High-rheological-property heat insulated mortar for outer wall of building

A technology for building exterior walls and thermal insulation mortar, which is applied in the field of external wall thermal insulation mortar, which can solve problems such as unstable thermal insulation performance of products and uneven distribution of lightweight materials, and achieve uniform size, prevent delamination or settlement, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

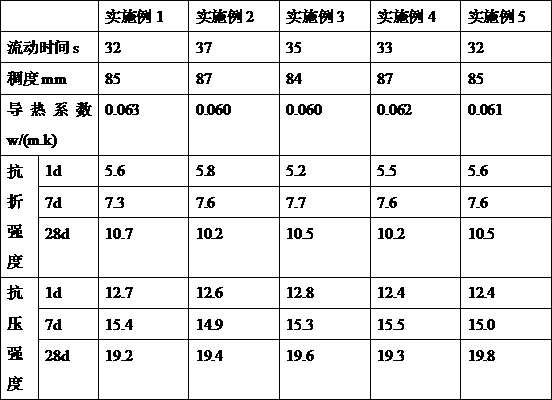

Embodiment 1

[0022] A building exterior wall thermal insulation mortar with good rheology and a manufacturing method thereof,

[0023] The thermal insulation mortar for building exterior walls with good rheology includes parts by weight: 210 parts of cement, 12 parts of superfine phosphorus slag powder, 5 parts of quicklime, 100 parts of sand, 70 parts of modified expanded lightweight aggregate, and 20 parts of rheological agent , 7 parts of hydroxypropyl cellulose, 2 parts of polycarboxylate high-performance water reducer, 90 parts of water,

[0024] The method for manufacturing the thermal insulation mortar for building exterior walls with good rheology includes the following steps: firstly, prepare a rheological agent: heat 150ml of methyl methacrylate to 46-50°C, stir and add 12g of triisopropanolamine, and heat up for 60-70°C ℃, add 5g of sodium xylene sulfonate and 6g of sodium alginate to the reaction kettle, use a magnetic stirrer to stir the reaction at a speed of 230r / min, then a...

Embodiment 2

[0028] A building exterior wall thermal insulation mortar with good rheology and a manufacturing method thereof,

[0029] The building exterior wall thermal insulation mortar with good rheology includes parts by weight: 200 parts of cement, 14 parts of superfine phosphorus slag powder, 9 parts of quicklime, 120 parts of sand, 110 parts of modified expanded lightweight aggregate, and 24 parts of rheological agent , 6 parts of hydroxypropyl cellulose, 5 parts of polycarboxylate high-performance water reducer, 90 parts of water,

[0030] The method for manufacturing the thermal insulation mortar for building exterior walls with good rheology includes the following steps: firstly, prepare a rheological agent: heat 100ml of methyl methacrylate to 46-50°C, add 11g of triisopropanolamine with stirring, and heat up for 60-70°C ℃, add 6g of sodium xylene sulfonate and 6g of sodium alginate to the reaction kettle, use a magnetic stirrer to stir the reaction at a speed of 210r / min, then ...

Embodiment 3

[0034] A building exterior wall thermal insulation mortar with good rheology and a manufacturing method thereof,

[0035] The thermal insulation mortar for building exterior walls with good rheology includes parts by weight: 220 parts of cement, 14 parts of superfine phosphorus slag powder, 10 parts of quicklime, 120 parts of sand, 90 parts of modified expanded lightweight aggregate, and 22 parts of rheological agent , 7 parts of hydroxypropyl cellulose, 5 parts of polycarboxylate high-performance water reducer, 75 parts of water,

[0036]The manufacturing method of the thermal insulation mortar for building exterior walls with good rheological properties includes the following steps: firstly prepare a rheological agent: heat 130ml of methyl methacrylate to 48°C, stir and add 10g of triisopropanolamine, heat up to 62°C, and add to the reaction Add 5g of sodium xylenesulfonate and 7g of sodium alginate to the kettle, and use a magnetic stirrer to carry out stirring reaction at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com