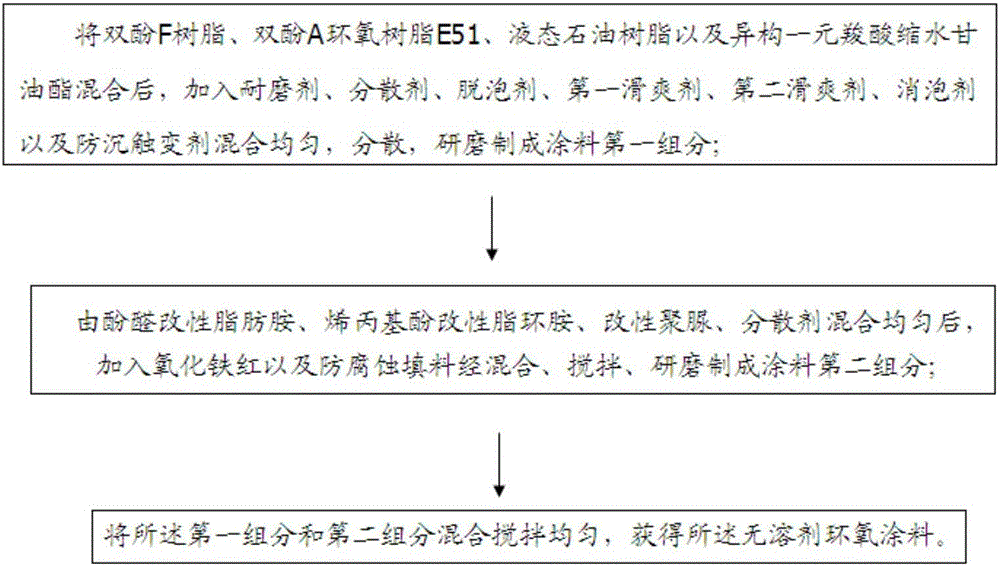

A kind of composite mineral powder water retention enhancer

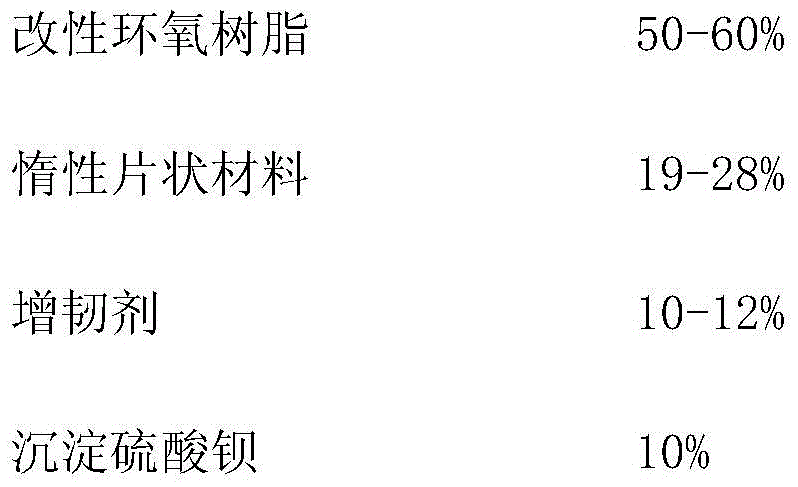

The invention relates to a compound mineral powder water-retaining reinforcing agent which is prepared from the following raw materials in percentage by weight: 70-90% of a functional base body material, 1-20% of a functional auxiliary material and 1-15% of a functional main body material. The compound mineral powder water-retaining reinforcing agent provided by the invention and used for building mortar has the advantages of being easily available, simple in process, low in price and broad in prospect.

Owner:张泽荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com