Composite coating layer material

A technology of composite coating and epoxy resin, applied in the direction of coating, anti-corrosion coating, epoxy resin coating, etc., can solve the problems of weak coating adhesion, poor anti-corrosion and wear resistance, insufficient mechanical strength, etc., and achieve easy Constructability, strong anti-corrosion performance, anti-sag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

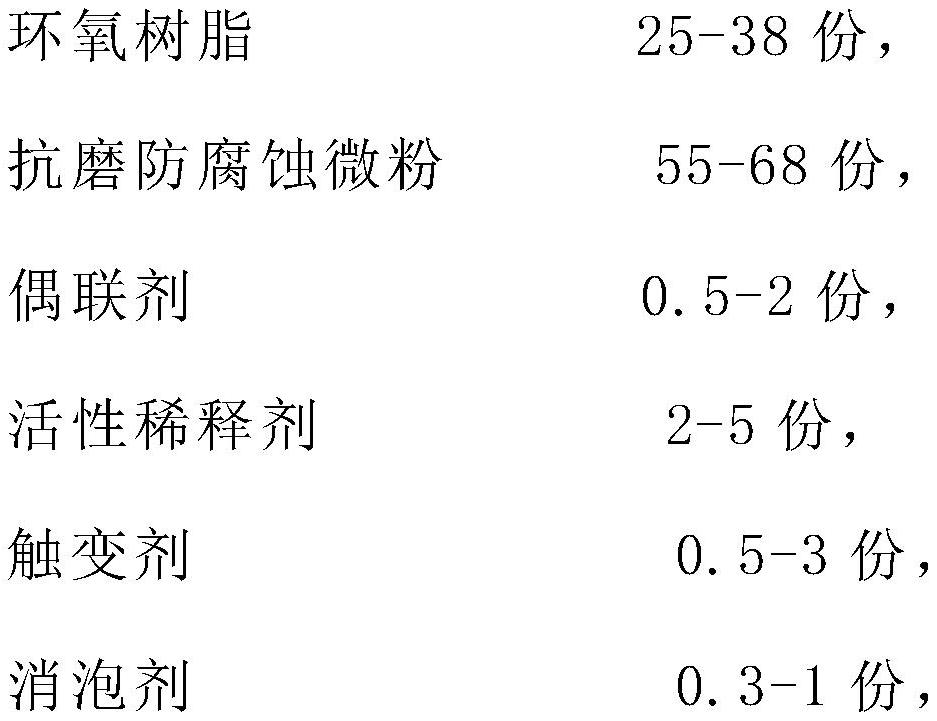

Method used

Image

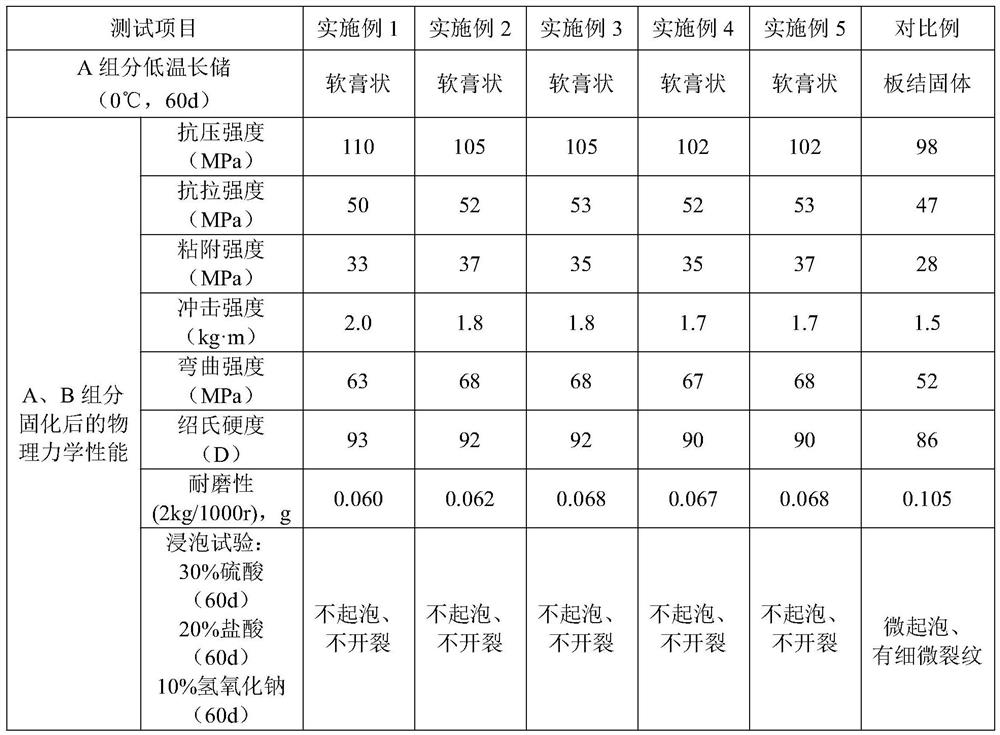

Examples

Embodiment 1

[0035] Diphenolic propane glycidyl ether, bisphenol F diglycidyl ether, CTBN modified epoxy resin, silicon micropowder, ceramic micropowder, mica powder, SiC powder, 3-glycidyl ether Oxypropylmethyldiethoxysilane (silane coupling agent), white carbon black, dodecyl to tetradecyl glycidyl ether and BYK-054 (defoamer) were put into the blending equipment, stirred for 2h, Obtain A component; put modified alicyclic amine, modified fatty amine, TAP and ADP-S471 (adhesion promoter) into the blending equipment, stir for 1h to obtain B component; combine A component and B component Mix evenly at a weight ratio of 9:1 to obtain a composite coating material.

Embodiment 2

[0037] Diphenolic propane glycidyl ether, bisphenol F diglycidyl ether, CTBN modified epoxy resin, silicon micropowder, ceramic micropowder, mica powder, SiC powder, 3-glycidyl ether Oxypropylmethyldiethoxysilane (silane coupling agent), white carbon black, dodecyl to tetradecyl glycidyl ether and BYK-054 (defoamer) were put into the blending equipment, stirred for 2h, Obtain A component; put modified alicyclic amine, modified fatty amine, TAP and ADP-S471 (adhesion promoter) into the blending equipment, stir for 1h to obtain B component; combine A component and B component Mix evenly at a weight ratio of 8.5:1 to obtain a composite coating material.

Embodiment 3

[0039] Diphenol propane glycidyl ether, bisphenol F diglycidyl ether, CTBN modified epoxy resin, ceramic micropowder, mica powder, SiC powder, porous powder quartz, 3-glycidol Put etheroxypropylmethyldiethoxysilane (silane coupling agent), white carbon black, dodecyl to myristyl glycidyl ether and BYK-054 (defoamer) into the blending equipment and stir for 2 hours , to obtain component A; put modified alicyclic amine, modified fatty amine, TAP and ADP-S471 (adhesion promoter) into the blending equipment, stir for 1 hour, and obtain component B; combine component A and group B The parts are mixed evenly according to the weight ratio of 7.5:1 to obtain a composite coating material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com