Method for preparing anti-corrosion and wear-resistant coating by using secondary aluminum ash as raw material

An anti-corrosion and wear-resistant, secondary aluminum technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high cost, low operating temperature, complex preparation process, etc., and achieve the effect of low cost, low price and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

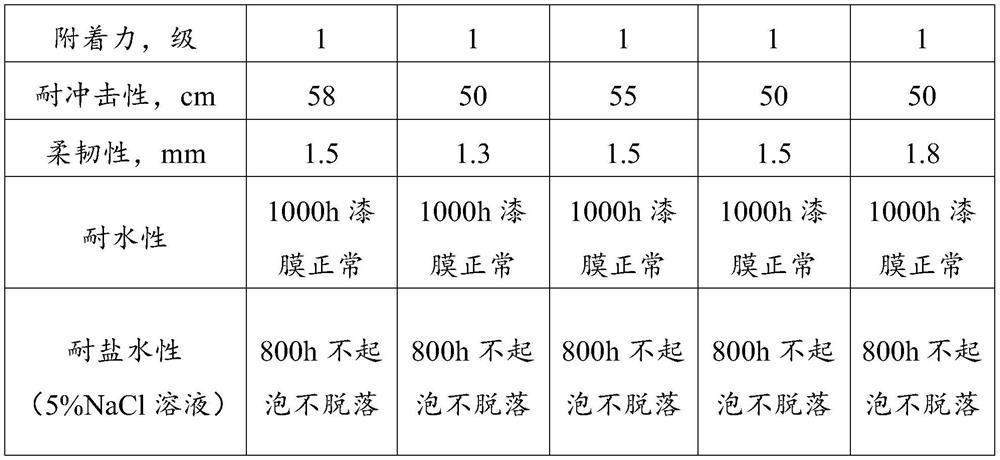

Examples

Embodiment 1

[0024] A method for preparing anti-corrosion and wear-resistant paint by utilizing secondary aluminum ash as a raw material, the steps of which are as follows:

[0025] S1. First, add 100 parts by mass of secondary aluminum ash to 300 parts by mass of water, mix evenly to obtain a mixed solution; then stir the mixed solution at 70°C for 3 hours, and filter to obtain a filter residue; The filter residue is washed and dried to obtain secondary aluminum ash pretreatment powder; wherein, the chemical composition of the secondary aluminum ash is: Al is 9.6wt%, Al 2 O 3 70.6wt%, SiO 2 is 8.7wt%, and other components are 11.1wt%;

[0026] S2, adding 100 parts of quality of the secondary aluminum ash pretreatment powder and 40 parts of quality silicon carbide into the planetary ball mill, and ball-milling for 10h at a rotational speed of 1750r / min to obtain mixed fine powder;

[0027] S3, the described mixed fine powder of 100 parts of quality and the high chlorinated polyethylene ...

Embodiment 2

[0030] A method for preparing anti-corrosion and wear-resistant paint by utilizing secondary aluminum ash as a raw material, the steps of which are as follows:

[0031] S1. First, add 100 parts by mass of secondary aluminum ash to 500 parts by mass of water, and mix evenly to obtain a mixed solution; then the mixed solution is stirred at 80°C for 3 hours, and filtered to obtain a filter residue; The filter residue is washed and dried to obtain secondary aluminum ash pretreatment powder; wherein, the chemical composition of the secondary aluminum ash is: Al is 5.2wt%, Al 2 O 3 69.4wt%, SiO 2 is 11.8wt%, and other components are 13.6wt%;

[0032] S2, adding 100 parts of mass of the secondary aluminum ash pretreatment powder and 30 parts of mass of silicon carbide into a planetary ball mill, and ball-milling for 8h at a rotational speed of 1600 r / min to obtain mixed fine powder;

[0033] S3, the described mixed fine powder of 100 parts of quality and the high chlorinated polye...

Embodiment 3

[0036] A method for preparing anti-corrosion and wear-resistant paint by utilizing secondary aluminum ash as a raw material, the steps of which are as follows:

[0037] S1. First, add 100 parts by mass of secondary aluminum ash to 410 parts by mass of water, and mix evenly to obtain a mixed solution; then the mixed solution is stirred at 65°C for 4 hours, and filtered to obtain a filter residue; The filter residue is washed and dried to obtain secondary aluminum ash pretreatment powder; wherein, the chemical composition of the secondary aluminum ash is: Al is 1.2wt%, Al 2 O 3 82.8wt%, SiO 2 is 5.4wt%, and other components are 10.6wt%;

[0038] S2, adding 100 parts of quality of the secondary aluminum ash pretreatment powder and 50 parts of quality silicon carbide into a planetary ball mill, and ball-milling for 10h at a rotational speed of 2000r / min to obtain mixed fine powder;

[0039] S3, the described mixed fine powder of 100 parts of quality and the high chlorinated pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com